Page 1

1

D

S

GB

F

J. Eberspächer

GmbH & Co.

Eberspächerstr. 24

D - 73730 Esslingen

Telefon (zentral)

(0711) 939 - 00

Telefax

(0711) 939 - 0500

www.eberspaecher.com

Contents Page

Items supplied .......................................................... 2, 3

Control elements, optional ........................................ 2

Government regulations and

safety instructions concerning installation .............. 4

Technical data ........................................................... 5

Sectional drawing ..................................................... 6

Principal dimensions / Installation ........................... 7

Mounting instructions / mounting example ................ 8, 9

Permissible mounting positions ............................... 10

Documentation

for installation*

Eberspächer®

Page

Type plate .................................................................. 10

Connection to the cooling water circuit ..................... 11 – 14

Conducting the combustion air / exhaust gas ........ 15

Fuel supply ................................................................ 16 – 19

Circuit diagrams ........................................................ 20 – 25

Function ..................................................................... 26

Controls and safety devices ..................................... 27

GGVS / TRS 003 / ADR / ADR 99 –

mode of operation ..................................................... 27

* Please hand this technical description / mounting instruction

to the customer after installation of the

HYDRONIC

.

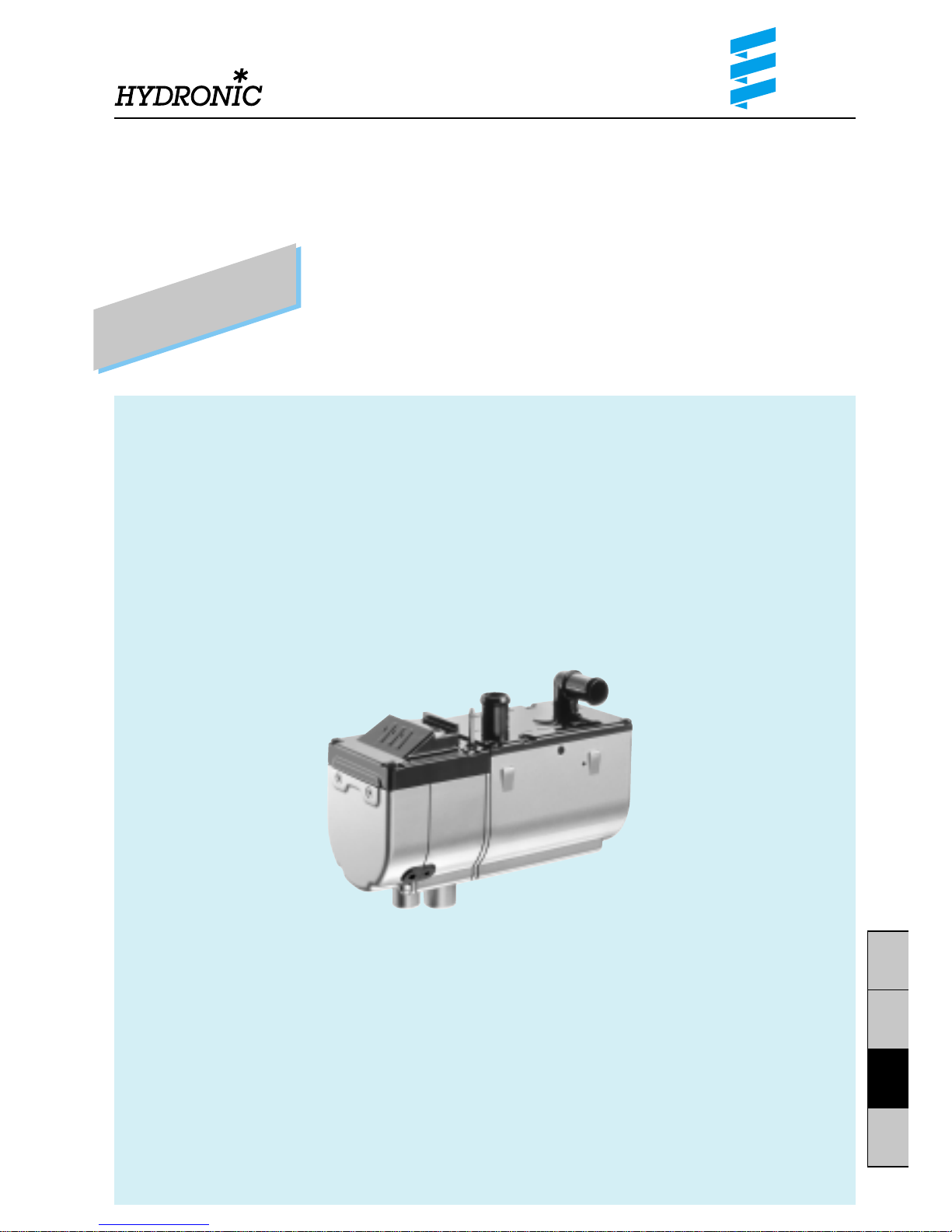

Engine-independent water heater

HYDRONIC

B 5 W S for petrol

Order No.

HYDRONIC

B 5 W S – 12 V 20 1819 05 00 00

Universal mounting kit 20 1819 80 00 00

HYDRONIC

B 5 W S – 12 V 20 1822 05 00 00

As a complete package

Subject to change

B 5 W S and D 5 W S

Technical Description

Mounting Instructions

HYDRONIC

D 5 W S for diesel

Order No.

HYDRONIC

D 5 W S – 12 V 25 2217 05 00 00

Universal mounting kit 20 1819 80 00 00

HYDRONIC

D 5 W S – 12 V 25 2228 05 00 00

As a complete package

HYDRONIC

D 5 W S – 24 V 25 2218 05 00 00

Universal mounting kit 25 2218 80 00 00

Page 2

2

D

S

GB

F

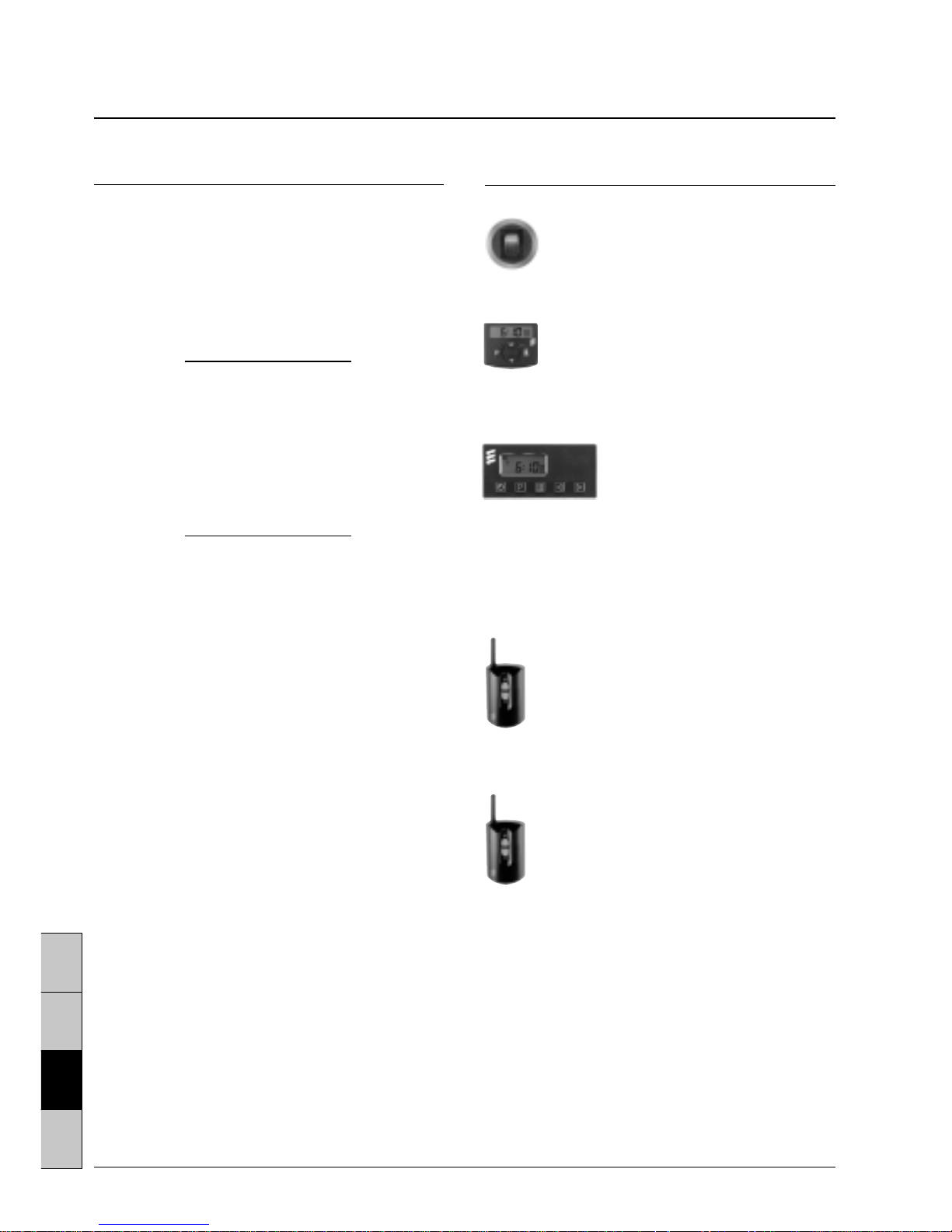

Control elements, optional

Quantity / Designation Order No.

1 Change-over switch 22 1000 31 89 00

‘heating / ventilating’ 12 / 24 volt

Can only be used in combination

with a control element.

1 Mini-clock – 12 / 24 volt 22 1000 31 31 00

1 Module clock – 12 / 24 volt 22 1000 30 34 00

with temperature preselection

1 Mounting parts for the 25 1482 70 01 00

module clock – only required

when installed with a shade

1 TP 41i radio remote control 22 1000 31 39 00

12 / 24 volt

1 TP 4i radio remote control 22 1000 30 99 00

12 / 24 volt

Please note!

Control elements must be selected in accordance

with the intended use of the

HYDRONIC

and on the

basis of the distinction: air or water heater, simple

switching on and off, programme preselection and /

or radio remote control. The control elements are

supplied with operating instructions. These are

intended to be handed over to the customer together

with the mounting and operating instructions for the

HYDRONIC

.

The TP 41i radio remote control

can be used on its own or in combination

with the mini-clock – Order No. 22 1000 31 31 00.

The mini-clock can be combined with

the TP 41i radio remote control.

The module clock can be

combined with the TP 4i

radio remote control.

The TP 4i radio remote control can only be used

in combination with the module clock.

Items supplied

Quantity / Designation Order No.

1

HYDRONIC

B 5 W S – 12 volt 20 1819 05 00 00

To be additionally ordered:

1 Universal mounting kit 20 1819 80 00 00

or

1

HYDRONIC

B 5 W S – 12 volt 20 1822 05 00 00

As a complete package*

1

HYDRONIC

D 5 W S – 12 volt 25 2217 05 00 00

To be additionally ordered:

1 Universal mounting kit 20 1819 80 00 00

or

1

HYDRONIC

D 5 W S – 12 volt 25 2228 05 00 00

As a complete package*

1

HYDRONIC

D 5 W S – 24 volt 25 2218 05 00 00

To be additionally ordered:

1 Universal mounting kit 25 2218 80 00 00

* The complete package consists of:

1

HYDRONIC

B 5 W S or D 5 W S

1 Universal mounting kit

Optional extras

1 Check valve, Ø 18 mm 254 00 070

1 Check valve, Ø 20 mm 254 00 074

1 Comfort mounting kit for engines from 2.5 l

cubic capacity 24 0132 00 00 00

The comfort mounting kit includes the following:

1 thermostat, Ø 18 mm

1 T-piece, Ø 18 mm

1 check valve, Ø 18 mm

1 water hose, Ø 18 mm

10 hose clamps

Please refer to the Extra Parts Catalogue for other

additional parts.

Attention!

Before switching on or preprogramming the heating, put

the vehicle’s heating lever (provided the vehicle is

equipped with one) to “HOT” (maximum position) and

the fan to “slowest speed” (low current consumption).

For vehicles with automatic heating, put the heating

lever to “MAX.” and the desired damper position to

“OPEN” before switching off the ignition.

Page 3

3

D

S

GB

F

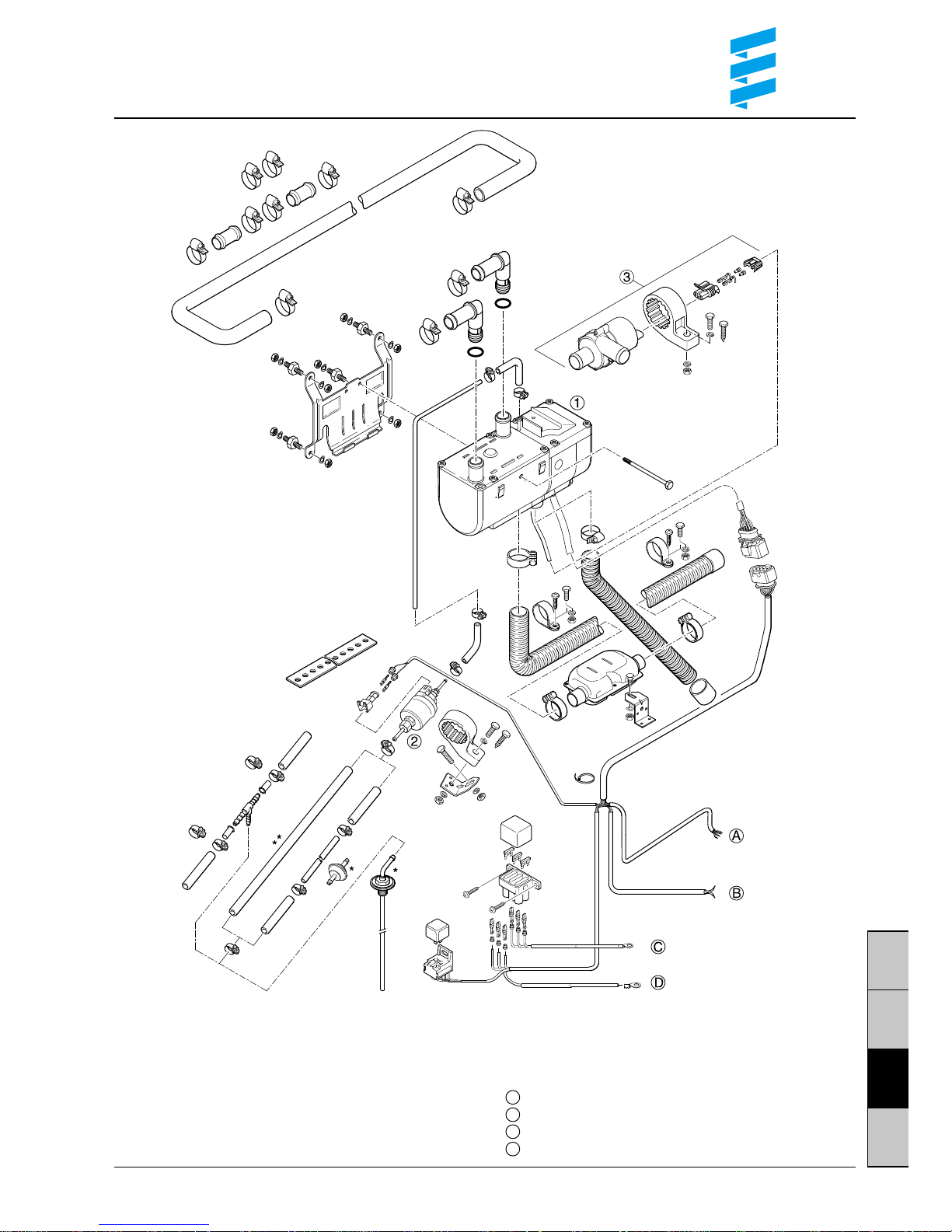

Scope of the delivery

햲

HYDRONIC

B 5 W S / D 5 W S

햳 Dosing pump

햴 Water pump

Parts without drawing number are included

in the universal mounting kit.

* Part only contained in universal mounting kit of

HYDRONIC

24 V.

** Part only contained in universal mounting kit of

HYDRONIC

12 V.

Cable harness “control elements”

Cable harness “fan control”

Positive cable

Negative cable

A

B

C

D

Page 4

4

D

S

GB

F

ATTENTION !

!

§

Safety instructions concerning the

installation and repair of the

HYDRONIC

Danger of burns and injury!

Before commencing any work on the

HYDRONIC

,

disconnect the vehicle battery.

Always switch off the

HYDRONIC

prior to any repair work

and allow hot components to cool down.

Statutory regulations concerning

the installation of the

HYDRONIC

• For installation in motor vehicles subject to the

Regulations authorizing the Use of Vehicles for Road

Traffic (StVZO), the air heater has been approved by

the German Federal Office for Motor Traffic in keeping

with the ‘General Design Certification’ (AGB) and the

official test symbol is marked on the type plate of the

heater.

HYDRONIC

B 5 W S S 288

HYDRONIC

D 5 W S S 274

• The mounting requirements associated with the General Design Certification (AGB) and further statutory

regulations have been printed in the corresponding

sections of these mounting instructions.

• When the air heater is installed in special vehicles, the

regulations governing such vehicles must be taken into

account (e.g. GGVS / TRS 003 / ADR / ADR 99 for

vehicles used to transport dangerous substances).

• The year in which the air heater was operated for the

first time must be permanently recorded on the type

plate. To this end, 3 different years have been printed

on the corresponding field of the type plate. The valid

year is to be identified by removing (detaching) those

two years which are not applicable.

• Heaters have to be installed in accordance with the

mounting instructions. The installation must be

checked by an officially approved specialist or

inspector for road traffic, a motor vehicle specialist or

an employee in accordance with paragraph 7.4 a of the

Annex to the StVZO, and must be certified on the

confirmation of acceptance included in the copy of the

general model approval (ABG) according to

a) § 20 StVZO in case of a type approval of vehicles;

b) § 32 StVZO in case of an individual approval;

c) § 19 StVZO in case of an appraisal.

For case c), the vehicle manufacturer, vehicle model

and vehicle identification number must also be

specified.

The validity of the model approval depends on this.

The confirmation of acceptance must be carried in

the vehicle.

• For vehicles not subject to the StVZO, it is necessary

to observe the specific regulations and mounting

instructions applicable to the given vehicle.

• The heater may only be installed or repaired – in case

of the heater being handed in for repair or guarantee

reasons – by a specialist workshop approved by the

manufacturer (service partner) in keeping with these

mounting instructions and possible special installation

recom-mendations.

• The information sticker ‘Switch off heater before

refuelling’ suppplied with the heater must be attached

in a suitable position on the vehicle (close to the fuel

filler neck).

Important instructions for

the installation and repair

of the

HYDRONIC

When mounting or repairing the heater, only original

accessories and original spare parts may be used.

Changes to the

HYDRONIC

or to components relevant to

the heating, the use of outside parts not approved by

Eberspächer as well as an installation or operation

differing from the statutory, safety and /or function relevant specifications contained in the mounting instructions and in the operating instructions are not permissible:

this applies in particular to the electric wiring (circuit

diagrams), the fuel supply, the combustion air and exhaust gas duct.

Fuel pipes and exhaust pipes must be safely fastened,

to avoid damage from vibrations (recommendation: at

intervals of approx. 50 cm).

Ensure that the insulation of electrical lines cannot be damaged due to abrasion, kinking, squeezing or by exposure

to heat.

Only the control elements provided and / or approved by

us, either on their own or in a given combination, may be

used to operate the

HYDRONIC

. The use of other control

elements may lead to malfunctions of the heater / heating

operation.

Non-compliance with the statutory, safety and / or

function relevant specifications leads to the lapse of the

General Design Certification (ABG) of the

HYDRONIC

and to the exclusion of guarantee and liability on the part

of the company J. Eberspächer GmbH & Co.

Please note!

• Further ‘Safety instructions concerning the installation

and repair of the

HYDRONIC

’ as well as ‘Important

instructions concerning the installation’ have been

printed directly in the corresponding sections of these

mounting instructions.

• The confirmation of acceptance has been enclosed

with the documents for the

HYDRONIC

.

Page 5

5

D

S

GB

F

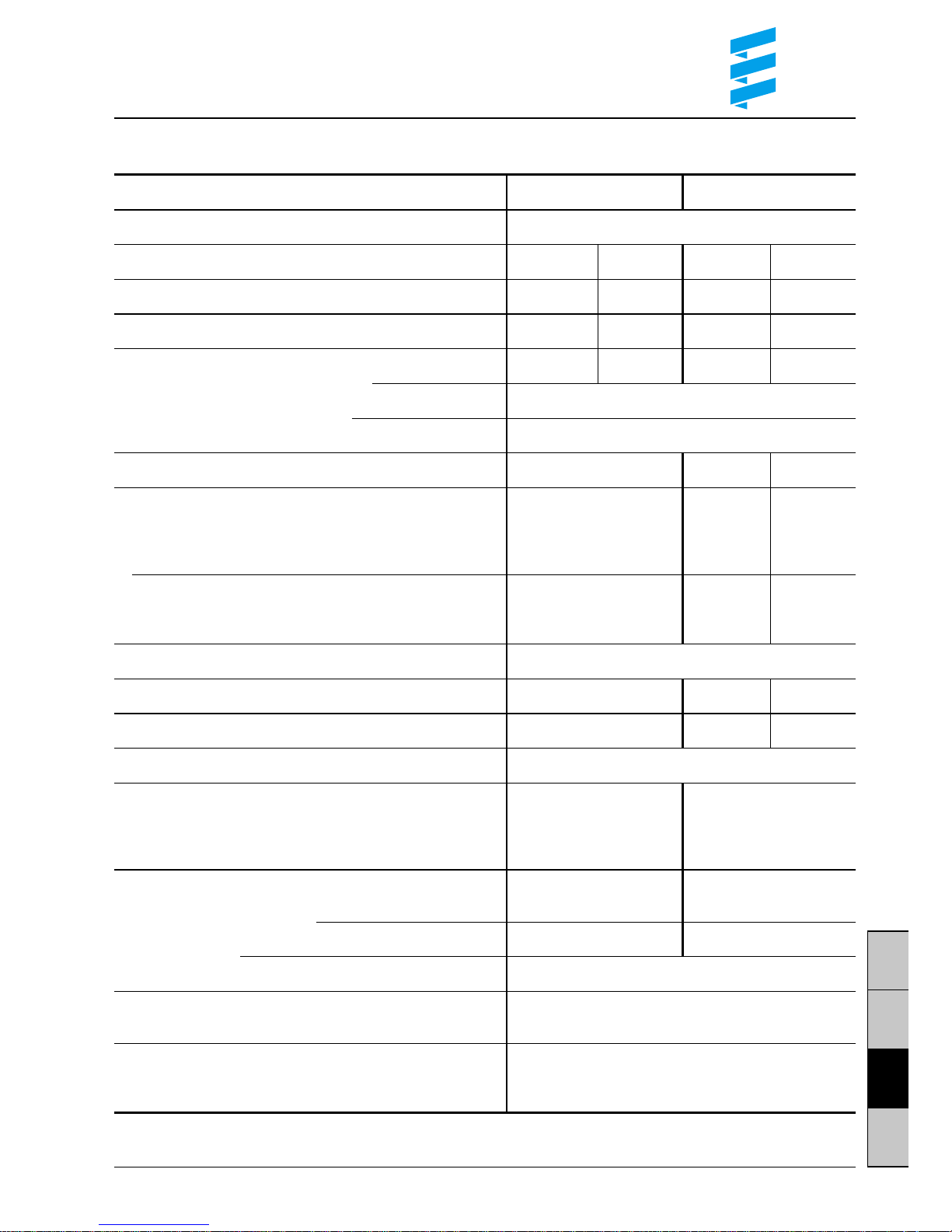

Technical data

Heater B 5 W S D 5 W S

Heating medium Water, glycol compounds

Heat flow settings Large Small Large Small

Heat flow (watt) 5000 1500 5000 2400

Fuel consumption (l/h) 0.69 0.20 0.62 0.27

Electrical input (watt) During operation 37 10 37 10

When starting 110

During after running 8

Rated voltage 12 V 12 V 24 V

Operating range

Lower voltage limit 10.2 V 10.2 V 20.4 V

An under-voltage protecting device in the controller

turns off the heater at approx. 10 V (after 20 seconds)

Upper voltage limit 16 V 16 V 32 V

An over-voltage protecting device in the controller

turns off the heater at approx. 16 V (after 20 seconds)

Permissible working pressure up to 2.5 bar excess pressure

Water throughput of water pump against 0.1 bar 800 l/h 800 l/h 950 l/h

Electric power consumption water pump 16 W 16 W 12 W

Min. water flow rate of heater 250 l/h

Fuel Commercial petrol Commercial diesel fuel

For “Fuel quality” and “Fuel at low temperatures” (to DIN 51600 (to DIN EN 590)

see Operating Instructions and DIN EN 228)

PME (acc. to DIN V 51606)

only at D 5 W S, 24 V

Permissible ambient temperature

Operation –

HYDRONIC

–40 °C to +80 °C –40 °C to +80 °C

Operation – Dosing pump –40 °C to +20 °C –40 °C to +80 °C

Storage –

HYDRONIC

/ Dosing pump –40 °C to +105 °C

Degree of radio interference suppression 5 for VHF / SW / MW

2 for LW

Weight

without water and add on pieces approx. 2.3 kg

including water pump and dosing pump approx. 2.9 kg

All technical data ± 10 %

Page 6

6

D

S

GB

F

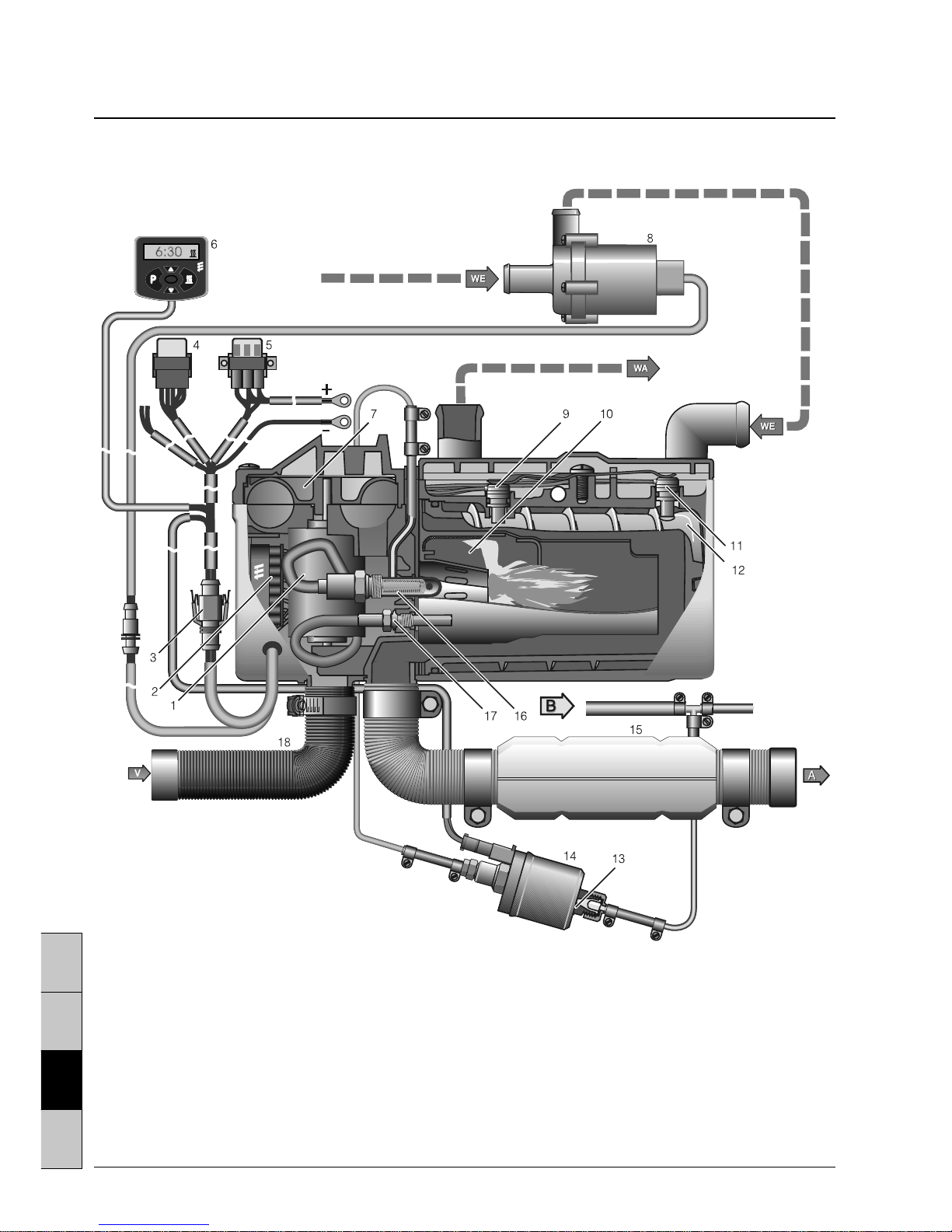

1 Electric motor

2 Controller

3 Intersection /

8-channel connector

4 Relay, vehicle fan

5 Main fuse / fuse holder

6 Module clock

7 Combustion air blower

8 Water pump

9 Temperature probe

A = Exhaust gas

B = Fuel

V = Combustion air

WA = Water outlet

WE = Water inlet

Sectional drawing (shown here is the

HYDRONIC

B 5 W S)

10 Combustion chamber

11 Overheating sensor

12 Heat exchanger

13 Cup strainer, built into dosing pump

14 Dosing pump

15 Exhaust piping with exhaust muffler

16 Glow plug

17 Flame sensor

18 Combustion air tube

from vehicle engine

to heat exchanger

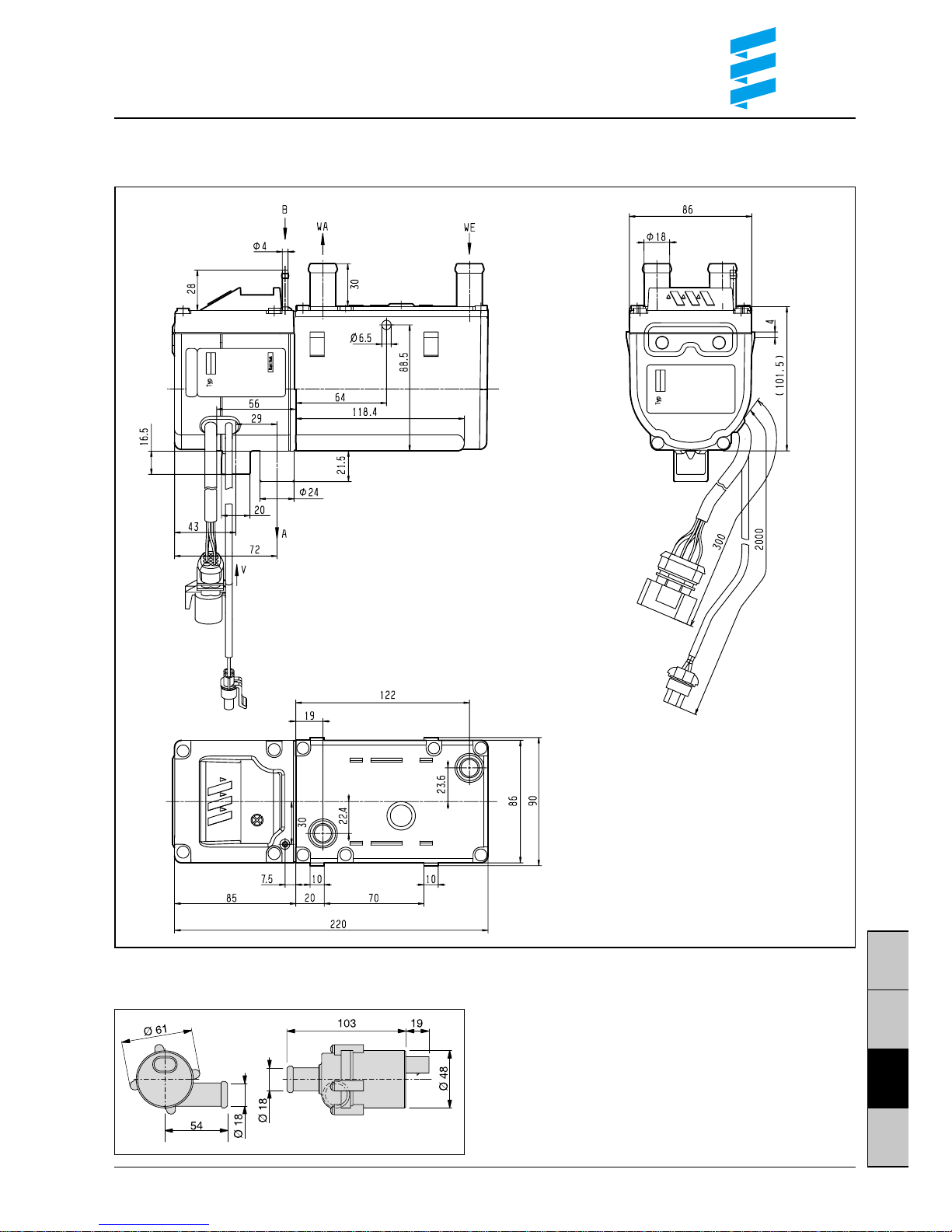

Page 7

7

D

S

GB

F

Principal dimensions

HYDRONIC

A = Exhaust gas

B = Fuel

V = Combustion air

WA = Water outlet

WE = Water inlet

Water pump

Page 8

8

D

S

GB

F

1

7

8

2

3

5

4

10

9

11

6

10

5

8

2

3

1

4

6

11

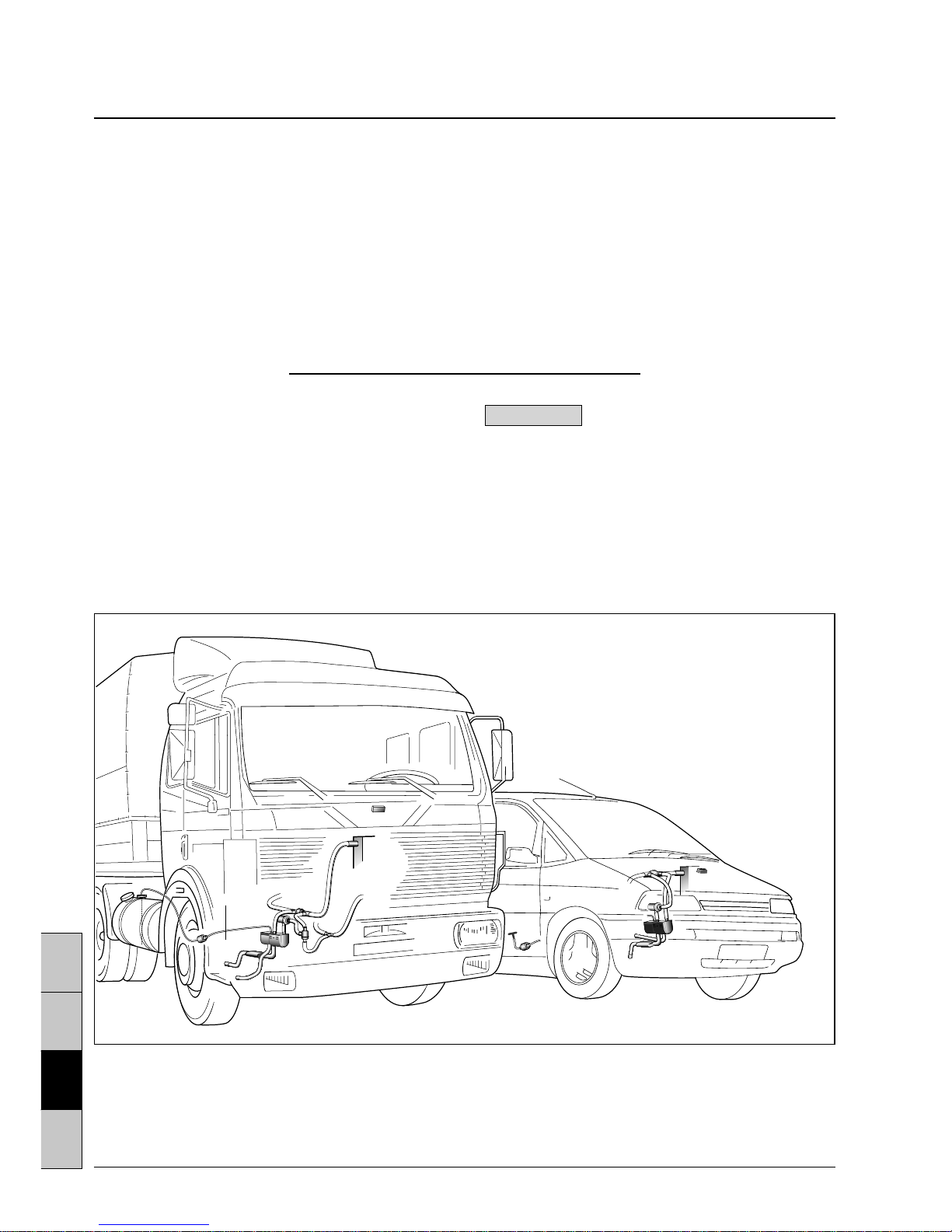

Mounting example

햲 Heater

햳 Exhaust piping with exhaust muffler

햴 Combustion air tube

햵 Water pump

햶 Check valve

햷 T-piece (water circulation system)

햸 Thermostat

햹 Vehicle’s heat exchanger

with fan

햺 Tank connection / T-piece (fuel)

햻 Dosing pump

햽 Module clock

Mounting the heater and water pump

Point of installation is the engine compartment. Mount

the heater as deeply as possible so that heat exchanger and water pump can deaerate automatically.

Observe permissible mounting positions as well as

operating and storage temperatures.

Mounting instructions

The heater, in conjunction with the vehicle’s heating

system, is used to preheat the engine, to heat the

passenger compartment and to defrost the window

panes.

The heater is connected to the vehicle’s coolingwater circulation, electrical system and fuel system.

If it is wired accordingly, the heater will operate as

additional heater, thereby increasing the heat flow of

the vehicle’s own heating – in particular in the case

of motors with optimised fuel consumption – to a

comfortable level.

(It is not permissible) to install the heater inside

vehicles used for the transport of hazardous substances, inside the passenger compartment, driver’s

cab, working cabin, seating compartment (troop

carrier, mini busses, motorbusses*) and generally in

rooms used by people is not permissible. When

installing the heater in special-purpose vehicles

valid regulations have to be complied with.

* Vehicles with more than 9 seats.

Please note!

The proposed points of installation given in these

mounting instructions are examples.

Other points of installation are also permissible

if they comply with the installation requirements

specified in these mounting instructions.

Further information concerning the installation

(e.g. for boats and ships) may be obtained from

the manufacturer on request.

Page 9

9

D

S

GB

F

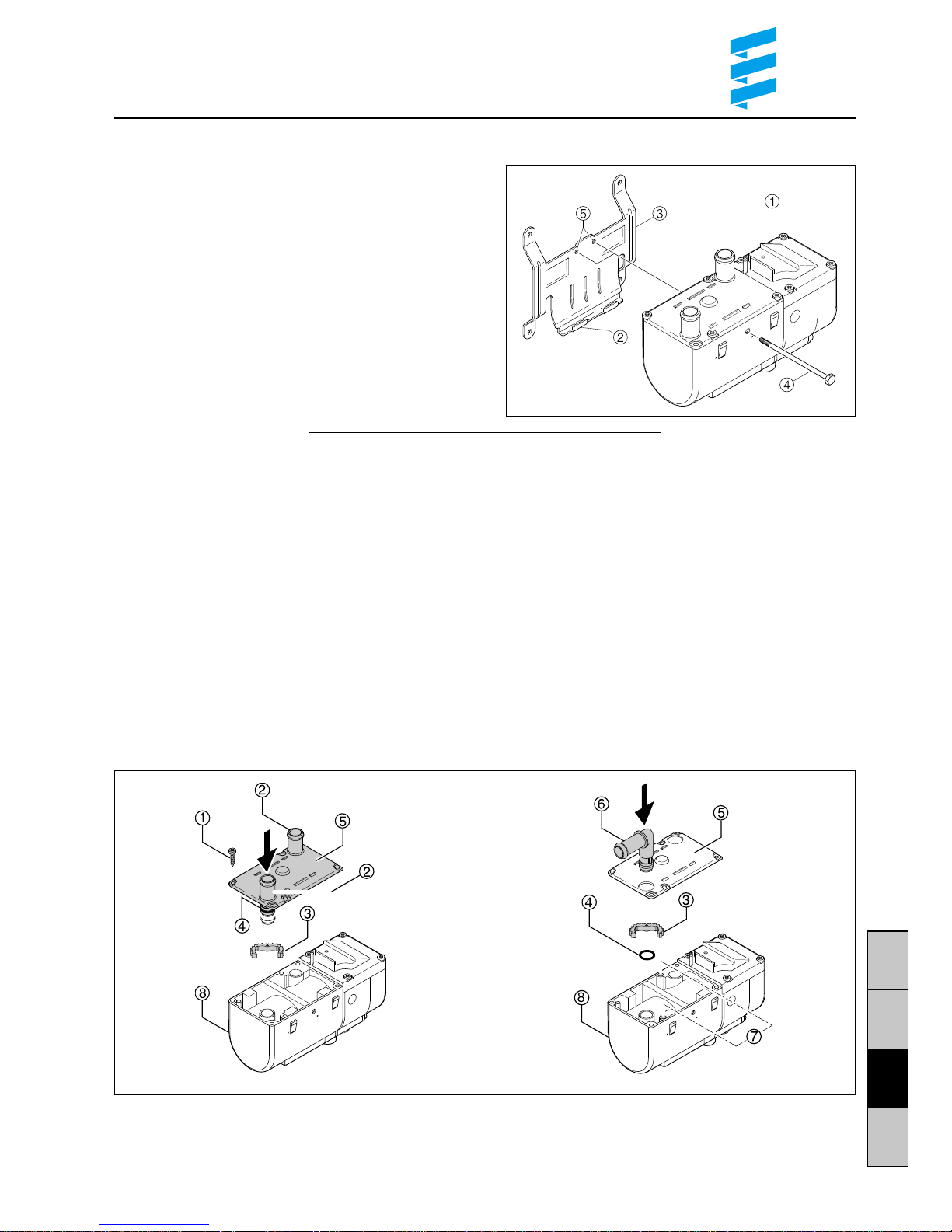

Mounting the heater onto the holder

• Insert heater in retaining lugs on holder.

• Screw heater onto holder with fastening screw

(6

+0.5

Nm).

Note:

Depending on the installation space, it is possible

to move the heater inside the holder and to secure it

with screws in one of the two fastening threads.

햲

HYDRONIC

햳 Retaining lugs

햴 Holder

햵 Fastening screw

햶 Fastening threads

Installation of the angular connection piece

HYDRONIC

B 5 W S and D 5 W S are supplied with

straight connection pieces. Depending on the

installation conditions, it may be necessary to install

angular connection pieces.

• Unscrew fastening screws on lid and remove lid.

• Push straight connection piece downwards.

• Undo serrated ring and remove O-ring.

• Pull connection piece out of lid.

• Push angular connection piece into lid, insert new

O-ring into the groove provided for that purpose

and grease sparingly.

• Mount serrated ring on angular connection piece,

twist connection piece depending on the installation

position and insert into the lid’s toothed ring.

• Screw lid back onto the casing with four screws –

torque 4 Nm.

Should the angular connection piece cover the

previous screw opening, the adjacent screw hole

has to be used.

This must be done as follows:

• A thread has to be tapped beforehand in the hole

of the

HYDRONIC

’s aluminium casing by

screwing one of the tapping screws into the hole

and unscrewing it again.

• Put on lid and screw in all four screws – torque

4.5 Nm.

Note:

The threads have to be tapped prior to mounting

the lid.

햲 Fastening screws

햳 Straight connection

햴 Serrated ring

햵 O-ring

햶 Lid

햷 Angular connection

햸 Hole

햹

HYDRONIC

Page 10

10

D

S

GB

F

Water pump

Normal position horizontal with permissible swivel

range.

Please note!

The outlet nozzle must be pointing 5° upward,

as shown in the drawing.

Permissible mounting positions

The heater and the water pump are to be installed

in the standard position. Depending on prevailing

installation conditions, the heater and the water

pump can be tilted as shown in the drawing.

or

The maximum permissible deviations from the normal position are indicated in the drawing.

Please consult the manufacturer if wider deviations

are necessary.

HYDRONIC

Normal position horizontal (exhaust pipe to the

bottom) with permissible swivel range.

Type plate

The type plate must be clearly visible after the

heater has been installed. If necessary, a second

type plate (duplicate) with the same details as the

original one can be mounted at a clearly visible

point on the air heater or a cover in front of the air

heater.

A second type plate is not necessary if the original

type plate is clearly visible under a cover that can

be removed without having to use tools. The type

plate is mounted on the basic unit.

Page 11

11

D

S

GB

F

Connection to the cooling water circuit

A careful deaeration of the water cycle (including

heater) after installation of the heater is necessary for

the perfect functioning of the device:

1. Fill heater and water hoses with coolant after installation, but before connection to the cooling water

cycle. The vent screw must remain open during

filling. If water issues from the opening of the vent

screw, the heater is deaerated. Close the vent

screw again.

2. Afterwards, the entire cooling system must be

deaerated to remove any bubbles in accordance

with the engine manufacturer’s instructions.

The pressure in the water cycle must be limited

to max. 2.5 bar excess pressure inside a pressure

control valve (e.g. radiator filler cap).

Attention!

During operation with auxiliary heating, the vehicle’s

heating valve must always be kept completely open

either electrically or mechanically.

Recommendation:

Use switches with final position contact (“break

contact”) for all heating cycles.

Please note!

If the heater is integrated in a vehicle engine’s cooling

system, it is part of this cooling system.

The following points thus need to be taken into account:

• The heater must always be mounted beneath the

min. cooling water level (coolant recovery bottle,

radiator, vehicle heat exchanger) in such a manner

that it works in the direction of flow of the engine

cooling cycle. After installation, the entire cooling

system including the heater must be deaerated to

remove any bubbles in accordance with the engine

manufacturer’s instructions. This also applies after

every interference with the cooling water system

(repair, exchange of cooling water). All water connections (clamps) have to be perfectly tightened

and retightened after the vehicle has been driven

for 2 hours or approx. 100 km. Any water-carrying

pipes must be protected against chafing and excessive temperatures (radiant heat from exhaust

pipes). To prevent corrosion, the cooling water must

contain at least 10% antifreeze all the year round.

The coolant must contain sufficient antifreeze for low

temperatures.

• Operating the heater with frozen coolant is dangerous and thus inadmissable.

When refilling coolant, only use the one authorized by

the vehicle manufacturer. Compare the vehicle’s

operating instructions. Mixing it with unauthorized

coolant may lead to damage to the engine and heater.

Before remounting a heater into another vehicle, rinse

all water carrying parts of the heater with clear water.

Page 12

12

D

S

GB

F

5

2

1

4

3

2. Inserting the check valve into the inflow line

Cut open the inflow line running from the vehicle

engine to the heat exchanger and insert the check

valve.

Insert the heater and the water pump into the water

circulation system as shown in the drawing.

Check valve Ø 18 mm – Order No. 254 00 070

Check valve Ø 20 mm – Order No. 254 00 074

Characteristic heating curve as for water cycle “1”

Advantage:

No loss of efficacy of engine heating with the stationary heating switched off.

햲 Heater

햳 Water pump

햴 Check valve

햵 Vehicle’s heat exchanger

햶 Vehicle engine

4

2

1

3

햲 Heater

햳 Water pump

햴 Vehicle’s heat exchanger

햵 Vehicle engine

There are several possibilities:

1. Inserting heater into inflow line –

this arrangement is the simplest one

Cut open the inflow line running from the vehicle

engine to the heat exchanger and insert the heater

and the water pump.

Characteristic heating curve:

With the stationary heating switched on, the heat is

first fed to the vehicle engine. After the cooling water

temperature has reached approx. 30 °C, the heat is

also fed to the passenger compartment, depending

on the fan position selected.

Page 13

13

D

S

GB

F

3. Integrating the deluxe installation kit

into the water circulation system

Deluxe installation kit, Order No. 24 0132 00 00 00

Cut open the inflow line running from the vehicle

engine to the heat exchanger and insert the check

valve.

Cut open the return line running from the heat

exchanger to the vehicle engine and insert the

T-piece. Insert the heater, thermostat and water

pump into the water circulation system as shown

in the drawing.

Characteristic heating curve:

First, up to a cooling water temperature of approx.

70 °C the heat of the auxiliary heating is only fed to

the passenger compartment = small cycle, fast heating up. If the cooling water temperature continues to

rise, the thermostat gradually changes over to the

large cycle = additional preheating of engine (full

change-over is reached at 75 °C).

Please note!

Execute connections 1, 2 and 3 as described in

the drawing.

7

2

1

6

3

4

5

t<70 °C = 3 closed

2 open

t>75 °C = 3 open

2 closed

Thermostat, Ø 18 mm

(always open)

햲 Heater

햳 Water pump

햴 Check valve

햵 Thermostat

햶 T-piece

햷 Vehicle’s heat exchanger

햸 Vehicle engine

Page 14

14

D

S

GB

F

6

1

5

2

3

4

4. Water cycle with combination valve

Mounting the combination valve – 5 connections

If the water flow pipe and water return pipe from the

vehicle engine to the heat exchanger in the engine

compartment have been spaced apart, the combination valve with 5 connections and one T-piece have

to be used.

Cut open the inflow line running from the vehicle

engine to the heat exchanger and insert the combination valve.

Cut open the return line running from the heat exchanger to the vehicle engine and insert the T-piece.

Mounting the combination valve – 6 connections

If the water flow pipe and water return pipe from the

vehicle engine to the heat exchanger in the engine

compartment have been installed parallel to each

other, the combination valve with 6 connections

(without T-piece) may be used.

Cut open the inflow and return lines running from

the vehicle engine to the heat exchanger and insert

the combination valve.

Combination valve with 5 connections:

Order No. 330 00 177

and additional

T-piece Ø 20 for return line:

Order No. 20 1673 80 11 00

Combination valve with 6 connections:

Order No. 330 00 176

Characteristic heating curve:

With the stationary heating switched on, the heat is

exclusively fed to the passenger compartment =

small cycle, fast heating up.

Once the vehicle engine is put into operation – at low

speed – a part of the heat is fed to the vehicle engine

(partial cycle) which leads to a shortening of the

vehicle engine’s warm-up period.

At increased engine speeds (> 2000 rpm), the entire

heat is distributed to the passenger compartment and

vehicle engine = large cycle, auxiliary heating function, further shortening of the warm-up period.

햲 Heater

햳 Water pump

햴 Combination valve (5 connections)

햵 T-piece

햶 Vehicle’s heat exchanger

햷 Vehicle engine

Combination valve (6 connections)

HYDRONIC

from vehicle

engine

to vehicle

engine

to vehicle

heat exchanger

from vehicle

heat exchanger

Page 15

15

D

S

GB

F

Conducting the combustion air / exhaust gas

Conducting the combustion air

The combustion air must be drawn in from the outside (not from the passenger compartment

or boot).

As described in these mounting instructions, the

heater is installed inside the engine compartment. If

the air intake fitting for the combustion air is situated

in an area where the combustion air does not reach

temperatures exceeding 25 °C, and where neither

road spray nor dust / dirt are to be expected, the

combustion air intake is already complete. If this is

not the case, a flexible hose with an inner diameter of

20 mm and up to 1.5 m long has to be connected to

take the combustion air from an area complying with

this condition.

The inlet opening of the combustion air pipe may in

that case not be built in against the air stream and

must be installed in such a manner that it cannot be

clogged by dirt and snow and that penetrated water

may run off.

Push on the end sleeves so that a 16 mm diameter

ball cannot be inserted (requirement of StVZO

“Technical Demands Expected of Heaters”).

Conducting the exhaust gas

The items supplied include a flexible exhaust hose

with an inner diameter of 24 mm and 1000 mm long.

It must be cut apart at a suitable place and the exhaust silencer inserted (compare diagram on page 3);

the exhaust tailpipe 햶 should be much shorter than

the exhaust pipe 햴. If necessary, the exhaust hose

pipe may be shortened or extended up to a maximum

length of 2 m.

The exhaust gas pipe must not protrude beyond the

external limits of the vehicle.

The exhaust pipe must either slope downwards

slightly, or a 5 mm diam. hole must be drilled into

the lowest point of the pipe to allow condensate to

drain off.

Always fasten the silencer; longer exhaust pipes must

always be fastened at intervals of approx. 50 cm.

bis 1,5m

bis 2m

1

2

4

35

up to 1.5 m

up to 2 m

햲 Heater

햳 Combustion air hose

햴 Exhaust gas pipe

햵 Exhaust gas silencer

햶 Exhaust tail pipe

Arrange the exhaust gas outlet in such a manner

that the exhaust gas cannot be immediately drawn

in again.

The exhaust gas outlet must lead out into the open air.

The exhaust gas pipe must be arranged in such a

manner that exhaust gas cannot enter the vehicle,

be drawn in by the vehicle's fan or by the heater

fan

1)

, nor must it impair the function of vital vehicle

parts in any way (ensure that an adequate distance

is maintained).

Run the exhaust gas pipe in such a manner that

it cannot be clogged up by dirt, snow or water

(draining hole). Do not position the outlet opening of

the exhaust gas against the air stream.

An end sleeve crossed with a web must be mounted

on the end of the exhaust gas pipe so that a 16 mm

diameter ball cannot be inserted (requirement of

StVZO “Technical Demands Expected of Heaters”).

1)

This requirement is considered to be fulfilled when

the end of the exhaust gas pipe is run upwards or

to the side, or when the exhaust gas pipe passes

underneath the vehicle floor to the vicinity of the

side or rear limits of the driver's cab or the passenger compartment.

!

Danger of poisoning and burns!

Every combustion process creates exhaust gas

which contains toxic constituents; for this reason

and due to the high temperatures occurring, the

exhaust gas duct needs to be absolutely carried out

in accordance with the specifications of these

mounting instructions.

During heating operation, avoid any work in the area

of the exhaust gas duct.

In such a case, switch off the

HYDRONIC

beforehand and wait until all parts have completely

cooled down.

If necessary, wear protective gloves.

Page 16

16

D

S

GB

F

a

8

b

Fuel supply

Operation with bio-diesel (PME) –

HYDRONIC

D 5 W S - 24 V

HYDRONIC

D 5 W S - 24 V is certified for operation

with bio-diesel as per DIN V 51606 in free-flowing

state (decreases at temperatures under 0 °C).

1. Tapping fuel with the T-piece from the fuel

supply line

Precondition:

Fuel lines must be tight.

A maximum preliminary pressure of 0.3 bar can

arise in the fuel lines in any operating mode.

Please note!

Deviations from the instructions given here are

impermissible, otherwise functional disorders

can arise.

Tapping fuel from the supply line downstream of the

delivery pump is prohibited in cars, since pressures

of up to 10 bars can occur.

Before the air heater is turned on it is first necessary

to start up the vehicle's engine so that the fuel lines

can be filled.

To engine

mechanical fuel pump

or injection pump

햲 Inflow line running from tank fitting to engine –

insert T-piece into inflow line upstream of delivery

pump

햳 Return line running

햴 Dosing pump

햵 T-piece

햶 Fuel filter – only required if fuel is contaminated

햷 Fuel hose, 5 x 3 (inner diameter = Ø 5 mm) –

HYDRONIC

B 5 W S only

햸 Fuel pipe, 6 x 2 (inner diameter = Ø 2 mm)

햹 Fuel pipe, 4 x 1,25

(inner diameter = Ø 1,5 mm)

햺 Fuel hose, 5 x 3 (inner diameter = Ø 5 mm),

approx. 50 mm long

햻 Fuel hose, 3,5 x 3 (inner diameter = Ø 3,5 mm),

approx. 50 mm long

Permissible line lengths

Suction side

a = max. 2 m

Pressure side

b = max. 4 m for petrol

b = max. 6 m for diesel

!

Danger of fire and explosion!

Poisonous fumes!

Caution when handling fuel. Before filling up and

when working on the fuel supply, switch off the

vehicle’s engine and the

HYDRONIC

.

Avoid open fire when handling fuel.

Do not smoke; this also applies there where

the presence of fuel is only noticeable on account

of its characteristic smell.

Do not inhale petrol fumes.

Page 17

17

D

S

GB

F

a

10

b

2. Tapping fuel with rising tank connection

installed in the vehicle tank or in the tank

fitting

If it is not possible to install a separate rising pipe in

cars with fuel injected engines the return line can be

tapped by means of a T-piece.

Condition:

• No valve may be installed in the return line

in the tank.

• The pressure inside the return line may reach

a max. of 2 bar. In case of pressures above 0.3

and up to 2 bar a pressure reducer (add-on part,

order No. 20 1645 89 30 00) must be installed

in front of the dosing pump.

Permissible line lengths

Suction side

a = max. 2 m

Pressure side

b = max. 4 m for petrol

b = max. 6 m for diesel

햲 Tank connection for metal tank,

inner diameter = Ø 2 mm,

external diameter = Ø 6 mm,

order no. 25 1226 89 50 00

햳 Tank connection for tank fitting,

inner diameter = Ø 2 mm,

external diameter = Ø 4 mm,

order no. 20 1645 89 35 00

햴 Dosing pump

햵 Fuel filter – only required if fuel is contaminated

햶 Fuel hose, 5 x 3 (inner diameter = Ø 5 mm) –

HYDRONIC

B 5 W S only

햷 Fuel pipe, 6 x 2 (inner diameter = Ø 2 mm)

햸 Fuel pipe, 4 x 1 (inner diameter = Ø 2 mm)

햹 Fuel hose, 3,5 x 3 (inner diameter = Ø 3,5 mm),

approx. 50 mm long

햺 Fuel hose, 5 x 3 (inner diameter = Ø 5 mm),

approx. 50 mm long

햻 Fuel pipe, 4 x 1,25 (inner diameter = Ø 1,5 mm)

햽 Connecting piece, external diameter = 4 mm

Page 18

18

D

S

GB

F

Mounting position of the dosing pump

Permissible suction and pressure level

of the dosing pump

햲 Dosing pump

햳 Maximum fuel level

햴 Minimum fuel level

햵 Connection on the heater

Mounting position of the dosing pump

Mount the dosing pump in the vehicle with the pres-

sure side rising by at least 15° and maximum 90°.

If possible the fuel lines from the dosing pump to

the heater should rise continuously.

Permissible suction and pressure level

Pressure level from the vehicle's tank to the dosing

pump:

a = max. 3000 mm

Suction level with a pressureless vehicle tank:

b = max. 500 mm for petrol

b = max. 1000 mm for diesel

Please note: Check the tank venting.

Suction level with a vehicle tank in which fuel tapping produces a vacuum (valve with 0.03 bar in the

tank closure):

b = max. 150 mm for petrol

b = max. 450 mm for diesel

Pressure level from the dosing pump to the heater:

c = max. 2000 mm

pressure side

Page 19

19

D

S

GB

F

• Always fasten the fuel pipes at intervals of approx.

50 cm.

• Always use a rubber hose to connect the fuel

branching piece – never use a plastic pipe.

• The fuel pipe must always be butt-jointed where

there is a connection between fuel pipes and

a fuel hose (see Drawing A).

• When incorporating a T-piece ensure that the

mounting position indicated on Drawing B is

observed.

•§§ 45 and 46 of StVZO also apply correspondingly to the fuel lines and additional heater tanks.

Please note!

• A pressure reducer (Order No. 20 1645 89 30 00)

or a separate tank connection (see page 13) must

be used if the pressure in the fuel line exceeds

0.2 bar to maximum 2.0 bar.

• A separate tank connection if the pressure in

the fuel line exceeds 2.0 bar or if the return line

incorporates a check valve.

• Fuel tapping in a car after the conveying pump

is prohibited!

• Fuel hoses and pipes must be cut to length with

a sharp knife; the cut-off point must not be dented

and must be burr-free.

• Protect the fuel line, filter and dosing pump

from impermissible heat, and do not mount in

the vicinity of silencers and exhaust gas pipes.

Drawing A: Drawing B:

correct

incorrect

Page 20

20

D

S

GB

F

Circuit diagram

HYDRONIC

B 5 W S / D 5 W S – 12 volt

Parts list

1.1 Burner motor

1.2 Glow plug

1.5 Overheating sensor

1.12 Flame sensor

1.13 Temperature probe

2.1 Controller

2.2 Dosing pump

2.5.7 Relay, vehicle fan

2.7 Main fuse 20 A

2.7.1 Fuse, actuation 5 A

2.7.5 Fuse, vehicle fan 25 A

2.12 Water pump

5.1 Battery

5.1.2 Fuse strip in vehicle

5.9.1 Switch, vehicle fan

5.10 Vehicle fan

Cable colours

sw = black

ws = white

rt = red

ge = yellow

gn = green

vi = violet

br = brown

gr = grey

bl = blew

li = purple

a) for auxiliary heating option connect to D+

f) cut open wire

g) only with petrol

h) only with diesel

k) switch (auxiliary heating, e.g. outside temperature

< 5 °C or change-over switch for summer / winter)

Length ‘plus’ + length ‘minus’:

< 5 m: cross section 4 mm

2

> 5 m < 8 m: cross section 6 mm

2

Cable ends that are not being used must be isolated.

Plug and socket case are shown from the cable entry

side.

20 1777 00 96 01 B

Page 21

21

D

S

GB

F

20 1777 00 97 01 A

Parts list

2.15.9 Sensor, outside temperature

3.1.9 Change-over switch ‘heating / ventilating’

3.1.16 Key button, radio remote control

3.2.6 Timer, mini-clock

3.2.9 Timer, module clock

3.2.12 Timer, mini-clock

3.3.6 TP 41i radio remote control (receiver)

b) Connect to terminal +15 if heating operation

> 2 hrs (with the ignition switched on) is desired

c) Lighting terminal 58

d) Stationary ventilation (optional)

e) External switch ON / OFF (optional)

i) Connection radio module receiver TP 4i

Length ‘plus’ + length ‘minus’:

< 5 m: cross section 4 mm

2

> 5 m < 8 m: cross section 6 mm

2

Cable ends that are not being used must be

insulated.

Plug and socket case are shown from the cable

entry side.

Please note!

For vehicles with automatic heating or airconditioning,

vehicle fan control must be in accordance with our

vehicle-related workshop information. If no workshop

information is available, the vehicle manufacturer’s

instructions with regard to the connection and / or point

of intersection for the fan control must be adhered to.

Cable colours

sw = black

ws = white

rt = red

ge = yellow

gn = green

Circuit diagram

Control elements – 12 volt

vi = violet

br = brown

gr = grey

bl = blew

li = purple

Page 22

22

D

S

GB

F

25 2147 00 96 01Parts list

1.1 Burner motor

1.2 Glow plug

1.5 Overheating sensor

1.12 Flame sensor

1.13 Temperature probe

2.1 Controller

2.2 Dosing pump

2.5.7 Relay, vehicle fan

2.7 Main fuse 15 A

2.7.1 Fuse, actuation 5 A

2.7.5 Fuse, vehicle fan 25 A

2.12 Water pump

5.1 Battery

5.1.2 Fuse strip in vehicle

5.9.1 Switch, vehicle fan

5.10 Vehicle fan

Cable colours

sw = black

ws = white

rt = red

ge = yellow

gn = green

vi = violet

br = brown

gr = grey

bl = blew

li = purple

f) cut open wire

Length ‘plus’ + length ‘minus’:

< 5 m: cross section 4 mm

2

> 5 m < 8 m: cross section 6 mm

2

Cable ends that are not being used

must be isolated.

Plug and socket case are shown

from the cable entry side.

Please note!

The vehicle ventilator runs immediately

after the heater has been started.

Circuit diagram

HYDRONIC

D 5 W S – 24 volt

Page 23

23

D

S

GB

F

Circuit diagram

Control elements – 24 volt

Please note!

For vehicles with automatic heating or airconditioning,

vehicle fan control must be in accordance with our

vehicle-related workshop information. If no workshop

information is available, the vehicle manufacturer’s

instructions with regard to the connection and / or

point of intersection for the fan control must be

adhered to.

Cable colours

sw = black

ws = white

rt = red

ge = yellow

gn = green

vi = violet

br = brown

gr = grey

bl = blew

li = purple

Parts list

2.15.9 Sensor, outside temperature

3.2.9 Timer, module clock, TRS

3.2.12 Timer, mini-clock

b) Connect to terminal +15 if heating operation

c) Lighting terminal 58

e) External switch ON / OFF (optional)

i) Connection radio module receiver

Length ‘plus’ + length ‘minus’:

< 5 m: cross section 4 mm

2

> 5 m < 8 m: cross section 6 mm

2

Cable ends that are not being used

must be insulated.

Plug and socket case are shown

from the cable entry side.

Page 24

24

D

S

GB

F

25 2147 00 97 01 C

Cable colours

sw = black

ws = white

rt = red

ge = yellow

gn = green

vi = violet

br = brown

gr = grey

bl = blew

li = purple

Circuit diagram

HYDRONIC

D 5 W S – 24 volt, GGVS / TRS 003 / ADR / ADR 99

Page 25

25

D

S

GB

F

Circuit diagram

Control elements – 24 volt, GGVS / TRS 003 / ADR / ADR 99

Parts list

1.1 Burner motor

1.2 Glow plug

1.5 Overheating sensor

1.12 Flame sensor

1.13 Temperature probe

2.1 Controller

2.2 Dosing pump

2.5.7 Relay, vehicle fan

2.7 Main fuse 15 A

2.7.1 Fuse, actuation 5 A

2.7.5 Fuse, vehicle fan 25 A

2.12 Water pump

3.2.9 Timer, module clock, TRS

5.1 Battery

5.1.2 Fuse strip in vehicle

5.2.1 Battery operating switch m)

(operation e.g. controlled

via ignition lock)

5.2.2 Battery separating switch m)

(Emergency-shutdown function in the case

of GGVS / TRS 003 / ADR / ADR 99)

5.3 Accessory drive HA+

5.3.1 Switch auxiliary drive

5.5 Generator D+

5.9.1 Switch, vehicle fan

5.10 Vehicle fan

b) Connect to terminal +15

c) Lighting terminal 58

f) Cut open wire

g) Insulate cable and tie back

m) if only one control element is used for items 5.2.1

and 5.2.2, it must be ensured that, if the function

‘opening of battery separating switch’ is

actuated (emergency shutdown-function in the

case of GGVS / TRS 003 / ADR / ADR 99) and

similar), the switch always breaks contact

without delay (without consideration for the

heater mode) and breaks all of the heater’s

circuits from the battery.

Length ‘plus’ + length ‘minus’:

< 5 m: cross section 4 mm

2

> 5 m < 8 m: cross section 6 mm

2

Cable ends that are not being used

must be isolated.

Plug and socket case are shown

from the cable entry side.

Please note!

The cables drawn in as dashed lines have to be

additionally laid and connected. Prior to doing so,

disconnect the wire harness at the positions marked

with f). Cable seals and push-on contacts for the

connector B1 and the ventilator relay are contained

in the installation kit.

The vehicle ventilator runs immediately after the

heater has been started.

For vehicles with automatic heating or airconditioning,

vehicle fan control must be in accordance with our

vehicle-related workshop information. If no workshop

information is available, the vehicle manufacturer’s

instructions with regard to the connection and / or

point of intersection for the fan control must be

adhered to.

Page 26

26

D

S

GB

F

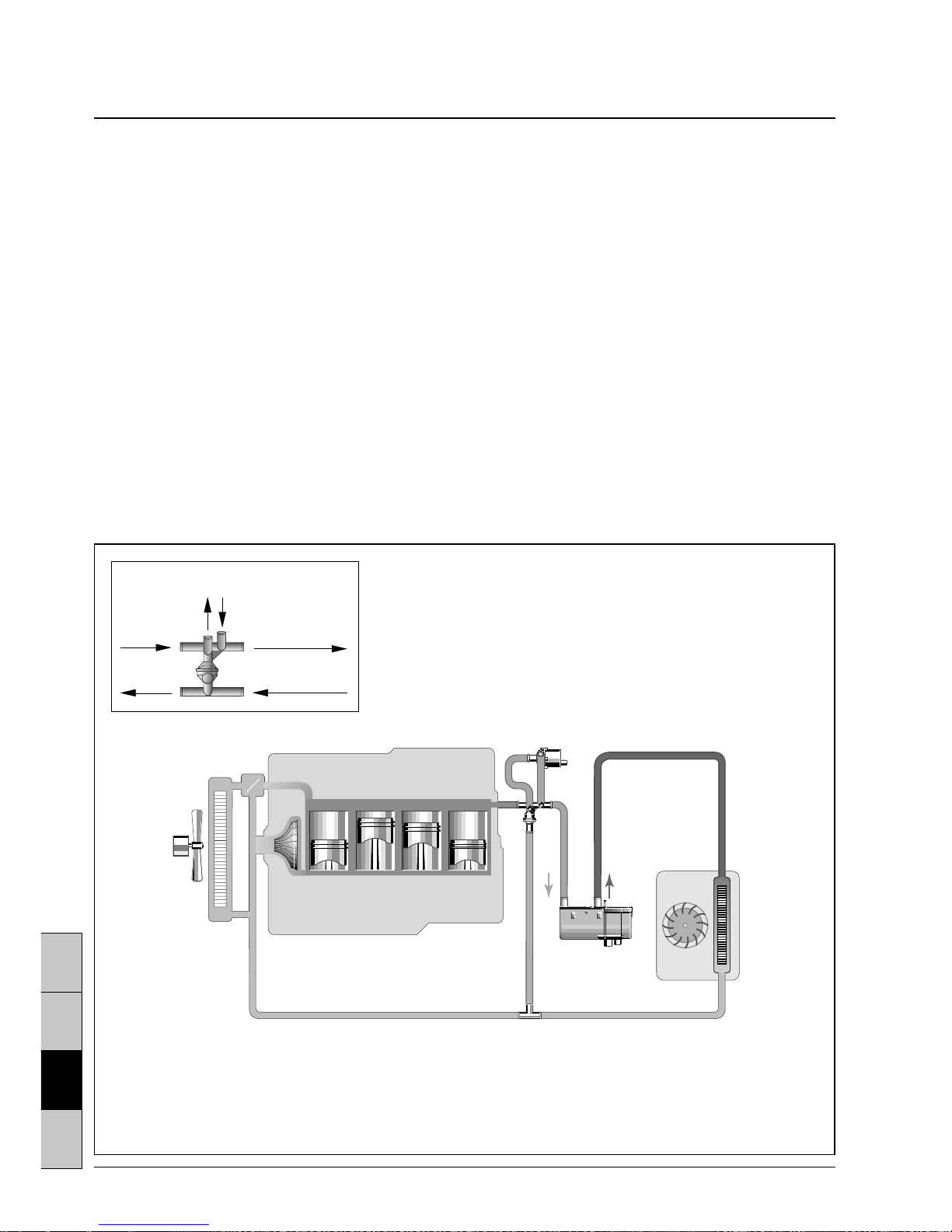

Function

Depending on the wiring, the heater can be operated

as purely stationary heater or as combined stationary

and auxiliary heater to compensate for an insufficient

output of heat by the vehicle engine.

Stationary heating operation

Switching on

The pilot lamp in the control unit lights up when the

heater is switched on (switch, timer ...). The water pump

starts and after a fixed programme with prerinsing and

preheating, combustion air fan, glow plug and fuel dosing pump set combustion going. Once a stable flame

has formed, the glow plug is switched off by a timer.

Heating operation

Depending on the heat requirement, the heater may

be adjusted to the following levels:

“LARGE” or “SMALL”.

The temperature thresholds have been fixed programmed in the electronic control device. If the heat

requirement at level “SMALL” is so low that the cool-

ing water temperature reaches 85 °C, the device

goes into the control interval. This is followed by the

fan continuing to run for approx. 130 seconds. The

pilot lamp also lights up during the control interval

and the water pump continues to run up to the next

controlled start.

Check the following points in the event of faults:

The heater does not start when it is switched on:

Turn-off the heater and then switch it on again,

but not more than twice in succession.

If the heater still does not start:

Is there fuel in the tank?

Has the fuse blown?

Are all electrical lines and connections ok?

Is the combustion-air duct or exhaust-gas duct

blocked?

Conduct a diagnostic test with the JE diagnostic

instrument or the module clock as described in

“Trouble Shooting and Repairs Instructions”

for the

HYDRONIC

B 5 W S / D 5 W S.

Page 27

27

D

S

GB

F

Controls and safety devices

• If the heater does not ignite within 90 seconds

after fuel pumping has started, then the start

procedure must be repeated in the described

manner.

A fault shut-down is effected if the air heater once

again fails to ignite after 90 seconds of fuel

pumping.

After an excessive number of unsuccessful

attempts to start the heater, the control will be

locked*.

• A renewed start must be completed if the flame

extinguishes itself during operation. A fault shutdown is effected if the air heater fails to ignite

within 90 seconds after renewed fuel pumping or

if it does ignite but then extinguishes itself within

the next 15 minutes.

It is possible to override a fault shut-down by

briefly switching the heater off and then on again.

Do not repeat this more than twice

in succession!

• In case of overheating (lack of water, badly vented

cooling water cycle), the overheating sensor will

respond, the fuel supply will be interrupted and a

fault shut-down is effected. Once the cause of

overheating has been eliminated, the device can

be restarted by switching it off and on again

(condition: device has sufficiently cooled down,

cooling water temperature < 70 °C).

After an excessive number of switching-offs due

to overheating the control will be locked*.

• A fault shut-down is effected when the upper

or lower voltage limit is reached.

• The air heater will not start if the glow plug is

defective or if the electrical line to the dosing

pump is interrupted.

• The rotating speed of the fan motor is continuously

monitored. A fault shut-down is effected after

60 seconds if the fan motor does not start, if it is

blocked or if the rotating speed drops below 40 %

of the desired speed.

* Reading off errors and cancelling of locking:

1. by means of the built-in module clock

(3.2.9 in the circuit diagram)

2. if other control elements have been built in,

by means of connecting the diagnostic device

22 1512 89 00 00 instead of these other control

elements.

Operation and list of errors see operating instructions

for the diagnostic device and / or the trouble-shooting

and repair instructions

HYDRONIC

B 5 W S /

D 5 W S.

Stationary ventilation with change-over switch

‘heating / ventilating’

Stationary ventilation means that it is possible to

directly control the vehicle fan by means of the heating device preselector or – even more effectively – via

the radio remote control TP4i / TP41i, thus bypassing

the heating operation. This serves the purpose of

ventilating the passenger compartment shortly before

departure with fresh air as it often heats up considerably during summer time (separate wiring).

GGVS / TRS 003 / ADR / ADR 99 –

mode of operation

Please note!

The

HYDRONIC

D 5 W S – 24 volt is suitable and

certified for installation in vehicles used to transport

dangerous substances according to the regulations

in accordance with GGVS / TRS 003 / ADR / ADR 99

(detailed information is contained in an information

sheet with print no. 25 2069 95 13 50).

Forced cut-off in GGVS / TRS 003 / ADR / ADR 99

mode

When vehicles are used to transport dangerous

substances (e.g. road tankers), the heater must be

switched off before entering the hazardous area

(refinery, petrol station, etc.). If this is not observed,

then the heater will automatically shut-down when:

– The vehicle's engine is turned off.

– An accessory unit is switch on (e.g. auxiliary drive

for the unloading pump).

– A vehicle door is opened (TMD regulation; only in

France).

After shut-down the fan will continue to run for max.

40 seconds.

Please note!

• To prevent corrosion, the coolant must contain

at least 10 % antifreeze all the year round.

• The controller must be protected while electric

welding work is being completed on the

vehicle by disconnecting the “plus” pole from

the battery and connecting it to the chassis.

Loading...

Loading...