Page 1

Eberspächer

J. Eberspächer

GmbH & Co. KG

Eberspächerstr. 24

D -73730 Esslingen

Telephone

(switchboard)

(0711) 939-00

Facsimile

(0711) 939-0500

www.eberspaecher.com

25 1866 90 98 29 EN 12.2005 Subject to changes Printed in Germany © J. Eberspächer GmbH & Co. KG

Air heater 3 L

Technical description

Installation instructions

Operating instructions

Maintenance instructions

Air heater for petrol and diesel fuel,

operating independently of the engine

Heater Order number

B 3 L C, 12 V 20 1717 05 00 00

Heater Order number

D 3 L C, 12 V 25 1867 05 00 00

D 3 L C, 24 V 25 1844 05 00 00

Please give this manual to the customer

after installation of the heater.

Page 2

Contents

Chapter Title Contents Page

2

7

6

5

4

3

2

1 Introduction

Introduction

Product information

Installation

Operation and function

Electric

Faults

Maintenance

Service

Environment

• Contents .................................................................................................... 2

• Concept of this manual .............................................................................. 3

• Special text structure, presentation and picture symbols ......................... 4

• Important information before starting work ............................................... 4

• Statutory regulations ............................................................................. 5, 6

• Safety instructions for installation and operation .................................. 6, 7

• Accident prevention .................................................................................. 7

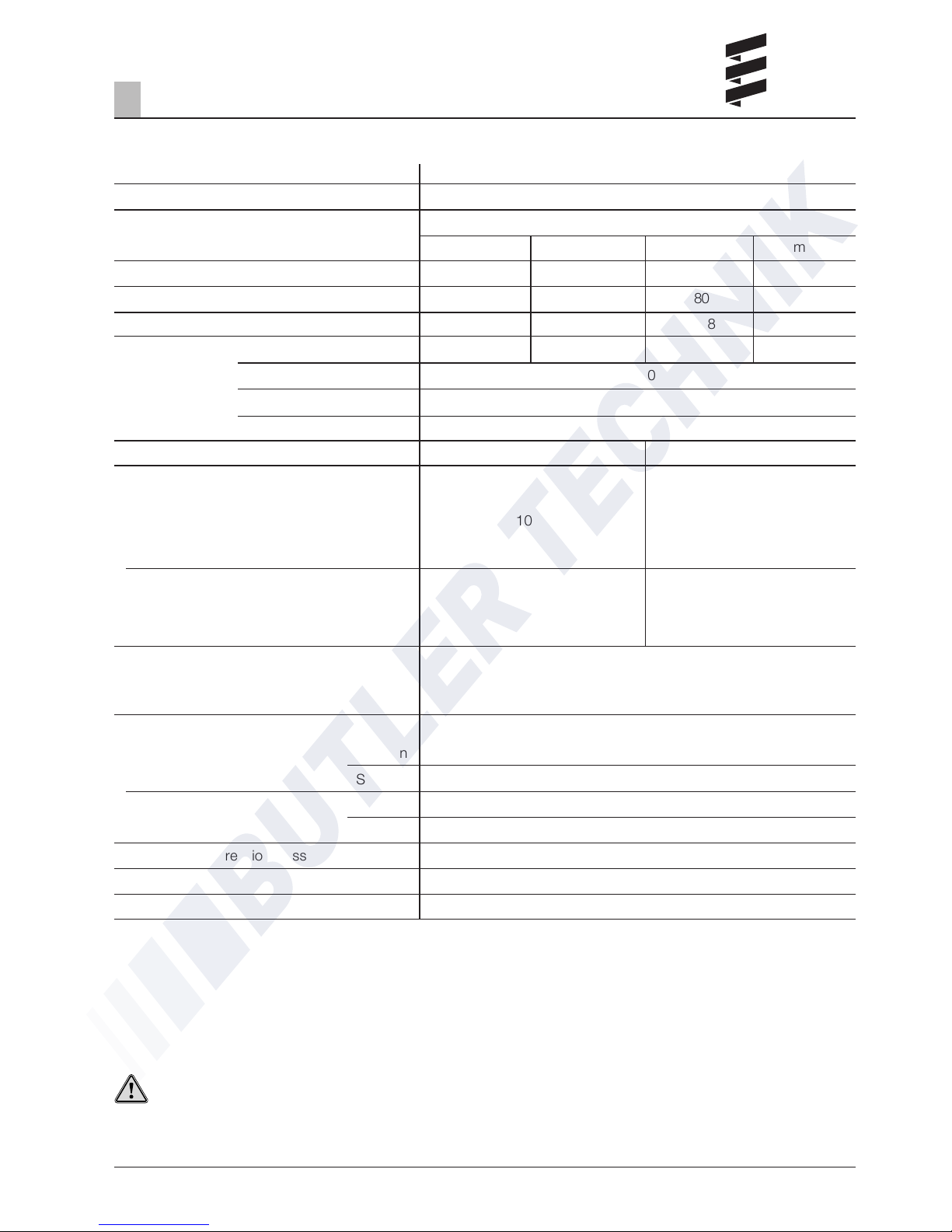

• Technical data for the B / D 3 L C ............................................................ 8

• Technical data for the B / D 3 L C ............................................................ 9

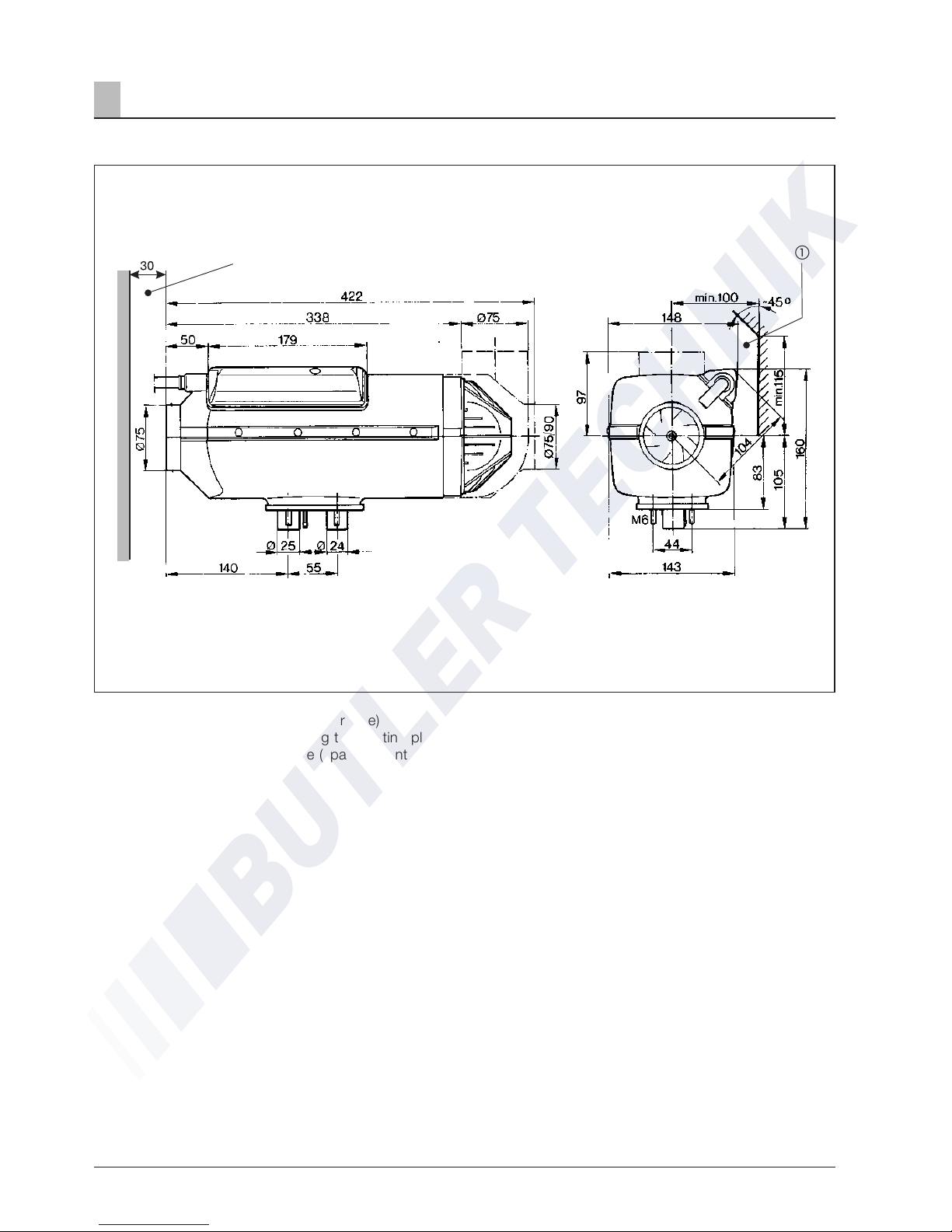

• Main dimensions ....................................................................................... 10

• Installation and location ........................................................................... 11

• Installing the 24 V heater in a vehicle

for the transport of dangerous goods ....................................................... 11

• Installation location .................................................................................. 12

• Possible installation positions................................................................... 13

• Mounting and fastening ............................................................................ 14

• Nameplate ................................................................................................ 15

• Heater air system ..................................................................................... 16

• Exhaust system ......................................................................................... 17

• Combustion air system .............................................................................. 18

• Fuel supply ...................................................................................... 19 – 23

• Operation instructions / important information for operation ................... 24

• Initial commissioning ................................................................................. 24

• Description of functions ............................................................................25

• Control and safety devices / EMERGENCY OFF ....................................... 26

• Mounting the controller ............................................................................ 27

• Heater wiring ............................................................................................ 27

• Parts list for heaters / control elements ................................................. 28

• Circuit diagrams at the end of this manual

• Troubleshooting procedure ....................................................................... 29

• Maintenance instructions ......................................................................... 29

• Service .....................................................................................................29

• Certification .............................................................................................. 30

• Disposal .................................................................................................... 30

• EU Declaration of Conformity .................................................................... 30

1

Page 3

3

Introduction1

Concept of this manual

This manual aims to support the service company

installing the heater and to provide the user with all

important information about the heater.

The manual has been divided into 7 chapters to make

it easier to find the corresponding information quickly.

1

2

3

4

5

6

7

Introduction

Here you find important introductory information

about installation of the heater and about the

structure of the manual.

Product information

Here you will find information about the scope of

supply, the technical data and the dimensions of

the heater.

Installation

Here you will find important information and

instructions referring to installation of the

heater.

Operation and function

Here you will find information about the

operation and function of the heater.

Electric

Here you will find information about the

electronic system and electronic components of

the heater.

Troubleshooting / maintenance / service

Here you will find information about possible

faults, troubleshooting, servicing / maintenance

and the service hotline.

Environment

Here you will find information about certification

and disposal of the heater together with the EU

Declaration of Conformity.

Page 4

4

1 Introduction

Special text structure, presentation and

picture symbols

This manual uses special text structures and picture

symbols to emphasize different contents.

Please refer to the examples below for the

corresponding meanings and associated actions.

Special structure and presentations

A dot (•) indicates a list which is started by a

heading.

If an indented dash (–) follows a dot, this list is

subordinate to the dot.

Picture symbols

Regulation!

This picture symbol with the remark “Regulation“

refers to a statutory regulation.

Failure to comply with this regulation results in expiry

of the type permit for the heater and preclusion of any

guarantee and liability claims on J. Eberspächer

GmbH & Co. KG and its associated companies.

Danger!

This picture symbol with the remark “Danger“ refers to

the risk of fatal danger to life and limb.

Under certain circumstances, failure to comply with

these instructions can result in severe or life-

threatening injuries.

Caution!

This picture symbol with the remark „Caution“ refers

to a dangerous situation for a person and / or the

product.

Failure to comply with themes instructions can result

in injuries to people and / or damage to machinery.

These remarks contain application recommendations

and useful tips for installation of the heater.

Please note!

Important information before starting

work

Range of application of the heater

The air heater operating independently of an engine is

intended for installation in the following vehicles:

• All types of motor vehicles and their trailers

• Construction machinery

• Agricultural machinery

• Boats, ships and yachts (only diesel heaters)

• Camper vans

• The heater is approved for installation inside vehicle

spaces used by people (max. 9 seats), subject to

compliance with the statutory requirements and

notes given in the contents of these instructions.

• The D 3 L C – 24 Volt heater can be installed in

vehicles used for the transport of hazardous goods

according to ADR / ADR99.

Purpose of the heater

• Pre-heating, de-misting windows

• Heating and keeping the following warm:

– Driver and working cabs, ship’s cabins

– Freight compartments

– Passenger and crew compartments

– Camper vans

On account of its functional purpose, the heater is

not approved for the following applications:

• Long-term continuous operation, e.g. for preheating

and heating of:

– Residential rooms, garages

– Work huts, weekend homes and hunting huts

– House boat, etc.

• Heating or drying of:

– Living creatures (people or animals) by blowing hot

air directly at the subject

– Objects

– Blowing hot air into containers

Caution!

Safety instructions for application and proper

purpose!

• The heater must only be used and operated for the

range of application stated by the manufacturer in

compliance with the “Operation instructions“

included with every heater.

Please note!

Page 5

5

Introduction1

Regulation!

• Arrangement of the heater

– Parts of the structure and other components near

the heater must be protected from excess heat

exposure and possible contamination from fuel or

oil.

– The heater must not pose a fire hazard even when

it overheats. This requirement is deemed to be

fulfilled when adequate clearance to all parts is

observed during installation, sufficient ventilation is

provided and fire-proof materials or heat plates are

used.

– The heater must not be mounted in the passenger

compartment of vehicles in class M2 and M3. But a

heater in a hermetically sealed enclosure which

otherwise complies with the conditions stated

above may be used.

– The factory nameplate or duplicate must be affixed

so that it can still be easily read when the heater

is installed in the vehicle.

– All appropriate precautions must be taken when

arranging the heater to minimise the risk of

injuries to persons or damage to other property.

• Operating status display

– A clearly visible operating display in the user’s field

of vision must indicate when the heater is

switched on an off.

• Fuel supply

– The fuel intake connection must not be located in

the passenger compartment and must be sealed

with a properly closing lid to prevent any fuel

leaks.

– In heaters for liquid fuel where the heater fuel is

separate from the vehicle fuel, the type of fuel and

intake connection must be clearly identified.

– A warning sign is to be fixed to the intake

connection indicating that the heater must be

switched off before refuelling.

• Exhaust system

– The exhaust outlet must be arranged so as to

prevent any penetration of exhaust fumes into the

vehicle interior through the ventilation system,

warm air intakes or open windows.

• Combustion air intake

– The air for the heater combustion chamber must

not be sucked in from the passenger compartment

of the vehicle.

– The air intake must be arranged or protected in

such a way that it cannot be blocked by other

objects.

• Heater air intake

– The heater air supply must consist of fresh air or

circulated air and be sucked in from a clean area

not contaminated by exhaust fumes of the drive

machine, the combustion heater or any other

source in the vehicle.

– The intake pipe must be protected by a grid or

other suitable means.

• Hot air outlet

– The hot air pipes within the vehicle must be

arranged or protected in such a way that there is

no risk of injury or damage if they are touched.

– The air outlet must be arranged or protected in

such a way that it cannot be blocked by any

objects.

Statutory regulations

The Federal Road Transport Directorate has issued an

"EC type approval" and an "EMC type approval" for the

heater for installation in motor vehicles and with the

following official type approval marks, noted on the

heater name plate.

Air heater 3L EC- e1 00 0056

EMC- e1 021064

Page 6

6

1 Introduction

Safety instructions for installation and

operation

Danger!

Risk of injury, fire and poisoning!

• The heater must only be started up when the

maintenance flap is closed and the outlet hood is

mounted in position.

• The maintenance flap must not be opened during

operation.

• Disconnect the vehicle battery before starting any

kind of work.

• Before working on the heater, switch the heater off

and let all hot parts cool down.

• The heater must not be operated in closed rooms,

e.g. in the garage or in a multi-story car park.

• Adjustable hot air outlets must always be adjusted

so that they cannot blow hot air directly at living

creatures (people, animals) or object sensitive to

temperature (loose and / or fastened).

Caution!

Safety instructions for installation and operation!

• The year of initial commissioning must be marked on

the nameplate.

• The heat exchanger of air heaters is a component

subject to high thermal loads which must be

replaced 10 years after initial commissioning of the

heater. In addition, the installation date must be

entered on the plate “original spare part“ enclosed

with the heat exchanger. Then affix the plate next to

the nameplate on the heater.

• The heater must only be installed by a JE partner

authorised by the manufacturer according to the

instructions in this manual and possibly according to

special installation recommendations; the same

applies to any repairs to be carried out in the case

of repairs or guarantee claims.

• Only the control elements approved by

J. Eberspächer GmbH & Co. KG may be used to

operate the heater. Use of other control elements

can cause malfunctions.

Statutory regulations

Regulation!

Mounting the heater in a vehicle for the transport of

dangerous goods as per ADR / ADR99

• When the heater is to be installed in vehicles for the

transport of dangerous goods, the regulations of

ADR / ADR99 must be observed.

• Compliance with the statutory regulations and safety

instructions is prerequisite for guarantee and liability

claims. Failure to comply with the statutory

regulations and safety instructions and incorrect

repairs even when using original spare parts make

the guarantee null and void and preclude any

liability for J. Eberspächer GmbH & Co. KG.

• Detailed information about the regulations of ADR /

ADR99 are contained in the information leaflet no.

25 2161 95 15 80 (see also page 11 and 26).

• Subsequent installation of this heater must comply

with these installation instructions.

• The statutory regulations are binding and must also

be observed in countries which do not have any

special regulations.

• When the heater is to be installed in vehicles not

subject to the German Ordinance for the Registration of Motor Vehicles (StVZO), for example ships,

the specially valid regulations and installation

instructions for these special applications must be

observed.

• Installation of the heater in special vehicles must

comply with the regulations applying to such

vehicles (for example for vehicles for the transport of

dangerous goods as per ADR / ADR99).

• Other installation requirements are contained in the

corresponding sections of this manual.

Please note!

Page 7

7

Introduction1

Safety instructions for installation and

operation

Caution!

Safety instructions for installation and operation!

• Repairs by unauthorised third parties and / or not

using original spare parts are dangerous and

therefore not allowed. They result in expiry of the

type permit of the heater; consequently, when

installed in motor vehicles they can cause expiry of

the vehicle operating licence.

• The following measures are not allowed:

– Changes to components relevant to the heater.

– Use of third-party components not approved by

Eberspächer.

– Nonconformities in installation or operation from

the statutory regulations, safety instructions or

specifications relevant to safe operation as stated

in the installation instructions and operating

instructions. This applies in particular to the

electrical wiring, fuel supply, combustion air

system and exhaust system.

• Only original accessories and original spare parts

must be used during installation or repairs.

• When carrying out electric welding on the vehicle,

the plus pole cable at the battery should be

disconnected and placed at ground to protect the

controller.

• The heater must not be operated where there is a

risk of an accumulation of flammable vapours or

dust, for example close to

– fuel depot

– coal depot

– wood depot

– grain depots etc.

• The heater must be switched off when refuelling.

• When the heater is mounted in a safety housing

etc., the installation compartment of the heater is

not a stowage compartment and must be kept

clear. In particular fuel canisters, oil cans, spray

cans, gas cartridges, fire extinguishers, cleaning

rags, items of clothing, paper etc. must not be

stored or transported on or next to the heater.

• Defect fuses must only be replaced by fuses with the

prescribed rating.

• If fuel leaks from the heater fuel system, arrange for

the damage to be repaired immediately by a JE

service partner.

• After-running of the heater must not be interrupted

prematurely e.g. by pressing the battery

disconnecting switch, apart from in the case of an

emergency stop.

Accident prevention

General accident prevention regulations and the

corresponding workshop and operation safety

instructions are to be observed.

Page 8

8

Product information2

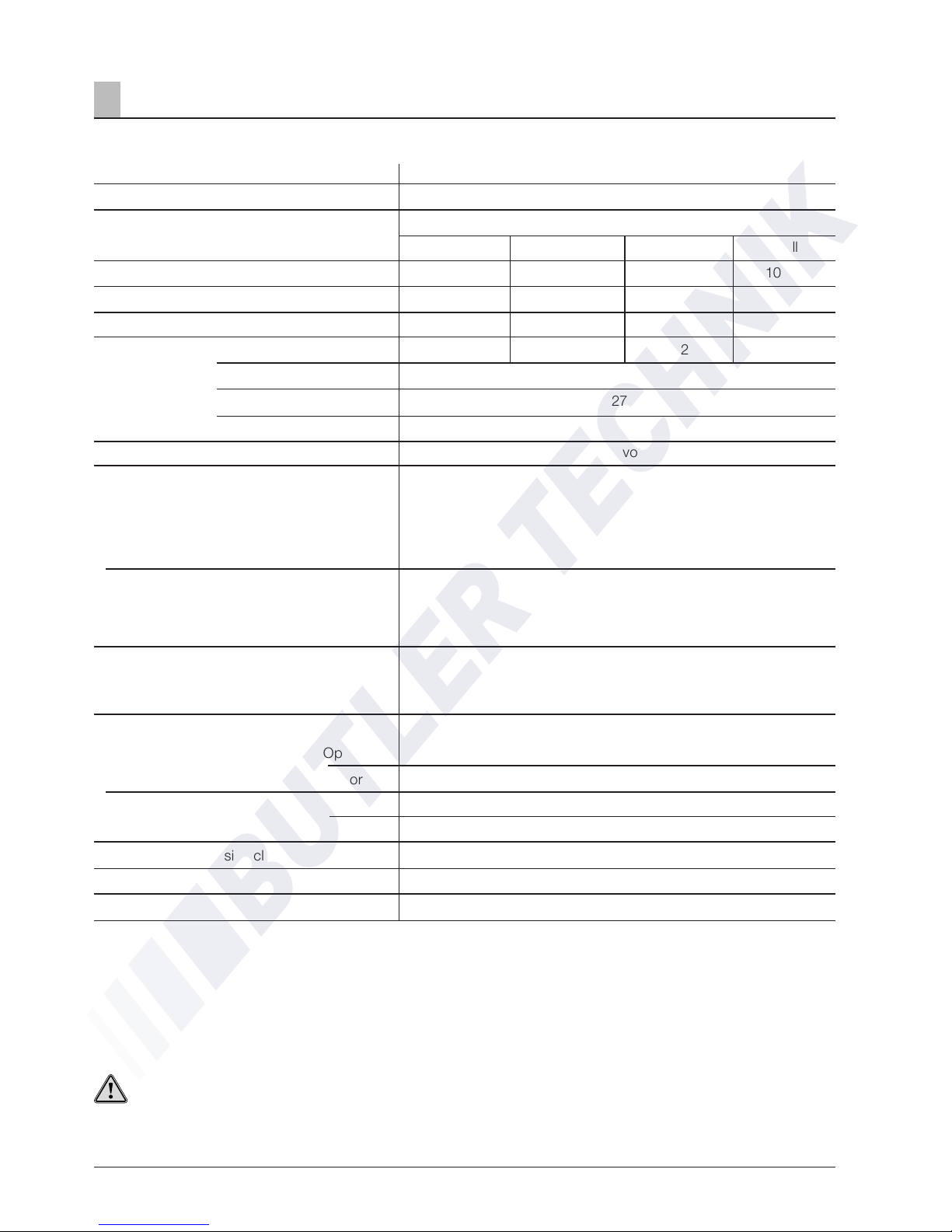

Technical data

Heater

Heating medium

Control of the heat flow

Heat flow (watt)

Heater air flow rate without counterpressure (kg/h)

Fuel consumption (l/h)

Electr. power (watt) in operation

at start – 12 volt

at start – 24 volt

in the control phase “OFF“

Rated voltage

Operating range

Lower voltage limit:

An undervoltage protection in the controller

switches the heater off on reaching the

voltage limit.

Upper voltage limit:

An overvoltage protection in the controller

switches the heater off on reaching the

voltage limit.

Fuel

“Fuel quality“ and “fuel at low temperatures“

see operating instructions page 23.

Tolerable operating temperature

Heater Operation

Storage

Dosing pump Operation

Storage

Interference suppression class

Fan operation

Weight

B 3 L C

Air

Stage

Power Large Medium Small

3500 2800 1500 1000

– 140 80 65

– 0.38 0.20 0.13

–301210

250

275

5

12 volt

10 volt

14 volt

Commercially available petrol

(DIN EN 228)

–40 °C to +50 °C

–40 °C to +85 °C

–40 °C to +20 °C

–40 °C to +85 °C

3 (further measures possible)

possible

ca. 6 kg

All technical data ±10 %

Caution!

Safety instructions for technical data!

Failure to comply with the technical data can result

in malfunctions.

Page 9

9

Product information2

Technical data

Heater

Heating medium

Control of the heat flow

Heat flow (watt)

Heater air flow rate without counterpressure (kg/h)

Fuel consumption (l/h)

Electr. power (watt) in operation

at start – 12 volt

at start – 24 volt

in the control phase “OFF“

Rated voltage

Operating range

Lower voltage limit:

An undervoltage protection in the controller

switches the heater off on reaching the

voltage limit.

Upper voltage limit:

An overvoltage protection in the controller

switches the heater off on reaching the

voltage limit.

Fuel

“Fuel quality“ and “fuel at low temperatures“

see operating instructions page 23.

Tolerable operating temperature

Heater Operation

Storage

Dosing pump Operation

Storage

Interference suppression class

Fan operation

Weight

D 3 L C

Air

Stage

Power Large Medium Small

3500 2800 1500 1000

– 140 80 65

0.42 0.37 0.18 0.12

–301210

250

275

5

12 volt 24 volt

10 volt 20 volt

14 volt 28 volt

Commercially available diesel (DIN EN 590)

Bio diesel PME (DIN V 51606)

–40 °C to +70 °C

–40 °C to +85 °C

–40 °C to +50 °C

–40 °C to +85 °C

3 (further measures possible)

possible

ca. 6 kg

All technical data ±10 %

Caution!

Safety instructions for technical data!

Failure to comply with the technical data can result

in malfunctions.

Page 10

10

Product information2

Main dimensions

Minimum installation distance (clearance) for

opening the cap and dismantling the heating plug.

Minimum installation clearance (space) for intake

of heater air.

A = Exhaust

B = Fuel

V = Combustion air

Page 11

11

Installation3

Installation and location

The heater is suitable and certified for installation in

parts of vehicles used by persons.

Installation in the cab or passenger compartments of

coaches or buses with more than 9 seats is not

allowed.

When installing in compartments used by persons, the

exhaust, combustion air and fuel pipes in these areas

must not have any detachable connections and must

be routed splash-waterproof in the breakthroughs.

For this reason, the heater can be mounted with its

foot using the flange seal in the foot to the vehicle

floor or to an outer wall of the vehicle.

The electronic control is integrated in the heater

which makes wiring during installation much easier.

Please note!

• When installing the heater, always make sure there

is sufficient clearance left for intake of the heater air

and for dismantling the glow plug and controller.

• Observe the regulations and safety instructions for

this chapter, given on page 4 – 7.

Installing the 24 V heater in a vehicle for

the transport of dangerous goods as per

ADR / ADR99

Heaters (24 volt) are allowed to be installed in

vehicles used for the transport of dangerous goods as

per ADR / ADR99.

The heater fulfils the regulations of ADR / ADR99 with

the corresponding electrical wiring, see circuit

diagrams at the end of this manual.

Detailed information about the regulations of ADR /

ADR99 is contained in the leaflet no.

25 2161 95 15 80.

Please note!

When the heater is to be installed in vehicles for the

transport of dangerous goods, the regulations of ADR

/ ADR99 must be observed.

Page 12

12

Installation3

Installation location

Installation in a car or people carrier

In a car or people carrier, the heater is preferably

installed in the passenger compartment or boot.

If it is not possible to install the heater in the

passenger compartment or boot, the heater can also

be mounted under the vehicle floor.

Heater in front of the passenger seat

Heater between the driver’s seat and the

passenger seat

Heater under the vehicle floor

Heater under the back seat

Heater in the boot

Installation in a truck

In a truck, the heater is preferably installed inside the

driver’s cab.

If it is not possible to install the heater inside the

driver’s cab, it can also be mounted in the tool box or

in a storage box.

Installation in an excavator cab

In an excavator, the heater is preferably installed in

the cab.

If it is not possible to install the heater in the cab, the

heater can also be installed in a storage box outside

the cab.

Heater in the passenger’s foot room

Heater on the cab rear wall

Heater under the bed

Heater in the tool box

Heater in the seat box

Heater on the cab rear wall

Heater in the safety housing

• The installation suggestions made in the installation

instructions are just examples. Other installation

locations are possible, as long as they correspond

to the installation requirements stated in these

instructions.

• Other installation information (e. g. for boats and

ships) is available from the manufacturer on request.

• Observe the tolerable installation position together

with the operating and storage temperatures.

Please note!

Page 13

13

Installation3

Possible installation positions

The heater is preferably installed in the normal

position as shown in the drawing.

Depending on the installation conditions, the heater

can be tilted by max. 30° (flow direction to the

bottom) or turned by max. 90° around its own

longitudinal axis (exhaust connection horizontal, glow

plug points upwards!).

Normal position horizontal (exhaust connection

downwards) with tolerable swivel range

Heater air intake opening (fan wheel)

Position of the glow plug

Direction of flow

In the heating mode, the heater can deviate from the

shown normal or maximum installation positions by up

to +15° in all directions because of a slanting position

of the vehicle or boat, without any impaired functions.

Page 14

14

Installation3

There must be sufficient clearance between the

heater and the vehicle floor – also check that the

fan wheel runs freely.

The mounting surface must be flat and smooth.

The flange seal must be mounted.

The vehicle wall must be flat and smooth.

Reinforcement plate (if required, see above)

Spring washer

Hexagon nut M6 (torque 5

+1

Nm)

Mounting and fastening

Make the through-holes for exhaust, combustion air

and fuel as shown in the drilling hole pattern.

The support surface for the heater foot must be flat.

An appropriate tool can be purchased from the

manufacturer for drilling the through-holes and also

smoothing the support surface.

The Ø 10.5 mm hole for the “dosing pump“ cables is

not included in the drilling hole pattern and must be

drilled depending on the installation.

Drilling hole pattern

Special tool

If the sheet metal of the support surface is thinner

than 1.5 mm, an additional reinforcement plate will

have to be fitted.

Order no: reinforcement plate 20 1577 89 00 03

Order no: special tool 99 1201 46 53 29

Fastening the unit on the vehicle floor Fastening the heater horizontally to the vehicle wall

Page 15

15

Installation3

Nameplate

The nameplate is fixed on the upper jacket shell.

The 2nd nameplate (duplicate) is included in the

heater’s scope of supply and, if necessary, can be

stuck onto an easily visible place on the heater or in

the area of the heater.

The regulations and safety instructions to be observed

for this chapter are stated on page 5.

Original nameplate

Please note!

Page 16

16

Installation3

Heater air system (example)

Heater air system

The universal installation kit includes a flexible pipe,

an outflow and a safety grid for the heater air system.

Danger!

Risk of burning and injuries!

• The hoses of the heater air system and the hot air

outlet are to be routed and fastened in such a way

that they pose no temperature risk to people,

animals or materials sensitive to temperature from

radiation / contact or blowing directly. If necessary,

a cover is to be fitted to the heater air system or hot

air outlet.

• The outflow hood must be fitted on the hot air

outflow side.

• A safety grid must be fitted to the heater air intake

side and outflow side if no air hoses are mounted, to

prevent any injuries from the heater air fan or burns

from the heat exchanger.

• High temperatures occur in the heater air system

during and after the heater has been working. This

is why it is important to avoid working in the vicinity

of the heater air system while the heater is working.

In such cases, switch the heater off beforehand and

wait until all parts have cooled down completely. If

necessary, wear safety gloves.

• Comply with the regulations and safety instructions

for this chapter given on page 4 – 7.

• When routing the hot air system, comply with the

guide numbers of the heater and the air duct parts

in the accessories catalogue.

Caution!

• The heater air intake openings must be arranged in

such a way that under normal circumstances, it is

not possible for exhaust from the vehicle engine and

heater to be sucked into the system, or for the

heating air to be contaminated with dust, salt spray,

etc.

• For circulating air, position the circulating air intake

in such a way that the outflowing hot air cannot be

directly sucked in again.

• In the event of possible overheating, it is possible for

local lot air temperatures of up to max. 150 °C or

surface temperatures of up to max. 80 °C to occur

immediately before the defect shutdown. Therefore

only temperature-resistant hot air hoses approved by

us must be used for the heater air system!

• When checking the functions, the mean outflow

temperature measured after the heater has been

running about 10 minutes at approx. 30 cm from the

outlet should not exeed 110 °C (at an intake

temperature of approx. 20 °C).

• If there is a risk of the driver and passengers

touching the heater when the vehicle is being

driven normally, a contact protection device must be

fitted.

Please note!

Safety grid

Outlet hood, Ø 75 mm / Ø 90 mm

Hose clip

Flexible hose, Ø 75 mm / Ø 90 mm

Rotating outflow

Connection fitting with safety grid

Page 17

17

Installation3

Exhaust system

Mounting the exhaust system

The universal installation kit includes a flexible

exhaust pipe, inner Ø 24 mm, 1000 mm long and an

exhaust silencer.

The flexible exhaust pipe can be shortened to 20 cm

or lengthened to max. 2 m, depending on the

installation conditions.

Fasten the exhaust silencer to a suitable position in

the vehicle.

Route the flexible exhaust pipe from the heater to the

exhaust silencer and fasten with pipe clips.

Connect an exhaust end pipe to the exhaust silencer

with a pipe clip.

After finishing all installation work, place an end

sleeve on the exhaust end pipe.

(Exhaust diagram see page 18).

Caution!

Safety instructions!

The whole exhaust system gets very hot during and

immediately after the heater has been working.

This is why the exhaust system must be routed

according to these installation instructions

• The exhaust pipe must end in the open air.

• The exhaust pipe must not protrude beyond the

lateral limits of the vehicle.

• Install the exhaust pipe sloping slightly downwards.

If necessary, make a drain hole approx. Ø 5 mm at

the lowest point to drain off condensation.

• Important functional parts of the vehicle must not be

impaired (keep sufficient clearance).

• Mount the exhaust pipe with sufficient clearance to

heat-sensitive parts. Pay particular attention to fuel

pipes (plastic or metal), electrical cables and brake

hoses etc.!

• Exhaust pipes must be fastened safely

(recommended clearance of 50 cm) to avoid damage

from vibrations.

• Route the exhaust system so that the emitted fumes

are not sucked in with the combustion air.

• The mouth of the exhaust pipe must not be clogged

by dirt and snow.

• The mouth of the exhaust pipe must not point in the

direction of travel.

• Always fasten the exhaust silencer to the vehicle.

Danger!

Risk of injuries and burns!

Every type of combustion produces high temperatures

and toxic exhaust fumes.

This is why the exhaust system must be routed

according to these installation instructions.

• Do not perform any work on the exhaust system

while the heater is working.

• Before working on the exhaust system, first switch

the heater off and wait until all parts have cooled

down completely, wear safety gloves if necessary.

• Do not inhale exhaust fumes.

• Comply with the regulations and safety instructions

for this chapter given on page 4 – 7.

Please note!

Page 18

18

Installation3

Combustion air system

Mounting the combustion air system

The universal installation kit includes a flexible

combustion air intake silencer, inner Ø 25 mm.

The flexible combustion air intake silencer can be

extended with a combustion air hose to max. 2 m

depending on the installation conditions.

Fasten the combustion air intake silencer to the

heater with a pipe clip and at suitable points with

hose clips or cable ties.

After finishing the work, put an end sleeve on the

combustion air intake silencer.

Order No. for the combustion air hose: see spare

parts catalogue.

Comply with the regulations and safety instructions for

this chapter given on page 4 – 7.

Please note!

Caution!

Safety instructions for the combustion air system!

• The combustion air opening must be free at all

times.

• Position the combustion air intake to be sure that

exhaust fumes cannot be sucked in with the

combustion air.

• Do not arrange the combustion air intake to

pointing against the wind blast.

• The combustion air intake must not get clogged

with dirt and snow.

• Install the combustion air intake system sloping

slightly downwards. If necessary, make a drain hole

approx. Ø 5 mm at the lowest point to drain off

condensation.

Exhaust and combustion air circuit

Combustion air silencer

Combustion air hose, di = 25 mm, optional

Flexible exhaust pipe, di = 24 mm

Exhaust silencer, optional

Intake / outlet opening – protect from wind, snow,

dirt and water

End sleeve for the combustion air silencer or

combustion air hose

End sleeve for flexible exhaust pipe

Page 19

19

Installation3

Correct connection

Incorrect connection – bubble formation

Fuel supply

Mounting the dosing pump, routing the fuel pipes

and mounting the fuel tank

The following safety instructions must be observed

when mounting the dosing pump, routing the fuel

pipes and mounting the fuel tank.

Deviations from the instructions stated here are not

allowed.

Failure to comply can result in malfunctions.

Danger!

Risk of fire, explosion, poisoning and injuries!

Caution when handling fuel.

• Switch off the vehicle engine and heater before

refuelling and before working on the fuel supply.

• No naked lights when handling fuel.

• Do not smoke.

• Do not inhale fuel vapours.

• Avoid any contact with the skin.

Caution!

Safety instructions for routing the fuel pipes!

• Only use a sharp knife to cut off fuel hoses and

pipes. Interfaces must not be crushed and must be

free of burrs.

• The fuel pipe from the dosing pump to the heater

should be routed at a continuous rise.

• Fuel pipes must be fastened safely to avoid any

damage and / or noise production from vibrations

(recommended clearance of approx. 50 cm).

• Fuel pipes must be protected from any mechanical

damage.

• Route the fuel pipes so that any distortion of the

vehicle, engine movements etc. cannot have any

lasting effect on the service life.

• Parts carrying fuel must be protected from

interfering heat.

• Never route or fasten the fuel pipes to the heater or

vehicle exhaust system. When the systems cross,

always ensure there is a sufficient heat clearance.

If necessary, install heat deflection plates.

• Dripping or evaporating fuel must never be allowed

to collect on hot parts or ignite on electric systems.

• When connecting fuel pipes with a fuel hose, always

mount the fuel pipes in a butt joint to prevent any

bubbles from forming.

Safety instructions for fuel pipes and fuel tanks in

buses and coaches

• In buses and coaches, fuel pipes and fuel tanks

must not be routed through the passenger

compartment or driver’s cab.

• Fuel tanks in buses and coaches must be positioned

in such a way that the exits are not in direct danger

from a possible fire.

Comply with the regulations and safety instructions for

this chapter given on page 4 – 7.

Please note!

Page 20

20

Installation3

Fuel supply

Fuel feed point with T-piece from the fuel supply line from the

tank fitting to the vehicle engine

Fuel feed pipe from tank connection

Fuel return pipe from tank connection

Dosing pump

T-piece, 8-6-8

Fuel filter – only necessary for contaminated fuel.

Fuel hose, 5 x 3 (di = Ø 5 mm), max. 150 mm long

Fuel pipe, 6 x 2 (di = Ø 2 mm)

Fuel pipe, 4 x 1.25 (di = Ø 1.5 mm)

Fuel hose, 5 x 3 (di = Ø 5 mm), ca. 50 mm long

Fuel hose, 3.5 x 3 (di = Ø 3.5 mm), ca. 50 mm

long

To the engine, mechanical fuel or injection pump.

Permissible pipe lengths for petrol heater

Intake side Pressure side

a = max. 2 m b = max. 4 m

Permissible pipe lengths for diesel heater

Intake side Pressure side

a = max. 5 m • For suction pipe di= Ø 2 mm

b = max. 6 m

• For suction pipe di= Ø 5 mm

b = max. 10 m

Installation position of the T-piece

Use the installation positions shown in the diagram

when inserting a T-piece.

Direction of flow from the fuel tank

Direction of flow to the vehicle engine

Insert the T-piece before the feed pump in the fuel

feed pipe.

Item is not included in the “installation set“, see

additional parts catalogue for Order No.

Please note!

Page 21

21

Installation3

Permissible pipe lengths for petrol heater

Intake side Pressure side

a = max. 2 m b = max. 4 m

Permissible pipe lengths for diesel heater

Intake side Pressure side

a = max. 5 m • For suction pipe di= Ø 2 mm

b = max. 6 m

• For suction pipe di= Ø 5 mm

b = max. 10 m

Fuel feed point with tank connection – ascending pipe, integrated in the vehicle tank

or in the tank fitting

Tank connection for metal tank

– di = Ø 2 mm, da = Ø 6 mm

Tank connection for tank fitting

– di = Ø 2 mm, da = Ø 4 mm

Dosing pump

Fuel filter – only required for contaminated fuel.

Fuel hose, 5 x 3 (di = Ø 5 mm)

Fuel pipe, 6 x 2 (di = Ø 2 mm)

Fuel pipe, 4 x 1 (di = Ø 2 mm)

Fuel hose, 3.5 x 3 (di = Ø 3.5 mm),

ca. 50 mm long

Fuel hose, 5 x 3 (di = Ø 5 mm), ca. 50 mm long

Fuel pipe, 4 x 1.25 (di = Ø 1.5 mm)

Connection fitting, da = Ø 4 mm

Fuel supply

Items are included in the “tank connection“

setup kit, see additional parts catalogue for Order No.

Item is not included in the “installation set“, see

additional parts catalogue for Order No.

Caution!

Safety instructions for the fuel supply

• The fuel must not be conveyed by gravity or

overpressure in the fuel tank.

• Withdrawel of the fuel after the vehicle’s fuel pump

is not allowed.

• When the pressure in the fuel pipe is more than 0.2

bar to max. 4.0 bar, use a pressure reducer (order

no. 22 1000 20 08 00) or a separate tank

connection.

• When the pressure in the fuel pipe is more than 4.0

bar or there is a non-return valve in the return pipe

(in the tank), a separate tank connection must be

used.

• When using a T-piece in a plastic pipe, always use

support sleeves in the plastic. Connect the T-piece

and the plastic pipe with corresponding fuel hoses

and secure with hose clips.

Please note!

Page 22

22

Installation3

Possible suction and pressure height of the dosing

pump

Pressure height from vehicle tank to dosing pump:

a = max. 3000 mm

Intake height in pressure-less vehicle tank:

b = max. 0500 mm for petrol

b = max. 1000 mm for diesel

Intake height in vehicle tanks with withdrawal by

negative pressure (valve with 0.03 bar in tank cap):

b = max. 150 mm for petrol

b = max. 400 mm for diesel

Pressure height of the dosing pump to the heater:

c = max. 2000 mm

Check tank venting.

Connection to heater

Max. fuel level

Min. fuel level

Please note!

Fuel supply

Installation position of the dosing pump

Always mount the dosing pump with the pressure side

rising upwards.

Every installation position over 15° is allowed,

although an installation position between 15° and 35°

is preferable.

Installation position between 0° – 15° is not allowed.

Preferred installation position in range 15° to 35°.

Installation position in range 35° to 90° is allowed.

Caution!

Safety instructions for installing the dosing pump

• Always mount the dosing pump with the pressure

side rising upwards – minimum incline 15°.

• Protect the dosing pump and filter from intolerable

heat, do not mount near to the silencers and exhaust

pipes.

Page 23

23

Installation3

• Mixtures with used oil are not allowed!

• After refuelling with winter or cold diesel or the

listed blends, the fuel pipes and the dosing pump

must be filled with the new fuel by letting the heater

run for 15 mins.!

Please note!

Fuel supply

Fuel quality

The heater can easily run on the commercially

available fuel you use for your engine.

Fuel for special cases

In special cases (above 0 °C), the heater can also run

on fuel oil EL or parafin.

Fuel for low temperatures

Refineries and fuel service stations automatically

adjust the fuel to normal winter temperatures (winter

diesel).

This means that difficulties are only to be expected for

extreme drops in temperature, as also apply to the

vehicle engine.

Please also refer to the vehicle manual.

If the heater is run from a separate tank, please

comply with the following rules:

For temperatures above 0 °C, any kind of diesel fuel

as per DIN EN 590 can be used.

If no special diesel fuel is available for low

temperatures, then paraffin or petrol should be mixed

with the fuel according to the following table:

Temperature Winter diesel Addition

0 °C to –25 °C 100 % –

–25 °C to –40 °C 50 %* 50 % paraffin

or petrol

* or 100 % special cold diesel fuel (Arctic diesel)

Operation with bio diesel (PME)

The heater D 3 L C is certified for operation with bio

diesel as per DIN V 51606 in flowing state.

• The fluidity of bio diesel decreases at temperatures

below 0 °C.

• When using 100 % bio diesel, the heater should be

operated twice a year with diesel fuel (in the middle

and at the end of a heating period) to burn off any

possible PME deposits. To do so, let the vehicle

tank run almost empty and fill with diesel fuel

without adding any bio diesel.

While running on this tank filling, switch the heater

on 2 to 3 times for 30 minutes at a time at the

highest temperature setting.

• When operating with diesel / bio diesel mixtures of

up to 50 % bio diesel, intermediate operation with

pure diesel fuel is not necessary.

Please note!

Page 24

24

Operation and function4

Operating instructions

The heater is operated by a control element.

• The control device is used to switch the heater on

and off and to set the required room temperature.

The green LED display installed serves as a check

whether the heater is on.

• The time switch can be used to immediately switch

the heater on and off or to preselect the switch-on

point.

The control elements (e.g. mini timer, module timer)

are accompanied by detailed operating instructions

which you will receive from the company installing the

heater.

Important instructions for operation

Safety checks before the start

After a longer interval in operations (after the summer

months) the fuse must be put in position and / or the

heater connected up to the battery.

Check that all parts fit firmly (tighten screws where

necessary).

Check the fuel system visually for any leaks.

Heating at high altitudes

When using the heater at high altitudes, please note:

• Heating at altitudes up to 1500 m:

– Unlimited heating possible.

• Heating at altitudes over 1500 m:

– Heating is possible for short periods at this altitude

(e.g. driving over a mountain pass or taking a

break in a journey).

– Heating is not possible for longer periods at this

altitude (e.g. winter camping).

Please contact a JE partner.

Please note!

Initial commissioning

The following points are to be checked by the

company installing the heater during initial

commissioning.

• After installation of the heater, the coolant circuit

and the whole fuel supply system must be vented

carefully. Comply with the instructions issued by the

vehicle manufacturer.

• During the trial run of the heater, check all water

and fuel connections for leaks and firm fitting.

• If the heater shows a fault during operation, find and

eliminate the cause of the fault using a diagnosis

unit.

Page 25

25

Operation and function4

Description of functions

Switching on

When the heater is switched on, the control lamp in

the control element lights up.

The glow plug is switched on and the fan starts at

low speed.

If there is still too much residual heat in the heat

exchanger from when the heater was last used, firstly

only the fan starts up (cold blowing).

Once the residual heat has been cleared, the heater

starts.

Start

After approx. 15 seconds the fuel supply starts and

the fuel / air mixture in the combustion chamber

ignites.

After the flame has been detected the glow plug is

switched off.

Rapid heating up takes place in the “POWER“ control

stage with maximum heating current until the heat

exchanger has reached its operating temperature.

Temperature selection with the control element

Select the required passenger compartment

temperature with the knob. The temperature setting

can be between +10 °C and +30 °C depending on

the size of the room being heated and the prevailing

outside temperature.

The required setting of the knob is an empirical value.

Control in heating mode

During the heating mode, the room temperature or

the temperature of the sucked in heating air is

constantly measured.

If the temperature is greater than the temperature

preselected at the control element, the heater

changes the heater to the “LOW“ step and then runs

with a lower fan speed.

If the heat flow in the “LOW“ control step no longer

suffices, the heater switches to the “MEDIUM“ control

step.

The fan continues to run at a low speed.

In most cases the “LOW – MEDIUM – LOW“ control at

a low speed will cover the required heating

requirements.

If the heat flow in the “MEDIUM“ control step is

insufficient, the heater switches back to the “HIGH“

control step.

This in turn requires the full fan speed.

If the set temperature is still exceeded in the smallest

control stage, the heater goes to the “OFF“ stage

with the fan running on for approx. 4 minutes to cool

down.

Then the fan continues at minimum speed (circulation

mode) or is switched off (fresh air mode) until the

heater is started again.

The restart takes place in the “MEDIUM“ control step

at a low fan speed.

Switching off

When the heater is switched off, the control lamp

goes off and the fuel supply is switched off.

The fan runs on for approx. 3 minutes to cool down.

While the fan is running on, the glow plug is switched

on for approx. 15 seconds to clean.

Special case:

If no fuel has been supplied or if the heater is in the

“OFF“ stage until it is switched off, the heater is

stopped without any after running.

Please note!

Page 26

26

Electric5

Forced shut-down for ADR / ADR99 operation

In vehicles for the transport of dangerous goods (e.g.

tanker trucks), the heater must be switched off before

the truck drives into a danger area (refinery, fuel

service station, etc.)

Failure to comply results in the heater switching off

automatically when:

• The vehicle engine is switched off.

• An additional unit is started up (e.g. auxiliary drive

for unloading pump etc.).

• A vehicle door is opened (ADR99 regulation, only in

France).

The fan then runs on for max. 40 seconds.

Control and safety devices

• If the heater does not ignite within 90 seconds after

starting the fuel pump, the start is reapeated. If the

heater still does not ignite after another 90 seconds

of pumping fuel, the heater is switched off, i.e. the

fuel supply is off and the fan runs on for approx. 3

minutes. After an unacceptable number of failed

start attempts, the controller is locked.

• If the flame goes off by itself during operation, the

heater is restarted. If the heater does not ignite

within 90 seconds after the fuel pump has started,

or ignites and goes off again within 15 minutes, the

heater is switched off, i.e. the fuel supply is off and

the fan runs on for approx. 3 minutes. This status

can be remedied by briefly switching off and on

again. Do not repeat the switching off / on routine

more than twice.

• In the case of overheating, the combined sensor

(flame sensor / overheating sensor) triggers, the fuel

supply is interrupted and the heater switched off.

Once the cause of the overheating has been

eliminated, the heater can be re-started by

switching off and on again. After an unacceptable

number of failed start attempts, the controller is

locked.

• If the lower or upper voltage limit is reached, the

heater is switched off after 20 seconds.

• The heater does not start up when the glow plug is

defect or when the electric lead to the dosing pump

is interrupted.

• When the heater is switched off, the glow plug is

switched on for 20 seconds (after glowing) while the

fan runs on to clean off any combustion residues.

Do not repeat the switching off / on routine more than

twice.

Please note!

Emergency shutdown – EMERGENCY OFF

If an emergency shutdown – EMERGENCY OFF – is

necessary during operation, proceed as follows:

• Switch the heater off at the control element or

• pull the fuse out or

• disconnect the heater from the battery.

Page 27

27

Electric5

Mounting the controller

Mount the controller in a splash-proof position.

The controller must not be mounted outside.

The best installation position is inside the vehicle,

with the connectors of the controller pointing

downwards.

Heater wiring

Caution!

Safety instructions!

The heater must be electrically connected in

accordance with the manufacturer’s instructions.

Incorrect wiring can lead to faults, for this reason the

following notes must always be followed:

• Ensure that the insulation of electrical cables is not

damages. Avoid: chafing, kinking, jamming or

exposure to heat.

• In waterproof connectors, seal any connector

chambers not in use with filler plugs to ensure they

are dirt-proof and water-proof.

• Electrical connections and ground connections must

be free of corrosion and firmly connected.

• Lubricate connections and ground connections

outside the heater interior with contact grease.

Comply with the following when wiring the heater and

the control element:

• Electrical leads, switchgear and controllers must be

arranged in the vehicle so that they can function

perfectly under normal operating conditions (e. g.

heat exposure, moisture etc.)

• The following cable cross sections are to be used

between the battery and heater. This ensures that

the max. tolerable voltage loss in the cable does not

exceed 0.5 V for 12 V or 1 V for 24 V rated voltage.

Cable cross sections for a cable length of

(pluscable + minuscable):

– up to 5 m = cable cross section 4 mm

2

– from 5 m to 8 m = cable cross section 6 mm

2

• If the plus cable is to be connected to the fuse box

(e. g. terminal 30), the vehicle cable from the

battery to the fuse box must be included in the

calculation for the total cable length and redimensioned if necessary.

• Insulate unused cable ends.

Please note!

Page 28

28

Electric5

Parts list for heater circuit diagrams

1.1 Burner engine

1.2 Glow plug

1.5 Overheating switch

1.7 Printed circuit board with control temperature

sensor, speed governor, spark plug timer and

distributor plug

1.12 Flame sensor

1.13 Temperature sensor

2.1 Controller

2.2 Dosing pump

2.7 Main fuse, 25 A

3.1.12 Fault code query (workshop)

5.1 Battery

c) When connecting the temperature sensor, pull

off the existing receptacle housing and push

on the receptacle housing for the temperature

sensor.

d) Connection of control elements on heater

Cable colours

sw = black

ws = white

rt = red

ge = yellow

gn = green

vi = violet

br = brown

gr = grey

bl = blue

li = purple

• The circuit diagrams are printed at the end of this

manual.

• Connectors and bush housings are shown from the

cable inlet side.

Please note!

Parts list for control element circuit

diagrams

2.15.9 Temperature sensor (external temperature)

3.1.11 Control device

3.1.12 Fault code query (workshop)

3.1.16 Button radio remote control

3.2.8 Module timer (ADR / ADR99 – potentiometer)

3.2.12 Timer, mini – 12 volt

3.2.14 Mini clock, 12 V, continuously lit

3.3.6 TP41 radio remote control

3.6.1 Cable harness for 3.1.11

3.6.5 Cable harness for 3.2.8

3.8.1 Relay timer 12 / 24 volt

b) Terminal 15

c) Lighting, terminal 58

g) Connection, control element on heater

i) Connection, radio module

j) Connection, temperature sensor

(external temperature)

k) Connection of external button ON / OFF

Page 29

29

Troubleshooting / maintenance / service6

If any faults occur, please check the

following items

• If the heater does not start after being switched on:

– Switch the heater off and on again.

• If the heater still won’t start, then

check whether:

– There is fuel in the tank?

– The fuses are OK?

– The electrical cables, connections etc. are OK?

– Anything is clogging the combustion air supply or

exhaust system?

Troubleshooting

If, after checking these items, the heater is still faulty

or another malfunction occurs in your heater, please

contact:

• If factory-installed, your contract workshop / garage.

• If subsequently installed, the workshop / garage

which installed the heater.

Please note that warranty claims can expire if the

heater is modified by a third party or if non-original

parts are installed.

Please note!

Maintenance instructions

• Switch the heater off once a month for about 10

minutes, even outside the heating period.

• Before the heating period starts, the heater should

undergo a trial run. If persistent extreme smoke

develops, unusual burning noises or a clear fuel

smell can be perceived or if electric / electronic

parts heat up, the heater must be switched off and

put out of service by removing the fuse. In this case,

the heater should not be started up again until it

has been checked by qualified staff who have been

trained on Eberspächer heaters.

• Check the openings of the combustion air supply

and exhaust system after longer standstill periods,

clean if necessary!

Service

If you have any technical queries or problems with

your pre-heater, dial the following service phone

number:

Hotline

Phone 0800 / 1234300

Fax hotline

Phone 01805 / 262624

Page 30

30

Environment7

EU Declaration of Conformity

With regard to the following products

Heater type Air heater 3L

• B 3 L C

• D 3 L C

we herewith confirm that it conforms with the prime

safety requirements stipulated in the directives of the

EU Council for harmonisation of the legal regulations

of the member states with regard to electromagnetic

compatibility (89 / 336 / EEC).

This declaration applies to all products produced

according to the production drawings for the

aforementioned heaters – which are a part of this

declaration.

The following standards / directives have been used

to assess the product with regard to electromagnetic

compatibility:

• EN 50081 – 1 Basic form interference emission.

• EN 50082 – 1 Basic form of interference immunity.

• 72 / 245 / EEC – Modification status 95 / 54 / EU

interference suppression in motor vehicles.

Certification

The high quality of Eberspächer’s products is the key

to our success.

To guarantee this quality, we have organised all work

processes in the company along the lines of quality

management (QM).

Even so, we still pursue a large number of activities

for continuous improvement of product quality in order

to keep pace with the similarly constantly growing

requirements made by our customers.

All the steps necessary for quality assurance are

stipulated in international standards.

This quality is to be considered in a total sense.

It affects products, procedures and customer /

supplier relationships.

Officially approved public experts assess the system

and the corresponding certification company awards

a certificate.

Eberspächer has already qualified for the following

standards:

Quality management as per

DIN EN ISO 9001:2000 and ISO/TS 16949:1999

Environment management system as per

DIN EN ISO 14001:1996

Disposal

Disposal of materials

Old devices, defect components and packaging

material can all be separated and sorted into puregrade factions so that all parts can be disposed of as

required in an environment-friendly manner recycled

where applicable.

Electric motors, controllers and sensors (e.g.

temperature sensors) are deemed to be “electronic

scrap“.

Dismantling the heater

The heater is dismantled according to the repair

stages in the current troubleshooting / repair

instructions.

Packaging

The packaging of the heater can be kept in case it

has to be sent back.

Page 31

31

Heater circuit diagram

B 3 L C – 12 V / 24 V

D 3 L C – 12 V / 24 V

25 1822 00 96 01 D

Page 32

32

Circuit diagram for control elements

25 1822 00 97 01 G / Part 1

Page 33

33

Circuit diagram for control elements

25 1822 00 97 01 F / Part 2

Page 34

Loading...

Loading...