Page 1

Air

heaters

B5L/D5L

/

B5LC/D5LC

'.

Trouble.hooting and repair manual

The Troubleshooting and Repair Manual Is valid

for

the

following

heaters:

BOL

201707

05

00

00 -

12

Volt

20 1708 05

00

00 - 24 Vol1

D5L

2517290500

00 -

12

Volt

25 1730

05

00

00 -24 Volt

Contents

sectional view

___

_ ,

..... , ...... " .............

. ,

......................

,

Description

of

operation.

In the event

of

fault

s,

first

check

the following point

s",

Function and fault test...

Wiring diagrams

Repair instructions .

................

..........

. .

Measuring

the

fuel quantity" ..

Using the test adapter

25186195086

2 04.1995

ModifIca

tion

reserved.

BOLC

2017350500

00 -12

Vc>1

20

1736 05

00 00 -24

Volt

D5LC

251861

05 00

00

-12

VoI1

25

1862

05 00

00 -24

van

Page

2

3

4

4

.5

6. 7

8-13

14

15, 16

Printed

In

GIIrmany. C Copyright J. Eb6'spAchef

J. Ebersp

ilc

her

GmbH

&Co

Ebersp:tcherst

r.

24

0·73130

Esslinge

n

Telefon (

zentla

l)

(011 1) 939-00

TelelllJ(

(0111 ) 93>1

{)500

http:lt-w

.

eberspaec

he,-de

C29/C3O

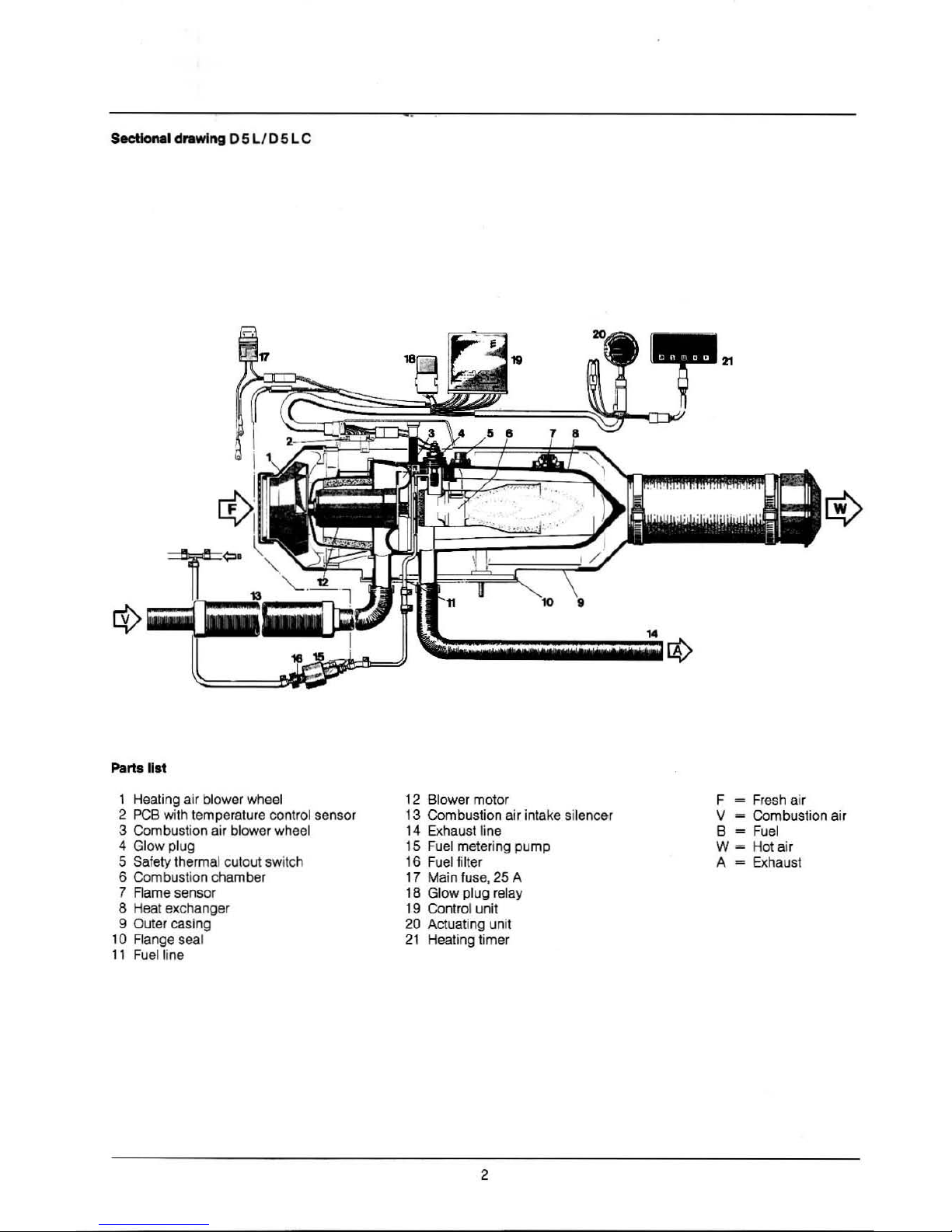

Page 2

Sectionlil dl'llwtng 0

SL

ID 5 L C

Parts list

1 Heating air blower wheel

2

PCB

wi

th

temperature contrOl sensor

3 Combusti

on

air blower wheel

4 Glow plug

5 Safety thermal cutout switch

6 Combustion chamber

7 Rame sensor

8 Heat exchanger

9 Outer casing

10 Flange seal

11 Fuel line

Wi

12 Blower motor

13 Combustion air intake silencer

14 Exhaust line

15 Fuel metering pump

16 Fuel filter

17 Main

fu

se, 25 A

18 Gl

ow

plug relay

19 Control unit

20 Actuating unit

21

Healing timer

2

F

~

Fresh air

V

~

Combustion air

B

~

Fuel

W-

Hot air

A -

Exhaust

Page 3

_01

___

_---on

,

=;

Switch-on: green pilot light

in

the operating unit

~ON·.

After about 1 s&cond: healing coil of glow plug

NON-.

Blower 'ON" at full speed.

After

33 -

70

seconds: fuel

pump

·OW.

Once a stable llame has been obtained. the

glow

plug is

switched

off.

To

reach

the

operating temperature

of

the heat exchanger

quickly, the healer

is

operated

at

an

increased heating ca-

pacily

of

5.5

kW

after being switched

on.

Once

the

heat exchanger operating temperature

has

been

reached,

the

heating capacity is reduced

10

4.8

1NoI.

The

duration of heater operation

with

Increased capacity

depends

on

the

ambient temperature.

Reguldon

In heatlna opention

Once the intakelroom temperature as set at the operating

unit has been reached,

the

heater switches

to

the

"lOW"

setting and then continues to

run

at low blower motor

speed.

If

the

heating capacity

In

the

NLOW"

control setting

is

in-

sufficient,

the

heater switches to

the

"MEDIUM~

setting.

The

blower continues to operate

at

low speed.

In

most cases,

the

LOW/MEDIUM/LOW

settings

at

low

speed will provide

the

required heal.

If

the

heat

ing

capacity

in

lhe Q

MEDIUM"

sening

is

insuffi-

cient. the heater switches back to

the

-HIGW setling. This

entails full speed

tor

the

blower motor again. _

If

in

some cases

even

less heating capacity is needed

than

the

heater supplies in

the

"LOW' sening. the heater

switches to

the

·OFf" setting.

The

heater continues to

run

after shutdown, followed

by

constant after-ventilation prior to

restart.

The

constant after-ventilation applies only lor heaters

In

reci

rculated air mode.

The

subsequent restart is

in

the

-MEDIUMM setting

at

low

blower motor speed.

When

the

heater

is

finally switched

off.

the

green pilot light

goes out and

the

blower continues to

run

until

II

coots

down. During continued operation,

the

glow plug is

switched on

for

approx.

30

sees

. to dean it

of

combustion

residues.

Th

is continued operation will always

end

after about 4

to

5 minutes

at

low speed.

3

Control_nd

ufety

equipment

The

flame

is

monitored

by

the

flame sensor

(7).

the

maximum permitted temperature by the safety thermal cutout

switch (5).

Both

of

them affect the control unit

(19),

which switches off

the

heater in

the

event

of

fauNs

.

. 1.

If

the healer does not ignite wtthin 90 seconds of

the

start

of

fuel

pumping, starting is repealed as described.

If

the healer still does not ignite after a further 90 se-

conds,

fauN

shutdown follows.

2.

If

lhe flame goes out

by

itself during operation, a restart

follows

first.

If

the heater does

not

ignite within 90 seconds

of

fuel

pumping being switched

on.

or

It

does Ignite but then

goes out within

10

minutes, fault shutdown follows.

The fault shutdown can be cancelled out

by

briefly

switching

the

heater

off

and back

on

again.

3. In the event

of

overheating, the safety thermal cutout

switch (5)

leacts

,

the

fuel

supply is interrupted, and fault

shutdown follows.

If

overheating

is

the cause of a fault shutdown,

the

switch-on pilot light

(green)

in

the

operating unit flashes

steadily.

Once

the

cause

of

the overheat

has

been remedied,

the

heater

can

be restarted

by

switching

it

off

and then

back

on

again.

4. Further

fauN

indicating signals cen be obtained

with

additional equipment, and

are

described in

the

trouble-

shooting and repair Instructions

on

pages

4 and 5.

5.

If

the voltage drops

below about

10.5

or

21

V.

Of

rises

above

15

or

30 V as

the

cese may be, fault shutdown

follows.

6.

If

the glow plug

is

defective and the electric line to the

metering pump

has a break,

the

heater will

not

start.

7. When

the

heater

is

started

the

functioning of

the

blower

motor is checked

once.

11

it

does not

start,

the

heater

will undergo fault shutdown.

During operation,

the

blower motor

is

monitored

in

cyc-

les

(4

mlns.).

If

the molor speed

Is

below the permitted

limit,

lauN

shutdown follows.

PIe8

..

not.:

For

electric welding work

on

the

vehicle, the positive ter-

minal

of

the battery must

be

disconnected and earthed

in

order to protect

the

control

unit.

I

Page 4

e

Fuel

in

the tank?

eFusesOK?

e Electrical

lines

and

connecttons OK?

·

c.

• Combustion air and exhaust piping

!'Iystems

tree?

When

combustion produces

soot,

check

the

following:

Combustion air and exhaust piping systems clogged?

.........

Remove cause of clogging.

Fuel

metering pump conveying too much?

.........

Measure fuel quantity, replacing

fuel

metering pump

if

necessary.

Deposits

in

the

heat exchanger?

.........

Clean heat exchanger, or replace

illf

necessary,

Cliling

of

dIIlftOdc

......

18

Connec1

a switch to terminals 4 and 6 of

the

operating

unil.

Turn

on

the switch

and

compare the diagnostic signal

displayed

by

the

operating unit

with

the

list

on

page 5,

Deal

with

lhe Irouble

as

descnbed

under

'Remedy".

Checkweluee

Speed

of

blower

motof

in

HIGH

set1ing

: 5000

rpm

±10%

in

MEDIUM

and

LON

settlng5: 3000 rpm ± 10%

in continued

operation:

3000 rpm ± 10%

in

after

ventilation:

850

rpm

(

only

In

recirculated

air

mode)

4

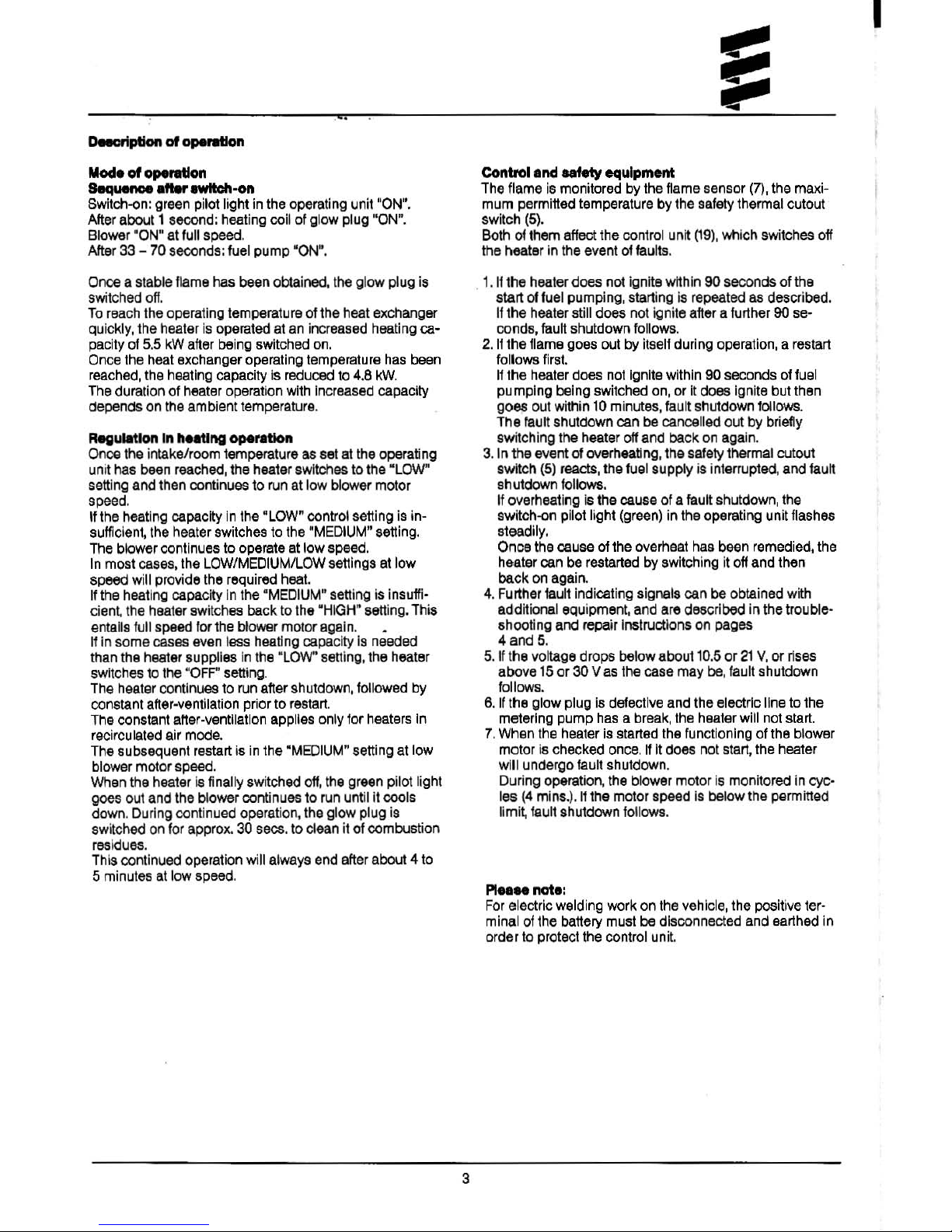

Page 5

I

DIopIojod

by

......

LID o 1

2

31

r n r

SOCS.

A-.dy

Operation

Warning of olJer-lundelVoltage

•••

Check controller, charge battery

Overvoltage cutout

••

Check

controller, jf

necessary

test

charger.

Heater must be connected directly to

the

battery.

Undervollage cutout

•

Charge

battery,

check

control~r

.

Check

glow plug.

glow

plug

series

resistor(for B 5

LI

Glow

plug break

••••

05L

24

V),

replace. Check connecting lines

and

connection, check connection

to

glow

plug

relay.

Burner

motor

does

not

turn,

Check

mdtor

speed

(test

adapter),

If

necessary

speed changeover relay does nol

replace

blower.

Check

speed

changeover

function

(tast

adapter),

if

necessary

replace

PCB.

Rated speed: high =

4500±

10%rpm,

medlumJlow - 3000 ±

10

% rpm

ShOf1-circuit

at

glow-plug

~I

Replace glow-plug relay

relay

contacts

Saf~ty

time exceeded

•••

Check

fuel

supply, test glow plug 0nterrupted coil,

no start

yet

sooty

connection),

replace

if

necessary.

I

,

Check heating air lines inlet and outlet

for

clogging,

Overheat

~

.....

---

if necessary remove clog. Check electrical lines,

contacts to metering pump. Check safety thermal

cutout switch

(test

adapter).

Short circuil

of

fuel

~

..

Check metering pump and supply lines,

metering pump replace

if

necessary.

Plug

connection to temperature sensor

in

cable

harness made internally/externally? Check

PCB,

Temperature sensor defective

~.

internal temperature sensor

(test

adapter).

If

neces-

sary test

the

external temperature sensor directly.

Check connection

to

operating device, and check

the latter (test equipment

for

operating device).

Flame

sensor defective

~.

•

Check flame sensor or connection,

and

also

PCB

(test

adapter).

•

Rame goes out

at

"Low"

or

••

Check fuel quantity

-Medium" stage

Check blower speed

Heater

goes

out

by

Itself

Rame goes out

at

"

High~

stage

•••

Check

fuel

quantity

Heater goes out

by

Itself Check blower speed

Control unit defective

Replace control unit

External

disturbing voltages

•

••

Remove

cause

Er

roneous

flame reoognition

•

Check flame sensor.

5

Page 6

'"

·UD

,

I"

.

.......

. ,

..

c ....... . ,_

, I

~ t~=, ·~·'

......

"

1.1 Burner

motor

1,2 Glow plug

1.5 Safety thermal

cutout

switch

1.7

PCB

with temperature control

sensor, speed change and

multiple-blade

connector

1.12

Aameaenaor

1.13 Tcmperaturesensor

2.1 Control unit

2.2

Fuel metering

pump

2.5.1 Glow plug relay

2.7 Main fuse.

25

A

IUD

,O!

,

i

~

<

~

i

:.a

(ill

3.1.11 Actuating unit

3.1.12 Fauhcodeenquiry

3.2.3

Timer, digitel

.•

quare

3.2.4

Timer, digital. rectangular

5.1 Battery

,

,

,

1$,""-

~

f-

•

I i] I

25172900

96

01

C

_)

test

(wOfbhopl

digital

timer

b)

to terminlll15

c)

lighting, terminel58

dl

if

timer

Is connected,

break

lin.

here

81

If

tempenltlire sensor is connected.

<M1ach

existing socket housing and fit

todc:et

houlirtg

of

tempenture

sentor

:;;

s:

,s

I

~

.

I

..

..

r-

,

o

'"

r-

I

-

'"

R

Page 7

i

(ill

~

!

~ @~

i

-

ljg

dt

.

.,

F-J

""

I

},

/.],

<ID

~

,

<=

I

a

.

~

.

~

~

(ill

U:.

.

•.

..

-

..

...

t •

•.

_ ·

·_

..............

~

. ''''''

--

/

I

.

.1..1.5..2..1

ll

IT,

;;D

[]A

LL

A.LIR

Il.

, T

CID

1.1

Bumermot

Of

1.12

Fla

me sensor

1.2 Glow

plug

1.13 Tempera

tu

re sensor

1.2.1

Gl

ow

plug resistor

2.1

Control un

it

1.5

Safety

thermal cut

out

switc

h

2.2

Fuel metering

pump

1.7

PCB

with

temperatur

e control

2.5.1

Glow

plug

relay

se

nsor,

speed

chenge and

2.7

Main fuse,

25

A

multiple-blade connecto

r

<ID

~

®

cflI,,'s@!

:,<j

<=

..

-~ ~W

.

~

f

H::-J

I

CDD_ ..

.

r,.

,.-,{

~

l

nr.:'1

~1

.

LJL;'T

~

1

--1:J

I

[

~

'T'

~

r

·

~

"

J

~

.

~

,,

4~

~

Is

~

(3.1.12)

ill)

2

51730

00

96

01 C

3.1.

11

Actuat

ing un

it

0'

teat (

wo

rkshop)

digital

ti

lT'lM

3.1 .12 Fault code enquiry

b'

to t

enni

nal15

3.2

.3

Timer,

dig

ital. square

.,

li

ght

ing, terminal

58

3.2.4

Timer, digita

l. rect

angular

.,

if

timer

15

connected.

5.1

Ba

tte

ry

braak

lina

hare

. ,

if temperatura sensor is connected •

detach existing

socket housing and fit

sock

et:

housing of

temperature

. sensor

,

ID

'"

,...

,

c

'"

,...

,

:1

;;

,.

'ttl

Page 8

Wiring dillgrom -

B5LC/D5LC

---

-~

--

~~

;-r

I:':IHI~

l.',,'

L'"Jft_

u_

--'

I !

CIT

em

<TIl

hrts

u.t

1.1 Burner motor

1.2 Glow plug

' .6 Safety thermal cutout switch

1.7

PCB

with controller temperature

,ensor, speed regulator

and plug distributor

1.12 Fleme monitor

1.

13

Temp.retur sensor

••

--'-'

"""'"

1.1

---I

I,..,

I~~~

1 1 1 'I' 1

IIW

1 1

@D

1 1

1 1

1 1

-

: :

" .

~

~.

!

-

,

~tifU

Ie

[]A

T T

2.1 Controt unit

2.2

Fuel

metering pump

2.5.1 Current

r-suletor

2.7 Main fuse

126

Al

3.1.12

Fault

cod.

enquiry (garllge)

5.1

Battery

8

251830

00

96

01

' 1 to connect

the

tMnperature MnSCW.

detach

the

receptacle housing

provided and fit the receptacle

hcuaing

of

the

temp.retur.

senIOr

instead.

!ill Connection control elements

to h

••

ter

Plug housi

ng

and locket housing ahown

from the

lid.

where line enters.

Page 9

h'

Wiring dIag

.....

-

B5LCfD5LC

51

GlD

"

51

.DII

••

ac;;

51

"

52

8Z

5l

-.~

'"

~

~

RJ"

1=1

1:

1

H

~:!

.

0.1

...

~

1:1

<fl

~

:

I-I

UD

1_

H

"'I

bl

1=1

•••

Li!~

.

-.

1-1

~l~

~l~

¥:+=:::=-::JS'l

V

I

'_,_,_.="

I

':

I:

t;-r;t I'

f'l;,

5'

I

l!:t1.

~I

~

1.

• J

Bl

..

B5

,

1)

ffi

• •

• •

· ,

•

II

II

I'll

51

(ill)

~

~.[Il

•••••

.

~

I

8Z

I~

"

(ill)

rmm

Bl

-y-

'1:-1

fiII~'

~

..

j.

...•

..

,",

,

'bit

1:1

.,11:11

J •

1::1

1

i~1

I~

!'

r'"

Il

l:1

I:I~

I

I'

1;1

1;1:::1

1

.i._

_,_,_._._._

---

I

,

I

.,

I

,

I~

..

aID

I I

.!

I

II

•

' M

,

!-

'.

i_

-

----

-

......

,

I

I.!

al1l

,

...

1

0.5_

0

,

52

.

~l~

Ii

B2

B2

S2

,

."

IDL.!

53

III

FI

'

(liD

51

I

~,

' M

,

:F

,

•

o.

,

I

PIIrt.

List

2.15.9 S.nlOr,

.xt.rn.'

t.mp

....

tur.

3.1.1 1 Op.r.tlng unit

3.1

.12 Fault code enquiry (garage)

3.1.13

Op.r.tlng unit

3.1.14 Operating unit

3.2.5 Timer

3.2.6 Tlm.r

3.2.7 Timar

"

..

<liD~

m:~

I'

E11

r'

...

",

I~I:

...

j<I'

1 ' ,

,(,- , ,

la=lt:S':Jtj-

..

,

[;

l •

3.6.1 Cable harness

for

3.1.

11

3,6,2 Cable harness

for

3.

1.13

3.B.3

Cabl.

harn.

s.

for

3.1.14

3.6.4 Ceble harness for 3.2 .7

3.S.1 Timer relay

9

251112200 97

01

C

al

Te"

(garag') digital timer

b)

to terminal 15

c)

lighting t.rmin.1

68

d)

break line here to connector

tim.r

f)

3.2.

6/

3.2.

6/3.2.7

to be

connected here

g) Connection control elements

to

h.at.r

hI

Remov. S 3 and

fit

S 2

Page 10

r

1

22

1 Combustion air blower

2

Blower wheel

3

Cover

4 Uning

5 Seal

6 Blower

7 Seal

8

PCB

9

Heat

exchanger

10 Cover

11

Seal

.

•

~

-

"".

-

"

10

17

12 Safety thermal cutout switch

13

Flame

sensor

14 Plug strainer

15 Glow plug

16

Series resistor

(for

BSL/D5

L 24 V only)

17

Upper

casing half

18

Lower

casing

half

19 Intake end piece

20 Outlet end piece

21

Flange seal

22 Sealing

23 Carrier

Page 11

--

1.

Remove

cable

harness

plus

cap

2.

Rem

ove glow plug

3.

Remove plug strainer

4.

Remove

PCB

5. Remove outlet end pi

ece

6. Remove upper casing

half

end upper

heat protection plate

7. Remove safety thenna! cutout switch

1. R ....

ove o.bIe

hi.,....

plUi

ClIp

Unscrew the cap

from

the heater and detach the plug

connector

from

the

PCB

and glow plug.

2. _

glow

plug

Unscrew the glow plug conn9dQf.

Unscrew the glow plug.

When fitting _ new glow plug,

pI

__

note

the

following:

Check the plug strainer in the glow plug connection, clean

it

if

necessary, or failing that replace

it.

3. Remove

plug

etIIIlMI'

Take

the plug strainer out

of

the plug connection usi

ng

pliers.

Clean the plug

st

raine

r,

replace it if necessary .

•

."."".ntIWhen

fitting the plug strainer. ensure the nose

is

in

the right position.

Slide in the plug straine r carefully

as

far

as

it

will go.

Th

e hole for plug area ventilation must then

be free.

11

a.

Remove

flame

sensor

9.

Remove

series

resistor

for glow

plug

(8

5L105L

24

Von~)

10. Remove

blower

wheel

11.

Remove cover from blower

motOf

and

f

it

new lining

12. Remove

blower

from

heat

exchanger

13, Remove cover from heat exchanger

I

Page 12

4.

Aemove

PCB

Detach

the

plug connector

from

the

PCB

.

Press

the

PCB

downwards

and

pull

it

out.

5.

___

"'-

· .

Unscrew

the

four

fastening

screws

of

the

outlet

end

piece,

then

remove

the

end

piece.

e.Romoveu

__

hoII

__

_

protection

-

Unscrew

the

fastening screws

of

the casing

half,

then

remove

the

casing

half.

Remove

both

securing clips

from

the

heat

protection

plale.

Remove

the

heat

protection

plate.

ImpotUlnt

: Use

new

securing clips when putti

ng

the heat

protection plate beck in.

12

Page 13

7. Remove safety thermal cutout switch

De

tach t

he

plug connector from the

PCB.

Remove both securing clips from t

he

safety therma l

cutout switc h.

Remove the safety

thermal cutout switch.

Important! Use new securing clips when pulling the

safely

thermal cutout switch back in.

Removing the safety thermal cutout

SWitch

8. Remove flame sensor

Remove the retaining spring wi

th

a screwdriver.

Remo

ve

the lIame sensor and the intermediate piec

e.

See

also page

12.

Fitting the safety thermal cutout switch

13

Page 14

Removing the flame sensor

9. Remove series resistor for glow plug

(

85

L ID 5 L 24 V only)

Note on removal:

The series resistor is f

i"ed

with a clamping ring,

not a thread!

Unscrew the connectio n at the series resistor.

Remove the series resistor as shown in the f

ig

ure.

Fitting the series resislor:

Drive the series

res

istor with an

18

x 1 diameter pipe

into its mounting by

lighl hammer blows.

10. Remove bktwer whee'

Remove the lock ring from the blower wheel using a

screwdri

ver.

Pull the blower wheel off the shalt of the electric molor.

Filling the flame sensor

14

Page 15

11.

"-nove

c::cwerfrom

blower motor end tit

new

1InI""

Un

screw the

fas

tening screws from the cap. Remove the

cap, and

fit

a

new

lining

if

necessary.

Importantl When

fitti

ng the cover, u

se

only the original

screws or

new

ones

(Taptile M5 x 1

2).

13. Removecovertrom hMtexchenger

Unscrew t

he

fastening screws from the cover. lift the

cover off the heal exchanger using an angled hook

through

th

e exhaust connection.

Importantl Slide the pipe

of

the combustion air system

i

nt

o the caver.

When fitting the cover,

use

a new

seal.

When

fitting

the caver,

use only the original

screws or new ones (Taplite M5 x 1

2)

.

1 Heal exchanger

2 Cover

3

Pipe

of

combustion air system

15

12. Remove blower from heat

.xct.nger

Un

screw the

fas

tening screws from the support. Remove

th

e support trom the blower.

Un

screw the fastening screws from the blower.

Rem

ove

t

he

blower and dear the heal exchanger and blower

of

sealing residues.

Importantl When assembling the heal exchanger and

blower, replace the

seal.

5

1 Cover

2 Lini

ng

3 Support

4

Blowe

r

5 Heal exchanger

1

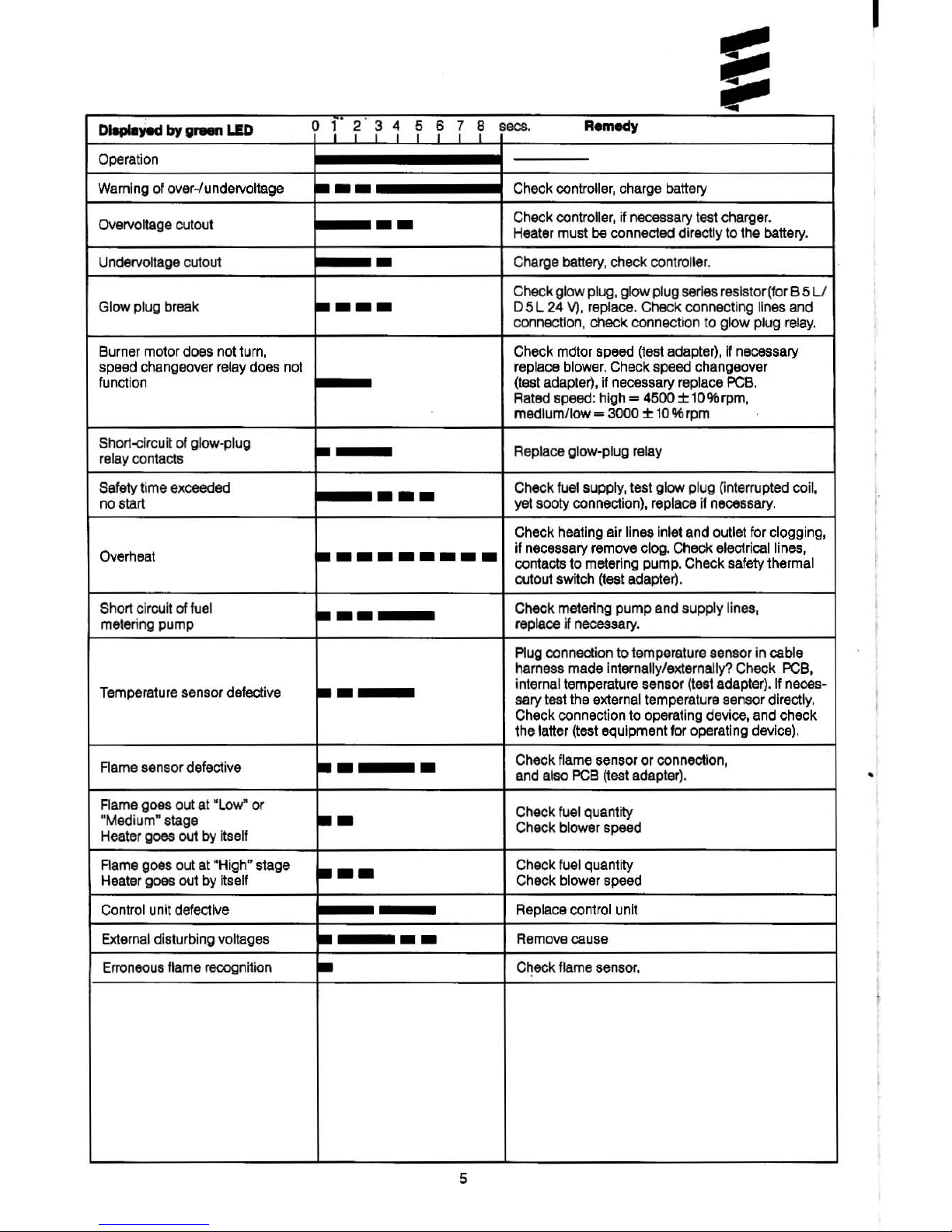

Page 16

M_rtno

lIMo

fuoI_

IMPORTANTl

Only measure the fuel when the battery is

sufficienlly charged.

AI least 11/22 V or

max.

1

312

6 V

shou

ld

be

applied to the control unit

during

measurement

1.

__

Detach the

plug

connector under the cover cap

on

the

healer

and

connect a lest lamp. Detach the

luelline

from

the healer

and

insert

it

into a measuring glass.

Connect a voltmeter to the 4-pin

plug, terminals 3 (+)

and

4

H,

of the control unit.

Switch on the heater; when fuel is being

pumped

steadily

(around

25 -55

sees. aft

er s

witch-o

n),

the

fuel

line

is

filled

and free of air.

Switch o

ff

the heater

and empty

the measuring glass.

2.

Meuurement

Switch

on the healer.

Fuel is

pumped after about

25 -55

sees. aft

er switch-on.

Hold the measuring glass

al

the level of

lhe

plug during

measurement.

Read

off

the

voltage at the voltmeter.

After 90

sees.

of fuel p

um

pin g, this stops automatically.

Switch

otlt

he heater.

Read off the fuel

quant

ity In the measuring

glass

.

Test ap.,.ret:ue

------,

3.

Evaluation

Transpose the readings onto the graph.

Fuel consumpti

on

is

OK

when the inler

s9CI

ion 01

roth

vatues

is within the limit curv

e.

If the intersection is outside

the CUNe,

the lu

el

metering

pump must

be

replaced.

~

OOSek

21

,---------

-,

----

----

-,

19

r---------

-+----

~

17

15

1

3r---------t-

--------~

11

r-

--------t---------

~

9

7

---

~

11

22

12

24

13

26

Vo/1

The fuel metering pump, when swi1ched on, supplies:

-lor B 5 L the fuel quantity for the

~

High

~

setting.

Rated quantity at 12

Vl24 V"'"'

16

.25

ml/90

sees .

• for 0 5 L the fuel quantity for the

~

Medium~

setting.

Rated quantity at

12

Vl24 V - 8.5

ml/90

sees.

=

oon1l0l unH

Voltmeler

'~

B[A"

0

0

"0

~

, ,

, .

'"

'

,,-=

---

,

j

Test~mp!!

Q

~=

16

~

--

/tw

,

Connection

01

vOltmeter to control uM

Page 17

-.

U.&ng

the

teet

adapter

and

the

test Instrument

for

the

oper1ItIng

unit

To

identify certain

faults

(see

page

5),

the

test adapter

(PCB)

and

the test instrument for the operating unit a

re

necessary.

1.

T..tIng

the

blower motor

Detach

the plug fr

om

the PCB. instead conn

ect

up

a lest

adapter. A

ppl

y operali

ng

vol

tag

e +

and -10 the adapter.

An o

hmm

eter is

nol

required for this measuremenl

Th

e blower

molor

mus

t start

up

at once.

Measuring the speed:

Switch

closed,

3000

rpm

Swit

ch

open,

800

rpm

Press button: the mo

lor

switches to high speed,

5OCX)

rpm.

"

the

motor does

not

run

:

Ch

eck

PCB visua lly for burnouts.

If OK, c

hange the

blower.

If t

he

speed changeover does not work, change

the

PCB.

2. T

..

ting the

Ntety

thennal

cutout

,witch:

The test

lamp must come

on

as

soon

as the operati

ng

voltage

has

been co

nnected.

11

it

does not

come on,

check

the PCB, cable, plug con-

tacts for breaks, ch

eck

the safety thermal cutout switch for

continuity.

Teat

adapter

for PCB

3.

Tutlng

the

temperature

.ensor

(lntemal)

and

flame

..

ntor:

The internal temperature

sensor

arranged on the PCB and

the flame

sensor arranged on the heat exchanger can

be

tested as follows (operating voltage

does

not ha

ve

to

be

co

nnected) :

Connect an

oh

mmeter to

the test adapter

as

shown

in t

he

sketch. The values given in

the

ske

tch mu st

be

complied

with.

In the event of a fault, check the PCB for breaks

or

short-

cir

cuits.

If

the

tempe

rature sensor is defective, replace the PCB;

il the

fl

ame senso r value is

00,

replace the

Ilame

sensor.

"

an

external temperature

senso

r

is

co

nnected, its res i-

stance

va

lue

must

be

in the

same

range. For this purpose,

co

nnect the extemal temperature sensor directly to the

ohmmeter.

,)

1 br/ws

2

swlge

..

-----

·

~I

2

6

7 gr

8 sw/ws

17

I'

7

18

12

19

6

10

br

~O16

9

In

~,

10

11

,

l1rt

~

...

12

12

br

Temperature sensor

1

800 -22

000

Flame sen

sor

900

-11()()0

whe

n heater is cold

(when heat

exchanger is ho

t,

up

to

22000)

-----

-----

~

~

Test la

mp

co

thermal cutout

mes on

when safety

switch

is

OK

+

~

Pushbutt

on: speed changeover

to

5000

rpm

Switch: speed changeover fr

om

800 r

pm

to

3000 rpm

17

Page 18

Teet unit for

opeq

tlng de¥ice

Delach Ihe plug of the operaling device from the cable

harness, inslead connect Ihe lesl

unill

o Ihe operaling device, and apply operating vonage.

Sellhe switch on the operating device 10 Ihe -Heating

and Vemilation" position. The appropriate lights must

come on.

The pilot light in the switch must

also come on

.*

• This test is unnecessary

in

operation with heating timer.

Tnt

unit

for operating device

-

----

gn

1 .

1800-

22

000

~pl

gn

,3

Ventilation

4

'5

6

' 9

±

L::.

___

18

Turn off the switch in the operating device. Call up lighting

wi

th key 1.

Pr

ess key 1, press key 2 in addilion.

Pi

lot lig

ht must change from

red

to green.

Connec1 ohmmeler, turn ralary knob. Set value of 800

10

1200 must be maintained without a break.

tn the event

of

an error change the operating device .

sw

--

'

---

'

- Key 2

lEO

green

+ Key 1

lig

hting red

t

. _

____ . ...l

Loading...

Loading...