Page 1

UH Structures Inc. dba Ebtech Industrial

2241 Industrial Drive

Connellsville, PA 15425-6181

Telephone: 724-628-6100

Fax: 1-412-774-2429

www.ebtechindustrial.com

Office Installation Guidelines

Page 2

INTRODUCTION

These construction and installation guidelines are provided to assist in the

installation of the Ebtech products and may not apply to every situation.

Manufacturer accepts no responsibility or liability for the use of these or other

installation guidelines.

DESIGNER, INSTALLER, AND END USER SHALL DEFEND AND HOLD

EBTECH INDUSTRIAL HARMLESS FROM ANY AND ALL CLAIMS OR

DAMAGES CAUSED BY INSTALLER, IT’S AGENTS OR CONTRACTORS, BY

THEIR ACTIONS OR OMISSIONS, OR RELATED TO THE ASEEMBLY OF THE

EBTECH INDUSTRIAL MODULAR COMPONENTS.

ATTENTION: This installation guide is intended to provide general

information for the designer, installer and end user. The following guidelines

should help you safely and properly install the Ebtech modular structure.

We urge you, and anyone installing these products, to read these guidelines

in order to minimize risks of safety hazards and to help prevent voiding any

applicable warranties. This manual is a general installation guide and does

not cover every installation condition or requirement. You acknowledge that

it is solely your obligation for all safety requirements and code compliance.

Ebtech Safety Guideline Recommendations:

FOLLOW ALL OSHA REGULATIONS AND ANY OTHER SAFETY GUIDELINES

AND SAFETY BEST PRACTICES APPLICABLE TO YOUR LOCATION. -USE

APPROVED SAFETY EQUIPMENT, BELTS AND/OR HARNESSES OR OTHER

FALL PROTECTION EQUIPMENT AS REQUIRED.

Overview: This Ebtech modular structure is comprised of Ebtech wall panels and

support beams as well as other assembly components. The following installation

steps are presented as a general outline of the installation process. These are

manufacturer recommendations only. YOU ARE FULLY AND SOLELY

RESPONSIBLE AND SHALL HOLD EBTECH INDUSTRIAL HARMLESS FOR

ANY LIABILITY, CLAIMS, OR DAMAGES, FOR THE INSTALLATION AND

COMPLIANCE WITH ALL SAFETY REQUIRMENTS. Good construction and

safety practices should be followed at all times.

Page 2 of 20 Effective 09-14-2011 Rev004 Doc003

Page 3

TABLE OF CONTENTS

Section

Page #

Suggested Tool List

3

Parts Identification

4

Building Layout

5

Bottom Track Installation Recommendations

7

Wall Panel Installation Recommendations

8

Window & Window Panel Installation Recommendations

11

Top Track Installation Recommendations

12

Door Installation Recommendations

13

Steel Dust Cover Installation Recommendations

16

Acoustical Grid Ceiling Installation Recommendations

17

Roof Deck Support Beam installation Recommendations

18

Wall Starter Installation Recommendations

19

Stair & Landing Installation Recommendations

20

SUGGESTED TOOL LIST

1. Hammer Drill with 114" Percussion Bit

2. Cordless Drift with Bits

3. #2 & #3 Phillips Screw Tip with Magnetic Holder

4. Circular Saw with Carbide Tip Blade

5. Nut Drivers with 5116" and 114" Heads

6. Ratchet Wrench 5/8" Socket

7. Rubber Mallet

8. Metal Snips

9. Putty Knife with Wide Blade

10. Utility Knife

11. Hack Saw

12. Screw Drivers - Phillips and Flat

13. Measuring Tape and Ruler

14. Level – 48" Minimum Length

15. Large Carpenter's Square

16. Chalk Line

17. Gloves

18. Eye Protection

Page 3 of 20 Effective 09-14-2011 Rev004 Doc003

Page 4

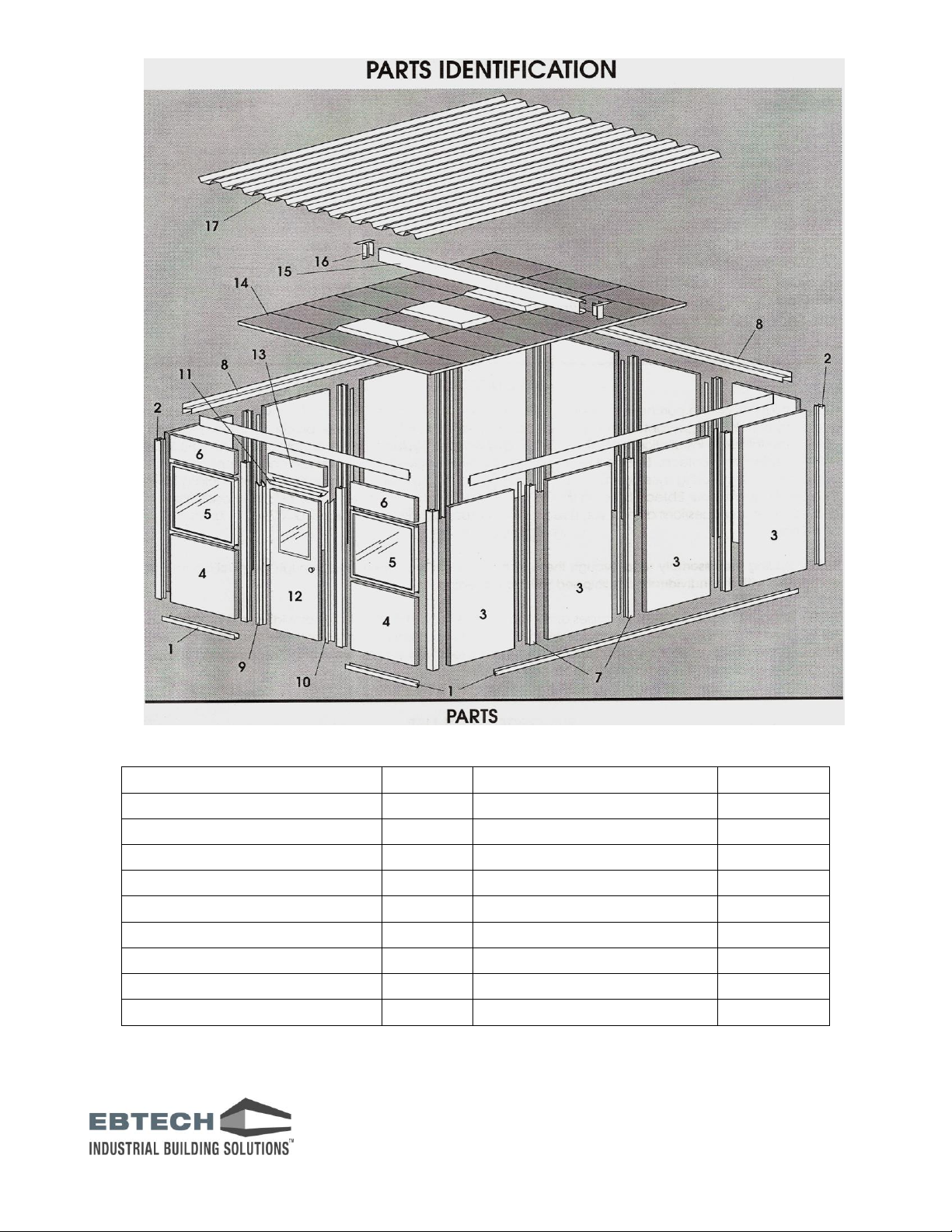

Part Description

ID #

Part Description

ID #

Bottom Track

1

Strike Side Door Jamb

10

Corner Post

2

Top Door Jamb

11

Wall Panel

3

Door (window optional)

12

Bottom Window Panel

4

Door Header Panel

13

Window

5

Acoustic Grid Ceiling

14

Top Window Panel

6

Support Beam

15

Wire Stud 1

7

Support Beam Hanger

16

Top Track

8

Steel Dust Cover

17

Hinge Side Door Jamb

9

Wire Stud Note #1:

EB-200 – 1 piece w/cover & EB-300 – 2 piece w/cover

Page 4 of 20 Effective 09-14-2011 Rev004 Doc003

Page 5

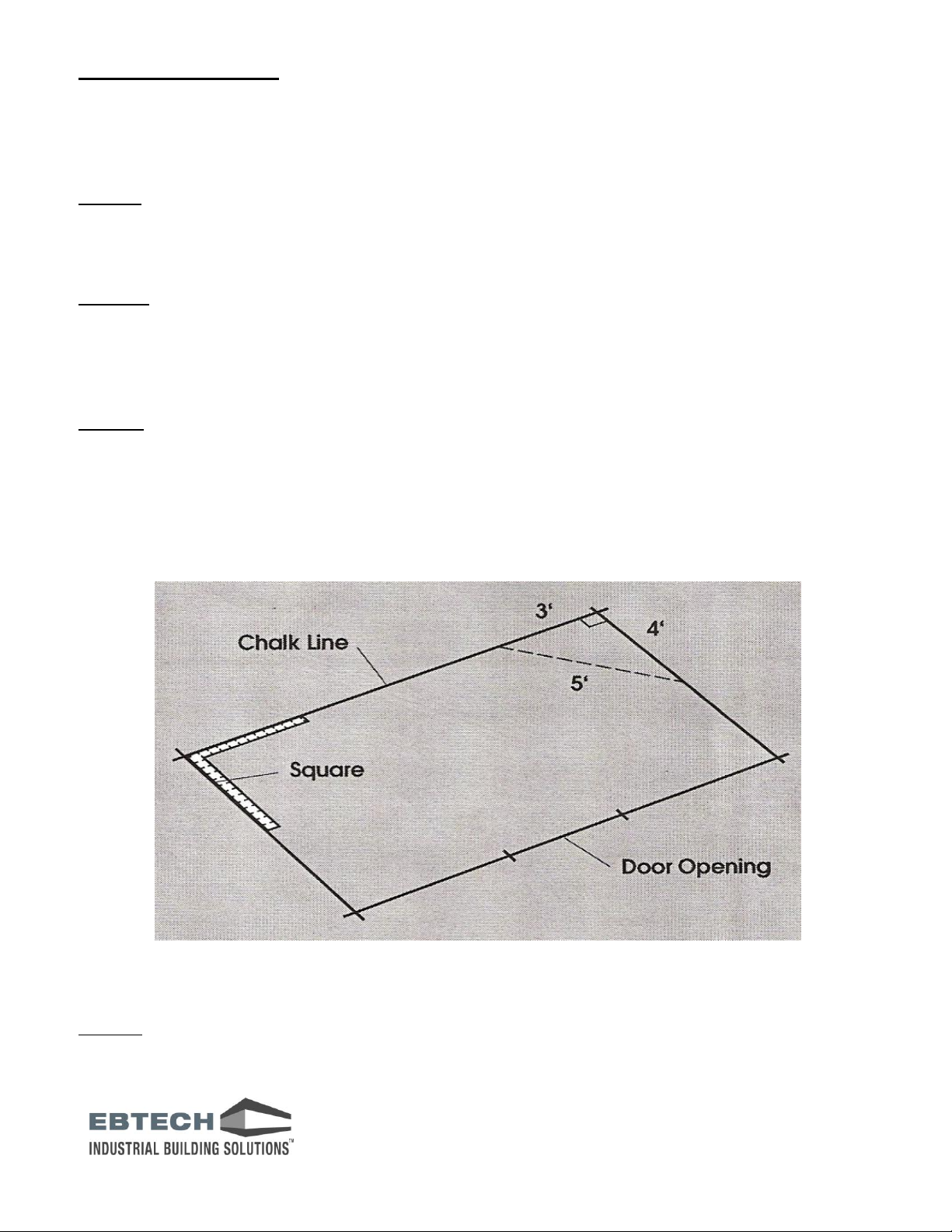

BUILDING LAYOUT

The proper and accurate installation of the Bottom Track is crucial to your building

assembly success. Therefore, we strongly recommend that you check and

recheck your measurements. A few extra moments taken now can save significant

time and frustration.

Step 1 – For ease of installation it is important that you work in a clean, safe, and

spacious area. For assembly purposes, allow several feet of extra space around

the building location. Sweep the work area all debris and remove any objects that

might impede the assembly process.

Step 2 – Refer to the Bottom Track Layout in Packing List for the exact

dimensions of your Ebtech building. Strike a chalk line on the floor for your first

wall. Where you begin chalking is not important chalking, but we suggest you

frequently verify your layout sheet for proper lengths and miters.

NOTE: All chalk lines will represent the outside edge of the Base Track.

Step 3 – Construct a 90 degree corner at your walls using one of two methods

shown in Figure #1. Use a large square or the 3-4-5 triangular method to make an

accurate 90 degree corner. Strike a chalk line through this point to mark the

outside edge of the cross wall.

NOTE: It is very important this dimension be established accurately now because

it is very difficult to make modifications when you begin installation.

Figure #1

Step 4 – Complete the perimeter of your building using the dimensions shown on

the Bottom Track drawing.

Page 5 of 20 Effective 09-14-2011 Rev004 Doc003

Page 6

Step 5 – Locate any door openings and carefully mark these on the floor

accordingly. The space between the Bottom Track for each single standard size

door opening is 38 1/2”.

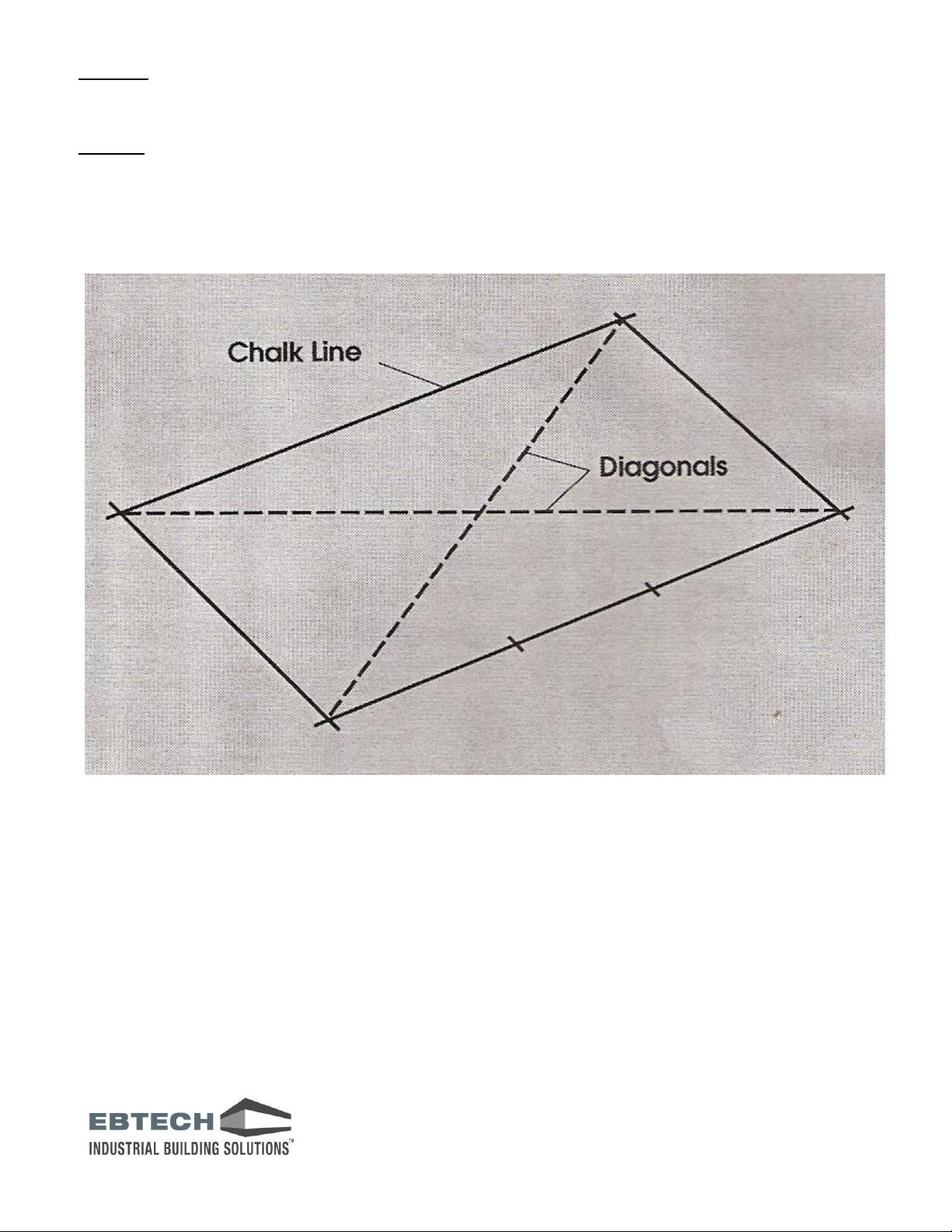

Step 6 – In a square or rectangular building an easy way to double check the

accuracy of your layout is to measure the diagonals. They should be the some

length. (See Figure #2 below)

Figure 2

Page 6 of 20 Effective 09-14-2011 Rev004 Doc003

Page 7

BOTTOM TRACK INSTALLATION RECOMMENDATIONS

Wood Floor

¼” x 1 ¼” lag bolts

Concrete Floor

Powder actuated fasteners, 1” nails with #3 charge or

1 ½” nails with #4 charge or various expansion

anchors

Steel Floor

#14x1” sheet metal screws

Step 1 –Ebtech provides you with carefully measured precut, mitered, and clearly

marked Bottom Track pieces. Refer to your Bottom Track drawing sheet included

in your packing list and begin placing the outside edge of your Bottom Track

pieces along the chalk lines you created in the building layout step.

Step 2 – Anchor the Bottom Track using appropriate for the type of floor in your

office/plant. Ebtech does not furnish these fasteners. A list of recommended

fasteners follows:

See figure #3 for fastener locations. Ensure measurements prior to installing

anchors, because removing anchors is difficult and may damage the Bottom

Track. Make sure you place a fastener near the end of each piece of track and

approximately every 3' along the length of the track.

Figure #3

Page 7 of 20 Effective 09-14-2011 Rev004 Doc003

Page 8

WALL PANEL INSTALLATION RECOMMENDATIONS

Step 1 – Beginning at a corner (choose any corner), place a Corner Post into the

Bottom Track (see figure #4).

Figure #4

Step 2 – Use the wall panel layout drawing provided packing list to determine the

walls panels to be inserted into the Bottom Track and Corner Post as shown in

Figure #5.

Figure #5

Page 8 of 20 Effective 09-14-2011 Rev004 Doc003

Page 9

Step 3 - Make sure the Corner Post is plumb and fasten it to the wall panels using

#8x5/8" self drilling screws. Place screws approximately 3" from the top of the wall

panels, through the Corner Post and into the wall panel as shown in figure #6.

Figure #6

Note:

Depending on building style and configuration, you will be installing H-Studs or

Wire Studs and Covers between wall panels. H-Studs are AL extrusions placed

between wall panels. EB-200 Wire Studs and Covers are made from two AL

extrusions and are shown in Figure #7. EB-300 Wire Studs and Covers are made

from three AL extrusions and are shown in Figure #8.

Figure #7 Figure #8

Page 9 of 20 Effective 09-14-2011 Rev004 Doc003

Page 10

Wire Studs and Covers are used to conceal electrical, data and communication

lines. It is recommended that you assemble the two EB-300 pieces together prior

to installing them inside the AL Bottom Track. Assemble loosely with #8x5/8" selfdrilling screws. Make sure a fastener is placed in each pre-punched hole of the

AL Wire Stud. You will be advised later in this manual when to tighten the screws.

We recommend you install any electrical or switch boxes inside the AL Wire Studs

prior to installing. The AL Cover Plates can be cut to fit around the electrical boxes

and snapped into place after all your wiring is complete.

Note: Make sure the AL Covers are facing the inside of the office.

Step 4 – Install the H-Stud or Wire Stud into the AL Bottom Track and over both

sides of the wall panel. Make sure the H-Stud or Wire Stud cover the previous

panel sides and is plumb. Care should be taken if you need to tap the stud into

place over the wall panel (a wooded block placed inside the stud will help prevent

many hammer marks).

Step 5 - Fasten the H-Stud or Wire Studs to both the AL Bottom Track and the

previous wall panel using #8x5/8" self drilling screws. Place screws approximately

3" from the top of the wall panels, through the H-Studs or Wire Studs and into the

wall panel as shown in figure #6.

Step 6 – Install successive wall panels and H-Studs or Wire Studs by repeating

steps the above steps.

IMPORTANT NOTE AND CAUTION:

TEMPORARILY BRACE WALLS AS NEEDED

MAINTAIN A SAFE AND SECURE AREA IN AND AROUND YOUR ASSEMBLY

ZONE

Page 10 of 20 Effective 09-14-2011 Rev004 Doc003

Page 11

WINDOW & WINDOW PANEL INSTALLATION RECOMMENDATIONS

Windows and Window Panels have three sections and are installed in a similar

manner as the regular Wall Panels. Consult the layout drawing for placement of

windows.

Step 1 – First install the bottom panel in the same manner as a regular Wall

Panel. This panel is usually 48" wide x 42" tall.

Step 2 – Next place the assembled window unit over the Bottom Wall Panel and

into Wire Stud.

Step 3 – Place the Top Panel over the window unit (See Figure #9). Make sure

the window unit is plumb and that all aluminum pieces are fit tightly against one

another. Windows should be flush with the surrounding walls.

Figure #9

Page 11 of 20 Effective 09-14-2011 Rev004 Doc003

Page 12

TOP TRACK INSTALLATION RECOMMENDATIONS

Once a wall section has been completed (see Figure #10), place proper mitered

and length AL Top Track over the H-Studs or AL Wire Studs and Wall Panels.

Consult the AL Top Track Layout Drawing as needed.

Figure 10

Fasten the Top Track to the Comer Posts and Wire Studs using the #8x5/8" self

drilling screws provided (Figure #11)

Figure 11

Continue to install wall panels and windows to complete the other office walls,

leaving the door panel as the last panel to install.

Page 12 of 20 Effective 09-14-2011 Rev004 Doc003

Page 13

DOOR INSTALLATION RECOMMENDATIONS

Step 1 – Install the two narrow door side panels in the AL H-Studs or AL Wire

Studs.

Step 2 – Install the two narrow AL H-Studs on top of the narrow door side panels,

these will cover the interface between the narrow side panels and the door header

panel.

Step 3 – Install the steel hinge side frame over the wall panel and outside of the

AL Bottom Track.

Step 4 – Install the steel door top jam mating the tabs in the side frame into the

top jam as shown in Figure #12.

Figure #12

Step 5 – Install the steel door strike side frame mating the tabs in the top jam as

shown in Figure #13. Tilting during the strike side frame assembly, will make this

a simple process.

Figure #13

Page 13 of 20 Effective 09-14-2011 Rev004 Doc003

Page 14

Step 6 – Ensure both steel hinge and strike side are plum, then insert #6x1 5/8"

self drilling screws to secure the steel door installation to the AL Bottom Track as

shown in Figure #14

Note: Make sure that you have the same Door Frame opening on the top and

bottom. Adjust the built-in plumb screws, if necessary.

Figure #14

Step 7 – Install the door header panel as shown in Figure #15.

Figure #15

Page 14 of 20 Effective 09-14-2011 Rev004 Doc003

Page 15

Step 8 – After removing the hinge pins. Install the three hinges sides on the door.

Step 9 – Install the three hinges sides on the steel door frame.

Step 10 – Hang the door and insert the hinge pins into the two halves of the

hinges as shown in Figure #16

Figure #16

Step 11 – Install the lockset.

Reminder Note: Go back and fully tighten all of the AL H-Studs or AL Wire Studs

screws in both the AL Bottom Track and the AL Top Track to ensure structure

integrity.

Page 15 of 20 Effective 09-14-2011 Rev004 Doc003

Page 16

STEEL DUST COVER INSTALLATION RECOMMENDATIONS

Note: For spans greater than 12 feet refer to Appendix A for placement and

installation recommendations of Support Beams prior to installing the Dust Cover.

Step 1 – Place corrugated roof panels on the AL Top Track one panel at a time.

Roof panels have lap joints on the sides.

Do not overlap roof panels beyond these joints until you reach the lost panel. The

last roof panel can be over lapped to fit. (See Figure 18) If building is square and

plumb, roof panels should butt securely to outside lip of AL Top Track.

Step 2 – Fasten roof panels to the AL Top Track approximately every 12" with

#10x¾” self drilling screws. Make sure you fasten the ends at each lap joint and at

least at one point in between. Fasten the sides every 24" at a minimum.

Note: Standard Roof Deck is non load bearing and intended to only support

lights and the ceiling. Be very careful when fastening lap joints.

Figure 18

Page 16 of 20 Effective 09-14-2011 Rev004 Doc003

Page 17

ACOUSTICAL GRID CEILING INSTALLATION RECOMMENDATIONS

See the Grid Ceiling Layout drawing included in the packing slip for the designed

pattern of the ceiling tile.

Step 1 – Install the Wall Angle around the entire perimeter between 6”–12” below

the Dust Cover. Fasten the Wall Angle to each AL H-Stud or AL Wire Stud with

#8x5/8" self drilling screws.

Note: It is best not to fasten the Wall Angles directly to the Wall panels.

Step 2 – Mark the locations of the Main Ceiling Tees with chalk line on the

underside of the corrugated roof panels. Insert the self drilling 5/8”x1 ¼”

acoustical eye screws along the chalk lines at 24” intervals at a minimum.

Step 3 – Thread the 12GA Tie Wires through the eye’s of the screws and loop the

Tie Wires into the Main Tee’s. See Figure #19.

Note: Make sure the Main Tees are level and at the same height from the floor as

are the Wall Angles.

Figure #19

Step 4 – Snap the Cross Tees into the Main Tees according to the Grid Ceiling

layout drawing.

Step 5 – Install the fluorescent light fixtures into the Grid Ceiling according to the

Grid Ceiling layout drawing.

Note: Recheck that the Main Tees are level, because of the weight of the light

fixtures, it may be necessary to adjust some of the Tie Wires.

Step 6 – Install the Ceiling Tiles into the grid according to the Grid Ceiling layout

drawing.

Page 17 of 20 Effective 09-14-2011 Rev004 Doc003

Page 18

ROOF DECK SUPPORT BEAM INSTALLATION RECOMMENDATIONS

Note: For spans greater than 12 feet Support Beams are needed to support the

corrugated steel roofing material.

The Support Beam should be located and installed according to the Wall Panel

layout drawing.

Step 1 – Place Steel Support Beam Hangers on the top of the AL Top Track and

directly over the AL Wire Stud. Fasten the Steel Support Hangers to the AL Top

Track with the screws provided.

Step 2 – Insert the Steel Support Beam into the Hangers. Secure the beam to the

hanger with two self drilling screws provided.

NOTE: The finished Steel Support Beam installation should resemble Figure #20

Figure #20

Page 18 of 20 Effective 09-14-2011 Rev004 Doc003

Page 19

WALL STARTER INSTALLATION RECOMMENDATIONS

A Wall Starter is necessary when attaching or starting a wall from an existing wall.

The Bottom Track should already be in place and butted up against the wall

before installing the Wall Starter.

Step 1 – Place the Wall Starter into the end of the Bottom Track then locate

against the existing wall. Ensure the Wall starter is plumb as shown in Figure #21.

Figure #21

Step 2 – Securely fasten the Wall Starter with an appropriate fastener for the type

of wall.

Page 19 of 20 Effective 09-14-2011 Rev004 Doc003

Page 20

STAIR & LANDING INSTALLATION RECOMMENDATIONS

(Figure #22)

Step 1 – Bolt columns to one piece landing platform.

Step 2 – Position landing per drawing and attach top stair clips.

Note: When raised into position the opening of the landing should face the

mezzanine.

Step 3 –Secure stair stringers to top clips.

Step 4 – Bolt stair threads to both stair stringers.

Step 5 – Anchor columns and bottom of the stair stringers in their final position.

Figure #22

Page 20 of 20 Effective 09-14-2011 Rev004 Doc003

Loading...

Loading...