Page 1

EBS

Ink Jet Systems

BASIC MANUAL

EBS-1500 SERIES PRINTER WITH

ONE PIEZOCERAMIC PRINT HEAD

VERSION: 20060214#1.0

Page 2

EBS Ink-Jet Systems GmbH, Alte Ziegelei 19-25, D-51588 Nümbrecht, Germany. +49 (0)2293/939-0, FAX. +49 (0)2293/939-3, e-mail: mail@ebs-inkjet.de

TABLE OF CONTENTS

1. General Information........................................................................................................................3

2. Printing System Elements .............................................................................................................3

3. Safety Requirements......................................................................................................................3

4. Operating the Printer......................................................................................................................4

4.1. Switching the Printer On.............................................................................................................4

4.2. Operation Panel .........................................................................................................................4

4.2.1. LCD display.............................................................................................................................................4

4.3. Control MENU............................................................................................................................5

4.4. Opening and Editing a New File .................................................................................................5

4.5. Setting Print Parameters............................................................................................................8

4.6. Printing.......................................................................................................................................9

4.6.1. Starting the Printing.................................................................................................................................9

4.6.2. Viewing a File to be Printed on the Terminal Display...........................................................................10

4.6.3. Stopping the Printing.............................................................................................................................11

4.7. Switching the Printer Off...........................................................................................................11

5. Routine Maintenance....................................................................................................................11

5.1. Replacing Ink Bottle .................................................................................................................11

5.2. Removing Air from the Print Head............................................................................................12

2 20060214#1.0 edited on 2006.02.14 12

Page 3

EBS Ink-Jet Systems GmbH, Alte Ziegelei 19-25, D-51588 Nümbrecht, Germany. +49 (0)2293/939-0, FAX. +49 (0)2293/939-3, e-m ail: mail@ebs-inkjet.de

1. General Information

The complete information on the printer’s accessories, installation, configuration and operation are contained in

The

EBS-1500

stop the EBS-1500 series printer, input a text to be printed, print the text, exchange an ink bottle and rinse

out nozzles if they are choked up.

Printer User’s Manual. This document contains only basic information on how to start and

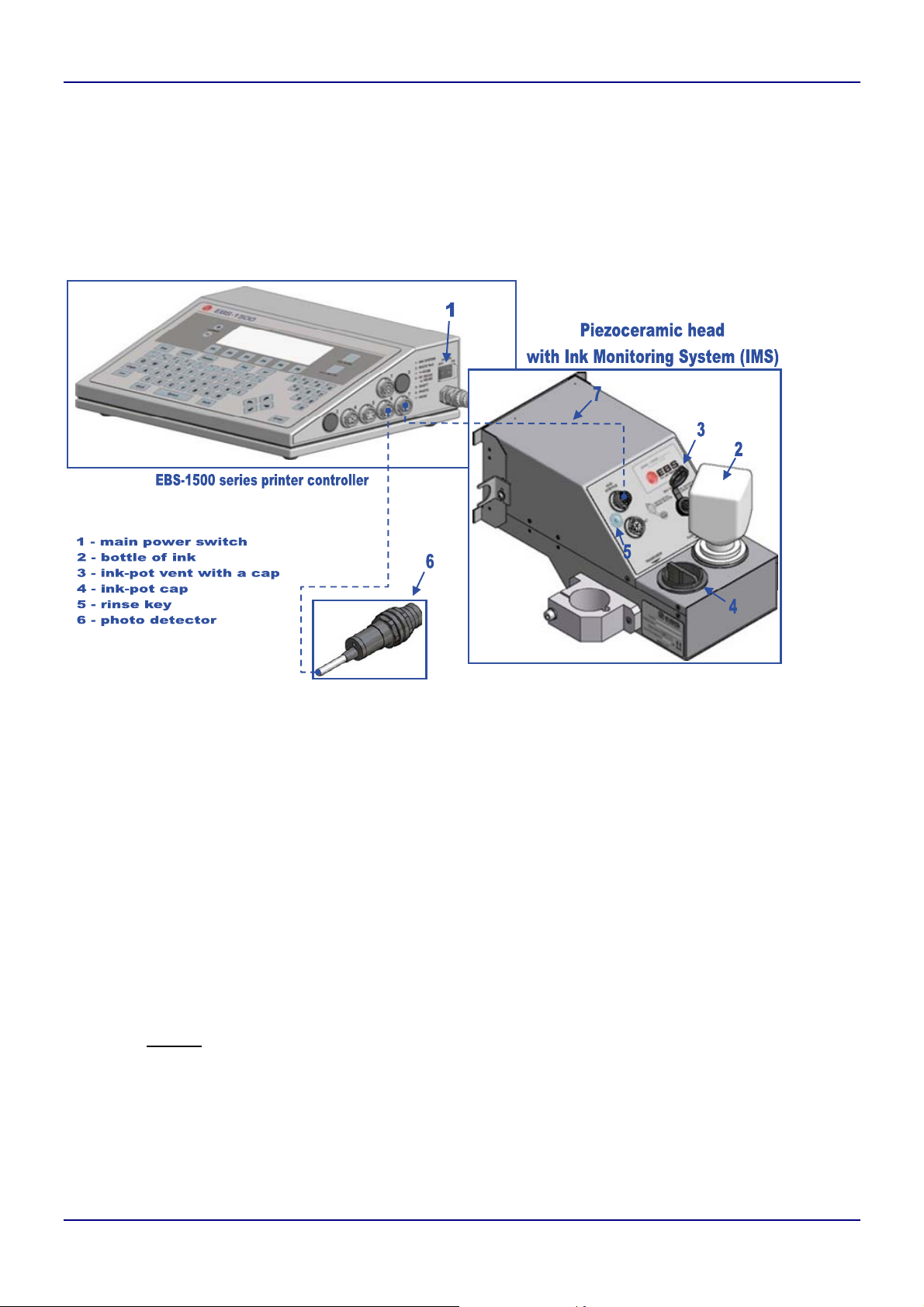

2. Printing System Elements

Major components of the printer with a single piezoceramic head are shown in Fig. 2.1.

Fig. 2.1

In addition, the printing system may contain many other subassemblies such as a shaft-encoder, assembly jigs and

tubes, cables (e.g. a cable to connect the printer controller with the head – see item 7 in Fig. 2.1), an additional

external signalling device and many others. For more details refer to section Installtion of the Printer in The

EBS-1500

Printer User’s Manual.

3. Safety Requirements

NOTE:

• The printer should be operated by trained staff.

• Place a fire extinguisher in the vicinity of the printer (to put out electrical equipment or flammable

solvents should they be on fire).

• Do not print in rooms which are at risk from explosion.

• Do not print on objects whose temperature exceeds 100°C at the time of printing.

• Do not use open fire or spark generating devices in the area where the printer works.

• Plug in the printer to the socket that is equipped with equipment earth.

• Do not point the head outlet to persons or animals during printing.

• Wear protective clothes while performing operations in the ink system.

• Do

• Do not leave ink, solvent or wash-up in open vessels.

• Before approaching flammable liquids discharge static electricity by touching an earthed, metal object (e.g.

• Only original agents are approved for use with the printer or otherwise all rights to claim under the

not use plastic vessels for washing. Metal vessels are recommended.

the earthed printer housing).

guarantee will be lost !!!

12 20060214#1.0 edited on 2006.02.14 3

Page 4

EBS Ink-Jet Systems GmbH, Alte Ziegelei 19-25, D-51588 Nümbrecht, Germany. +49 (0)2293/939-0, FAX. +49 (0)2293/939-3, e-mail: mail@ebs-inkjet.de

In the case of accident...

´ When ink or solvent spills occur, the spilled fluid should be wiped with a piece of absorbent material and then

removed in compliance with fire and health and safety at work (HSE) regulations.

´ If the clothing has been splashed, remove it as soon as possible.

´ Should the eyes or skin get irritated:

EYES need to be rinsed with running water for at least 15 minutes, then you should see your oculist,

SKIN needs to be washed with water and soap.

4. Operating the Printer

Before starting the printing system ensure that the appropriate operating conditions are satisfied, paying especial

attention to the following:

Power supply: 100-240V/45-440Hz (AC) or 90-350V (DC),

Head position during printing: horizontal.

4.1. Switching the Printer On

The ON/OFF power switch is situated on the right side wall of the unit next to the feeder cable. It

isolates both power leads from the mains (see item 1 in Fig. 2.1).

POWER

OFF

ON

If the printer controller and head connectors are all connected, it is enough to switch the power switch

to the ON position. Then, the starting procedure is initiated.

If no errors are displayed on the printer controller screen or signalled with a sound alarm during the starting

procedure, the printer is ready for printing. A detailed description of errors and alarms is contained in The

EBS-1500

Piezoceramic print heads are heated up (over 5 ÷ 10 minutes) to the rating temperature of about 70°C (!!! MIND

THE HIGH TEMPERATURE !!!). If the START PRINT command is selected before the rating temperature has

been reached in the head, the command will not be executed (message UNIT NOT ACTIVE will be displayed).

Printer User’s Manual.

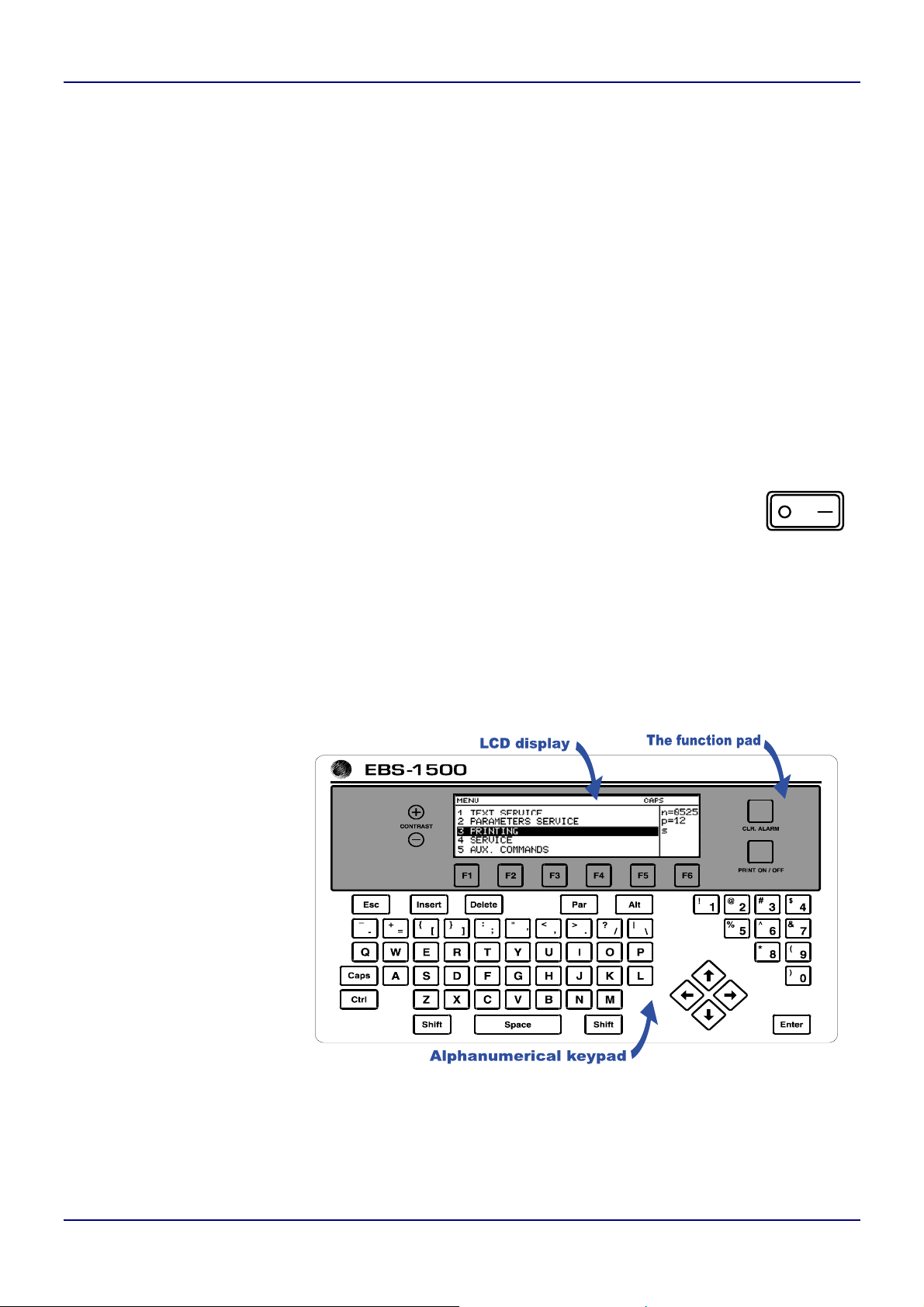

4.2. Operation Panel

The operation panel enables the

printer operator to control and

monitor the unit’s operation, and

initiate actions as might be

required in given circumstances.

It is also used for performing

such basic operations as turning

the print mode on or off, locating

faults, clearing alarms, etc. For

more details refer to chapter

Operating the Printer in The

EBS-1500

Manual.

Printer User’s

4.2.1. LCD display

The display area is divided into separate sections called windows.

4 20060214#1.0 edited on 2006.02.14 12

Page 5

EBS Ink-Jet Systems GmbH, Alte Ziegelei 19-25, D-51588 Nümbrecht, Germany. +49 (0)2293/939-0, FAX. +49 (0)2293/939-3, e-m ail: mail@ebs-inkjet.de

Fig. 4.2.1

The windows are designed for the following:

• The terminal status window – contains information on the current terminal settings, and indicate for example,

the graphic cursor co-ordinates (while editing graphics), whether the © key (to switch between block/small

letters) or the Y or « buttons are pressed or not, which character input mode (INSert or OveRwrite) is

used, etc.

• The operating window – it is the main window of the display to show the service MENU and various

parameters and messages, to edit text files, etc.

• The printer status window – contains information about the head status in the printer’s various operating

modes (p for print, s for stop, the print height, etc.).

4.3. Control MENU

After the printer has been switched on, the control MENU is shown in the operating window on the terminal

display. The MENU has a multilevel tree structure. Commands are executed directly at the lowest level. No action

is initiated by moving from one menu branch to the other. Only the execution of a command initiates an action such

as starting the printing, moving to the word processor, changing parameters, etc.

The first character (a digit or letter) of every MENU item corresponds to the so called hot key (see Fig. 4.2.1).

When this key is pressed on the keypad, the cursor bar is positioned on the required item.

The following keys are used to move within the MENU tree:

£ Moves the cursor one menu item upwards.

¤ Moves the cursor one menu item downwards.

Y ¢ or Y £ - Move the cursor to the first item.

Y ¡ or Y ¤ - Move the cursor bar to the last item.

V Moves to a lower level in the MENU (to the next MENU branch) or confirms the selection.

U Moves to a higher level in the MENU or cancels the selection. When you press the U key

several times, it brings you back to the main MENU.

NOTE:

After a command has been confirmed with the V key, you may not be able to cancel it. Some

commands are executed immediately.

4.4. Opening and Editing a New File

Both simple and more complex texts can be printed with EBS printers. They can contain time markers, date,

expiry dates (via the so called variable fields). Also barcodes and graphics (either built-in or created by the user

with a graphics processor) can be printed. For more details refer to section Controlling the Printer in The

EBS-1500

Example of how to input a text containing an expiry date and up-to-date time)

Printer User’s Manual.

NOTE:

• The expiry date and time, which are shown in the illustrations in the following example depend on the up-

to-date settings for date and time in the printer.

• Every aspect of the printer operation procedure is described in the following example.

The following text should be printed: .

12 20060214#1.0 edited on 2006.02.14 5

Page 6

EBS Ink-Jet Systems GmbH, Alte Ziegelei 19-25, D-51588 Nümbrecht, Germany. +49 (0)2293/939-0, FAX. +49 (0)2293/939-3, e-mail: mail@ebs-inkjet.de

¤

£

V

¤

£

V

–

V

Two of them (1 and 3 in the figure on the left) are

The text file consists of four subfiles:

regular Text type subfiles, while the other two

(2 and 4 in the figure on the left) are also Text type

subfiles but their contents are updated automatically

via variable fields. Subfile 2 contains the expiry date

(which is formed by adding a specific offset to the

current date – the Date+offs. variable field), while

subfile 4 contains the current time (the Time variable

field). The entire text will be printed in Latin 7x5 (every

character will be 7 dots high and 5 dots wide).

Type in the text name (up to 8 characters

block or small letters, digits and characters

excluding / \ : * ? ” < > | ), e.g. DATE.

Block letters are set by default –

block/small letters can be

switched over with the © key.

6 20060214#1.0 edited on 2006.02.14 12

Page 7

EBS Ink-Jet Systems GmbH, Alte Ziegelei 19-25, D-51588 Nümbrecht, Germany. +49 (0)2293/939-0, FAX. +49 (0)2293/939-3, e-m ail: mail@ebs-inkjet.de

¨ - national characters

Q

«

two space display modes.

to switch between

-

create subtext 2 on the

right of the previous one

« ¡

Y – characters

shown in the top left part

of the keys

§ - set parameters for subtext 1:

Type : Text,

Char. set : Latin 7x5 ¢ ¡

Typeface : Normal

£ Distance : 2

Rotation : None

¤ Spec.reg. : None

Front dis : 0

Back dist : 0

§ - set parameters for subtext

4 as for subtext 2 except for::

Spec.reg. : Time

create subtext 4 on the

right of subtext 3

« ¡

§ - set parameters for subtext 2

as for subtext 1 except for:

Spec.reg. : Date+offs.

create subtext 3 below the

previous ones

§ - set parameters for subtext 3

(as for subtext 1)

NOTE:

If subtexts use variable fields (subtexts 2 and 4), the

litters (in the case of date) and digits (in the case of

time) will be replaced with values during printing (e.g.

DA will be repla ced with dozens and units of the day

of month, MO with dozens and units of the month of

year, whereas YE with dozens and units of the year).

« ¤

The above example contains only some of the options that can be used to edit text files. Other useful functions are:

Y ¢¡

Y £¤

¥

¦

« ¦

To move the cursor to the first or to the last character in an ASCII subfile.

To move the entire subfile by one pixel (dot) upwards or downwards.

To switch between two character insertion modes: INSert/OveRwrite.

To delete a character at the cursor position in a subfile.

To delete the entire subfile.

Example of how to edit a barcode

The following barcode should be printed:

.

12 20060214#1.0 edited on 2006.02.14 7

Page 8

EBS Ink-Jet Systems GmbH, Alte Ziegelei 19-25, D-51588 Nümbrecht, Germany. +49 (0)2293/939-0, FAX. +49 (0)2293/939-3, e-mail: mail@ebs-inkjet.de

¤

£

V

¤

£

V

V

V

p

¤

£

V

¤

£

Type in the text file name (up to 8 characters –

block, small letters, digits and characters

excluding / \ : * ? ” < > |), e.g. BARC.

§ - set the parameters of the subfile:

Type : Barcode

Code : EAN-13 ¢ ¡

Contents : 500746300621

£ Height : 32

Elongat.X : 1

¤ Corrector : 0

Spec.reg. : None

Front dis : 0

Back dist : 0

Signature : 5 pix

Sign.dist : 1 pix

Inversion : NO

Block letters are set by default –

you can switch between block/

small letters with the © key.

Set the subtext parameters to the values

ecified in the table.

s

4.5. Setting Print Parameters

Before the text prepared in section 4.4 is printed all the required print parameters need to be set. The

parameters determine the print rate, the location of the print on objects to be labelled, the direction in which the

object moves in front of the print head, the date offset (to set expiry date), etc.

Set the print parameters in the way and to the values presented in the following figures:

V

8 20060214#1.0 edited on 2006.02.14 12

Page 9

EBS Ink-Jet Systems GmbH, Alte Ziegelei 19-25, D-51588 Nümbrecht, Germany. +49 (0)2293/939-0, FAX. +49 (0)2293/939-3, e-m ail: mail@ebs-inkjet.de

g

The distance from the point where the

photo detector has been activated to the

point where printing of a text file is start.

Printing in the vertical direction.

Prints can be made normally or

up side down.

The distance between the

beginnings of texts (if

Text rpt. > 1).

The direction (left or right) in

which objects move in front of the

print head.

An offset (number of days) from

the current date to the expiry

date. The parameters are used by

variable fields Date+offs.

and Date+offs.2.

The number specifying how many

times every vertical row will be

printed.

The source of timing signals:

internal generator or shaftencoder.

Character resolution.

The speed at which an object

moves in front of the print head if

the internal generator is used for

timing (Generator = GEN).

The number of pulses generated

by the shaft-encoder over the

distance of 1 metre. Print rate

must suit the conveyor travel rate

(Generator = SHAFT).

Number of printing text

repetitions.

Print height.

Incremental/decremental counter

increment/decrement. Th

parameter is used by the

Up counter and Down count.

variable fields.

Vert. direct. : UP

Space : 2,0 mm

Text rpt. : 1

Rpt.dist. : 30,0 mm

Direction : LEFT

Height : head-specific

Offset : 100

Offset2 : 1

Counter delta : 1

Row repetit. : 1

Generator : GEN

Resol. dot/cm : 80

Cnv spd m/min : 10,0

Enc const p/m : 10000

No of Clean Strokes : 0

Clean. period (sec) : 300

The parameters enable the user

to print additional complete rows

between prints. The objective of

such printing is to prevent ink

drying in the nozzles if prints are

made at lon

time intervals.

e

The parameter to be modified is selected with the £ ¤ keys. Parameter settings are changed with the ¢ ¡

keys or by typing in a setting via the keyboard (this applies to numerical parameters) and confirming with the V

key. In the example referred to above, the Offset parameter needs modifying only. The default settings can be

used for the other parameters.

NOTE:

• If the Generator parameter is set to GEN, the printer will make prints regardless of whether an object

moves in front of the print head or not. If the object remains still, the text will be jetted onto one place

giving a vertical line only. While testing the printer where an internal generator is used for timing it is

advisable to set the Text rpt. parameter to a higher value.

• If the Generator parameter is set to SHAFT, the head will make prints only when a so called

shaft-encoder is connected and its axle rotates (for more details on this optional device refer to section

Adjusting the Print Rate in The

EBS-1500

Printer User’s Manual). If this is the case, there may be

the need (especially during trials) to complete the printing of the current text by turning the shaft-encoder

axle manually.

4.6. Printing

4.6.1. Starting the Printing

The printing can be initiated in two parallel and independent ways:

• With the START PRINT command selected on the terminal (description on the figures).

12 20060214#1.0 edited on 2006.02.14 9

Page 10

EBS Ink-Jet Systems GmbH, Alte Ziegelei 19-25, D-51588 Nümbrecht, Germany. +49 (0)2293/939-0, FAX. +49 (0)2293/939-3, e-mail: mail@ebs-inkjet.de

¤

£

V

¤

£

V

V

¤ £

¡ ¢

V

p

¤

£

V

¤

£

V

• With the PRINT ON/OFF key on the operation-panel function pad. When the key is pressed, the latest

subfile is printed. The key can be used no matter where the cursor is positioned within the control menu

(for example, you can start printing while editing a subfile).

In order to print the text file called DATE or BARC prepared in the example in section 4.4 follow the step below:

Type in the text file name (up to 8 characters –

or

Press ¨ if you wish to select

a text file from the library

Return to the printing MENU – the printing

status is indicated in the head status

window

block, small letters, digits and characters

excluding / \ : * ? ” < > | ), e.g. DATE.

Block letters are set by default –

you can switch between block/

small letters with the © key.

– print

Overprint height

4.6.2. Viewing a File to be Printed on the Terminal Display

press V or U to return to MENU

or

10 20060214#1.0 edited on 2006.02.14 12

Page 11

EBS Ink-Jet Systems GmbH, Alte Ziegelei 19-25, D-51588 Nümbrecht, Germany. +49 (0)2293/939-0, FAX. +49 (0)2293/939-3, e-m ail: mail@ebs-inkjet.de

¤ £

V

¤

£

V

¤

£

V

¤

£

V

4.6.3. Stopping the Printing

The printing can be terminated in three ways:

• With the STOP PRINTING command.

The current text file is printed to

the end and the printing is

terminated

• With the QUICK STOP command.

The printing of the current text

file is interrupted

• With the PRINT ON/OFF key on the operation-panel function pad (when the key is pressed, the

STOP PRINTING command is executed). The key can be used no matter where the cursor is positioned

within the control menu (for example, you can stop the printing while editing a subfile).

4.7. Switching the Printer Off

POWER

OFF

The printer may be switched off at any time (even during printing). Just switch the Power switch

the OFF position.

ON

to

On switching the unit off protect the heads. You need to do the following.

• plug the ink pot vent with a cap (item 3 in Fig. 2.1),

• place a seal cover onto the nozzle plate and push it down until it snaps. The cover will protect the nozzles from

getting dirty and ink from drying up inside the nozzles.

seal cover

Fig. 4.7.1

5. Routine Maintenance

5.1. Replacing Ink Bottle

A low ink level in the ink bottle is signalled with the INK INK LACK messages in the terminal operating window. A

new bottle of ink should be installed before the ink in the bottle is consumed completely (and the no-ink condition is

12 20060214#1.0 edited on 2006.02.14 11

Page 12

EBS Ink-Jet Systems GmbH, Alte Ziegelei 19-25, D-51588 Nümbrecht, Germany. +49 (0)2293/939-0, FAX. +49 (0)2293/939-3, e-mail: mail@ebs-inkjet.de

signalled with the INK: EMPTY BOTTLE messages). For more details refer to chapter Replacing Ink bottle in The

EBS-1500

Printer User’s Manual. Follow the procedure by performing the steps given below:

1. Prepare a new bottle of ink. The replacement procedure can be followed without interrupting the printing.

2. Remove the transponder of the currently used bottle from the transponder seat (secured with a cap, item 4 in

Fig. 2.1) - the following message can be displayed on the terminal: INK: NO BOTTLE

3. Place the transponder of a new sealed bottle (without removing the bottle from the ink-pot). One or more

messages may be displayed. If this is the right bottle, that is, a new bottle that has never been used (or

approved) before, the following message should appear at first: BOTTLE VERIFYING:

WAIT 10 SECONDS PLEASE.

4. If a BOTTLE ACCEPTED message is displayed within 10 seconds, it means that the new bottle and the

transponder are right for a given printer. In such a case leave the approved transponder in its seat. Unscrew

the old bottle, unseal the new one and screw it in to the ink pot (if the transponder is removed from its seat, a

NO BOTTLE message can be displayed).

5. If no bottle error occurs, the message NO BOTTLE should be replaced with the normal status indication in the

printer status window.

5.2. Removing Air from the Print Head

Transport, manipulations to the ink system, or other

reasons may result in accumulation of air within the

print head. In consequence ink drops are not jetted

from some or all nozzles. This is illustrated in the

sample on the right.

In order to remove air from the print head, follow the instructions below:

a). Screw the ink bottle out (item 2 in Fig. 2.1) and screw the ink pot plug tight (item 4 in Fig. 2.1).

b). Open the vent cap (item 3 in Fig. 2.1).

c). Remove the seal cover from the front of the print head - see Fig. 4.7.1.

d). Place a vessel under the nozzle outlet.

e). Press the rinse key

(item 5 in Fig. 2.1) at the back of the head housing for about 1second. The ink pump

starts running to pump ink from the ink pot to the head chamber. As pressure is generated, air bubbles and ink

start jetting out of the system.

f). Release the rinse key

.

g). Wipe the front of the head with dust-free cloth (supplied by the Manufacturer) crosswise, with reasonable

pressure.

wipe with cloth in this direction

wipe with cloth in this direction

h). Start printing a sample file and check the quality of printing with every nozzle.

12 20060214#1.0 edited on 2006.02.14 12

Loading...

Loading...