Page 1

CC2530 Wireless Module

E18 Series

This manual may be modified based on product upgrade, please refer to the latest version.

All rights to interpret and modify this manual belong to Chengdu Ebyte Electronic Technology Co., Ltd.

Version

Date

Description

Issued by

1.00

2017/11/2

Initial version

huaa

User Manual

Page 2

CC2530 Wireless Module User Manual of E18 Series Modules

Copyright ©2012–2017, Chengdu Ebyte Electronic Technology Co., Ltd. 2 / 15

Contents

GENERAL INTRODUCTION..................................................................................................................................................3

1. TECHNICAL PARAMETERS......................................................................................................................................... 3

1.1. GENERAL PARAMETERS...................................................................................................................................................3

1.2. ELECTRICAL PARAMETERS.............................................................................................................................................. 4

1.2.1. Transmitting current................................................................................................................................................. 4

1.2.2. Receiving current......................................................................................................................................................4

1.2.3. Turn-off current........................................................................................................................................................ 4

1.2.4. Voltage supply.......................................................................................................................................................... 4

1.2.5. Communication level................................................................................................................................................5

1.3. RF PARAMETERS............................................................................................................................................................. 5

1.3.1. Transmitting power...................................................................................................................................................5

1.3.2. Receiving sensitivity................................................................................................................................................ 5

1.4. TESTED PARAMETERS...................................................................................................................................................... 5

1.4.1. Tested distance..........................................................................................................................................................5

2. MECHANICAL CHARACTERISTICS..........................................................................................................................6

2.1. E18-MS1-PCB............................................................................................................................................................... 6

2.2. E18-MS1-IPX.................................................................................................................................................................7

2.3. E18-MS1PA1-PCB.........................................................................................................................................................8

2.4. E18-MS1PAI-IPX.......................................................................................................................................................... 9

3. USAGE..............................................................................................................................................................................10

3.1. DEVELOPMENT..............................................................................................................................................................10

4. PROGRAMMING...........................................................................................................................................................10

4.1. TI ZIGBEE FAQ............................................................................................................................................................12

4.1.1. How to select proper protocol stack from different ZigBee protocol stacks of TI?.............................................. 12

4.1.2. How to apply for standard ZigBee test certification?............................................................................................ 12

4.1.3. How to forbid node from searching network, or extend the interval for sending Beacon Request?.................... 13

4.1.4. How to put End Device into low power consumption mode, how to set up sleep time?...................................... 13

4.1.5. What new features does ZigBee 3.0 stack have?...................................................................................................13

4.1.6. About the difference between OAD and OTA in TI protocol stack?.....................................................................14

4.1.7. Which protocol stack shall be selected for developing private application based on ZigBee Mesh?...................14

5. PRODUCTION GUIDANCE......................................................................................................................................... 14

5.1. REFLOW SOLDERING TEMPERATURE.............................................................................................................................14

5.2. REFLOW SOLDERING CURVE..........................................................................................................................................14

6. FAQ....................................................................................................................................................................................15

6.1. COMMUNICATION RANGE IS TOO SHORT.......................................................................................................................15

6.2. MODULE IS EASY TO DAMAGE...................................................................................................................................... 15

7. IMPORTANT NOTES.....................................................................................................................................................15

8. ABOUT US....................................................................................................................................................................... 15

Page 3

CC2530 Wireless Module User Manual of E18 Series Modules

Copyright ©2012–2017, Chengdu Ebyte Electronic Technology Co., Ltd. 3 / 15

General introduction

E18 series are small-sized 2.4GHz SMD wireless modules, which are designed and produced by Chengdu Ebyte. The space between each

pin is 1.27mm. E18 series have been put into stable bulk production, they are applicable for various applications (especially smart home).

E18 series adopt the original CC2530 RF chip of TI, the chip is integrated with 8051 MCU and wireless transceiver. The modules are

applicable for ZigBee design and 2.4GHz IEEE 802.15.4 protocol. All IO ports of the MCU have been pinned out for multiple development.

Model

Antenna connector

PCB packing

Transmitting power

Referential distance

E18-MS1-PCB

PCB antenna

SMD

4dBm

200m

E18-MS1-IPX

IPEX

SMD

4dBm

200m

E18-MS1PA1-PCB

PCB antenna

SMD

20dBm

1000m

E18-MS1PA1-IPX

IPEX

SMD

20dBm

1000m

E18 series are ZigBee modules, which can be used directly and support secondary development.

1. Technical parameters

1.1. General parameters

Model

Core IC

Size

Net weight

Operating

temperature

Operating

humidity

Storage

temperature

E18-MS1-PCB

CC2530

14.1*23.0 mm

1.2±0.1g

-40 ~ 85°C

10% ~ 90%

-40 ~ 125°C

E18-MS1-IPX

CC2530

14.1*20.8 mm

1.2±0.1g

-40 ~ 85°C

10% ~ 90%

-40 ~ 125°C

E18-MS1PA1-PCB

CC2530

16.0*27.0 mm

1.58±0.1g

-40 ~ 85°C

10% ~ 90%

-40 ~ 125°C

E18-MS1PA1-IPX

CC2530

16.0*22.5 mm

1.46±0.1g

-40 ~ 85°C

10% ~ 90%

-40 ~ 125°C

Page 4

CC2530 Wireless Module User Manual of E18 Series Modules

Copyright ©2012–2017, Chengdu Ebyte Electronic Technology Co., Ltd. 4 / 15

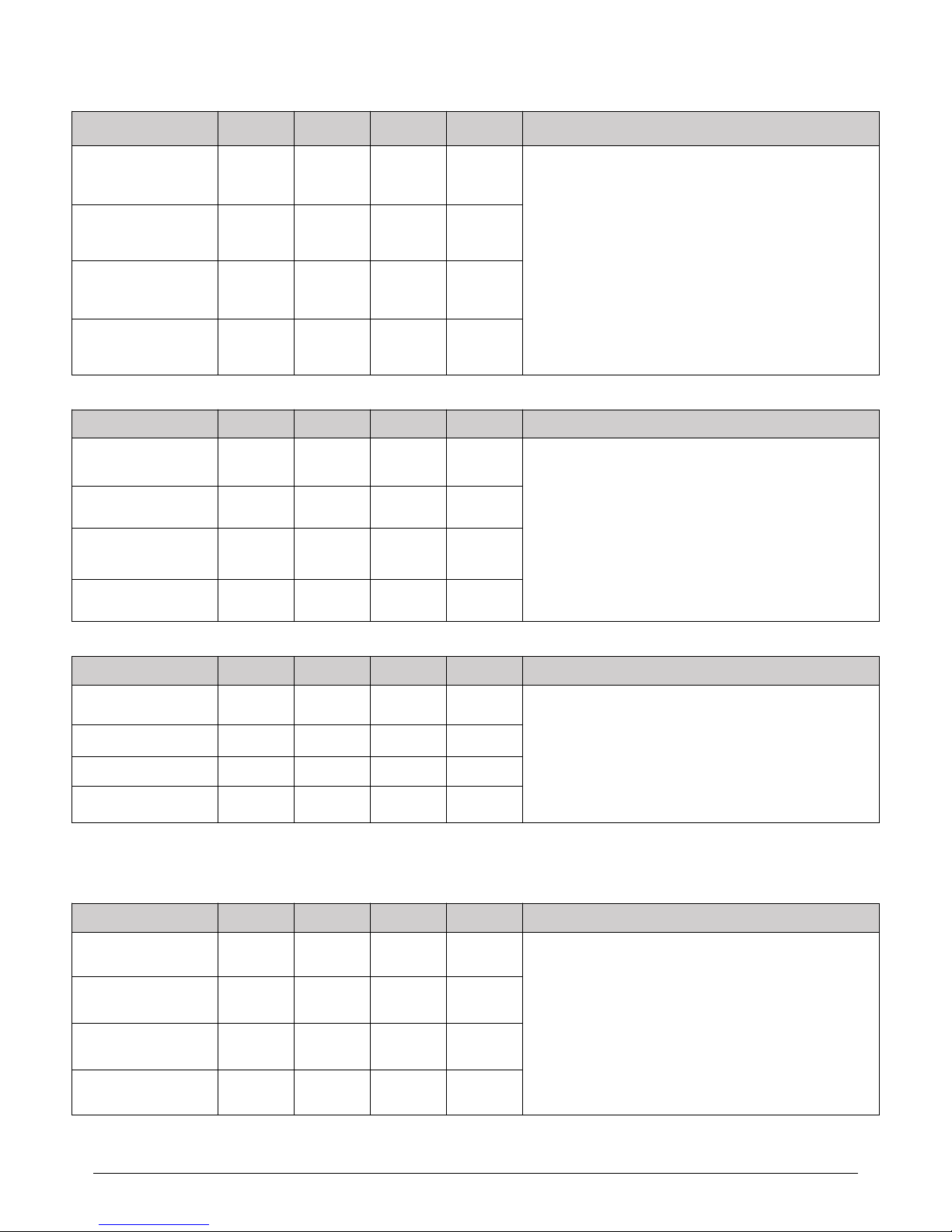

1.2. Electrical parameters

1.2.1. Transmitting current

Model

Min

Typ

Max

Unit

Remarks

E18-MS1-PCB

25.8

28.0

30.8

mA

● When designing current supply circuit, 30% margin is

recommended to be remained so as to ensure long-term

stable operation of the whole module;

● The current at the instant of transmitting may be high,

but the total energy consumed may be lower due to very

short transmitting time;

● When using external antenna, the impedance matching

degree at different frequency points between antenna

and module may affect the transmitting current value at

different levels.

E18-MS1-IPX

25.8

28.0

30.8

mA

E18-MS1PA1-PCB

128.8

140.0

154

mA

E18-MS1PA1-IPX

128.8

140.0

154

mA

1.2.2. Receiving current

Model

Min

Typ

Max

Unit

Remarks

E18-MS1-PCB

24.8

27.0

29.7

mA

● The current consumed when the RF chip is only working

at receiving mode is called as receiving current,the tested

receiving current may be higher for some RF chips with

communication protocol or the developers have loaded

their own protocol to the whole module.

● The current at pure receiving mode will be mA level, the

users have to realize µA level receiving current through

firmware development.

E18-MS1-IPX

24.8

27.0

29.7

mA

E18-MS1PA1-PCB

38.6

42.0

46.2

mA

E18-MS1PA1-IPX

38.6

42.0

46.2

mA

1.2.3. Turn-off current

Model

Min

Typ

Max

Unit

Remarks

E18-MS1-PCB

0.6

1.2

1.8

µA

● The turn-off current means the current consumed when

CPU, RAM, Clock and some registers remain operating while

SoC is at very low power consumption status.

● The turn-off current is always lower than the current

consumed when the power supply source of the whole

module is at no-load status.

E18-MS1-IPX

0.6

1.2

1.8

µA

E18-MS1PA1-PCB

0.6

1.2

1.8

µA

E18-MS1PA1-IPX

0.6

1.2

1.8

µA

1.2.4. Voltage supply

Model

Min

Typ

Max

Unit

Remarks

E18-MS1-PCB

2.0

3.3

3.6

V DC

● If the voltage is at maximum value for long time, the

module may be damaged;

● The power supply pin has certain surge-resistance ability,

but the potential pulse higher than the maximum power

supply voltage;

● The power supply voltage is recommended to be higher

than 3.0V, if the voltage is lower than 3.0V, the RF

parameters will be affected at different degrees.

E18-MS1-IPX

2.0

3.3

3.6

V DC

E18-MS1PA1-PCB

2.0

3.3

3.6

V DC

E18-MS1PA1-IPX

2.0

3.3

3.6

V DC

Page 5

CC2530 Wireless Module User Manual of E18 Series Modules

Copyright ©2012–2017, Chengdu Ebyte Electronic Technology Co., Ltd. 5 / 15

1.2.5. Communication level

Model

Min

Typ

Max

Unit

Remarks

E18-MS1-PCB

2.0

3.3

3.6

V DC

● If the communication level is higher than the allowed

maximum value, the module may be damaged;

● Although the communication level can be switched with

various methods, the power consumption of the whole

module will be affected at great degree.

E18-MS1-IPX

2.0

3.3

3.6

V DC

E18-MS1PA1-PCB

2.0

3.3

3.6

V DC

E18-MS1PA1-IPX

2.0

3.3

3.6

V DC

1.3. RF parameters

1.3.1. Transmitting power

Model

Min

Typ

Max

Unit

Remarks

E18-MS1-PCB

9.8

4.0

4.6

dBm

● Due to the error of the materials, each LRC component

has ±0.1% error, so error accumulation will occur since

multiple LRC components are used in the whole RF circuit,

and the transmitting currents will be different at different

modules;

● The power consumption can be lowered by lowering

the transmitting power, but the efficiency of the internal PA

will be decreased by lowering transmitting power due to

various reasons;

● The transmitting power will be lowered by lowering the

power supply voltage.

E18-MS1-IPX

9.8

4.0

4.6

dBm

E18-MS1PA1-PCB

9.8

20.0

21.2

dBm

E18-MS1PA1-IPX

9.6

20.0

20.5

dBm

1.3.2. Receiving sensitivity

Model

Min

Typ

Max

Unit

Remarks

E18-MS1-PCB

-95.8

-96.4

-97.0

dBm

● The sensitivity is tested under the air data rate of

250kbps;

● Due to the error of the materials, each LRC component

has ±0.1% error, so error accumulation will occur since

multiple LRC components are used in the whole RF circuit,

and the transmitting currents will be different at different

modules;

● The receiving sensitivity will be reduced and

communication range will be shortened while increasing the

air data rate.

E18-MS1-IPX

-95.8

-96.4

-97.0

dBm

E18-MS1PA1-PCB

-97.3

-97.6

-98.0

dBm

E18-MS1PA1-IPX

-97.3

-97.6

-98.0

dBm

1.4. Tested parameters

1.4.1. Tested distance

Model

Min

Typ

Max

Unit

Remarks

E18-MS1-PCB

180

200

230

m

● The external antenna used is of 5dBi gain and vertical

polarization;

● The interval between each data packet is 2s, sending 100

packets with 30 bytes in each packet, the range at data lose

rate of lower than 5% is valid range;

● In order to obtain meaningful and reproduceable results,

we conducted the tests under in clear weather with little

electromagnetic interference at suburb areas;

● Distance may be shorter with interference or obstacles.

E18-MS1-IPX

220

240

260

m

E18-MS1PA1-PCB

960

800

1220

m

E18-MS1PA1-IPX

540

1000

670

m

Page 6

CC2530 Wireless Module User Manual of E18 Series Modules

Copyright ©2012–2017, Chengdu Ebyte Electronic Technology Co., Ltd. 6 / 15

2. Mechanical characteristics

2.1. E18-MS1-PCB

Pin No.

Pin item

Pin direction

Application

1

GND

Input

Ground, connecting to power source referential ground

2

VDD

Input

Power supply, must be 2.0 ~ 3.6V

3

P2.2

Input/Output

MCU GPIO

4

P2.1

Input/Output

MCU GPIO

5

P2.0

Input/Output

MCU GPIO

6

P1.7

Input/Output

MCU GPIO

7

P1.6

Input/Output

MCU GPIO

8

NC

Reserved

9

NC

Reserved

10

P1.5

Input/Output

MCU GPIO

11

P1.4

Input/Output

MCU GPIO

12

P1.3

Input/Output

MCU GPIO

13

P1.2

Input/Output

MCU GPIO

14

P1.1

Input/Output

MCU GPIO

15

P1.0

Input/Output

MCU GPIO

16

P0.7

Input/Output

MCU GPIO

17

P0.6

Input/Output

MCU GPIO

18

P0.5

Input/Output

MCU GPIO

19

P0.4

Input/Output

MCU GPIO

20

P0.3

Input/Output

MCU GPIO

21

P0.2

Input/Output

MCU GPIO

22

P0.1

Input/Output

MCU GPIO

23

P0.0

Input/Output

MCU GPIO

24

RESET

Input

Reset port

★ Please refer to TI official CC2530 Datasheet for module pin definitions, software driver and protocol ★

Page 7

CC2530 Wireless Module User Manual of E18 Series Modules

Copyright ©2012–2017, Chengdu Ebyte Electronic Technology Co., Ltd. 7 / 15

2.2. E18-MS1-IPX

Pin No.

Pin item

Pin direction

Application

1

GND

Ground, connecting to power source referential ground

2

VDD

Power supply, must be 2.0 ~ 3.6V

3

P2.2

Input/Output

MCU GPIO

4

P2.1

Input/Output

MCU GPIO

5

P2.0

Input/Output

MCU GPIO

6

P1.7

Input/Output

MCU GPIO

7

P1.6

Input/Output

MCU GPIO

8

NC

Reserved

9

NC

Reserved

10

P1.5

Input/Output

MCU GPIO

11

P1.4

Input/Output

MCU GPIO

12

P1.3

Input/Output

MCU GPIO

13

P1.2

Input/Output

MCU GPIO

14

P1.1

Input/Output

MCU GPIO

15

P1.0

Input/Output

MCU GPIO

16

P0.7

Input/Output

MCU GPIO

17

P0.6

Input/Output

MCU GPIO

18

P0.5

Input/Output

MCU GPIO

19

P0.4

Input/Output

MCU GPIO

20

P0.3

Input/Output

MCU GPIO

21

P0.2

Input/Output

MCU GPIO

22

P0.1

Input/Output

MCU GPIO

23

P0.0

Input/Output

MCU GPIO

24

RESET

Input

Reset port

★ Please refer to TI official CC2530 Datasheet for module pin definitions, software driver and protocol ★

Page 8

CC2530 Wireless Module User Manual of E18 Series Modules

Copyright ©2012–2017, Chengdu Ebyte Electronic Technology Co., Ltd. 8 / 15

2.3. E18-MS1PA1-PCB

Pin No.

Pin item

Pin direction

Application

1

GND

Input

Ground, connecting to power source referential ground

2

VCC

Input

Power supply, must be 2.0 ~ 3.6V

3

P2.2

Input/Output

MCU GPIO

4

P2.1

Input/Output

MCU GPIO

5

P2.0

Input/Output

MCU GPIO

6

P1.7

Input/Output

MCU GPIO

7

P1.6

Input/Output

MCU GPIO

8

NC

Reserved

9

NC

Reserved

10

P1.5

Input/Output

MCU GPIO

11

P1.4

Input/Output

MCU GPIO

12

P1.3

Input/Output

MCU GPIO

13

P1.2

Input/Output

MCU GPIO

14

P1.1

Output

MCU GPIO, PA transmitting control pin

15

P1.0

Output

MCU GPIO, PA receiving control pin

16

P0.7

Output

MCU GPIO, PA receiving high gain control pin

17

P0.6

Input/Output

MCU GPIO

18

P0.5

Input/Output

MCU GPIO

19

P0.4

Input/Output

MCU GPIO

20

P0.3

Input/Output

MCU GPIO

21

P0.2

Input/Output

MCU GPIO

22

P0.1

Input/Output

MCU GPIO

23

P0.0

Input/Output

MCU GPIO

24

RESET

Input

Reset port

★ Please refer to TI official CC2530 Datasheet for module pin definitions, software driver and protocol ★

Page 9

CC2530 Wireless Module User Manual of E18 Series Modules

Copyright ©2012–2017, Chengdu Ebyte Electronic Technology Co., Ltd. 9 / 15

2.4. E18-MS1PAI-IPX

Pin No.

Pin item

Pin direction

Application

1

GND

Input

Ground, connecting to power source referential ground

2

VCC

Input

Power supply, must be 2.0 ~ 3.6V

3

P2.2

Input/Output

MCU GPIO

4

P2.1

Input/Output

MCU GPIO

5

P2.0

Input/Output

MCU GPIO

6

P1.7

Input/Output

MCU GPIO

7

P1.6

Input/Output

MCU GPIO

8

NC

Reserved

9

NC

Reserved

10

P1.5

Input/Output

MCU GPIO

11

P1.4

Input/Output

MCU GPIO

12

P1.3

Input/Output

MCU GPIO

13

P1.2

Input/Output

MCU GPIO

14

P1.1

Output

MCU GPIO, PA transmitting control pin

15

P1.0

Output

MCU GPIO, PA receiving control pin

16

P0.7

Output

MCU GPIO, PA receiving high gain control pin

17

P0.6

Input/Output

MCU GPIO

18

P0.5

Input/Output

MCU GPIO

19

P0.4

Input/Output

MCU GPIO

20

P0.3

Input/Output

MCU GPIO

21

P0.2

Input/Output

MCU GPIO

22

P0.1

Input/Output

MCU GPIO

23

P0.0

Input/Output

MCU GPIO

24

RESET

Input

Reset port

★ Please refer to TI official CC2530 Datasheet for module pin definitions, software driver and protocol ★

Page 10

CC2530 Wireless Module User Manual of E18 Series Modules

Copyright ©2012–2017, Chengdu Ebyte Electronic Technology Co., Ltd. 10 / 15

3. Usage

3.1. Development

No.

Keyword

Remark

1

Programming

Embedded 8051 MCU, Program-download can only use specified downloader CC-DeBu

gger,, UART or any other tools like JTAG、ISP、ICP cannot be used for download.

Demo program can be provided for user as reference. User can download the compiled HEX

file directly, or modify on the basis of primary code to achieve their needs.

2

Test board

N/A

Below function available for PA version module

No.

Keyword

Remark

1

Burn firmware

The module is with built-in 8051 MCU,to download program please use downloader YHT15-A2(click

to open)

Page 11

CC2530 Wireless Module User Manual of E18 Series Modules

Copyright ©2012–2017, Chengdu Ebyte Electronic Technology Co., Ltd. 11 / 15

2

Initiate PA

Initiate PA , modify it in file hal_board_cfg.h.

3

Parameter

setting

The setting of CC2592 in zstack,CC2530 pin: P1.1、P1.0、P0.7 are connected with CC2592 pin :PA_EN、

LNA_EN、HGM. Meanwhile, LNA_EN is in high level,and it is in receiving mode.

4

Program

modification

Find macRadioTurnOnPower() from mac_radio_defs.c,and modify.

5

Power

modification

Find static CODE const macPib_t macPibDefaults from file mac_pib.c. Modify in the red signed below.

Page 12

CC2530 Wireless Module User Manual of E18 Series Modules

Copyright ©2012–2017, Chengdu Ebyte Electronic Technology Co., Ltd. 12 / 15

4. Programming

You are recommended to use the Code Composer Studio (CCS) integrated development environment (IDE) applicable for wireless.

Code Composer Studio is a kind of IDE, it supports TI MCU and embedded processor series products. Code Composer Studio covers a

whole set of tools for development and embedded application. It covers the C/C++ compiler for optimizing, source code editor, project

building environment, debugger, descriptor and many other functions. The IDE provides individual user interface, it can help you complete

every step in developing. Familiar tool and interface enables users to start more quickly. Code Composer Studio integrates the advantages

of Eclipse software frame and the embedded debugging function of TI and provides a knockout and functionable development

environment.

4.1. TI ZigBee FAQ

4.1.1. How to select proper protocol stack from different ZigBee protocol stacks of TI?

From the Z-Stack 0.1 to Z-Stack 2.5.1a and the current Z-Stack Home 1.2.1, Z-Stack Lighting 1.0.2, Z-Stack Energy 1.0.1, Z-Stack Mesh 1.0.0,

TI mainly upgraded the protocol stack through: 1) adding some new features according to ZigBee Specification of the ZigBee Alliance, for

example, ZigBee2007 tree-shape route, adding Mesh route in ZigBee Pro, and raising MTO and Source Routing algorithms so TI added

some new functions to the protocol stack, also did some correction of bugs in Spec such as some unclear descriptions; 2) Correction of

bugs of TI ZigBee protocol itself. You can find the differences between one protocol stack and the previous version in the Release Note of

the installation directory.

After the Z-Stack 2.5.1a, TI did not publish the protocol stack in the form of Z-Stack 2.6.x but in Application Profile form, because TI hopes

the developers could select proper protocol stack based on actual applications. The protocol stacks like Z-Stack Home 1.2.1 includes two

parts: 1)Core Stack, it is the follow-up versions of Z-Stack 2.5.1a, it can be found from the Z-Stack Core Release Notes.txt, Version 2.6.2. 2)

Profile-related part, this part is related to the actual application, Home Automation stack is about the realization of ZigBee Home

Automation Profile. Meanwhile, Z-Stack Lighting 1.0.2 and Z-Stack Energy 1.0.1 are Core Stack with Profile for application.

1) Z-Stack Home 1.2.2a is specific for smart home products development.

2) Z-Stack Lighting 1.0.2 is specific for ZLL products development.

3) Z-Stack Energy 1.0.1 is specific for intelligent energy, meter, In Home Display, and so on.

4) Z-Stack Mesh 1.0.0 is specific for private applications, it only utilizes the function of standard ZigBee protocol, Mesh route and so on,

the application layer shall be defined by the developer.

After the publish of ZigBee 3.0 protocol, the latest ZigBee protocol stack is Z-Stack 3.0, it supports CC2530 and CC2538.

4.1.2. How to apply for standard ZigBee test certification?

Take standard ZigBee Home Automation products as example, developers must develop according to the description in the ZigBee Home

Automation Profile Specification, this document can be found from www.zigbee.or. After developing the product, developers need to

learn the ZigBee Home Automation Profile Test Specification, this document described the items to be tested by the Test House, it can be

downloaded from www.zigbee.org also, in addition, there is another PICS document, it is specific for describing the functions supported,

developers confirm the functions by checking the boxes according to the actual functions and the required functions in the Specification,

as below are the testing procedure:

1) Join the ZigBee alliance, generally assisted by testing labs;

2) Send samples to testing lab, complete the PICS file;

3) First round pre-testing, the testing lab feedback the testing results, developers modify the sample codes.

4) The testing lab verify the modified sample, and starts formal test;

5) The testing lab assists developers to complete the ZigBee alliance online certification application;

6) The testing lab submits the test report to ZigBee alliance. The alliance will review and issue certificate.

Currently, there are two testing labs in China who can complete standard ZigBee test:

1) CESI in Beijing;

2) Element Shenzhen Office (headquartered in England)

Please refer to below wiki link for details:

http://processors.wiki.ti.com/index.php/ZigBee_Product_Certification_Guide

Page 13

CC2530 Wireless Module User Manual of E18 Series Modules

Copyright ©2012–2017, Chengdu Ebyte Electronic Technology Co., Ltd. 13 / 15

How to select the 64-bit MAC address of the device?

There are two IEEE addresses in CC2530/CC2538/CC2630, one is Primary IEEE address, the other is Secondary address. Primary IEEE

address is stored in Information Page of the chip, this address is bought by TI from IEEE, each chip has one unique address. Users could

only Read this value and cannot modify or erase it. By reading the address in the protocol stack, users can obtain

osal_memcpy(aExtendedAddress, (uint8 *)(P_INFOPAGE+HAL_INFOP_IEEE_OSET), Z_EXTADDR_LEN). Secondary address is stored in the

last Page of the Flash of CC2530, users can Read/Write with the function HalFlashRead(HAL_FLASH_IEEE_PAGE, HAL_FLASH_IEEE_OSET,

aExtendedAddress, Z_EXTADDR_LEN).

When the protocol stack is operating, how to select Primary IEEE address or Secondary address as MAC address? Please operate in the

function zmain_ext_addr(void).

1) Read IEEE address from NV, if it already exists (not 0xFF), use this address as MAC address;

2) If not in 1), read from the Secondary IEEE address storage place, if it exists (not 0xFF), write the address into NV, and use this address

as MAC address;

3) If not in 2), read from the Primary IEEE address storage place, if it exists (not 0xFF), write the address into NV, and use this address as

MAC address;

4) If not in 3), generate one 64-bit variable randomly, write it into NV, use it as MAC address.

4.1.3. How to forbid node from searching network, or extend the interval for sending Beacon Request?

End Device is low power consumption device powered by battery, after cutting from network, how to forbid the node from searching

network, or how to extend the interval for sending Beacon Request.

1) Start searching network uint8 ZDApp_StartJoiningCycle(void)

Stop searching network uint8 ZDApp_StopJoiningCycle(void)

2) Change the Beacon Request sending period

Modify the variable zgDefaultStartingScanDuration

// Beacon Order Values

#define BEACON_ORDER_NO_BEACONS 15

#define BEACON_ORDER_4_MINUTES 14 // 245760 milliseconds

#define BEACON_ORDER_2_MINUTES 13 // 122880 milliseconds

#define BEACON_ORDER_1_MINUTE 12 // 61440 milliseconds

#define BEACON_ORDER_31_SECONDS 11 // 30720 milliseconds

#define BEACON_ORDER_15_SECONDS 10 // 15360 MSecs

#define BEACON_ORDER_7_5_SECONDS 9 // 7680 MSecs

#define BEACON_ORDER_4_SECONDS 8 // 3840 MSecs

#define BEACON_ORDER_2_SECONDS 7 // 1920 MSecs

#define BEACON_ORDER_1_SECOND 6 // 960 MSecs

#define BEACON_ORDER_480_MSEC 5

#define BEACON_ORDER_240_MSEC 4

#define BEACON_ORDER_120_MSEC 3

#define BEACON_ORDER_60_MSEC 2

#define BEACON_ORDER_30_MSEC 1

#define BEACON_ORDER_15_MSEC 0

4.1.4. How to put End Device into low power consumption mode, how to set up sleep time?

After the POWER_SAVING is enabled in the protocol stack macro definition, put DRFD_RCVC_ALWAYS_ON=FALSE in f8wConfig.cfg file,

then the End Device will enter sleep mode.

The sleep time is decided by the OSAL operating system, the latest Event Timeout to occur will be set as sleep time. There is description in

the protocol stack hal_sleep function.

There are two kinds of timeout: one is the timeout of application layer event, the other is the timeout of MAC layer event.

1) Timeout of application layer, can be obtained through osal_next_timeout() of osal_pwrmgr_powerconserve(void) function;

2) Timeout of MAC layer, can be obtained through MAC_PwrNextTimeout() of halSleep(uint16 osal_timeout) function.

4.1.5. What new features does ZigBee 3.0 stack have?

Please refer to below link, it describes the new features of the ZigBee 3.0 stack as compared with the previous ZigBee Home

Automation/ZigBee Light Link.

http://processors.wiki.ti.com/index.php/What%27s_New_in_ZigBee_3.0

About the status switch in the TI ZigBee protocol stack

http://www.deyisupport.com/question_answer/wireless_connectivity/zigbee/f/104/t/104629.aspx

Page 14

CC2530 Wireless Module User Manual of E18 Series Modules

Copyright ©2012–2017, Chengdu Ebyte Electronic Technology Co., Ltd. 14 / 15

4.1.6. About the difference between OAD and OTA in TI protocol stack?

OAD is short for Over the Air Download, OTA is short for Over the Air. The functions of these two are the same, they can be called the

software upgrade on air. In the earlier ZigBee protocol standard, there was no standard for node software upgrading on air, but many

customers have such requirements, thus TI developed their own protocol stack for software upgrading on air, and named it as OAD. After

that, ZigBee alliance noticed the more and more requirements for upgrading on air, so they developed the upgrading on air standard and

named it as OTA, this standard has taken the TI OAD method as reference and has made some modification. The upgrading on air in TI’s

earlier protocol stack, it is called OAD, and in the later stack, it is called OTA as following the ZigBee alliance stack.

4.1.7. Which protocol stack shall be selected for developing private application based on ZigBee Mesh?

Many customers only need to apply the function of ZigBee Mesh network in their system or products, and do not need to do according to

the application layer as defined by the ZigBee, especially for some industrial applications, as for such requirements, how to select proper TI

protocol stack for developing products?

http://www.deyisupport.com/question_answer/wireless_connectivity/zigbee/f/104/t/132197.aspx

5. Production guidance

5.1. Reflow soldering temperature

Pre-heating area: maximum temperature rise is 2.5℃/s;

Thermal insulation area: temperature is 150~190℃, time is 60~90s,maximum temperature rise is 2.5℃/s;

Reflowing area: maximum temperature is 235~245℃, time for above 217℃ is 40~80s;

Cooling area: maximum temperature drop is 4℃/s.

5.2. Reflow soldering curve

Page 15

CC2530 Wireless Module User Manual of E18 Series Modules

Copyright ©2012–2017, Chengdu Ebyte Electronic Technology Co., Ltd. 15 / 15

6. FAQ

6.1. Communication range is too short

The communication distance will be affected when obstacle exists.

Data lose rate will be affected by temperature, humidity and co-channel interference.

The ground will absorb and reflect wireless radio wave, so the performance will be poor when testing near ground.

Sea water has great ability in absorbing wireless radio wave, so performance will be poor when testing near the sea.

The signal will be affected when the antenna is near metal object or put in a metal case.

Power register was set incorrectly, air data rate is set as too high (the higher the air data rate, the shorter the distance).

The power supply low voltage under room temperature is lower than 2.5V, the lower the voltage, the lower the transmitting power.

Due to antenna quality or poor matching between antenna and module.

6.2. Module is easy to damage

Please check the power supply source, ensure it is 2.0V~3.6V, voltage higher than 3.6V will damage the module.

Please check the stability of power source, the voltage cannot fluctuate too much.

Please make sure antistatic measure are taken when installing and using, high frequency devices have electrostatic susceptibility.

Please ensure the humidity is within limited range, some parts are sensitive to humidity.

Please avoid using modules under too high or too low temperature.

7. Important Notes

All rights to interpret and modify this manual belong to Ebyte.

This manual will be updated based on the upgrade of firmware and hardware, please refer to the latest version.

Please refer to our website for new product information.

8. About us

Technical support: support@cdebyte.com

Documents and RF Setting download link: www.cdebyte.com/en/

Tel:+86-28-61399028

Fax:028-64146160

Web:www.cdebyte.com/en/

Address:Innovation Center D347, 4# XI-XIN Road,Chengdu, Sichuan, China

Loading...

Loading...