Page 1

EBS-6100

®

EBS

Ink-Jet Systems

USER'S MANUAL

Page 2

Page 3

®

EBS

Ink-Jet Systems

INDUSTRIAL INK-JET PRINTER

EBS-6100

USER’S MANUAL

VERSION 20070529#20.5

EBS Ink-Jet Systems GmbH

Alte Ziegelei 19-25, D-51588 Nümbrecht

+49 (0)2293 / 939-0

Fax +49 (0)2293 / 939-3

http://www.ebs-inkjet.de

Page 4

EBS-6100 Printer User's Manual

EBS

Ink-Jet Systems

®

© 2000 - 2007 EBS Ink-Jet Systems GmbH, D-51588 Nümbrecht

2

20070529#20.5

Page 5

®

EBS

Ink-Jet Systems

EBS-6100 Printer User's Manual

TABLE OF CONTENTS

1. GENERAL INFORMATION ..................................................................................7

1.1. APPLICATION .....................................................................................................................7

1.2. PRINCIPLE OF OPERATION ................................................................................................10

2. INSTALLING THE PRINTER..............................................................................11

2.1. SAFETY REQUIREMENTS ...................................................................................................11

In the case of accident ….....................................................................................11

2.2. POWER SUPPLY REQUIREMENTS.......................................................................................12

Mains Requirements.............................................................................................12

2.3. INSTALLING THE PRINTER .................................................................................................12

2.3.1. Standard and Optional Accessories ..........................................................................12

2.3.2. Preparatory Steps ........................................................................................................13

2.3.3. Removing transport protections ................................................................................14

2.3.4. Connections..................................................................................................................15

2.3.5. Connecting bottles of ink and solvent.......................................................................16

2.4. REMOVING THE HEAD CASING............................................................................................16

3. STARTING THE PRINTER................................................................................. 17

3.1. SWITCHING THE PRINTER ON ............................................................................................18

3.2. SWITCHING THE PRINTER OFF...........................................................................................18

3.2.1. Switching the Printer Off in the Regular Mode .........................................................18

3.2.2. Switching the Printer Off in the Emergency and Service Modes............................19

4. OPERATING THE PRINTER.............................................................................. 20

4.1. CONTROL PANELS............................................................................................................20

4.1.1. External Panel...............................................................................................................20

4.1.2. Internal Panel................................................................................................................22

4.2. OPERATING THE PRINTER WITH THE CONTROL MENU .......................................................24

4.3. PRINT HEAD STATUS........................................................................................................27

4.4. CONTROLLING THE PRINTER .............................................................................................29

4.4.1. Text Files.......................................................................................................................29

4.4.1.1. General Information on Text Files ...........................................................................29

WORD PROCESSOR - A Description of Control Keys........................................31

4.4.1.2. Opening and Editing a New Text File ......................................................................31

Subfile Type: Text - ASCII Characters .................................................................32

Subfile Type: Graphics..........................................................................................34

GRAPHICS PROCESSOR - A Description of Function Keys ..............................35

Subfile Type: BAR CODE ........................................................................................35

Subfile Type: TEXT NAME.......................................................................................37

4.4.1.3. Editing an Existing Subfile .......................................................................................37

4.4.1.4. Copying and Editing a Text File...............................................................................38

4.4.1.5. Deleting a Text File..................................................................................................38

4.4.1.6. Deleting the File Library...........................................................................................38

4.4.1.7. Accessing the File Library........................................................................................38

4.4.1.8. Linking File Names with Parameter-Block Names ..................................................39

4.4.1.9. Using the Password.................................................................................................40

Defining a User Password ....................................................................................40

Enabling the User Password ................................................................................40

Changing the User Password...............................................................................40

20070529#20.5

3

Page 6

EBS-6100 Printer User's Manual

Deleting the User Password.................................................................................41

4.4.1.10. Using Special Registers...........................................................................................41

Object Counters....................................................................................................42

Date and Time ......................................................................................................42

Universal Counter.................................................................................................43

Universal Date and Time......................................................................................48

Expiry Date Registers...........................................................................................49

Special Channel Data...........................................................................................50

4.4.2. Using Print-Parameter Blocks ....................................................................................50

4.4.2.1. Creating and Editing a New Parameter Block .........................................................51

Modifying Parameters...........................................................................................51

4.4.2.2. Editing Existing Blocks of Parameters.....................................................................52

4.4.2.3. Copying and Editing Blocks of Parameters .............................................................52

4.4.2.4. Deleting a Block of Parameters ...............................................................................52

4.4.2.5. Deleting the Parameter-Block Library......................................................................53

4.4.2.6. Accessing the Parameter Block Library...................................................................53

4.4.3. Printing..........................................................................................................................54

4.4.3.1. Stopping the Printing ...............................................................................................54

4.4.3.2. Starting the Printing .................................................................................................54

4.4.3.3. Quick Stopping the Printing .....................................................................................55

4.4.3.4. Suspending printing, editing the text and resuming the printing..............................56

4.4.3.5. Print Parameters......................................................................................................56

Modifying Print Parameters ..................................................................................57

Vertical Direction ..................................................................................................57

Initial Distance ......................................................................................................57

Number of Repetitions..........................................................................................58

Distance Between Overprints...............................................................................58

Horizontal Direction ..............................................................................................58

Print Height...........................................................................................................59

Date Offset ...........................................................................................................59

Counter Increment................................................................................................59

Row Repetition .....................................................................................................59

Print-Rate Mode ...................................................................................................60

Print Rate..............................................................................................................60

Interleaving ...........................................................................................................60

Timing Mode.........................................................................................................60

Print Resolution ....................................................................................................61

Travel Speed ........................................................................................................61

Number of Pulses Generated by External Encoder .............................................61

4.4.3.6. Saving Current Parameters in a Block ....................................................................61

4.4.3.7. Monitoring the Counting...........................................................................................62

Accessing Object Counters ..................................................................................62

Modifying Object Counters ...................................................................................63

4.4.3.8. Monitoring the Print Rate .........................................................................................63

4.4.3.9. Printing with the Use of a Code Switch ...................................................................64

4.4.3.10. Viewing Files on the Terminal Display.....................................................................64

4.4.4. Servicing the Head.......................................................................................................65

4.4.4.1. Service Mode...........................................................................................................65

4.4.4.2. Sucking Ink/Solvent .................................................................................................65

4.4.4.3. Closing and Opening the Ink Valve .........................................................................65

4.4.4.4. Turning the Head off Quickly ...................................................................................66

4.4.4.5. Turning the Ink Flow on ...........................................................................................66

4.4.4.6. Turning the Head off ................................................................................................67

4.4.4.7. Turning the Flow of Solvent On ...............................................................................67

4.4.4.8. Adjusting the Ink Jet Path ........................................................................................67

4.4.4.9. Switching the Stroboscope Over .............................................................................71

4.4.4.10. Monitoring High Voltage during Printing ..................................................................71

4.4.4.11. Defining Some Print Parameters by Measuring Conveyor Travel Speed ...............72

4.4.4.12. Other Commands ....................................................................................................72

4.4.5. Auxiliary Commands....................................................................................................72

EBS

Ink-Jet Systems

®

4

20070529#20.5

Page 7

®

EBS

Ink-Jet Systems

4.4.5.1. System Data ............................................................................................................72

4.4.5.2. Accessing Alarm Messages.....................................................................................73

4.4.5.3. Clearing Alarms .......................................................................................................73

4.4.5.4. Accessing Error Reports..........................................................................................73

4.4.5.5. Setting Date and Time .............................................................................................73

4.4.5.6. Viewing Printer Operation Time...............................................................................74

4.4.5.7. Selecting a Language ..............................................................................................74

4.4.5.8. Releasing Protections..............................................................................................75

4.4.6. Ink and Solvent Bottle Monitoring System................................................................76

4.4.6.1. Checking the Validity Date.......................................................................................78

4.4.6.2. Printer Operation Time vs. Solvent Consumption Time Limit..................................79

4.4.6.3. Accessing Ink Monitoring System Data ...................................................................79

4.4.6.4. Checking How Many Text Files Can be Printed with 1 litre of Ink...........................79

4.4.6.5. Printer Operation Problems During the Replacement of Ink and Solvent

4.5. ALARMS, ERRORS AND INDICATIONS.................................................................................81

4.5.1. Clearing Alarms............................................................................................................87

4.6. ADJUSTING THE PRINT RATE.............................................................................................87

4.6.1. Internal Generator ........................................................................................................87

4.6.2. Shaft-encoder ...............................................................................................................88

4.6.3. Defining the Maximum Print Rate for a Given Text File ...........................................90

4.6.4. Information for advanced users .................................................................................91

4.6.5. Problems with reaching the maximum print rate when a shaft-encoder is

used ...............................................................................................................................92

4.6.6. The Maximum Print Rate vs. Resolution Settings ....................................................94

General Information..............................................................................................76

Replacing the Bottle of Ink (Solvent) ....................................................................77

Bottles ......................................................................................................................81

Ink Monitoring System Flow Diagram...................................................................81

EBS-6100 Printer User's Manual

4.7. SYNCHRONIZING PRINT HEADS .........................................................................................95

5. EXAMPLES OF HOW TO OPERATE THE PRINTER .......................................96

5.1. HOW TO PRINT THE FIRST SAMPLE TEXT FILE ...................................................................96

5.2. CREATING AND PRINTING VARIOUS TEXT FILES .................................................................98

5.2.1. How to Print the Current Date and Time....................................................................98

5.2.2. How to Print Consecutive Numbers...........................................................................99

5.2.3. How to Print Expiry Date ...........................................................................................100

5.2.4. How to Print Logos ....................................................................................................101

5.2.5. How to Print a Bar Code ............................................................................................102

5.2.6. How to Print a Complex Subfile................................................................................103

6. SERVICE AND MAINTENANCE...................................................................... 105

6.1. ROUTINE MAINTENANCE..................................................................................................105

6.2. CHECKING THE ADJUSTMENTS ........................................................................................106

6.3. WHEN PROBLEMS ARISE DURING OPERATION OR SERVICE ..............................................107

6.3.1. The printer cannot be started ...................................................................................107

6.3.2. Misaligned jet of ink...................................................................................................107

6.3.3. Clogged nozzle - cleaning the nozzle.......................................................................108

6.3.4. No nominal ink pressure can be generated by the pump......................................110

6.3.5. Occluded Ink Filter in the Gun..................................................................................110

Replacing the Main Ink Filter ..............................................................................110

Replacing Ink Filter Inside the Gun ....................................................................112

Replacing air filter element in the electronic chamber ventilation system..........113

6.3.6. Reduced partial vacuum............................................................................................115

6.3.7. No flow of solvent in the head ..................................................................................116

6.3.8. The lower part of the print is missing ......................................................................116

6.3.9. Some vertical rows of the print are spaced widely.................................................117

20070529#20.5

5

Page 8

EBS

EBS-6100 Printer User's Manual

6.3.10. Irregular defects of print quality...............................................................................118

6.3.11. Slopping, rippled or jagged print..............................................................................118

6.3.12. Names of text files in the library are changed - the battery is discharged ..........119

6.4. HOW TO CONTACT THE SERVICE POINT...........................................................................119

Ink-Jet Systems

7. STORAGE AND TRANSPORTATION............................................................. 121

7.1. STORING THE PRINTER ...................................................................................................121

7.2. TRANSPORTING THE PRINTER .........................................................................................124

8. TECHNICAL SPECIFICATIONS ...................................................................... 125

9. LAYOUT OF CYRILLIC CHARACTERS ON THE PRINTER’S TERMINAL

KEYPAD...........................................................................................................128

10. LAYOUT OF ARABIC CHARACTERS ON THE PRINTER’S TERMINAL

KEYPAD...........................................................................................................129

Index......................................................................................................................130

®

Dear User,

This Manual contains very useful information on how to operate your InkJet Printer. Please read this Manual carefully.

This edition of the document includes most of the changes introduced to the EBS

printers for software version 21_1C and the descriptions contained therein

correspond to the printers that are equipped with this software version.

As the machine and options can be customised, the product delivered to you

depends on your specific order. Therefore some descriptions or illustrations may

differ slightly from your equipment. As we need to keep pace with new

technological advancement, we reserve the right to introduce changes in the

design and technical solutions adopted. In view of the above, no data,

illustrations or description shall make grounds for any claims. Should your printer

be equipped with options that are not described or illustrated in the Manual or

should you have additional queries after having read the Manual, please contact

any EBS Ink-Jet Systems representative for more information.

6

20070529#20.5

Page 9

EBS

Ink-Jet Systems

®

EBS-6100 Printer User's Manual

Paragraph 1 - General Information

1. General Information

NOTE:

There are warning and information signs on the right or left hand-side margins of some pages to

attract user’s attention to messages that are provided next to them. They are the following signs:

!

!

Information signs indicating:

• that the actions described should be taken carefully,

• additional, printer-specific option and features,

• untypical behaviour of the unit,

• other hints.

A warning not to take the action that might have a critical impact on the

proper operation of the unit. It requires the user to follow closely the

instructions given therein.

A sign informing that the installation or service operation can be performed by

the user who does not need to be qualified for servicing EBS equipment.

EBS

A sign informing that the installation or service operation should be performed

by the user who is qualified for servicing EBS equipment.

The Manufacturer reserves the right to introduce changes whose description may not

!

be provided in this manual.

The Manufacturer shall not be liable for any damages resulting from the failure to follow

the instructions or consequences of editorial or publishing errors within the

instructions.

1.1. Application

EBS-6100 is a non-contact ink-jet printer designed for putting print on objects of

various types, moving for example, on a factory conveyor. The printer provides clear

and firm overprints on materials such as:

• paper and cardboard,

• plastics,

• fabric,

• leather and leatherette,

• wood and wood-like products,

• glass and ceramic products,

• metal surfaces of any type, etc.

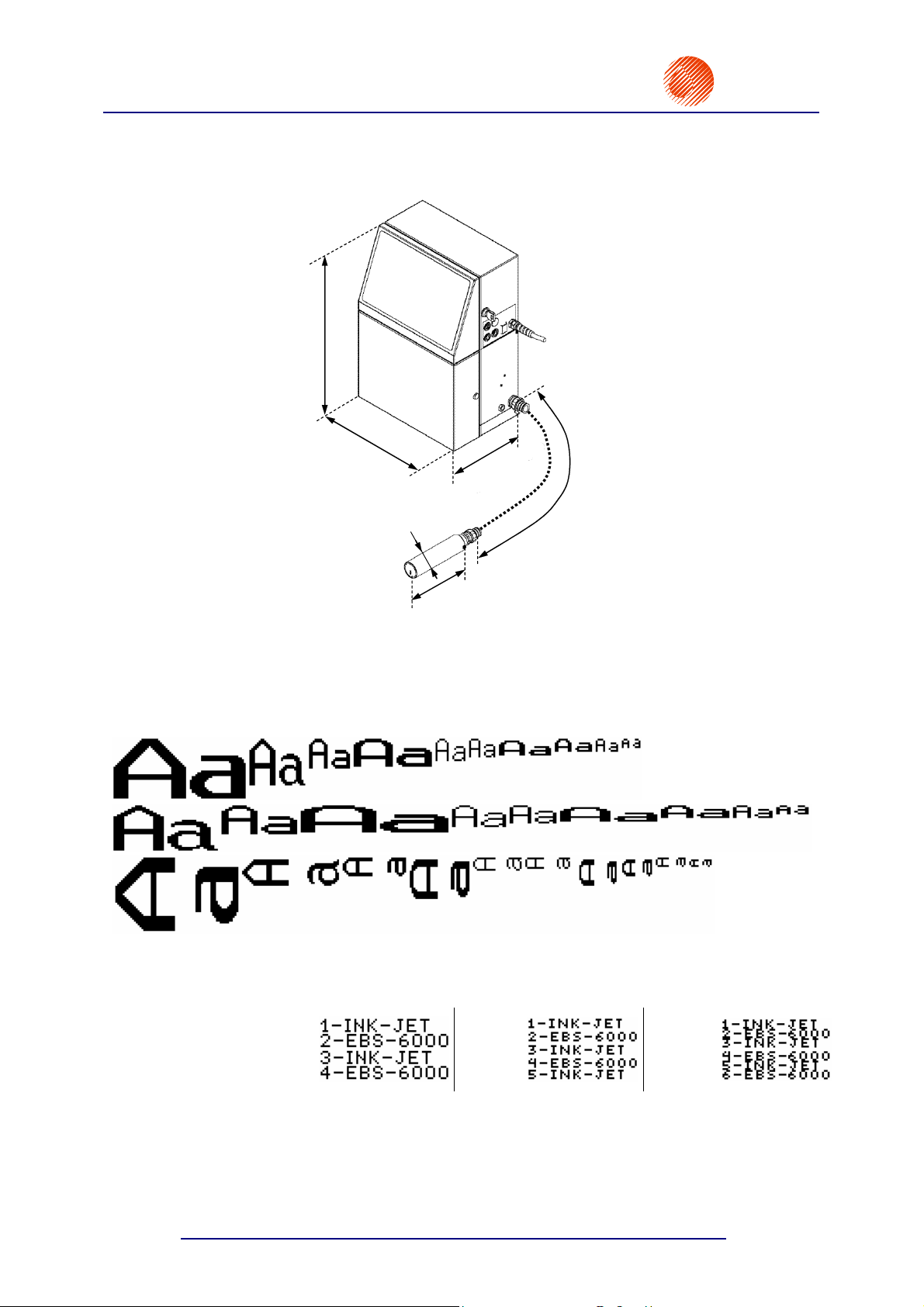

Short description of the printer:

The unit is equipped with one print head of small outer dimensions.

20070529#20.5

7

Page 10

EBS-6100 Printer User's Manual

Paragraph 1 - General Information

The head produces print varying between 1.5 and 14 mm in height.

The head can be set at any position.

The head is connected with the controller via a 4 m long flexible cord as standard.

435

EBS

Ink-Jet Systems

®

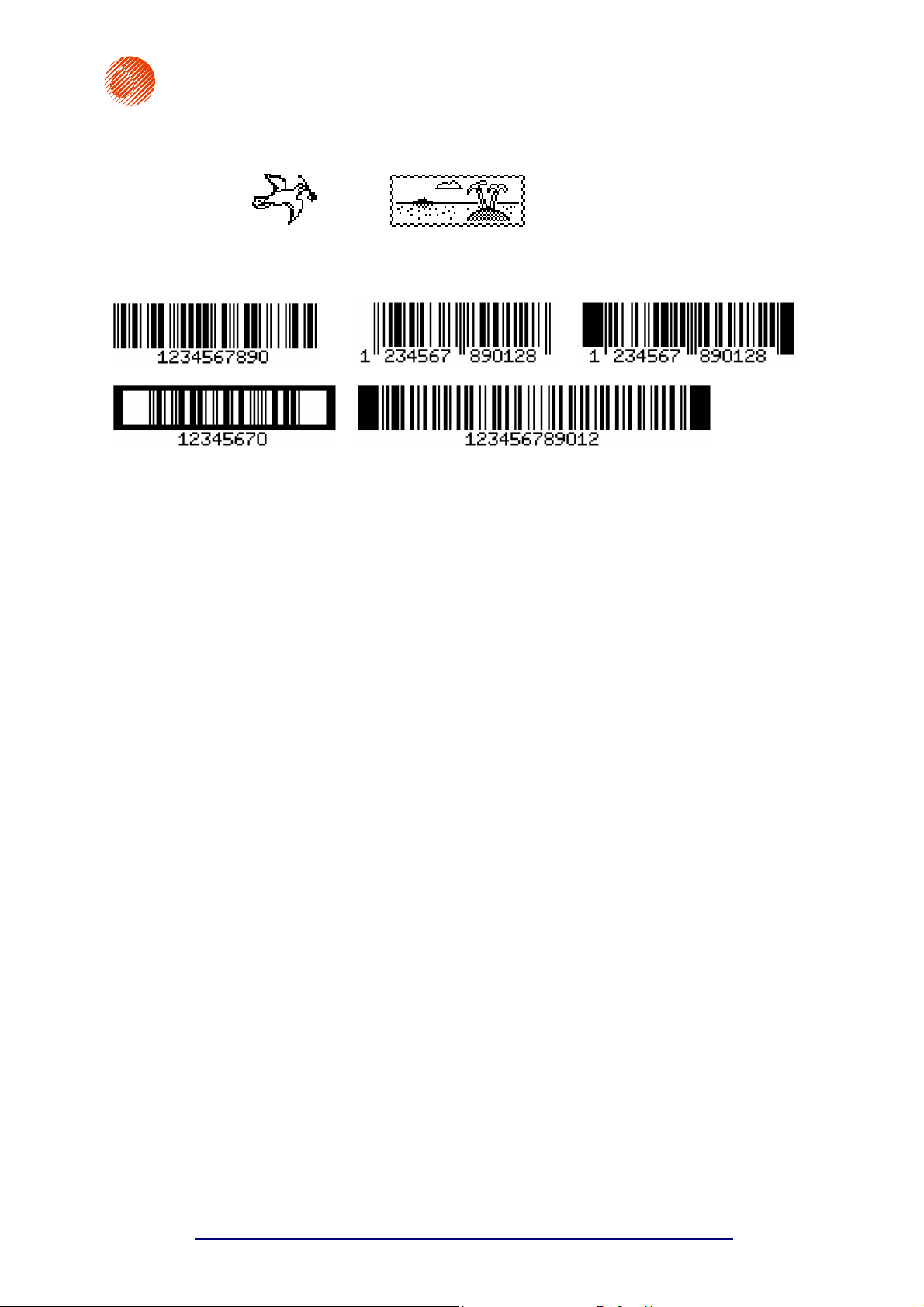

Fig. 1.1.1.

Printing capabilities:

• texts composed of small and capital letters out of various matrices, also printed in

boldface or rotated,

300

40

151

202

4000

8

• several lines of text printed during a single run of an object in front of the print

head: a maximum of four lines (with 1-dot space between the lines for the 7x5

matrix) or six lines (with no space between the lines for the 5x5 matrix), with a

maximum print height of 32 dots,

4

lines

(7x5)

5

lines

(5x5)

6

lines

(5x5)

• diacritical national characters,

20070529#20.5

Page 11

EBS

Ink-Jet Systems

• graphics – a built-in set of ready-to-use graphic symbols and a tool-kit for creating

• bar codes of various kinds, printed in a regular way or in reverse, with or without

• variable data - such as current date, warranty expiration date, current time,

®

user-defined graphics,

a numerical caption; an option of introducing on-going changes to the digital

contents of the code (bar code as an incremental or decremental counter),

ascending and descending numbering (counters), any types of data, which are

transferred from a PC or external devices (via an optional special channel), as

required and arranged by the user.

EBS-6100 Printer User's Manual

Paragraph 1 - General Information

Texts to be printed can be input or modified easily with the use of a built-in terminal, an

external code switch or a PC (via RS-232C or RS-485 interface).

An optional PC can be connected in order to:

• control the operation of one printer via the EdGraf program,

• allow a number of EBS printers of various types, linked together into a network, to be

controlled from one computer via the InkNet program.

Objects to be labelled are detected by a photo-detector.

Fully automatic printer’s operation with the status indication and instructions for

performing service operations.

Full monitoring of ink and solvent bottles. For this reason, bottles designed for different,

incompatible types of EBS printer will not be accepted.

The unit can operate continuously over 24 hours a day.

20070529#20.5

9

Page 12

EBS-6100 Printer User's Manual

Paragraph 1 - General Information

1.2. Principle of Operation

Printing with continuous ink jet printers (CIJ printers).

Ink

Gun

Nozzle

Ink return

Gutter

INK-JET

Charging

electrode

HV deflection

electrode

®

EBS

Ink-Jet Systems

Overprints are produced in the following

way:

• A continuous ink jet is broken into

droplets.

• Then the droplets are charged and

deflected in an electric field.

• Every label consists of drop-wide

vertical rows.

• The droplets are deflected on the

vertical plane. Every droplet within a row

is broken off the continuous jet, then

charged and deflected while passing

under a high-voltage electrode.

• Objects to be labelled move in front of

the print head and vertical rows are

printed one by one to complete the

entire label.

• Uncharged droplets fall into a gutter and

from there are pulled back and returned

to the ink system cylinders.

This method of printing is applied to all CIJ

printers.

Fig. 1.2.1. Labelling with Continuous Ink-Jet printers

The EBS-6100 printer incorporates many unique solutions, including those protected by

patents. Therefore it is in the top flight of units of this type in the world.

10

20070529#20.5

Page 13

®

r

EBS

Ink-Jet Systems

2. Installing the Printer

2.1. Safety Requirements

All efforts have been put into designing this printer carefully and making it safe and reliable.

However, the safe operation of the device is conditioned by the user’s awareness of, and

obedience to the following safety rules and precautions.

EBS-6100 Printer User's Manual

Paragraph 2 - Installing the Printe

The unit should be operated by the staff that has been trained.

the operation of the printer is supervised.

It is recommended that

1. A fire extinguisher designed to extinguish electrical equipment and flammable

solvent fires must be placed within easy reach of the unit.

2. The unit must not be operated in rooms where an explosion hazard exists.

3. No overprints can be made on products whose temperature exceeds 100°C at the

time of printing.

4. No open fire or spark producing devices are allowed in the area where the unit

operates.

5. Power supply cord must be connected to a socket where an earthed pin is used.

The efficiency of earth should comply with the applicable standards. Additionally, in some

cases the printer-housing earth terminal needs to be connected appropriately

(according to the instructions given in section 2.3.4 Connections).

6. As high voltage occurs in the printer, make sure that all manipulations in the

electrical part of the system and inside the head are performed after power has

been switched off.

7. The outlet of the head must not be directed towards persons, animals or accidental

objects during printing in order to avoid splashing anybody or anything with ink.

8. Protective clothes and possibly protective glasses need to be warn by persons

performing any work on the ink system.

!

9. No plastic vessels should be used to do the washing as they collect static electricity.

10. Air contaminated with solvent should be carried away to the outside of the building

11. No ink, solvent or wash-up (or waste fluid remaining after the head has been washed)

WARNING:

Static electricity collected by people (on their plastic clothes or in their hair, for example) may

spark-over to ink or wash-up vessels when they have been left open. The ink and wash-up

are inflammable and may ignite! Therefore, before you approach the open vessels

containing inflammable fluids, discharge static electricity by touching the metal printer

housing or another metal object that is connected to the earth.

In the case of accident …

When ink or solvent spills occur, the spilled fluid should be wiped with a piece of

If the clothing has been splashed, remove it as soon as possible.

20070529#20.5

Metal vessels are recommended.

through a clear duct.

should be left in open vessels as these inflammable fluids may ignite from accidental

sources of fire.

absorbent material and then disposed of in compliance with fire, health and safety at work

(HSE) regulations.

11

!

!

Page 14

EBS-6100 Printer User's Manual

Paragraph 2 - Installing the Printer

Should the eyes or skin get irritated:

EYES need to be rinsed with running water for at least 15 minutes, then you

should see your eye doctor,

SKIN needs to be washed with water and soap.

EBS

Ink-Jet Systems

®

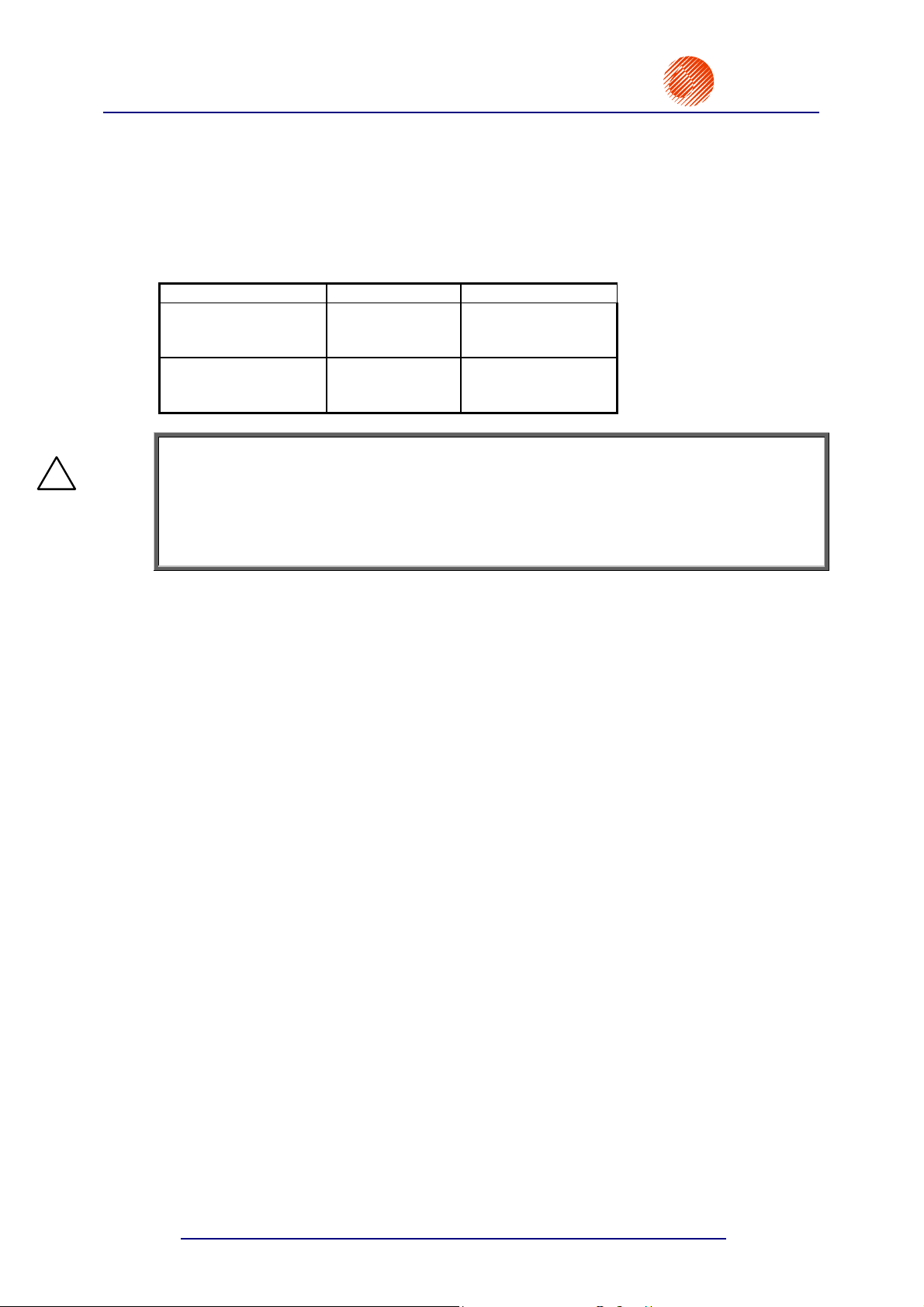

2.2. Power Supply Requirements

Mains Requirements

Standard Option

Supply voltage

Mains frequency

NOTE:

!

• The mains electricity must meet the requirements of the applicable standards. Otherwise

measures need to be taken or devices used to ensure that the proper power is applied to

the printer.

• The mains socket should be equipped with a protective pin properly connected to

earth. The efficiency of the earth needs to comply with the applicable standards.

100-240V (AC)

45-440Hz

90-350V (DC)

DC

2.3. Installing the Printer

2.3.1. Standard and Optional Accessories

As a variety of configurations of EBS-6000 series printers are available, the set of

accessories installed by the user depends on a specific user application. Typical printer

accessories include:

a). Elements and units which are needed for printing in every configuration,

b). Additional and supportive elements and units which are needed for a given configuration

to satisfy user requirements.

List of the accessories that are used most frequently in various printer configurations:

1. Printer (control cabinet and the head),

2. Complete head holder,

3. Photo detector, an optical sensor,

4. Shaft-encoder, a conveyor’s travel-speed indicator,

5. Bottle of ink,

6. Bottle of solvent,

7. Bottle of wash-up,

8. Wash-up spray,

9. Filters:

a). Main ink filter,

b). Ink filter in the head gun,

c). Filter elements for suction tubes in bottles,

d). Air filter,

e). Air filter element for electronic chamber ventilation system.

10. RS232 interface cable to PC,

11. Original rack for EBS-6000 series printers,

12

20070529#20.5

Page 15

®

r

EBS

Ink-Jet Systems

12. Holder for labelling immovable objects manually,

13. Additional external alarm device,

14. Additional external alarm device with conveyor control and stop indication,

15. External code switch,

16. Movable platform with a cable for making overprints manually.

In addition, a variety of special service tools are available, such as:

a). Open end spanner to unscrew the nozzle,

b). Service microscope to adjust ink jet parameters in the head,

c). Service tool: a template for adjusting the HV electrode position,

d). Service tool: a template for adjusting the distance between the gutter and nozzle.

e). Service tool for shaping Ø 3 Teflon pipe tips.

NOTE:

• The above list shall not be considered a specification of accessories (to be) delivered

together with a printer or printing system.

• The list of accessories may vary from country to country.

2.3.2. Preparatory Steps

EBS-6100 Printer User's Manual

Paragraph 2 - Installing the Printe

!

In order to prepare a new or transported printer to operation, you should perform the following

activities:

Place the unit in a room that is free from vibration, shocks, dust, smoke, soil, aggressive

or inflammable vapours and gases.

NOTE: The room shall meet the following requirements:

Environmental conditions: operating temperature from +5°C to +40°C,

relative humidity up to 90% without condensation.

Mechanical requirements: max. vibration 1g at the max. frequency of 10Hz,

max. shocks of 1g over the maximum of 2ms.

Ensure that free and easy access to the

unit is provided.

Place the printer on a 0.7 to 1.1 m high

horizontal table or original rack for

EBS-6000 series printers for

convenience.

Check for mechanical damages to the

unit, head and connecting hose, which

might have been caused during

transportation.

!

Secure the print head holder in a convenient position.

20070529#20.5

Fig. 2.3.2.1.

13

Page 16

EBS-6100 Printer User's Manual

Paragraph 2 - Installing the Printer

Head holder

37 mm

2xM5

Fig. 2.3.2.2. Fixing the standard head holder to a conveyor

Photo detector holder

Head axis

EBS

Ink-Jet Systems

®

Secure the print head in the holder in any required position.

Install the photo detector in clamps fixed to the head holder or in any other place which

would be most suitable for the object under print.

!

NOTE: If conveyor vibration is too strong, it would be better to fasten the head holder

on a stable rack or on a wall, provided that the rack and the wall are not in

contact with the conveyor.

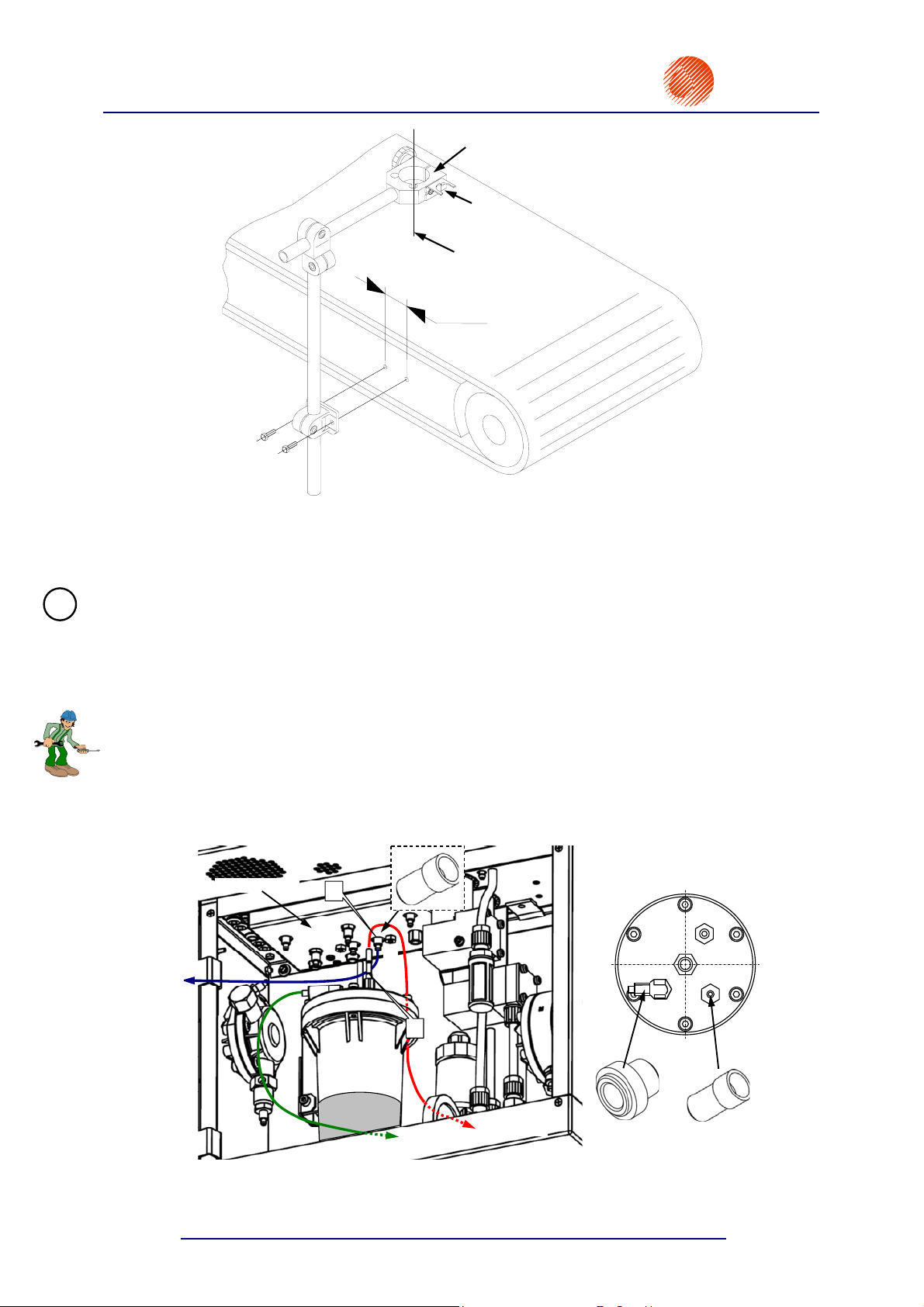

2.3.3. Removing transport protections

The cylinders are protected against spilling the liquid contents in the event the printer tilts or

shakes during transportation. Therefore some of the internal connections are separated,

pipes are removed and the holes are plugged. The protections need to be removed and each

of the connections restored.

1. Remove plugs from the connectors (couplings)

, , .

2. Connect corresponding pipes according to the following diagram.

valve manifold

bottle of ink

V3

VAC

R3

tank

RET

14

R3

air filter

head gutter

Fig. 2.3.3.1. View of connections on tank covers and inside the unit.

20070529#20.5

Page 17

®

r

–

EBS

Ink-Jet Systems

A description of how to reconnect connectors after the unit has been delivered:

• Tank R3: RET - to connect a return pipe in order to transfer ink from the

• Valve manifold: V3 - to connect ink bottle to V3 valve

VAC - to connect the tank to a vacuum pump.

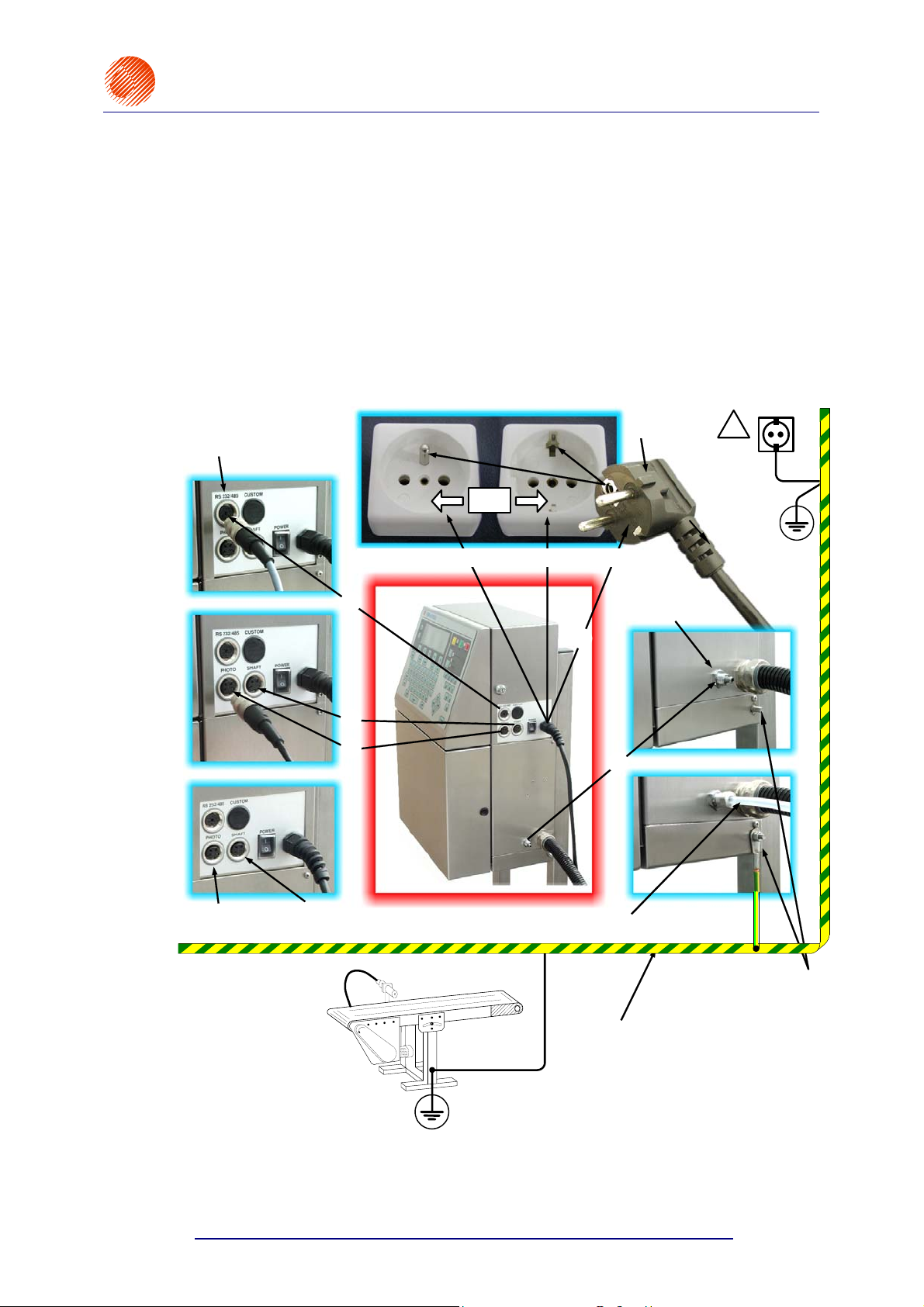

2.3.4. Connections

On putting the printer in place and removing transport protections make the connections

that are shown in the figure below, following the order indicated by the numbers

, .

EBS-6100 Printer User's Manual

Paragraph 2 - Installing the Printe

head gutter back to the tank;

in the valve manifold.

, , , ,

Special-channel interface

connector (to connect a PC)

B

B

or

Mains electricity with an earthing contact

Mains plug

Waste-air pipe

connector

M5

!

B

A

A

Photo detector

socket

Head casing is electrically

connected with an earthed

Fig. 2.3.4.1. Major connections in the EBS-6100 printer

20070529#20.5

conveyor

Shaft-encoder

socket

min. 4 mm hose to vent contaminated air

between points A and B and

Earth bar

between A and C should be

C

Earth terminal

maximum resistance

0.1 Ohm when the mains

plug is out of the mains

socket

the

15

Page 18

EBS-6100 Printer User's Manual

Paragraph 2 - Installing the Printer

2.3.5. Connecting bottles of ink and solvent

1. Insert suction pipes to the bottles of ink and solvent. Check for filters on the pipe tips. The

caps of ink and solvent bottles can be distinquished from each other by the number of

pipes going from the printer's ink system to either cap. The ink bottle cap contains one

pipe whereas the solvent bottle cap - three pipes.

2. Screw the bottles into the caps where the pipes are inserted and place them in a cavity in

the ink system door.

EBS

Ink-Jet Systems

®

!

NOTE:

• Make sure that the original ink and solvent are contained in the bottles. A possible

mistake may result in damage to ink contained in the unit’s containers (due to a change

to the chemical structure of ink) and cause many serious problems.

• Avoid misplacing the bottles of ink and solvent or placing the bottle of solvent

where the bottle of ink should be.

• Different types of ink must not be mixed. Do not add to the bottle any ink whose

shelf life has expired.

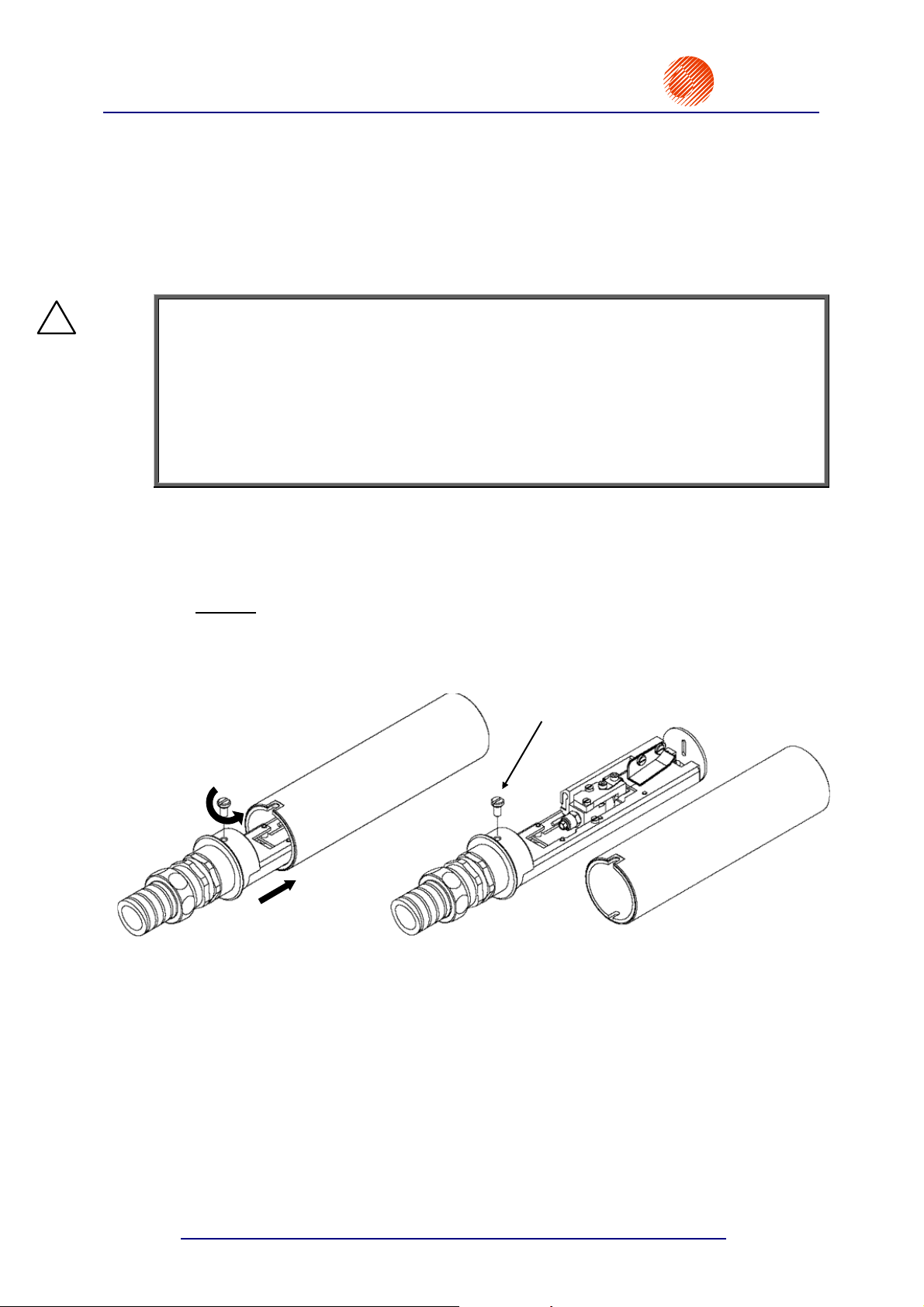

2.4. Removing the head casing

To gain access to inner parts of the head, remove the head from the holder and remove the

casing. The operation involves the following steps:

• Unscrew

• Remove the head from the casing carefully

the fixing screw on the head casing ,

.

The screw secures the head

casing and ensures electrical

contact between the metal

casing and the printer earth

Unscrew in

this direction

Fig. 2.4.1.

16

X

Y

Direction

of removal

Head

casing

20070529#20.5

Page 19

®

r

EBS

Ink-Jet Systems

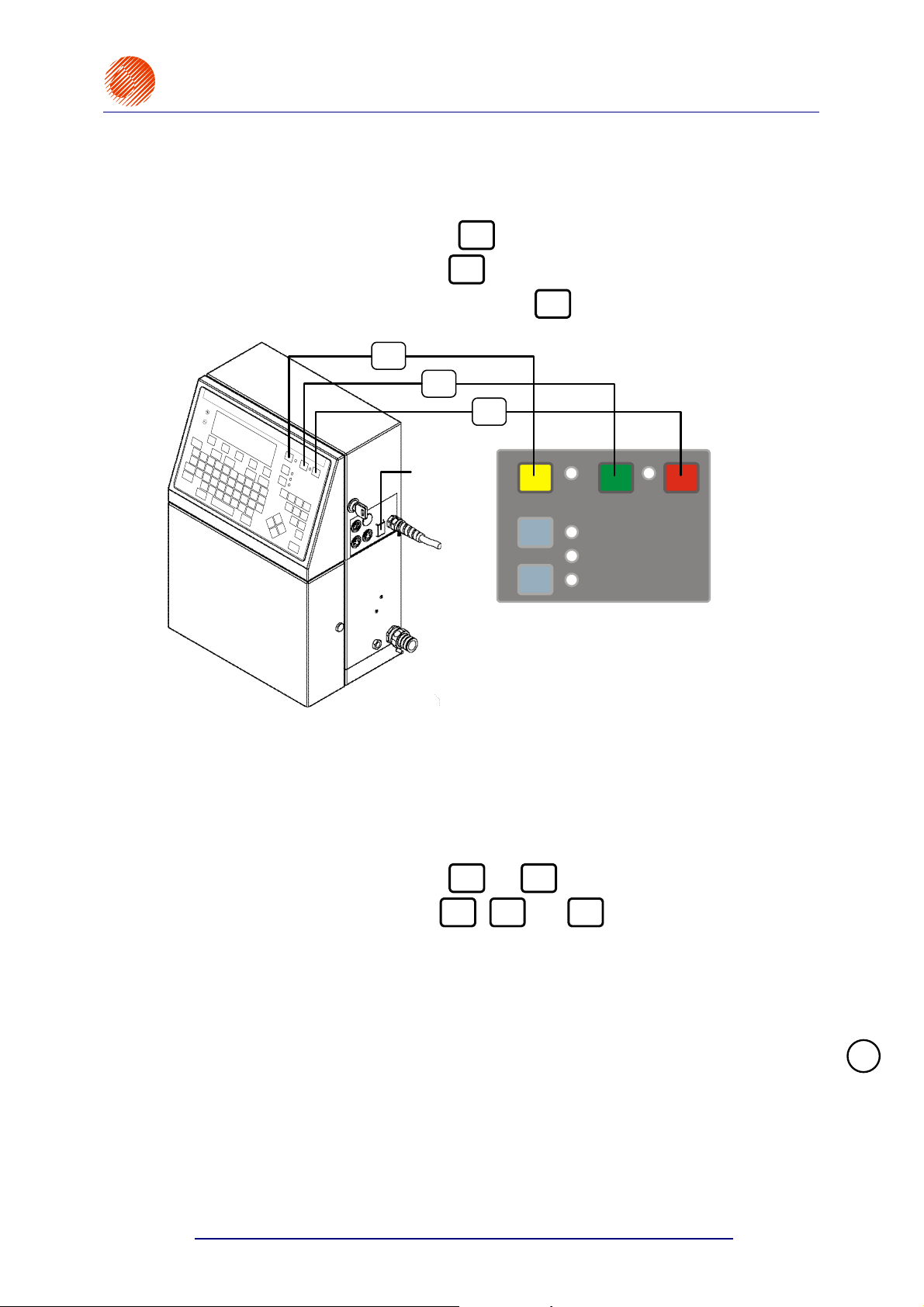

3. Starting the Printer

EBS-6100 Printer User's Manual

Paragraph 3 - Starting the Printe

The following key descriptions are used throughout the manual:

ON

OFF

,

OFF

,

CLR.

ALARM

.

• The green ON key is marked with

• The red OFF key is marked with

• The yellow CLR. ALARM key is marked with

CLR.

ALARM

ON

Main power

switch

ERROR

CLR. ALARM

PRINT ON / OFF

READY

INK ON / OFF

OFF

ON

Fig. 3.1.

The EBS-6100 printer is equipped with a power supply with a watch circuit. There are

two power switches that differ from each other over the way mains electricity is switched on or

off:

1. The main (bi-stable) power switch, which separates electrically two power wires

from the mains; it is located on the right-hand side of the unit next to the mains

cord. After the main power switch has been turned on, the printer triggers to the watch

mode and the red lamp between the

2. The electronic power switch (the

ON

ON

designed to turn the printer on and off by changing the printer’s mode from the watch

mode (the lamp emits red light) to the operation mode (the lamp emits green light) and

vice versa. The keys should normally be used to switch the unit on and off.

If it needs to be separated electrically from the mains, the unit should be turned off,

as described in section 3.2 Switching the Printer Off, and then the main power

switch should be turned off.

NOTE: The description below relates to the printer in its watch mode, i.e. with its

main switch in the ON position.

and

,

OFF

OFF

keys comes on.

CLR.

ALARM

and

keys on the external panel)

!

20070529#20.5

17

Page 20

EBS-6100 Printer User's Manual

Paragraph 3 - Starting the Printer

3.1. Switching the Printer On

If all the connections are made properly, then it is enough to press the green

the external panel) (see Fig. 3.1).

Then, the starting procedure is initiated. It involves the following steps:

1. Power voltage is applied and electronic cards are tested.

2. The high voltage module is set to the value that is already stored in the memory (it takes

from a few to a dozen or so seconds).

3. The nozzle is rinsed with solvent (for about 10 seconds).

4. Solvent is sucked out (for about 2 seconds).

5. The flow of ink in the head starts and the printer waits until ink parameters stabilize.

Afterwards, the automatic process of breaking the ink jet into droplets starts, initiating the

phasing procedure and ink viscosity measurement (it takes about 2 minutes).

If no head should work after the printer has been turned on, the turning on should be followed

by the FAST OFF command within the submenu SERVICE. The above mentioned starting

procedure consists of step 2 only. Use the INK ON command to activate the head.

EBS

Ink-Jet Systems

ON

button (on

®

During the starting procedure the red READY lamp (on the internal panel available on the

electronic card, after the upper door has been opened) - see Fig. 4.1.2.2, indicates the

following:

no light - ink is supplied to the head and ink parameters stabilize,

flashing - the ink breaking process stabilizes,

steady light - the head is ready for printing. The START PRINT command can be

selected.

During the entire starting procedure both the parameters and text files can be selected and

modified. If the START PRINT command is selected before the READY lamp comes on, the

command is not executed (the message UNIT NOT ACTIVE is displayed instead). Some

errors may also delay the readiness of the unit for operation by about 2 to 3 minutes. Check

for error indications on the terminal or the internal panel.

If the EBS-6100 printer has not been used for a period of at least 2 weeks, ink pressure

may drop and the following error messages may appear twice or three times after the unit has

been started: INK PUMP TIME-OUT or INK PRESSURE DROP. You can clear the alarm with

CLR.

the yellow

ALARM

key and continue operating the unit as usual.

3.2. Switching the Printer Off

There are several modes of switching the printer off:

Regular mode (to switch the printer off for a period of up to 1 week),

Emergency mode,

Service mode,

Switch-off mode preparing the printer for storage over a longer time (up to 3 months

or longer than 3 months) – for a detailed description refer to 7.1 Storing the Printer.

3.2.1. Switching the Printer Off in the Regular Mode

In order to switch the printer off in the regular mode you just need to press the red

18

(see Fig. 3.1) on the external panel and wait a few minutes for the printer to turn off. Then the

ON

lamp between the

and

SWITCHING THE PRINTER OFF ..... message is displayed on the terminal and the time till

the end of the switching off procedure is counted down in the status window.

OFF

keys changes colour from green to red. The

OFF

key

20070529#20.5

Page 21

r

®

EBS

Ink-Jet Systems

The following processes are involved when the printer is switched off in the regular mode:

Ink is sucked from the ink pipes,

The pipes, gun, nozzle and gutter are rinsed,

The pipes connected to the head are filled with solvent.

NOTE:

If the printer is switched off in the regular mode too often, the ink becomes excessively

diluted and the ink system may be overfilled and then the following message is displayed

to inform you about that:

THE INK SYSTEM CAN BE

OVERFILLED BY MULTIPLE

SWITCHING OFF !!

If you need to switch the unit off for a short time (up to about 1 hour) to perform a service

or other operation, switch it off in the service mode - see section 3.2.2 Switching the

Printer Off in the Emergency and Service Modes.

If the printer needs to be switched off for a longer time (over 1 week), it should be

switched off in accordance with the instructions given in 7.1 Storing the Printer.

EBS-6100 Printer User's Manual

Paragraph 3 - Starting the Printe

3.2.2. Switching the Printer Off in the Emergency and Service Modes

In order to switch the printer off in the emergency mode, press the red

holding it down press and release the yellow

can cut off the supply of electricity to the printer with the main power switch. This type

of switching off is allowed only in the event of an evident printer failure, especially

when the failure to switch the printer off in the regular mode may cause more extensive

or additional damage (such as an ink spill).

NOTE:

On switching the printer off in the emergency mode, do not leave it in the off state for longer

than about 30 minutes. The head may be splashed with ink which may dry. Therefore sprinkle

the nozzle with solvent before you switch the printer off.

You can switch the printer off in the service mode in the same way, as you proceed in the

emergency mode. The service mode is used to switch the printer off quickly (without rinsing)

for a few minutes in order to perform a service operation (see the note below). If the unit

needs to be switched on and off frequently, then the service mode should only be used in

order to prevent ink from getting diluted excessively and the ink system from getting overfilled.

NOTE:

• After the unit has been switched off in the emergency or service modes, wash the inner

part of the head (especially around the gutter) with solvent.

• If you switch on the unit that has been switched off in the service or emergency modes,

the following warning message is displayed on the terminal:

OPERATORS ERROR !!! :

THE HEAD WAS NOT FLUSHED

BEFORE SWITCHING THE PRINTER OFF.

CLR.

ALARM

key (see Fig. 3.1). Or alternatively, you

OFF

key and while

!

!

20070529#20.5

19

Page 22

EBS-6100 Printer User's Manual

Paragraph 4 - Operating the Printer

4. Operating the Printer

4.1. Control Panels

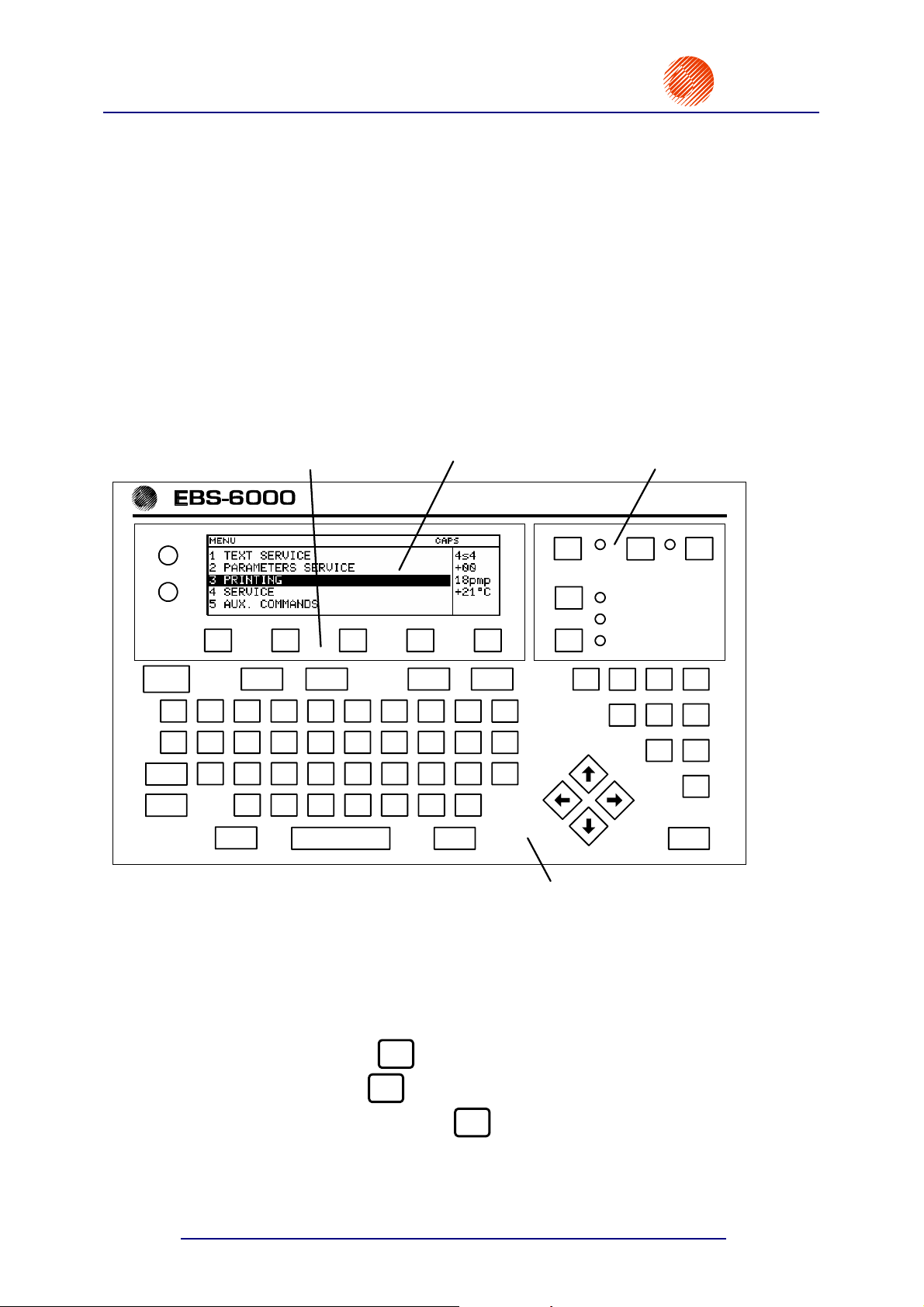

4.1.1. External Panel

EBS

Ink-Jet Systems

®

Terminal

is used by the operator to communicate with the printer. It helps to control the printer's

operation, edit text files to be printed and store them in the printer's memory, access and modify

system parameters and monitor the printer's condition. The terminal is located on the external panel

and consists of a graphic display, an alphanumerical QWERTY keypad and contrast-control and

function keys. All terminal features are described further on in this chapter.

+

CONTRAST

–

F1 F2 F3 F4 F5

Esc Insert Delete Par Alt

_

+

-

Q T W R E UY I O P

Caps

Ctrl

[

=

A S D F G H J

4

;

]

X Z

, .

'

BV C

2

? |} : " < >{

K

NM

1

ERROR

CLR. ALARM

!

\/

L

PRINT ON / OFF

READY

INK ON / OFF

@

253 4

1

% ^

ON OFF

$

#

&

*

(

8 0 9

)

7 6

Shift Space Shift Enter

Fig. 4.1.1.1. External panel with the terminal section

1 The main pad contains the following elements:

Keys

• the green ON key

• the red OFF key

• the yellow CLR. ALARM key

• the dark blue PRINT ON/OFF key to start and stop the printing,

• the dark blue INK ON/OFF key to start and stop the flow of ink inside the print

head.

20

ON

- to switch the printer on,

OFF

- to switch the printer off,

CLR.

ALARM

3

- to clear alarms,

20070529#20.5

Page 23

r

EBS

Ink-Jet Systems

LEDs

• the red / green lamp between the ON and OFF keys to indicate the printer’s on or

• the red ERROR lamp next to the CLR. ALARM key to indicate the alarm state,

• the green lamp next to the PRINT ON/OFF key to indicate that the printer is in the

• the yellow lamp next to the READY key to indicate that the head is ready for

• the green lamp next to the INK ON/OFF key to indicate that the flow of ink in the

®

off state,

print mode or is not,

printing,

print head is on or off.

EBS-6100 Printer User's Manual

Paragraph 4 - Operating the Printe

2 Graphic display (the display) with a resolution of 240x64 pixels

divided into independent sections (windows).

a

b

a Terminal status window one line high, contains the following data

(from the left-hand side):

• short 12-character messages (e.g. on the condition of the pen during the

edition of a graphics subfile or the name of a MENU option),

• 3-character typing mode (INSert, OVeRwrite),

• the position of the

lower case letters,

• the indication that the

• coordinates of the graphics cursor (during the edition of graphics).

© key that is used to switch between capital and

Y or « function keys have been pressed,

b Working window five lines high, it is the main display window to show

the control MENU, parameters and messages, to edit text files, etc.

c

1

. The display area is

c Printer status window five lines high, located to the right of the working

window, contains data on the head status for different printer operation modes

- see section 4.3 Print Head Status.

3 Alphanumerical keypad to start control functions and introduce the accompanying

sequences of digits and letters (characters).

The keys are grouped on the terminal keypad according to application.

Group of control keys

Group of numerical keys

1

Pixel - any of the smallest elements that together form a graphical image. It can be on or off.

20070529#20.5

the following keys:

U ¥ ¦ § ¨

© « Y V - and the arrow

keys on a light blue background

¢ ¡ £ ¤ (see Fig. 4.1.1.1).

the following numerical keys: 1, 2, ... , 9, 0.

:

21

Page 24

EBS-6100 Printer User's Manual

Paragraph 4 - Operating the Printer

EBS

Ink-Jet Systems

®

Group of alphabetical keys

All the above specified characters are available immediately after the corresponding

key has been pressed.

Each time you want to type in a character marked in the top left corner of some

keys, press the Y key before the character is selected. This does apply to the

following characters: _ + { } : " < > ? | ! @ # $ % ^ & * ( ).

4 Special function keys comprising:

• contrast control keys,

+

- to increase the contrast, –- to reduce the contrast

F1 F2 F3 F4 F5

•

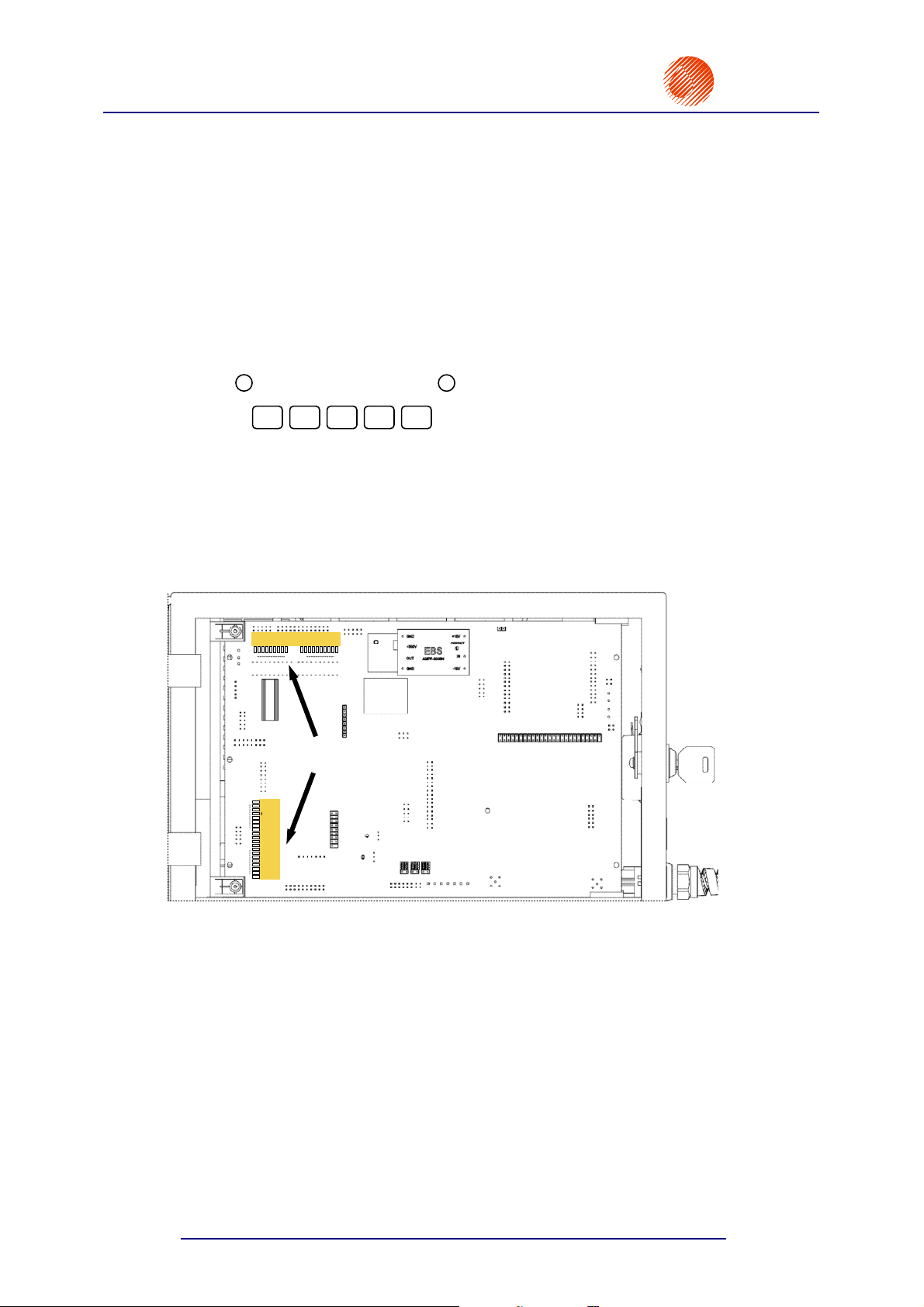

4.1.2. Internal Panel

The internal panel is used to indicate the condition of inner assemblies of the printer,

errors, alarms and failures. The condition, errors, alarms and failures are indicated with a

number of lamps (two rows of light-emitting diodes, L1 - L20, L21 - L39) located on the

printer's main electronics card, that is available after the upper door has been opened (see

Fig. 4.1.2.1).

the letter keys A, B, C, ... , Z, the keys - = [ ] ;

' , . / \ and the

ª key.

function keys to define various additional functions.

/

V91

VAC.

V01

POWER

V92

V82

V12

V81

V11

PREAS-

SURE

V2 A()ALARM

V2VV3V4V5V6

V02

L21

L21 - L39

V7

VX

L39

Internal panel

LEDs

L20

300V ERR.

CHK V. ER.

V1/V7 ERR.

FILL. ERR./

PRESS.DROP

SOLV. BAD

INK LACK

SOLV. LACK

PRESS.LACK

PH. ERR.2

PH. ERR.1

HV2 ON

READY 2

L1 - L20

HV1 ON

READY 1

+VIS (SOLV)

-VIS (INK)

St1

Sb1

St3-OVER

L1

Sb3

Fig. 4.1.2.1. Location of internal panel indication LEDs

22

20070529#20.5

Page 25

r

EBS

Ink-Jet Systems

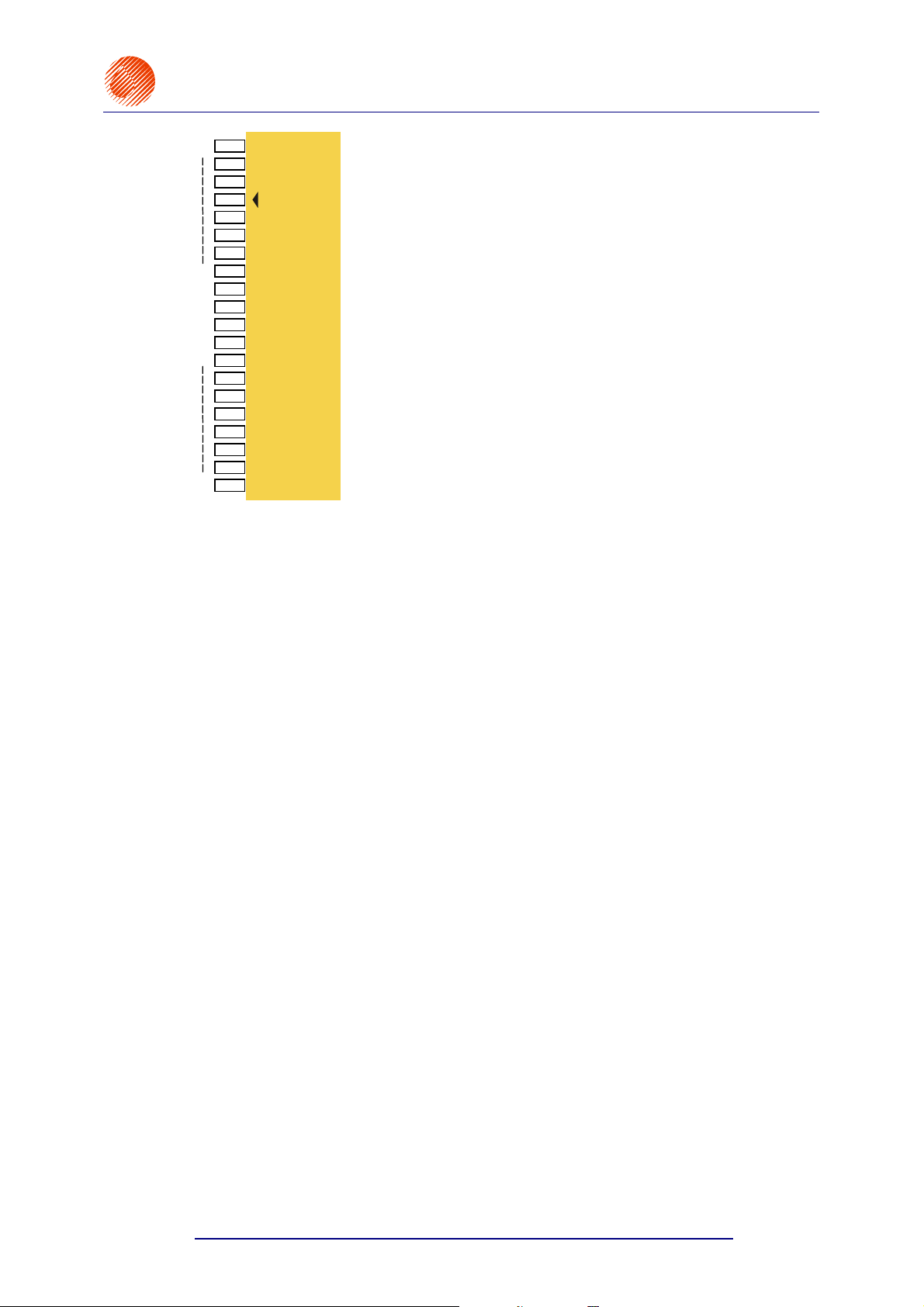

L20

L1 - L20

L1

®

300V ERR.

CHK V. ER.

V1/V7 ERR.

FILL. ERR./

PRESS.DROP

SOLV. BAD

INK LACK

SOLV. LACK

PRESS.LACK

PH. ERR.2

PH. ERR.1

HV2 ON

READY 2

HV1 ON

READY 1

+VIS (SOLV)

-VIS (INK)

St1

Sb1

St3-OVER

Sb3

EBS-6100 Printer User's Manual

Paragraph 4 - Operating the Printe

A vertical row of lamps L1 - L20 is accompanied by

captures on the right of the LEDs. The lamps can emit

steady light or flicker. The meanings of the two states of

each lamp and the procedure to be followed if a failure

occurs are described in section 4.5 Alarms, Errors and

Indications.

Fig. 4.1.2.2. Error and status lamps emitting red light

300V ERR. +300V voltage failure 0,

CHK V. ER. not used,

V1/V7 ERR. V11(V1) valve failure,

FILL. ERR./

PRESS.DROP ink pressure dropped down below its nominal value (PRESS.DROP),

SOLV. BAD not used,

INK LACK no ink in the bottle,

SOLV. LACK no solvent in the bottle,

PRESS.LACK ink pressure exceeds its nominal value ,

PH. ERR. phasing error in the head,

HV ON this has two meanings:

• the lamp emits steady light - high voltage has been applied to the

head,

• the lamp flickers - HV failure or the failure to keep the voltage at the

required level,

READY this has three meanings:

• no light - the head is not ready for printing, the flow of ink can be

turned on,

• the lamp flickers - ink flow to the head is turned on, the process of

breaking ink into drops stabilizes,

• the lamp emits steady light - ink jet is supplied, the head is ready for

printing,

+VIS (SOLV) the system is refilled with solvent - ink viscosity is greater than the nominal

value,

-VIS (INK) the system is refilled with ink - ink viscosity is smaller than the nominal

value,

St1 not used,

Sb1 not used,

St3-OVER the indication of high ink level in cylinder R3; this has two meanings:

• the lamp emits steady light - cylinder R3 is overfilled

permanently - a failure,

• the lamp flickers- cylinder R3 is overfilled temporarily (e.g. due to ink

surge in the cylinder),

Sb3 the indication of low ink level in cylinder R3,

20070529#20.5

23

Page 26

EBS-6100 Printer User's Manual

Paragraph 4 - Operating the Printer

EBS

Ink-Jet Systems

®

/

V91

VAC.

V81

V11

V01

POWER

V92

V82

V12

V02

L21

Fig. 4.1.2.3. Indication lamps emitting green light

POWER the lamp indicates that a power signal has been applied to keep the

printer’s power supply in the on state,

V01 the indication that electrovalve V0 is turned on to supply ink to the head,

V11 the indication that electrovalve V1 is turned on to suck ink from the head,

PREASSURE the indication that the ink pressure pump is turned on,

V2(A) the indication is not used,

V2V the indication is not used,

ALARM the indication that an alarm is generated (the duplication of the ERROR

lamp on the main pad of the external panel),

V3 the indication that electrovalve V3 is turned on to refill ink from bottle,

V4 the indication that electrovalve V4 is turned on to refill solvent from bottle,

V5 the indication that electrovalve V5 is turned on - underpressure is

generated in the solvent pump to ensure that solvent is taken from solvent

bottle,

V6 the indication that electrovalve V6 is turned on – ink is supplied to the

solvent pump under pressure to rinse the head with solvent,,

V7 the indication is not used,

V91/VAC. the indication that the vacuum pump is turned on,

V92 the indication is not used,

V02 the indication is not used,

V12 the indication is not used,

V81 the indication is not used,

V82 the indication is not used.

L21 - L39

PREAS-

SURE

()

V2 A

ALARM

V2V

V3V4V5V6V7

VX

L39

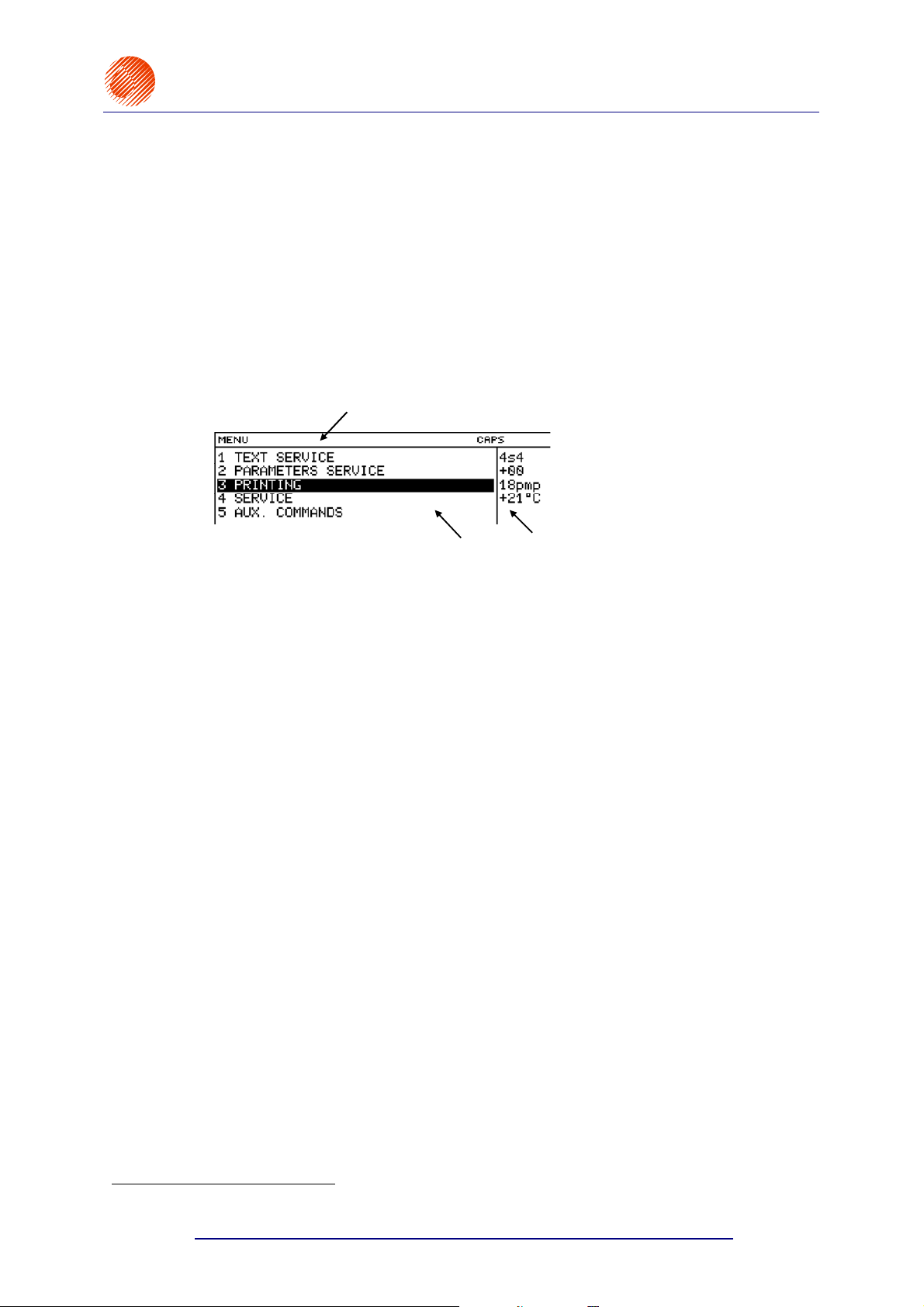

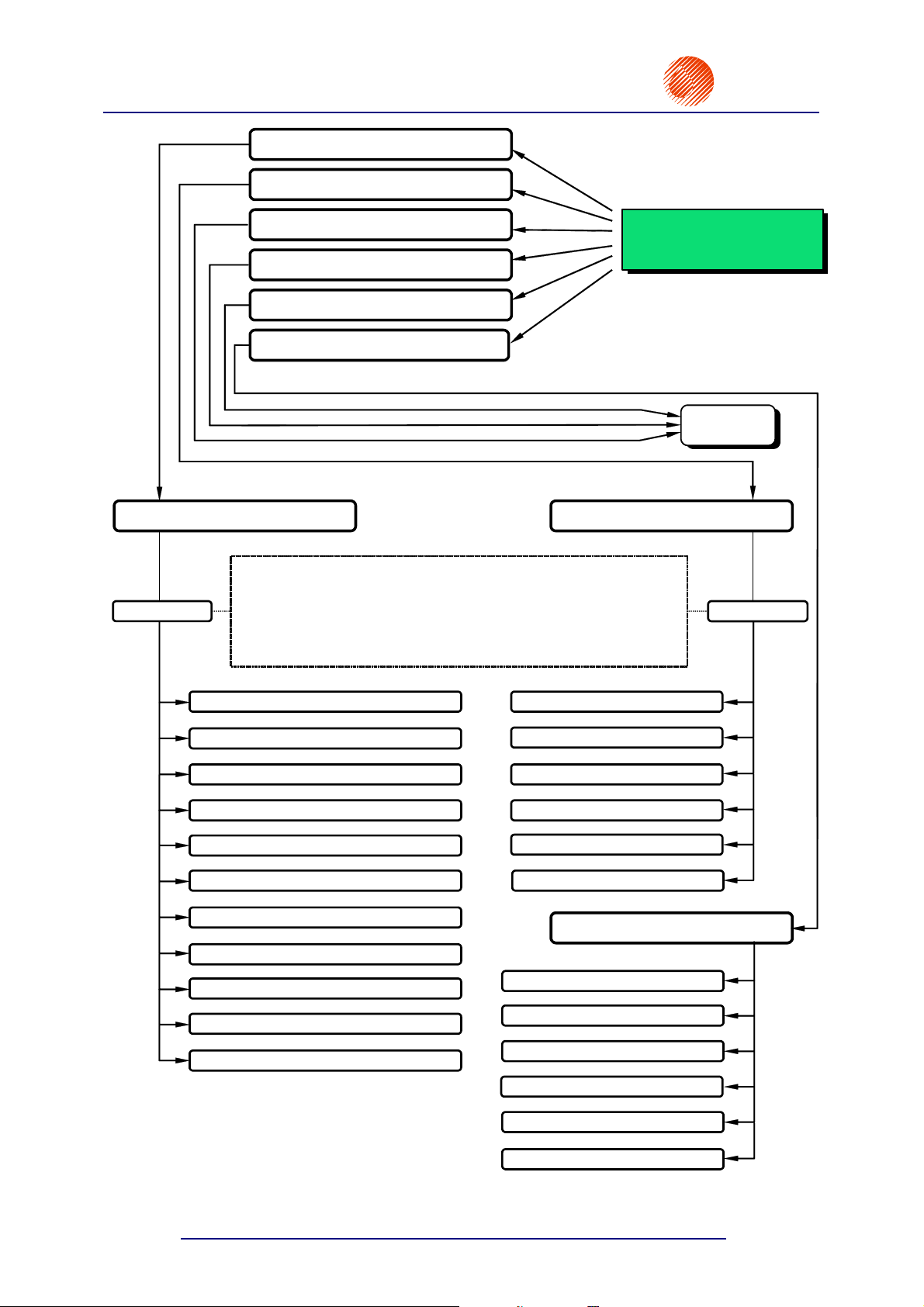

4.2. Operating the Printer with the Control MENU

After the printer has been switched on, the control menu is displayed in the operating

window of the graphic terminal. The MENU has a multilevel tree structure. Commands are

executed directly at the lowest level. The moving from one menu branch to the other involves

no action. Only the execution of a command implies an action in the unit, for example printing,

moving to the word processor, modifying parameter settings, etc.

Fig. 4.2.1. View of the primary (main) MENU branch, also called MAIN MENU

The first character (a digit or letter) in each MENU option is a hot key. When this key is

pressed, the cursor bar is immediately positioned on the selected option.

The following keys help you to move along the tree:

£ To move the cursor one menu item upwards.

¤ To move the cursor one menu item downwards.

Y ¢ or Y £ - to move the cursor to the first item.

24

20070529#20.5

Page 27

r

EBS

Ink-Jet Systems

®

EBS-6100 Printer User's Manual

Paragraph 4 - Operating the Printe

Y ¡ or Y ¤ - to move the cursor to the last item.

V To move one level downwards (to the next MENU branch) or to confirm

the selected command for execution.

U To move one level upwards or cancel the selected command. If you press

the U key several times, you are always moved back to the main MENU

level.

NOTE:

After the selection of a command has been confirmed with the V key, it is not always

possible to cancel the command. Some commands are executed immediately.

!

20070529#20.5

25

Page 28

EBS-6100 Printer User's Manual

Paragraph 4 - Operating the Printer

1 TEXT SERVICE

2 PARAMETERS SERVICE

3 PRINTING

4 SERVICE

5 AUX. COMMANDS

6 BOTTLE INFORMATION

EBS

Ink-Jet Systems

MAIN MENU

see next

page

®

TEXT SERVICE

PASSWORD

PARAMETERS SERVICE

The password can be used only if it was defined by the user before.

The user can protect many commands from unauthorised access - see

section 4.4.1.9. Using the Password

The password can be defined, modified and cancelled only in the

TEXT SERVICE menu branch. If all characters of the password are

deleted (with the

1 TEXT EDITION

2 CREATE NEW TEXT

3 COPY & EDIT

4 DELETE TEXT

5 CLEAR LIBRARY

6 READ LIBRARY

7 LINK PARAMETERS

8 CREATE/CHANGE PASS

¦ key), the password-based protection is released.

1 EDIT PARAM. BLOCK

2 CREATE NEW BLOCK

3 COPY & EDIT BLOCK

4 DELETE PARAM. BLOCK

5 CLEAR PARAM.LIBRARY

6 READ LIBRARY

BOTTLE INFORMATION

PASSWORD

26

9 ACTIVATE PASSWORD

A UNIV.DATE REG. CONFIGURATION

Z LIBRARY INFO

1 INK EXPIRE DATE

2 SOLVENT - TIME TO WORK

3 PRINTER/INK/SOLV. TYPE

5 No. OF TXT/1l

8 REMOVE PROTECT TIME

9 IMSVERSION

20070529#20.5

Page 29

r

EBS

Ink-Jet Systems

®

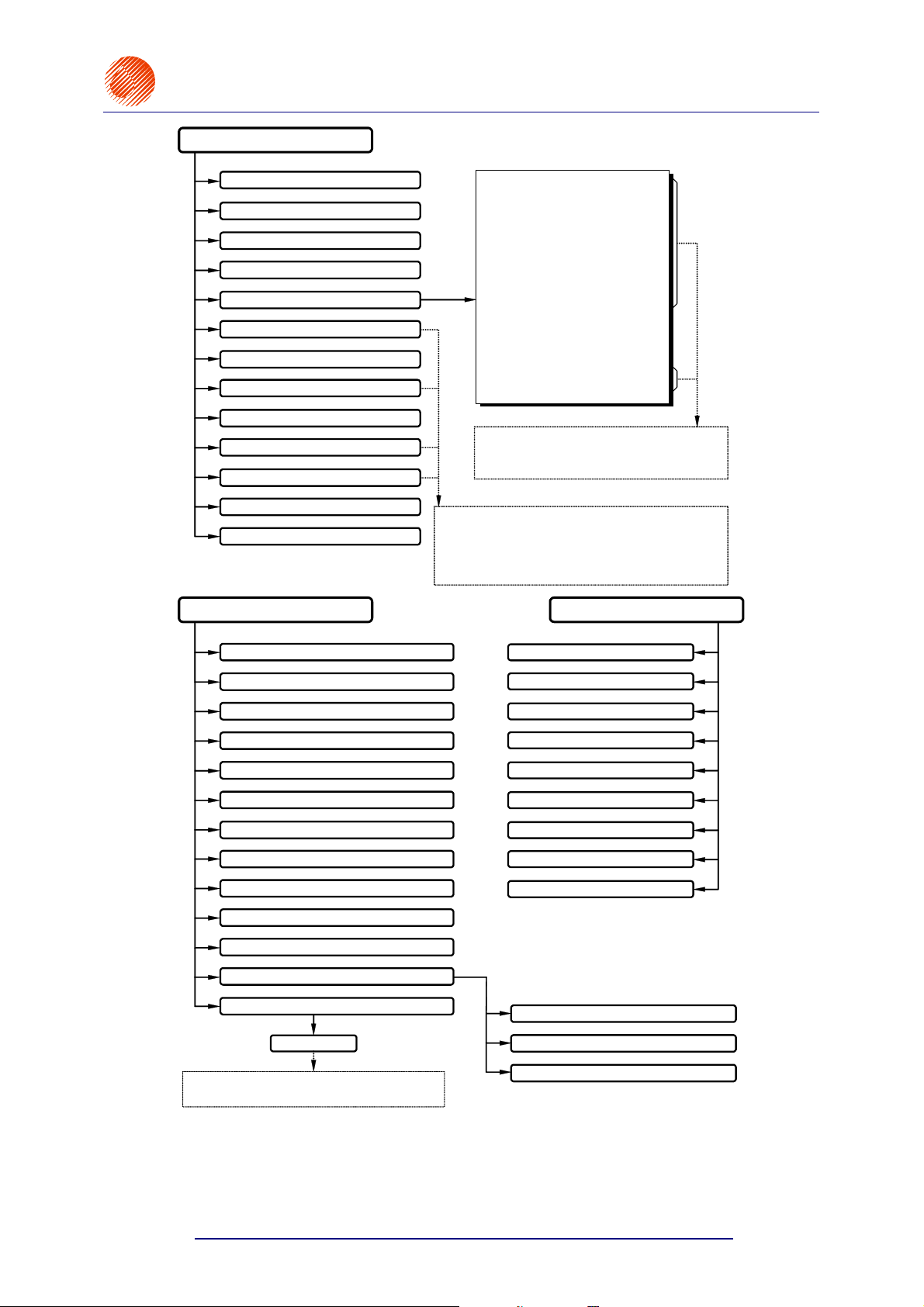

PRINTING

EBS-6100 Printer User's Manual

Paragraph 4 - Operating the Printe

0 EDIT & PRINT CURRENT TEXT

1 STOP PRINTING

2 START PRINT

3 QUICK STOP

4 PRINTING PARAMETERS

5 SAVE CURRENT PARAM.

6 SHIFT COUNTER

7 SET SHIFT COUNTER

8 ROWS SPEED

9 GLOBAL COUNTER

A SET GLOBAL COUNTER

C PRINT SWITCH

D DISPLAY PRINTED TEXT

SERVICE

Vert. direct. : UP

Space : 2,0 mm

Text rpt. : 1

Rpt.dist. : 30,0 mm

Direction : LEFT

Height : LARGE

Offset : 1

Offset2 : 1

Counter delta : 1

Row repetit. : 1

Mode : NORMAL

Speed : SLOW

Interleave : STANDARD

Generator : GEN

Resol. dot/cm : 30

Cnv spd m/min : 10,0

Only some parameters can be modified during

the printing. The settings of others are only

displayed.

If the TEXT SERVICE menu option is protected by a

user password, any modifications to a block of

parameters, change counter and global counter as well

as access to the global counter are allowed only after

the right password has been typed in.

AUX. COMMANDS

1 SERVICE

2 CLEAN NOZZLE

3 V0 OFF

4 V0 ON

5 FAST OFF

6 INK ON

7 INK OFF

8 SOLVENT

9 SET INK STREAM

A STROBOSCOPE

B HV VALUE,PHOTO,SHAFT,AirP state

C SERVICE COMMANDS

D OTHERS

PASSWORD

This is a special service password that protects

an extended set of service commands.

1 OPTIONS

2 DISPLAY ERRORS

3 CLEAR ERRORS

4 READ ERRORS REPORT

5 TIMEAND DATE

6 ACTIVITY TIME

7 LANGUAGE

8 UNLOCK PROTECTION

B SOFTWARE OPTIONS

1 CONVEYER MEASUREMENTS

2 INK FILTER CHANGE

3 PRINTER STORAGE PREPARATION

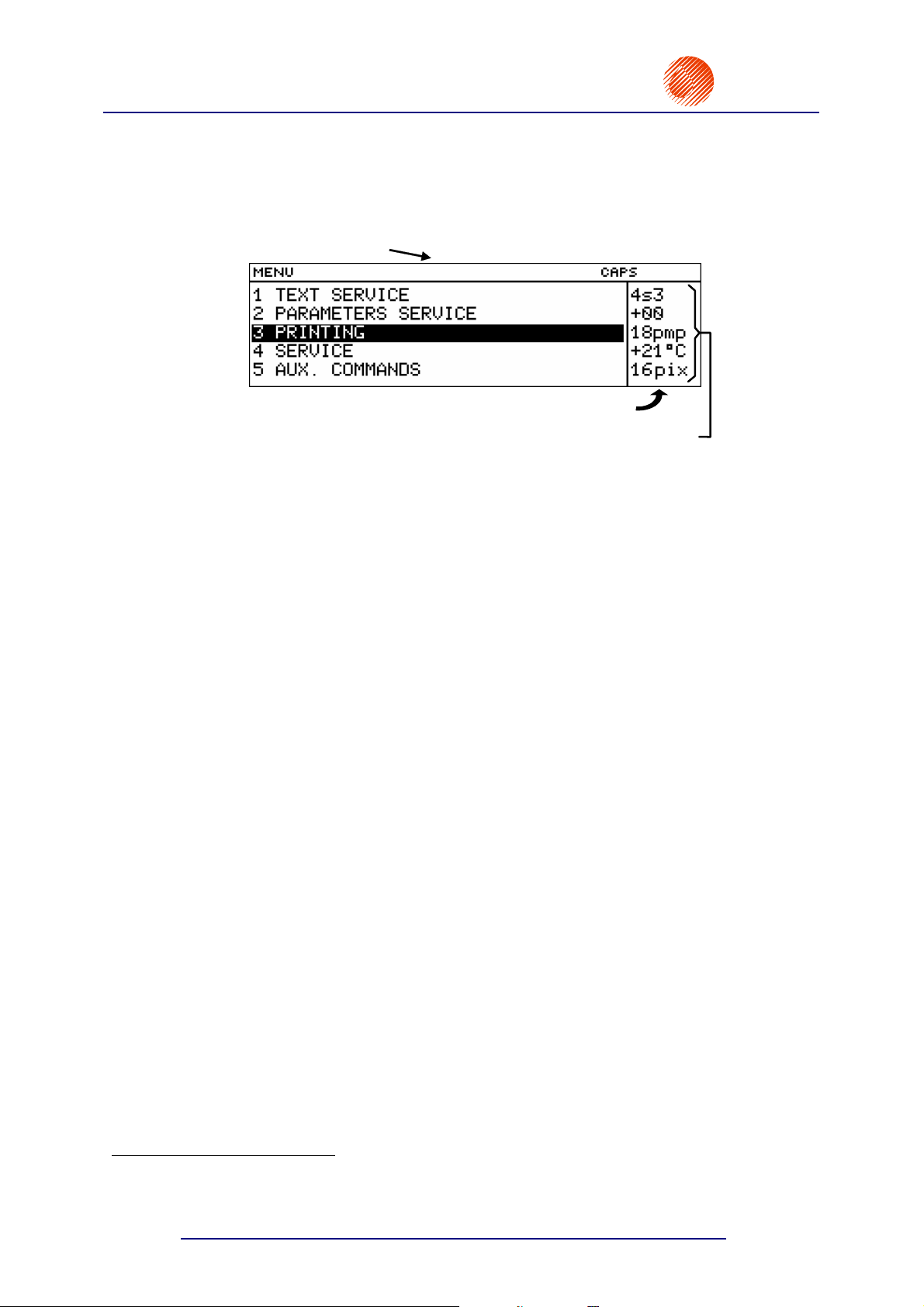

4.3. Print Head Status

The print head operates in the right way, if the ink jet is properly broken into droplets, the

droplets are properly charged and a flow of unused ink droplets falls into the gutter generating

20070529#20.5

27

Page 30

EBS-6100 Printer User's Manual

Paragraph 4 - Operating the Printer

the correct measurement phasing signal2. Therefore vital parameters are measured within the

print head continuously. The settings of these parameters form the so called print head

status and are shown on the terminal display in the printer status window.

EBS

Ink-Jet Systems

®

A sample head status is given below.

Graphic display

Printer status window

Head status block

The characters of the status block have the following meaning:

The first digit on the first line indicates the quality of phasing - it can vary between 2 and

6 (with 4 being the optimum). Frequent fluctuations of the quantity from the optimum

indicate that the unit is tuned improperly. A question mark

position from time to time means erroneous measurement of phasing. If the mark is

displayed frequently or continuously, this means that the unit is not tuned properly,

especially within the head, and may lead to a phasing error and an alarm.

The second digit on the first line (one character) indicates the head operation mode. The

head can be in one of the following four modes:

? which may appear at this

Fig. 4.3.1.

r (restart) the head operation has been restarted (no phasing, the printing

disabled, the READY lamp on the internal panel is off),

s (stop) the head is ready to start the printing (phase and ink viscosity are

measured, the READY lamp on the internal panel generates steady light),

p (print) the head performs the operation of printing as the result of the

START PRINT or PRINT SWITCH commands (high voltage is turned on, phase

and viscosity are measured, the READY lamp and the HV lamp on the internal

and external panel generate steady light),

v (service) the head is in service mode and enables the user to perform service

operations (phase and ink viscosity are measured, no alarm is indicated if a

phasing error occurs).

The third digit on the first line (one character) indicates the number of the best phase

determined during the phasing process. It can vary between 0 and 7. Variations in

magnitude every now and again at few-second intervals indicate that ink parameters vary

too quickly (and these are allowed only for a short period after the unit has been switched

on). Changes by ±1 are normal for this parameter.

Three positions on the second line are used to show ink viscosity and other information.

The viscosity is given in relation to its rated value of +00. Positive numbers indicate that

viscosity levels are higher than the rated value, with negative numbers the viscosity is

smaller than the rated value. The correct value ranges between +15 and -05. Two other

characters such as > (<) can be displayed at the position in emergency cases: when ink

viscosity rises (drops) above (below) the value of 99.

The following messages may also occur on the second line:

Per phasing error.

2

Phasing - automatic process of controlling the charging of ink droplets. The breaking point at which a continuous ink jet

breaks into droplets varies slightly with time. Therefore the control system needs to update time relations between

the charging and breaking of an ink jet into droplets on an on-going basis.

28

20070529#20.5

Page 31

r

EBS

Ink-Jet Systems

Tge time gap error indicating too high a printing speed that makes it impossible to

Der drop error indicating the failure to apply the optimal breaking voltage.

Aer indicating that no compensation can be made for the KOMPENS option due to

Ter temperature error indicating that the head temperature has fluctuated by

Ovr (overrun) the maximum print rate has been exceeded. This indication may

®

measure phasing and viscosity or too small a distance (see the Rpt.dist. print

parameter) between successive labels as for a given print rate.

too small a value of the Space print parameter or too small a distance (the

Rpt.dist. print parameter) between labels to be printed.

more than 10°C in the print mode. This may result from the improper breaking

of ink into droplets and requires the printing to be stopped for about 60

seconds (high voltage to be turned off with the STOP PRINTING or

QUICK STOP commands) in order to ensure that the droplet break off point is

adjusted automatically to a new temperature. If the working temperature

fluctuates by more than 15°C in relation to the temperature at which the

breaking circuit has been synchronized, adjust the breaking voltage before

starting the operation in such conditions, so that the control equipment

operates in the entire temperature range. The adjustment should be performed

by a service person. In general, the lower the temperature, the higher the

breaking voltage.

appear only when a shaft-encoder is used and it is connected with a sound

signal. The alarm can be cleared with one of the following commands:

START PRINT (even if it is rejected), STOP PRINTING, QUICK STOP and

SERVICE (from the SERVICE submenu).

EBS-6100 Printer User's Manual

Paragraph 4 - Operating the Printe

The third line is not used in EBS-6100 printers.

The fourth line indicates the temperature (°C) inside the head.

The fifth line (ending with “pix”) indicates the type of correction table (7, 16, 25 or 32 pix)

used for printing the current label after the START PRINT command has been selected.

Otherwise, the actual height of the label currently printed is displayed.

NOTE:

• If the START PRINT command has been selected and the

during the printing, the name of a text file printed is displayed (for about 1 second) in

place of the print height. If the

displayed longer.

• If the user is allowed to use the printer for a limited period (under a separate agreement

stating that if the period expires, the printer stops working automatically), the first status

line is displayed in inverted colours (light characters on a dark background, for example

).

4.4. Controlling the Printer

4.4.1. Text Files

F4

function key is pressed

F4

key is pressed several times, the text name is

!

4.4.1.1. General Information on Text Files

All operations related to texts to be printed are available from the TEXT SERVICE

ubmenu.

20070529#20.5

29

Page 32

EBS-6100 Printer User's Manual

Paragraph 4 - Operating the Printer

NOTE:

!

If the TEXT SERVICE submenu is protected by a user-defined password, the user is

prompted to give the password before the submenu is displayed. For details on using a user

password in the printer, see section 4.4.1.9 Using the Password.

Text files are stored in a library in the printer’s memory. Each text file is identified by a name

of up to 8-characters. The name can be built up of alphabetical (small and capital) letters,

digits and some symbols except spaces, dots or characters such as: \ / : * ? ” < > |, e.g.

12345678, AB#%CD&, Weight-5, JUICE-12, DATEtime, Q1, @8, etc. Text names and the

arrangement of text names in the library enable the user to move through even a large set of

text files easily and find the right file without any problems.

Every text file in the library can have the read only attribute assigned to it in order to prevent

it from being deleted or modified by an unauthorised person. The read only attribute can be

assigned to/removed from a single text file or all text files stored in the library. For more

information refer to paragraph 4.4.1.7 Accessing the File Library.

Some commands show the library contents in alphabetical order in the operating window of

the display.

EBS

Ink-Jet Systems

®

The following facilities enable the user to move along the file name directory freely:

• the ¡¢¤£ keys to move the cursor from one name to the other,

• the leading character (a letter or digit) to move the cursor to the first name that starts

with this character,

• the Y¢ (HOME) or Y£ keys to move the cursor to the first name in the

library,

• the Y¡ (END) or Y¤ keys to move the cursor to the last name in the library.

NOTE:

!

If the printer memory is overflowed (with a lot of or very long text files or parameter blocks),

the file names may not be arranged in alphabetical order and some facilities may not be

effective.

The files can be divided into two groups:

simple text files,

complex text files.

The simple text files include the following types of text:

a string of ASCII characters,

a graphical image,

a bar code,

a subfile (another text called by its name).

30

In every case you can create a complex text file from the very beginning or merge text files

(hereinafter called subfiles) that already exist in the library (merging by name). A file created

by merging may be used as part of another file.

20070529#20.5

Page 33

r

®

EBS

Ink-Jet Systems

NOTE:

• Once created, a text file remains in the printer’s memory even if the power supply

has been switched off. A file is removed from the library only when deleted.

• The maximum file length is restricted by the volume of the printer memory available.

• Up to 6 special registers

Registers below).

can be used in a complex text file (see 4.4.1.10 Using Special

EBS-6100 Printer User's Manual

Paragraph 4 - Operating the Printe

WORD PROCESSOR - A Description of Control Keys

¢¡£¤

To navigate within a given subfile or between text files.

!

Y ¢¡

Y £¤

« ¢¡£¤

¥

¦

¨

§

to move the cursor to the first or to the last character in an ASCII

subfile.

To move the entire subfile by one pixel (dot) upwards or

downwards.

To create a new subfile in a given position in relation to the current

subfile.

To switch between two character insertion modes:

INSert/OveRwrite.

To delete a character at the cursor position in a subfile.

To switch between national characters on the keypad. The

selection is indicated in the terminal status window, for example

K:POL.

German characters Polish characters

indication:

character ä corresponds to a characters ąĄ correspond to aA

ö o ćĆ cC

ß s ęĘ eE

ü u łŁ lL

Ä A ńŃ nN

Ö O óÓ oO

ß S śŚ sS

Ü U żŻ xX

źŹ zZ

To edit (modify) parameters of a subfile and to change the subfile

type.

K:GER indication: K:POL

« ¦

« V

U

V

«

Q

To delete the entire subfile.

To edit a graphics subfile.

To cancel the edition (modification) of a current text.

To indicated the end of the edition (save the file in the library).

To switch between two space display modes3. Spaces can be

displayed as (by default) or as blanks. Spaces are always

printed as blanks no matter which display mode is active.

4.4.1.2. Opening and Editing a New Text File

In the main MENU select the TEXT SERVICE item and then the CREATE NEW TEXT

item, type in a subfile name consisting of up to eight characters and confirm.

3

Space – a blank distance between characters; insert it with the ª terminal key.

20070529#20.5

31

Page 34

EBS-6100 Printer User's Manual

Paragraph 4 - Operating the Printer

NOTE:

If the file name exists in the library, the file appears on the terminal display and can be edited.

The word processor starts and various types of simple and complex files can be created. The

word processor opens a simple ASCII file of the maximum height. The file contains one

space. Now you can use the keypad to input a text to be printed. A description of control keys

is given in section 4.4.1.1 General Information on Text Files, paragraph WORD

PROCESSOR - A Description of Control Keys.

EBS

Ink-Jet Systems

®

You can modify text file attributes or type by entering the subfile menu with the

The first item in the subfile menu is Type. All subfile types available together with parameters

and default settings are described later on in this document.