Page 1

Operating Instructions

v.

20080908#3.0

EN

English

Page 2

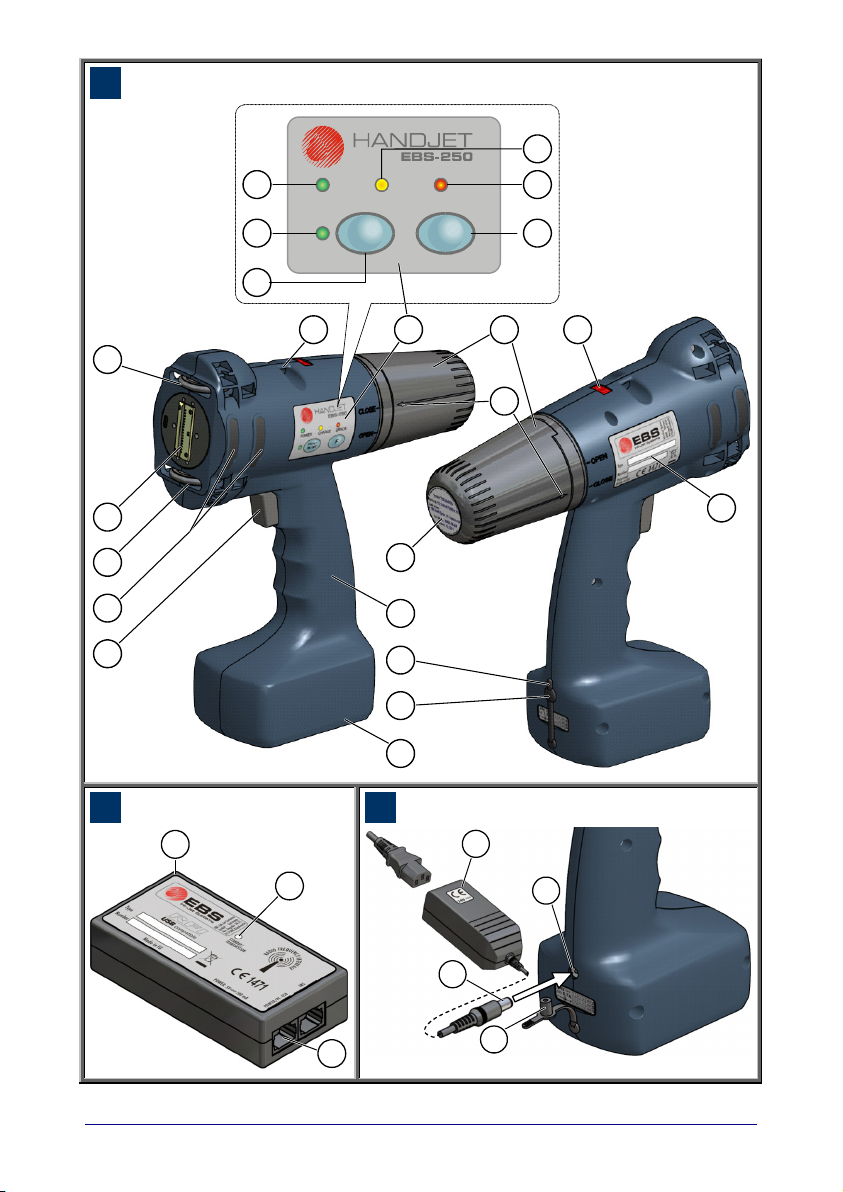

A

21

16

17 19

18

1

2

3

4

5

POWER ERRORCHARGE

PRINT

ON / OFF

8

F

9 34

11

7

15

14

6

20

10

12

13

B

2

22

24

EBS Ink-Jet Systeme

23

C

26

25

15

14

20080908#3.0

Page 3

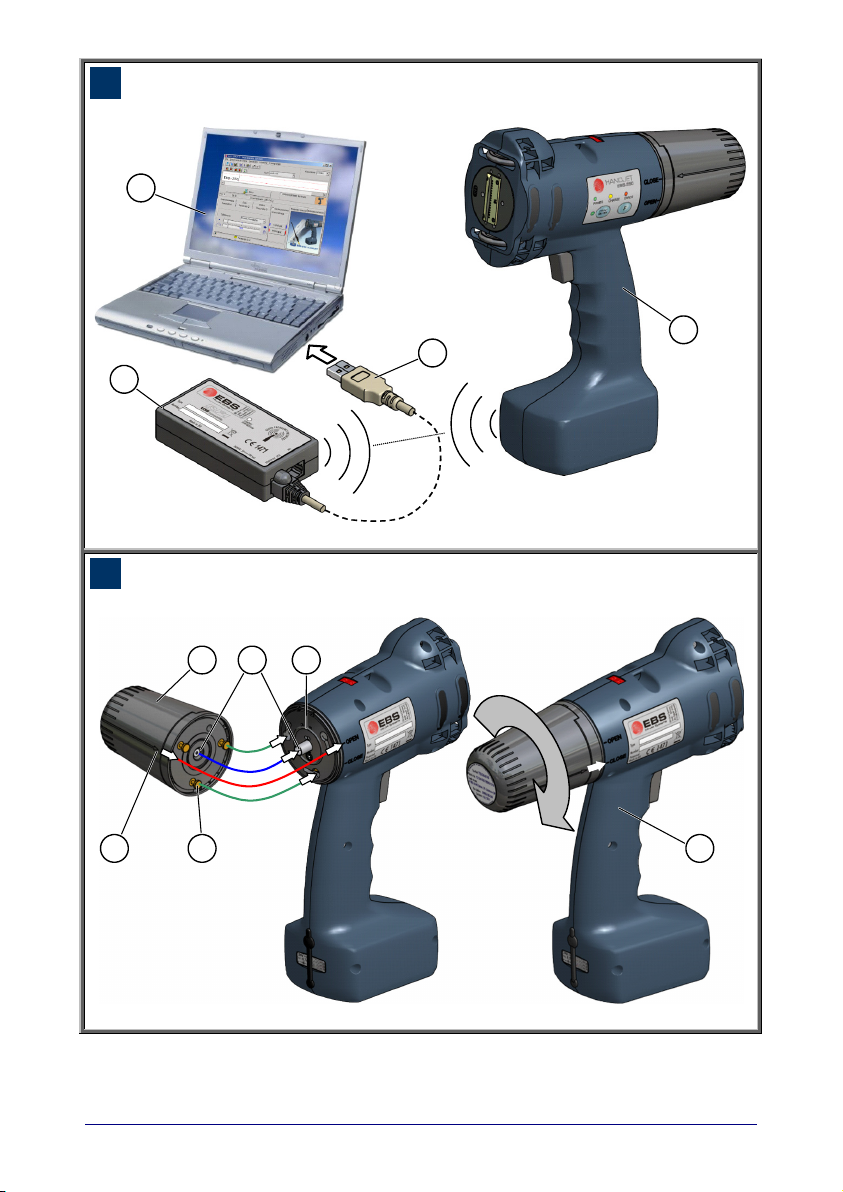

D

28

22

E

12 31

10

30

32

USB

29

27

29

20080908#3.0

EBS Ink-Jet Systeme

3

Page 4

EN

A

Components of the Port-

able Printer System

See figures A B C D E

1. Upper guide roll.

2. Nozzle plate - front part of the

print head (ink outlet).

3. Lower guide roll, to synchronise

printing.

4. Openings with plugs for adjusting

electromagnets.

5. Release - a printing release but-

ton, also used by other functions.

6. Printer base, battery compart-

ment.

7. Printer holder.

8. Hanger.

9. Control panel and keypad.

10. Ink container.

11. Ink container label.

12. Container OPEN-CLOSED indi-

cator.

13. Name plate.

14. Battery charge socket.

15. Charge plug.

16. Power LED indicator.

17. PRINT ON/OFF LED indicator

(the print state).

18. PRINT ON/OFF button.

19. Function key F.

20. Error LED indicator.

21. Charge LED indicator.

22. RFI Module - for wireless (radio)

communications via USB interface.

23. Socket to connect cable from the

computer communications port.

24. Radio transmission LED indica-

tor.

25. Power pack to charge printer

batteries or power supply RFI

module 22, with RS-232 interface.

26. Plug of power pack 25.

27. Cable for series communication

between computer (USB port)

and RFI module.

EN

4

EBS Ink-Jet Systeme

F

.

28. Computer.

29. HANDJET

®

EBS 250 Printer.

30. Non-return valves in the ink con-

tainer and ink system.

31. Guide bayonets in the ink con-

tainer.

32. Ink container gasket.

33.

Buzzer - a buzzing signal

generator, located inside element

7 of the printer.

34. LED display showing the number

of a text file that is ready for printing.

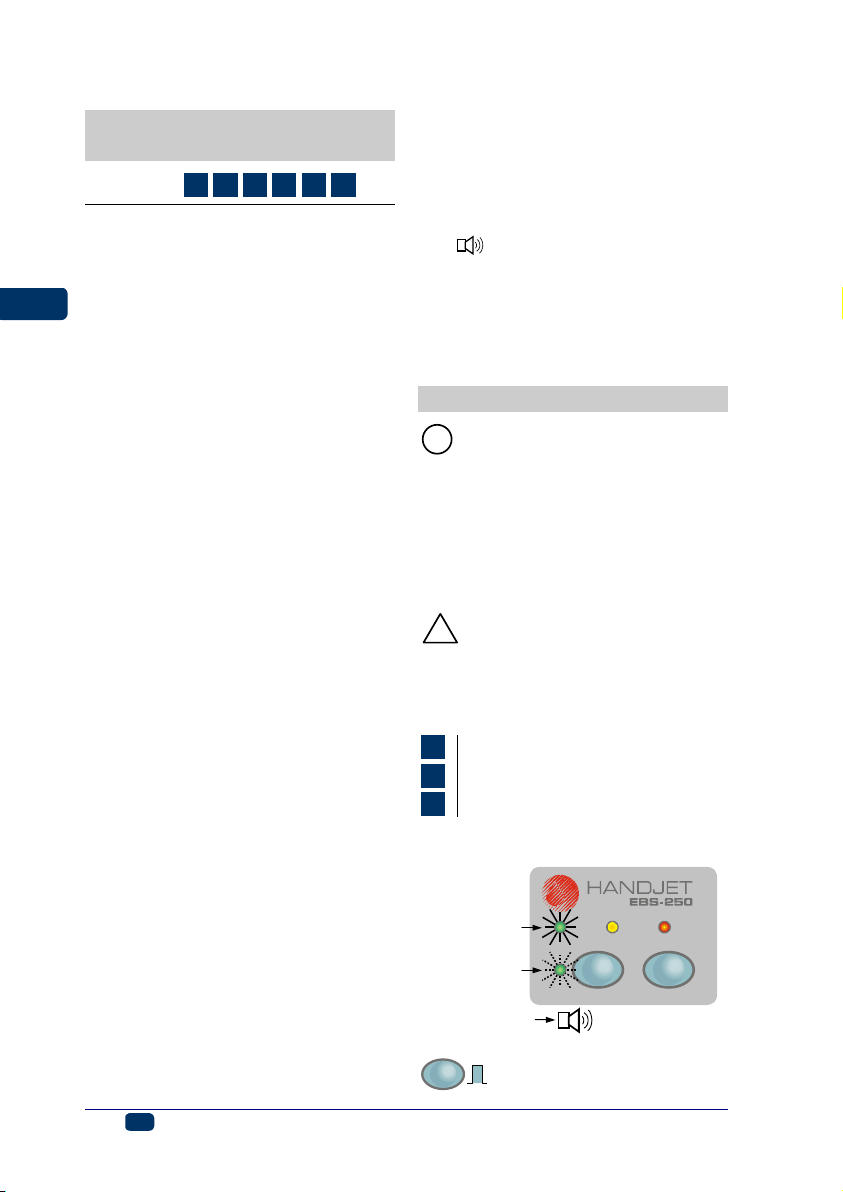

Signs

!

Information signs indicating:

6 that the actions described need to be

taken with extra or special care,

6 the printer’s additional or specific func-

tions or options, which are not described

anywhere else,

6 untypical behaviour of the printer and

other hints.

!

A warning not to perform the

operation that might be unsafe or critical for the printer. It requires the user to

follow closely the instructions given

therein.

Figure numbering notation

B

C

The meaning of LED and other indicators:

The lamp glows

The lamp f lashes

Buzzer

PRINT

ON/OFF

PRINT

ON/OFF

PRINT ON/OFF button (18)

should be pressed for a short

time (<1 sec)

CHARGEPOWER

ERROR

F

20080908#3.0

Page 5

w

w

F

PRINT

ON/OFF

F

Editing markers:

F button (19) should be

pressed for a short time (<1

sec)

PRINT ON/OFF button (18)

3 sec.

should be pressed for a longer

time (>3 sec)

F button (19) should be

3 sec.

pressed for a longer time (>3

sec)

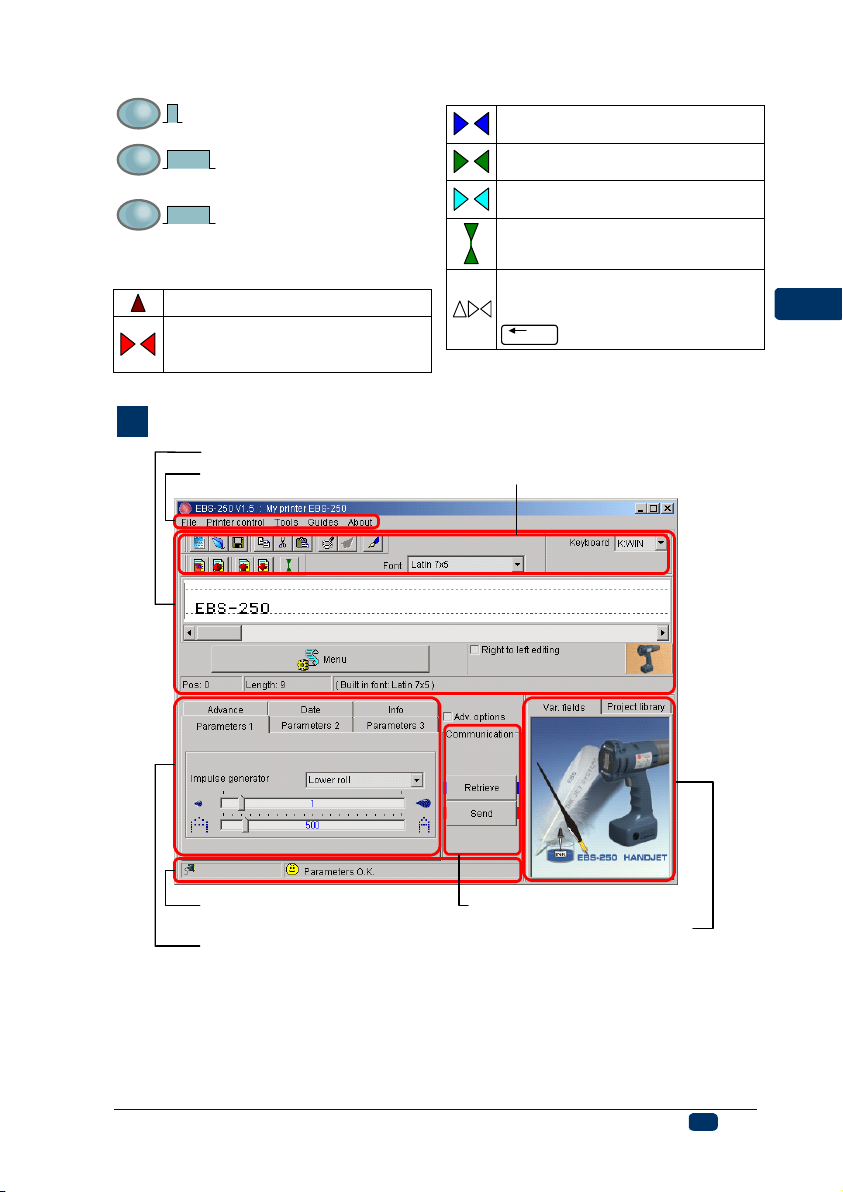

Font change marker - brown

Beginning-of-monospaced-text

marker (inserts F1) and end-ofmonospaced-text (inserts F2) - red

F

Text edit windo

Control Program MENU

Editing markers:

Variable field - incremental counter

(inserts Shift+F1) - blue

Variable field - decremental counter

(inserts Shift+F2) - green

Variable field - universal date and

time (inserts Shift+F12) - turquoise

Wraparound marker - green

A marker white in colour means that

the cursor is just on the left of the

marker (it can be deleted with the

BackSpace

key).

tool bar

EN

Transmission and error status

windo

Parameter tab window

20080908#3.0

EBS Ink-Jet Systeme

Printer communication window

Special register and text

library window

EN

5

Page 6

EN

TABLE OF CONTENTS

COMPONENTS OF THE

PORTABLE PRINTER

SYSTEM.................................... 4

SIGNS ....................................... 4

OPERATIONAL SAFETY ......... 7

G

ENERAL SAFETY INSTRUCTIONS

P

ROTECTING THE BATTERY PACK

W

HEN INK OR WASH-UP SPILLS

C

ONTROL OF ELECTROMAGNETIC

INTERFERENCE

M

EDICAL EQUIPMENT

Pacemaker.......................................... 9

Other medical equipment.................... 9

O

PERATION IN EXPLOSION HAZARD

AREAS

O

PERATION IN AREAS OF BLASTING

C

ONFIRMITY MARKING

E

NVIRONMENTAL PROTECTION

.......................................8

..............................9

....................................................9

.............................9

.............7

............8

...............8

..........9

..............10

APPLICATION ........................ 10

INSTALLING AND

STARTING UP ........................ 10

P

REPARING THE PRINTER FOR

O

PERATION

C

LOW-

I

NSTALLING AND REPLACING THE INK

C

ONTAINER

I

NSTALLING THE INK CONTAINER IN

THE

H

ANY

R

S

WITCHING THE PRINTER ON AND

...................................... 10

HARGING THE BATTERY

BATTERY INDICATOR

......................10

.....................11

...................................... 11

P

RINTER

OW TO CHECK WHETHER THERE IS

EPLACING THE INK CONTAINER

........................................11

I

NK IN THE INK CONTAINER

? ...........11

...........12

OFF................................................. 12

S

WITCHING THE PRINTER ON

S

WITCHING THE PRINTER OFF

I

NSTALLING AND STARTING THE

P

RINTER CONTROL PROGRAM

I

NSTALLING THE CONTROL PROGRAM

S

TARTING THE CONTROL PROGRAM

C

ONNECTING THE PRINTER WITH A

C

OMPUTER (VIA

USB

................12

...............12

............ 12

INTERFACE

....12

......13

) ...... 13

TEXT FILES AND PRINT

PARAMETERS ....................... 14

H

OW TO CREATE A TEXT TO BE

P

RINTED

? .........................................14

R

EGULAR TEXT

Changing proportional spacing and

monospacing ....................................14

Using and Changing Built-in Fonts

of the Printer .....................................15

Using and Changing Windows®

Fonts.................................................15

V

ARIABLE FIELDS

Date and Time ..................................16

Universal Date and Time ..................17

Object Counters................................18

P

RINT PREVIEW

H

OW TO CREATE AND EDIT A

GRAPHICS FILE FOR PRINTING

H

OW TO MODIFY PRINT PARAMETERS

Character Resolution ........................ 20

Intensity of Ink Drops ........................ 20

Mode of Timing ................................. 20

Inverting and Reversing a Text.........21

Repeating a Text (Repetition)...........21

Print Delay ........................................22

Distance between Texts ...................22

Row Repetition ................................. 22

I

NTELLIGENT CONTROL OF HAND

MOVEMENT

H

OW TO TRANSFER/SAVE TEXT

F

ILES TO/IN THE PRINTER

H

OW TO CHANGE A TEXT FILE

S

TORED IN THE PRINTER

PRINTING ................................23

P

RINTING A TEXT FILE SAVED IN THE

P

RINTER

L

INE PRINTING

U

SING A NUMBER OF TEXTS

C

REATING A TEXT LIBRARY IN THE

P

RINTER

Q

UICK SAVING/RETRIEVING TEXT

F

ILES TO/FROM THE TEXT LIBRARY

P

RINTING TEXT FILES FROM THE

L

IBRARY

S

AVING THE PROJECT LIBRARY ON A

C

OMPUTER DISC

MAINTENANCE, STORAGE

AND TRANSPORT ..................27

USER SUPPORT .....................27

P

ROBLEMS WITH FUNCTIONING AND

O

PERATION OF THE PRINTER

..................................... 14

.................................. 16

.................................... 19

?............20

........................................22

....................23

.....................23

............................................23

...................................24

................25

............................................... 25

............................................... 26

.................................. 26

...............27

..20

........ 25

6

EN

EBS Ink-Jet Systeme

20080908#3.0

Page 7

Some of the nozzles do not jet ink ... 27

Rinse the nozzles ............................. 27

The printer does not print ................. 28

Boldfaced or Blurred Prints .............. 28

Q

UESTIONS AND PROBLEMS

E

LECTRONIC GUIDES

............... 28

.......................... 28

C

ONNECTING THE PRINTER TO A

C

OMPUTER (VIA

TECHNICAL PARAMETERS.. 29

P

RINTER ACCESSORIES

RS-232 I

..................... 32

NTERFACE

).. 28

Dear Users of EBS Ink-Jet SystemH equipment,

Please read this manual necessarily in order to get full information about the

operation of your device.

Disclaimer:

• We shall bear no responsibility for damage to the device if it is operated improperly,

i.e., inconsistently with this manual.

• As we wish to keep pace with permanently progressing technological development

and individual requirements of our clients, we need to reserve the right to change the

form, make and technical solutions of our devices. Therefore no data, illustrations or

descriptions of this manual shall form any grounds for claims.

• We spare no effort to ensure that this manual is reliable, includes all modifications

and is free from errors. However, the drawing up and publication process is complex

and an error can occur in spite of our endeavours and wishes. We shall bear no re-

sponsibility for the consequences of editorial and printing errors in this manual.

If your device contains a particular piece of equipment or needs performing an operation

that have not been illustrated or described in this manual, or if you have queries on reading this manual, please contact any representative of EBS Ink-Jet Systeme for additional

information.

EBS Ink-Jet Systeme, the manufacturer, shall not be responsible for damages to the device due to the operation that is inconsistent with the Operating Instructions or due to consequences of drafting or printing errors in

these Instructions.

The printer control program to be installed on your computer is a versatile tool for operating

EBS-200 series stationary printers and EBS 250 series manual printers. Therefore some of

!

its components and functions which (i) are used exclusively for EBS-200 series printers or

(ii) could be used in EBS-250 series printers but are of little significance for manual printers,

will not be described in these Instructions or will be described only briefly.

These instructions apply to EBS-250B printers with the control program

version 1.5.135. In order to check the version of your program view the

About menu.

EN

Operational Safety

Before you start your printer for

the first time read the hints

given below and follow the un-

!

derlying principles for your own

and other persons’ safety.

20080908#3.0

EBS Ink-Jet Systeme

General safety instructions

1. The device must not be operated

in rooms where explosion hazard

exists.

2. No prints can be made on objects

whose temperature exceeds

100°C at the time of printing.

3. No open fire or spark producing

devices or objects are allowed in

EN

7

Page 8

EN

the area where the device operates.

4. During printing ink drops invisible

to people’s eye are jetted out of

the head at pressure. Do not aim

head outlet 2 at any persons,

animals or casual objects because they may get splashed

with ink unintentionally.

5. The following requirements need

to be met when washing, cleaning and maintenance operations

are performed or ink containers

are replaced:

6 The operations can only be per-

formed in a workplace that is especially designed for that purpose, when the device is

switched off and protective clothing is worn. A fire extinguisher

designed to extinguish electrical

devices and flammable solvent

fires must be placed within easy

reach of the device. Air ventilation needs to be ensured at the

workplace.

WARNING: The ink is inflammable!

6 Be careful not to splash the ink.

Especially eyes need protect-

ing. It is advisable to wear protective glasses.

6 Protect the ink and the solvent

(also waste fluid remaining after

the printer has been washed)

against fire, high temperature,

sparks, electric arc and other

electric discharge as they may

cause ignition of these inflammable fluids!

6 Do not use plastic vessels to do

the washing. Metal vessels are

recommended.

6. Protect the printer against dirt,

heavy dust and excessive moisture.

7. EBS Ink-Jet Systeme is able to

ensure perfect and safe opera-

tion of the printer only when

original, printer-specific accessories and consumables are used.

Protecting the Battery Pack

The following principles need to be

obeyed to protect the batteries that

are built into the printer:

6 Protect the printer against exces-

sive temperature and fire. Do not

expose it to strong solar radiation

for a longer time.

6 Avoid a sudden change in tem-

perature (cold Æ hot) that might

cause vapour condensation inside the printer and thereby

speed up battery discharge and

electronic circuit corrosion. Condition the printer for about 1 hour

before use after it has been

moved from a cool place to a

warm one.

When Ink or Wash-up Spills

6 Should the eyes or skin get irri-

tated with ink or wash-up:

EYES rinse the eyes with

running water for at least 15

minutes, then see your oculist.

!

SKIN wash the skin with

water and soap.

6 If the clothing has been splashed,

take it off as soon as possible.

6 When ink or wash-up spill, wipe

out the spilled fluid with a piece

of absorbent material, and then

remove the material in compliance with fire and health and

safety-at-work regulations.

Control of electromagnetic interference

1. Properties of high-frequency

devices.

Your Ink-Jet printer contains a highfrequency transmitter and receiver. When

8

EN

EBS Ink-Jet Systeme

20080908#3.0

Page 9

it is in the ON state, the printer receives

and transmits high-frequency (HF) signals.

The controller of the Ink-Jet printer system

controls energy emitted during printer

operation on an on-going basis.

The HANDJET® EBS 250 printer

complies with all the requirements of

the regulations concerning the impact

of the HF energy on humans in your

country.

2. Printer accessories.

If you do not use original EBS parts or

printer accessories, including batteries or electronic components, the

statutory requirements may not be

met and the HF electromagnetic

emission limits may be exceeded.

Medical equipment

Pacemaker

Pacemaker manufacturers recommend that the distance between a

transmitter and the pacemaker be at

least 15 cm so that any mutual interference between the two devices is

avoided.

Other medical equipment

If you use a piece of medical equipment, please ask the equipment

manufacturer whether the equipment

is sufficiently shielded against electromagnetic radiation. In certain circumstances your doctor may help you

gain the information you require.

Operation in explosion hazard

areas

If you work in an explosion hazard

area, switch your Ink-Jet printer off,

do not replace the batteries or do not

remove them from the printer and

follow all instructions and precautions.

Sparking generated by batteries may

cause an explosion and/or fire in this

hazardous area and result in personal

injuries or even death.

20080908#3.0

EBS Ink-Jet Systeme

The regions where a potential explosion hazard exists are usually marked

appropriately. The examples of such

regions are: solvent storage areas,

fuel storage areas and petrol stations,

below-decks onboard ships, storage

areas for explosive gases, air mixtures, chemicals and metal or flour

powders.

Operation in areas of blasting

In order to avoid interference during

blasting (shot firing) the printer should

be switched off in blasting areas or in

places where the use of radio devices

is prohibited.

Follow the operating instructions and

information signs.

Confirmity marking

®

The HANDJET

EBS 250 printer has

been subjected to conformity assessment procedure which resulted in

the issue of Declaration of Conformity. This forms the basis for the

statement that the HANDJET

®

EBS 250 printer and the manufacturer’s accessories to which this Declaration also relates are in compliance

with the requirements of the following

European Community Directives and

subsequent amendments to these

Directives:

89/336/EEC, 91/263/EEC, 92/31/EEC,

93/68/EEC, 1999/5/EC.

and that they meet the following

norms that are harmonised with the

above Directives

EN 61000-6-2:2001,

EN 61000-6-4:2001,

EN 300 220-1 V1.3.1,

EN 300 220-3 V1.1.1,

EN 301 489-1 V1.5.1,

EN 301 489-3 V1.4.1,

EN 60950-1:2001,

EN

9

EN

Page 10

EN

A

if the printer and the accessories are

installed and used following the

manufacturer’s instructions.

The HANDJET

RFI modules will bear the following

mark:

Environmental protection

After the printer and RFI

modules have been put out

of service, do not take them

out together with other do-

mestic waste.

According to Directive No 2002/96/EC

of the European Council on electrical

and electronic equipment waste, the

HANDJET

modules that have been put out of

service must be separated from domestic waste and processed in an

environmentally friendly way.

Application

The HANDJET® EBS 250 printer is

designed for marking, labelling, putting prints and simple graphics wherever the use of a manual labelling

device is required or preferred.

Prints are put on objects in a noncontact INK-JET way.

Installing and Starting up

®

EBS 250 printer and

1471

®

EBS 250 printer and RFI

Preparing the Printer for Operation

Charging the Battery

A LI-ION top-quality battery has been

installed in the printer. It can be recharged at any stage of printer operation.

The battery that is new or has not

been used for a long time cannot be

charged up to its full capacity. Therefore, in order to form the battery follow

three charge-and-then-discharge cy-

cles. See figures

1. Pull out plug 15 from socket 14

and tilt it.

2. Insert power pack connector 26

to socket 14, and connect power

pack 25 to a wall outlet.

3. Lamp 21 glows when the battery

is being charged. Wait until the

charging is over and lamp 21

starts flashing.

4. Remove the power pack plug 26

and secure socket 14 with plug

15. Detach the power pack from

the mains and place it into the

bag.

5. Do not recharge the battery until

it is completely discharged - see

Low-battery indicator

The HANDJET

should be stored with its batteries

charged. If the printer is to be stored

for a longer time (6 months or longer)

and its batteries are not recharged, it

may work for a shorter time after it

has been recharged afterwards or in

certain circumstances even stop

working. Such a phenomena is

caused by the properties of the batteries, which are always subject to the

process of self-discharging. In the

consequence of self-discharging and

long-term storage in the discharge

state, the maximum capacity of the

batteries may lower or the batteries

may get damaged completely.

In order to avoid such a situation, it is

necessary to charge batteries of the

HANDJET

twice a year (however not less

frequently than every 6 months).

Otherwise, the printer may stop work-

®

EBS 250 printer at least

and C.

.

®

EBS 250 printer

EN

10

EBS Ink-Jet Systeme

20080908#3.0

Page 11

ing or the printer operation time after

recharging may shorten dramatically.

The battery is not replaceable as

standard.

When the battery is charged, the

!

printer cannot communicate with

the computer but the printer can

be used for printing at that time.

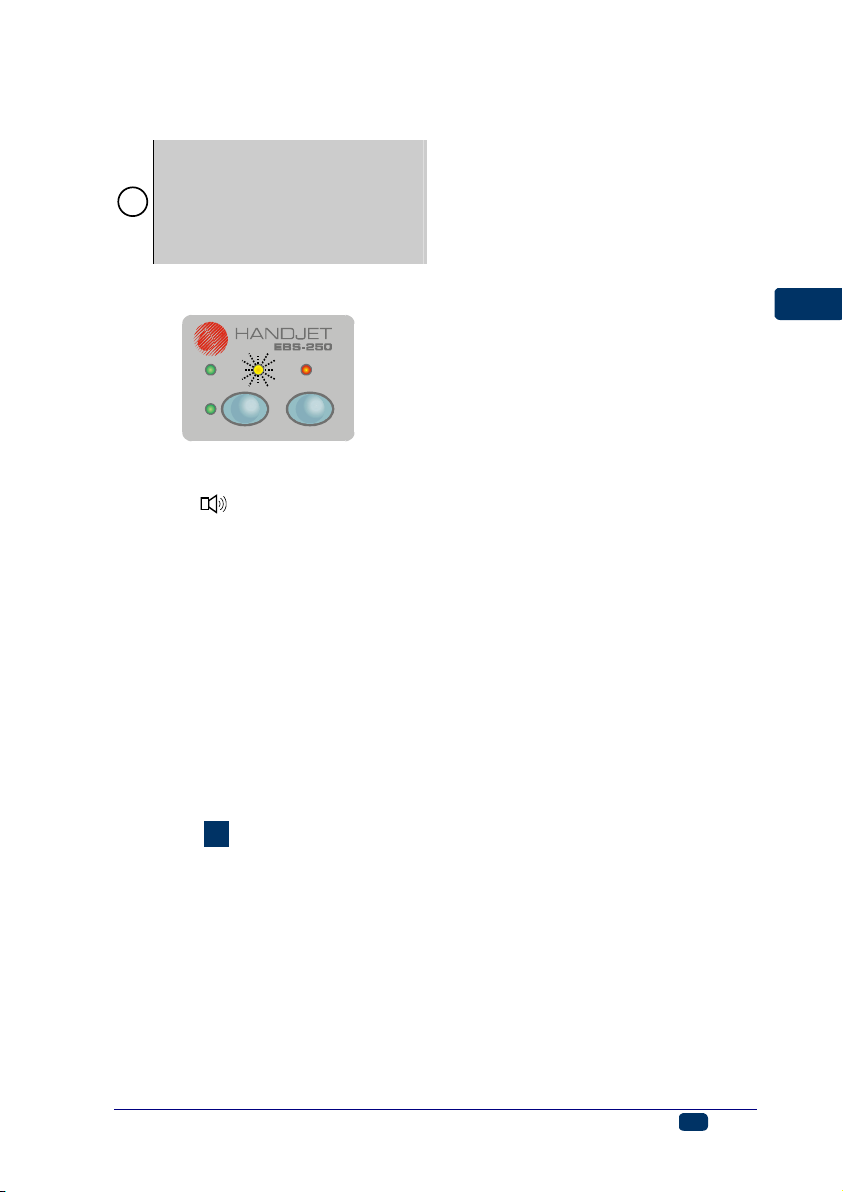

Low-battery indicator

POWER ERRORCHARGE

PRINT

ON/OFF

F

The printer indicates the low-battery

condition with a buzzing signal from

buzzer 33

and flashing lamp 21:

6 Short-time, regular flashes mean

that the battery is almost discharged, the printer can still be operated,

6 Uniform blinking means that the

battery is almost completely discharged. In this condition any further operation may be discontinued

because the printer can switch off

automatically. Recharge the battery.

Installing and Replacing the Ink

Container

See figure E.

Installing the Ink Container in the

Printer

When the printer is delivered, the ink

container is detached. Follow the

steps below in order to install the

container:

1. Remove the container from packing 10.

2. Position the container in relation

to the back of the printer so that

three bayonets 31 of the container aim at guide holes of the

container connector. At that moment arrow 12 indicates the

OPEN position.

3. Insert bayonets 31 into the guide

holes and while pressing the container against the printer turn it

clockwise, so that arrow 12 is in

the CLOSE position.

When the ink container is installed,

the printer is ready for operation

within about 10 seconds after it has

been switched on.

How to Check Whether There is

any Ink in the Ink Container?

When the printer stops printing make

sure that there is no ink in the container. You can assess the ink level in

the container in two ways:

1. Weigh the printer on installing a

new container - write down the

weight. When the container is

empty, the weight of the printer is

smaller by about 83 grams.

2. Detach the full container from the

printer, place it with its bayonets

31 up into a vessel whose diame-

ter is slightly greater than the diameter of the container and pour

water so that the container starts

floating without turning upside

down. Mark the water level on

the vessel before (line 1) and after (line 2) the full container has

been immersed. Then insert the

empty container and mark the

immersion level (line 3). You can

check the ink consumption level

at any time by immersing the

container in water and comparing

the current level with the previous

lines (lines 2 and 3). Make sure

there is always the same water

level in the vessel (line 1).

EN

20080908#3.0

EBS Ink-Jet Systeme

EN

11

Page 12

EN

full ink

container

empty ink

container

2

3

1

Replacing the Ink Container

If possible, replace the container

in dustfree conditions so as to

minimise the amount of

contaminants getting in to the

printer’s ink system.

Do not leave the printer with the

!

ink container detached for a

longer time than that required to

replace the container. While

detaching or installing the container be careful not to splash

anyone or anything with ink.

1. Turn the printer off - see

Switching the Printer Off

.

E

See figure

.

4. If gasket 32 and contact plates in

the guide holes for bayonets are

dirty, remove ink leftovers from

them with wash-up.

5. Install a new container - see

Installing the Ink Container in the

.

Printer

Switching the Printer On and

Off

See figure A.

Switching the Printer On

PRINT

Press key 18,

ing it down press release button 5.

When the printer is switched on, lamp

16 glows and a sound signal is heard

from buzzer 33

Once the printer has been switched

on, you can start printing a text that is

stored in the printer memory - see

Printing

.

ON/OFF

, and while hold-

.

a

12

10

b

2. Put the printer in such a way that

the container points downwards,

turn empty container 10 to the left

(a) so that arrow 12 points to the

OPEN position. Wait about 3

seconds while holding the container to equalize the pressure.

3. Remove the container carefully

(b).

EN

12

EBS Ink-Jet Systeme

Switching the Printer Off

3 sec.

Press key 19,

F

, and release

button 5 at the same time and keep

them down for a few seconds until all

lamps stop glowing after buzzing 33

has been heard.

Installing and Starting the

Printer Control Program

Installing the Control Program

1. Insert the CD supplied along with

the printer to the CDROM drive in

your computer and wait for the

program to start.

If the programs on the CD do not

start running on the computer

!

automatically, start setup.exe

from the CD’s main directory.

20080908#3.0

Page 13

2. After the program MENU has

been displayed, choose the installation option.

3. Follow the instructions displayed

during the installation.

4. After all control program components and USB drivers required

have been installed, you can

communicate with your printer via

a radio link - see

Printer with a Computer (via USB

interface)

.

Connecting the

Starting the Control Program

1. Click the EBS printer icon on the

control panel or, if there is no

such an icon, start EBS-200.exe

from the folder where the control

program has been installed

(C:\Program Files\ EBS_printers\

EBS-200\ as standard).

2. Once started, the control program automatically activates the

find-the-printer(s) function and

signs the printer on, if the printer

is on and the radio communications link operates properly.

Connecting the Printer with a

Computer (via USB interface)

See figures B, D and F.

The printer communicates with the

computer through module 22 via a

radio link. The module uses an USB

interface

to communicate with the computer - see

Connecting the Printer to a Computer

(via RS-232 Interface)

1. Find a free USB port in your

2. Use cable 27 to connect the USB

or optionally a RS232 interface

.

computer.

port in your computer with socket

23 of module 22.

If USB drivers of module 22 have

been installed during the installation

of the control program (see

the Control Program

!

is automatically detected and installed on your computer. Otherwise

you are prompted to indicate the

location of the drivers on the CD.

), then the module

Installing

3. Fix module 22 appropriately in

order to reach the widest radio

transmission range.

Do not cover module 22 with unnecessary shields or objects, especially

metal ones. Optimally, place module

!

22

at a certain height, to avoid any

obstacles between the printer and

module 22.

4. Switch the printer on.

5. Start the control program. The

program will find the printer,

communicate with it and display

a Printer is found message.

6. Click the

key (the key is

available in the communication

window only after the Adv. op-

tions item has been ticked) to

view the printer configuration.

Data have been transmitted

properly if an O.K. message is

displayed in the transmission

status window.

If you cannot communicate with the

printer, try to configure it in the system once again. From the Guides

!

menu start the Network configura-

tion creator and follow the creator’s

prompts.

EN

20080908#3.0

EBS Ink-Jet Systeme

EN

13

Page 14

EN

Text Files and Print Pa-

rameters

How to Create a Text to be

Printed?

Regular Text

See figure

Insert texts in the text edit line in the

edit window.

Use a mouse and the following keyboard keys to edit a text as standard

and as you do in other Windows®

applications:

¡ to move the cursor hori-

¢ to move the cursor hori-

G

.

zontally to the right,

zontally to the left,

Y¡ to move the cursor hori-

zontally to the right and

highlight the text,

Y¢ move the cursor horizon-

tally to the left and highlight the text,

Delete

to delete one character to

the right of the cursor,

BackSpace

to delete one character to

the left of the cursor,

Home

to move the cursor to the

beginning of the text,

End

to move the cursor to the

end of the text.

You can type in up to 1300 charac-

!

ters in one text.

G

cursor position in the text

Text edit window

total length of text

copy a text to the clipboard (Ctrl+C)

cut and copy a text to the clipboard (Ctrl+X)

paste a text from the clipboard (Ctrl+V)

preview a print

preview other prints

sample position of the cursor

printer font type at the current cursor position

F2

end-of-monospaced-text marker

MENU button (corresponds to the right mouse button)

F1

beginning-of-monospaced-text marker

Changing proportional spacing and

monospacing

Proportional fonts are used to insert

texts as standard. This means that

each letter takes a space proportional

to the character width. For example, a

change font

maximum text

max

H

max

height H

text edit line

character

insertion mode

letter W takes more space than a

letter I.

When monospaced fonts are used,

the character width does not depend

on the character. In other words, each

character has the same width. The

beginning of a monospaced piece of

14

EN

EBS Ink-Jet Systeme

20080908#3.0

Page 15

r

text is usually marked with the F1 key

and the end of a monospaced piece

of text is usually marked with the

F2

key from your computer keyboard.

The markers can be deleted as any

Delete

other characters - with the

BackSpace

keys.

and

The spacing between proportional

(monospaced) characters is set with

the Character spacing (Selective

char. spacing) parameter from the

Parameters 2 tab sheet.

Using and Changing Built-in Fonts

of the Printer

The program uses built-in fonts as

standard. In order to change the font

type and size at any point of the text,

follow the steps below:

1. Position the cursor in the text edit

line exactly where another font is

to be inserted.

2. Holding the cursor on the text

edit line, press the right mouse

button (or the MENU button) and

select Font from the menu displayed. Then select the font type

you need from the list displayed,

e.g. Latin 16x10. You can also

do that using the pull-down list

called Font on the tool bar of the

F

text edit window (see figure

).

The printer fonts are at the top of

the list and marked with the sym-

bol

.

3. Move the cursor to another position and insert another fontchange marker.

20080908#3.0

EBS Ink-Jet Systeme

If only one font-change marker

has been inserted, all characters from

the marker position to the end of the

text are displayed (printed) with the

use of the replaced font.

font-change marker (Latin 7x5)

font-change marker (Latin 16x10)

Using and Changing Windows®

Fonts

You can also use Windows® fonts to

create texts in your printer.

1. Move to the Font list and replace

build-in font with one of fonts installed in your Windows®. You

can change the font Size and the

keyboard "language" in

Windows®. While increasing the

text height do not exceed H

line because otherwise the excessive top part of the text will be

cut off.

change Windows® keyboard languag e

other parameters of Windows® fonts

the line indicating

the maximum print height H

if you use Windows

in characters in this widow

change the font

®

fonts type

max

character insertion mode

for Windows® fonts

excessive-font-size indicato

EN

max

change

the font

size

15

EN

Page 16

EN

2. Move the cursor to the position

where you want to start a text

and type in the text. You can

change the font at any time.

3. There are three character

insertion modes you can use:

Single character, mode 1,

Single character, mode 2, Multi

character. Each of them

matches Windows® font characters with the capabilities of your

printer in a different way according to the font type, language and

character insertion mode (the

Right to left editing parameter).

The number of characters to be

input with the use of the Win-

!

dows fonts is limited – it depends

on the font type and size.

Variable fields

Variable fields are designated fields of

text whose contents are updated

automatically after every print. The

following events can impact on the

contents of variable fields: change in

date, change in time, activation of

release button 5 and other.

Up to 10 variable fields can be used

in one text at the same time.

Only the printer built-in fonts can

be used to print variable fields;

!

no Windows® fonts can be used.

Date and Time

In order to synchronize the date and

time of your printer with those of your

computer move to the Date tab and

click the

keys successively.

EN

16

EBS Ink-Jet Systeme

and

You can set a different date or time in

your printer by setting them in the

Date tab and transferring to the

printer with the

In order to insert the date (time) field

that is updated automatically, follow

the steps below:

1. In the text edit line position the

cursor in the place where you

want the date (time) to be displayed.

2. While holding the cursor on the

text edit line press the right

mouse button (or the MENU button) and select the command

Define variable field from the

menu displayed. Then select

Insert date (Insert time) in the

list displayed. You can also do

that using the

tool bar of text edit window.

3. You can insert a font-change

marker on the left or right of the

date (time) field.

4. You can change separators inside the date (time) field by replacing the existing separators

with different characters. You can

also remove proportional-text

markers.

key.

( ) key on the

20080908#3.0

Page 17

Universal Date and Time

Various components of the current

date and time can be printed automatically on every object with the use

of a Univ. date & time variable field.

Below, there is a list of characters that

can be used to encode the date and

time components. The date and time

components can be preceded, separated and followed by any characters

different from those specified below or

by a space.

D tens of day in the current date,

A units of day in the current date,

M tens of month in the current date,

O units of month in the current date,

R thousands of year in the current

date,

L hundreds of year in the current

date,

Y tens of year in the current date,

E units of year in the current date,

B tens of hour in the current time in

the 24-hour system,

C units of hour in the current time in

the 24-hour system,

I tens of minute in the current time,

J units of minute in the current

time,

T tens of second in the current

time,

U units of second in the current

time,

P hundreds of day number in the

year

Q tens of day number in the year

S units of day number in the year

N number of day in the week

below).

The following encoding system is used as

standard: 1-Sunday, 2-Monday, 3-Tuesday, ... ,

7-Saturday).

The numbering of weekdays can be changed in

the following way: on checking the time on your

(see

computer (by clicking the

on your printer (by clicking the

change the number-of-weekday parameter in the

Day of week box for the date displayed.

For example, Monday, 21

as the second day of the week as standard. But

if you set 1 in the Day of week box and save the

modified parameters (of time, date and day of

week) to the printer (with the

then the following encoding applies: 1-Monday,

2-Tueday, ... , 7-Sunday. And if you set 5 in the

Day of week box and save the setting to the

printer, then the following encoding applies: 1Thursday, 2-Friday, 3-Saturday, 4-Sunday, 5Monday, 6-Tuesday, 7-Wednesday.

st

April 2008 is encoded

In order to insert a field consisting of

various components of the current

date and time to be updated automatically, follow the steps below:

1. In the text edit line type in a text

containing a subset of the above

specified coding characters. The

coding characters can be input in

any order.

2. Select the characters of the field

with the mouse.

3. While holding the cursor on the

text edit line press the right

mouse button (or the MENU button) and select the command

Define variable field in the

menu displayed. Then select

Univ. date and time in the list

displayed. The same operation

can be performed with the menu

shortcut Shift+F12.

key) or

key)

key),

EN

20080908#3.0

EBS Ink-Jet Systeme

EN

17

Page 18

On selecting the print preview option

Print Preview

(see

) you can see what

the print will look like on 25-04-2008

at 11:08:01 hours or later.

EN

Object Counters

You can print a consecutive number

of print on every object being labelled

or at a specified interval on long objects with the use of incremental or

decremental counters.

In order to insert the field of an incremental (decremental) counter to be

updated automatically follow the steps

below:

1. In the text edit line position the

cursor in the place where you

want the counter to be displayed.

Insert a font-change or other

markers, if required.

2. Type in the setting for the coun-

ter: the maximum required number of digits, e.g. zeros, if the

counter is to start counting from

zero. If counting is to start from a

specific number, type in the

number and add leading zeros to

fill in all counter positions.

3. Highlight the counter setting with

the mouse.

4. While holding the cursor on the

text edit line press the right

mouse button (or the MENU button) and select the command

Define variable field in the

menu displayed. Then select Up

counter (Down counter) in the

list displayed. The same operation can be performed with the

menu shortcut Shift+F1

(Shift+F2).

5. The operation described at points

2, 3 and 4 can be performed by

pressing the

( ) key on the

tool bar (a 4-digit counter is inserted and you can adjust its

length appropriately).

6. You can change other parameters of the counter. Double-click

the counter in the variable field

list. You can change the increment or select the Auto save parameter of the counter.

18

EN

EBS Ink-Jet Systeme

Ö

20080908#3.0

Page 19

The contents of a volatile counter are

lost after the printer has been

switched off. With a non-volatile

counter the counting can be resumed

from its last setting after the printer

has been switched on again.

If you place the mouse cursor in the

!

text edit window, above the characters within the counter field, the

colour of the non-volatile counter on

the variable field list changes from

blue to pink (for the volatile counter

the colour changes from black to

red).

NOTE: An increment (decrement) is added to the

counter each time button

contents of the incremental (decremental)

counter increases (decreases). The only exception is when a text is to be printed repeatedly,

that is when the print parameter Text repeti-

tions>1 or is set to Continuous. In such a

situation button

prints but rather groups of prints. The Refresh

var.fields parameter from the Parameters 3 tab

decides whether every successive repetitive print

modifies the contents of the counters or not. The

distance between the beginnings of two consecutive prints produced with repetitive printing

is defined with the Rep. distance parameter

from the Parameters 2 tab.

Example: For the counter defined as above set

the Text repetitions parameter to 3.

a). If the Refresh var.fields parameter is set to

OFF, the following prints can be produced:

If release button

is pressed for xth

time

b). If the Refresh var.fields parameter is set to

ON, the following prints can be produced:

If release button

is pressed for xth

time

5

5

1 0000 0000 0000

2 0001 0001 0001

3 0002 0002 0002

--- --- --- ---

999 0999 0999 0999

5

1 0000 0001 0002

2 0003 0004 0005

3 0006 0007 0008

4 0009 0010 0011

--- --- --- --333 0996 0997 0998

334 0999 1000 1001

5

is pressed and the

does not time each of the

The following counter

contents are printed:

The following counter

contents are printed:

Print Preview

On creating a text to be printed with

the use of the variable fields you can

check for proper operation of the

counters using the print preview option.

Use the

key to preview a print and

initiate variable fields.

The

key is used to preview suc-

cessive prints; it is available after the

key has been pressed once.

Define a text containing one or more

variable fields

counters, date and time)

(incremental or decremental

.

Check if the variable fields operate

properly by using the print preview

option. Press

. In the Print Preview

window you can see what the text

looks like after the text, print and the

printer’s general parameters required

have been applied.

If a text to be printed is defined as

above, then the following contents

can be printed on 21-04-2008 from

12:10 hours on, when printing is released with button 5 of the printer

(simulated by the

key in the pro-

gram):

EN

20080908#3.0

EBS Ink-Jet Systeme

EN

19

Page 20

EN

How to create and edit a graphics file for printing?

The graphics (bitmap) editor enables

a user to create and edit drawings

which can then be inserted into texts

to be printed.

The graphics editor can be called up

with the

figure

The window where graphics can be

created/edited consists of dots and

enables a user to generate graphics

with a maximum height of 16 dots and

length of 60 dots.

Description of functions performed by

the bitmap editor keys:

key on the toolbar (see

F

).

- to insert bitmap into text file

being edited,

- to delete drawing being

edited,

- to select draw

mode.

This parameter defines resolution (a

number of rows/metre) of a text to be

printed. The visual effect of any

change in the Text width parameter

is a change in the character width and

in consequence, in the length of the

entire text.

The settings of the parameter can

vary between 5 and 4000 with the

increment of 1.

The settings of the Text width print parameter are restricted not only by the

above mentioned range limits. The current

setting is controlled by the printer control

!

program and can be further reduced

according to the settings of other print

parameters. Any attempt to set too high a

print rate is automatically rejected.

Intensity of Ink Drops

This parameter impacts on the volume of every ink drop jetted out of the

print head. If you increase intensity,

you make the diameter of drops and

colour saturation in the print increase.

The settings of the Dot size parameter range from 0 to 10 with the inter-

val of 1.

Any increase in intensity setting increases

!

ink consumption.

Mode of Timing

How to Modify Print Parameters

Character Resolution

EN

20

EBS Ink-Jet Systeme

Timing determines the moments at

which vertical rows of text are printed.

Timing can be synchronised using:

• Lower guide roll 3 - set the

Impulse generator parameter to

Lower roll. The movement of the

roll makes the axis of the built-in

20080908#3.0

Page 21

encoder rotate (rotational speed

converter).

• Internal generator - set the

Impulse generator parameter to

Fixed speed.

The program makes it impossible to set

the Fixed speed parameter unless the

EBS-250 Safe mode option in the Tools

menu, the Preferences submenu is

unchecked. This limit has been set in order

to reduce the risk of accidental print

release – if theFixed speed and Text

repetitions - Continuous parameters are

!

set, the printer starts printing as soon as

printing is enabled with button 18

PRINT

ON/OFF

!!!

When printing is timed by an internal

generator, the print rate is not synchronised with the printer travel rate.

Inverting and Reversing a Text

The directions are defined as the

printer "sees" them.

Select the Upside down parameter in

order to make the print look like it is

turned over.

The following examples can be used

in practice when the Shaft direction

parameter is set to Disabled (this

!

parameter is available in the

Advance tab sheet after the Adv.

options box has been ticked).

the printer

travels from

left to right

or from right

to left

The reverse or inverse printing options can also be used to make prints

on transparent surfaces and the prints

need to be legible from the other side

(mirror images in the vertical or horizontal directions).

Select the Upside down and

Reverse parameters in order to make

proper prints when objects to be labelled are positioned upside down.

the printer

travels from

left to right

Reversed

view of the

print

Repeating a Text (Repetition)

EN

Select the Reverse parameter if you

need to label objects by moving the

printer from the right-hand side to the

left-hand side.

20080908#3.0

EBS Ink-Jet Systeme

The Text repetitions parameter

defines how many times printing

needs to be repeated from the start

point, after the printing has been

initiated with release button 5. You

can print a text repeatedly on one

object - this is a so called text repeti-

EN

21

Page 22

EN

,

,

,

tion. For long objects (such as pipes,

hoses, cables, strips) you can set the

repeated printing parameter to

Continuous. This is possible after the

Impulse generator parameter is set

to Fixed speed. The interval between

texts is set with the Rep. distance

parameter - see further below.

Print Delay

The Print delay parameter defines

the distance between the point at

which printing is released (with release button 5) and the point at which

printing should start. The distance is

given as a number of empty rows to

be timed after printing has been released until real printing starts. With it

you can adjust the position of a print

in relation to a reference point, for

example the edge of an object.

The settings of the Print delay parameter range from 0 to 9999 with the

increment of 1.

Distance between Texts

The Rep. distance parameter defines

the distance between the beginnings

of the texts that are printed repeatedly

(Text repetitions>1). The distance is

specified as a number of vertical rows

(timed by a timing system).

The settings of the Rep. distance

parameter range from 0 to 9999 with

the increment of 1.

Example of printing for Text repetitions=3

printing released with the release button

the printer travels in this direction

0

5,7

14

...

...

Print delay Rep. distance Rep. distance

If the distance set with the Rep.

distance parameter is smaller than

the text length (given as a number of

!

rows), then the texts will be printed

one after another.

34 rows

...

Row Repetition

The parameter defines how many

times printing of each vertical row

should be repeated. It is used for

intensifying the prints on porous surfaces, which soak up ink heavily, on

which printed characters are poorly

visible due to surface granulation, if

the characters are built of ink dots of

the same sizes.

Intelligent control of hand

movement

The printer system controls the printing process and makes it impossible

to produce a misprint should the operator’s hand or the printer be withdrawn by chance. The control is

enabled if the Shaft direction parameter is set to Compatible with

printing direction or Contrary to

printing direction

objects are labelled from left to right or from right

. The system detects every with-

to left)

drawal of the printer automatically and

suspends printing. After the printer

has returned to its proper position,

(depending on whether

EN

22

EBS Ink-Jet Systeme

20080908#3.0

Page 23

printing is resumed from the place

/text part in which the printer was

drawn back.

The Shaft direction parameter is

available in the Advance tab sheet

after the Adv. options box has been

ticked. If the parameter is set to

Disabled, the printer will produce

labels in either direction.

In order to ensure that printing is

resumed exactly in the place where it

was interrupted, the lower roll, 3, of

!

the printer needs to have contact with

the surface to be labelled on a continuous basis.

How to Transfer/Save Text Files

to/in the Printer

See figure F. In order to send a text

and print parameters to the printer,

you need to click the

key or

use the command Send text and

parameters from the Printer control

menu. Wait until an O.K. message is

displayed in the transmission status

window.

If you use the extended parameter

panel (which is available after the

Adv. options box has been ticked),

the key has a different

function. When such a panel is used

and text is sent to the printer, the text

file is not saved in the printer’s nonvolatile memory at the same time. If

the printer is switched off the text file

!

is lost. In order to save the text file in

the non-volatile memory press the

and parameters command from the

Save text and parameters menu. If

you do that and switch the printer off

and on, the text will be immediately

ready for printing.

key or use the Save text

How to Change a Text File

Stored in the Printer

Every text file can be changed in two

ways.

20080908#3.0

EBS Ink-Jet Systeme

Method One:

1. Retrieve a text file from the printers memory by clicking the

key or the command

Retrieve text and parameters.

2. Modify the text file and/or print

parameters with the text editor.

3. Save the text file in the nonvolatile memory of the printer by

clicking the

, bearing in

mind that an O.K. message

should be displayed in the transmission status window each time

a file is saved.

See also the note in section How to

Transfer/Save Text Files to/in the

Printer.

Method Two:

1. Open a project (text and parameters) with the command Open

project or only a text file with the

command Open text (without

parameters) on your computer.

2. Save the text file in the nonvolatile memory of the printer by

clicking the

, bearing in

mind that an O.K. message

should be displayed in the transmission status window each time

a file is saved.

See also the note in section How to

Transfer/Save Text Files to/in the

Printer.

Printing

Printing a Text File Saved in the

Printer

See figure A.

1. Switch the printer on.

2. Press and then release button

PRINT

ON/OFF

18,

- lamp 17 starts lighting. If ink pressure in the ink container is insufficient, a micro

compressor starts to add some

EN

23

EN

Page 24

EN

air. Wait until the micro compressor stops working.

3. Move the head of the printer to

an object to be labelled to ensure

that drive rolls 1 and 3 touch the

surface of the object.

4. Press print release button 5 (the

release button) and move the

printer along the object ensuring

that the drive rolls roll at a uniform speed.

the printer moves along the object

here printing is released

with the release button

5. Make successive prints by pressing release button 5.

6. After all prints have been made

press and then release button 18,

PRINT

ON/OFF

. Lamp 17 goes out. If the

Stop printing method and you

press button 18, lamp 17 will

flash. This means that you have

pressed release button 5 but not

finished printing. In such a case

you can finish printing or abandon printing by pressing button

18 once again. If the Stop printing method parameter is set to

Immediate stop the printer will

not remind you about the unfinished printing.

The Stop printing method

parameter is available in the

Advance tab sheet after the

Adv. options box has been

ticked).

If the printer has been idle for longer

than about 30 minutes, the nozzle

outlets might become covered with

dry ink. Before you start printing

make a trial printing or use the rinsethe-nozzles function for a while in

order to clear the nozzles - see

Rinse the nozzles.

If you label objects whose height is

!

smaller than 60 mm (the distance

between the rolls is 60 mm), make

sure that at least lower roll 3 (designed for synchronising printing)

touches the object being labelled -

see figure I. The rule does not

apply if printing is synchronised by

the internal generator.

Line Printing

Line printing is used to print a few

texts manually in a fast way:

• on consecutive lines as shown in

the figure below:

• or in different places on an object

as shown in the figure below:

Create texts to be printed in the following way:

1. Create TEXT 1 in the text edit

line. Every line of the text can

have all the text elements (such

as variable fields, various fonts,

etc.) described previously.

24

EN

EBS Ink-Jet Systeme

20080908#3.0

Page 25

2. Place the cursor at the end of

text TEXT 1 and insert a textchange marker. You can do that

in a few ways:

• while holding the cursor on the

text edit line press the right

mouse button (or the MENU button) and select the commands

Insert mark and Insert text divider in the menu displayed,

• press the

key on the tool bar

of the text edit window,

• use the F3 shortcuts.

3. Type in successive texts separating them with the text-change

marker.

4. Transfer the text to the printer

and you can start printing.

Each text is selected and printed with

release button 5.

The number of texts to be printed in

separate lines is not limited. Instead, the

total number of characters in all lines is

!

subject to limitation: it must not exceed

1300 characters.

(such as variable fields, various fonts,

etc.), and also the line printing function.

Creating a Text Library in the

Printer

1. In the Project library window,

type in the name of a first text

and confirm the name with the

V key.

Ö

2. In the text edit line create a complete text and set print parameters for the text.

3. When the printer is on, click the

key of the printer control

program in order to send the text

file to the printer.

See also the note in section How to

Transfer/Save Text Files to/in the

Printer.

4. Repeat steps from 1 to 3 in order

to programme other texts.

You can save the project list to a text

file using the Copy list to editor

command which is available after the

right mouse button has been pressed

above the text library window.

EN

Using a Number of Texts

You can store up to 10 projects (30

optionally) in the printer memory.

Each project can contain any of the

text elements described previously

20080908#3.0

EBS Ink-Jet Systeme

Quick Saving/Retrieving Text Files

to/from the Text Library

In order to save the entire text library

to the printer use the command Send

and save text library.

EN

25

Page 26

EN

Similarly you can retrieve the text

library from the printer using the

command Retrieve text library.

The command

library

!

the non-volatile memory of the printer.

Send and save text

erases all text files contained in

Printing Text Files from the Library

Select texts stored in the text library

of your printer one by one by pressing

3 sec.

button 19 -

F

bussing is heard from buzzer 33

for a while until

.

Such a switching operation can be

performed regardless whether the

printer is in the print state (lamp 17

lights) or not. The buzzing from

buzzer 33 is different for a first

text. On display 34 you can see which

of the library texts is selected. The

number displayed corresponds to the

number in the text library.

1. Start printing by pressing button

18 -

PRINT

ON/OFF

.

2. Print a text.

3. Switch the printer to print another

text by pressing button 19 -

3 sec.

F

.

4. Print the successive text.

In order to ensure that the printer

skips over text files during the text

switching operation (to be performed

with function key 19) delete the text

name in the library and save such an

empty text name in the printer.

!

3 sec.

F

Saving the Project Library on a

Computer Disc

The project (text and print parameter)

library can be saved on a computer

disc with the command Save project

library from the File menu.

Similarly you can open the project

library on your computer with the

command Open project library.

26

You can quick-load the project library

from the computer disc to your printer

with two successive commands Open

project library and Send and save

text library.

EN

EBS Ink-Jet Systeme

20080908#3.0

Page 27

Maintenance, Storage

and Transport

6 It is recommended that the outer

face of the print head, especially

the nozzle plate 2, and possibly

the guide rolls 1 and 3 should be

washed in order to remove the

remnants of ink and dirt after the

work has been finished and the

printer has been switched off.

The washing should be done in

the following way:

• Place the HANDJET printer

on its side and tilt its face

downwards carefully (see

the drawing below); in such

a position dirty wash-up can

flow freely out of the printer,

• Place a piece of absorptive

cloth or a metal vessel, e.g.

a tray, under the printer face,

• Wash the printer face with

the use of a wash-up atomiser.

may partially dry in printer components. Therefore follow the

storage instructions given below

not to be disappointed when you

try to use your printer afterwards:

• if the printer has already

been used before, store it

with ink container 10 fastened to it,

• protect the printer against

dust, dirt, any influence of

aggressive vapours and

gases and excessive temperature and moisture. Ideally, place the printer in a

polyethylene tight bag, remove air from the bag and

close it tightly. Then place it

in the packing case.

6 The printer should be stored and

transported in the packing case

delivered with the printer. During

normal operation avoid exposing

the printer to strong mechanical

shocks (protect the printer, especially nozzles 2, rolls 1 and 3 and

panel 9 against impact, falling

onto hard surfaces or scratching

with sharp objects).

EN

If the printer face is washed in a

different way than that shown

above, then wash-up may get in

to the printer’s movable, bearing-based parts or inner electronic subassemblies uninten-

!

tionally. In effect, the roll guides

may seize or ever lockup permanently and the (shaftencoder) position sensor and

other electronic subassemblies

may get damaged.

6 If the printer remains idle for a

longer period (over 3 weeks), ink

20080908#3.0

EBS Ink-Jet Systeme

User Support

Problems with Functioning and

Operation of the Printer

Some of the nozzles do not jet ink

Rinse the nozzles

Some drops are missing on a print.

or

6 Aim the nozzle outlet at a vessel,

for example the one you use to

wash the printer.

6 Wash the nozzles with wash-up,

if they are covered with dried ink.

EN

27

Page 28

EN

6 Start the rinse-the-nozzle func-

tion. Press release button 5 three

times and hold it down for a few

seconds. This causes all electromagnets in the head to open

and ink to pour out at pressure

after a warning buzzing signal

has been generated by buzzer 33

!

6 When ink starts jetting regularly

out of each nozzle, release button 18.

Frequent and long-lasting use of

the rinse function increases ink

!

consumption.

The printer does not print

On starting printing and making an

attempt to print you can hear the

electromagnets of the nozzle valves

operating but ink drops are not always

jetted out of the nozzles properly. The

quality of printing deteriorates or no

print is produced.

After about 100 standard ink containers (or over 10 litres of ink) have been

consumed, the built-in ink filter may

need replacing. It is recommended

that the replacement operation be

performed by qualified or EBS service

staff.

Boldfaced or Blurred Prints

The print is heavily saturated with ink,

ink drops blur and the entire print

seems to spread over the object being labelled.

Decrease the setting of the Dot size

parameter by moving the parameter

slider to the left.

Questions and Problems

If these Instructions and other support

in the form of electronic files contained on the installation CD, which

has been delivered together with the

printer, do not provide answers to all

your questions, then:

6 look through the web site of the

printer’s manufacturer,

EBS Ink-Jet Systeme and try to

find the answers to your queries,

6 try asking the question to the

manufacturer’s representative,

6 present the problem in the con-

tact form available on the manufacturer’s web site and forward

the form following the instructions

given therein.

Electronic guides

Some operating instructions and

programming operations are presented via interactive creators/guides

available from the Guides menu of

the control program. The creators are

installed together with the control

program.

Connecting the Printer to a

Computer (via RS-232 Interface)

See figure H.

The other elements of the portable printer

system:

35. RFI Module for wireless (radio) com-

munications with an RS-232 interface.

36. Cable for series communications

between a computer (via COM port)

and the RFI Module (via RS-232).

37. Socket to connect a cable from a

communications port in the computer.

38. RFI Power socket (with RS-232).

28

EN

EBS Ink-Jet Systeme

20080908#3.0

Page 29

39. LED indicator to indicate radio trans-

mission in the RFI Module.

22

As an alternative to module

USB) you can use RFI Module

(RFI via

35

that

communicates via RS-232.

1. Find an unoccupied series port

(COM) in your computer.

2. Connect the port COM of your com-

37

puter with socket

cable

36

3. Install module

in module 35 via

35

in such a way that

the optimal range for radio transmission is ensured.

Do not cover module 35 with unnecessary shields or objects, especially

metal ones. Ideally, place module

!

at a certain height, to avoid any

35

obstacles between the printer and

module 35.

4. Insert connector

to power socket

26

of power pack 25

38

of module 35 and

connect the power pack to a wall outlet.

H

5. Switch the printer on.

6. Start the control program. The program identifies the printer and if it

communicates with the printer successfully, the following message is

displayed: Printer is found.

7. Click the

key (the key is

available in the communication window only after the Adv. options item

has been ticked) in order to view the

printer configuration. If an O.K. message is displayed, data have been

transmitted correctly.

If you find it difficult to communicate

with the printer, try and configure it

once again in the system. Start the

!

Network configuration creator from

the Guides menu and follow the

instructions.

EN

28

25

Technical Parameters

Parameter Description

Number of nozzles 16

20080908#3.0

EBS Ink-Jet Systeme

1

5

6 9

COM

36

35

39

37

26

38

29

EN

29

Page 30

Parameter Description

EN

Nozzle diameter

Print height 27 mm

Height of objects to be labelled

Working position in 3D space any

Number of text lines per run 1

Line printing

Maximum number of characters

per text

Number of texts and accompa-

nying print-parameter

the printer’s memory at the same

(stored in

time)

Printing of graphics (logo, spe-

cial graphics characters )

Special characters

Variable fields

tents vary dynamically according to

occurrence of a specific event)

(texts whose con-

150µm as standard

optionally: 120µm, 170µm, 200µm.

from 70 mm (contact with both rolls),

from 35 mm (contact with the lower roll

to print with for example 7 nozzles only -

see figure

I

).

A guide and rolls can be used optionally

to support rectilinear printing; they are

most useful for line printing, for labelling

pipes, barrels and other cylindrical objects.

Supports printing of up to 10 texts in

successive lines.

1300 (including control characters for

the printer’s built-in fonts).

from 1 to 10. Texts are loaded to the

printer via a PC.

from 1 to 30 Optionally.

Ability to edit and print text and graphic

symbols with the application of Win-

®

fonts (True Type fonts) as well as

dows

with a bitmap editor, as standard.

National (diacritical) characters, graphic

characters for information, warning,

transport and other purposes (a character set defined by the manufacturer), etc.

Date and time in any format, expiry date,

incremental or decremental counters.

30

EN

EBS Ink-Jet Systeme

20080908#3.0

Page 31

Parameter Description

Programming

Power supply

Approximate operating time

with the battery fully charged

Re-charging

Container capacity

Timing

Ink

• Wireless (radio) line (with the range of

up to 50 m),

• Text and parameter processing soft-

ware compatible with Windows®

98SE / ME / NT / 2000 / XP / Vista®,

If Windows NT® is running on your PC,

the printer communicates with the PC exclusively via an RS-232 interface (not

via USB).

• Programming with the use of T200

Terminal (optionally),

• The option of networking of up to 60

printers; such a network is radiocontrolled via a PC.

Either synchronised with rotational speed

of the lower guide roll or at time intervals

by an internal generator regardless of the

printer’s travel rate during printing.

Battery powered with a pack of 3 Li-Ion

cells.

50 hours of non-stop printing at the

temperature of 20°C, automatic lowbattery indication.

Automatically via an external 24V

/

1 A DC power pack.

Charging time - less than 150 minutes

(<2.5 hours).

Number of charging cycles: 500 (up to

70% of initial capacity).

It is available in easy detachable containers. It is made on the basis of alcohol,

acetone or water, in various colours

(among others in white, yellow, blue,

green, red or black) to be ordered from a

catalogue.

110 ml enough to print about 100 000

characters with 7x5 dot matrix or

about 17 000 characters with

16x10 dot matrix,

EN

20080908#3.0

EBS Ink-Jet Systeme

EN

31

Page 32

Parameter Description

EN

Working pressure

from 0.03 MPa to 0.04 MPa

(from 0.3 bar to 0.4 bar)

Operating temperature range from +5°C to +40°C

Storage temperature range

(over a longer period)

from +1°C to +45°C, if water-based ink is

used for printing.

from -10°C to +45 °C if acetone or ethanol -based ink is used for printing.

Up to 95% without steam condensa-

tion - at temperatures higher than the

Humidity

dew point (the printer can be operated

when it rains provided that the surface to

be labelled is dry).

980±10 g

Weight

printer with a battery and full ink container, without power pack and cable.

Dimensions in vertical position

(length / width / height)

Dimensions in working position

240 / 130 / 265 mm

See figure I below (provided that the

surface to be labelled is vertical).

Printer Accessories

NOTE: some elements may not be part of a typical delivery or other elements

which are not specified below may be included, depending on your order.

The following elements are delivered most frequently as part of a typical

system:

• Packing case to hold all accessories............................................. 1 unit

• HANDJET® EBS 250 Printer ......................................................... 1 unit

• Power pack (24V /1A) with cable ............................................... 1 unit

• Ink container................................................................................ 2 units

• RFI Radio Communications Module (USB interface) .................... 1 unit

• Cable to connect RFI Module to PC (USB interface)..................... 1 unit

• CD with utility software, operating instructions and user-

support files (instructions, advice, help in electronic form) .......... 1 disc

Other elements to be delivered with the order as part of the system or

separately:

• RFI Radio Communications Module (RS232 interface; to be powered

with a standard power pack available in the typical system),

• Cable to connect RFI Module to a PC (RS232 interface),

• Double guide rolls to support rectilinear printing,

• Quadruple guide rolls to support rectilinear printing,

EN

32

EBS Ink-Jet Systeme

20080908#3.0

Page 33

• Guide rolls on cylinder-shaped elements to support rectilinear printing

(at the radius length – along the perimeter),