Page 1

Echelon

ANSI Electric Meter v3.1

User’s Guide

078-0384-01 Rev 01

PRELIMINARY DRAFT

Page 2

Echelon, Networked Energy Services Powered By Echelon,

NES Powered By Echelon and the Echelon logo are

registered trademarks of Echelon Corporation.

No part of this publication may be reproduced, stored in a

retrieval system, or transmitted, in any form or by any means,

electronic, mechanical, photocopying, recording, or

otherwise, without the prior written permission of Echelon

Corporation.

This document is furnished for informational use only, is

subject to change without notice, and should not be

construed as a commitment by Echelon Corporation.

Echelon Corporation assumes no responsibility or liability for

any errors or inaccuracies that may appear in this

document.

Echelon ANSI Electric Meter v3.1 User’s Guide

Printed in the United States of America.

Copyright ©2008 by Echelon Corporation.

Echelon Corporation

550 Meridian Ave

San Jose, CA 95126, USA

www.echelon.com

Page 3

FCC Compliance

If the WAN Card will be integrated into an ANSI IP Meter and used within the

United States of America, then the complete ANSI IP Meter (including the WAN

Card) must comply with FCC regulations. In addition, the accompanying

documentation for the complete product would need to include a notice such as the

following:

This equipment has been tested and found to comply with the limits for a Class B

digital device pursuant to Part 15 of the FCC Rules per sections 15.107 and

15.109. These limits are designed to provide reasonable protection against

harmful interference in a residential installation. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the manufacturer’s instruction manual, may cause interference

with radio communications. However, there is no guarantee that interference

will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning

the equipment off and on, you are encouraged to try to correct the interference by

one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and the receiver.

Connect the equipment into an outlet on a circuit different from that

which the receiver is connected.

Consult the dealer or an experienced radio/television technician for help.

Changes or modifications not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

RF Statements

This equipment also complies with the limits for wireless devices per sections 15.203,

15.205, 15.207, 15.209 and 15.247. It uses frequency 2.4GHz per IEEE 802.15.42006, and uses a frequency bandwidth from 2400MHz to 2483.5MHz.

This equipment complies with the FCC RF radiation exposure limits set forth for an uncontrolled

environment. This equipment should be installed and operated with a minimum distance of 20

centimeters between the radiator and your body.

This transmitter must not be co-located or operating in conjunction with any other antenna or

transmitter.

ANSI Electric Meter v3.1 User’s Guide i

Page 4

Table of Contents

Introduction 1

About This Guide.............................................................................................1

Related Documentation...................................................................................1

Meter Features................................................................................................1

Meter Installation 1

Safety Warnings..............................................................................................1

Visual Meter Inspection.............................................................................1

Provisioning the Meter.....................................................................................1

Mounting the Meter..........................................................................................1

Operating Environment.............................................................................1

Mounting Surface ...............................................................................1

Meter Test Links........................................................................................1

Determining Load Disconnect and Relay State without Line Power...............1

Determining Load Disconnect State .........................................................1

Determining Control Relay State ..............................................................1

Testing for Correct Meter Operation................................................................1

Test Mode........................................................................................................1

Meter Operation 1

Meter Operation Overview...............................................................................1

Reading the Display ........................................................................................1

Error and Caution Display Messages .......................................................1

Display Value ID Code..............................................................................1

Nameplate Message Identifiers ................................................................1

Low Voltage Display..................................................................................1

Display Value Items.........................................................................................1

Push Button Operation....................................................................................1

Self Tests and Diagnostic Messages ..............................................................1

Understanding Display Diagnostic Codes ................................................1

Diagnostic Event Descriptions............................................................1

Reading Diagnostic Code Combinations............................................1

Diagnostic Code Interpretation Examples..........................................1

Look-Up Table for Code Combinations..............................................1

Power Quality ..................................................................................................1

THD Calculations......................................................................................1

Event Log.........................................................................................................1

Status Events .....................................................................................1

Alarm Events......................................................................................1

Standard Tables.................................................................................1

Manufacturer Tables...........................................................................1

Standard Procedures..........................................................................1

Manufacturer Procedures...................................................................1

Tamper Detection............................................................................................1

Main Cover Removal.................................................................................1

Display Indicator for Cover Tamper Switch........................................1

Reverse Energy ........................................................................................1

Phase Inversion ........................................................................................1

Current Flow with No Voltage...................................................................1

Magnetic Tamper......................................................................................1

ii Table of Contents

Page 5

Tilt Conditions ...........................................................................................1

Load Disconnect..............................................................................................1

Display Indicator for Disconnect Position and Load Side Voltage............ 1

Disconnect Push Button............................................................................1

Remote Disconnect...................................................................................1

Disconnect Status.....................................................................................1

Locking the Disconnect in the Open State................................................1

Prepaid Metering.......................................................................................1

Switching to Maximum Power when Prepay is Exhausted ................1

Emergency Prepay Credit .................................................................. 1

Audible Low Prepay Credit Alarm ......................................................1

Meter Settings for Prepay...................................................................1

Maximum Power Disconnect ....................................................................1

Primary and Secondary Maximum Power Level Thresholds .............1

Primary and Secondary Maximum Power Duration Thresholds ........1

Disconnect Power Trip Point Source..................................................1

Power Threshold on Exhausted Credit...............................................1

Load Disconnect Re-Synchronization.......................................................1

Disconnect Switch Error Event Argument Formats............................1

Low Voltage Operation .............................................................................1

Control Relay...................................................................................................1

Display Indicator for Control Relay Position .............................................1

Remote Relay Status................................................................................1

Pulse Output Signal (KYZ) ..............................................................................1

Optical Port Communication............................................................................1

Power Line Carrier Communication ................................................................1

PLC Display Indicators..............................................................................1

PLC Traffic Detection Indicator ..........................................................1

Received Message Quality Indicator..................................................1

Battery Backup ................................................................................................1

Clock Settings.................................................................................................. 1

Load Profile Back-fill Upon Power-up..............................................................1

Start-up Time...................................................................................................1

Energy Measurements and Calculations.........................................................1

Energy Register Capacity................................................................................1

Error Occurrence Recording............................................................................1

Self-Reads.......................................................................................................1

One-Time Reads.............................................................................................1

Daily Energy Consumption..............................................................................1

Time-of-Use (TOU) Tariffs...............................................................................1

TOU Calendar Identifier............................................................................1

Pending TOU Calendar.............................................................................1

Load Profiles....................................................................................................1

Meter UTC and DST Time Assignment...........................................................1

Meter Parameters Set to UTC ..................................................................1

Meter Parameters Set to Local Time........................................................1

Meter Data Collection...................................................................................... 1

Read-Only Key..........................................................................................1

Security............................................................................................................1

Group Broadcasting.........................................................................................1

Meter Firmware Updates.................................................................................1

Demand Metering 1

Demand Calculations and Settings.................................................................1

Demand Settings.......................................................................................1

Demand Calculations................................................................................1

ANSI Electric Meter v3.1 User’s Guide iii

Page 6

Demand Resets...............................................................................................1

Reset Lockout Period................................................................................ 1

Demand Interruptions......................................................................................1

End of Interval Display Icon.............................................................................1

MEP Devices 1

MEP Interface..................................................................................................1

Electrical Specification..............................................................................1

Meter Troubleshooting 1

Meter Specifications 1

Glossary 1

Model Changes 1

Model 83011-83301 Changes.........................................................................1

iv Table of Contents

Page 7

1

Introduction

This chapter provides a description of the content of

this document, a list of related documentation, and an

overview of the capabilities of the Echelon ANSI

electric meter.

ANSI Electric Meter v3.1 User’s Guide 1

Page 8

About This Guide

This document describes the installation and operation of the Echelon ANSI 8301183301 electric meter, and is intended for use by metering administrators, installers,

and meter technicians. ANSI electric meters are designed to be part of a utility

metering system that is supervised by Echelon’s Data Concentrator in conjunction

with Networked Energy Services (NES) System Software.

The following chapters are included:

Chapter 1: Introduction

Chapter 2: Meter Installation

Chapter 3: Meter Operation

Chapter 4: Demand Metering

Chapter 5: MEP Devices

Appendix A: Meter Troubleshooting

Appendix B: Meter Specifications

Appendix C: Glossary

Appendix D: Model Changes

Related Documentation

The following Echelon documentation provides operating instructions and

descriptions of the various components of the Networked Energy Services (NES)

metering system:

ANSI Electric Meter Quick Installation Guide

DC-1000/SL Data Concentrator User’s Guide

NES Provisioning Tool User’s Guide

NES System Getting Started Guide

NES System Software Installation Guide

NES System Software Programmer’s Guide

NES System Software API Reference Guide

NES System Software Version Compatibility Guide

Meter Features

Echelon electric meters and the NES system that the meters operate within provide

a comprehensive set of energy services. Some of these services are: automated twoway meter reading, Time-of-Use metering, remote electronic disconnect and local

physical reconnect, distribution system asset optimization, outage detection and

restoration management, blackout and brownout detection, comprehensive revenue

protection, real-time direct load control, and more.

ANSI electric meters include the following features:

Power line carrier (PLC) communication with an Echelon Data Concentrator,

using Echelon’s A-Band power line carrier technology

Optical communication port provides an interface for direct communication

with a computer or hand-held reader.

2 Introduction

Page 9

Meter display provides a scrolling list of up to 30 items (with an ID code for

each item) including energy data, time, date, remaining credit (if prepay

metering is in effect), tariff-specific energy values, and more.

Push button provides immediate advancement to next display item and is

used to silence the audible prepay low credit alarm.

Display characters and icons indicate various operating conditions, such as:

when main cover is properly installed, that PLC communication has occurred,

and the open/closed state of the load disconnect and control relay.

Nameplate message indicators are illuminated on the display when a listed

item or action is programmed into the meter.

Load disconnect switch with prepay and remote disconnect capability. When

remotely set to off state, cannot be turned on manually. 200 amps maximum.

Data log intervals of 5, 15, 30, 60 minutes, or 1-day.

Up to 180 days of single-channel load profile memory storage in meter at a

60-minute log interval and 2094 days at a 1-day interval. Up to 8 channels

can be recorded on the same interval.

Four Time-of-Use kWh and kvarh tariff registers. Perpetual calendar: 4

seasons, 15 holidays. 2 holiday day schedules per season, 3 separate day

schedules per season, 10 tariff periods per day schedule.

A second Time-of-Use calendar schedule can be programmed into the meter

for activation at a preset future date.

Daylight Saving Time changeover with perpetual calendar.

Battery-backed Real Time Clock (RTC) to maintain time accuracy and

tamper detection during power outages.

Alarms for customer tamper and meter operating variances.

Power quality measurements for: sag, swell, number of over-current

occurrences, number of long power outages, duration and time of the last 10

long power outages, number of short power outages, maximum and minimum

frequency, phase loss, and total harmonic distortion (THD) events.

Prepay metering. Energy credit is loaded into the meter and customer power

is automatically turned off when credit becomes zero. Emergency credit

allows power to continue after standard credit is exhausted, with the option

of a reduced power mode. A configurable audible alarm warns customer of

low credit.

Data transmission accuracy ensured using CRC for optical communication

and authentication and handshaking for PLC communication.

Security is provided by password protection for optical communication,

encryption and authentication for PLC communication.

Signal relay for control of external contactor or other devices, with activation

linked to the currently active tariff period or controlled by remote command

(optional feature).

KYZ pulse output (optional feature).

Demand metering. The meter optionally offers various types of demand

calculations that can be performed to measure the peak active and reactive

power being delivered to the system. Demand measurements are useful in

that they provide information on peak usage as opposed to accumulation over

time. Consult Chapter 4 for more information on demand metering.

ANSI Electric Meter v3.1 User’s Guide 3

Page 10

An optional MEP (Multipurpose Expansion Port) port that is capable of

connecting to a smart device and allowing that device (referred to as a MEP

device) to access meter data, run meter procedures, and have limited write

access to the meter.

Figure 1.1: Echelon ANSI Electric Meter

4 Introduction

Page 11

2

Meter Installation

This chapter includes safety warnings, meter installation

instructions, and initial start-up procedures.

ANSI Electric Meter v3.1 User’s Guide 5

Page 12

Safety Warnings

Before you install and operate your meters, you should be familiar with all regulatory

agency, manufacturer, and utility industry safety precautions. Observe these safety

precautions during all steps of meter installation, operation, and service. Failure to

comply with these precautions, or with specific warnings or instructions elsewhere in this

guide, violates safety standards of design, manufacture, and the intended use of the

meter. Echelon assumes no liability for failure to comply with these requirements.

The information presented in this guide is intended to be an aid to qualified metering

personnel. It does not replace the extensive training necessary to handle metering

equipment in a safe manner.

!

Safety Warning: Any work on or near energized meters or other metering

equipment presents the danger of electrical shock. Only qualified electricians

and metering specialists should be authorized to work with the meters, in

accordance with local utility safety practices, utility requirements, and other

safety precautions as dictated by local code, regulations, or statutes.

Visual Meter Inspection

Before installing the meter, inspect the meter case, display, optical port, and blades to

make sure they are not damaged.

!

Safety Warning: Return damaged meters and components to Echelon; do

not attempt to repair the damage. The meter has no user-serviceable parts.

Any attempt to remove or repair internal parts voids the meter warranty.

Provisioning the Meter

Before a meter can operate correctly in your system, it must be configured with specific

operating parameters. This configuration is called “provisioning” and is performed by

writing programs with preset values into the meter, either from NES System Software

via the Data Concentrator, or directly to the meter optical port from a computer using

the NES Provisioning Tool application. The parameters in the Provisioning Tool

programs are set by administrative staff at the governing utility, and the programs can

be distributed to technicians for meter provisioning operations.

The meter provisioning may be performed by Echelon prior to shipment, at a service

depot before transportation to the meter installation site, or at the installation site.

After a meter is installed, updates to program settings are usually performed by sending

the updated information from NES System Software to the Data Concentrator that is

supervising the meter. The Data Concentrator writes the update to the meter and

confirms the successful implementation back to NES System Software. For more

information on the Data Concentrator, see the DC-1000/SL and DC-1000/SLE Data

Concentrator User’s Guide.

You can also use the Provisioning Tool to view meter data and diagnostic information.

For instructions on provisioning meters, see the NES Provisioning Tool User’s Guide.

6 Meter Installation

Page 13

Mounting the Meter

The form, current class and rated voltage of the ANSI meter are marked on the front of

the meter, as shown in Figure 2.1. Before mounting the meter in its socket, you should

make sure that these settings match the form, maximum current and rated voltage for

the socket you are using.

Operating Environment

The meter is designed to operate in an indoor or outdoor (IP54 rating) location, in a nonhazardous environment. You should make sure to mount the meter in a well-ventilated

enclosure that will prevent condensation from forming inside the meter.

Mounting Surface

The meter is designed to be installed in an upright position on a flat vertical surface.

Figure 2.1 Form, Current Class and Rated Voltage

ANSI Electric Meter v3.1 User’s Guide 7

Page 14

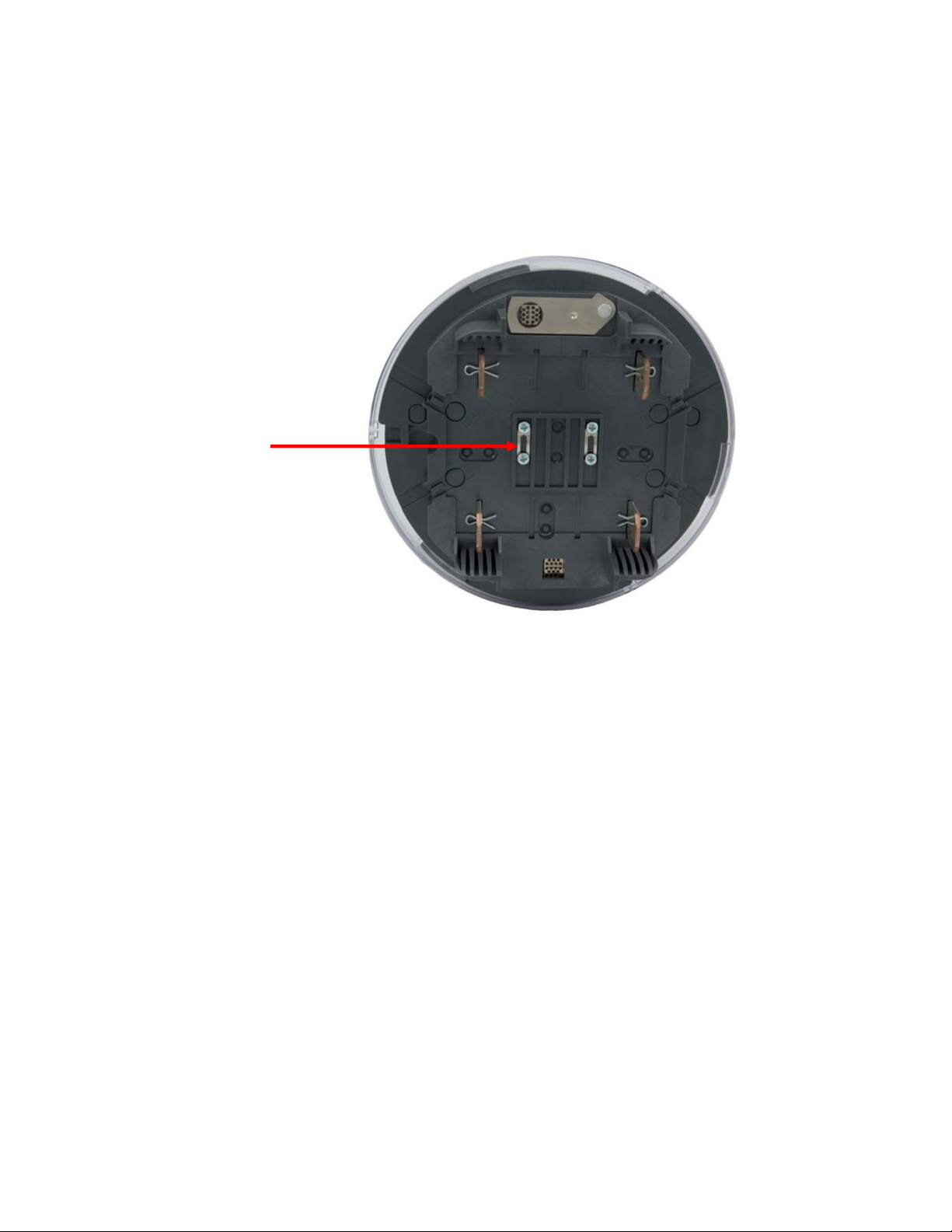

Meter Test Links

The test links of the back of the ANSI meter must be in the closed position before you

mount and begin using the ANSI meter, as shown in Figure 2.2.

Meter Test Links

Figure 2.2 Meter Test Links

8 Meter Installation

Page 15

Determining Load Disconnect and Relay State

without Line Power

The meter’s load disconnect contactor and control relay open or closed state cannot be

visually determined before line power is supplied to the meter. When in the closed state,

power will be delivered to the load when line power is supplied to the meter.

Determining Load Disconnect State

To determine if the meter load disconnect contactor is in the open or closed state when

power is not supplied to the meter, follow this procedure:

1. Set a multi-meter to continuity test mode or use a continuity tester.

2. Connect one continuity test probe to L1 line-in terminal and one probe to L1 load

terminal.

3. If there is NO continuity in the signal path the disconnect is Open (Off). If there

IS continuity in the signal path the disconnect is Closed (On).

Determining Control Relay State

To determine if the control relay is in the open or closed state when power is not

supplied to the meter, follow this procedure:

1. Set a multi-meter to continuity test mode or use a continuity tester.

2. Connect the continuity test probes to the two control relay wires.

3. If there is NO continuity in the signal path the control relay is Open (Off). If

there IS continuity in the signal path the control relay is Closed (On).

ANSI Electric Meter v3.1 User’s Guide 9

Page 16

Testing for Correct Meter Operation

When power is applied to the meter, the following can be checked to determine if the

meter is operating properly:

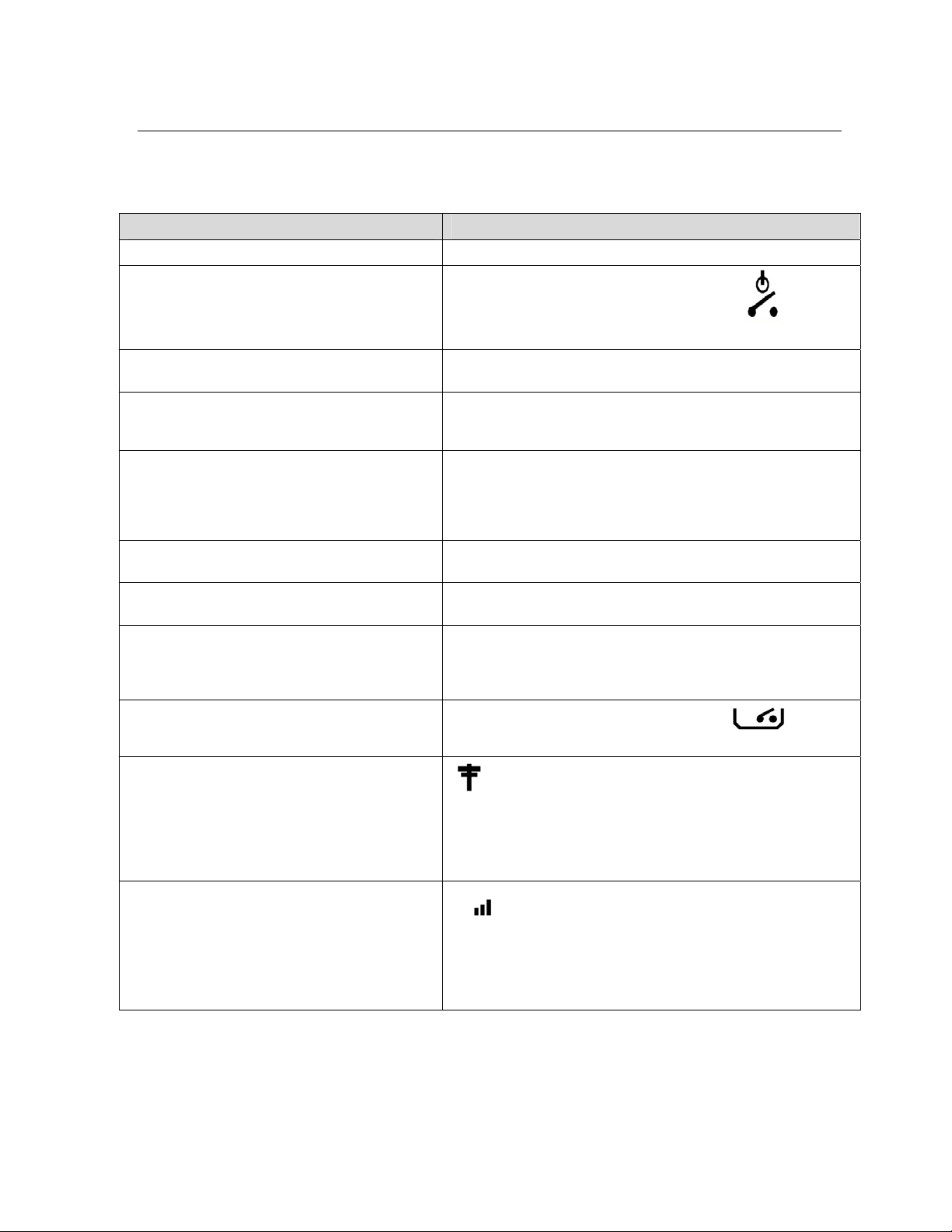

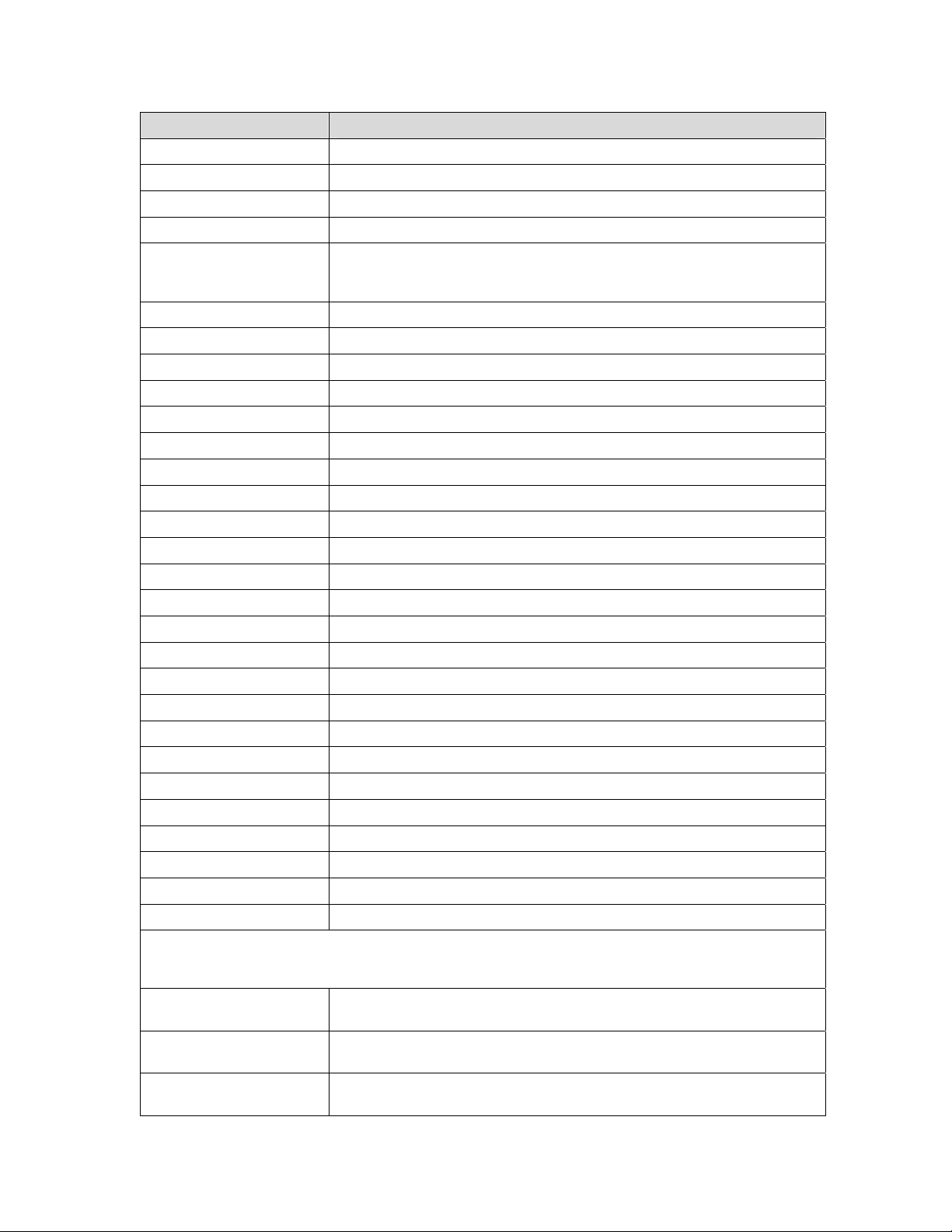

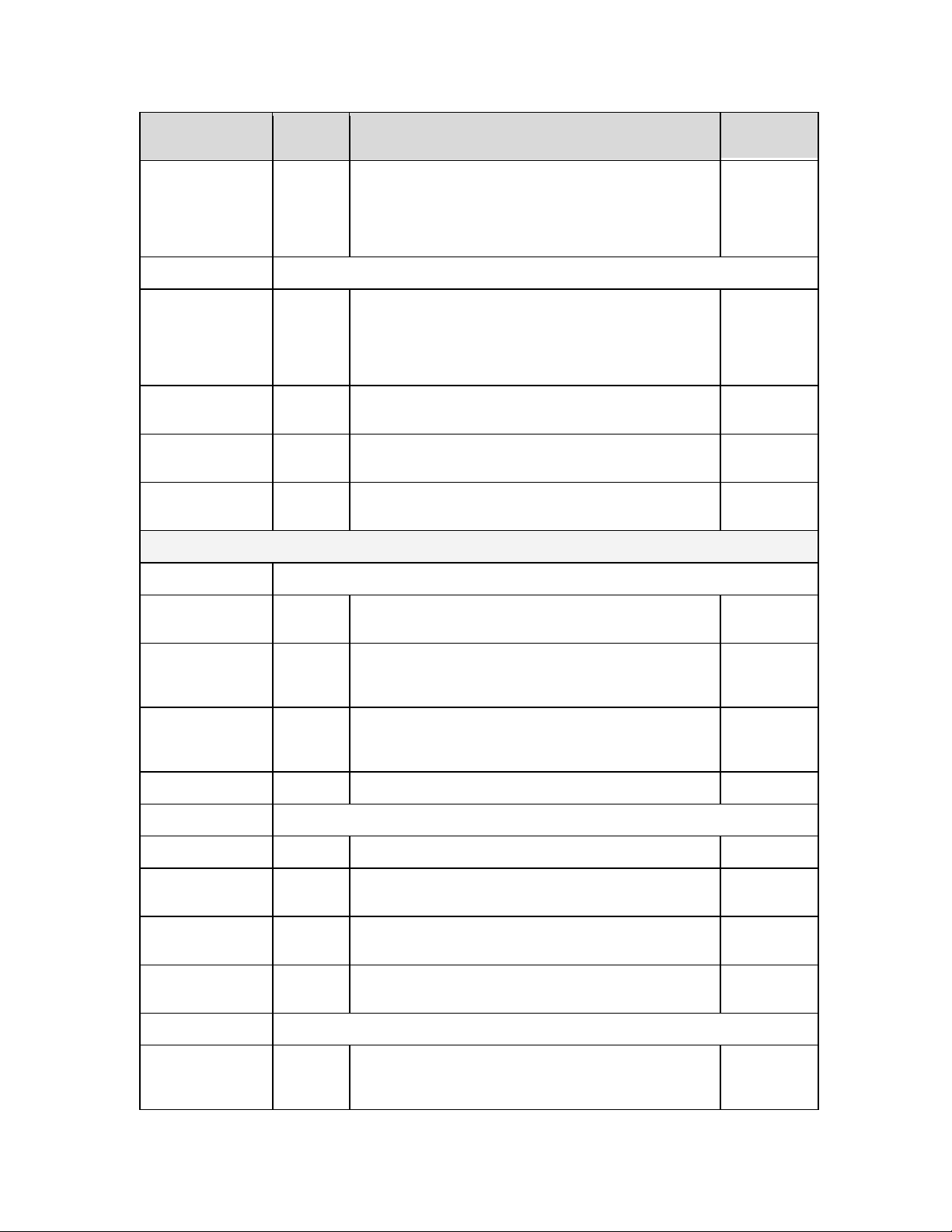

Function/Operation Indicated By

Power to meter is On The display is active (shows information).

Power to load is On

(load disconnect contactor is in the On, or closed,

position)

All necessary phases are connected to the meter

and providing voltage

Polyphase only: The phases are connected to

the meter correctly (Does not detect reversed line

and load wires or swapped line and neutral)

Polyphase only: The phases are not connected

to the meter in the correct order (Does not detect

every possible incorrect connection order such as

L3L1L2, reversed line and load wires, or

swapped line and neutral)

The metered building is consuming active energy

(forward active)

The metered building is generating active energy

(reverse active)

A self-test failed, a tamper condition has been

detected, or an alarm condition has occurred

The main cover has been properly installed and

the cover tamper switch is closed

PLC network communication is occurring

PLC communication has occurred with the meter

(See “Reading the Display” in Chapter 3 for more

information)

The “disconnect open” display indicator

is Not illuminated, indicating that the

disconnect contactor is closed.

The L1 and/or L2 phase indicators are lit on the display,

signifying the phases that have voltage present

L1, L2, L3 (L1, L3 for 2s/12s) indicators are lit on the display

(verification only available for 3-phase, 4-wire electrical service)

L1, L2, L3 (L1, L3 for 2s/12s) indicators are lit on the display

(verification only available for 3-phase, 4-wire electrical service)

The ““ arrow is lit on the display

The ““ arrow is lit on the display

An error code may lock the display or a caution code may be

shown at the end of the scrolling display list, if these codes have

been configured to be active. See “Self Tests and Diagnostic

Messages” on page 1 for information on messages

The “tamper switch open” display indicator

is Not illuminated, indicating that the cover is installed properly

This icon is lit when PLC communication on the network

has been detected by the meter. This icon can be used during

installation to see if network communication can be ‘heard’ by

the meter before the meter is accepted by the system as an

active device. See “Power Line Carrier Communication” on

page 1 for detailed information.

This icon indicates that PLC communication occurred

with this specific meter within the last X minutes (X is

configurable from 1 to 65535 minutes) and shows the quality of

the most recent received PLC message.

See “Power Line Carrier Communication” on page 1 for detailed

information.

10 Meter Installation

Page 17

Test Mode

Test mode is an optional feature that is only supported by some NES version 3.1 ANSI

meters. While in test mode, the meter will suspend standard energy accumulations,

standard demand calculations, power quality analysis, tariff register calculations,

automated control of the disconnect switch, and automated control of the control relay.

In addition, all standard operation demand calculations that were interrupted by test

mode activation will be considered completed and the values will be calculated as if the

full time of the demand interval has elapsed (the non-elapsed time is considered to have

had an energy accumulation of zero). You may find test mode useful if you want to test

the meter’s accuracy without disrupting its billing registers. The meter display includes

an icon that will be enabled when the meter enters test mode.

ANSI Electric Meter v3.1 User’s Guide 11

Page 18

3

Meter Operation

This chapter describes the operation and features of the

Echelon ANSI electric meters.

12 Meter Operation

Page 19

Meter Operation Overview

The Echelon ANSI electric meter provides a comprehensive set of energy services

when operating within the NES system. The meter supplies automatic encrypted

data transfer and diagnostic reporting to NES System Software by communicating

with an Echelon Data Concentrator over local power lines using PLC technology. An

optical port provides local communication for direct programming and data reading.

The meter measures active power and energy for both forward and reverse, reactive

power and energy for import and export, voltage, current, power factor, and

frequency. Data can be recorded in up to 4 perpetual-calendar Time-of-Use (TOU)

registers. The data can be logged in intervals of 5, 15, 30, 60 minutes, or 1-day, with

up to 8 channels per interval.

A programmable display presents comprehensive local information on meter

operation and customer power consumption. Additional messaging features supply

power quality information and tamper detection. LEDs are included for test

functions. An optional KYZ output is also available.

Remote or local disconnect of customer power allows automatic prepay metering

functions, power limiting, and service cancellation control. An optional control relay

can turn an external device on or off based on tariff periods, or by command from

NES System Software or the Provisioning Tool.

NES version 3.1 meters optionally support demand metering, which offer various

types of calculations that can be performed to measure the peak active and reactive

power being delivered to the system over a designated time period. For more

information on demand metering, see Chapter 4, Demand Metering.

NES version 3.1 meters also include a Multipurpose Expansion Port (MEP) that

allows external MEP devices to connect to the meter and access meter data and run

meter procedures. For more information on MEP devices, see Chapter 6, MEP

Devices.

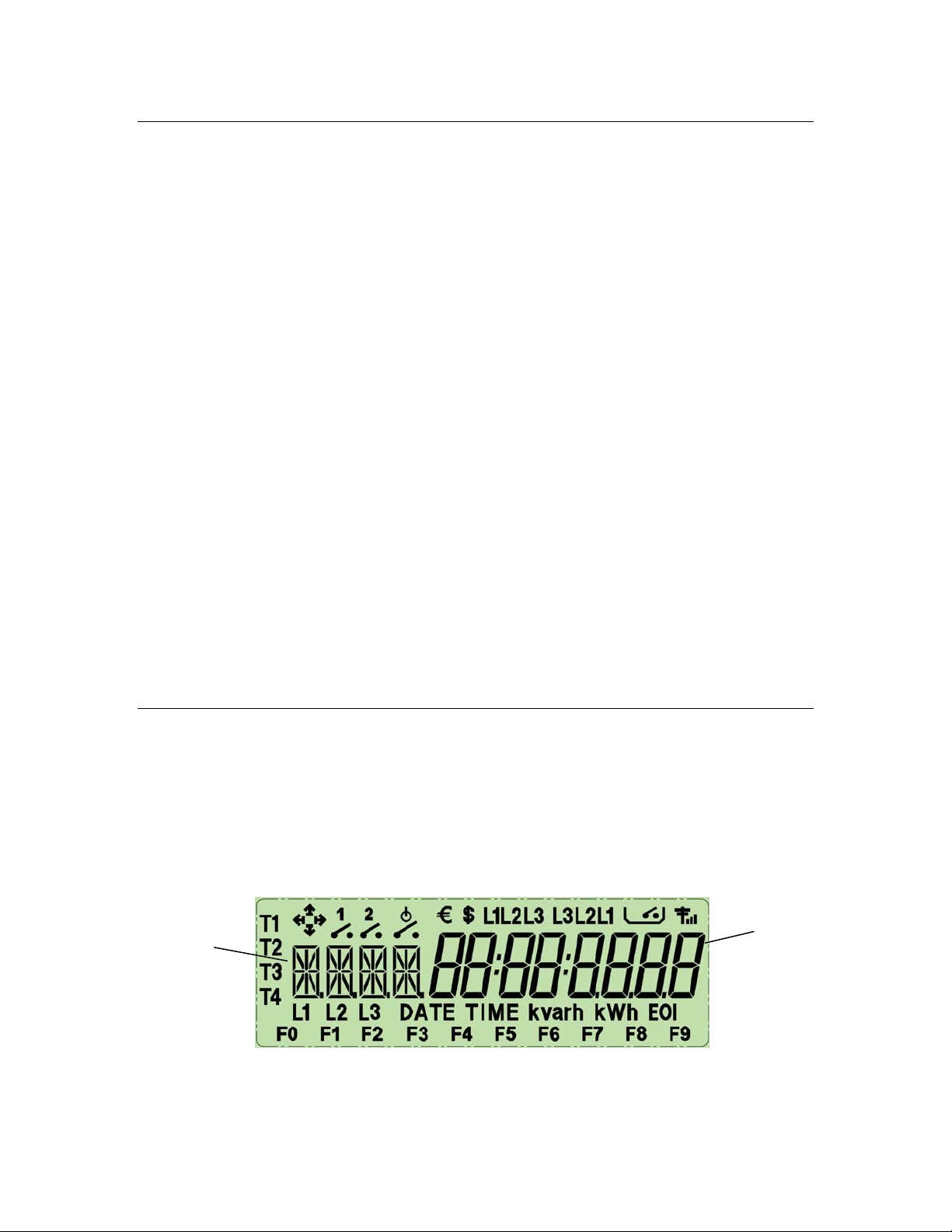

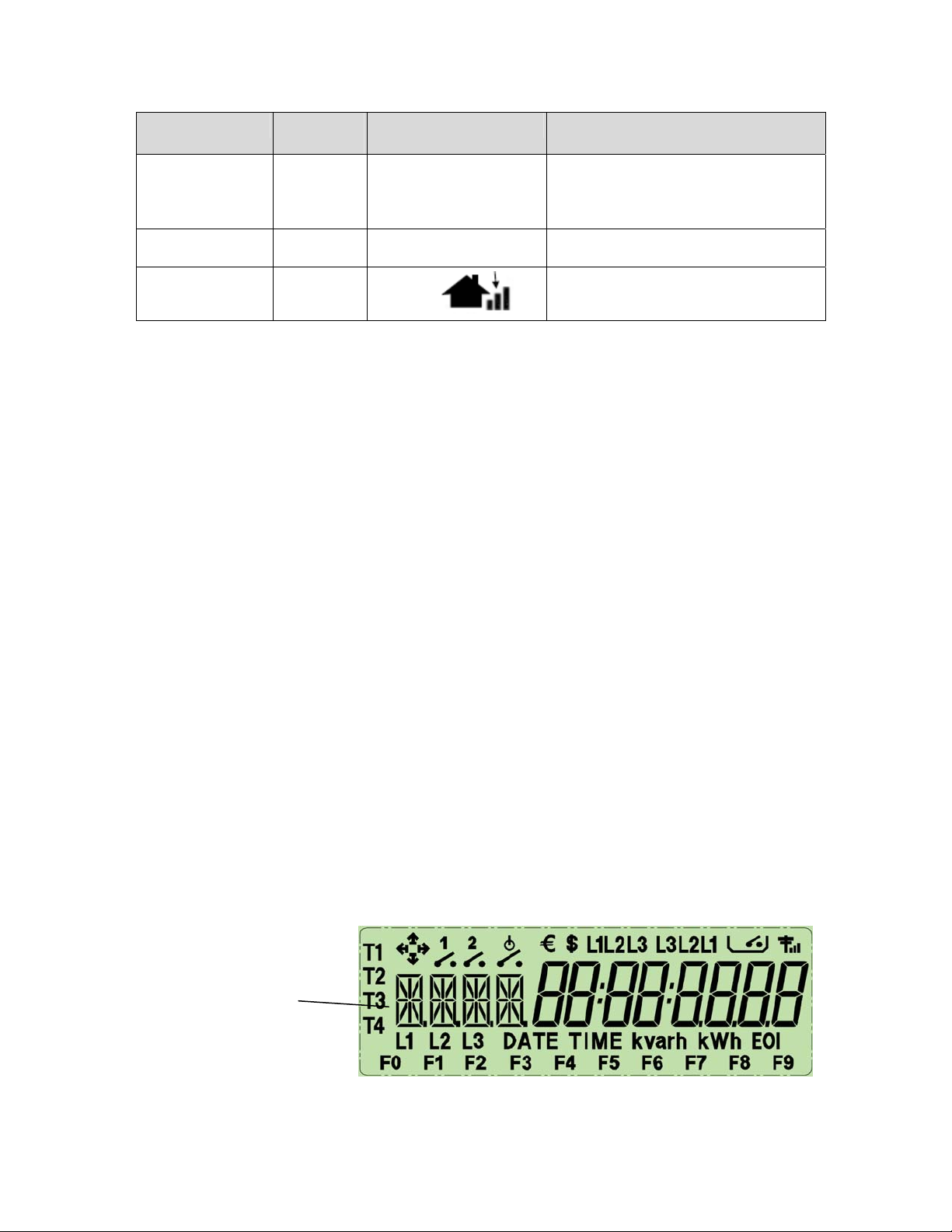

Reading the Display

The indicators on the meter display designate which value is being displayed and

provide indication of various operating parameters. The format of the 8-digit value is

configurable as to the number of digits, viewing of leading zeros, and the decimal

point location. See the NES Provisioning Tool User’s Guide for information on

configuring display options. Refer to Figure 3.1 and the following table for a

description of the display features:

Value ID

code, 4

characters.

Value,

8 digits.

Figure 3.1: Meter Display, All Segments Lit

ANSI Electric Meter v3.1 User’s Guide 13

Page 20

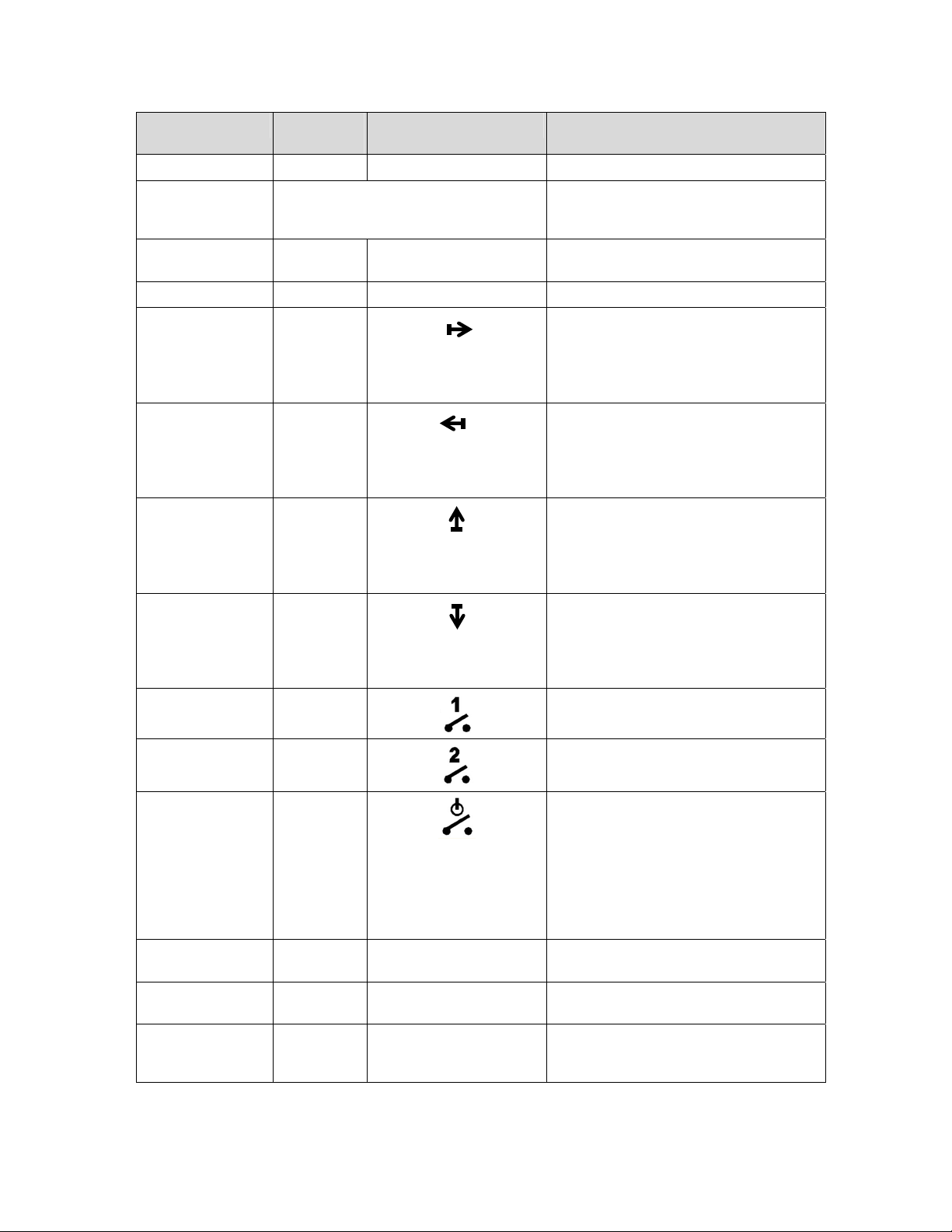

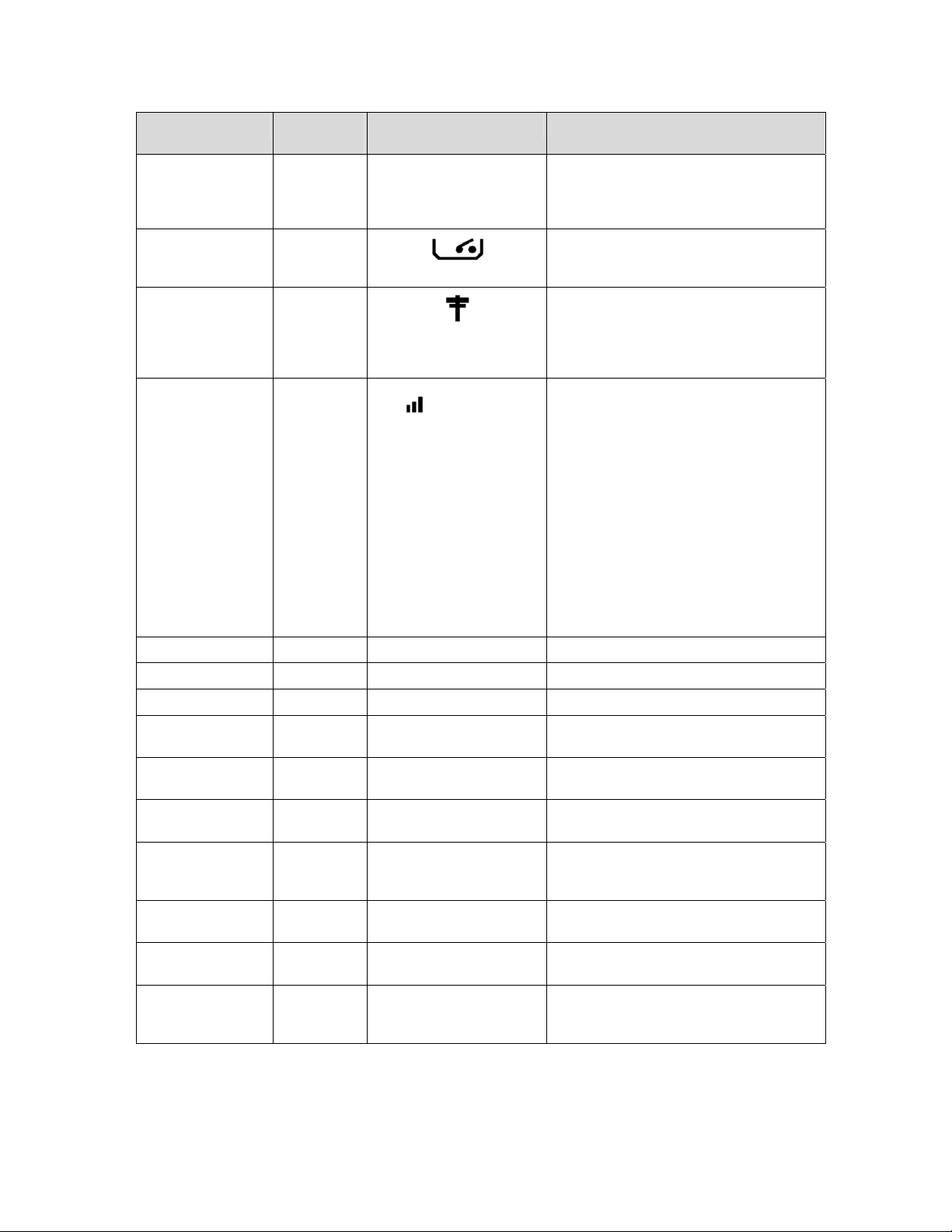

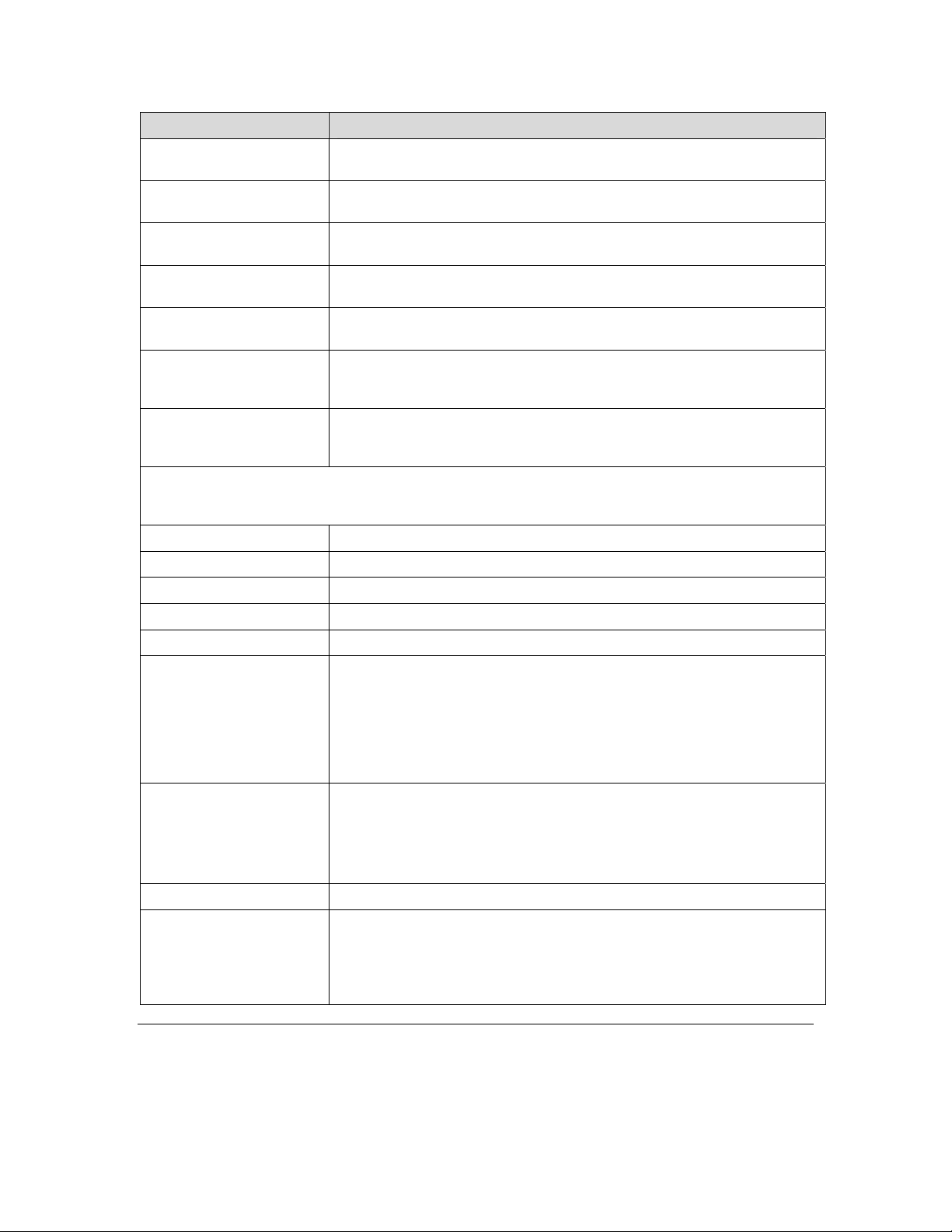

Item Displayed Value

Format

All segments lit All Confirms proper operation of the display.

Value ID code Any letter or number

x.x.x.x.

Value xxxxx.x.x.x Number value. Maximum of 8 numbers and

Present tariff period

Forward active

energy

Reverse active

energy

Import reactive

energy

Export reactive

energy

Control relay 1 open

Control relay 2 open

Indicator Function

Identification code for present displayed

value. Maximum of 4 characters, letters or

numbers.

decimal point of 3 possible places.

T1, T2, T3, T4

Indicates the present operating tariff period.

Indicates that forward active energy is

flowing.

This is also displayed if there is no present

active energy flow and the previous flow

was in the forward direction.

Indicates that reverse active energy is

flowing.

This is also displayed if there is no present

active energy flow and the previous flow

was in the reverse direction.

Indicates that import reactive energy is

flowing.

This is also displayed if there is no present

reactive energy flow and the previous flow

was in the import direction.

Indicates that export reactive energy is

flowing.

This is also displayed if there is no present

reactive energy flow and the previous flow

was in the export direction.

Indicates that control relay 1 is in the open

position.

Not used.

Load disconnect

open

Dollar value xxxxx.x.x.x

Euro value xxxxx.x.x.x

Correct 3-phase

wiring

$

€

L1L2L3

This display indicator can be configured by

the user to either reflect the current state of

the load disconnect contactor, or to indicate

whether or not load side voltage has been

detected by the meter.

For more information on this, see “Display

Indicator for Disconnect Position and Load

Side Voltage” on page 1.

(Not used) Currency value of prepay credit

remaining is displayed in Dollars.

(Not used) Currency value of prepay credit

remaining is displayed in Euros.

Correct wiring configuration order for all 3

phases. (Does not detect reversed line and

load wires or swapped line and neutral.)

14 Meter Operation

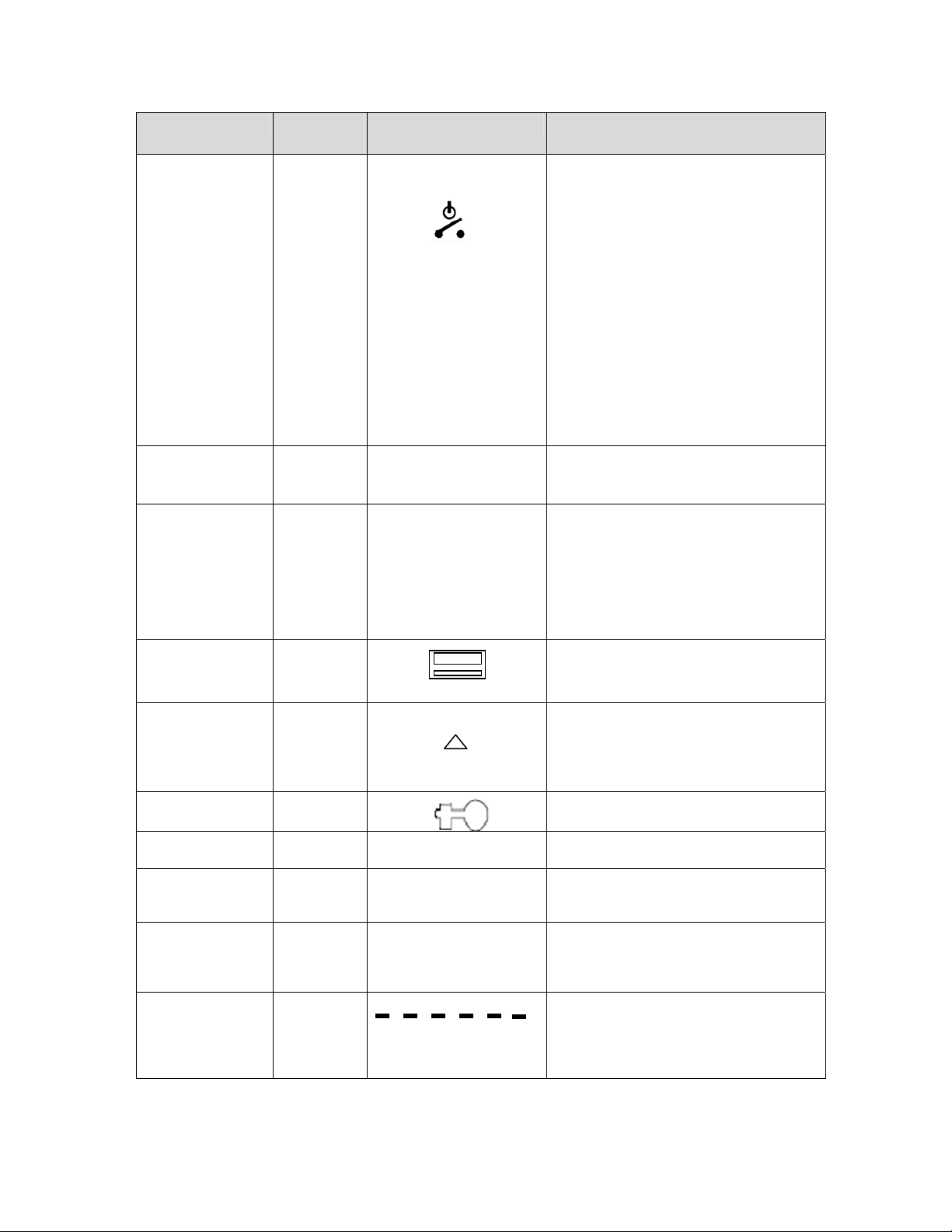

Page 21

Item Displayed Value

Format

Reverse 3-phase

wiring

Tamper switch open

PLC traffic detection

PLC received

message occurrence

and quality

Line 1 voltage

Line 2 voltage

Line 3 voltage

Meter date dd:mm:20yy

Meter time hh:mm:ss

Reactive energy xxxxx.x.x.x

Active energy xxxxx.x.x.x

Reactive power xxxxx.x.x.x

Active power xxxxx.x.x.x

End of Interval

Indicator Function

L3L2L1

L1

L2

L3

DATE

TIME

kvarh

kWh

kvar

kW

EOI

Indicates that 3-phase wiring is installed in

the wrong order. (Does not detect reversed

line and load wires or swapped line and

neutral.)

Indicates that the main cover tamper switch

is open. The cover is not installed or not

installed correctly.

This icon is lit when PLC communication on

the network has been detected by the

meter. See “Power Line Carrier

Communication” on page 1 for detailed

information.

This icon indicates that PLC

communication occurred with this specific

meter within the last X minutes (X is

configurable from 1 to 65535 minutes) and

shows the quality of the most recent

received PLC message.

– No bars = no message received for this

meter

– Smallest bar = a poor quality message

– Both smallest and medium bar = a

medium quality message

– All three bars = a high quality message

See “Power Line Carrier Communication”

on page 1 for detailed information.

Indicates that voltage is present on line 1.

Indicates that voltage is present on line 2.

Indicates that voltage is present on line 3.

Present local date in meter, or a self-read

record date, is displayed.

Present local DST time in meter, or a self-

read record time, is displayed.

Accumulated import or export reactive

energy is displayed.

Accumulated kilowatt-hours of forward,

reverse, forward + reverse, or forward –

reverse active energy is displayed.

Import or export reactive power is

displayed.

Kilowatts of forward or reverse active power

is displayed.

(Not used) Indicates that a demand reset

has occurred and that a new demand

interval has started.

ANSI Electric Meter v3.1 User’s Guide 15

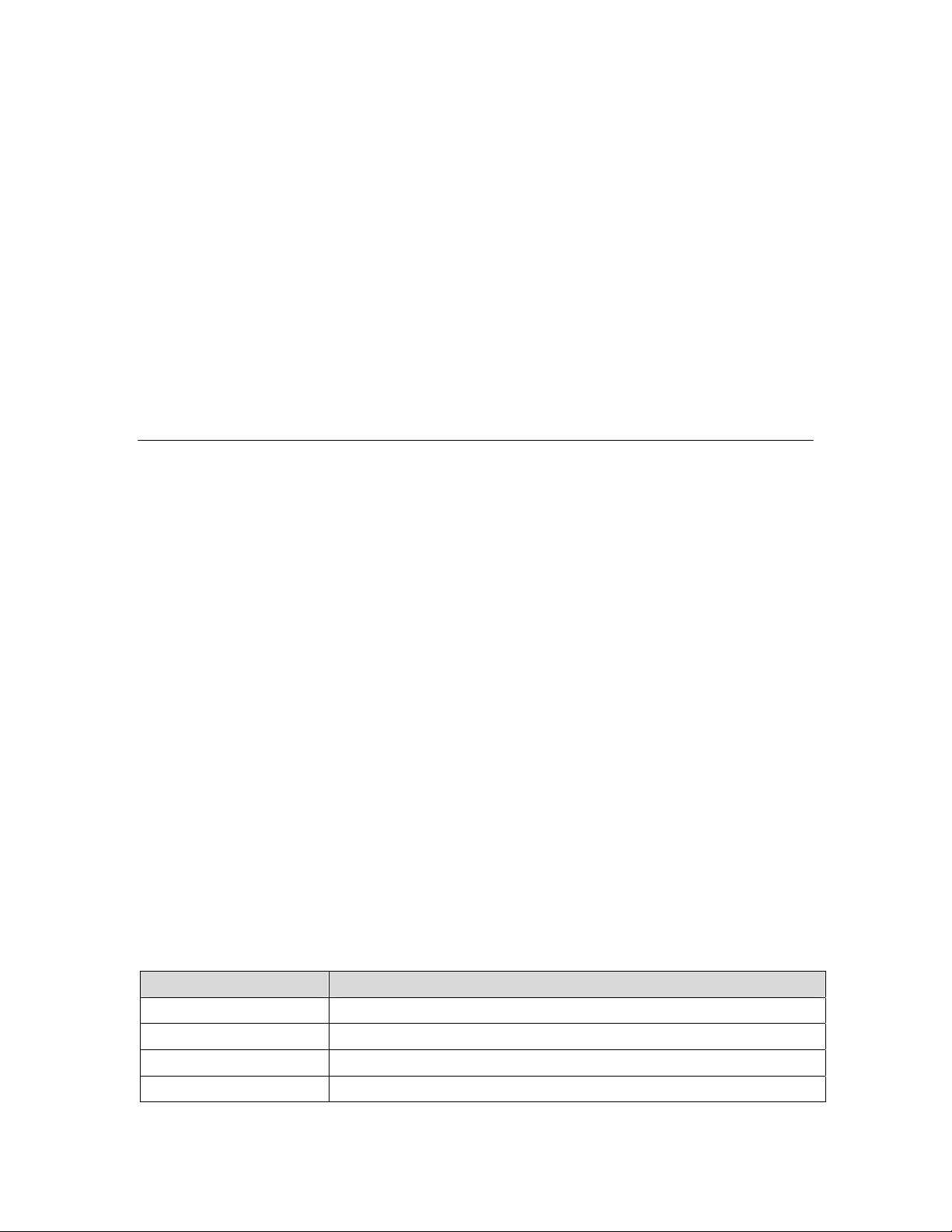

Page 22

Item Displayed Value

Format

Disconnect status

Nameplate message

active

Load side voltage

detected

Prepay enabled

Self-read/One-time

read error

Access lockout

override in effect

Negative number

indicator

Test mode indicator

Tilt sensor indicator

Simulated

mechanical wheel

Indicator Function

F0, F1, F2

F4

This display indicator, can be configured by

the user to either reflect the current state of

the load disconnect contactor, or to indicate

whether load side voltage has been

detected by the meter.

If it is configured to reflect the current state

of the load disconnect contactor, it will be

illuminated when the load disconnect

contactor is in the open position.

If it configured to indicate whether or not

load side voltage has been detected by the

meter, it will be illuminated when there is no

load side voltage detected by the meter.

For more information on this, see “Display

Indicator for Disconnect Position and Load

Side Voltage” on page 1.

Indicates the nameplate messages that are

presently active in the meter. See additional

description following this table.

Depending on your meter’s

configuration, this icon may be used to

indicate whether or not load side voltage

has been detected by the meter.

For more information on this, see “Display

Indicator for Disconnect Position and Load

Side Voltage” on page 1.

(-)

TEST

TILT

Prepay is enabled in the meter.

Indicates that the current Self-read or

One-time-read record that is being

displayed has errors that may affect

register accuracy.

The access lockout settings are

deactivated by hardware screw.

The number displayed is negative

The meter is in test mode. This icon turns

on when the meter enters test mode, and

turns off when it exits test mode.

The meter includes a sensor that will detect

when the meter has been tilted. This icon

indicates that the sensor has detected a tilt

condition.

The simulated mechanical wheel will scroll

through each of the six indicators at a rate

that indicates the amount of energy

consumed/produced as well as the

direction of energy flow.

16 Meter Operation

Page 23

Item Displayed Value

Format

ANSI meter form

indicator

Name plate

message

MEP communication

indicators

Indicator Function

2S

MP

This icon will be used to display the present

ANSI meter form being used. All ANSI v3.1

meters use form 2S.

Indicates that the MEP device connected to

the meter is registered.

These icons can be configured to flash or

remain on when communication with a

MEP device is occurring.

Error and Caution Display Messages

Various error and caution message codes can be shown on the display. A diagnostic

event can be configured by the user to be shown as either an error or caution

message, or can be set to not appear on the display. The action of each type is:

Caution message codes are shown at the end of the regular scroll list, when a

caution is present. Scrolling continues for all display items.

Error message codes override all regular display items and only the error

message codes are displayed. Scrolling stops for regular display items when

an error is displayed.

Once an error or caution occurs, the display continues to show the error or caution

code until it is cleared. The codes persist across power outages and continue to

display after the meter is powered down and back up. The error or caution codes are

read and cleared by NES System Software via PLC communication with the Data

Concentrator, or directly with the Provisioning Tool via the meter optical port.

All error and caution message codes can be read by the Data Concentrator and sent

to NES System Software, even when not selected to appear on the display.

If more than one error or caution is active, the displayed characters are a

combination of the error or caution values. See “Self Tests and Diagnostic Messages”

on page 1 for a list of the diagnostic messages and an explanation of display codes.

Display Value ID Code

The display value ID code is the user configurable 1 to 4 character alpha/numeric

identifying code for the value currently shown in the 8-digit value field of the meter

display. Different codes are used for power values and error and caution diagnostic

values. See the NES Provisioning Tool User’s Guide for more information on

creating value ID codes. Figure 3.2 shows the 4-character display value ID location.

4-character

value ID code.

Figure 3.2: Display, 4-Character Value ID Code

ANSI Electric Meter v3.1 User’s Guide 17

Page 24

Nameplate Message Identifiers

Various messages may be listed on the front of the meter in the nameplate area.

These messages describe certain states, functions, or actions that could be operating

in the meter. When any of the message states or functions are active in the meter,

the corresponding identifier F0, F1, or F2 is illuminated on the display. The meter

nameplate also includes an erasable strip that can be used to add more data to the

meter display.

Low Voltage Display

During a brownout condition, the meter display will show VOLT LO. This will

continue to be displayed until the meter is powered back up, or until it is completely

powered off. The meter display will also briefly show VOLT LO when the meter is

powered down normally, although the message will not persist in this case.

Display Value Items

The meter can display up to 30 numeric value items, which are chosen from the

available total and tariff energy measurements, as well as time, date, and prepay

energy credit remaining. The display scrolls through each item, with a

programmable scroll-time for each item of 6 to 15 seconds. The scroll-time is the time

that the value is shown on the display before scrolling to the next item. Each item

has a unique programmable 4-character ID code that is displayed along with the

value item.

You can use the meter push button to automatically advance to the next display

value item, before the scroll-time expires. Alternatively, you can disable automatic

scrolling, so that the push button must be used to advance the meter display to the

next item at all times. For more information on the meter push button, see “Push

Button Operation” on page 1.

The decimal point location for energy values is configurable, with an available range

of 1 to 8 digits to the left and 0 to 3 digits to the right of the decimal point. The

display of leading zeros can also be suppressed. The decimal point location and zero

suppression apply only to register values and prepay totals. Other display items,

such as date, time, firmware version, TOU calendar ID, and diagnostic codes are not

affected by the decimal point location and zero suppression settings.

When an actual value is larger than the number of digits configured to the left of the

decimal point, the most significant digits are not displayed. This allows the most

frequently changing digits to display. The actual stored values are not affected.

The following are the choices of items that are available to be shown on the meter

display. The summation and self-read items can be per-tariff or a total of all 4 tariffs,

except for the power outage values, the error counter, which show only totals.

Value Type Item Description

Summation / accumulators Forward active kWh L1+L2+L3

Summation / accumulators Reverse active kWh L1+L2+L3

Summation / accumulators Forward + reverse active kWh L1+L2+L3

Summation / accumulators Forward – reverse active kWh L1+L2+L3

18 Meter Operation

Page 25

Value Type Item Description

Summation / accumulators Import reactive kvarh L1+L2+L3

Summation / accumulators Export reactive kvarh L1+L2+L3

Summation / accumulators Power outage duration minutes (accumulation of all outages since last reset)

Summation / accumulators Power outage count (number of outages since count was last reset to 0)

Summation / accumulators Error Counter - A count of the number of alarms that have occurred for RAM

Failure, Non-Volatile Memory Failure, Clock Error, Measurement Error,

Cover Removed, and Save-All Aborted.

Present / instantaneous Forward active kW L1+L2+L3

Present / instantaneous Reverse active kW L1+L2+L3

Present / instantaneous Import reactive kvar L1+L2+L3

Present / instantaneous Export reactive kvar L1+L2+L3

Present / instantaneous RMS current L1

Present / instantaneous RMS current L2

Present / instantaneous RMS current L3

Present / instantaneous RMS voltage L1

Present / instantaneous RMS voltage L2

Present / instantaneous RMS voltage L3

Present / instantaneous Power factor L1

Present / instantaneous Power factor L2

Present / instantaneous Power factor L3

Present / instantaneous VA power L1+L2+L3

Present / instantaneous Frequency

Present / instantaneous Sine of phase angle L1 (angle between voltage and current on L1)

Present / instantaneous Sine of phase angle L2 (angle between voltage and current on L2)

Present / instantaneous Sine of phase angle L3 (angle between voltage and current on L3)

Demand Date/time

Demand Previous demand value

Demand Present demand value

Demand Cumulative demand value

Demand Continuous cumulative demand value

Demand Maximum demand value

Note: The demand values listed above are available to be displayed for any of the 8 configurable demand

sources. The 8 demand sources are forward power, reverse power, forward + reverse power, and forward

- reverse active power, as well as for reactive power for all 4 quadrants.

Self-read/One-time-read/

Historical demand reset

Self-read/One-time-read/

Historical demand reset

Self-read/One-time-read/

Historical demand reset

Forward active kWh L1+L2+L3

Reverse active kWh L1+L2+L3

Forward + reverse active kWh L1+L2+L3

ANSI Electric Meter v3.1 User’s Guide 19

Page 26

Value Type Item Description

Self-read/One-time-read/

Historical demand reset

Self-read/One-time-read/

Historical demand reset

Self-read/One-time-read/

Historical demand reset

Self-read/One-time-read/

Historical demand reset

Self-read/One-time-read/

Historical demand reset

Self-read/One-time-read/

Historical demand reset

Self-read/Historical

demand reset date and

time

Note: Self-read and One-time-read values can be configured to display from any of the 24 Self-read or

One-time-read data sets stored in the meter, and for 12 of the historical demand reset data stored in the

meter.

Date Local DST (Daylight Saving Time) date in meter

Time Local DST (Daylight Saving Time) time in meter

Pre-pay, total Prepay credit remaining, in Wh

Pre-pay, emergency Prepay emergency credit remaining, in Wh

TOU calendar ID Identifier of the Time-of-Use calendar that is presently operating

Firmware version Firmware version currently running in the meter. You can configure the

Disconnect Open The meter can be configured to display the reason the load disconnect

Demand Resets The number of demand resets that have occurred.

Load Side Voltage

Detected

Forward – reverse active kWh L1+L2+L3

Import reactive kvarh L1+L2+L3

Export reactive kvarh L1+L2+L3

Power outage duration seconds (accumulation of all outages since last

reset)

Power outage count (number of outages since count was last reset to 0)

Error Counter – A count of the number of alarms that have occurred for RAM

Failure, Non-Volatile Memory Failure, Clock Error, Measurement Error,

Cover Removed, and Save-All Aborted.

Date and time that a self-read occurred

meter to display its firmware version for 1-15 seconds on power-up, if

desired.

When the firmware version is shown on the meter display, the alphabet

character portion is shown as a numeric value. The letter “a” is shown as

01, “b” as 02, “c” as 03, and so on through the alphabet. For example,

firmware version 1.00a is shown on the meter display as 01 00 01.

contactor has been opened as a user-specified text string. The follo wing

characters are not supported: K, M, Q, V, W, X.

Note that the digit “2” is used to represent the letter “Z,” the digit “1” is used to

represent the letter “I” and the digit “5” is used to represent the letter “S.”

The meter can be configured to automatically reject remote closing of the

load disconnect contactor when load side voltage is present, and to display

the reason for this as a user-specified text string. The same character

restrictions as described for the Disconnect Open display item above apply.

For more information on this feature, see “Remote Disconnect” on page 1.

Push Button Operation

The push button on the front of the meter (next to the display and labeled LCD),

performs various functions. The button functions are:

20 Meter Operation

Page 27

Display Advance: When pushed and released in less than 3 seconds, the

display immediately advances to the next item. After a change to a new item

due to the activation of the push button, the display shows the item until

either the button is pushed again or the regular scroll time (on time) expires,

whichever occurs first. Once the regular scroll time expires, the display

returns to its normal operation.

Prepay Credit Alarm Silencing: When the audible prepay credit alarm is

activated (due to a low or exhausted prepay credit level) the button can be

pushed for any length of time to silence the alarm.

Push Button Hold Time: When the button is pushed and held down for

longer than 3 seconds, the display changes to show the number of seconds

that the button has been held, and the ID code changes to “PTIM.” This

allows you to track how long the button has been held in order to activate a

desired function.

Self Tests and Diagnostic Messages

The meter performs a comprehensive self-test at power-up and periodically performs

additional diagnostics and self-tests, with messages created to indicate the

occurrence of alarm or error conditions. Some self-tests are performed every second,

minute, hour, daily, or weekly, and some self-tests are performed on power-up only.

Detected faults can be read by the Data Concentrator and transmitted to NES

System Software, and can also be read directly from the meter via the optical port

using the Provisioning Tool. Diagnostic or alarm flags are set for the specific

condition and must be cleared either via the optical port (using the Provisioning Tool)

or by NES System Software through the Data Concentrator. You can configure the

meter to show selected message codes on the display as cautions or errors.

Understanding Display Diagnostic Codes

The diagnostic codes are hexadecimal values, which will allow all possible diagnostic

events to be shown on the display simultaneously. If more than one error or caution is

occurring, the displayed characters are a combination of the error or caution values.

Diagnostic Event Descriptions

The following table lists the diagnostic events that can generate error or caution

messages. The Display Code column shows the value for each event, and is the value

shown on the meter display when only one event in each digit position is being

reported. When more than one event is being reported for the same digit position, the

displayed value is the sum of the event codes. Message codes are displayed on 2

screens, with scrolling between them occurring at the standard scroll time set for the

normal display sequence.

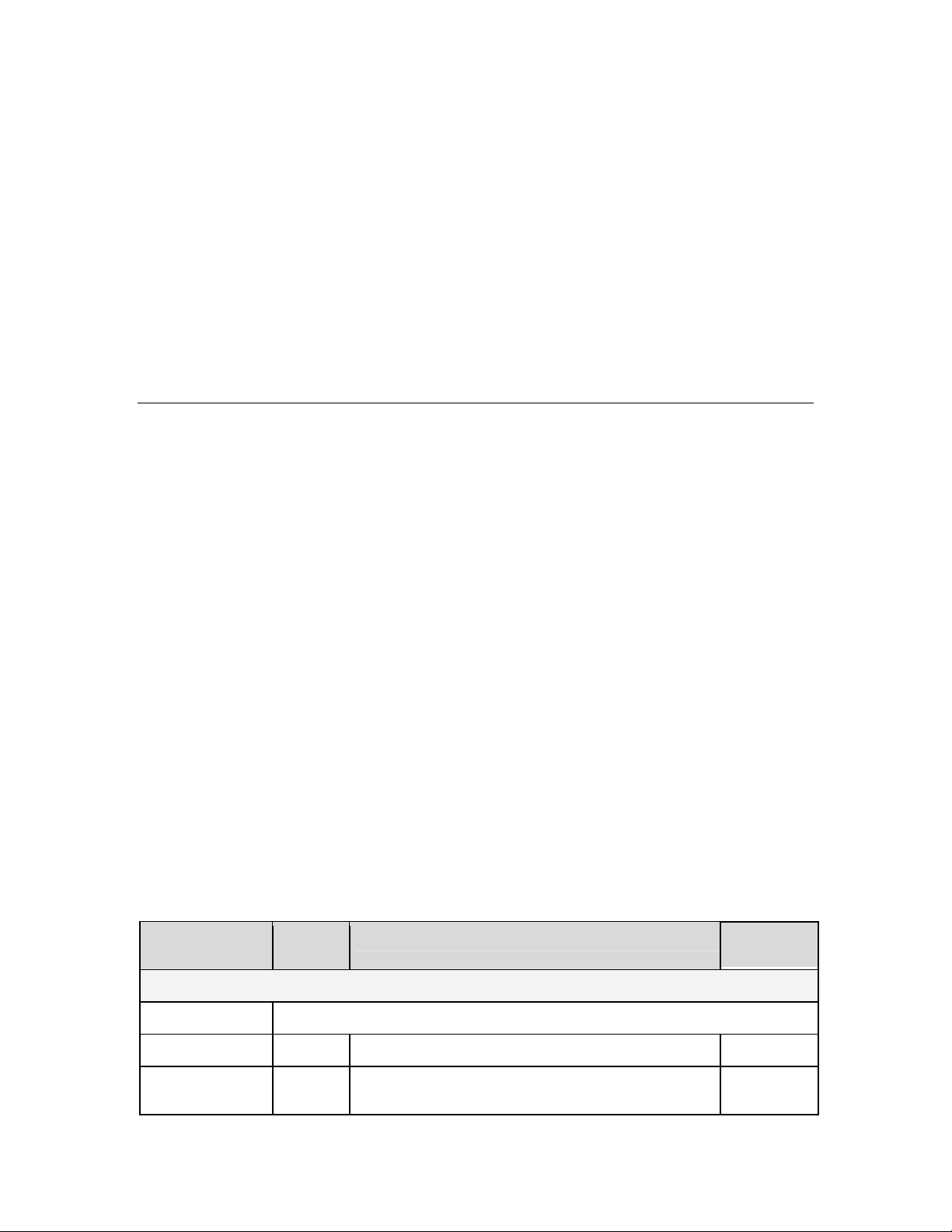

Error or Caution

Item

Display

Code

Description Self-Test

Schedule

Screen 1

Configuration Error 00000002 PLC communications IC initialization failed At power-up

System Reset 00000004 Watch-dog reset or event buffer overflow occurred. May

ANSI Electric Meter v3.1 User’s Guide 21

Display Code Digit Position 8

be due to momentary voltage interruption.

Upon

occurrence

Page 28

r

Error or Caution

Item

RAM Failure 00000008 Memory corruption occurred. Upon

ROM Failure 00000010 Invalid CRC in Bootrom

Non-Volatile

Memory Failure

Clock Error 00000040 Loss of clock memory data or clock functions have been

Measurement Error 00000080 Metering error occurred. Once per

Low Battery 00000100 Real Time Clock backup battery is below 2.5V. Daily

Power Failure 00000800 Power failure occurred since this flag was last cleared.

Display

Code

Display Code Digit Position 7

00000020 CRC verification failed. Memor y may have been

Display Code Digit Position 6

Display Code Digit Position 5

Description Self-Test

corrupted.

suspended due to meter having been without AC power

for an extended period of time.

Detected upon occurrence at time of power-down.

Schedule

occurrence

At power-up

At power-up

second

Upon

occurrence

Cover Removed 00001000 The meter main cover has been removed. Considered a

tamper event.

Reverse Energy 00002000 Meter has registered reverse power for 10 consecutive

seconds. Considered a possible tamper event.

Data Backup

Incomplete

Disconnect Switch

Error

Load Profile

Overflow

Self-Read Occurred 02000000 New self-read has be en recorded. Diagnostic event

Load Disconnect

Open

00004000 A data backup procedure did not complete. At power-up

00008000 Disconnect open/closed state may be incorrect.

Note: This flag is also set when the voltage isolation link is

removed for accuracy testing.

Display Code Digit Position 2

01000000 Load profile memory overflow occurred; unread records

have been overwritten.

coincides with self-read schedule.

04000000 Disconnect switch has been o pened (turned off) by meter

internal command.

Once per

second

Once per

second

Upon

occurrence

Every loadprofile interval

At self-read

Upon

occurrence

and every hou

while off

command is

active

22 Meter Operation

Page 29

Error or Caution

Item

Control Relay Open 08000000 Control relay is in open state. Upon

Phase Loss 10000000 Phase loss detected. By default, this indicates that voltage

Phase Inversion 20000000 Phase inversion detected. Neutral and one phase have

PLC Config Failure 40000000 Error reading PLC configuration data. Data may be

General Error 80000000 Power-down process error and/or display read-back failed. Upon

Display

Code

Display Code Digit Position 1

Display Code Digit Position 8

Description Self-Test

below 61% of rated voltage has been detected on at least

one phase. However, the percentage that constitutes a

phase loss is user-configurable. Considered a possible

tamper event.

been swapped. Considered a possible tamper event.

corrupted.

Screen 2

Schedule

occurrence

and every hour

while relay is

open

Upon

occurrence

Upon

occurrence

At power-up

occurrence

Invalid Password 00000001 An invalid password was entered during optical

communications.

Remote

Communications

Inactive

Current on Missing

or Unused Phase

Reserved 00000008 N/A N/A

Reserved 00000010 N/A N/A

Software CRC Error 00000020 Image ID or CRC error during boot-up procedure. Upon

Code Bank

Changed

Load Profile Backfill

Failed

MEP Installed or

Removed

00000002 Remote communications (PLC) inactiv e for the last 24

hours, by default. The duration required to trigger this

alarm is now user-configurable.

00000004 Current flow greater than 2A detected on a phase with low

or no voltage. This usually indicates that a Potential Test

Link is open. Considered a possible tamper event.

Display Code Digit Position 7

00000040 Active (executing) code bank has been ch anged. Upon

00000080 Load profile was not backfilled at power-up because meter

was off across midnight.

Display Code Digit Position 6

00000100 Indicates that a MEP (Multipurpose Expansion Port)

module has been field installed or removed from the

electric meter.

Upon

occurrence

Daily

Upon

occurrence

occurrence

occurrence

Upon

occurrence

Upon

occurrence

ANSI Electric Meter v3.1 User’s Guide 23

Page 30

Error or Caution

Item

MEP Alarm 00000200 A MEP alarm has occurred. Upon

Reserved 00000400 N/A N/A

Phase Rotation

Changed

Prepay Credit

Exhausted

Prepay Warning

Acknowledged

Event Log Overflow 00004000 The event log is within 10% of using its total capacity. Upon

Mfg Log Entry

Available

Log Dimension

Changed

Display

Code

00000800 Wiring positions for a 3-phase meter have changed, or any

Display Code Digit Position 5

00001000 Prepay credit has gone to 0 (zero). Upon

00002000 User has pushed the button on the front of the meter to

00008000 A meter One-time-read or M-Bus One-time-read has

Display Code Digit Position 4

00010000 The size of one or more logs has chang ed, possibly

Description Self-Test

Schedule

occurrence

Once per

of the phases are inactive or missing.

turn off the audible prepay low credit alarm.

occurred.

impacting how the data is read. For internal use only.

second

occurrence

Upon

occurrence

occurrence

Upon

occurrence

Upon

occurrence.

Not used 00020000

Access Lockout

Override

Power Quality

Event Detected

Event Log Unread

Entries

THD Event

Detected

Unread Entries

Exist in Load Profile

00040000 The access lockout has been deactivated. The access

lockout settings were not, or are not, in effect.

00080000 A power quality event (sag/su rge/over-current) has been

detected on one or more phases.

Display Code Digit Position 3

00100000 One or more unread entries exist in the event log. This

alarm is cleared automatically when there are 0 unread

entries.

00200000 A THD (total harmonic distortion) event has occurred. Upon

00400000 Unread entries exist i n the load profile log. Upon

Reading Diagnostic Code Combinations

The diagnostic codes are assigned a display digit position, with up to 4 items

assigned to each position. When more than one diagnostic event is being reported for

the same digit position, the displayed value is the sum of all event codes. When the

Upon

occurrence

When any new

event is

detected on

any phase, or

when any

event is

removed from

any phase.

Upon

occurrence

occurrence

occurrence

24 Meter Operation

Page 31

added value of the code digits exceeds 9, it will be represented by a hexadecimal

letter. The following table shows the numeric equivalent of the hexadecimal letter.

Hexadecimal Character

Shown on Display

A 10

B 11

C 12

D 13

E 14

F 15

Numeric

Value

Figure 3.3 shows the reference numbering of the display digit positions, and the 4character value ID location.

Diagnostic code display digit position: 1 2 3 4 5 6 7 8

4-character

value ID.

Figure 3.3: Display, All Segments Lit. Diagnostic Code Display Character Locations

Diagnostic Code Interpretation Examples

The display shows on screen 1: 0E001000

For this example, “E” is in Display Code Digit Position 2. E = a numeric value of

14. The following diagnostic events are indicated since their display code sum is

14: “Self-Read Occurred, Disconnect Switch Open, and Control Relay Open.”

“1” is in Display Code Digit Position 5. The following diagnostic event is

indicated: “Cover Removed.”

The display shows on screen 2:

For this example, “1” is in Display Code Digit Position 6. The following diagnostic

event is indicated since its display code sum is 1: “Low Battery.”

“8” is in Display Code Digit Position 7. The following diagnostic event is indicated

since its display code sum is 8: “LP Fill Error.”

00000180

ANSI Electric Meter v3.1 User’s Guide 25

Page 32

r

Display

Characte

1

2

3

4

5

6

7

8

9

A

(=10)

B

(=11)

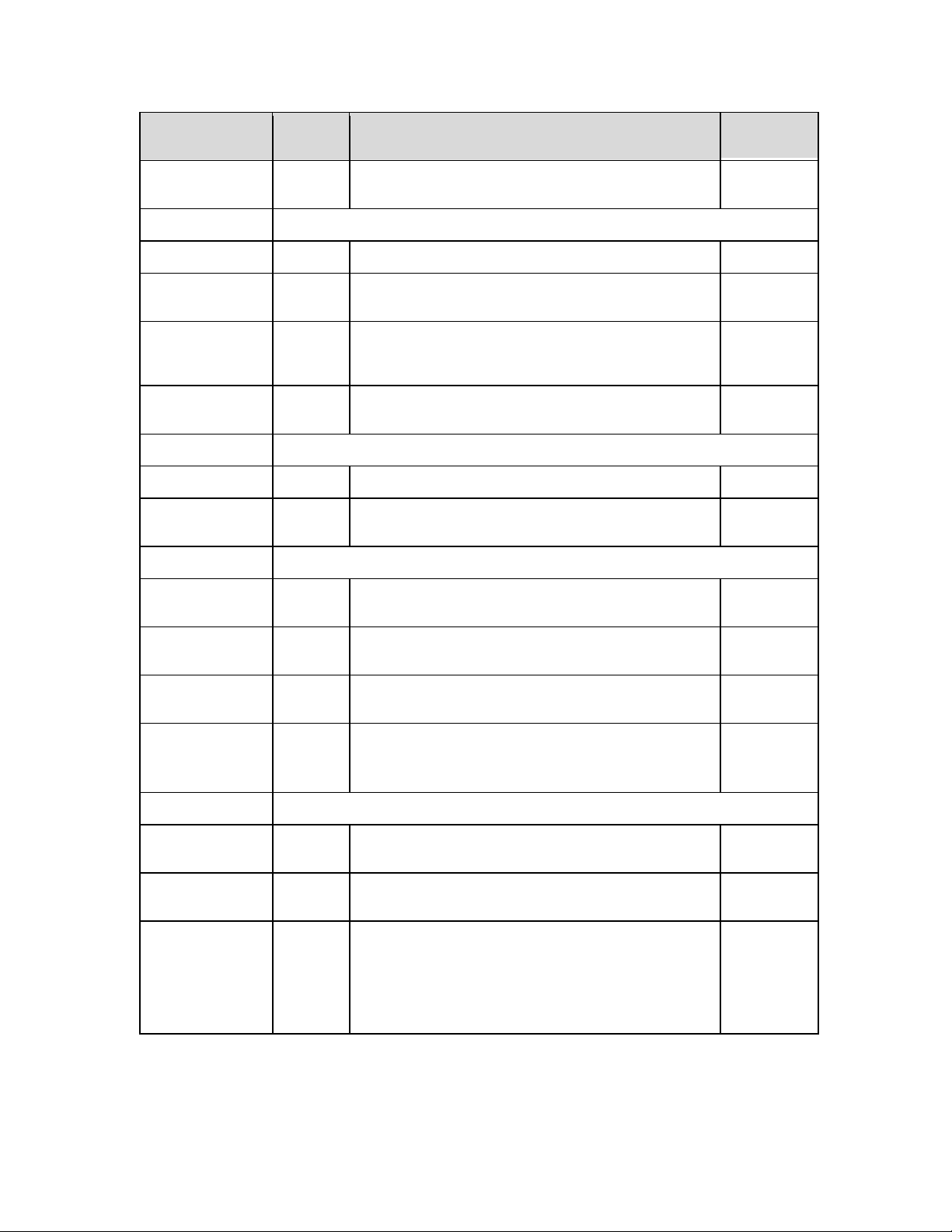

Look-Up Table for Code Combinations

The following look-up tables show the diagnostic events indicated for all possible

display characters in each digit position for screen 1 and screen 2.

Codes for screen 1:

Digit Position – Screen 1

1 2 3

(not used) 4 (not used)

Phase

Loss

Phase Inv. Self-Read Rev. Energy NV Mem

Phase

Loss

Phase Inv. Self-Read Rev. Energy

PLC Fail Disconnect

Phase

Loss

PLC Fail Disconnect

Phase Inv. Self-Read Rev. Energy NV Mem

PLC Fail Disconnect

Phase Loss LP Overflow Cover Off ROM

Phase Inv. Self-Read Rev. Energy NV Mem

PLC Fail Disconnect

General

Error

Phase

Loss

General

Error

Phase Inv. Self-Read Rev. Energy NV Mem

General

Error

Phase

Loss

Phase Inv. Self-Read Rev. Energy

LP Overflow Cover Off Low Battery ROM

LP Overflow Cover Off ROM

Backup

Open

LP Overflow Cover Off ROM

Backup

Open

Backup

Open

Backup

Open

Relay Open Disconnect

LP Overflow Cover Off Low Battery ROM

Relay Open Disconnect

Relay Open Disconnect

LP Overflow Cover Off ROM

5 6 7 8

Failure

Fail

Failure

NV Mem

Fail

Clock Error System

Incomplete

Failure

Clock Error

Incomplete

Fail

Clock Error System

Incomplete

Failure

Fail

Clock Error

Incomplete

Power Fail Meas. Error RAM Failure

Switch Error

Failure

Power Fail Meas. Error

Switch Error

Fail

Meas. Error RAM Failure

Switch Error

Failure

NV Mem

Fail

Config Error

Reset

Config Error

Reset

Config Error

26 Meter Operation

Page 33

r

ter

Display

Characte

C

(=12)

1 2 3

General

Error

PLC Fail Disconnect

General

Error

Relay Open Disconnect

Open

Relay Open Disconnect

Digit Position – Screen 1

5 6 7 8

(not used) 4 (not used)

Switch Error

Backup

Incomplete

Switch Error

Meas. Error

Clock Error System

Reset

Meas. Error RAM Failure

D

(=13)

E

(=14)

F

(=15)

Phase

Loss

PLC Fail Disconnect

General

Error

Phase Inv. Self-Read Rev. Energy NV Mem

PLC Fail Disconnect

General

Error

Phase

Loss

Phase Inv. Self-Read Rev. Energy NV Mem

PLC Fail Disconnect

General

Error

LP Overflow Cover Off ROM

Backup

Open

Relay Open Disconnect

Backup

Open

Relay Open Disconnect

LP Overflow Cover Off ROM

Backup

Open

Relay Open Disconnect

Incomplete

Switch Error

Incomplete

Switch Error

Incomplete

Switch Error

Failure

Clock Error

Meas. Error

Fail

Clock Error System

Meas. Error RAM Failure

Failure

Fail

Clock Error

Meas. Error

Config Error

Reset

Codes for screen 2:

Digit Position – Screen 2

Display

Charac-

1

2

3

ANSI Electric Meter v3.1 User’s Guide 27

1

(not used) 2 (not used) 3 (not used) 4 (not used)

Event Log

Unread

Entries

THD Event

Detected

Event Log

Unread

Entries

THD Event

Detected

Dimension

Change

Not Used Prepay

Dimension

Change

Not Used Prepay

5 6 7 8

Prepay

Exhausted

Warn Ack

Prepay

Exhausted

Warn Ack

MEP Install

/ Remove

N/A SW CRC

MEP Install

/ Remove

N/A SW CRC

N/A Bad PW

Error

N/A Bad PW

Error

No Comm

No Comm

Page 34

ter

Display

Charac-

4

5

6

7

8

9

A

(=10)

B

(=11)

Digit Position – Screen 2

1

(not used) 2 (not used) 3 (not used) 4 (not used)

Unread

Entries Exist

in Load

Profile

Event Log

Unread

Entries

Unread

Entries Exist

in Load

Profile

THD Event

Detected

Unread

Entries Exist

in Load

Profile

Event Log

Unread

Entries

THD Event

Detected

Unread

Entries Exist

In Load

Profile

Power

Dimension

Power

Not Used Prepay

Power

Dimension

Not Used Prepay

Access

Lockout

Override

Dimension

Change

Access

Lockout

Override

Not Used Prepay

Acces

Lockout

Override

Dimension

Change

Not Used Prepay

Acces

Lockout

Override

Quality

Event

Detected

Change

Quality

Event

Detected

Quality

Event

Detected

Change

5 6 7 8

Event Log

Overflow

Prepay

Exhausted

Event Log

Overflow

Warn Ack

Event Log

Overflow

Prepay

Exhausted

Warn Ack

Event Log

Overflow

Mfg Log

Entry

Available

Prepay

Exhausted

Mfg Log

Entry

Available

Warn Ack

Mfg Log

Entry

Available

Prepay

Exhausted

Warn Ack

N/A Code Bank

MEP Install

/ Remove

N/A Code Bank

N/A SW CRC

N/A Code Bank

MEP Install

/ Remove

N/A SW CRC

N/A Code Bank

Phase

Changed

MEP Install

/ Remove

Phase

Changed

N/A SW CRC

Phase

Changed

MEP Install

/ Remove

N/A SW CRC

0 V Current

Changed

N/A Bad PW

0 V Current

Changed

No Comm

Error

0 V Current

Changed

N/A Bad PW

No Comm

Error

0 V Current

Changed

LP Fill Error N/A

N/A Bad PW

LP Fill Error N/A

No Comm

Error

LP Fill Error N/A

N/A Bad PW

No Comm

Error

28 Meter Operation

Page 35

ter

Display

Charac-

C

(=12)

D

(=13)

E

(=14)

F

(=15)

Digit Position – Screen 2

1

(not used) 2 (not used) 3 (not used) 4 (not used)

Power

Quality

Event

Detected

Access

Lockout

Override

Power

Quality

Event

Detected

Dimension

Change

Access

Lockout

Override

Power

Quality

Event

Detected

Not Used Prepay

Access

Lockout

Override

Power

Quality

Event

Detected

Dimesnion

Change

Not Used Prepay

Access

Lockout

Override

Power

Quality

Event

Detected

5 6 7 8

Mfg Log

Entry

Available

Event Log

Overflow

Mfg Log

Entry

Available

Prepay

Exhausted

Event Log

Overflow

Mfg Log

Entry

Available

Warn Ack

Event Log

Overflow

Mfg Log

Entry

Available

Prepay

Exhausted

Warn Ack

Event Log

Overflow

Mfg Log

Entry

Available

Phase

Changed

N/A Code Bank

Phase

Changed

MEP Install

/ Remove

N/A Code Bank

Phase

Changed

N/A SW CRC

N/A Code Bank

Phase

Changed

MEP Install

/ Remove

N/A SW CRC

N/A Code Bank

Phase

Changed

LP Fill Error N/A

0 V Current

Changed

LP Fill Error N/A

N/A Bad PW

0 V Current

Changed

LP Fill Error N/A

No Comm

Error

0 V Current

Changed

LP Fill Error N/A

N/A Bad PW

No Comm

Error

0 V Current

Changed

LP Fill Error N/A

Power Quality

The meter monitors various parameters for power quality. Power quality events can

be read by the Data Concentrator and transmitted to NES System Software, and can

also be read directly from the meter via the optical port. When a power quality event

ANSI Electric Meter v3.1 User’s Guide 29

Page 36

occurs, the status must return to normal for at least 1 second for another power quality

event to be recorded. The meter provides power quality measurements for:

Voltage (RMS) sag (under voltage): Records the number of voltage sag

occurrences on any one phase. A voltage sag must last continuously for the

time set in the meter Sag/Swell Duration Threshold to be recorded as an

event. The threshold that determines if a voltage sag is recorded, is

configurable as a percentage below the factory-rated voltage. The threshold

range is 1 to 99%. The lowest voltage that occurred during the most recent

sag (after the duration threshold is met) is recorded, as well as the date and

time that the lowest recorded voltage occurred.

The user-configurable Sag/Swell Duration Threshold sets the number of

minutes that a voltage sag or swell must be sustained to be recorded as an

event. A setting of 0 (zero) forces the recording of every detected event. The

range is 0 to 255 minutes.

Voltage (RMS) swell (over voltage): Records the number of voltage swell

occurrences on any one phase. A voltage swell must last continuously for the

time set in the meter Sag/Swell Duration Threshold to be recorded as an

event. The threshold that determines if a voltage swell is recorded is

configurable as a percentage above the factory-rated voltage. The threshold

range is 1 to 99%. The highest voltage that occurred during the most recent

swell (after the duration threshold is met) is recorded, as well as the date and

time that the highest recorded voltage occurred.

Over-current (RMS): Records the number of over-current events on any one

phase. The over-current condition must last continuously for 10 seconds to be

recorded as an event. The threshold that determines if an over-current condition

is recorded is configurable as a percentage above the maximum current (as

labeled on the meter cover) on any one phase.

Power outages: Records the duration, power on date and time, and power off

date/time of the last 10 long power outages. Records a count of all short power

outages. The voltage must be below the internal power outage level and last

longer than the time (in seconds) set in the user-configurable Power Outage

Duration Threshold to be recorded as a long power outage event. The internal

power outage level is permanently set to approximately 74% of the rated voltage.

The range of the Power Outage Time Threshold is 0 to 65,535 seconds. Power

outages that are shorter than the Power Outage Time Threshold, but at least

200 milliseconds (approximately), are counted as a short power outage. If the

Power Outage Duration Threshold is set to 0 (zero) the duration and date/time of

every power outage event longer than approximately 200 milliseconds is

recorded, with complete records for the last 10 long outages. In this case, the

short outage count is not incremented.

Frequency: The frequency is constantly monitored (except for the first 1 to 2

seconds after power-up) and the maximum and minimum values, since last

reset, are recorded along with the time of the event.

Phase loss: Records the number of phase loss occurrences on any one phase

as well as the date and time of the last occurrence. Voltage (RMS) drop on

any phase below the internal phase loss level for a sustained duration of 10

seconds is considered a phase loss. The internal phase loss level is set to

approximately 61% of the rated voltage by default, although this figure is

user-configurable as of version 3.1. Since this event can affect the accuracy of

the meter, energy accumulation is automatically reconfigured to exclude the

lost phase. A phase loss error message can be shown on the display if

30 Meter Operation

Page 37

configured by the user. Phase loss also causes a diagnostic code to be

activated.

Total harmonic distortion (THD): Records three types of total harmonic

distortion: voltage total harmonic distortion (VTHD), current total harmonic

distortion (ITHD) and VA (volts-amperes) total harmonic distortion

(VATHD). THD is a ratio of the voltage or current at harmonic frequencies to

the voltage or current at the fundamental frequency for the meter, expressed

as a percentage. A THD event occurs when the value of any THD

measurement exceeds the defined threshold for the duration specified for that

threshold. For ANSI meters, THD measurements are made for the system

and not per phase, meaning that if you have different harmonics on separate

phases, the THD value reported by the ANSI meter will be a combination of

those values.

The number of total harmonic distortion events, the date/time of the last

occurrence, the average value of the last occurrence, and the maximum value

of the last occurrence are stored as power quality data, and can be recorded