Eberspächer HYDRONIC 16, HYDRONIC 30, HYDRONIC 24, HYDRONIC 35 Troubleshooting And Repair Instructions

Troubleshooting and Repair Instructions

L

D16WN 25 2395 Rev L

S/N 0612051698

16kW

The Troubleshooting and Repair Instructions are applicable to the

following unit versions:

Normal version Order No. Basic unit No.:

HYDRONIC 16 – 24 volt 25 2165 02 00 00 25 2165 01 00 00

HYDRONIC 24 – 24 volt 25 1817 02 00 00 25 1817 01 00 00

HYDRONIC 30 – 24 volt 25 1818 02 00 00 25 1818 01 00 00

HYDRONIC 35 – 24 volt 25 1819 02 00 00 25 1819 01 00 00

J. Eberspächer GmbH

& Co. KG

Eberspächerstr. 24

D – 73730 Esslingen

Telephone (switchboard)

(0711) 939-00

Facsimile

(0711) 939-0500

www.eberspaecher.com

Compact version Order No. Basic unit No.:

HYDRONIC 24 – 24 volt 25 1817 05 00 00 25 1817 01 00 00

HYDRONIC 30 – 24 volt 25 1818 05 00 00 25 1818 01 00 00

HYDRONIC 35 – 24 volt 25 2041 05 00 00 25 1819 01 00 00

Normal version

25 1818 95 20 12 09.2008 Subject to change without notice Printed in Germany © J. Eberspächer GmbH & Co. KG

Compact version

Introduction

1

Contents

This list of contents provides precise information about the

contents of these Troubleshooting and Repair Instructions.

Chapter Title Contents Page

Introduction

1

Function

2

Product information

3

Troubleshooting

4

Repair instructions

5

• Contents ................................................................................................... 2 – 3

• Foreword ........................................................................................................ 4

• Safety instructions for installation and repair .................................................... 4

• Accident prevention ........................................................................................ 4

• Special text structure, presentation and picture symbols ................................. 4

• Important information before starting work ...................................................... 4

• Cutaway view .................................................................................................. 5

• Structure of the heater .................................................................................... 6

• Special features of the heater .......................................................................... 6

• Operating instructions ..................................................................................... 6

• Description of functions ................................................................................... 6

• Functional diagram .......................................................................................... 7

• Control diagram .............................................................................................. 7

• Control and safety devices .............................................................................. 8

• Emergency stop (EMERGENCY OFF) .............................................................. 8

• Technical data, heater ..................................................................................... 9

• Technical data, water pump .......................................................................... 10

– Pumping and pressure loss characteristic curves ....................................... 10

• What to check fi rst in case of faults ............................................................... 11

• Locking the control box ................................................................................. 11

• Cancelling the control box lock ...................................................................... 11

• Fault diagnosis – fl ashing code ...................................................................... 12

• Overview of the individual test equipment and control units ........................... 13

• External diagnostic system ............................................................................ 13

• Fault diagnosis using the diagnostic unit ................................................. 14, 15

• Fault diagnosis: EDiTH customer service program with ISO adapter .............. 16

• Fault diagnosis: EDiTH customer service program with basic adapter ........... 17

• Fault diagnosis using the module timer .......................................................... 18

• Fault diagnosis using the radio remote control TP5 ....................................... 19

• Fault diagnosis with EasyStart R+ radio remote control

and EasyStart T timer .................................................................................... 20

• Fault code table .................................................................................... 21 – 24

• Repair instructions ........................................................................................ 25

• Always observe the following safety instructions before working on the heater . 25

• AMP release tool ........................................................................................... 25

• Assembly drawing .................................................................................. 26, 27

– Component parts ..................................................................................... 27

• Removing the hood ....................................................................................... 28

• Dismantling the burner .................................................................................. 28

• Dismantling the control box ........................................................................... 28

• Dismantling the burner motor ........................................................................ 29

• Checking the function and speed of the burner motor

using the burner tester .................................................................................. 29

• Dismantling the ignition electrodes ................................................................ 30

• Dismantling the fuel nozzle ............................................................................ 30

• Dismantling the ignition unit ........................................................................... 31

• Testing the ignition unit using the burner tester .............................................. 31

• Dismantling the solenoid valve ....................................................................... 32

• Testing the solenoid valve using the burner tester .......................................... 32

• Dismantling the nozzle block ......................................................................... 33

– Nozzle block made of brass ....................................................................... 33

– Functional check of the heating cartridge ................................................... 33

• Dismantling the fl ame tube ............................................................................ 34

If you are looking for a specifi c term, use the index at the end

of this document.

2

Introduction

1

Contents

Chapter Title Contents Page

5

Repair instructions

Circuit diagrams

6

Service

7

• Dismantling the temperature and overheating sensor .................................... 35

• Temperature and overheating sensor resistance values ................................. 35

– Table of characteristic values - temperature sensor ................................... 35

– Temperature sensor diagram ..................................................................... 35

– Table of characteristic values - overheating sensor ..................................... 36

– Overheating sensor diagram ...................................................................... 36

• Dismantling the gauze fuel fi lter ..................................................................... 37

• Notes on the fuel fl ow rate and the pressure in the fuel system ...................... 36

• Measuring the CO2 content ........................................................................... 37

• Adjusting the combustion air ......................................................................... 37

• Dismantling the water pump (standard design) .............................................. 39

• "Bus 2000" water pump ................................................................................ 39

• Dismantling the FLOWTRONIC 5000 water pump ......................................... 40

• Heater circuit diagram – Part 1 (HYDRONIC 16 / 24 with temperature switch) .. 41

• Heater circuit diagram – Part 1 (HYDRONIC 16 – 35 without temperature

switch) .......................................................................................................... 42

• Heater circuit diagram – Part 2 with water pump (standard design)

and "Bus 2000" water pump ......................................................................... 43

• Heater circuit diagram – Part 3 with FLOWTRONIC water pump .................. 44

• Circuit diagram / parts list for control units ............................................... 45, 46

• Parts list for circuit diagram - EasyStart control units .................................... 47

• EasyStart R control unit circuit diagram ......................................................... 48

• EasyStart R+ control unit circuit diagram ....................................................... 49

• EasyStart T control unit circuit diagram ......................................................... 50

• Certifi cation ................................................................................................... 51

• Disposal ........................................................................................................ 51

• EC Declaration of Conformity ........................................................................ 51

• Representatives abroad .......................................................................... 52, 53

• List of key words ..................................................................................... 54, 55

3

Introduction

1

Foreword

These Troubleshooting and Repair Instructions are applicable

to the heaters listed on the title page, to the exclusion of all liability claims.

Depending on the version or revision status of the heater,

there may be differences between it and these Troubleshooting and Repair Instructions.

The user must check this before carrying out the repair work

and, if necessary, take the differences into account.

Important!

Safety instructions for installation and repair!

Special text structure, presentation and

picture symbols

Special text formats and picture symbols are used in these

instructions to emphasise different situations and subjects.

Please refer to the following examples for their meanings and

appropriate action.

Special text formats and presentations

• A dot (•) indicates a list, which is started by a heading.

– If an indented dash (–) follows a "dot", this list is a sub-

section of the black dot.

Improper installation or repair of Eberspächer heaters can

cause a fi re or result poisonous exhaust entering the inside of

the vehicle. This can cause serious and even fatal risks.

The heater may only be installed according to the specifi cations in the technical documents or repaired using original

spare parts by authorised and trained persons.

Installation and repairs by unauthorised and untrained persons, repairs using non-original spare parts and without the

technical documents required for installation and repair are

dangerous and therefore are not permitted.

A repair may only be carried out in connection with the respective unit-related technical description, installation instructions, operating instructions and maintenance instructions.

This document must be carefully read through before / during installation and repair and followed throughout. Particular

attention is to be paid to the offi cial regulations, the safety instructions and the general information.

Please note!

The relevant rules of sound engineering practice and any information provided by the vehicle manufacturer are to be observed during the installation and repair.

Eberspächer does not accept any liability for defects and

damage, which are due to installation or repair by unauthorised and untrained persons.

Compliance with the offi cial regulations and the safety instructions is prerequisite for liability claims. Failure to comply with

the offi cial regulations and safety instructions leads to exclusion of any liability of the heater manufacturer.

Picture symbols

Danger!

This information points out a potential serious or fatal danger.

Ignoring this information can result in severe injuries.

Important!

This information points out a dangerous situation for a person

and / or the product. Failure to comply with these instructions

can result in injuries to people and / or damage to machinery.

Important information before starting

work

Initial commissioning of the heater or functional test

after a repair

• After installing the heater, the whole fuel supply system must

be carefully vented: please refer to and follow the vehicle

manufacturer's instructions.

• During the heater trial run, all fuel connections must be

checked for leaks and secure, tight fi t.

• If faults occur while the heater is running, use a diagnostic

unit to determine and correct the cause of the fault.

Accident prevention

General accident prevention regulations and the corresponding workshop and operating safety instructions are to be observed.

4

Function

2

Cutaway view

Sketch 1

1 Impeller

2 Electric motor

3 Solenoid valve

4 Flame tube

5 Control box

6 Combustion

chamber

7 Heat exchanger

8 Ignition unit

9 Ignition electrodes

10 Fuel nozzle

11 Coupling

12 Temperature sensor

13 Overheating sensor

14 Relay (vehicle blower control)

15 Fuses

16 Module timer

17 Water pump

18 Exhaust pipe

19 Fuel connection

20 Hood (CO

21 Flame detection photocell

22 Nozzle block with integrated heating

element

adjustment)

2

A Exhaust

B Fuel

V Combustion air

WA Water outlet

WE Water inlet

5

Function

2

Structure of the heater

The heater consists of a heat exchanger and a removable

burner. A combustion chamber consisting of a fl ame tube with

integrated mixer is inserted in the heat exchanger. The fl ame

tube can be pulled out of the heat exchanger if necessary.

The control box and electric motor are fi xed to the burner

fl ange under the burner hood. The fuel pump is integrated in

the burner housing.

The following additional parts are required for operation of the

heater:

• Water pump

• Additional parts for connection to the water circuit

• Additional parts for the fuel supply

• Additional parts for the exhaust system

• Control unit

Order No. see technical description, for further additional parts

see additional parts catalogue.

Special feature of the heater

Description of functions

Switching on the heater

When the heater is switched on, a component test is carried

out (3 seconds) and then the water pump is started up.

Note:

If the water temperature is < 5 °C the nozzle pre-heater is

switched on for 60 seconds; the burner start is delayed by

this length of time.

Burner start

The electric motor starts and drives the combustion air impeller and the fuel pump.

After approx. 10 seconds, the ignition is switched on and then

the fuel solenoid valve opens. Within these 10 seconds a rotational check of the electric motor is carried out. The fuel and

combustion air in the combustion chamber form an ignitable

mixture.

The mixture is ignited by a high-voltage ignition spark. The

fl ame detection photocell detects the fl icker frequency of the

fl ame and switches off the ignition unit. The hot fuel gases

fl ow through the heat exchanger and transfer the heat to the

heating medium.

• If the water fl ow rate is too low, the water outlet temperature

is limited by premature correction.

• The temperature rise of the heating medium is monitored

over time. If it rises too fast (water fl ow rate too low) the

heater automatically switches "OFF" and begins the afterrun, the cycle then begins again.

• Constant comparison of the measured temperature sensor

and overheating sensor values provides additional heater

safety. If the difference between the measured values is

too large (water fl ow rate too low) the heater prematurely

switches "OFF".

Operating instructions

The heater is operated by a control unit. Detailed operating instructions are supplied with the control unit.

Please note!

The operating instructions are issued to you by the garage /

workshop that installs the heater.

Please note!

• The heater operates depending on the heat requirement,

therefore the length of the burner's on-time and off-time

periods differ.

• The water pump continues to run throughout the whole operating period, even during pause mode periods and during

the after-run.

Options

• When the temperature drop is activated the "ON / OFF"

control temperatures are lowered by approx. 8K.

For connection of the ON / OFF switch for temperature

drop, see circuit diagram on pages 43 and 44.

• The water pump can also be operated independently of the

heater, if an appropriate control is installed. For connection of the additional "ON / OFF" switch for separate water

pump control, see circuit diagram on pages 43 and 44.

• For vehicle blower control, the vehicle blower is switched on

and off at the following water temperatures.

– Water temperature > 55 °C —>Vehicle blower "ON"

– Water temperature < 50 °C —>Vehicle blower "OFF"

Switching off the heater

If the heater is switched off, the fuel solenoid valve closes and

at the same time the approx. 3 minute after-run begins.

After the after-run has fi nished the heater is automatically

switched off.

Please note!

Until it is switched off, including during the after-run, the fuel is

circulated.

6

Function

2

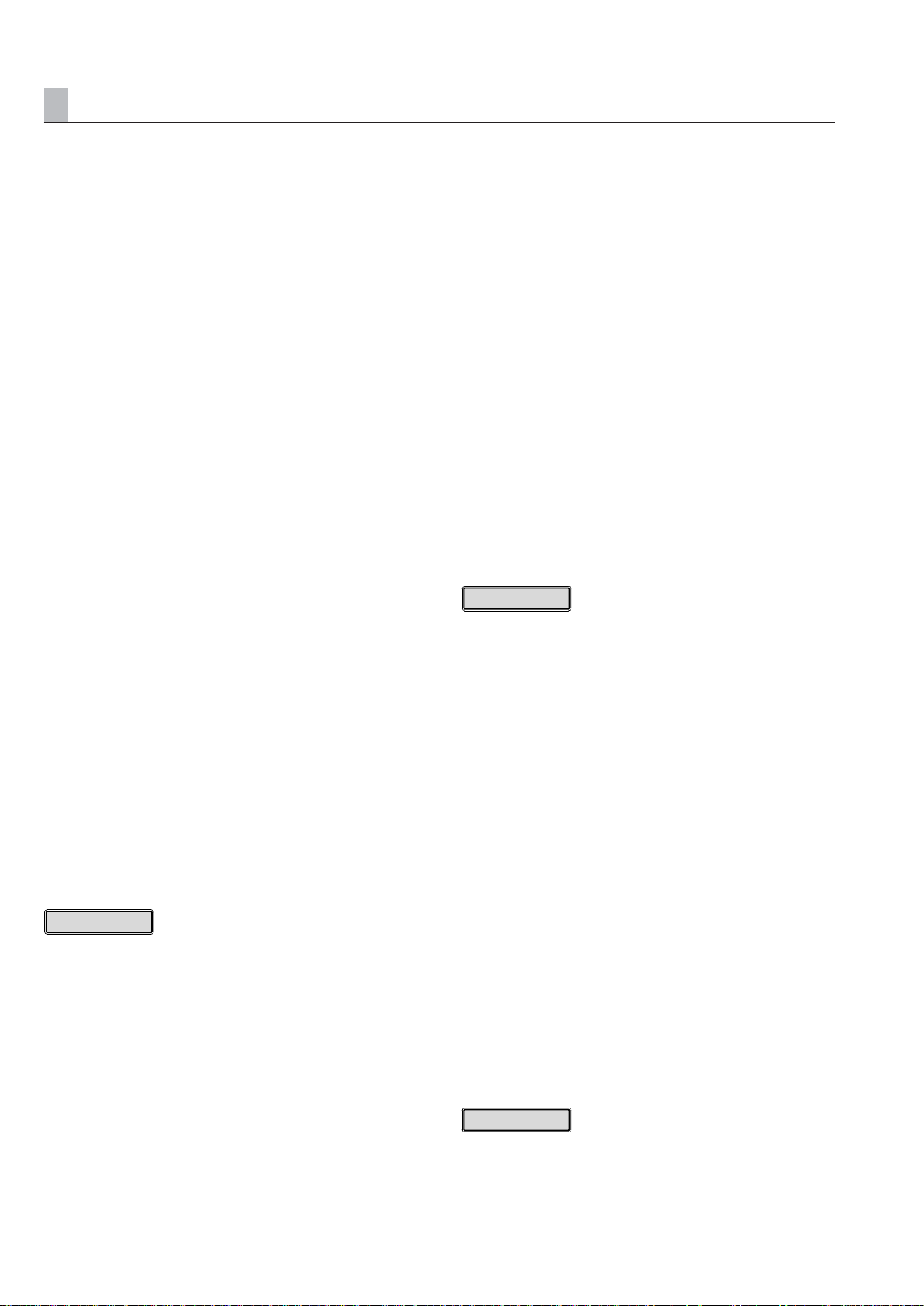

Functional diagram

Heater ON

Components test

Heating mode

Heater OFF

Nozzle block heating

(ON at temperature <5 °C)

Water pump

Solenoid valve

Ignition unit

Electric motor

Sketch 2

Control diagram

60 sec.

3 sec.

From control box 25 1818 53 00 00,

switching "OFF / ON" of the nozzle block

heating is temperature controlled

From control box 25 1818 53 00 00

10 sec.

10 sec.

After running

180 sec.

Vehicle blower ON

Vehicle blower OFF

Sketch 3

Heater ON NORMAL OPERATION Heater OFF

ON ONOFF OFF

After-run – 3 min.

Control – Normal

Control – Temperature drop

7

Function

2

Control and safety devices

The heater is equipped with the following control and safety devices.

• If the heater does not ignite the control box* is locked after

an impermissible number of failed start attempts.

• If the water fl ow rate is too low, the water outlet temperature

is limited by premature correction.

• The temperature rise of the heating medium is monitored

over time. If it rises too fast (water fl ow rate too low) the

heater automatically switches "OFF" and begins the afterrun, the cycle then starts again.

• Constant comparison of the measured values for the temperature sensor and overheating sensor provides additional

heater safety, as a premature lockout (shutdown on faults)

occurs if the difference between the measured values is too

high (the water fl ow rate is too low).

After an impermissible number of lockouts, the control box

is locked.*

• If the lower or upper voltage limit is reached, a lockout

(shutdown on faults) occurs.

• If the fl ame sensor detects a fl ame during the heater's afterrun a lockout occurs (shutdown on faults).

After an impermissible number of lockouts, the control box

is locked.*

* The lock can be cancelled and the faults read out:

• with the module timer / EasyStart T timer

• with the radio remote control TP5 / EasyStart R+.

For other control units by connecting:

• the diagnostic unit

• the customer service program KD2000 / EDiTH.

For details of operation and fault list, see these Trouble-

shooting and Repair Instructions from page 13.

Emergency shutdown – EMERGENCY

OFF

If an emergency shutdown –

EMERGENCY OFF – is required during operation, execute

the following:

• Switch the heater off at the control unit or

• remove the fuse or

• disconnect the heater from the battery.

8

Product information

0.53 Gal/Hr

6 GPM

3

Technical data, heater

Type

Heating medium Mixture of water and refrigerant (max. 50 % refrigerant fraction)

Heat fl ow in watt (at ambient temperature 20 °C) 16 000 24 000 30 000 35 000

Temperature values – at water inlet ON 73 °C / OFF 78 °C

Temperature values – at water outlet ON 85 °C / OFF 118 °C

Fuel Diesel – standard commercial (DIN EN 590) Heating oil EL (DIN 51603)

Fuel consumption (at ambient temperature –10 °C) 2.0 l/h 2.9 l/h 3.65 l/h 4.2 l/h

Rated voltage 24 volt

Operating range

• Lower voltage limit:

An undervoltage protector installed in the control box

switches off the heater if the voltage limit is reached.

• Upper voltage limit:

An overvoltage protector (surge suppressor) installed

in the control box switches off the heater if the voltage

limit is reached.

Electrical power consumption

(in combustion mode / without circulating pump)

D 16 W N D 24 W N D 30 W N D 35 W N

60 watt 80 watt 105 watt 120 watt

HYDRONIC L

19 volt

30 volt

Water content of the heat exchanger approx 2 l

Water content of the water circuit min. 10 l

Minimum heating medium fl ow rate (±200 l/h) 1400 l/h 2000 l/h 2600 l/h 3000 l/h

Permissible ambient temperature in operation:

during transport / storage:

for the combustion air:

Pumped medium:

Operating pressure (water circuit) < 2.5 bar

values (% vol) 9 – 11 9 – 11 9 – 11 9.5 – 11.5

CO

2

CO in the exhaust < 0.04

Smoke spot no. (Bacherach) < 4

Weight approx 18 kg

Interference suppression class VHF 4 / SW 3 / MW 5 / LW 3 according to DIN 57879 / Part 1

Protection IP 64

–40 °C to +85 °C

–40 °C to +100 °C

< 60 °C

–40 °C to +90 °C,

short-term up to +120 °C

VDE 0879

Important!

Safety instructions for technical data!

Failure to comply with the technical data can result in malfunctions.

Please note!

If no limit values are given, the technical data listed is with the

usual heater tolerances of ± 10 % at nominal voltage, 20 °C

ambient temperature and Esslingen reference altitude.

9

Product information

3

Technical data, water pump

Heating medium Mixture of water and refrigerant (max. 50 % refrigerant fraction)

Delivery rate 5200 l/h ±10 % at 0.2 bar discharge pressure

Water circuit operating pressure max. 2 bar

Weight (without bracket, clamp and refrigerant) 2.14 kg

Rated voltage 24 volt

Operating range 20 – 28 volt

Power consumption at 5200 l/h and 0.2 bar discharge pressure

Interference suppression class 3 according to DIN 57879 / Part 1 VDE 0879

Protection IP 54A according to DIN 40 050 Sheet 1

Electrical fusing for third party control 15 A

Temperature conditions Heating medium –40 °C to + 90 °C [short-term (15 min.) +115 °C]

Ambient, operation

Dry running No

Blocking Within a period of max. 6 seconds the motor is undamaged.

Shaft - impeller connection Mechanical seal

FLOWTRONIC 5000

104 watt ±10 %

–40 °C to 90 °C [short-term (15 min.) +115 °C]

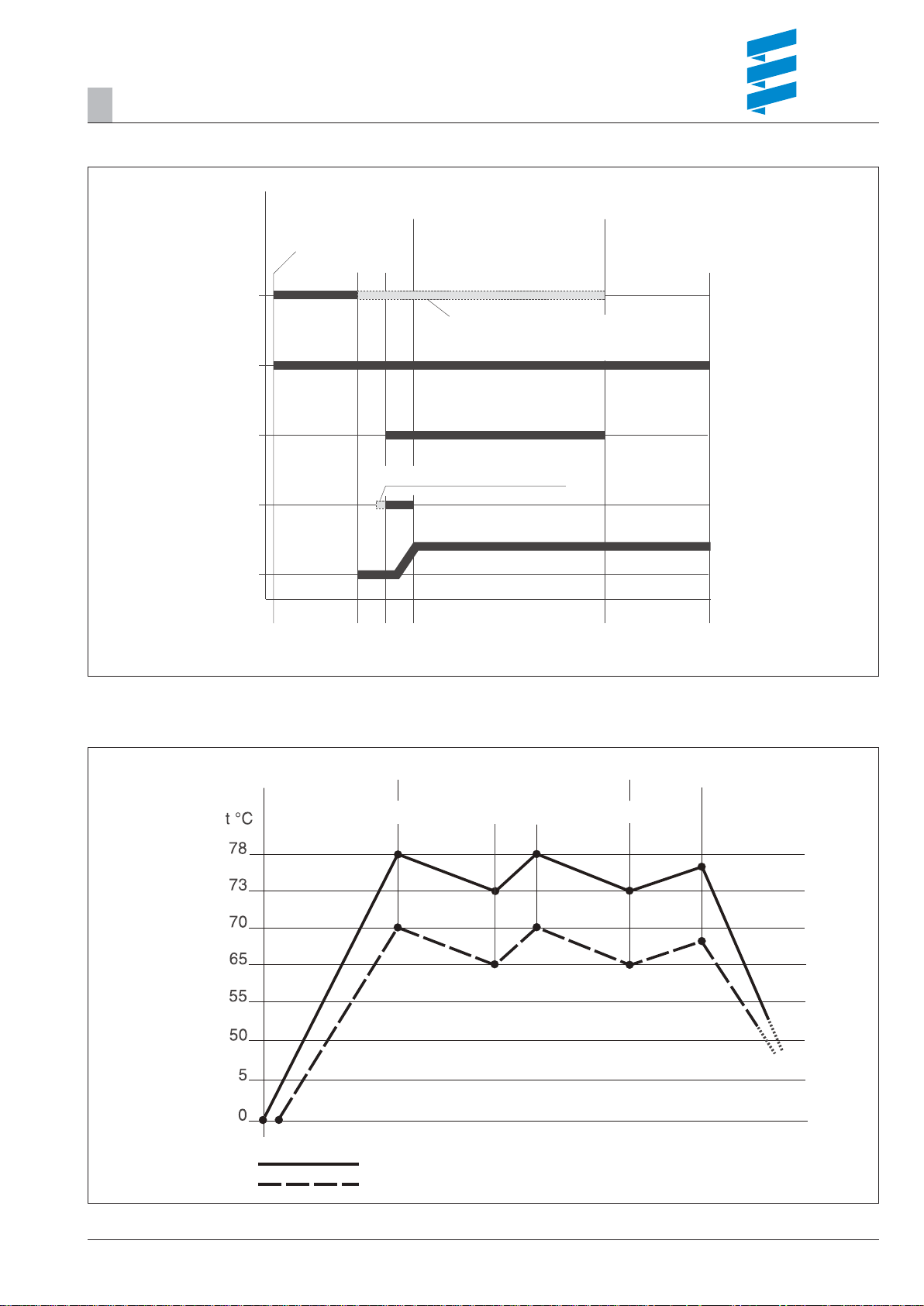

Pumping and pressure loss characteristic curves

Sketch 4

Please note!

• If no limit values are given, the technical data listed is with

the usual heater tolerances of ± 10 % at nominal voltage,

20 °C ambient temperature and Esslingen reference altitude.

• The FLOWTRONIC 5000 water pump is installed in com-

pact design heaters.

• If water pumps are ordered separately, please refer to the

documentation supplied with them for the relevant technical

data, installation positions, etc.

Flow resistance (when pump at rest)Volumetric fl ow rate (with water at 20 °C)

Important!

Safety instructions for technical data!

Failure to comply with the technical data can result in malfunctions.

10

Troubleshooting

4

What to check fi rst in case of faults

• Faulty wiring (short circuits, interruption).

• Visual inspection for

– corroded contacts

– defective fuses

– damaged electrical leads, connections and terminals

– damaged exhaust and combustion air circuit.

• Battery voltage when heater started <19 Volt (measure voltage at control box).

• Check fuel supply.

• On changeover to winter service: Is summer diesel still in

the line?

• Delayed start –> nozzle block heating switched on for

60 seconds.

• The Bus 2000 water pump and the HYDRONIC are automatically switched off shortly after the start if there is no

refrigerant or if the pump impeller is blocked.

Locking the control box

The control box is locked if the following faults occur:

• Overheating

If the heater overheats 3x in succession – fault code 012, is

displayed as AF 015 –> the control box is locked.

• Flame in after-run

If the fault "fl ame in after-run" is signalled 3x in succession

– fault code 058, is displayed as AF 016 –> the control box

is locked.

• Too many attempted starts

If the heater carries out ten failed start attempts in succes-

sion – fault code 052, is displayed as AF 050 –> the control

box is locked.

Cancelling the control box lock

Cancellation of the control box lock is described on pages 15

to 20.

Cancelling control box lock without diagnostic equip-

ment

If the heater is switched on, apply plus at 18-pin cable harness connector, pin 13, cable 1

control) for approx. 3 sec. –> the control box is unlocked.

Additional option from control box

25 1818 53 00 00 with Bus 2000 water pump fault

Apply plus at 18-pin cable harness connector, pin 9, cable 1

bl/sw for approx. 3 sec. –> the control box is unlocked.

2

ge/rt (water pump third party

2

11

Troubleshooting

Too many attempted

starts

4

Fault diagnosis – fl ashing code

(LED with series resistor)

The electronic control box can store up to 5 faults.

The defective component and type of fault are output by the

control box as a fl ashing code and are displayed by an LED

with series resistor (approx. 1 kΩ / 1W).

The LED with series resistor is connected to the 8-pin connector of the heater cable harness (chamber 2, cable 12 bl/ws

and chamber 5, cable 1

2

ge).

The fl ashing codes of the defective components and the corresponding fault codes are described on page 12.

Possible causes and remedial action are explained in the fault

code tables (pages 21 – 24).

Flashing code

400 ms pause at the start

of the fl ashing code

Operation without faults

Flame detection photocell,

Fault code 16, 51, 58

Safety time exceeded,

Fault code 50, 52

LED and series resistor

Sketch 5

8 sec. 16 sec.

resistor

LED

connector B2

chamber 5

chamber 2

8

64

2

1753

connector B1

1

4

5

2

3

6

Flame cutout

Fault code 54

Overheating

Fault code 12, 15

Burner engine

Fault code 32, 33

Undervoltage cut-off

Fault code 11

Overvoltage cut-off

Fault code 10

Temperature sensor

Fault code 14, 60, 61, 71, 72

Connection error

Fault code 20, 21, 25, 37 – 39, 44 – 49, 80 – 83

Control box

Fault code 90 – 97

Short pulse – fl ash duration: 0.4 sec.

Long pulse – fl ash duration: 2.0 sec.

Pause between the pulses: 0.4 sec.

Period of a fl ashing sequence: 8.0 sec.

Sketch 6

12

Troubleshooting

4

Overview of the individual test equipment

and control units

The electronic control box can store up to 5 errors, which can

be read out and displayed. The following test equipment can

be used to query the fault memory in the control box and if

necessary to delete the control box locking:

Test equipment Order No.:

• Diagnostic unit 22 1529 89 00 00

additionally required:

Adaptor cable 22 1000 31 66 00

• EDiTH customer service program

– Basic adapter with software 22 1532 89 00 00

additionally required:

HYDRONIC L extension 22 1539 89 00 00

– ISO adapter 22 1524 89 00 00

additionally required:

Adaptor cable 22 1000 31 66 00

• Burner tester 22 1527 89 00 00

If a diagnostics cable is connected, the following control units

can also be used to query the fault memory in the control box

and if necessary to delete the control box locking:

Control units Order No.:

• Module timer 22 1000 30 34 00

• TP5 radio remote control 22 1000 32 01 00

• EasyStart T 22 1000 32 88 00

• EasyStart R+ 22 1000 32 80 00

Please note!

If the fault memory cannot be read out, check the diagnostics

cable for correct laying and possible damage.

External diagnostic system

With an external, vehicle-specifi c diagnostic system

–> contact the vehicle manufacturer.

13

Troubleshooting

4

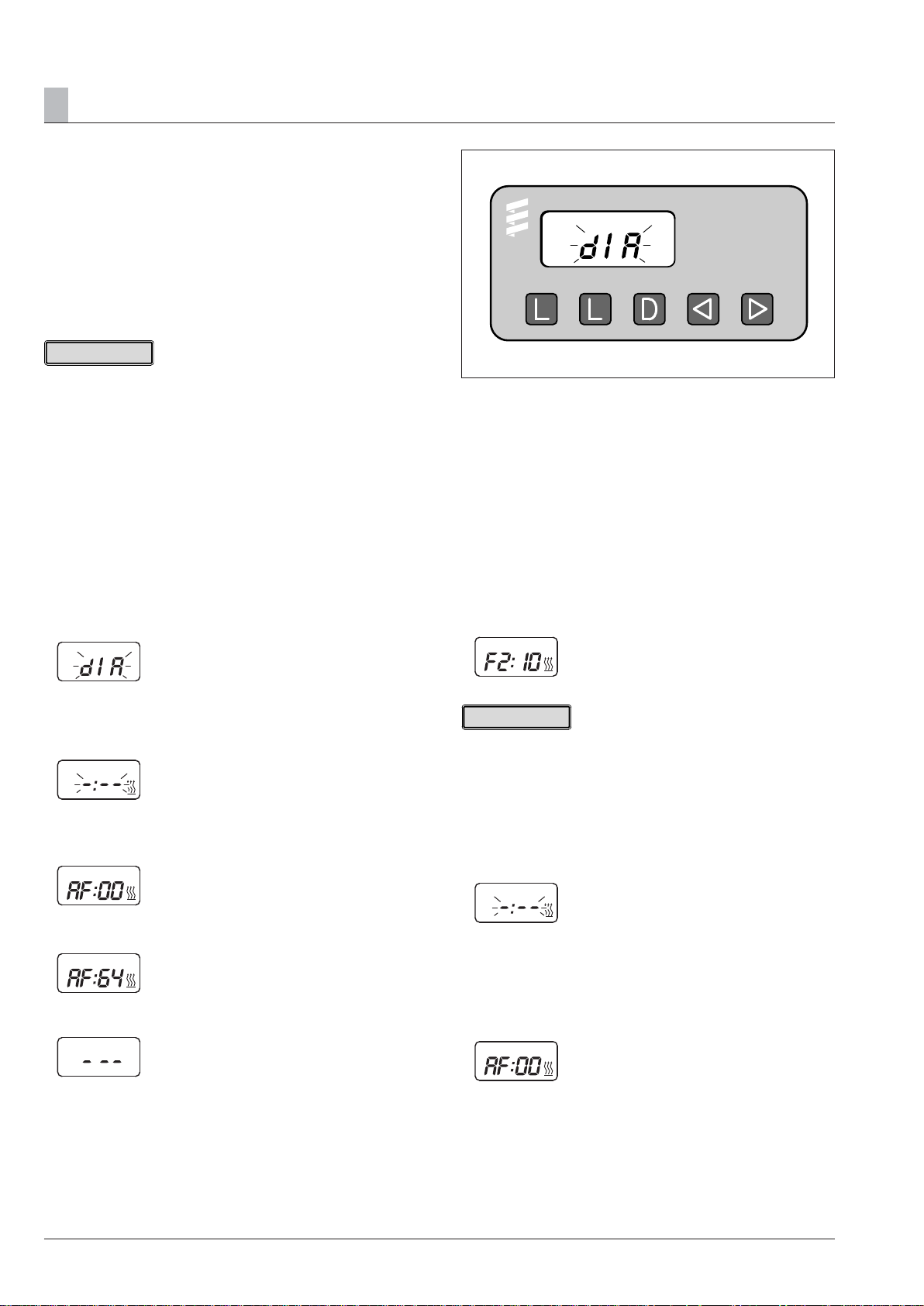

Diagnostic unit

(Order No.: 22 1529 89 00 00)

To connect the diagnostic unit, an additional

adapter cable is required (Order No.: 22 1000 31 66 00).

The current fault is displayed as "AF“ and a 2-digit number

and is always written in the memory location F1.

Preceding faults are moved to the memory locations F2 – F5,

if necessary the contents of memory location F5 is overwritten.

Please note!

• Not only the defective component, but also a defective current circuit results in a fault being displayed.

• Fault code, fault description, cause / remedial action are

described on Pages 21 – 24.

Connect diagnostic unit

• Disconnect the 8-pin connector of the heater's cable harness and connect the adapter cable.

• Connect the diagnostic unit to the adapter cable.

Display is as follows:

Query fault memory

• Use the D key to switch on the heater.

Display is as follows:

• After 8 sec the following is displayed:

Display is as follows:

Sketch 7

– Delete fault memory

l

– Delete fault memory

l

– Switch heater on / off, request diagnosis

d

– Return, F5 – F1

e

– Flow, F1 – F5, current fault (AF)

f

Display of the fault memory F1 – F5 or F5 – F1

• Press the

display the fault memory.

Display is as follows:

e.g. fault memory 2 / fault code 10

Please note!

Only the fault memory locations with an error assigned to

them are displayed.

Delete fault memory

• Press both L buttons simultaneously until the following appears in the display:

Display is as follows:

or f button again, or press several times, to

e

Heater has no malfunction

or

e.g. current error / fault code 64

or

Fault diagnosis not possible

Possible causes:

– Adapter cable is not properly connected.

– Control box is defective or is not capable of diagnosing

(not a universal control box).

14

• If the fault memory has been deleted the most recent current fault is displayed. The current fault is not reset to 00

until the heater is restarted – provided there is no new, more

recent fault.

Display is as follows:

Heater has no faults

Troubleshooting

4

Cancel the control box lock

• Delete the fault memory as described and switch off the

heater using the d key.

• The control box lock is cancelled and the diagnosis closed.

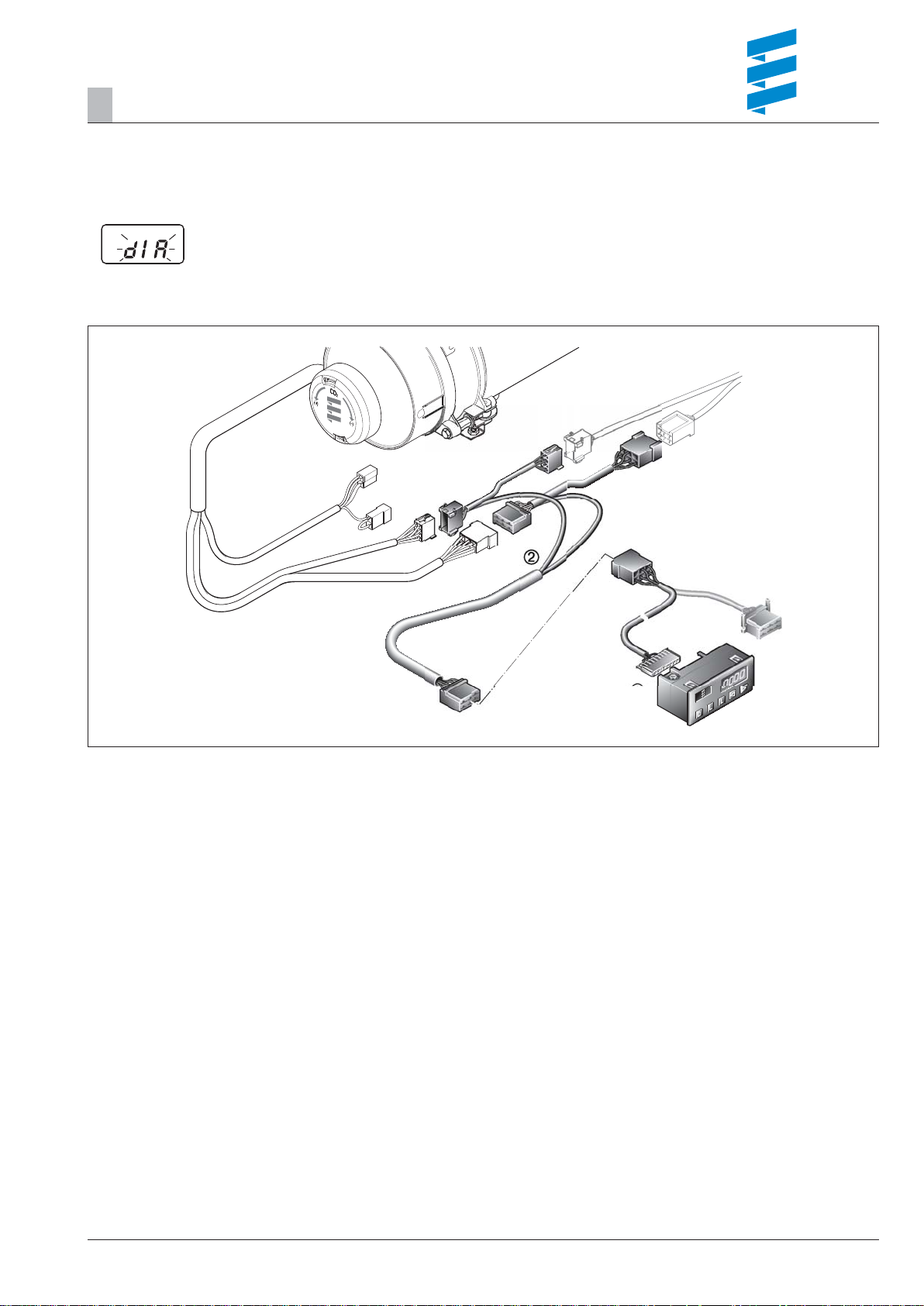

Display is as follows:

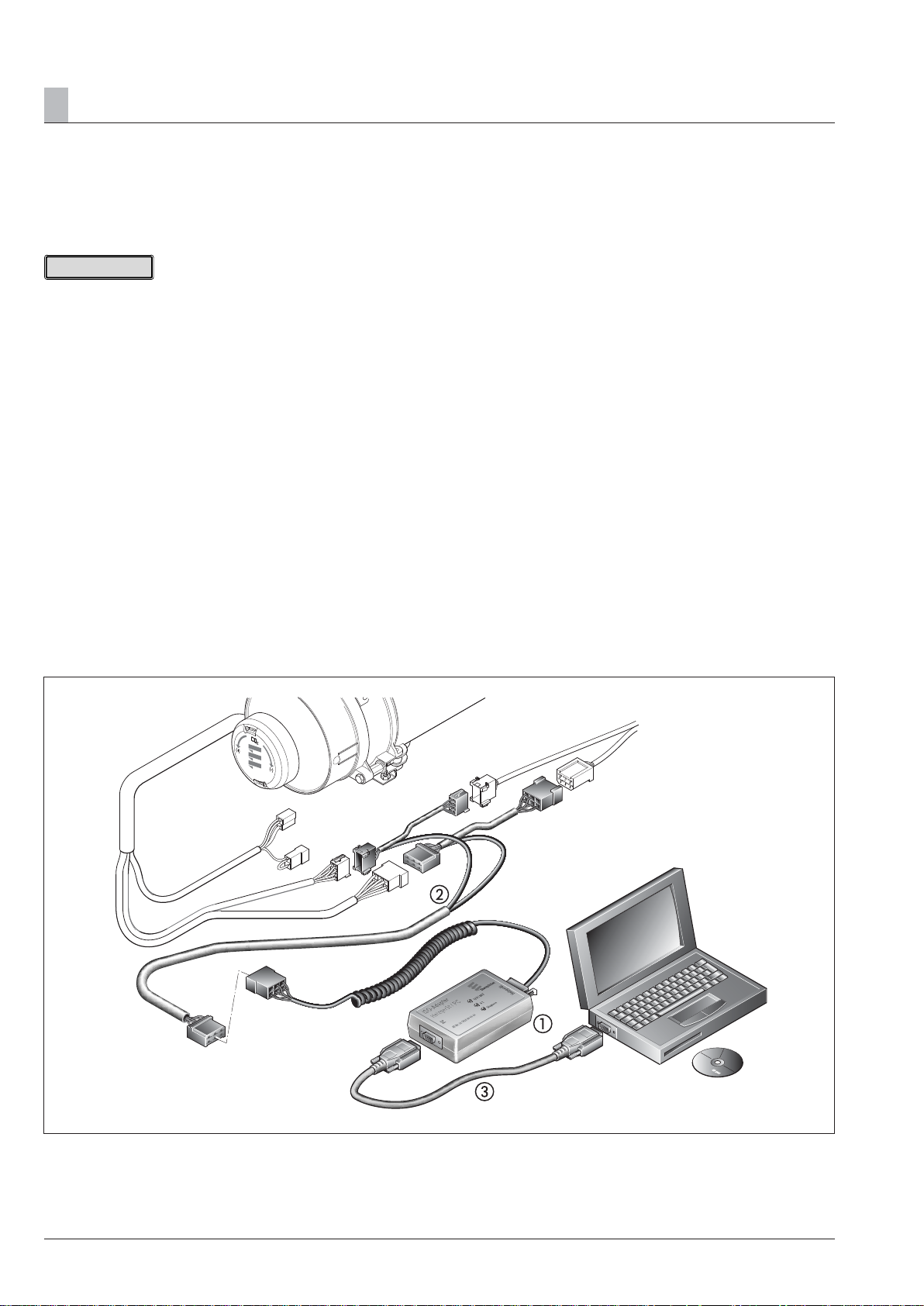

Sketch 8

Diagnostic unit with connection cable

Adaptor cable

15

Troubleshooting

4

EDiTH customer service program

with ISO adapter

(Order No.: 22 1524 89 00 00)

An additional adapter cable is required to connect the ISO

adapter (Order No.: 22 1000 31 66 00).

Please note!

• It is very important to always install in the given order.

• Not only the defective component, but also a defective current circuit results in a fault being displayed.

• Fault code, fault description, cause / remedial action are

described on Pages 21 – 24.

• The EDiTH customer service program software is not included in the scope of supply, it must be downloaded from

the service portal.

• Faults 1 – 5 only are displayed in heaters up to serial No.

12 000.

In addition to faults 1 –5, measured values are also dis-

played in heaters from serial No. 12 001.

Connect ISO adapter

• Disconnect the heater's cable harness.

• Connect the adapter cable to the cable harness – as shown

in the sketch.

• Connect the adapter cable to the ISO adapter.

• Connect the SUB-D connection cable with the PC and the

ISO adapter.

Installing software on the PC

• Double-click "setup.exe" fi le to start and

follow the SETUP program instructions.

Query / delete fault memory F1 – F5

or cancel the control box lock

• Start the software at the PC:

– on the desktop —> double-click the "EDiTH" icon

– Select heater type

– Press the "GO" button.

• Delete fault memory or cancel the control box lock:

– Press the "Delete fault memory" button

—> the stored faults F1 – F5 are deleted and the control

box is unlocked.

Quit diagnosis

• Press the "STOP" button —> fault memory query is ended.

Sketch 9

ISO adapter

Adaptor cable

SUB-D connection cable

16

Troubleshooting

4

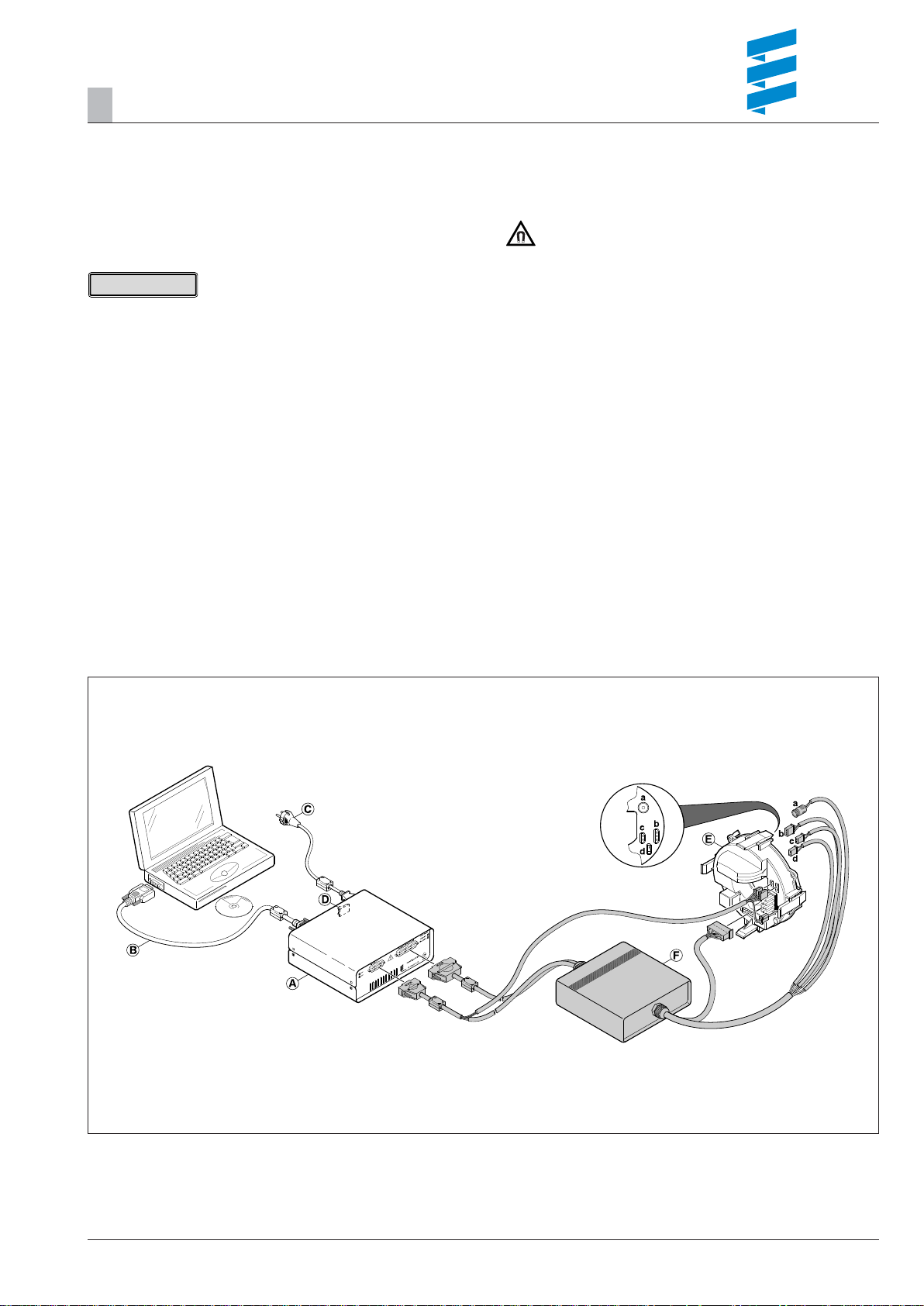

EDiTH customer service program

with basic adapter

EDiTH basic adapter

(Order No.: 22 1532 89 00 00)

An additional extension is required to check the control box

(Order No.: 22 1539 89 00 00).

Please note!

• It is important to always follow the precise connection order

as given below!

• The fl ame failure safeguard integrated in the control box can

only be tested properly if the corresponding mating connector (a) is connected.

• Only push or pull on the connectors, not on the cables!

• Only use the network cable and RS232 cable with snap

ferrites included in the scope of supply. Use original accessories with snap ferrites only to connect the test equipment.

• Not only the defective component, but also a defective current circuit results in a fault being displayed.

• Fault code, fault description, cause / remedial action are

described on Pages 21 – 24.

Important!

Magnetic fi eld!

During the test operation a magnetic fi eld develops at the

adapter. Therefore, do not place any objects such as data

media, credit cards, etc. on the adapter or in its immediate vicinity.

Connect basic adapter

• Start computer and wait until the system has successfully

booted.

• Start PC software.

• Insert the unit connector of the mains cable in the basic

adapter and connect the mains connection to the mains.

• Connect the SUB-D connection cable with the PC and

basic adapter.

Connect extension and test control box

• Connect the extension to the basic adapter.

• Connect extension and basic adapter to control box.

• Switch on basic adapter at mains switch.

• Select the control box version and operating voltage

(12 V / 24 V) in the PC software.

• Start the control box test with the PC software.

A more detailed description of how to operate the basic

adapter is given in the EDiTH online help.

(A) Basic adapter

(B) SUB-D connection cable

(C) Mains connection

(D) Mains switch

(E) Control box

(F) Extension

Sketch 10

17

Loading...

Loading...