Eberspächer Hydronic M-II, Hydronic M8 Biodiesel, Hydronic M12, Hydronic M10 Technical Description, Installation, Operation And Maintenance Instructions

HYDRONIC M-II

Technical description, installation,

operation and maintenance instructions.

Heater Order no.

Hydronic M8 Biodiesel 12 V 25 2470 05 00 00

24 V 25 2471 05 00 00

Hydronic M10 12 V 25 2434 05 00 00

24 V 25 2435 05 00 00

Heater Order no.

Hydronic M12 12 V 25 2472 05 00 00

24 V 25 2473 05 00 00

Water heater for diesel,

operating independently of the engine.

25 2435 90 99 80

08.2009

2

1

Introduction

Contents

Chapter

1

2

3

4

5

6

7

8

Title

Introduction

Product information

Installation

Operation and

function

Electrical system

Troubleshooting

Maintenance

Service

Environment

Lists

Contents

• Contents...................................................................................................... 2

• Concept of this manual ................................................................................ 3

• Special text structure, presentation and picture symbols ..............................4

• Important information before starting work ................................................... 4

• Statutory regulations ................................................................................ 5, 6

• Safety instructions for installation and operation .......................................... 7

• Accident prevention .................................................................................... 7

• Scope of supply ...................................................................................... 8, 9

• Technical data.................................................................................... 10 – 12

• Main dimensions ........................................................................................ 13

• Installation location ....................................................................................14

• Installing the 24 V heater in a vehicle for the transport of

dangerous goods as per ADR / ADR 99 .................................................... 14

• Possible installation positions ..................................................................... 15

• Mounting and fastening .............................................................................15

• Nameplate ................................................................................................. 16

• Connection to the cooling water circuit .............................................. 17 – 20

• Exhaust system ........................................................................................ 21

• Combustion air system .............................................................................. 22

• Fuel supply ........................................................................................ 23 – 27

• Operating instructions ............................................................................... 28

• Initial commissioning .................................................................................. 28

• Important information for operation ............................................................ 28

• Description of functions .............................................................................28

• Control and safety devices / EMERGENCY OFF ........................................ 29

• Heater wiring .............................................................................................30

• Parts list for the circuit diagrams .................................................... 30, 33, 35

• Circuit diagrams..................................................................... 31, 34, 36 – 39

• In case of faults, please check the following points ...................................40

• Troubleshooting ......................................................................................... 40

• Maintenance instructions ........................................................................... 40

• Service ......................................................................................................40

• Certification ............................................................................................... 41

• Disposal .................................................................................................... 41

• EU Declaration of Conformity ..................................................................... 41

• List of key words ................................................................................. 42, 43

• List of abbreviations ................................................................................... 43

3

1

Introduction

Concept of this manual

This manual aims to support the service company

installing the heater and to provide the user with all

important information about the heater.

The manual has been divided into 8 chapters to make

it easier to find the corresponding information quickly.

Introduction

1

Here you will find important introductory information about installation of the heater and about the

structure of the manual.

Product information

2

Here you will find information about the scope of

supply, the technical data and the dimensions of

the heater.

Installation

3

Here you will find important information and instructions referring to installation of the heater.

Operation and function

4

Here you will find information about the operation

and function of the heater.

Electric system

5

Here you will find information about the electronic

system and electronic components of the heater.

Troubleshooting / maintenance / service

6

This section contains information on possible

faults and malfunctions, troubleshooting, maintenance and the service hotline.

Environment

7

Here you will find information about certification

and disposal of the heater together with the EU

Declaration of Conformity.

Lists

8

Here you will find the key word list and abbreviations list.

4

1

Introduction

Special text structure, presentation and

picture symbols

This manual uses special text structures and picture

symbols to emphasise different contents.

Please refer to the examples below for the corresponding meanings and associated actions.

Special structure and presentations

A dot (•) indicates a list which is started by a heading. If

an indented dash (–) follows a dot, this list is subordinate to the dot.

Picture symbols

Regulation!

This picture symbol with the remark “Regulation” refers

to a statutory regulation. Failure to comply with this regulation results in expiry of the type permit for the heater

and preclusion of any guarantee and liability claims on J.

Eberspächer GmbH & Co. KG.

Danger!

This picture symbol with the remark “Danger!” refers to

the risk of a fatal danger to life and limb. Under certain

circumstances, failure to comply with these instructions

can result in severe or life-threatening injuries.

Caution!

This picture symbol with the remark “Caution!” refers to

a dangerous situation for a person and/or the product.

Failure to comply with these instructions can result in

injuries to people and / or damage to machinery.

Please note!

These remarks contain application recommendations

and useful tips for installation of the heater.

Important information before starting work

Range of application of the heater

The water heater operating independently of an engine

is intended for installation in the following vehicles,

depending on its heating output:

• Vehicles of all kinds

• Construction machinery

• Agricultural machinery

• Boats, ships and yachts

Please note!

• Installation of the heater is permitted in vehicles used

for the transport of dangerous goods as per ADR.

• The heater is not approved for installation in vehicle

compartments used by persons (more than 8 passenger spaces) in Class M2 and M3 vehicles (vehicles for

the transport of passengers / commercial buses).

• The heater is not approved for installation in the driver

or passenger compartments of Class M1 vehicles

(vehicles for the transport of passengers / cars) and

Class N vehicles (vehicles for the transport of goods).

On account of its functional purpose, the heater is not

permitted for the following applications:

• Long-term continuous operation, e.g. for pre-heating

and heating of:

– Residential rooms

– Garages

– Work huts, weekend homes and hunting huts

– Houseboats, etc.

Caution!

Safety instructions for application and proper

purpose

The heater must only be used and operated for the

range of application stated by the manufacturer in

compliance with the “Operating instructions” included

with every heater.

5

1

Introduction

Statutory regulations

The Federal Road Transport Directorate has issued an

“EC type approval“ and an “EMC type approval“ for

the heater for installation in motor vehicles and with

the following official type approval marks, noted on the

heater name plate.

Hydronic M-II EG- e1 00 0215

EMV- e1 035075

Regulation!

Directive 2001 / 56 / EU of the European Parliament and the Council

• Arrangement of the heater

– Parts of the structure and other components near

the heater must be protected from excess heat

exposure and possible contamination from fuel or

oil.

– The heater must not pose a fire hazard even when it

overheats.

This requirement is deemed to be fulfilled when

adequate clearance to all parts is observed during

installation, sufficient ventilation is provided and fireproof materials or heat plates are used.

– The heater may not be mounted in the passenger

compartment of Class M

A unit may however be used in a hermetically sealed

housing which also corresponds to the conditions

stated above.

– The factory nameplate or duplicate must be affixed

so that it can still be easily read when the heater is

installed in the vehicle.

– All appropriate precautions must be taken when

arranging the heater to minimise the risk of injuries

to persons or damage to other property.

and M3 vehicles.

2

• Fuel supply

– The fuel intake connection must not be located in

the passenger compartment and must be sealed

with a properly closing lid to prevent any fuel leaks.

– In heaters for liquid fuel where the heater fuel is

separate from the vehicle fuel, the type of fuel and

intake connection must be clearly identified.

– A warning sign is to be fixed to the intake connec-

tion indicating that the heater must be switched off

before refuelling.

• Exhaust system

– The exhaust outlet must be arranged so as to

prevent any penetration of exhaust fumes into the

vehicle interior through the ventilation system, warm

air intakes or open windows.

• Combustion air intake

– The air for the heater combustion chamber must not

be sucked in from the passenger compartment of

the vehicle.

– The air intake must be arranged or protected in such

a way that it cannot be blocked by other objects.

• Operating status display

– A clearly visible operating display in the user’s field of

vision must indicate when the heater is switched on

and off.

6

1

Introduction

Regulations

Additional regulations for certain vehicles

named in Directive 94 / 55 / EC (ADR Framework Directive)

Scope

This appendix applies to vehicles for which the special

provisions of Directive 94 / 55 / EC apply to combustion

heaters and their installation.

Definition of terms used

For the purposes of this appendix, the vehicle designations „EX / II“, „EX / III“, „AT“, „FL“ and „OX“ according

to Chapter 9.1 of Annex B of Directive 94 / 55 / EC are

used.

Technical regulations

General provisions (EX / II, EX / III, AT, FL and OX

vehicles)

Avoid heating and ignition

The combustion heaters and their exhaust gas routing

shall be designed, located, protected or covered so as

to prevent any unacceptable risk of heating or ignition

of the load. This requirement shall be considered as

fulfilled if the fuel tank and the exhaust system of the

appliance conform to provisions in 3.1.1.1 and 3.1.1.2.

Compliance with these regulations shall be checked in

the complete vehicle.

Fuel tanks

Fuel tanks for supplying the heater shall conform to the

following regulations:

• In the event of any leakage, the fuel shall drain to the

ground without coming into contact with hot parts of

the vehicle or the load;

• fuel tanks containing petrol shall be equipped with

an effective flame trap at the filler opening or with a

closure enabling the opening to be kept hermetically

sealed.

Exhaust system and exhaust pipe layout

The exhaust system as well as the exhaust pipes shall

laid out or protected to avoid any danger to the load

through heating or ignition. Parts of the exhaust system

situated directly below the fuel tank (diesel) shall have

a clearance of at least 100 mm or be protected by a

thermal shield.

Switching on the combustion heater

The combustion heater may only be switched on manually. Automatic switching on via a programmable switch

is not permitted.

EX / II and EX / III vehicles

Combustion heaters for gaseous fuels are not permitted.

FL vehicles

Combustion heaters must be able to be taken out of

service/disabled at least by the methods described in

the following:

a) Switching off manually in the driver‘s cabin

b) Switching off the vehicle‘s engine; in this case the

heater may be manually switched back on by the

vehicle driver;

c) Starting up of a feed pump installed in the vehicle for

the dangerous goods carried.

Combustion heater after-run

After-running of the switched off combustion heater

is permitted. In the cases named in the „FL vehicles“

paragraph under letters b) and c) the supply of combustion air must be interrupted by suitable means after a

maximum after-run period of 40 seconds. Only combustion heaters whose heat exchangers are verifiably not

damaged by the reduced after-run period of 40 seconds

beyond their usual use period may be used.

Please note!

• Compliance with the statutory regulations, the additional regulations and safety instructions is prerequisite

for guarantee and liability claims.

Failure to comply with the statutory regulations and

safety instructions and incorrect repairs even when

using original spare parts make the guarantee null

and void and preclude any liability for J. Eberspächer

GmbH & Co. KG.

• Subsequent installation of this heater must comply

with these installation instructions.

• The statutory regulations are binding and must also be

observed in countries which do not have any special

regulations.

• When the heater is to be installed in vehicles not

subject to the German Ordinance for the Registration

of Motor Vehicles (StVZO), for example ships, the

specially valid regulations and installation instructions

for these special applications must be observed.

• Installation of the heater in special vehicles must

comply with the regulations applying to such vehicles.

• Other installation requirements are contained in the

corresponding sections of this manual.

7

1

Introduction

Safety instructions for installation

and operation

Danger!

Risk of injury, fire and poisoning

• Disconnect the vehicle battery before starting any kind

of work.

• Before working on the heater, switch the heater off

and let all hot components cool down.

• The heater must not be operated in enclosed rooms,

e.g. in the garage or multi-storey car park.

Caution!

Safety instructions for installation and operation

• The heater must only be installed by a JE partner

authorised by the manufacturer according to the

instructions in this manual and possibly according

to special installation recommendations; the same

applies to any repairs to be carried out in the case or

repairs or guarantee claims.

• Repairs by non-authorised third-parties or with not

original spare parts are dangerous and therefore not

allowed. They result in expiry of the type permit of the

heater; consequently, when installed in motor vehicles

they can cause expiry of the vehicle operating licence.

• The following measures are not allowed:

– Changes to components relevant to the heater.

– Use of third-party components not approved by

J. Eberspächer GmbH & Co. KG.

– Nonconformities in installation or operation from the

statutory regulations, safety instructions or specifications relevant to safe operation as stated in the

installation instructions and operating instructions.

This applies in particular to the electrical wiring, fuel

supply, combustion air system and exhaust system.

• Only original accessories and original spare parts must

be used during installation or repairs.

• Only original accessories and spare parts may be

used for installation or repairs.

• Only the controls approved by Eberspächer may be

used to operate the heater. The use of other controls

can result in malfunctions.

• Before the heater is installed again in another vehicle,

rinse the heater parts carrying water with clear water.

• When carrying out electric welding on the vehicle, the

plus pole cable at the battery should be disconnected

and placed at ground to protect the controller.

• The heater must not be operated where there is a risk

of an accumulation of flammable vapours or dust, for

example close to

– fuel depot

– coal depot

– wood depot

– grain depots etc.

• The heater must be switched off when refuelling.

• When the heater is mounted in a safety housing etc.,

the installation compartment of the heater is not a

stowage compartment and must be kept clear.

In particular fuel canisters, oil cans, spray cans, gas

cartridges, fire extinguishers, cleaning rags, items of

clothing, paper etc. must not be stored or transported

on or next to the heater.

• Defect fuses must only be replaced by fuses with the

prescribed rating.

• If fuel leaks from the heater fuel system, arrange

for the damage to be repaired immediately by a JE

service partner.

• When topping up the coolant, only use the coolant

permitted by the vehicle manufacturer, see the vehicle

operating manual. Any blending with unpermitted

coolant can cause damage to the engine and heater.

• After-running of the heater must not be interrupted

prematurely e.g. by pressing the battery disconnecting

switch, apart from in the case of an emergency stop.

Accident prevention

General accident prevention regulations and the corresponding workshop and operation safety instructions

are to be observed.

8

2

Product information

Scope of supply

Quantity / Designation Order number

1 Hydronic M8 Biodiesel

12 Volt 25 2470 05 00 00

24 Volt 25 2471 05 00 00

To be ordered separately:

1 Universal installation kit 25 2435 80 00 00

1 Control unit* –

1 Hydronic M10

12 Volt 25 2434 05 00 00

24 Volt 25 2435 05 00 00

To be ordered separately:

1 Universal installation kit 25 2435 80 00 00

1 Control unit* –

1 Hydronic M12

12 Volt 25 2472 05 00 00

24 Volt 25 2473 05 00 00

To be ordered separately:

1 Universal installation kit 25 2435 80 00 00

1 Control unit* –

* Control units see price list / accessories catalogue..

Please note!

• The cable harness, Order No. 25 2435 80 06 00, is

also required for vehicles used for transporting dangerous goods.

• Please consult the additional parts catalogue if any

other parts are required for installation.

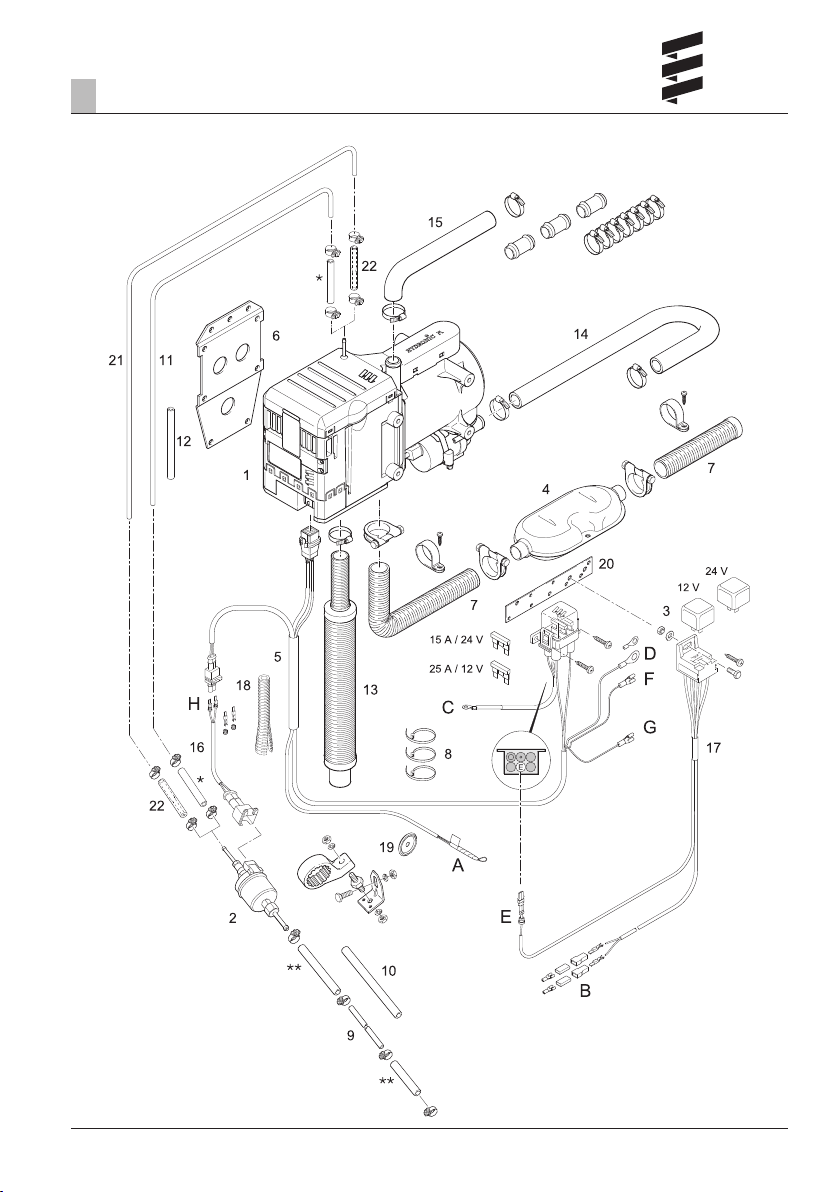

Parts list for the „Scope of supply“ figure on

page 9

Hydronic M8 Biodiesel heater scope of supply

Picture-No. Designation

1 Heater

2 Metering pump

21 Tube, Ø 6 x 1. length 6 m

22 Transition piece Ø 3.5 / 5, (2 x)

– Hose clamp Ø 10, (4 x)

Hydronic M10 / M12 heater scope of supply

Picture-No. Designation

1 Heater

2 Metering pump

Universal installation kit scope of supply

Picture-No. Designation

3 Relay 12 V / 24 V

4 Exhaust silencer

5 Cable tree, heater

6 Bracket, heater

7 Flexible exhaust pipe

8 Cable ties (10 x)

9 Pipe, Ø 6 x 1, length 1,5 m

10 Hose, Ø 5 x 3, length 0,5 m

11 Pipe, Ø 4 x 1, length 6 m

12 Hose, Ø 3,5 x 3, length 10 cm

13 Intake silencer for cumbustion air

14 Water hose

15 Water hose

16 Lead harness, metering pump

17 Lead harness, blower

18 Corrugated tube,

Inner Ø 10 mm, length 2 m

19 Grommet

20 Bracket

– Small parts

Cable harnesses

A „Controls“ lead harness

B „Blower control“ lead harness

C Positive cable

D Negative cable

E Connection, blower relay positive supply cable at

the fuse holder

F Connection at blower relay, terminal 85 (1-pole,

brown)

G Connection at blower relay, terminal 86 (1-pole,

red/yellow)

H Metering pump connection

9

2

Product information

Scope of supply

* make from Item 12

** make from Item 10

10

2

Product information

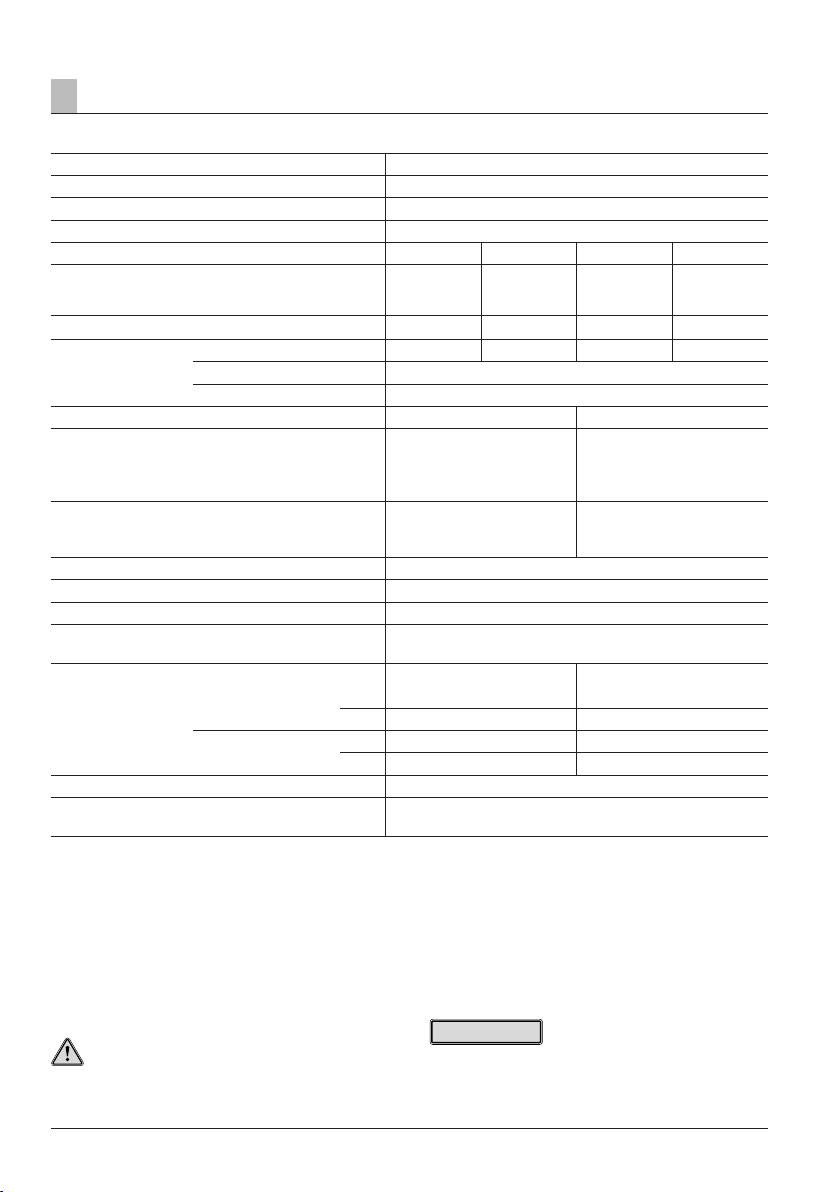

Technical data

Heater type

Heater Hydronic M8 Biodiesel

Version D 8 W

Heating medium Mixture of water and coolant (max. 50 % water, 50 % coolant)

Control of the heat flow Power Large Medium Small

Heat flow (watt)

Figures for operation with diesel fuel. If operated with FAME

the heat flow can reduce by up to 15 %.

Fuel consumption (l/h) 0.90 0.65 0.40 0.18

Electrical power (watt) in operation 55 46 39 35

at start – after 25 Sek. 200

in the control phase “OFF” 32

Rated voltage 12 Volt 24 Volt

Operating range

• Lower voltage limit: An undervoltage protection in

the controller switches the heater off on reaching the

voltage limit.

• Upper voltage limit: An overvoltage protection in the

controller switches the heater off on reaching the

voltage limit.

Tolerable operating pressure up to 2 bar overpressure

Flow rate of the water pump at 0.14 bar 1400 l/h

Minimum water flow rate of the heater 500 l/h

Fuel – see also “Fuel quality diesel heaters” page 27

Tolerable operating temperature Operation Not running

Heater / Control box

Dosing pump

Interference suppression class interference suppression class 5 to DIN EN 55 025

Weight with controller and water pump,

without dosing pump

Diesel –40 °C to +80 °C –40 °C to +85 °C

FAME –8 °C to +80 °C –40 °C to +85 °C

Diesel –40 °C to +50 °C –40 °C to +85 °C

FAME –8 °C to +50 °C –40 °C to +85 °C

8000 5000 3500 1500

10 Volt 20 Volt

15 Volt 30 Volt

Commercially available diesel (DIN EN 590)

FAME – for diesel engines according to DIN EN 14 214

Hydronic M-II

approx. 6.2 kg

Caution!

Safety instructions for technical data

Failure to comply with the technical data can result in

malfunctions.

Please note!

Provided no limit values are given, the technical data

listed is subject to the tolerances usually applicable to

heaters of ±10% for nominal voltage, ambient temperature 20 °C and reference altitude Esslingen.

11

2

Product information

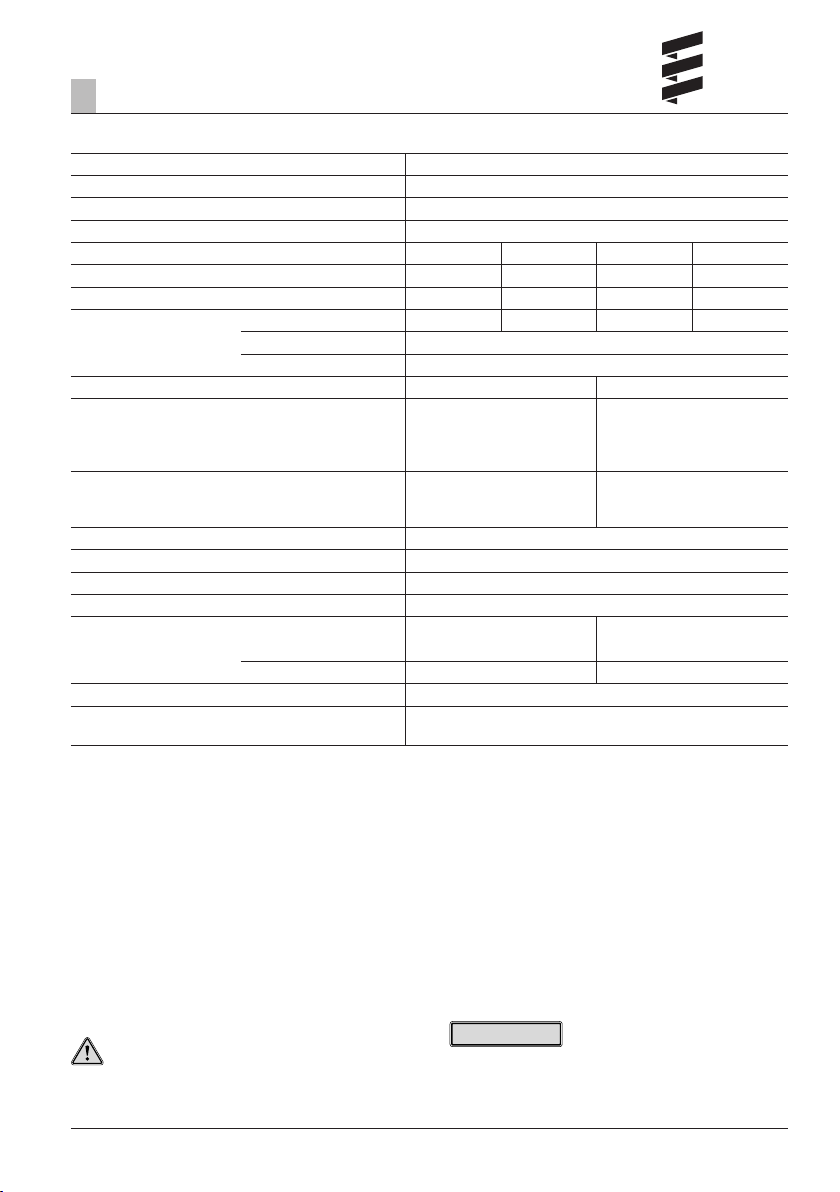

Technical data

Heater type

Heater Hydronic M10

Version D 10 W

Heating medium Mixture of water and coolant (max. 50 % water, 50 % coolant)

Control of the heat flow Power Large Medium Small

Heat flow (watt) 9500 8000 3500 1500

Fuel consumption (l/h) 1.2 0.9 0.4 0.18

Electrical power (watt)(l/ in operation 86 60 39 35

at start – after 25 Sek. 120

in the control phase “OFF” 32

Rated voltage 12 Volt 24 Volt

Operating range

• Lower voltage limit: An undervoltage protection in

the controller switches the heater off on reaching the

voltage limit.

• Upper voltage limit: An overvoltage protection in the

controller switches the heater off on reaching the

voltage limit.

Tolerable operating pressure up to 2 bar overpressure

Flow rate of the water pump at 0.14 bar 1400 l/h

Minimum water flow rate of the heater 500 l/h

Fuel – see also “Fuel quality diesel heaters” page 27 Commercially available diesel (DIN EN 590)

Tolerable operating temperature Operation Not running

Heater / Control box –40 °C to +80 °C –40 °C to +85 °C

Dosing pump –40 °C to +50 °C –40 °C to +85 °C

Interference suppression class interference suppression class 5 to DIN EN 55 025

Weight with controller and water pump,

without dosing pump

10 Volt 20 Volt

15 Volt 30 Volt

Hydronic M-II

approx. 6.2 kg

Caution!

Safety instructions for technical data

Failure to comply with the technical data can result in

malfunctions.

Please note!

Provided no limit values are given, the technical data

listed is subject to the tolerances usually applicable to

heaters of ±10% for nominal voltage, ambient temperature 20 °C and reference altitude Esslingen.

12

2

Product information

Technical data

Heater type

Heater Hydronic M12

Version D 12 W

Heating medium Mixture of water and coolant (max. 50 % water, 50 % coolant)

Control of the heat flow Power Large Medium 1 Medium 2 Medium 3 Small

Heat flow (watt) 12000 9500 5000 3500 1500 1200

Fuel consumption (l/h) 1.5 1.2 0.65 0.40 0.18 0.15

Electrical power (watt)(l/) in operation 132 86 46 39 35 34

at start – after 25 Sek. 120

in the control phase “OFF” 32

Rated voltage 12 Volt 24 Volt

Operating range

• Lower voltage limit: An undervoltage protection in

the controller switches the heater off on reaching the

voltage limit.

• Upper voltage limit: An overvoltage protection in the

controller switches the heater off on reaching the

voltage limit.

Tolerable operating pressure up to 2 bar overpressure

Flow rate of the water pump at 0.14 bar 1400 l/h

Minimum water flow rate of the heater 500 l/h

Fuel – see also “Fuel quality diesel heaters” page 27 Commercially available diesel (DIN EN 590)

Tolerable operating temperature Operation Not running

Heater / Control box –40 °C to +80 °C –40 °C to +85 °C

Dosing pump –40 °C to +50 °C –40 °C to +85 °C

Interference suppression class interference suppression class 5 to DIN EN 55 025

Weight with controller and water pump,

without dosing pump

10 Volt 20 Volt

15 Volt 30 Volt

Hydronic M-II

approx. 6.2 kg

Caution!

Safety instructions for technical data

Failure to comply with the technical data can result in

malfunctions.

Please note!

Provided no limit values are given, the technical data

listed is subject to the tolerances usually applicable to

heaters of ±10% for nominal voltage, ambient temperature 20 °C and reference altitude Esslingen.

13

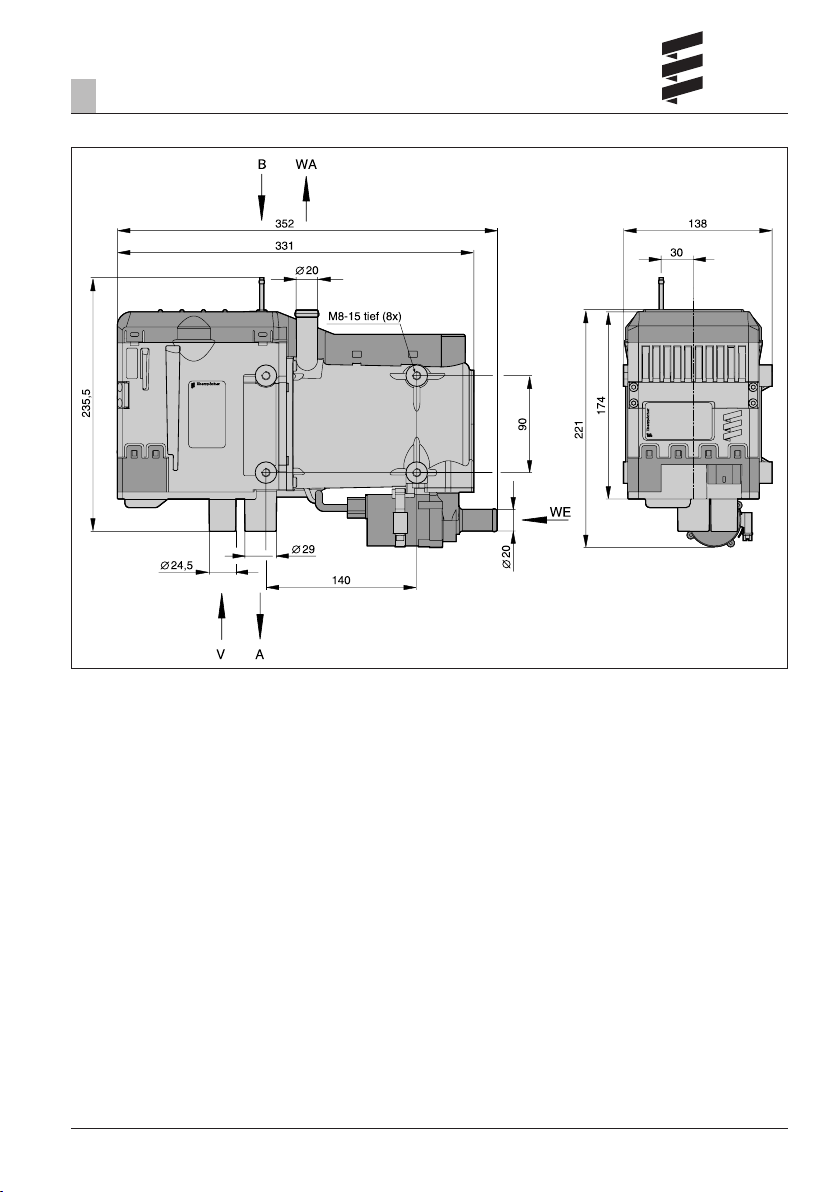

2

Product information

Main dimensions

A Exhaust

B Fuel

V Combustion air

WA Water outlet

WE Water inlet

14

3

Installation

Installation location

The installation location for the heater is the engine

compartment. The heater must be mounted below the

min. cooling water level (compensation tank, cooler, vehicle heat exchanger) for automatic venting of the heat

exchanger of the heater and the water pump.

Please note!

• In a truck, the water heater is preferably fastened

underneath the driver’s cab in the longitudinal beam

near the vehicle engine.

• The regulations and safety instructions to be observed

for this chapter are stated on page 4 – 7.

• The installation suggestions made in the installation

instructions are examples. Other installation locations

are possible if they correspond to the installation

requirements stated in these installation instructions.

• Other installation information (e.g. for boats and ships)

is available from the manufacturer on request.

• Please take note of the installation locations together

with the operating and storage temperatures.

Installation example heater in a truck

1 Heater

2 Exhaust pipe with exhaust silencer

3 Combustion air intake silencer

4 Fan relay

5 Fuse bracket

6 Controls

7 Dosing pump

8 Tank connection

Installing the 24 V heater in a vehicle for the

transport of dangerous goods as per ADR

For installation of the heater in vehicles for the transport

of dangerous goods, the regulations of

ADR / ADR99 must be observed.

With the appropriate electrical wiring the heater fulfils

the ADR regulations, see the “Additional Regulations” on

Page 6, the “Control and Safety Devices” on Page 29

and the “Circuit Diagrams” on Page 34 and 39.

Detailed information about the ADR regulations is contained in leaflet no. 25 2161 95 15 80.

Loading...

Loading...