Page 1

ECCO FINISHING AB, Box 93, S-532 22 SKARA, Sweden 9836 4056 01

Tel: +46 (0)511-134 45, Fax: +46 (0)511-180 13 2012-07

E-mail: info@eccofinishing.com • www.eccofinishing.com

EIB 12/15-01

0518 II 2 G EEx 0.24 mJ

Operation and Maintenance Manual

ECCO Xtatic

LP6000W

LP6000S

LP6000M

This manual contains important information on warnings and cautions. Read the

manual thoroughly before starting to operate this equipment, and follow the

instructions. Always keep the manual handy until such time as the equipment is no

longer being used. If your manual is lost or worn badly, do not hesitate to contact our

agency which is closest to you, or the ECCO Finishing AB, directly, and ask us to

send you a new one.

Air Electrostatic Spray Gun

Page 2

1

Thank you for your choice of ECCO Xtatic LP6000 series manual air electrostatic spray gun(s).

In order to ensure long and proper use of this equipment under the most optimum conditions,

please read all the contents of this Manual. You are requested to note and understand all of the

indicated specifications, warnings, prohibitions and cautions contained in this manual and to use

this equipment correctly following these instructions.

This spray gun is to be used in combination with the electrostatic coating controller Model BPS115.

The separate instruction manual for the controller should be used as a reference for the operation

of the entire system.

The equipment for which this Manual has been prepared is an apparatus for professional coating

work. The use of this product should only be by personnel who are well trained in handling and

operating, this equipment.

If there is anything in this Manual unclear to you, please ask our distributor in or contact us referring

to Model and Serial No. of the equipment in question, for a more detailed explanation.

Introduction

Page 3

2

Contents

1. For safety and correct use ··································· 1

2. Outline of the equipment ······································ 3

3. Specifications ···················································· 5

4. Features ·························································· 6

5. Exploded Diagram and names of parts ··················· 7

6. Installation ························································ 14

7. Safety control ···················································· 19

8. Checking before operation ··································· 21

9. Operation ························································· 22

10. Maintenance ····················································· 25

11. Trouble shooting on spray technique ······················ 27

12. Trouble shooting of equipment ······························ 30

13. Pars replacement and adjustment·························· 33

14. Service record ··················································· 39

15. Scope of warranty ·············································· 40

Page 4

- 1 -

Please read and follow all the technical and safety instructions in this manual.

Failure to do so may result in personal injury and/or property damage.

While all the safety precautions in the manual are very important, you should not consider them to

be as cure-all. They are nothing but minimum requirements. You may need some other types of

safety precautions: in fact, you may come across with other types of hazards not shown in the

manual down the road. And, of course, there are regulatory and voluntary safety requirements set

forth by the governments and businesses.

So, shown below and in the pages that follow are the basic minimum safety precautions in

connection with use of our product.

● Safety precautions are classified into three categories based on the severity of hazards involved.

WARNING

Alerts a hazardous situation which may result in personal injury, along with

hazard avoidance measures.

CAUTION

Alerts a hazardous situation which may result in equipment damage or

breakage, along with hazard avoidance measures.

NOTE

Indicates important methods and practical information.

※ Safety precautions classified into the CAUTION category could cause personal injury if not properly

followed. To ensure safety and prevent equipment failure, always observe the safety precautions and

follow the hazard avoidance measures.

1

For safety and correct use

Page 5

- 2 -

<<Range of Application of this equipment>>

Equipment covered by this Instruction Manual are electrostatic hand spray guns, Model

LP6000W/S/M which are to be used for manual paint spraying in a spray booth equipped with a

power exhaust.

This equipment is a manually operated spray gun used to apply paint to a grounded object.

If there is any question or if these instructions are not perfectly understandable, please consult

our distributor or contact a representative of ECCO Finishing AB for clarification.

The use of this equipment for any purpose other than that for which it is intended could cause

serious consequences.

<<CAUTIONS When Using the Painting Equipment>>

1. The object to be painted should be grounded without fail. Always use a conductive hanger.

Periodical cleaning should be performed so as to maintain conductivity.

2. All conductors or thinner container in the coating booth should be grounded. The structure of

the floor should have a preventive structure for static charge of 1M ohm or less.

3. The applicable area for the working floor of the open structure-coating booth is a rectangle

shaped area with a side of 1.5m (opening width + both sides) and the other side of 2.5m

(closer side of the opening part). This entire area should have a static charge preventive

structure of 1 M ohm. The area should be clean.

4. Operators should use bare hands or ware non-conductive gloves during operation.

5. Operators should ware the anti-electrostatic protective footwear.

6. Ventilation should properly be ensured during coating.

7. Fluid pressure and air pressure should be zero, and power switch of the control panel should

be turned off before the nozzle is washed. Do not touch nozzles during high voltage is

charged.

8. Do not use the metal brush for washing nozzles.

9. Do not immerse guns and hoses in the washing solvent.

10. Hoses should be hanged from the ceiling or side walls instead of being trailed on the floor.

11. Duct fan of the coating booth should always be cleaned to maintain cleanliness.

12. Distance between the nozzle end and the object to be painted should be 150mm or more.

13. Fire extinguisher should always be provided in the vicinity of the work site for in case of fire

caused by electrostatic.

14. Operator should take a safety-operational lesson regarding the applicable coating

equipment before operation.

Page 6

- 3 -

The electrostatic spray guns, LP6000W/SM, are to be used in combination with control unit EXC LP

and a paint supply system (pump, pressure tank, or circulating system).

1. A typical make up of an air electrostatic spray system:

2

Outline of the equipment

Fig.1 An example of a system composition

Control unit should be installed outside the spray booth and at least 1.5m from the opening or

entrance.

WARNING

Air electrostatic hand spray gun

Connecting method, refer to the Clause 6 “ Installation”.

◎

Object

100V AC

Controller EXC LP

◎

Connecting cable

Grounding

Air hose

Air supply

Paint hose

Air supply

Grounding

Paint supply system

Pump, Pressure tank,

Circulating system

Page 7

- 4 -

2. Main parts of <LP6000S>

3. Names of main parts on <LP6000W>

Material adjusting valve

Barrel

Pattern air adjusting valve

Power cable

Hook

Trigger

Grip

Paint hose

(milky white color)

Pattern air adjusting valve

Material adjusting valve

Hook

Barrel

Grip

Trigger

Paint hose

(milky white color)

Air hose (black)

Power cable

Air hose (black)

Page 8

- 5 -

Air electrostatic spray gun

Model

LP6000W/S/M

Maximum voltage to be charged

DC -60kV

Shorting current

80μA

Fluid pressure

Normal

0 to 0,3MPa

Max.

0,62MPa

Air pressure

Normal

0.05 to 4MPa

Max.

0.62MPa

Air consumption

Max. 150L/min (normal)

Outside dimensions

L207 × W55 × H219 (mm)

Weight

(excl. cable, hose and nozzle)

545g (W/SM)

Connecting cable length

10m (extendable up to 30m in increments of 10m)

Standard

Machinery Directive 2006/42/EC

Low-Voltage Directive 2006/95/EC

EMC Directive 2004/108/EC

ATEX Directive 94/9/EC

EN 50050:2001

Certification

Sira 10ATEX5053X

Sira Test & Certification Ltd.

Rake Lane, Eccleston

Chester, CH4 9JN, England

※ The cable length can be extended up to 30m by combining the extension and connecting cables.

Be very cautious in the use of a paint heating system. Material paint must be supplied at the

temperature not exceeding 40C. To high a temperature may cause the paint tube to soften and

disconnect.

Material supply system and fluid regulator:

Please refer to separate instruction manuals for each item.

Paint Materials should be used under pressures not to exceed 0. 6MPa.

If in doubt as to the selection of the proper material supply pump or system, please consult with

3

Specifications

CAUTION

Page 9

- 6 -

our Distributor or ECCO Finishing AB.

Page 10

- 7 -

1. Better maneuverability

The pattern adjusting valve at left side of gun body allows quick and easy adjustment. Lighter

weight and triggering provides less fatigue of workers.

2. High productivity

In addition to conventional electrostatic spray nozzles, newly developed flat spray nozzles are

featured to provide a more improved wrap-around effect resulting in higher transfer efficiency

and, the resultant material saving.

3. Easier maintenance

Most of the parts required for service are modularized which make them easier to replace. Also

the need of troublesome adjustment and re-tightening of packings is eliminated.

4. Longer parts life

Super hard alloy needle with a hardened material seat valve and self-sealing, spring loaded U

packings assure long working life.

5. High quality coating

Wide angle multi-step injection by flat spray nozzles can achieve beautiful finishes on flat

surfaces, particularly in metallic coating.

6. Wider range of material selection

Besides ordinary hi- solids paint, almost all types of conductive paints including metallic and

water-borne paints can be applied from an isolated material supply system.

7. Highly secured safety

Cascade built in the gun body means fewer areas being charged by high voltage and

substantially improved safety. High voltage control unit EXC LP has over-current protection

and resistance limitation, quick shut-off of high voltage electronic switching and buzzer alarm

system. These features ensure safety protection for the operator.

Safety is drastically enhanced because the area to which high voltage is applied is reduced by

incorporating a high voltage generator into the gun.

Features

4

Page 11

- 8 -

1. AIR ELECTROSTATIC GUN [LP6000W]

5

Breakdown drawing

B

C

Page 12

- 9 -

AIR ELECTROSTATIC GUN LP6000W

No

Part No.

Part Name

Qty

Note

No

Part No.

Part Name

Qty

Note

1

6004 0330 60

Body

1 36

6004 0330 85

E-shaped snap

ring

1

2

6004 0330 61

Grip end

1

*3

37

0663 9301 00

O-ring

1 3

6004 0330 62

Connector

1

*3

38

0663 9302 00

O-ring

1 4

6004 0330 63

Hose fitting

1 39

0663 9303 10

O-ring

1 5

6004 0330 96

Barrel

1 40

0663 9304 10

O-ring

2 6

6004 0330 64

Manifold

1 41

0663 9304 00

O-ring

2

7

6004 0330 97

Cascade

1 42

0663 9305 00

O-ring

2 8

6004 0330 98

Guide

1

*1

43

0663 9306 00

O-ring

2 9

6004 0330 65

Packing

1

*1

44

0663 9306 10

O-ring

2

10

6004 0330 66

Packing

1 45

0663 9307 00

O-ring

1

11

6004 0330 99

Needle

1

*2

46

6004 0330 29

Hex. socket bolt

1

12

6004 0330 67

Rod

1 47

6004 0330 28

Hex. socket bolt

1

13

6004 0330 68

Sleeve

1 48

6004 0330 36

Hex. socket bolt

with washer

3

14

6004 0330 69

Tappet

1 49

6004 0330 27

Two-point sems

screw

4

15

6004 0330 70

Washer

1 50

6004 0330 34

Hex. Nut

1 16

6004 0330 71

Retainer

1 52

6004 0330 91

Terminal cover

1

17

6004 0330 82

Packing

1 53

6004 0330 25

Trigger

1 18

6004 0330 83

Air valve seat

1 54

6004 0330 24

Nut

1 19

6004 0330 72

Spring

1 55

6004 0330 23

Hose support

1

20

6004 0330 73

Spring

1 56

6004 0330 22

Nylon screw

1

21

6004 0330 74

Spring

1 57

6004 0330 16

Paint hose

1

10m

22

6004 0330 75

Adapter

1 58

6004 0330 30

Cable

1

10m

23

6004 0330 76

Stopper

1 59

6003 7363 10

Air hose

1

10m

24

6004 0330 77

Adjuster

1 60

6004 0330 39

Hex. socket bolt

with washer

1 25

6004 0330 78

Air valve adjuster

1 61

6004 0330 38

Hex. socket bolt

with washer

2

26

6004 0330 79

Adapter

1 62

6004 0330 92

Plate

1

27

6004 0330 86

Pipe

1 63

6004 0330 93

Conical coil

spring

1

28

6004 0330 84

Gasket

1 64

6004 0330 35

Plain washer

1 29

6004 0330 87

Hook

1 65

6004 0330 94

Backup ring

1 30

6004 0330 17

Spring

1 66

6004 0330 95

Ring

1

*1

31

6004 0330 88

Sleeve

1 67

0663 9308 10

O-ring

1

*1

32

6004 0330 89

Stopper

1 A

6004 0330 81

Packing set

1

Set

33

6004 0330 48

Paint seat

1

*2 B 6004 0330 80

Needle set

1

Set

34

6004 0330 49

Valve seat ring

1 C

6004 0330 33

Grip end set

1

Set

35

6004 0330 90

Spacer

1

<Note> *1: A is a clamping part. This should be replaced by set unit.

*2: B needs wrapping at the time of replacement. This should be replaced by set unit.

*3: C needs bonding and soldering. This should be replaced by set unit.

Page 13

- 10 -

2. AIR ELECTROSTATIC GUN [LP6000S]

Breakdown drawing

C

B

Page 14

- 11 -

AIR ELECTROSTATIC GUN LP6000S

No.

PART №

Part Name

Qty

Note

No.

PART №

Part Name

Qty

Note

1

6004 0330 60

Body

1 36

6004 0330 85

E-shaped snap

ring

1

2

6004 0330 61

Grip end

1

*3

37

0663 9301 00

O-ring

1 3

6004 0330 62

Connector

1

*3

38

0663 9302 00

O-ring

1 4

6004 0330 63

Hose fitting

2 39

0663 9303 10

O-ring

1 5

6004 0330 96

Barrel

1 40

0663 9304 10

O-ring

2 6

6004 0330 64

Manifold

1 41

0663 9304 00

O-ring

2

7

6004 0330 97

Cascade

1 42

0663 9305 00

O-ring

2

8

6004 0330 98

Guide

1

*1

43

0663 9306 00

O-ring

2 9

6004 0330 65

Packing

1

*1

44

0663 9306 10

O-ring

2 10

6004 0330 66

Packing

1 45

0663 9307 00

O-ring

1 11

6004 0330 99

Needle

1

*2

46

6004 0330 29

Hex. socket bolt

1

12

6004 0330 67

Rod

1 47

6004 0330 28

Hex. socket bolt

1

13

6004 0330 68

Sleeve

1 48

6004 0330 36

Hex. socket bolt

with washer

3

14

6004 0330 69

Tappet

1 49

6004 0330 27

Two-point sems

screw

4

15

6004 0330 70

Washer

1 50

6004 0330 34

Hex. nut

1 16

6004 0330 71

Retainer

1 52

6004 0330 91

Terminal cover

1

17

6004 0330 82

Packing

1 53

6004 0330 25

Trigger

1 18

6004 0330 83

Air valve seat

1 54

6004 0330 21

Stay

1 19

6004 0330 72

Spring

1 55

6004 0330 20

Packing

2 20

6004 0330 73

Spring

1 56

6004 0330 26

Connector

2

21

6004 0330 74

Spring

1 57

6004 0330 18

Tube

1 22

6004 0330 75

Adapter

1 58

6004 0330 19

Cover

1 23

6004 0330 76

Stopper

1 59

6004 0330 30

Cable

1

10m

24

6004 0330 77

Adjuster

1 60

0663 9309 00

O-ring

1

25

6004 0330 78

Air valve

adjuster

1 61

6004 0330 39

Hex. socket bolt

with washer

1

26

6004 0330 79

Adapter

1 62

6004 0330 38

Hex. socket bolt

with washer

1

27

6004 0330 86

Pipe

1 63

6004 0330 92

Plate

1

28

6004 0330 84

Gasket

1 64

6004 0330 93

Conical coil

spring

1

29

6004 0330 87

Hook

1 65

6004 0330 35

Plain washer

1 30

6004 0330 17

Spring

1 66

6004 0330 94

Back-up ring

1

31

6004 0330 88

Sleeve

1 67

6004 0330 95

Ring

1

*1

32

6004 0330 89

Stopper

1 68

0663 9308 10

O-ring

1

*1

33

6004 0330 48

Paint seat

1

*2 A 6004 0330 81

Packing set

1

Set

34

6004 0330 49

Valve seat ring

1

B 6004 0330 80

Needle set

1

Set

35

6004 0330 90

Spacer

1

C 9004 0330 33

Grip end set

1

Set

<Note> *1: A is a clamping part. This should be replaced by set unit.

*2: B needs wrapping at the time of replacement. This should be replaced by set unit.

*3: C needs bonding and soldering. This should be replaced by set unit.

Page 15

- 12 -

3. AIR ELECTROSTATIC GUN [LP6000M]

Breakdown drawing

Page 16

- 13 -

AIR ELECTROSTATIC GUN LP6000M

No.

PART №

Part Name

Qty

Note

No.

PART №

Part Name

Qty

Note

1

6004 0330 60

Body

1 36

6004 0330 85

E-shaped snap ring

1

2

6004 0330 61

Grip end

1

*3

37

0663 9301 00

O-ring

1 3

6004 0330 62

Connector

1

*3

38

0663 9302 00

O-ring

1 4

6004 0330 63

Hose fitting

2 39

0663 9303 10

O-ring

1 5

6004 0330 96

Barrel

1 40

0663 9304 10

O-ring

2 6

6004 0330 64

Manifold

1 41

0663 9304 00

O-ring

2

7

6004 0330 97

Cascade

1 42

0663 9305 00

O-ring

2

8

6004 0330 98

Guide

1

*1

43

0663 9306 00

O-ring

2 9

6004 0330 65

Packing

1

*1

44

0663 9306 10

O-ring

2 10

6004 0330 66

Packing

1 45

0663 9307 00

O-ring

1 11

6004 0330 99

Needle

1

*2

46

6004 0330 29

Hex. socket bolt

1 12

6004 0330 67

Rod

1 47

6004 0330 28

Hex. socket bolt

1

13

6004 0330 68

Sleeve

1 48

6004 0330 36

Hex. socket bolt with

washer

3

14

6004 0330 69

Tappet

1 49

6004 0330 27

Two-point sems

screw

4

15

6004 0330 70

Washer

1 50

6004 0330 34

Hex. nut

1 16

6004 0330 71

Retainer

1 52

6004 0330 91

Terminal cover

1 17

6004 0330 82

Packing

1 53

6004 0330 25

Trigger

1 18

6004 0330 83

Air valve seat

1 54

6004 0330 21

Stay

1

19

6004 0330 72

Spring

1 55

6004 0330 20

Packing

1 20

6004 0330 73

Spring

1 56

6004 0330 26

Connector

2 21

6004 0330 74

Spring

1 57

6004 0330 37

Spiral tube set

1 22

6004 0330 75

Adapter

1 58

6004 0330 19

Cover

1

23

6004 0330 76

Stopper

1 59

6004 0330 30

Cable

1

10m

24

6004 0330 77

Adjuster

1 60

0663 9309 00

O-ring

1

25

6004 0330 78

Air valve

adjuster

1 61

6004 0330 39

Hex. socket bolt with

washer

1

26

6004 0330 79

Adapter

1 62

6004 0330 38

Hex. socket bolt with

washer

1

27

6004 0330 86

Pipe

1 63

6004 0330 92

Plate

1

28

6004 0330 84

Gasket

1 64

6004 0330 93

Conical coil spring

1 29

6004 0330 87

Hook

1 65

6004 0330 35

Plain washer

1 30

6004 0330 17

Spring

1 66

6004 0330 94

Back-up ring

1

31

6004 0330 88

Sleeve

1 67

6004 0330 95

Ring

1

*1

32

6004 0330 89

Stopper

1 68

0663 9308 10

O-ring

1

*1

33

6004 0330 48

Paint seat

1

*2

69

6004 0330 59

Packing

1 34

6004 0330 49

Valve seat ring

1

A 6004 0330 81

Packing set

1

Set

35

6004 0330 90

Spacer

1

B 6004 0330 80

Needle set

1

Set

C 9004 0330 33

Grip end set

1

Set

<Note> *1: A is a clamping part. This should be replaced by set unit.

*2: B needs wrapping at the time of replacement. This should be replaced by set unit.

*3: C needs bonding and soldering. This should be replaced by set unit.

Page 17

- 14 -

4. FLAT NOZZLE

FLAT NOZZLE Ø1,6

No.

Part No.

Part Name

Qty

Note

No.

Part No.

Part Name

Qty

Note

1

6004 0330 44

60 Air Cap

1 4

6004 0330 46

Stopper Ring

1 2

6004 0330 52

Paint Nozzle (1. 6)

1 5

6004 0330 47

Charge Electrode

1 3

6004 0330 45

Retaining Nut

1

FLAT NOZZLE Ø1,1

No.

Part No.

Part Name

Qty

Note

No.

Part No.

Part Name

Qty

Note

1

6004 0330 44

60 Air Cap

1 4

6004 0330 46

Stopper Ring

1 2

6004 0330 51

Paint Nozzle (1. 1)

1 5

6004 0330 47

Charge Electrode

1 3

6004 0330 45

Retaining Nut

1

FLAT NOZZLE Ø0,8

No.

Part No.

Part Name

Qty

Note

No.

Part No.

Part Name

Qty

Note

1

6004 0330 43

61 Air Cap

1 4

6004 0330 46

Stopper Ring

1 2

6004 0330 50

Paint Nozzle (0. 8)

1 5

6004 0330 47

Charge Electrode

1 3

6004 0330 45

Retaining Nut

1

Breakdown drawing

Page 18

- 15 -

The standard system composition with LP6000W/S/M guns are illustrated on Fig. 1 (page 3).

1. Connection of air supply

Connect air supply hose to air regulator on the control unit. (G 1/4 fitting)

2. Connection of grounding wire

Securely connect a grounding wire to control unit. Phillips screwdriver is required for this

operation.

Grounding wire for control unit should be 3.5mm2 or larger, and be connected to any place

prepared with Class 1 grounding (grounding resistance under 10Ω.)

Installation

6

CAUTION

Page 19

- 16 -

3. Connection of the power cable to the spray gun

After cleaning the metal connector at the end of power cable fixed to gun with clean cloth,

connect it securely to output terminal (OUTPUT) on the control unit.

Attach the cable to the gun by tightening it manually.

After the attachment, use a stopper for locking. Do not tighten excessively when the

attachment position does not seem to be correct. In such cases, attach the cable so that the

surface of the stopper may closely contact to the hexagonal plain part while loosening the nut.

Fix the cable and the air hose with the insulation lock at the position 70 to 80cm from the gun.

At this time, allowance is required for the cable so as not to apply load to the root part of the

connector.

When the cable, air hose, paint hose or the like are held together with a tape, a small allowance

is needed so as not to apply the tensile force to the cable. If a tension is applied to the cable

during operation, this might lead to breakage of the cable. See “6. CAUTIONS WHEN BANDING

L. V. CABLE WITH HOSES” for more details.

CAUTION

Page 20

- 17 -

4. Connection of air hose

Connect one end of the air hose to the nipple at rear side of the spray gun (next to power cable)

and the other end to the air exit on the control unit and tighten (G 1/4 fitting). It is recommended

that the spanner of 17mm be used.

*The case in which two hoses are used.

Be sure to use two spanners when the air hose or paint hose is attached to the gun in order to

prevent applying excessive force to the gun. In addition, do not allow the spanner to contact the

cable connector at the time of attaching or removing.

Effective atomization can be obtained by using an air hose of 3/8 inch when the air hose is longer

than 10m. Attach a joint bushing to have a screw opening of G 3/8.

5. Connection of paint hose

One end of the paint hose should be connected to the nipple at the front side and the lower end of

the gun grip (front side of the cable), and the other end of the paint hose is attached to the pump

system.

CAUTION

CAUTION

Page 21

- 18 -

6. CAUTIONS WHEN BANDING L. V. CABLE WITH HOSES

(1) In order to extend the life of the cable, follow the instructions on the cautions of banding the

cable with the hoses.

1) Do not band the connection cable at the length shorter than 70cm from the grip portion of

the gun.

2) When banding the cable, there should be enough allowance to the cable relative to the air

and paint hose so as not to cause excessive bending or tension to the cable when the gun

is faced upward, downward, left or right.

3) When banding the cable at a length longer than 70 cm from the grip portion of the gun,

make an enough allowance at 5cm intervals using resin bands (insulation lock) vinyl tape.

Do not wind the vinyl tape of wide-spiral tape continuously, because the wound part

becomes the rod-like shape and this might cause the breakage of the cable or hose.

(2) Do not operate the gun or do not band the cable so as not to cause excessive bending or

tensile to the cable, air hose and paint hose during painting. If this is not observed, breakage

might occur due to degradation of strength.

(3) Please pay attention not to step on the cable. Breakage might occur if you step on the cable

placed on the metal pallet.

(4) Do not wind on the cable the vinyl tape or the like continuously for reinforcement or

contamination-prevention, especially portion close to the gun connector. Breakage might

occur if you step on the cable placed on the metal pallet.

(5) Do not immerse cable into solvent or paint. It will shorten the cable life.

(6) Wipe off the solvent on the surface or air-blowing should be performed after washing of the

cable.

(7) Do not use metal cable ties, they will build a capacitance charge and discharge to nearest

ground.

CAUTION

Airhose (black)

L.V. cable

When banding the cable, there should be enough

allowance to the cable relative to the air and paint

hose so as not to cause excessive bending or

tension to the cable when the gun is faced upward

or downward.

Intervals: 5cm or longer at the

portion after 70cm

Approx. 70cm

Paint hose

Page 22

- 19 -

7. Assembly of nozzle with gun

1) Fix and tighten together the nozzle joint and material nozzle.

2) Put charging electrode into the material nozzle and fix nozzle joint to extension, tightening

it with the spanner (Hex. 10).

3) Put the air cap in the holding nut and fix them to the barrel and tighten by hand.

The fixing nut and air cap are to be put together as an assembly.

As it is made of resin, excessive tightening might lead to the damage to the inner screw of the

nozzle mount joint. Pay attention when attaching and removing.

Air cap can be slightly tightened by fingers. If it is tightened too much, paint nozzle might loosen

when changing the direction of the air cap. This might lead to coating failure.

Materials of air caps or nozzles are resin which can withstand the solvent. However, immersion

for long time might deteriorate the original performance. Wash them with solvent and dry

sufficiently with air blow before storage.

The Electrostatic spray nozzle is very precisely

made. Special cautions must be taken to keep it

clean and free from damage.

Nozzle Joint

Charge Electrode

Paint Nozzle

Air Cap

Fixing nut

Barrel

CAUTION

CAUTION

CAUTION

Page 23

- 20 -

In order to maintain safety of operation and good condition for the equipment, please note the

following issues for care not only before and during but after operation.

Securely ground the control unit.

It is one of the most basic provisions for safety to ground the control unit, as grounding for the

spray gun is also accomplished by grounding the control unit.

The object to be coated must be grounded.

The grounding resistance for the object should not exceed 1M ohm. (Resistance

measurement voltage to be 500V minimum) Objects can be normally grounded through

hangers and conveyors but excessive dried paint on hangers may degrade their conductivity

and allow electrostatic accumulation of a charge on the part which sometimes leads to

discharge a spark and a possible resultant fire. To prevent these dangers, hangers should be

cleaned regularly to remove dried paint that can act as an insulator.

All conductive articles in the spray booth must be grounded.

In the spray booth, high voltage may ionize the air around the coating equipment, which has

a danger of electrostatic accumulation on any conductive materials that are not grounded,

resulting in a possibility of sparking. Apparatuses such as coating equipment mounting

stand and safety guards made of metal must be securely grounded. Also do not place any

paint containers or tools which are unnecessary in the booth. Even outside the booth, solvent

containers should be grounded if they are close to or near to booth entrance.

Handle coating equipment with bare hands.

Though the gun grip is grounded through the cable and control unit, wearing of

non-conductive gloves on hands means insulation of human body where electrostatic is

accumulated, creating a danger of electric shock when any part of the body touches a

grounded article. If wearing of gloves is necessary for any reason, the glove should have a

hole so that bare skin of the hand can contact the gun grip.

Be sure to wear leather soled or anti-electrostatic shoes.

As indicated above, air in the spray booth is ionized by electrostatic coating and can

accumulate energy in the human body which will discharge to ground. Operators and other

people who intend to get in the booth are to be neighboring area should put on

anti-electrostatic shoes for safety. Such shoes should be also regularly cleaned not to allow

excessive accumulation of paint or other dirt. Naturally, the floor of working area should be

conductive.

The working floor should have static charge preventive structure. The close

structure-painting booth should have this preventive structure for the entire floor; the open

structure-coating booth should have this preventive structure for the area having both sides

of 1.5m and the front side of 2.5m. These area should have a static charge preventive

structure of 1 M ohm, and should be clean.

Whenever it is necessary to clean or wash nozzles, switch off the power to the control unit

and touch the electrode in the gun head to any ground to discharge any residual high voltage

in the system during the nozzle cleaning.

7

Safety control

WARNING

Page 24

- 21 -

Never use a metal brush to clean nozzles.

Nozzles are vital parts of the coating equipment and may be easily damaged by the use of

metal brushes, which can cause distorted paint atomization. When cleaning is required, use

a bamboo brush provided in the tool kit supplied with the equipment. Also be cautious of the

electrode pin on the nozzle. It is sharp and can penetrate your skin during nozzle cleaning.

Do not dip the entire gun, cable or hoses in solvent.

Electrostatic spray equipment may be easily damaged by soaking in solvent.

Do not drag cables and hoses on the floor. They should be suspended by hanging from

ceiling or wall as much as possible. If conductive paint is being dispensed, hang the hoses

away from ground with insulated “stand offs”.

Keep the inside of booth and the exhaust system (ducts, fan, etc. ) clean by regular cleaning.

If they are contaminated with paint or other dirt, they increase the possibility of an accidental

fire in the booth.

Fully drain water from air transformers, air compressors, etc.

Existence of water in the air line may cause poor coating appearance and may energize the

safety circuit causing the buzzer alarm to sound.

Keep a distance between the nozzle head and object surface at least 150mm. Normally

electrostatic spray guns are designed to decrease the hi-voltage potential automatically when

the spray gun approaches a grounded item. In cases where an insulated paint supply pump

is being used(for lower electric resistance paint like metallic paints, woodworking paints,

emulsion paint, etc. ), the guns potential is not decreased to the level of the pumps potential,

causing the possibility of a capacitance discharge and the resultant spark. Cares must be

taken to keep sufficient distance between the gun and ground at all times. Part swinging on

the conveyor can rapidly create this potential problem.

When using an isolation stand, keep it at least 500mm from other surrounding articles, being

sure it is protected from personnel with fencing. Provisions must be made to ground the

system after power is switched off. If in doubt concerning the proper safety grounding of a

fluid supply system, consult your distributor or ECCO Finishing AB for assistance.

An approved fire extinguisher must be available within 10 meters of the spray area.

Do not pull the trigger directing the gun head to any part of your body or to any other person.

Even if the equipment is out of service and turned off, there is a possibility of paint injection

because of remaining pressure. Always close material adjusting valve of the spray gun

whenever work is stopped.

Whenever re-starting the operation, be sure there is no air/paint leakage or loosened

connectors in any part of the system.

Follow the present laws and regulations for usage and installation of this equipment.

Follow the laws and regulations of the country in which the equipment is used.

WARNING

Page 25

- 22 -

1. Checking high voltage generator

(1) Open the air valve and adjust the air pressure on the regulator to 0.3 to 0.4MPa to supply

air to the system. Be sure that there is no air leakage from any hose connection.

(2) Holding gun grip, switch on power to control unit. Green pilot lamp should be on. At this

point, no high voltage is at the gun head.

(3) Pull the gun trigger. When air flows through the nozzle, the air flow switch incorporated in

the control unit energizes high voltage to the system. The high voltage indicator (red lamp) will

be on . High voltage is present at the gun head as long as the red lamp is on. (High voltage is

not generated if the switch at the gun grip is off.)

Switch off the control unit as soon as the equipment check is complete.

2. Paint adjustment

In this system, almost all synthetic resin paints can be sprayed with electrostatic energy and

there is no need to adjust the paint. Sometimes higher electrostatic effect can be obtained by

adjusting the solvent blend. There are some low electric resistance paints that cannot achieve

good electrostatic results. Check the resistance value of your paint using a resistance meter.

Good electrostatic results normally can be achieved by adjusting the resistance value to 15 to

70M ohm. If under 15MÙ, there will be some electrostatic effect, but too much paint will

bounce back in the direction of the gun and operator. This will necessitate higher exhaust

velocity and reduced transfer efficiency.

Electrostatic effect can be confirmed by spraying from the front side of a 20 to 30mm dia.

Steel pipe. It the paint wraps to the back side of the pipe, proper electrostatic effect is

confirmed.

No electrostatic results are expected when metallic, water-borne or other extremely low

resistance conductive paints are being used. In the case where high voltage is transmitted to

those types of paints, the high voltage shut-off circuit in the control unit may shut the system

down energizing the high voltage with buzzer alarm. Reset can be accomplished by turning

the power switch off and on.

Always use paint and solvent which have an ignition point at least 5°C higher than room

temperature

If there is any doubt, question or uncertainty in the suitability of your paint for this equipment,

consult our distributor or ECCO Finishing AB for assistance.

8

Checking before operation

CAUTION

CAUTION

Page 26

- 23 -

1. Preparation for operation

(1) Fill the paint supply system.

The viscosity of the paint normally used for this equipment ranges in 9 to 30sec/FC #4, but not

limited to viscosity. Consideration must me given to the type of paint and solvent, configuration of

the part to be coated, required film thickness and, other conditions. It is recommended that the

electric resistance value of the paint be measured before filling the supply system.

(2) Start the material delivery system to supply paint to the spray gun.

Be sure the supply pump is operated under low pressure (approx. 0. 1Mpa) using the air

regulator so that the pump will begin to cycle slowly to siphon the material and to prime the

system. Increase pump pressure gradually until the material regulator at pump outlet shows 0.2

to 0. 3 Mpa. If more precise fluid control is necessary or if the fluid flow pulsates, consider adding

a fluid regulator to the system between the material supply system and the electrostatic gun.

Confirm again that the control unit power is off.

(3) Inject the paint from the gun tip.

Turn off atomization air and pull the trigger to start flowing paint from the spray gun. Since there

may be air entrapped in the supply line continue t o flow paint until all remaining air pockets in

paint hose are removed. Paint output can be increased by turning adjuster valve at rear right

side of gun body counter-clockwise and stopped by fully turning it clockwise. When painting is

ceased, turn the valve fully clockwise to stop paint output, or curtail the pump pressure.

(4) Increase atomizing air gradually to observe the degree of atomization.

Adjust atomizing air pressure to 0.2 to 0.3 MPa and pull trigger to observe the degree of

atomization. Please understand that only enough atomization to break up the necessary paint

flow should be used. Excessive pressures will only accomplish increased over-spray and waste.

This atomizing air pressure should be adjusted to suit the nozzle and the requirements of the

process.

In addition, this gun uses inside airtight structure in order to prevent the paint come into gun body.

Small volumes of air always flow out from needle. Therefore it is not malfunction if there is sound

of airflow from needle.

(5) The spray pattern can be widened by turning the pattern width adjusting valve at the left rear of

the gun body counter-clockwise and narrowed by turning it clockwise.

Make sure that air is not leaking when returning the connection of the air hose and the trigger to

the original position. When air is discharged with the power supply on, a high voltage is

generated whether it is operating or not.

9

Operation

CAUTION

WARNING

Page 27

- 24 -

2. Starting operation

(1) Switch on the power to control unit. When trigger is pulled, red lamp is illuminated to indicate

high voltage is applied at the gun head. High voltage is not generated when switch at gun grip is

off.

Before switching on the control unit, confirm again that the unit is securely grounded through

a grounding wire.

Never wear gloves without a hole in the palm to handle the spray gun. Never wear rubber

soled shoes during operation of an electrostatic gun. The gun grip is at zero potential if the

control unit is grounded and there is no danger of electric shock if the gun grip is held by a

bare hand.

(2) Start the painting operation. Adjust the voltage level on the control unit to suit conditions.

Adjustment range is 20 to 60kV.

Before starting operation, check to see if the grounding resistance of the object to be coated

is under 1MΩ.

Do not touch object to be coated with the metal part of the nozzle. Normally potential at the

nozzle is automatically lowered as it approaches any grounded object, but there is a slight

danger of sparking in a case of a rapid approach gun to ground.

Do not touch the nozzle during high voltage is applied.

(3) When not painting, always switch off the power to the control unit.

Never leave the spray gun alone while the power switch on the controller is on.

If paint of low electric resistance (2MΩ or lower), is to be used, the paint supply pump should

be installed on an insulated stand. In this case, high voltage is also present at the pump.

Never touch the pump when the high voltage is on. When necessary to service the supply

equipment be sure to switch off the hi voltage by turning off the switch on the controller, then

be sure to ground the system as there is a good possibility that residual high voltage will be

retained.

3. Finishing operation (When re-starting within 24 hours is expected)

(1) Switch off power to control unit by one hand, and holding the spray gun in the other hand. Do

not place the gun on the floor or on a work bench.

(2) Lower the atomizing air pressure to 0Mpa at the regulator.

(3) Lower the air pressure supplying the delivery system to 0MPa.

(4) Pull the spray gun trigger to release remaining fluid pressure.

(5) To discharge remaining voltage, carefully touch the nozzle electrode to ground keeping the

trigger open.

CAUTION

CAUTION

CAUTION

Page 28

- 25 -

(6) Wipe off the nozzle and gun body and remove paint and dirt using solvent soaked cloth. To clean

a flat spray nozzle, remove its air guide and to clean the round spray nozzle remove its air cap.

Whenever coating work is curtailed, close the material adjusting valve on the gun body to

prevent any chance of paint flow.

To clean the nozzle and air cap, direct the gun head downward to prevent cleaning solvent

from finding a way inside the gun.

After cleaning, do not immerse the gun, cable or hoses in solvent. This equipment should be

considered as an electric instrument. Continuous dipping in solvent may cause degradation

of the durability and will damage the equipment due to solvent penetration.

If a two component paint or other chemically curing products are used, the same steps as

indicated in the next clause must be taken frequently depending on curing conditions.

4. Finishing operation (When re-starting within24 hours is not expected. )

(1) Switch off power to control unit.

(2) Lower atomizing air pressure to 0MPa.

(3) Take the suction pipe from the paint container.

(4) Lower the air pressure to the supply pump (approx. 0. 1PMa), allow the paint remaining in the

pump to bleed through the return.

(5) Pull gun trigger to reduce paint pressure remaining in hose and gun.

(6) Flush cleaning solvent through the system until the fluid passages are clear of paint.

(7) Pull gun trigger to reduce pressure from the cleaning solvent and to flush the gun and hose.

(8) Turn off air to the pump and release the remaining pressure from the gun.

(9) Wipe off nozzle and gun body using a solvent soaked cloth. Remove the nozzle from gun body

and clean the seating parts between the gun body and nozzle.

The cleaning and flushing should be started at least 10 seconds after switching off the control

unit. It should be noted that over 90% of fire accidents in electrostatic systems occur during

cleaning and flushing. Be sure to switch off the control unit before cleaning. An approved fire

extinguisher should be available.

Never wear gloves without a hole in the palm to handle the spray gun. Never wear rubber

soled shoes during operation of an electrostatic gun. The gun grip is at zero potential if the

control unit is grounded and there is no danger of electric shock if the gun grip is held by a

bare hand.

(10) For the disposing the waste solvent, recover and reuse the waste solvent by use of solvent

recovery system, or dispose them through the waste disposal company in accordance with lows

and regulations.

CAUTION

CAUTION

Page 29

- 26 -

1. Spray gun

(1) Always keep spray gun clean. To clean the spray gun, do not dip the gun body into solvent. Hold

it your hand and wash it carefully using a soft brush or cloth and solvent.

Replace the gun cover before being heavily contaminated. High voltage is likely to leak through

paint attached to the cover especially in the case of using metallic or water-based paint. This

might lead to overcurrent or electrical shock to the operator. Do not use the cover for such

circumstances.

(2) Do not disassemble the gun except in the case of the need for repair and parts replacement.

(3) When there is no work, keep the gun hooked on the gun holder. Never forget to switch off the

control unit whenever gun is not in use.

(4) There are many plastic parts contained in the LP6000 spray gun for minimizing weight.

Although these parts are designed to have enough strength for normal use, care should be

taken that they do not fall on the floor.

(5) It is possible that the rear upper part of the gun body may become warm due to heat produced

by the cascade. This condition is perfectly normal and should be ignored.

2. Nozzles

(1) Whenever the finishing operation is completed, clean the nozzles thoroughly.

(2) Do not use metal wire or pins to clear clogging of the nozzle holes. To remove clogged holes,

dip the nozzle in solvent a few minutes, then clear with a dust gun using compressed air. Do

not use a metal brush to clean the nozzle.

(3) Nozzles should be cleaned often even during coating operation. Paint sticking to the nozzle

may cause a distorted pattern, effect atomization and electrostatic efficiency.

Nozzle is worn out as paint injection is performed.

Measure the output periodically. When the specified amount cannot be output, replace the

nozzle.

Nozzle is ultra-precision part. Do not drop it or apply any impact.

Damaged nozzle might be causes of deteriorated atomization of paint or pattern shape, and

result in paint failure.

10

Maintenance

CAUTION

CAUTION

CAUTION

Page 30

- 27 -

3. Paint hose and power cable

(1) Hose and cable should be kept clean from paint accumulation.

(2) Use caution not to damage hoses and cables with heavy objects or vehicles.

Before any maintenance and/or service work, make sure that the power switch is turned off on

the control unit and the air/fluid pressure is released.

Any container used for cleaning solvent should be conductive and securely grounded.

CAUTION

CAUTION

Page 31

- 28 -

In cases where spray coating is unsatisfactory, the reasons for appearance defects may be complex

and can be a combination of several factors.

1. Poor atomization

Possible causes

Solution

(1) Too low atomization air pressure

(1) Increase pressure.

(2) Too high paint output

(2) Decrease output or increase atomizing air

pressure

(3) Too high a viscosity

(3) Lower the viscosity with solvent

(4) Nozzle electrode pin is bent.

(4) Straighten or replace the pin.

(5) Nozzle is damaged

(5) Repair or replace it.

(6) Solvent is not adequate

(6) Consult material supplier.

(7) Improper adjustment of nozzle air

guide (However, only round spray

nozzle HN54SA)

(7) Adjust the clearance with the air guide to

0.2mm. (one turn: 1mm)

2. Too much paint bouncing back

Possible causes

Solution

(1) Too long spray distance

(1) Keep the distance at 150 to 200mm.

(2) Too high atomizing air pressure

(2) Lower the pressure.

(3) Too low paint resistance value

(3) Adjust the resistance to 15 to 70M ohm-cm.

(4) Insufficient grounding of object

(4) Secure the grounding.

(5) Too low air exhausting speed

(5) Increase the exhaust fan speed.

3. Poor transfer efficiency

Possible causes

Solutions

(1) Inferior grounding of object

(1) Clean hangers

(2) Too high atomizing air pressure

(2) Adjust the pressure to an adequate level.

(3) Too far spray distance

(3) Keep the distance at 150 to 200mm.

(4) Too low charging voltage

(4) Increase high voltage output by adjusting

switch on control unit

(5) Too high air exhausting speed

(5) Slow the exhaust fan speed.

(6) Too high paint resistance value

(6) Adjust the resistance to 15 to 70M ohm-cm.

11

Trouble shooting on spray technique

Page 32

- 29 -

4. Tried stringy particles from the paint sticking to the nozzle, or pimples on coated

surface

Possible causes

Solutions

(1) Too fast evaporating solvent

(1) Change to slower solvent or adjust with

(2) Higher viscosity of paint

(2) Lower the viscosity.

5. Pimples on coated surface

Possible causes

Solutions

(1) Poor atomization of paint

(1) See above 1.

(2) Dirt in the spray booth

(2) Provide filters at air exhaust and remove dirt

on the surface.

(3) Contaminated atomizing air

(3) Clean or replace filter on air control.

(4) Inferior pigment dispersion

(4) Change solvent or filter the paint.

6. Orange peel on the coated surface

Possible causes

Solutions

(1) Too high booth temperature or too

fast evaporating solvent

(1) Adjust the temperature or change to slower

solvent.

(2) Higher object temperature

(2) Adjust drying furnace temperature.

(3) Too fast air flow of booth exhaust

(3) Adjust to 0. 5 to 1.0 m/sec. flow at object

surface.

7. Crawling on coated surface

Possible causes

Solutions

(1) Insufficient cleaning of the surface

(1) Clean sufficiently or degrease the surface.

(2) Contaminated atomizing air

(2) Clean or replace filter in air control.

(3) Poor air exhaust in baking furnace

(3) Be sure there is sufficient air exhaust.

8. Sags & runs on coated surface

Possible causes

Solutions

(1) Too thick coated film

(1) Decrease paint output or move spray gun

faster.

(2) Too low paint viscosity

(2) Adjust to higher viscosity.

(3) Slow evaporation of solvent

(3) Change to faster solvent.

Page 33

- 30 -

9. Poor hiding film

Possible causes

Solutions

(1) Insufficient paint output

(1) Adjust paint output, move gun faster and

consider overlapping spray.

(2) Too low paint viscosity

(2) Adjust the viscosity.

10. Pinholes on coated surface

Possible causes

Solutions

(1) Contaminated atomizing air

(1) Clean or replace filter in air control.

(2) Faster evaporating solvent

(2) Change to slower solvent.

(3) Higher object temperature

(3) Lower the temperature.

(4) Insufficient drying of undercoat

(4) Make sufficient drying.

(5) Too short setting time

(5) Take sufficient setting time

11. Blushing on coated surface

Possible causes

Solutions

(1) Higher temperature and humidity

inside and outside of booth

(1) Use slow evaporating solvent or check air

conditioning system.

(2) Inadequate selection of solvent

(2) Consult material supplier.

12. Bubbles on coated surface

Possible causes

Solutions

(1) Contaminated atomizing air

(1) Clean or replace filter in air control.

(2) Insufficient drying after water

Grinding

(2) Make sufficient drying.

(3) Too thick film build

(3) Lower paint output.

(4) Faster evaporating solvent

(4) Change to slower solvent.

(5) Higher drying furnace temperature

(5) Adjust the temperature.

13. Unfavorable pattern shaping

Possible causes

Solutions

(1) Paint or dust sticking at air and paint

outlets on the nozzle

(1) Thoroughly clean the nozzle with solvent and

a bamboo brush, and filter the paint.

(2) Higher viscosity of paint

(2) Lower the viscosity.

(3) Damaged front end of the nozzle

(3) Repair or replace the nozzle.

(4) Mis-adjusting of pattern air

(On flat spray nozzle only)

(4) Correctly by pattern adjusting knob.

(5) Failed nozzle assembling

(5) Check and tighten material nozzle and fix air

cap

Page 34

- 31 -

It is possible that the cause for trouble may be complex and could come from a combination of

various problems. In the following descriptions, the numbers in column “Ref. ” mean numbers of

article and clause in this instruction manual where detailed methods for solutions are explained.

For example, “6 – 5” indicate “6. Assembling of nozzles” in the article “5. Installation”.

1. Spray breathes during operation.

Possible causes

Solutions

Ref.

(1) Insufficient nozzle tightening

(1) Re-tighten the nozzle securely.

6-5

(2) Damage on seating face of valve

seat ring

(2) Replace valve seat ring

13-1

(3) Air mixed in paint

(3) Check paint supply system.

9-1

(4) Insufficient tightening of nozzle

fixing joint (On round spray nozzle

only)

(4) Re-tighten joint with box spanner.

6-5

(5) Extremely poor paint output air

pressure.

(5) Increase output or lower atomizing

9-1

2. Paint output is decreased.

Possible causes

Solutions

Ref.

(1) Trouble in paint supply system

(1) Check to be sure the paint pump, and

material regulator are functioning

properly.

2 - 1

(2) Paint or dirt plugging at the material

seat

(2) Remove and clean the material seat.

13 - 1

(3) Paint or dirt clogging at the nozzle

(3) Remove and clean the nozzle.

6 - 5

3. Paint leaks from the nozzle.

Possible causes

Solutions

Ref.

(1) Paint or dirt clogging at material

seat and needle

(1) Remove and clean the material seat

13 - 1

(2) Wear or chipping of the material

seat and needle

(2) Replace the material seat and needle.

13 - 1

(3) Fatigue in the needle spring or wear

of the O-ring in the needle set

(3) Replace needle set and O-ring.

13 - 2

(4) Too high paint pressure

(4) Lower paint supply pressure.

9 - 1

(5) Wear of O-ring of material seat

(5) Replace O-ring.

13 - 1

12

Trouble shooting of equipment

Page 35

- 32 -

4. Paint leaks from the barrel

Possible causes

Solutions

Ref.

(1) Defective packing and needle

section

(1) Remove material output adjuster and

replace the packing.

13 - 2

(2) Insufficient tightening or seating of

the guide

(2) Replace the guide.

13 - 2

5. Paint leaks from the nozzle even after trigger is released.

Possible causes

Solutions

Ref.

(1) Dirt clogging at the seating area in

the air valve

(1) Clean or replace the air seat and

tappet.

13 - 2

(2) Wear of the air seat and tappet

(2) Replace the air seat and tappet.

13 - 2

(3) Fatigue of the spring

(3) Replace the spring.

13 - 2

(4) Wear or breakage of the O-ring

(4) Replace the O-ring.

13 - 2

6. Air leakage from the air regulator

Possible causes

Solutions

Ref.

(1) Worn out or damaged O-ring

(1) Replace the O-ring.

13 - 4

7. Sparking occurs at the nozzle area(when no insulation stand is used).

Possible causes

Solutions

Ref.

(1) Damage in the cascade.

(1) Replace with a new cascade.

13 - 3

8. Sparking occurs at the nozzle area when insulation stand is used).

Possible causes

Solutions

Ref.

(1) Damage in the cascade.

(1) Replace the cascade in the gun grip.

13 - 3

(2) Changing from low resistance paint

to metallic paint

(2) Lower the voltage output by adjusting

the output voltage adjusting knob on

the controller

9 - 2

Page 36

- 33 -

9. Buzzer alarm sounds on the control unit (when no insulation stand is used).

Possible causes

Solutions

Ref.

(1) Paint has accumulated on the gun

extension.

(1) Clean the extension.

7

(2) Paint has built up on the paint tube.

(2) Clean the paint tube.

7

(3) Water has accumulated in the air

passage inside the barrel.

(3) Make sure water in air line is removed

After switching off control unit, pull the

trigger to blow water from the air

passage.

7

(4) Changing from low resistance paint

to metallic paint

(4) Use an isolation stand.

8 - 2

(5) Paint leakage due to damaged or

worn out needle packing section

(5) Replace packing set and replace

needle set and O-ring

13 - 2

10. Buzzer alarms on control unit(when insulation stand is used).

Possible causes

Solutions

Ref.

(1) Paint has accumulated on the gun

extension.

(1) Clean the extension.

7

(2) Paint has accumulated on the front

end of the paint hose.

(2) Clean the paint hose.

7

(3) Water accumulates in the air

passage inside the barrel.

(3) Make sure water in air line is removed.

After switching off control unit, pull

trigger to blow water from the air

passage.

7

(4) Grounded material adjacent to the

isolation stand

(4) Place the stand at least 300mm far

from any grounded object.

9 - 2

(5) Paint or dirt accumulates on the

insulation bar of isolation stand.

(5) Clean the insulation bar.

9 - 2

(6) Part of the isolation stand becomes

grounded.

(6) Remove the grounding object.

9 - 2

(7) Paint leakage due to damaged or

worn out needle packing

(7) Replace the packing.

13 - 2

Do not repair any part of this equipment by using a method not indicated in this manual.

CAUTION

Page 37

- 34 -

Replacement or repair of parts should be done according to the following procedures. Before

starting the work, be sure to shut off compressed air to the gun, switch off power to control unit,

relieve paint pressure from the fluid passages in the system and clean all paint passages.

(Numbers in the text indicate reference No. in the parts list and exploded drawing and parts No.)

1. Replacement of paint seat (*Paint seat and needle should be replaced together.)

(1) Remove paint seat 33 (6004 0330 48) at front end of gun barrel. Its removal and

replacement should be done with the trigger pulled.

(2) If the O-ring 40 (0669 9304 10) is damaged or swollen, replace it. If the valve seat ring 34

(6004 0330 49) is damaged, replace it.

To assemble the valve seat ring to the gun body, first replace the material seat 33 (6004 0330

48) to the barrel and install the valve seat ring, then tighten by screwing in the nozzle.

13

Parts replacement and adjustment

Page 38

- 35 -

2. Replacement of the material needle, material packing, air tappet and air packing

(1) Remove the hex. socket screw 46 (03-70310) and pivot 31 (6004 0330 88) remove the

trigger 52 (6004 0330 25). The hexagonal bar wrench of 3mm is required for this operation.

(2) Remove the adapter 22 (6004 0330 75) and take out three springs 19 (6004 0330 72), 20

(6004 0330 73) and 21 (6004 0330 74). The spanner of 8mm is required for this operation.

When assembling the adapter, be careful not to cross thread since all threads are made of

plastic.

(3) Push washer 15 (6004 0330 70) back and pull out the rod 12 (6004 0330 67) from rear side

of gun body. The radio pliers or a pliers is required for this operation.

CAUTION

Page 39

- 36 -

(4) Loosen hex. nut 50 (6004 0330 34), then replace the air seat 18 (6004 0330 83), tappet 14

(6004 0330 69), packing 17 (6004 0330 82), needle set 11(6004 0330 99) and O-ring 37

(0663 9301 00).

*For LP6000W, 63, 64 65 and 66 are changed to 62, 63, 64 and 65, respectively.

(5) Insert a hex wrench from the rear side and remove the guide 8(6004 0330 98). If it is difficult

because of s paint accumulation, push it out from the material seat side with a hex wrench.

The hexagonal bar wrench of 5cm is required for this operation.

When removing the guide, or replacing the packing 9 (6004 0330 65), replace with the

packing set (6004 0330 81).

In addition, when assembling the packing set, set the tip upward so as to prevent the

packing from being taken out.

(6) When assembling these parts, adjust the total length from the front end of the material

needle to rod end at approximately 163mm. Some additional adjustment will be necessary

due to wear on the seat, etc.

Page 40

- 37 -

3. Replacement of cascade

(1) Remove trigger taking the same steps as in 2 –(1).

(2)-1 <LP6000S>

Remove the tube 57 (6004 0330 18)

connected to the bottom of the barrel.

(2)-2 <LP6000W>

Remove hex. socket screw 61 (6004 0330 38), then

remove nut 54 (6004 0330 24) and hose support

55(6004 0330 23).

(3) Remove four hex. socket screws 48 (6004 0330 36) and hook 29 (6004 0330 87).

The hexagonal bar wench of 3mm is required for this operation.

(4) Remove barrel 5 (6004 0330 96) by pulling it slowly from front side.

Barrel shall be pulled out in a straight forward direction. If pulled on an angle, it may damage

cascade or needle.

CAUTION

Page 41

- 38 -

(5) Take out the cascade 7(6004 0330 97) from the barrel. The two O-rings 44(0663 9306 10)

should be replaced.

(6) Care must be taken not to connect the colored wires to their responding terminals on the

cascade.

The precision Philips screwdriver is required for this operation.

(7) To assemble the cascade, put it into body 1 (6004 0330 60) turning it a few times to make

sure the lead wires are correct, then attach the barrel. Make sure that the cushion 35 (6004

0330 90) is set in its correct position. Confirm that the shoulder part of cascade is in place

against the face of the gun body. Each time the barrel is removed, the gasket 28 (6004 0330

84) should be replaced.

Green(GND)

Yellow (SOURCE)

Red (RNT)

Page 42

- 39 -

4. Replacement of O-ring of the adjuster for pattern air

(1) Remove the adjust.

(2) Replace the O-ring 38 (0663 9302 00) at the tip of adjuster.

Air leaked into the gun is discharged from the dial portion of the adjuster when the O-ring is

damaged.

If operation is continued without replacing such O-ring, there might be a case that the control of

high voltage cannot be performed. Replace the O-ring without fail.

CAUTION

Page 43

- 40 -

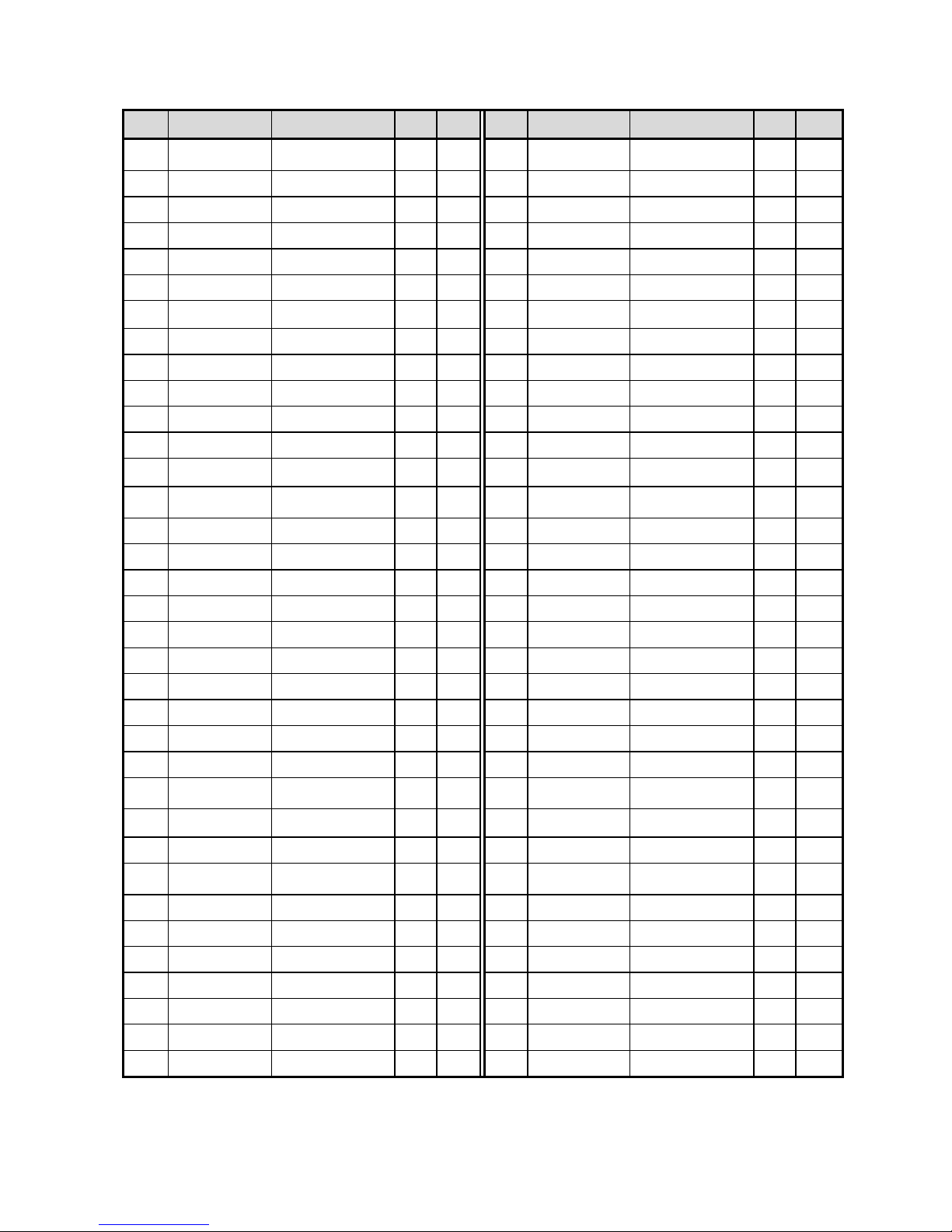

Shown below is a maintenance log format of a kind we recommend you to keep. Each time that you conduct a

maintenance service, such as replacement of a part, tear-down cleaning, post-failure repair, etc., record the

details. In the long run, you will find that such a log is very valuable in keeping your equipment in a

consistently good operating condition.

Equipment

name

Air wrap airless electrostatic spray gun

<ECCO Xtatic LP6000S/W/M>

Date of acquisition: YYYY/MM/DD

Date of service

Portion worked on

Description

Date of service

Portion worked on

In-house / ECCO Finishing AB

In-house / ECCO Finishing AB

In-house / ECCO Finishing AB

In-house / ECCO Finishing AB

In-house / ECCO Finishing AB

In-house / ECCO Finishing AB

In-house / ECCO Finishing AB

In-house / ECCO Finishing AB

In-house / ECCO Finishing AB

In-house / ECCO Finishing AB

In-house / ECCO Finishing AB

In-house / ECCO Finishing AB

In-house / ECCO Finishing AB

In-house / ECCO Finishing AB

In-house / ECCO Finishing AB

In-house / ECCO Finishing AB

In-house / ECCO Finishing AB

In-house / ECCO Finishing AB

In-house / ECCO Finishing AB

In-house / ECCO Finishing AB

In-house / ECCO Finishing AB

In-house / ECCO Finishing AB

In-house / ECCO Finishing AB

In-house / ECCO Finishing AB

In-house / ECCO Finishing AB

NOTE: Due to continuous improvements and modifications, the configurations and specifications of the

equipment specified herein are subject to change without prior notice.

14

Service record

Page 44

- 41 -

ECCO Finishing AB (the “Company”) shall provide the original purchaser (the “Purchaser”) with

warranty service against defects in material or workmanship for a period of one (1) year from the

date of purchase of the product, as follows:

Should you find defects in material or workmanship with regard to parts, ship them back to the

Company, freight prepaid. The Company shall repair or replace the parts free of charge and

reimburse the freight charges, provided that, as a result of an inspection and investigation of the

parts conducted by the Company, the defects are deemed to be to attributable to the factors

within the Company’s responsibility.

When, on the other hand, defects are found, as a result of inspection and investigation

conducted by the Company, to be attributable to natural wear, corrosion, negligence, accidents,

an act of God, installation contrary to the Company’s instructions, abusive use or misuse,

operation contrary to the instructions appearing in the manual, or unauthorized modification, this

warranty shall not apply. Neither shall it apply to any services that are conducted outside

Japan. In these circumstances, any costs that may be incurred on repair or freight shall be the

responsibility of the Purchaser.

In the event also of failure caused by use in conjunction with a hose or a gun, etc. of a maker not

approved by the Company, the warranty does not apply. In these circumstances, the Company

will submit a quotation for the costs of whatever corrective measures are necessary, repair or

replacement, including relevant terms and conditions.

As for items such as parts purchased by the Company from another manufacturer, the warranty

of that manufacturer shall apply.

As for any parts deemed to be defective, the Company shall not be held liable for any expenses

beyond the provision of replacement parts free of charge.

The Company shall not be held liable for any damage to the Purchaser caused by factors not

attributable to the Company, such as misuse of product, etc.

When a transfer of title of this equipment takes place, please see to it that this Operation and

Maintenance Manual is handed over to the new owner.

This equipment is manufactured in compliance with the Laws and Regulations of Europe.

In the rare eventuality of this equipment being used outside Europe, compliance with the safety

standards of the relevant countries is of course mandatory.

15

Scope of warranty

Page 45

ECCO FINISHING AB, Box 93, S-532 22 SKARA, Sweden

Tel: +46 (0)511-134 45, Fax: +46 (0)511-180 13

E-mail: info@eccofinishing.com • www.eccofinishing.com

Loading...

Loading...