Eberspächer HYDRONIC D 5 W Z, HYDRONIC B 5 W Z, HYDRONIC B 5 W SC, HYDRONIC B 4 W SC, HYDRONIC D 4 W SC Instruction Manual

...

1

J. Eberspächer

GmbH & Co. KG

Eberspächerstr. 24

D - 73730 Esslingen

Telefon (zentral)

(0711) 939 - 00

Telefax

(0711) 939 - 0500

www.eberspaecher.com

Eberspächer

25 2216 90 95 89 EN 10.2010 Subject to changes Printed in Germany © J. Eberspächer GmbH & Co. KG

Technical description

Installation instructions

Operating instructions

Maintenance instructions

Heater (additional heater) for vehicles with

petrol engine

Order no.

HYDRONIC

B 5 W Z – 12 volt 20 1818 05 00 00

Heater (additional heater) for vehicles with

diesel engine

Order no.

HYDRONIC

D 5 W Z – 12 volt 25 2216 05 00 00

Please give this manual to the customer

after installation of the heater.

2

Introduction

1

1

8

7

6

5

4

3

Contents

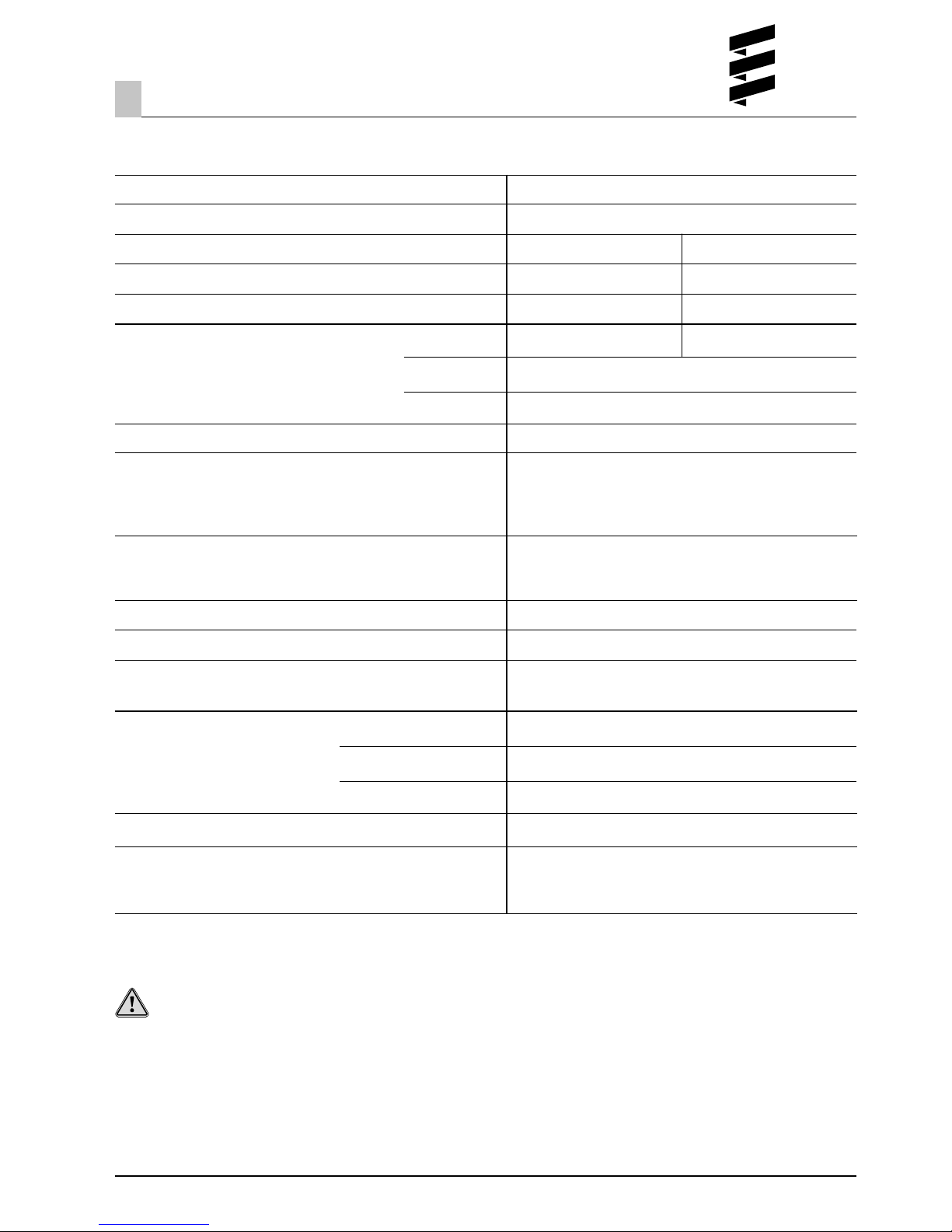

Chapter Title Contents Page

Introduction • Contents ................................................................................................ 2

• Concept of this manual ......................................................................... 3

• Special text structure, presentation and picture symbols ..................... 4

• Important information before starting work ............................................ 4

• Statutory regulations ......................................................................... 5, 6

• Safety instructions for installation and operation .............................. 6, 7

• Accident prevention .............................................................................. 7

Product information • Scope of supply ................................................................................. 8, 9

• Technical data petrol heaters .............................................................. 10

• Technical data diesel heaters .............................................................. 11

• Main dimensions .................................................................................. 12

Installation • Installation and location ...................................................................... 13

• Possible installation positions ............................................................. 14

• Mounting and fastening ....................................................................... 14

• Nameplate ........................................................................................... 15

• Connection to the cooling water circuit ......................................... 16, 17

• Exhaust system ................................................................................... 18

• Combustion air system ........................................................................ 19

• Fuel supply ..................................................................................20 – 24

Operation and • Operating instructions / important information for operation ............... 25

function • Initial commissioning ........................................................................... 25

• Description of functions ...................................................................... 25

• Control and safety devices ................................................................. 26

Electrical system • Heater wiring ........................................................................................ 27

• Circuit diagram ..................................................................................... 28

Troubleshooting • In case of faults, please check the following points ........................... 29

Maintenance • Troubleshooting procedure .................................................................. 29

Service • Maintenance instructions .................................................................... 29

• Service ................................................................................................ 29

Environment • Certification ......................................................................................... 30

• Disposal ............................................................................................... 30

• EU Declaration of Conformity ............................................................... 30

Lists • List of key words ........................................................................... 31, 32

• List of abbreviations ............................................................................ 32

2

3

Introduction

1

Concept of this manual

This manual aims to support the service company

installing the heater and to provide the user with all

important information about the heater.

The manual has been divided into 8 chapters to make

it easier to find the corresponding information quickly.

Introduction

Here you will find important introductory

information about installation of the heater

and about the structure of the manual.

Product information

Here you will find information about the scope

of supply, the technical data and the

dimensions of the heater.

Installation

Here you will find important information and

instructions referring to installation of the

heater.

Operation and function

Here you will find information about the

operation and function of the heater.

Electric system

Here you will find information about the

electronic system and electronic components

of the heater.

Troubleshooting / maintenance / service

This section contains information on possible

faults and malfunctions, troubleshooting,

maintenance and the service hotline.

Environment

Here you will find information about certification

and disposal of the heater together with the EU

Declaration of Conformity.

Lists

Here you will find the key word list and

abbreviations list.

2

3

4 8

7

6

51

4

Introduction

1

Special text structure, presentation and

picture symbols

This manual uses special text structures and picture

symbols to emphasise different contents.

Please refer to the examples below for the

corresponding meanings and associated actions.

Special structure and presentations

A dot (•) indicates a list which is started by a

heading. If an indented dash (–) follows a dot, this list

is subordinate to the dot.

Picture symbols

Regulation!

This picture symbol with the remark “Regulation”

refers to a statutory regulation. Failure to comply with

this regulation results in expiry of the type permit for

the heater and preclusion of any guarantee and

liability claims on J. Eberspächer GmbH & Co. KG and

its associated companies.

Danger!

This picture symbol with the remark “Danger!” refers

to the risk of a fatal danger to life and limb. Under

certain circumstances, failure to comply with these

instructions can result in severe or life-threatening

injuries

..

..

.

Caution!

This picture symbol with the remark “Caution!” refers

to a dangerous situation for a person and/or the

product.

Failure to comply with these instructions can result in

injuries to people and / or damage to machinery.

These remarks contain application recommendations

and useful tips for installation of the heater.

Important information before

starting work

Range of application of the heater

The heater operating independently of an engine is

intended for installation in the following vehicles,

depending on its heating output:

• Vehicles of all kinds

• Construction machinery

• Agricultural machinery

• Boats, ships and yachts

The heater must not be installed in motor vehicles

used to transport dangerous goods according to

ADR / ADR 99.

Purpose of the heater

(using the vehicle heat exchanger)

• Heat up the vehicle's water circuit together with the

vehicle engine for adequate heating of:

– Driver and working cabs

– Freight compartments

– Ship’s cabins

– Passenger and crew compartments

– Vehicle engines and units

On account of its functional purpose, the heater is not

permitted for the following applications:

• Long-term continuous operation, e.g. for pre-heating

and heating of:

– Residential rooms

– Garages

– Work huts, weekend homes and hunting huts

– Houseboats, etc.

Caution!

Safety instructions for application and

proper purpose

• The heater must only be used and operated for the

range of application stated by the manufacturer in

compliance with the “Operating instructions”

included with every heater.

Please note!

Please note!

5

Introduction

1

Statutory regulations

The Federal Road Transport Directorate has issued an

"EC type approval" and an "EMC type approval" for the

heater for installation in motor vehicles and with the

following official type approval marks, noted on the

heater name plate.

HYDRONIC

EC- e1 00 0023

EMC- e1 023971

Regulation!

Directive 2001 / 56 / EU of the European

Parliament and the Council

• Arrangement of the heater

– Parts of the structure and other components near

the heater must be protected from excess heat

exposure and possible contamination from fuel or

oil.

– The heater must not pose a fire hazard even when

it overheats.

This requirement is deemed to be fulfilled when

adequate clearance to all parts is observed during

installation, sufficient ventilation is provided and

fire-proof materials or heat plates are used.

– The heater must not be located in the passenger

compartment in vehicles of class M

1

, M2, M3 and N.

A unit may however be used in a hermetically sealed

housing which also corresponds to the conditions

stated above.

– The factory nameplate or duplicate must be affixed

so that it can still be easily read when the heater

is installed in the vehicle.

– All appropriate precautions must be taken when

arranging the heater to minimise the risk of injuries

to persons or damage to other property.

• Fuel supply

– The fuel intake connection must not be located in

the passenger compartment and must be sealed

with a properly closing lid to prevent any fuel leaks.

– In heaters for liquid fuel where the heater fuel is

separate from the vehicle fuel, the type of fuel and

intake connection must be clearly identified.

– A warning sign is to be fixed to the intake

connection indicating that the heater must be

switched off before refuelling.

• Exhaust system

– The exhaust outlet must be arranged so as to

prevent any penetration of exhaust fumes into the

vehicle interior through the ventilation system,

warm air intakes or open windows.

• Combustion air intake

– The air for the heater combustion chamber must

not be sucked in from the passenger compartment

of the vehicle.

– The air intake must be arranged or protected in

such a way that it cannot be blocked by other

objects.

• Operating status display

– A clearly visible operating display in the user’s

field of vision must indicate when the heater is

switched on and off.

6

Introduction

1

Statutory regulations

• Compliance with the statutory regulations and

safety instructions is prerequisite for guarantee

and liability claims.

Failure to comply with the statutory regulations and

safety instructions and incorrect repairs even when

using original spare parts make the guarantee null

and void and preclude any liability for

J. Eberspächer GmbH & Co. KG.

• Subsequent installation of this heater must comply

with these installation instructions.

• The statutory regulations are binding and must also

be observed in countries which do not have any

special regulations.

• Installation of the heater in special vehicles must

comply with the regulations applying to such

vehicles.

• Other installation requirements are contained in the

corresponding sections of this manual.

Safety instructions for installation

and operation

Danger!

Risk of injury, fire and poisoning!

• Disconnect the vehicle battery before starting any

kind of work.

• Before working on the heater, switch the heater off

and let all hot components cool down.

• The heater must not be used in closed rooms, e.g.

in the garage or in a multi-storey car park (do not

leave the engine running when the vehicle is at a

standstill).

Caution!

Safety instructions for installation and operation!

• The heater must only be installed by a JE partner

authorised by the manufacturer according to the

instructions in this manual and possibly according to

special installation recommendations; the same

applies to any repairs to be carried out in the case

or repairs or guarantee claims.

• Repairs by non-authorised third-parties or with not

original spare parts are dangerous and therefore not

allowed. They result in expiry of the type permit of

the heater; consequently, when installed in motor

vehicles they can cause expiry of the vehicle

operating licence.

• The following measures are not allowed:

– Changes to components relevant to the heater.

– Use of third-party components not approved by

J. Eberspächer GmbH & Co. KG.

– Nonconformities in installation or operation from

the statutory regulations, safety instructions or

specifications relevant to safe operation as stated

in the installation instructions and operating

instructions. This applies in particular to the

electrical wiring, fuel supply, combustion air

system and exhaust system.

Please note!

7

Introduction

1

Accident prevention

General accident prevention regulations and the

corresponding workshop and operation safety

instructions are to be observed.

Safety instructions for installation

and operation

Caution!

Safety instructions for installation and operation

• Only the controls approved by Eberspächer may be

used to operate the heater.

The use of other controls can result in malfunctions.

• Only when upgrading the additional heater:

Before the heater is installed again in another

vehicle, rinse the heater parts carrying water with

clear water.

• Before the heater is installed again in another

vehicle, rinse the heater parts carrying water with

clear water.

• When carrying out electric welding on the vehicle,

the plus pole cable at the battery should be

disconnected and placed at ground to protect the

controller.

• The heater must not be operated where there is a

risk of an accumulation of flammable vapours or

dust, for example close to

– fuel depot

– coal depot

– wood depot

– grain depots etc.

• The heater must be switched off when refuelling

(vehicle engine).

• When the heater is mounted in a safety housing

etc., the installation compartment of the heater is

not a stowage compartment and must be kept clear.

In particular fuel canisters, oil cans, spray cans,

gas cartridges, fire extinguishers, cleaning rags,

items of clothing, paper etc. must not be stored or

transported on or next to the heater.

• Defect fuses must only be replaced by fuses with

the prescribed rating.

• If fuel leaks from the heater fuel system, arrange

for the damage to be repaired immediately by a

JE service partner.

• When topping up the coolant, only use the coolant

permitted by the vehicle manufacturer, see the

vehicle operating manual. Any blending with

unpermitted coolant can cause damage to the

engine and heater.

• After-running of the heater must not be interrupted

prematurely e.g. by pressing the battery

disconnecting switch, apart from in the case of an

emergency stop.

8

• Please consult the additional parts catalogue for

any other parts required for installation, e.g. hose

clips.

• The heater can be upgraded from additional heater

to pre-heater with a mod kit. Please consult the

sales documents for the order number for vehiclespecific mod kits.

Recommendation:

Starting the heater can be limited with an outside

temperature switch, i.e. the heater switches on at a

temperature <5 °C or <10 °C.

In addition, an ON / OFF switch should be fitted for

vehicles frequently used for short distances.

This allows for the heater to be switched off with the

ON / OFF switch when used for short distances and

during the summer months.

The ON / OFF switch can be bought from a good parts

dealer.

Order number:

Outside temperature switch <5 °C 201 00 121

Outside temperature switch <10 °C 201 00 122

ON / OFF switch, 12 volt 201 00 123

Product information

2

Please note!

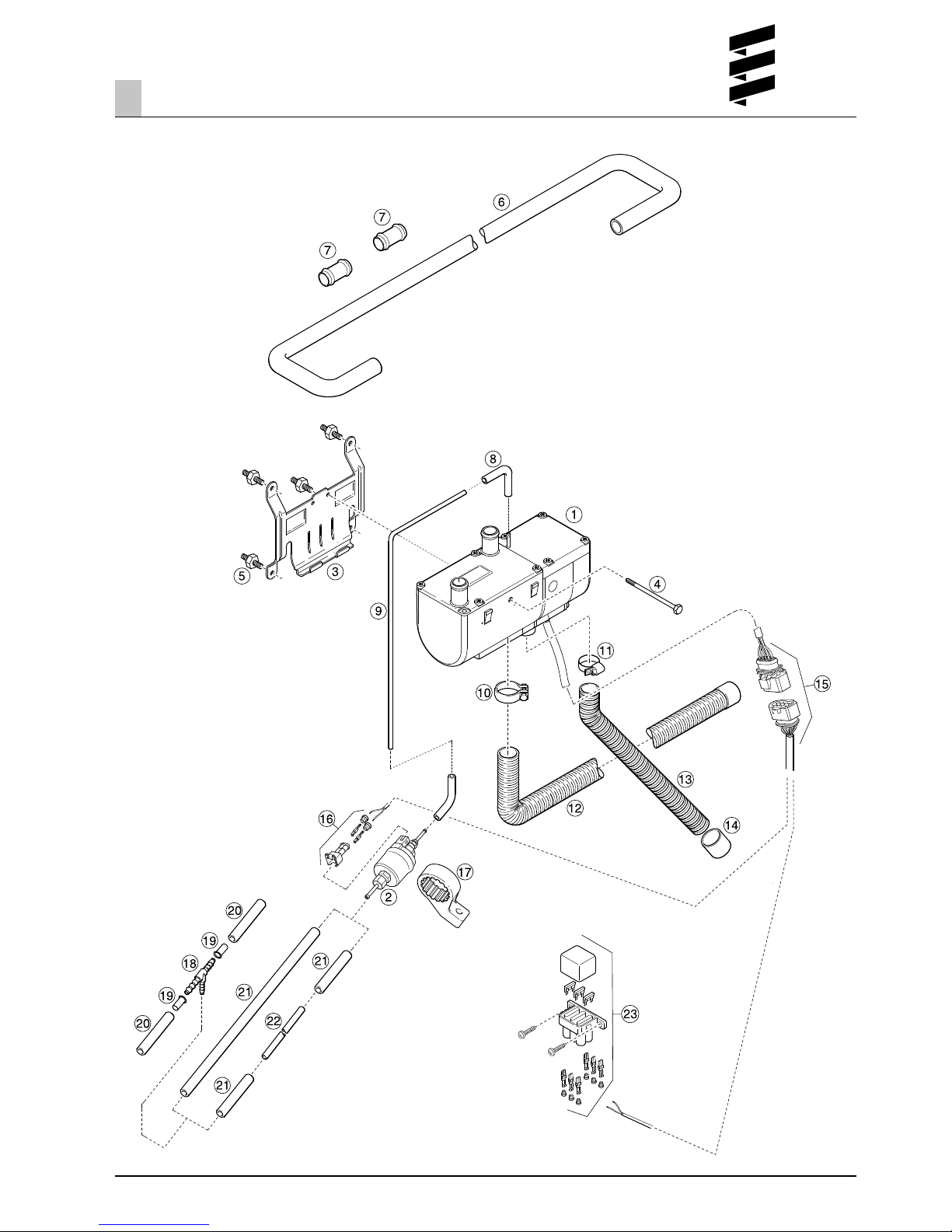

Scope of supply for petrol heaters

Picture No.

Quantity / Designation Order number

–1

HYDRONIC

B 5 W Z – 12 V 20 1818 05 00 00

–1

HYDRONIC

D 5 W Z – 12 V 25 2216 05 00 00

As complete package:

1 1 Heater --- 2 1 Dosing pum ----

To be ordered separately:

3 1 Heater bracket 25 2220 80 00 01

4 1 Central screw 100 10 258

5 4 Metal-rubber puffer 20 1185 00 00 01

6 1 Water hose Ø 20 25 1917 80 00 01

7 2 Connector Ø 20 mm 20 1534 88 00 01

8 p.m. Pipe 3,5 x 3 360 75 300

9 p.m. Pipe 4 x 1,25 090 31 118

10 1 Pipe clip 22 1000 50 05 00

11 1 Hose clip 10 2064 01 60 25

12 1 Flexible exhaust pipe 25 1774 80 02 00

13 1 Combustion air hose 360 00 099

14 1 End sleeve 25 1688 80 12 01

15 1 Plug 22 1000 30 10 21

16 1 Receptacle housing 22 1000 31 87 00

17 1 Bracket 22 1000 50 03 00

18 1 T-piece 8-6-8 262 31 151

19 2 Support sleeve 22 1000 20 02 00

20 p.m. Hose 7,5 x 2,5 360 31 070

21 p.m. Hose 5 x 3 360 75 350

22 p.m. Pipe 6 x 2 090 31 125

23 1 Fuse holder 22 1000 31 06 00

9

Scope of supply

Product information

2

10

Product information

2

Caution!

Safety instructions for technical data!

Failure to comply with the technical data

can result in malfunctions.

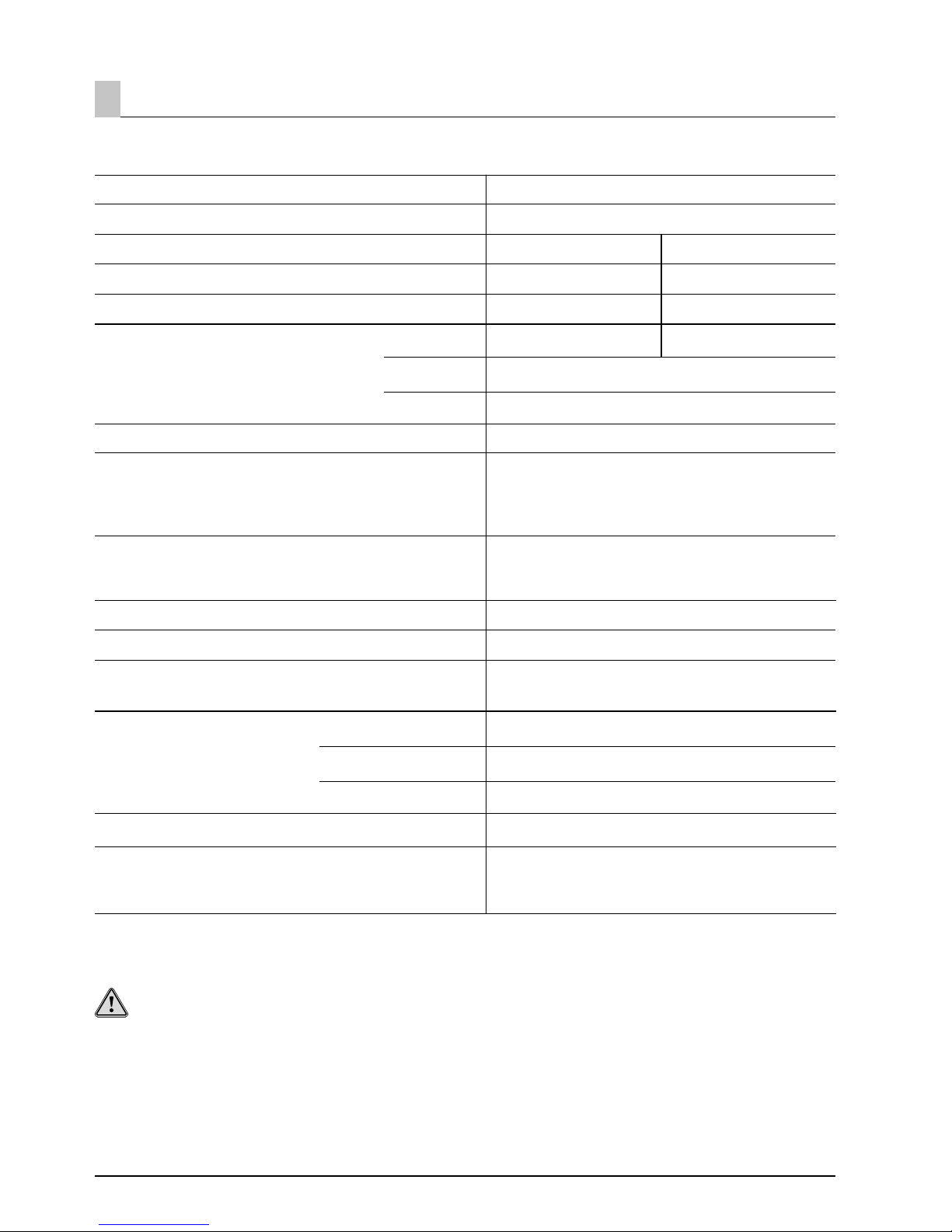

Technical data for petrol heaters

Heater B 5 W Z

Heating medium Water, cooling fluid

Control of the heat flow Large Small

Heat flow (watt) 5000 1500

Fuel consumption (l/h) 0.69 0.2

Mean electr. power (watt) in operation 37 10

at start 110

after-running 8

Rated voltage 12 volt

Operating range

• Lower voltage limit: An undervoltage protection 10.2 volt

in the controller switches the heater off on

reaching approx 10 volt.

• Upper voltage limit: An overvoltage protection

in the controller switches the heater off on 16 volt

reaching approx 16 volt.

Tolerable operating pressure up to 2.5 bar overpressure

Minimum water flow rate of the heater 250 l/h

Fuel commercially available petrol

(see also fuel supply, page 24). (DIN EN 228)

Tolerable operating temperature operation heater –40 °C to +80 °C

operating, dosing pump –40 °C to +20 °C

storage –40 °C to +105 °C

Interference suppression class 5 for VHF, SW, MW, 2 for LW

Weight

• without controller and cooling fluid ca. 2.3 kg

• with dosing pump and water pump ca. 2.5 kg

All technical data ±10 %

11

Product information

2

Technical data for diesel heaters

Heater D 5 W Z

Heating medium Water, cooling fluid

Control of the heat flow Large Small

Heat flow (watt) 5000 2400

Fuel consumption (l/h) 0.62 0.27

Mean electr. power (watt) in operation 37 10

at start 110

after-running 8

Rated voltage 12 volt

Operating range

• Lower voltage limit: An undervoltage protection 10.2 volt

in the controller switches the heater off on

reaching approx 10 volt.

• Upper voltage limit: An overvoltage protection

in the controller switches the heater off on 16 volt

reaching approx 16 volt.

Tolerable operating pressure up to 2.5 bar overpressure

Minimum water flow rate of the heater 250 l/h

Fuel commercially available diesel

(see also fuel supply, page 24). (DIN EN 590)

Tolerable operating temperature operation heater –40 °C to +80 °C

operating, dosing pump –40 °C to +80 °C

storage –40 °C to +105 °C

Interference suppression class 5 for VHF, SW, MW, 2 for LW

Weight

• without controller and cooling fluid ca. 2.3 kg

• with dosing pump and water pump ca. 2.5 kg

Caution!

Safety instructions for technical data!

Failure to comply with the technical data

can result in malfunctions.

All technical data ±10 %

12

Main dimensions

Product information

2

Fuel

inlet

Water: inlet / outlet

Combustion

air inlet

Exhaust outlet

13

Installation example

Diesel heater in a truck and in a delivery van

Heater

Exhaust silencer

Combustion air hose

Fuse holder

Dosing pump

Fuel suction pipe

T-piece

Installation location

The installation location for the heater is the engine

compartment. The heater must be mounted below the

min. cooling water level (compensation tank, cooler,

vehicle heat exchanger) for automatic venting of the

heat exchanger of the heater.

• The regulations and safety instructions to be

observed for this chapter are stated on page 4 – 7.

• The installation suggestions made in the

installation instructions are examples. Other

installation locations are possible if they

correspond to the installation requirements stated

in these installation instructions.

• Other installation information (e.g. for boats and ships)

is available from the manufacturer on request.

• Observe the tolerable installation position together

with the operating and storage temperatures.

Installation

3

Heater

Exhaust pipe

Combustion air intake silencer

Fuse bracket

Dosing pump

Fuel suction pipe

Installation example

Petrol heater / diesel heater in a car

Please note!

14

Installation

3

Mounting and fastening

Position the heater in the holding clips of the heater

bracket and fasten with fastening screw, M6 x 97

(torque 6

0.5

Nm). Mount the heater bracket in a suitable

position in the engine compartment, possibly using

anti-vibration pads if necessary.

Depending on the installation space available, the

heater can be moved sideways in the bracket and

screwed in one of the two fastening threads.

Possible installation positions

The heater should preferably be installed in the normal

position, horizontal with the exhaust connection down

to the bottom. Depending on the installation

conditions, the heater can also be mounted in the

permitted swivel range, see diagram.

Heater in normal position with

permitted swivel range

Swivel range from the normal position

up to max. 90° swivel upwards.

Swivel range from the normal position to

max. 90° swivel around the longitudinal axis.

When the heater is operating, the shown normal or

maximum installation positions can be varied briefly

by up to +15° in all directions. Such deviations

caused by the inclined position of the vehicle do not

impair the heater functions in any way.

Please note!

Heater

Bracket clips

Bracket holder

Fastening screw

fastening thread

15

Nameplate

The nameplate is fastened to the front of the heater.

The second nameplate (duplicate) is included in the

scope of supply of the heater.

If required, the duplicate nameplate can be adhered

in a clearly visible position on the heater or near to

the heater.

The regulations and safety instructions to be

observed for this chapter are stated on page 5.

Installation

3

Original nameplate

2nd nameplate (duplicate)

Please note!

16

Installation

3

Connection to the cooling water circuit

The heater is connected to the cooling water circuit

in the water feed pipe from the vehicle engine to the

heat exchanger. There are four possible alternative

installations here.

Danger!

Risk of injuries and burns!

It is possible for the coolant and components of the

coolant circuit to get very hot.

• Parts conveying water must be routed and fastened

in such a way that they pose no temperature risk to

man, animals or material sensitive to temperature

from radiation / direct contact.

• Before working on the coolant circuit, switch the

heater off and wait until all components have cooled

down completely, if necessary where safety gloves.

• When installing the heater and the water pump,

please note the direction of flow of the coolant

circuit.

• Fill the heater and water hoses with coolant before

connecting to the coolant circuit.

• Route the water hoses without any kinks, and in a

rising position if possible.

• When routing the water pipes, observe a sufficient

clearance to hot vehicle parts.

• Protect all water hoses / water pipes from chafing

and from extreme temperatures.

• Secure all hose connections with hose clips

(tightening torque = 1.5 Nm).

• After the vehicle has been operating for 2 hours or

travelled 100 km, tighten the hose clips again.

• The minimum water flow rate is only guaranteed if

the temperature difference of the heating medium

does not exceed 10 K between water inlet and water

outlet during heating.

• Only overpressure valves with an opening pressure

of min. 0.4 – max. 2 bar may be used in the coolant

circuit.

• The coolant liquid must contain at least 10 %

antifreeze all year round as corrosion protection.

• The cooling liquid must contain sufficient antifreeze

for low temperatures.

• Before commissioning the heater or after changing

the cooling liquid, the whole coolant circuit including

heater must be vented free of bubbles according to

the instructions issued by the vehicle manufacturer.

• Only top up with coolant approved by the vehicle

manufacturer.

Please note!

17

Installation

3

Heating characteristics

The heater starts in the "LARGE" setting.

Once the cooling water temperature has reached

approx. 80 °C, depending on the selected fan

setting, the heater switches to the "SMALL" setting.

If the heating output is inadequate in the "SMALL"

setting, the cooling water temperature falls to 75 °C:

the heater then switches back to the "LARGE"

settings.

If the heating output is sufficient in the "SMALL"

setting, the cooling water temperature increases to

85 °C: the heater switches to the pause setting.

Once the cooling water has cooled down to 75 °C in

the pause setting, the cycle starts up again in the

"LARGE" setting.

Connection to the cooling water circuit

Integrate the heater in the water feed pipe from

the vehicle engine to the heat exchanger “inline

connection”

Disconnect the water feed pipe from the vehicle engine

to the vehicle heat exchanger. Connect up the heater

with connection pieces and water hoses to the water

feed pipe.

Route and connect a water hose from the pressure

connection of the water pump to the water intake

connection of the heater.

Secure both connection parts with hose clips.

Heater

Connection piece

Heat exchanger

Vehicle engine

18

Installation

3

Exhaust system

(Exhaust diagram see page 19).

Mounting the exhaust system

The scope of supply of the universal installation kit

includes a flexible exhaust pipe, inner Ø 24 mm,

1000 mm long and an exhaust silencer.

The flexible exhaust pipe can be shortened to 20 cm

or lengthened to max. 2 m, depending on the

installation conditions.

Fasten the exhaust silencer to a suitable position in

the vehicle. Route the flexible exhaust pipe from the

heater to the exhaust silencer and fasten with pipe

clips. If necessary, also fasten the flexible exhaust

pipe with pipe clips at suitable positions in the vehicle.

Connect the exhaust end pipe to the exhaust silencer

with an end sleeve and fasten with a pipe clip.

Caution!

Safety instructions!

The whole exhaust system gets very hot during and

immediately after the heater has been working in the

heating mode. This is why the exhaust system must

be routed according to these installation instructions.

• The exhaust outlet must end in the open air.

• The exhaust pipe must not protrude beyond the

lateral limits of the vehicle.

• Install the exhaust pipe sloping slightly downwards.

If necessary, make a drain hole approx. Ø 5 mm at

the lowest point to drain off condensation.

• Important functional parts of the vehicle must not be

impaired (keep sufficient clearance).

• Mount the exhaust pipe with sufficient clearance to

heat-sensitive parts. Pay particular attention to fuel

pipes (plastic or metal), electrical cables and brake

hoses etc.!

• Exhaust pipes must be fastened safely

(recommended clearance of 50 cm) to avoid damage

from vibrations.

• Route the exhaust system so that the emitted fumes

are not sucked in with the combustion air.

• The mouth of the exhaust pipe must not get clogged

by dirt and snow.

• The mouth of the exhaust pipe must not point in the

direction of travel.

• Always fasten the exhaust silencer to the vehicle.

Danger!

Risk of injuries and burns!

Every type of combustion produces high temperatures

and toxic exhaust fumes. This is the reason why the

exhaust system must be installed according to these

instructions.

• Do not perform any work on the exhaust system

while the heater is working.

• Before working on the exhaust system, first switch

the heater off and wait until all parts have cooled

down completely, wear safety gloves if necessary.

• Do not inhale exhaust fumes.

• Comply with the regulations and safety instructions

for this chapter on page 4 – 7.

• If a silencer is fitted, the exhaust end pipe must be

much shorter than the flexible exhaust pipe between the heater and the exhaust silencer.

Please note!

19

Installation

3

Heater

Combustion air pipe

Exhaust pipe

End sleeve

Caution!

Safety instructions for the combustion air system

• The combustion air opening must be free at all

times.

• Position the combustion air intake to be sure that

exhaust fumes cannot be sucked in with the

combustion air.

• Do not arrange the combustion air intake to

pointing against the wind blast.

• The combustion air intake must not get clogged

with dirt and snow.

• Install the combustion air intake system sloping

slightly downwards. If necessary, make a drain

hole approx. Ø 5 mm at the lowest point to drain

off condensation.

Combustion air system

Mounting the combustion air system

The heater is mounted in the engine compartment, as

described in these instructions.

If the intake connection for combustion air is in a

position where the combustion air can be expected to

be no warmer than 25°C and whether neither splashed

water nor dust / dirt are expected, then no combustion

air hose is required.

Otherwise a flexible combustion hose must be

mounted with an inner Ø 20 mm and up to 1.5 m long,

to ensure that the intake of combustion air comes

from an area which complies with the above

conditions.

After completing all work, push an end sleeve over

the intake silencer / flexible pipe.

Comply with the regulations and safety instructions

for this chapter on page 4 – 7.

Please note!

min. 20 cmmax. 1.5 m to max. 2 m

20

Installation

3

Correct connection

Incorrect connection – bubble formation

Fuel supply

Mounting the dosing pump, routing the fuel pipes

and mounting the fuel tank

The following safety instructions must be observed

when mounting the dosing pump, routing the fuel pipes

and mounting the fuel tank.

Deviations from the instructions stated here are not

allowed.

Failure to comply can result in malfunctions.

Danger!

Risk of fire, explosion, poisoning and injuries!

Caution when handling fuel.

• Switch off the vehicle engine and heater before

refuelling and before working on the fuel supply.

• No naked lights when handling fuel.

• Do not smoke.

• Do not inhale petrol fumes.

• Avoid any contact with the skin.

Caution!

Safety instructions for routing the fuel pipes!

• Only use a sharp knife to cut off fuel hoses and

pipes.

Interfaces must not be crushed and must be free

of burrs.

• The fuel pipe from the dosing pump to the heater

should be routed at a continuous rise.

• Fuel pipes must be fastened safely to avoid any

damage and / or noise production from vibrations

(recommended clearance of approx. 50 cm).

• Fuel pipes must be protected from any mechanical

damage.

• Route the fuel pipes so that any distortion of the

vehicle, engine movements etc. cannot have any

lasting effect on the service life.

• Parts carrying fuel must be protected from

interfering heat.

• Never route or fasten the fuel pipes to the heater or

vehicle exhaust system. When the systems cross,

always ensure there is a sufficient heat clearance.

If necessary, install heat deflection plates.

• Dripping or evaporating fuel must never be allowed

to collect on hot parts or ignite on electric systems.

• When connecting fuel pipes with a fuel hose, always

mount the fuel pipes in a butt joint to prevent any

bubbles from forming.

Safety instructions for fuel pipes and fuel tanks

in buses and coaches

• In buses and coaches, fuel pipes and fuel tanks

must not be routed through the passenger

compartment or driver’s cab.

• Fuel tanks in buses and coaches must be

positioned in such a way that the exits are not in

direct danger from a possible fire.

Comply with the regulations and safety instructions

for this chapter on page 4 – 7.

Please note!

21

a

8

b

Installation

3

Fuel feed point with T-piece from the fuel supply line

from the tank fitting to the vehicle engine

Fuel feed pipe from tank connection – insert

T-piece before the fuel pump in the fuel feed pipe.

Fuel return pipe to the tank connection.

Dosing pump

T-piece, 8-6-8

Fuel filter – only necessary for contaminated fuel.

Fuel hose, 5 x 3 (di = Ø 5 mm)

Fuel pipe, 6 x 2 (di = Ø 2 mm)

Fuel pipe, 4 x 1.25 (di = Ø 1.5 mm)

Fuel hose, 5 x 3 (di = Ø 5 mm),

approx. 50 mm long

Fuel hose, 3.5 x 3 (di = Ø 3.5 mm),

approx. 50 mm long

To the engine, mechanical fuel or injection pump.

Possible pipe lengths

Intake side Pressure side

a = max. 2 m b = max. 4 m for petrol

b = max. 6 m for diesel

Fuel supply for petrol heaters

Installation position of the T-piece

Use the installation positions shown in the diagram

when inserting a T-piece.

Direction of flow from the fuel tank

Direction of flow to the vehicle engine

22

a

10

b

Installation

3

Fuel feed point with tank connection –

ascending pipe, integrated in the vehicle tank

Tank connection for metal tank –

di = Ø 2 mm, da = Ø 6 mm

Tank connection for tank fitting –

di = Ø 2 mm, da = Ø 4 mm

Dosing pump

Fuel filter – only required for contaminated fuel.

Fuel hose, 5 x 3 (di = Ø 5 mm)

Fuel pipe, 6 x 2 (di = Ø 2 mm)

Fuel hose, 4 x 1 (di = Ø 2 mm)

Fuel hose, 3.5 x 3 (di = Ø 3.5 mm),

approx. 50 mm long

Fuel hose, 5 x 3 (di = Ø 2 mm),

approx. 50 mm long

Fuel pipe, 4 x 1.25 (di = Ø 1.5 mm)

Connection fitting, da = Ø 4 mm

Possible pipe lengths

Intake side Pressure side

a = max. 2 m b = max. 4 m for petrol

b = max. 6 m for diesel

Items are included in the “tank connection “ kit

(order no. 22 1000 20 07 00).

Fuel supply for petrol heaters

Caution!

Safety instructions for the fuel supply!

• The fuel must not be conveyed by gravity or

overpressure in the fuel tank.

• Withdrawal of fuel after the vehicle’s fuel pump is

not allowed.

• When the pressure in the fuel pipe is more than

0.2 bar to max. 2 bar, use a pressure reducer

(order no. 22 1000 20 08 00) or separate tank

connection.

• When the pressure in the fuel pipe is more than

2 bar or there is a non-return valve in the return pipe

(in the tank), a separate tank connection must be

used.

• When using a T-piece in a plastic pipe, always use

support sleeves in the plastic. Connect the T-piece

and the plastic pipe with corresponding fuel hoses

and secure with hose clips.

Please note!

23

Possible suction and pressure height

of the dosing pump

Pressure height from vehicle tank to dosing pump:

a = max. 3000 mm

Intake height in pressure-less vehicle tank:

b = max. 500 mm for petrol

b = max. 1000 mm for diesel

Intake height in vehicle tanks with withdrawal by

negative pressure (valve with 0.03 bar in tank cap):

b = max. 150 mm for petrol

b = max. 400 mm for diesel

Pressure height of the dosing pump to the heater:

c = max. 2000 mm

Check tank venting.

Connection to heater

Max. fuel level

Min. fuel level

Installation

3

Fuel supply

Installation position of the dosing pump

Always mount the dosing pump with the pressure side

rising upwards. Every installation position over 15° is

allowed, although an installation position between 15°

and 35° is preferable.

Installation position between 0° and 15°

is not allowed.

Preferred installation position in range 15° to 35°.

Installation position in range 35° to 90° is

allowed.

Caution!

Safety instructions for installing

the dosing pump

• Always mount the dosing pipe with the pressure

side rising upwards – minimum incline 15°.

• Protect the dosing pump and filter from intolerable

heat, do not mount near to the silencers and

exhaust pipes.

Please note!

24

Installation

3

Fuel supply

Fuel quality for petrol heaters

The heater can run on commercially available fuel

as per DIN EN 228, as used in the vehicle tank.

Fuel quality for diesel heaters

The heater can run on commercially available fuel

as per DIN EN 590, as used in the vehicle tank.

Fuel for special cases

In special cases (above 0°C), the heater can also

run on fuel oil EL or paraffin.

Fuel for low temperatures

Refineries and fuel service stations automatically

adjust the fuel to normal winter temperatures (winter

diesel). This means that difficulties are only to be

expected for extreme drops in temperature, as also

apply to the vehicle engine. Please also refer to the

vehicle manual.

If the heater is run from a separate tank, please

comply with the following rules:

For temperatures above 0°C, any kind of diesel fuel

as per DIN EN 590 can be used.

If no special diesel fuel is available for low

temperatures, then paraffin or petrol should be mixed

with the fuel according to the following table:

Temperature Winterdiesel Addition

0 °C to –25 °C 100 % –––

–25 °C to –40 °C 50 %* 50 % paraffin

or petrol

* or 100% special cold diesel fuel (Arctic diesel)

Please note!

• Mixtures with used oil are not allowed!

• After refuelling with winter or cold diesel or the listed

blends, the fuel pipes and the dosing pump must be

filled with the new fuel by letting the heater run for

15 mins.!

Operation with biodiesel (PME)

The heater is not certified for operation with biodiesel.

25

Operation and function

4

Operating instructions

If the vehicle engine is not providing enough heat in

the warming-up phase, in city traffic or in traffic

congestion, the heater switches on automatically and

supports the vehicle's own heating system.

Important instructions for operation

Safety checks before the start

After a longer interval in operations (after the summer

months) the fuse must be put in position and / or the

heater connected up to the battery. Check that all

parts fit firmly (tighten screws where necessary).

Check the fuel system visually for any leaks.

Heating at high altitudes

When using the heater at high altitudes, please note:

• Heating at altitudes up to 1500 m:

– Unlimited heating possible.

• Heating at altitudes over 1500 mm:

– Heating is possible for short periods at this

altitude (e.g. driving over a mountain pass or

taking a break in a journey).

– Heating is not possible for longer periods at this

altitude (e.g. winter camping).

Initial commissioning

• After installation of the heater, the coolant circuit

and the whole fuel supply system must be vented

carefully. Comply with the instructions issued by the

vehicle manufacturer.

• Open the coolant circuit before the trial run (se the

temperature control to “OPEN”).

• During the trial run of the heater, check all water and

fuel connections for leaks and firm fitting.

• If the heater shows a fault during operation, find

and eliminate the cause of the fault using a

diagnosis unit.

Description of functions

Switching on (additional heating mode)

After a certain program sequence, the heater starts

the combustion air fan, glow plug and fuel dosing

pump. Once a stable flame has formed in the

combustion chamber, the glow plug switches off again

under time control.

Heating mode

Depending on heating requirements, the heater is

adjusted in the following stages:

LARGE – SMALL – OFF (pause).

The temperature limits are permanently programmed in

the electronic controller.

If the heating requirements in the “SMALL” stage are

so small that the cooling water temperature reaches

85 °C, the heater goes into the pause mode.

The heater continues to run on for approx. 130

seconds, then it switches off (pause mode).

The control lamp lights up and the water pump

continues to run, even in the pause mode.

26

Operation and function

4

Control and safety devices

• If the heater does not ignite within 90 seconds

after starting the fuel pump, the start is repeated.

If the heater still does not ignite after another

90 seconds, the heater is switched off. After an

unacceptable number of failed start attempts, the

controller is locked.*

• If the flame goes off by itself during operation, the

heater is restarted.

If the heater does not ignite within 90 seconds

after the fuel pump has started again, the heater is

switched off.

The fault shutdown can be cancelled by switching

off and on again briefly (ignition ON / OFF).

• In the case of overheating (e.g. lack of water, poorly

vented coolant circuit), the overheating sensor

triggers, the fuel supply is interrupted and the heater

switched off.

Once the cause of overheating has been eliminated,

the heater can be started by switching off and on

again (ignition ON / OFF), on condition that the

heater has cooled down again sufficiently, cooling

water temperature <70 °C.

After the heater has been switched off for

overheating an unacceptable number of times,

the controller is locked.*

• The heater is switched off if the upper or lower

voltage limit is reached.

• The heater does not start up when the glow plug is

defect or when the electric lead to the dosing pump

is interrupted.

• The speed of the fan motor is monitored continuously.

If the fan motor does not start up, if it is blocked or if

the speed falls below 40 % of the nominal speed, the

heater is switched off after 60 sec.

* The controller can be enabled again and the faults

read off:

• by connecting up a diagnosis unit

• using the customer service program KD2000.

For operation and fault list, please refer to the

enclosed operating instructions or the troubleshooting

and repair instructions for the heater.

Do not switch the heater off and on again more than

twice.

Emergency shutdown – EMERGENCY OFF

If an emergency shutdown – EMERGENCY OFF –

is necessary during operation, proceed as follows:

• Switch heater off (ignition OFF)

• pull the fuse out or

• disconnect the heater from the battery.

Please note!

27

Electrical system

5

Heater wiring

Caution!

Safety instructions for wiring the heater!

The heater is to be connected up electrically

according to the EMC directives.

EMC can be affected if the heater is not connected up

correctly. For this reason, comply with the following

instructions:

• Ensure that the insulation of electrical cables is not

damaged. Avoid: chafing, kinking, jamming or

exposure to heat.

• In waterproof connectors, seal any connector

chambers not in use with filler plugs to ensure they

are dirt-proof and water-proof.

• Electrical connections and ground connections must

be free of corrosion and firmly connected.

• Lubricate connections and ground connections

outside the heater interior with contact grease.

Comply with the following when wiring the heater and the

control element:

• Electrical leads, switchgear and controllers must be

arranged in the vehicle so that they can function

perfectly under normal operating conditions

(e.g.heat exposure, moisture etc.).

• The following cable cross sections are to be used

between the battery and heater. This ensures that

the max. tolerable voltage loss in the cables does

not exceed 0.5 V for 12 V or 1 V for 24 V rated

voltage.

Cable cross sections for a cable length of:

– up to 5 m (plus cable + minus cable) =

cable cross section 4 mm²

– from 5 to 8 m (plus cable + minus cable) =

cable cross section 6 mm²

• If the plus cable is to be connected to the fuse box

(e.g. terminal 30), the vehicle cable from the battery

to the fuse box must be included in rating the overall

cable length and possibly re-dimensioned if

necessary.

• Insulate unused cable ends.

Please note!

28

Electrical system

5

Parts list

1.1 Burner motor

1.2 Glow plug

1.5 Overheating sensor

1.12 Flame sensor

1.13 Temperature sensor

2.1 Control unit

2.2 Dosing pump

2.7 Main fuse 25 A

5.1 Battery

a) Diagnosis

b) +15

Option: a temperature switch and / or an

ON / OFF switch can be fitted in this line.

c) Alternator (AC)

Connectors and bush housings are shown

from the cable inlet side.

Cable colours

rt = red

bl = blue

ws = white

sw = black

gn = green

gr = grey

ge = yellow

vi = violet

br = brown

li = purple

Circuit diagram

25 1988 00 96 01 C

29

Troubleshooting / Maintenance / Service

6

In case of faults, please check the following

points

• If the heater does not start after being switched on:

– Switch the heater off and on again.

• If the heater still does not start, check whether:

– There is fuel in the tank?

– The fuses are OK?

– The electrical cables, connections etc. are OK?

– Anything is clogging the combustion air supply

or exhaust system?

Troubleshooting

If the heater remains faulty even after these points

have been checked, or another malfunction occurs

in your heater, please contact:

• For installation ex works, your contract workshop.

• For subsequent installation, the workshop who

installed your heater.

Please note that warranty claims can be become void

if the heater is changed by a third party or by this

installation of third party parts.

Maintenance instructions

• Before the heating period starts, the heater should

undergo a trial run. If persistent extreme smoke

develops, unusual burning noises or a clear fuel

smell can be perceived or if electric / electronic

parts heat up, the heater must be switched off and

put out of service by removing the fuse.

In this case, the heater should not be started up

again until it has been checked by qualified staff

who have been trained on Eberspächer heaters.

• Check the openings of the combustion air supply

and exhaust system after longer standstill periods,

clean if necessary!

Service

If you have any technical queries or problems with your

pre-heater, dial the following service phone number:

Hotline

Phone. 0800 / 12 34 300

Fax hotline

Fax 01805 / 26 26 24

Please note!

30

Environment

7

EU Declaration of Conformity

With regard to the following products

heater type

HYDRONIC

we herewith confirm that it conforms with the prime

safety requirements stipulated in the directives of the

EU Council for harmonisation of the legal regulations

of the member states with regard to electromagnetic

compatibility (89 / 336 / EEC).

This declaration applies to all heaters produced

according to the production drawings

HYDRONIC

which are an integral part of this declaration.

The following standards/directives have been used to

assess the product with regard to electromagnetic

compatibility:

• EN 50081 – 1 Basic form interference emission.

• EN 50082 – 1 Basic form interference resistance.

• 72 / 245 / EEC – Modification status 95 / 54 / EU

interference suppression in motor vehicles.

Certification

The high quality of Eberspächer’s products is the key

to our success.

To guarantee this quality, we have organised all work

processes in the company along the lines of quality

management (QM).

Even so, we still pursue a large number of activities

for continuous improvement of product quality in order

to keep pace with the similarly constantly growing

requirements made by our customers.

All the steps necessary for quality assurance are

stipulated in international standards.

This quality is to be considered in a total sense.

It affects products, procedures and customer/supplier

relationships.

Officially approved public experts assess the system

and the corresponding certification company awards

a certificate.

Eberspächer has already qualified for the following

standards:

Quality management as per

DIN EN ISO 9001:2000 and ISO/TS 16949:1999

Environment management system as per

DIN EN ISO 14001:1996

Disposal

Disposal of materials

Old devices, defect components and packaging

material can all be separated and sorted into puregrade factions so that all parts can be disposed of as

required in an environment-friendly manner or recycled

where applicable.

Electric motors, controllers and sensors (e.g.

temperature sensors) are deemed to be “electronic

scrap”.

Dismantling the heater

The heater is dismantled according to the repair

stages in the current troubleshooting/repair

instructions.

Packaging

The packaging of the heater can be kept in case

it has to be sent back.

31

Lists

8

List of key words A – Z

Keyword Page

A

Accident prevention ................................................... 7

Arrangement of the heater ......................................... 5

B

Biodiesel (PME) ......................................................... 24

Bubble formation ...................................................... 24

C

Cable colours ........................................................... 28

Certification .............................................................. 30

Circuit diagram .......................................................... 28

Combustion air system ............................................. 19

Concept of this manual .............................................. 3

Connection cooling water circuit ........................ 16, 17

Control and safety devices ...................................... 26

D

Description of functions ........................................... 25

Disposal .................................................................... 30

Dosing pump ............................................................. 23

E

Electrical system .............................................. 27 – 28

Electronic components ...................................... 33, 34

Emergency shutdown ................................................ 26

Environment .............................................................. 30

EU Decleration .......................................................... 30

EU Type Permit ............................................................ 5

Exhaust system ........................................................ 18

F

Fastening .................................................................. 16

Fuel supply ....................................................... 20 – 24

Fuel quality ............................................................... 24

G

Guarantee ................................................................ 31

H

Heater wiring ............................................................. 27

Heating operation ..................................................... 31

Heating mode ........................................................... 25

I

Initial commissioning ................................................ 25

Installation ........................................................ 13 – 24

Installation example ................................................. 13

Installation location .................................................. 13

Introduction ......................................................... 2 – 7

Keyword Page

L

Liability ..................................................................... 31

List of abbrevations ................................................. 32

M

Main dimensions ....................................................... 12

Maintenance instructions ......................................... 29

Mounting and fastening ............................................ 14

Mounting the exhaust system .................................. 18

N

Nameplate ................................................................ 15

O

Operating instructions .............................................. 25

Operation and function ..................................... 25 – 26

Operating status display ............................................ 5

P

Parts list ................................................................... 28

Picture symbols .......................................................... 4

Place of jurisdiction .................................................. 31

Possible pipe lengths ......................................... 21, 22

Power consumption ............................................ 10, 11

Presentations ............................................................. 4

Product information ............................................ 8 – 12

Proper use .................................................................. 4

Protection .......................................................... 10, 11

Purpose ...................................................................... 4

R

Rated voltage .................................................... 12, 13

Regulation ............................................................. 5, 6

S

Safety checks .......................................................... 25

Safety instructions ................................................ 6, 7

Scope of supply ..................................................... 8, 9

Service ..................................................................... 29

Special text structure ................................................. 4

Statutory regulations ............................................. 5, 6

Storage temperature .......................................... 10, 11

Switching on ............................................................. 25

32

Lists

8

List of key words A – Z

Keyword Page

T

Technical data ................................................... 10, 11

Text structure ............................................................. 4

T-piece ...................................................................... 21

Troubleshooting ........................................................ 29

V

Voltage .............................................................. 10, 11

Voltage limit ....................................................... 10, 11

W

When faults occur .................................................... 29

List of abbreviations

EC type approval

Permit awarded by the Federal Vehicle Office for the

production of a heater for installation in motorised

vehicles.

EMC directive

Electromagnetic compatibility.

JE partner

J. Eberspächer partner.

PME

Biodiesel as per DIN V 51606.

Loading...

Loading...