Eberspächer HYDRONIC S3 Installation Recommendations

VEHICLE HEATERS | TECHNICAL DOCUMENTATION

INSTALLATION RECOMMENDATIONS

EN

HYDRONIC S3 – B 5 E IN THE DODGE RAM

SPARE PARTS LIST

REPAIR INSTRUCTIONS

TECHNICAL DESCRIPTION

INSTALLATION RECOMMENDATION

THIS INSTALLATION RECOMMENDATION APPLIES TO VEHICLES FROM MODEL YEAR 2017 WITH

THE FOLLOWING MOTORISATION:

5.7 l cubic capacity / 8 cylinder V-engine / 295 kW - 401 HP (HSN: 1726)

A WORLD OF COMFORT

VEHICLE HEATERS – TECHNICAL DOCUMENTATION | 2

CONTENTS

CHAPTER CHAPTER DESCRIPTION PAGE

1 Introduction 3-5

2 Preparation of the vehicle 7

3 Preliminary assembly 8-15

4 Installation 16-31

5 After installation 32

6 Parts Overview 33

Initial commissioning EasyStart Timer 34-35

Diagnostics 36

Leaflet for the Customer 37

This installation recommendation documents the installation of the Hydronic S3 heater in a vehicle from model year

2017 with the following equipment:

with 2-zone automatic AirCon

with fog lamps

with daytime running lights

with LED headlights

with automatic gearbox

with four-wheel drive 4 x 4

with or without Prins LPG system

not tested:

manual air-conditioning

PLEASE NOTE!

This installation recommendation is valid for the above mentioned vehicle to the exclusion of all liability claims.

Deviating model years and/or deviating equipment may result in modifications to this installation recommendation.

It is therefore mandatory to check the feasibility of installing the heater in the vehicle before starting work.

All liability claims resulting from modifications to the vehicle are excluded.

Installation time: approx. 7 hours

1 INTRODUCTION

VEHICLE HEATERS – TECHNICAL DOCUMENTATION | 3

SPECIAL TEXT FORMATS, PRESENTATIONS AND PICTURE SYMBOLS

In this installation recommendation, special text formats and picture

symbols are used to emphasise different contents. Please refer to the

following examples for their meanings and appropriate action.

SPECIAL TEXT FORMATS AND PRESENTATIONS

This dot () denotes a list, which is started by a heading.

– If an indented dash (–) follows a “dot”, this list is a sub-section of

the black dot.

PICTURE SYMBOLS

DANGER!

This information points out a potential serious or fatal danger. Ignoring

this information can result in severe injuries.

Î This arrow indicates the appropriate precaution to take to avert the

danger.

CAUTION!

This information points out a dangerous situation for a person and / or

the product. Ignoring this information can result in injuries to people

and / or damage to machinery.

Î This arrow indicates the appropriate precaution to take to avert the

danger.

PLEASE NOTE!

These remarks contain recommendations for use and useful tips for the

operation, installation and repair of the heater.

SAFETY INSTRUCTIONS FOR INSTALLATION AND REPAIR

DANGER!

Improper installation or repair of Eberspächer heaters can cause a fire

or result in toxic exhaust entering the inside of the vehicle.

This can cause serious and even fatal risks.

Î Only authorised and trained persons may install the heater accord-

ing to the specifications in the technical documents or repair it

using original spare parts.

Î Installation and repairs by unauthorised and untrained persons,

repairs using non-original spare parts and without the technical

documents required for installation and repair are dangerous and

therefore are not permitted.

Î Installation according to this installation recommendation may only

be carried out in conjunction with the respective unit-related tech-

nical description, installation instructions, operating instructions

and maintenance instructions.

This document must be carefully read through before / during

installation and repair and followed throughout. Particular attention

is to be paid to the official regulations, the safety instructions and

the general information.

PLEASE NOTE!

The relevant rules of sound engineering practice and any information

provided by the vehicle manufacturer are to be observed during the

installation and repair.

When carrying out electric welding on the vehicle, the positive cable

at the battery should be disconnected and earthed to protect the

control box.

LIABILITY CLAIM / WARRANTY

Eberspächer does not accept any liability for defects and damage,

which are due to installation or repair by unauthorised and untrained

persons.

Compliance with the official regulations and the safety instructions is

prerequisite for liability claims.

Failure to comply with the official regulations and safety instructions

leads to exclusion of any liability of the heater manufacturer.

ACCIDENT PREVENTION

General accident prevention regulations / health and safety regulations

and the corresponding workshop, company and operating safety

instructions are to be observed.

1 INTRODUCTION

VEHICLE HEATERS – TECHNICAL DOCUMENTATION | 4

ADDITIONAL INFORMATION ON THE VALIDITY OF THE INSTALLATION

RECOMMENDATION

The installation recommendation is valid for the vehicle with the engine

and gearbox options listed in the following.

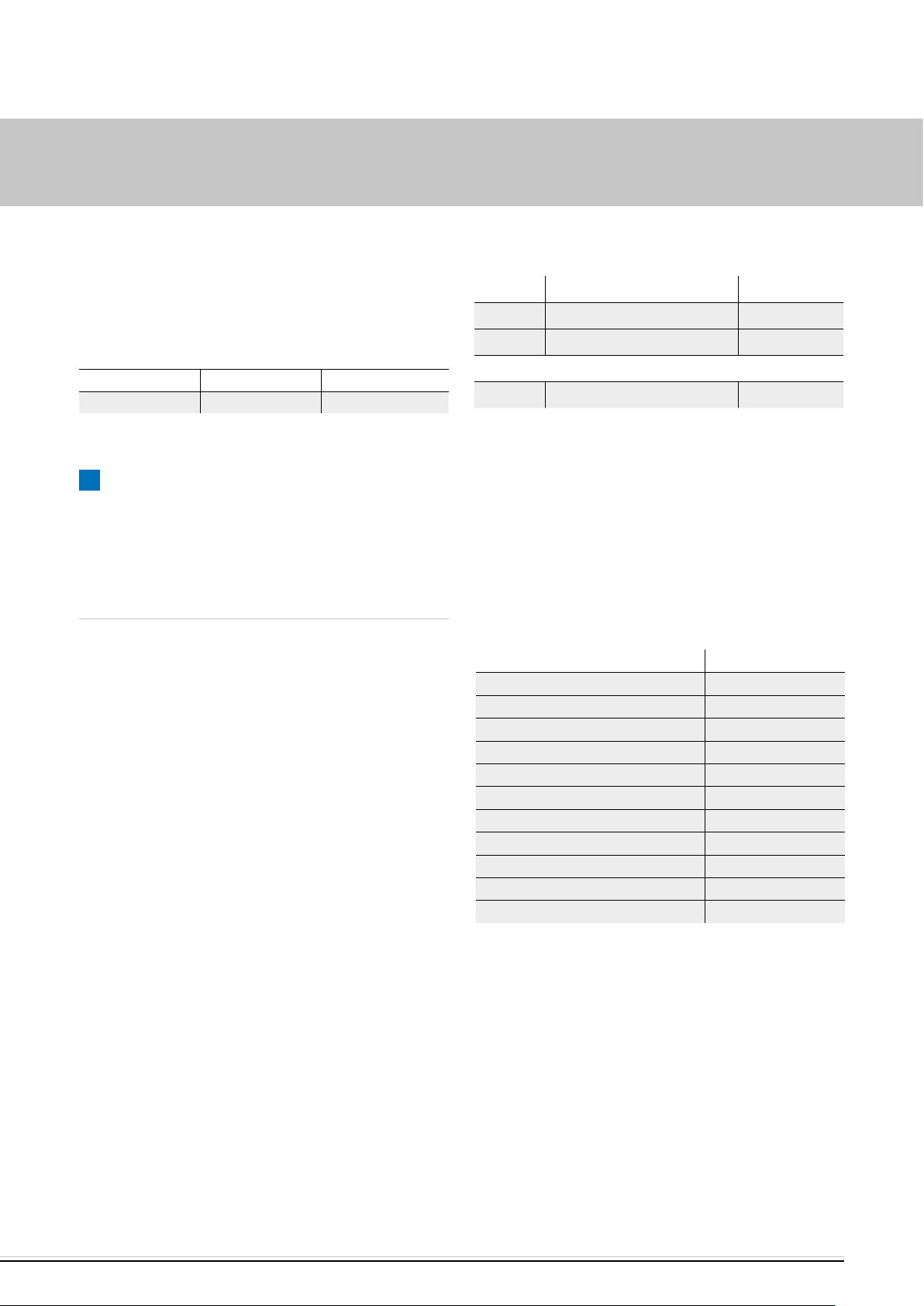

ENGINE AND GEARBOX OPTIONS

Cubic capacity kW / HP Gearbox

5.7 l V8 295 / 401 AT

AT = automatic transmission

PLEASE NOTE!

The installation recommendation is not valid for right-hand drive

vehicles.

Vehicle models, engine types and feature options not listed in this

installation recommendation, have not been tested.

Installation according to this installation recommendation can still be

possible.

INITIAL STARTUP OF THE HEATER OR FUNCTIONAL TEST

After installation or carrying out a repair on the heater, the coolant

circuit and the whole fuel supply system must be carefully vented.

Comply with the instructions issued by the vehicle manufacturer.

Open all heating circuits before the trial run (set the temperature

controller to “hot”).

During the heater trial run, all water and fuel connections must be

checked for leaks and secure, tight fit.

If faults occur while the heater is running, use a diagnostic unit to

correct the cause of the fault.

PARTS REQUIRED FOR INSTALLATION

QUANTITY DESIGNATION ORDER NO.

1 Hydronic S3 - B 5 E 20 1952 05 00 00

1 Vehicle-specific installation kit 24 8000 35 00 19

EasyStart control unit as chosen:

1 EasyStart Timer 22 1000 34 15 00

SPECIAL TOOLS REQUIRED

Necessary torque wrench

Anti-corrosion agent

Crimping tool

Pliers for spring band clamps

TIGHTENING TORQUES

If no tightening torques are specified, tighten the screw connections

according to the following table:

Part name Tightening torques

+0.5

+0.5

+1

+0.5

+0.5

+0.2

+1

+2

+2

+1

+0.5

Nm

Nm

Nm

Nm

Nm

Nm

Nm

Nm

Nm

Nm

Nm

Hex screw M6 10

Hex screw M8 20

Hex screw M10 45

Self-tapping M6 x 16 Torx screw 11

Screw M4 3

Screw M5 x 10 5

Screw M5 x 18 6.5

Pipe clip for exhaust pipe 7

Hose clip for water hose 3

Hose clip for combustion air pipe 5

Hose clip for fuel pipe 1

1 INTRODUCTION

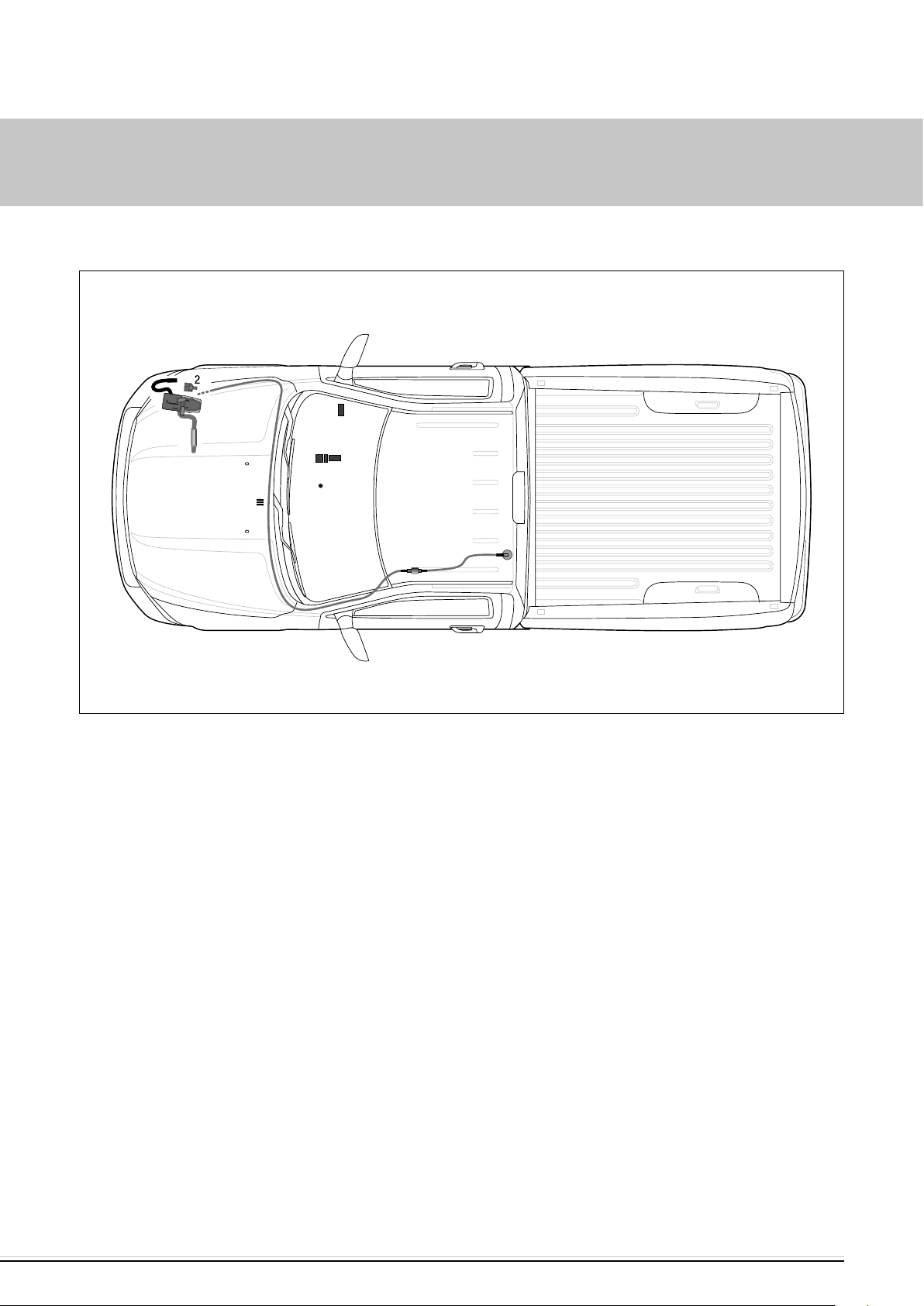

INSTALLATION DRAWING

4

1

VEHICLE HEATERS – TECHNICAL DOCUMENTATION | 5

7

3

5

6

8

1 Heater Hydronic S3

2 Water pump

3 Exhaust pipe with exhaust silencer

4 Combustion air tube

5 Fuse holder

6 Fan control box “EasyFan”, fan relay and isolating relay

7 Stationary

8 Button

9 Metering pump

10 Tank extractor

10

9

2 PREPARATION OF THE VEHICLE

PREPARATORY WORK ON THE VEHICLE

VEHICLE HEATERS – TECHNICAL DOCUMENTATION | 6

Disconnect the battery

Remove glove compartment

Remove top shelf

Remove air filter housing

Remove front right-hand wheel

(see photo 1)

Detach the retaining cable of the glove compartment out to the back.

Detach the glove compartment from the fastening points and remove.

Remove right-hand, front wheel arch liner

Remove lower gearbox cowling

Remove tank according to the manufacturer's instructions

Depressurise the cooling system

Drain coolant into a clean container

a

Fig. 1

a Glove compartment

b Detach retaining cable

b

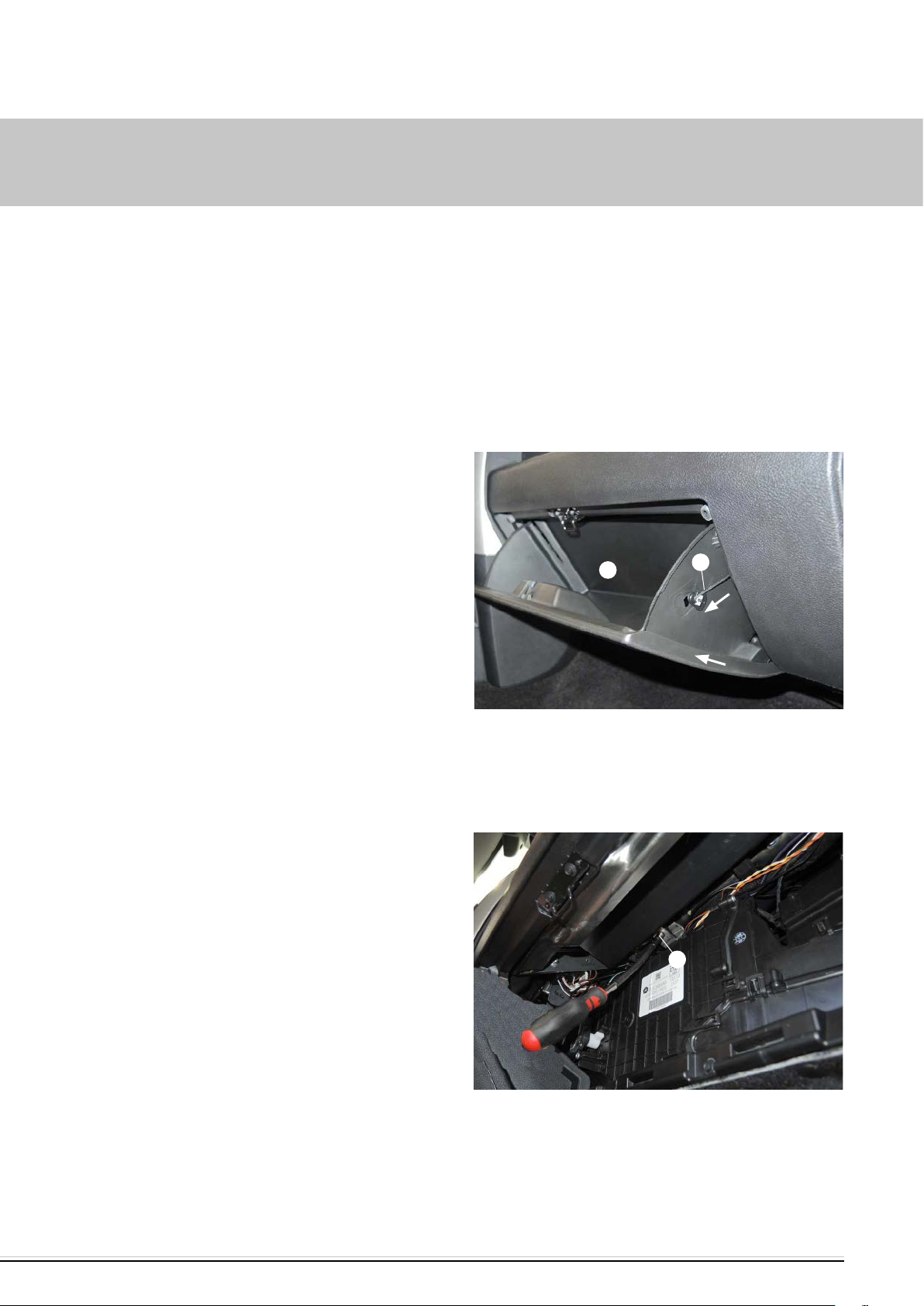

INSTRUCTIONS FOR REMOVING THE TOP SHELF

(see photos 2 to 4)

Unscrew the M4 screw of the top shelf.

a

Fig. 2

a Loosen M4 screw of top shelf

2 PREPARATION OF THE VEHICLE

Unscrew the four fastening screws of the top shelf and remove the

shelf.

VEHICLE HEATERS – TECHNICAL DOCUMENTATION | 7

a

b

Loosen the fastening clips of the lower trim moulding and remove the

trim moulding.

Fig. 3

a Upper shelf

b Loosen 4x fastening screw of the top shelf

b

a

Fig. 4

a Remove lower trim moulding of glove compartment

b Loosen fasten clips of lower trim moulding

3 PRELIMINARY ASSEMBLY

PREPARE HEATER

(see photos 5 and 6)

Mount the angled water connection socket to the heater as shown, see

“Assembly Steps”.

Remove the duplicate nameplate from the heater.

VEHICLE HEATERS – TECHNICAL DOCUMENTATION | 8

a

Fig. 5

a Heater

b Mount elbow connection

b

Installation steps

Grease the O-ring (5) and insert in the groove at the connection

socket.

Fit the connection socket (3 or 4) in the cut-outs of the sensor cover

(2). The collar of the connection socket is above the cover.

Position the connection socket with the gearing in the sensor cover

and fix accordingly.

Fit the sensor cover on the heater with the connection socket point-

ing forwards.

Press the connection socket completely into the corresponding holes

on the heat exchanger.

Adjust the direction for the angled connection socket:

– Raise the sensor cover up to the collar of the connection socket

– Turn the connection socket in the required direction

– Push the sensor cover down and readjust the position of the con-

nection socket so that the toothed edges engage again

Fasten sensor cover with M5 x 18 (1) screw

(tightening torque 6.5

+0.5

Nm).

Fig. 6

1 M5 x 18 screw 4 Angled connection socket

2 Sensor cover 5 O-ring

3 Connection socket, straight

3 PRELIMINARY ASSEMBLY

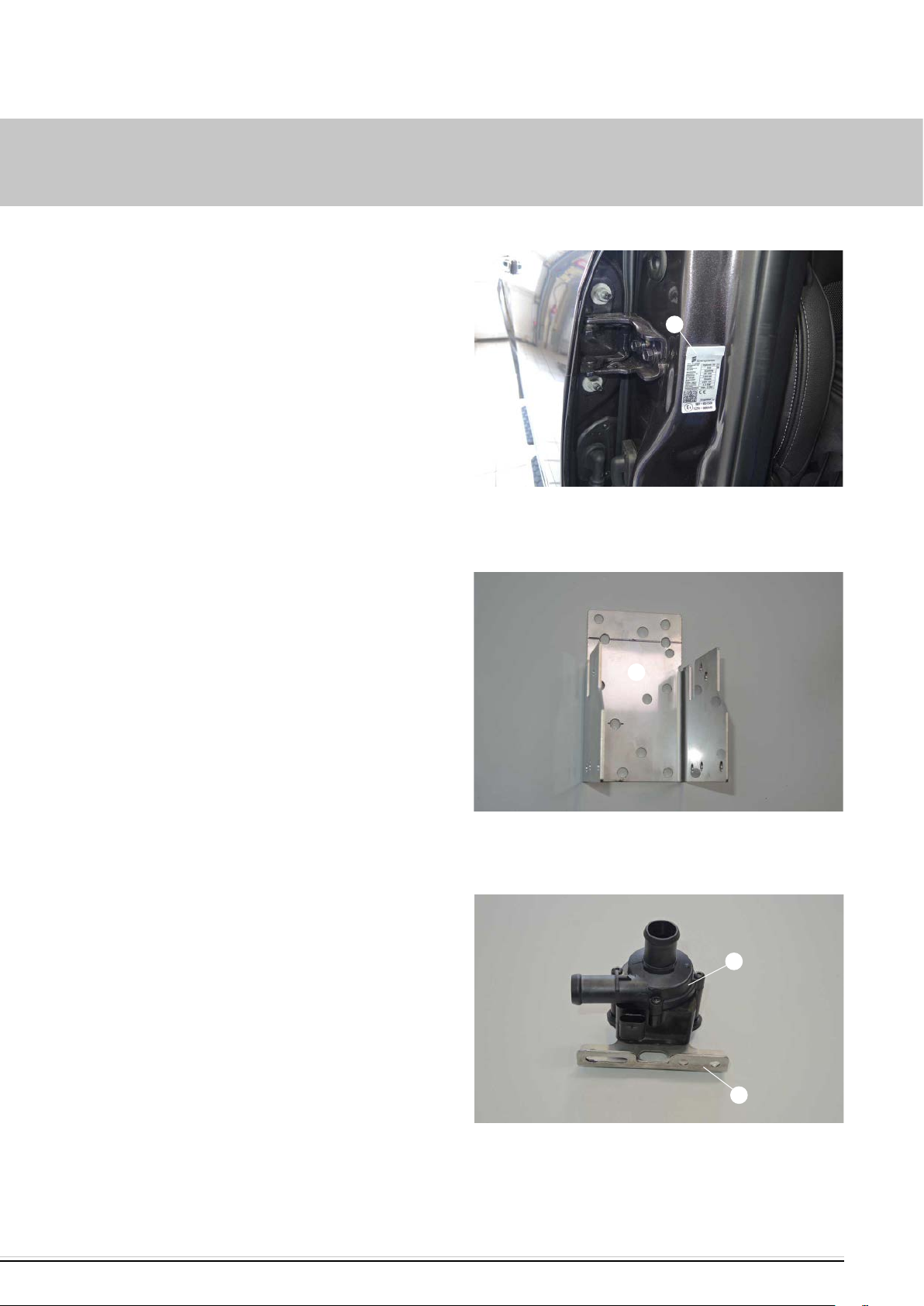

ADHERE DUPLICATE NAMEPLATE

(see photo 7)

VEHICLE HEATERS – TECHNICAL DOCUMENTATION | 9

Fit the duplicate nameplate to the B-pillar on the passenger side as

shown.

PREPARE HEATER BRACKET

(see photo 8)

Prepare the already premounted heater bracket for subsequent

installation.

a

a

Fig. 7

a Fit duplicate nameplate

a

PREMOUNT WATER PUMP

(see photo 9)

Insert the water pump in the water pump holder.

Fig. 8

a Heater bracket

b

a

Fig. 9

a Holder, water pump

b Water pump

3 PRELIMINARY ASSEMBLY

300

300

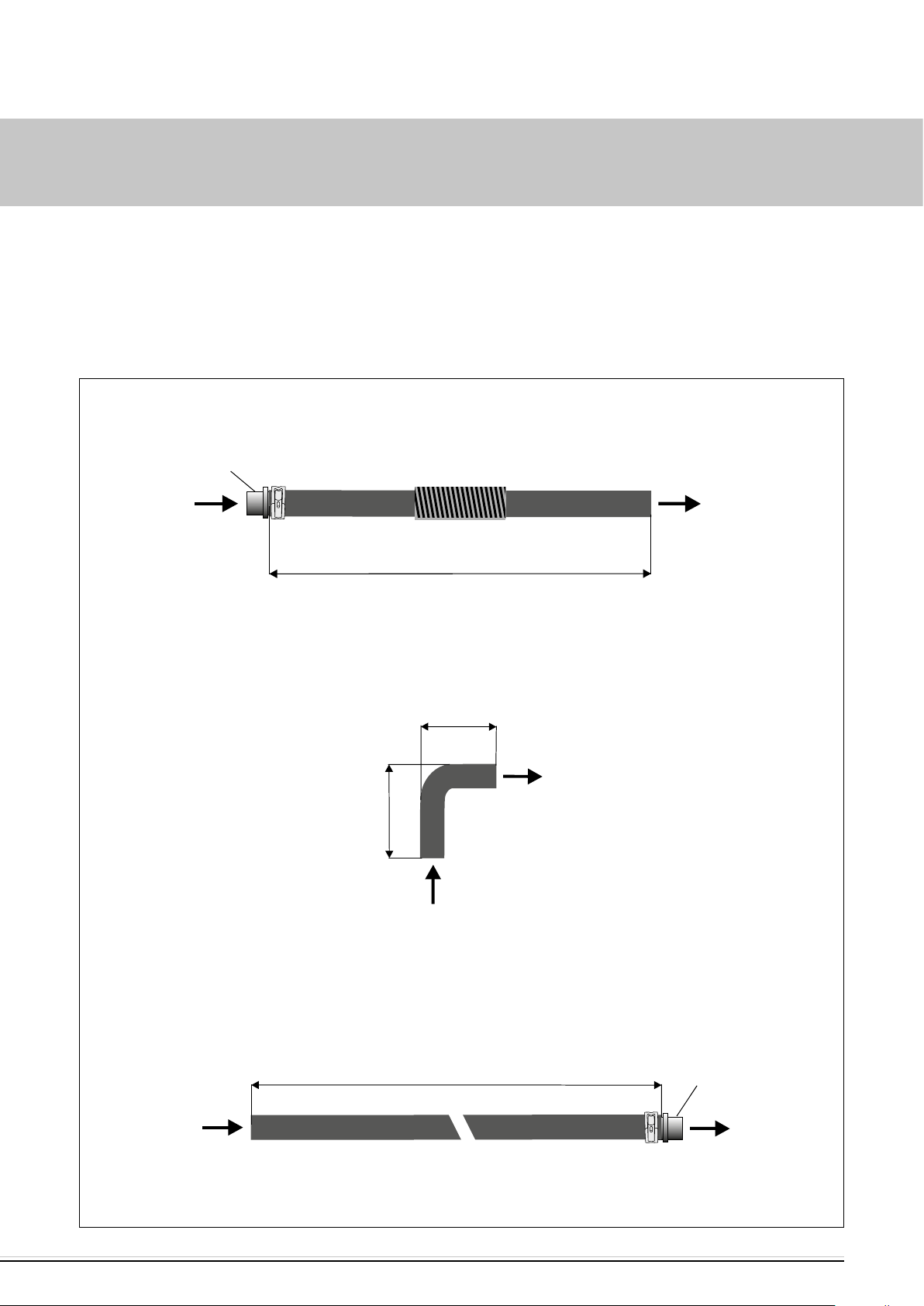

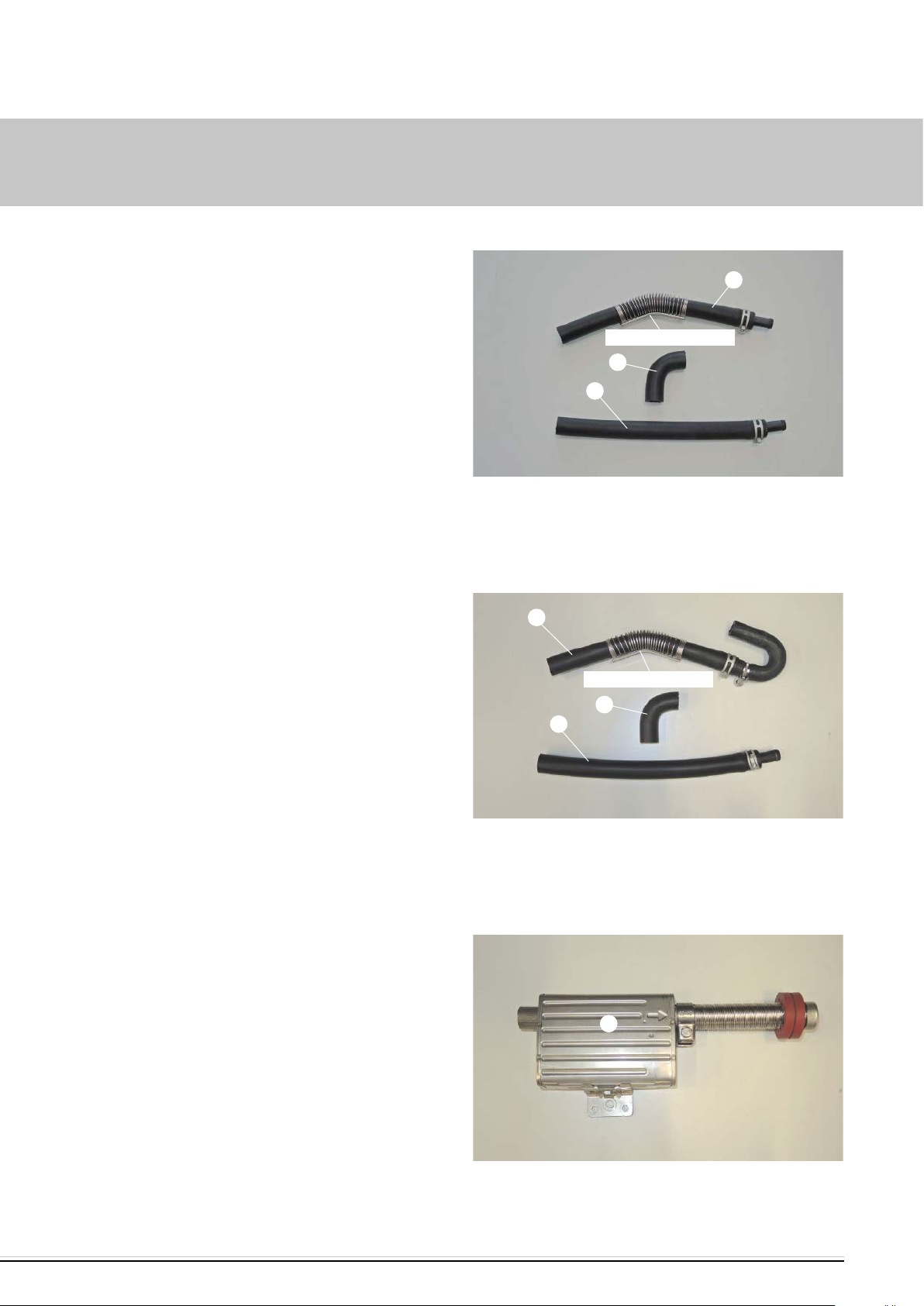

PREPARE WATER HOSES

(see photos 10 to 13)

For vehicles without Prins LPG system

The water hoses are already prepared as shown.

Reducer

20/15 mm

VEHICLE HEATERS – TECHNICAL DOCUMENTATION | 10

Water hose 1

from engine to water pump

Engine

Water pump

Water hose 2

from water pump to heater

55

Heater

70

Water pump

Fig. 10

Heater

Water hose 3

from heater to heat exchanger

Reducer

20/15 mm

Heat exchanger

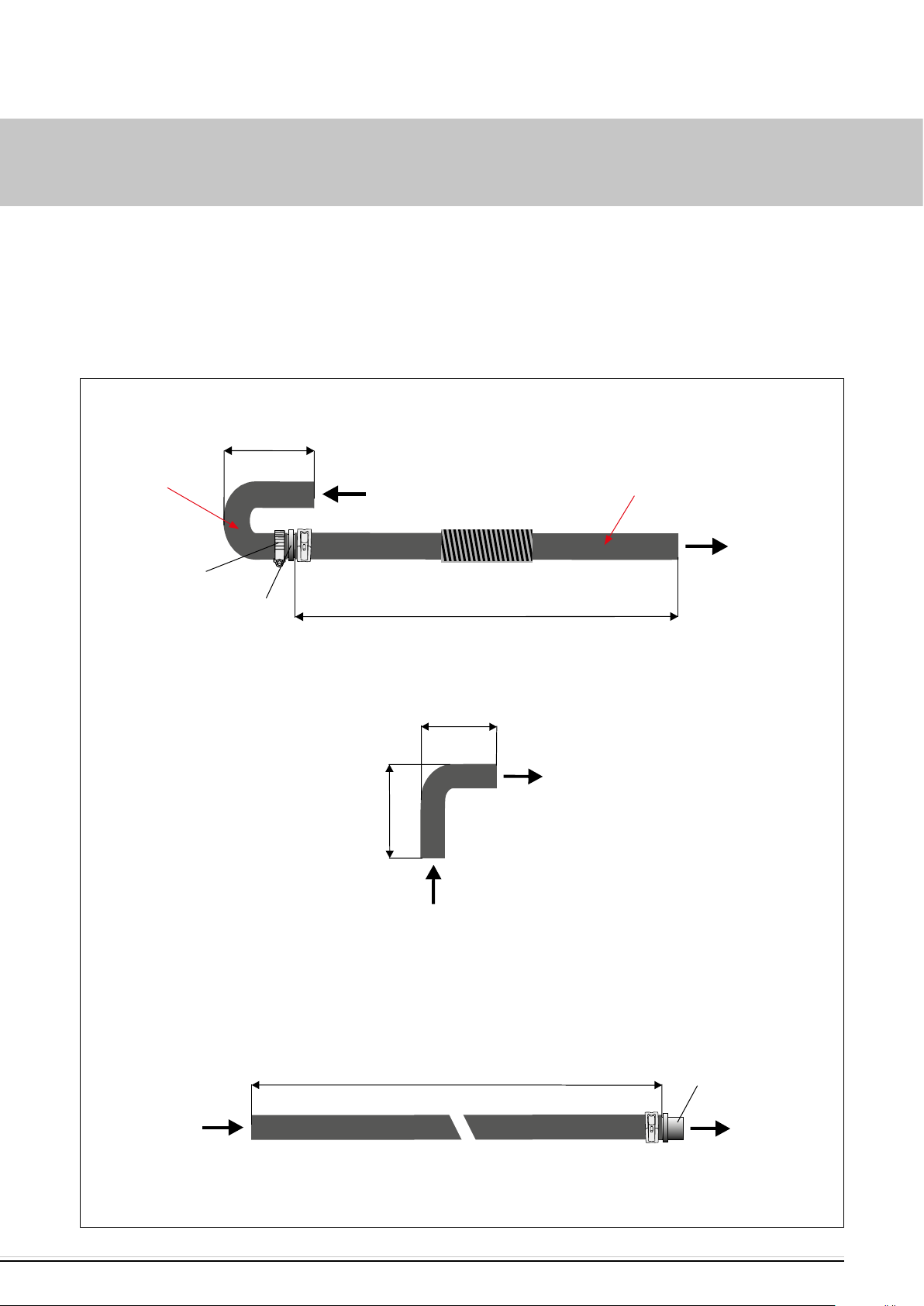

3 PRELIMINARY ASSEMBLY

270

90

300

PREPARE WATER HOSES

For vehicles with Prins LPG system

Prepare water hoses as shown.

Mount 180°

water hose

bend, Ø 15mm

Engine

VEHICLE HEATERS – TECHNICAL DOCUMENTATION | 11

Water hose 1

from engine to water pump

Shorten the

water hose to

L=270 mm

Hose clip,

16 - 25 mm Ø

Water pump

Reducer

20/15 mm

Water hose 2

from water pump to heater

55

Heater

70

Water pump

Water hose 3

from heater to heat exchanger

Fig. 11

Heater

Reducer

20/15 mm

Heat exchanger

3 PRELIMINARY ASSEMBLY

For vehicles without Prins LPG system

The figure shows the premounted water hoses 1 to -3.

VEHICLE HEATERS – TECHNICAL DOCUMENTATION | 12

a

Shape water hose 1 with the hose bending device (Unicoil) at the bend-

ing edge as shown.

For vehicles with Prins LPG system

The figure shows the premounted water hoses 1 to -3.

Shape water hose 1 with the hose bending device (Unicoil) at the bend-

ing edge as shown.

Unicoil bending edge

b

c

Fig. 12

a Water hose 1

b Water hose 2

c Water hose 3

a

Unicoil bending edge

b

c

PREPARE EXHAUST SILENCER

(see photo 14)

Prepare the already premounted exhaust silencer for subsequent

installation.

Fig. 13

a Water hose 1

b Water hose 2

c Water hose 3

a

Fig. 14

a Premounted exhaust silencer

Loading...

Loading...