Eberspächer Airtronic M D4, Airtronic M D2, Airtronic M D4S Installation, Operation And Maintenance Instructions

AIRTRONIC

AIRTRONIC D2, 12 V

AIRTRONIC D2, 24 V

AIRTRONIC D2

(Wiring goes to the right side housing of the casing) and, 12 V TK

Use instructions and parts based on

OEM Heaters,12 V

AIRTRONIC D2 CAMPER, 12 V

Order no.

25 2069 05

25 2070 05

25 2508 05

25 2440 05

25 2069 05

25 2326 05

AIRTRONIC M D4

AIRTRONIC M D4, 12 V

AIRTRONIC M D4, 24 V

AIRTRONIC M D4

use instructions and parts based on

25 2113 05

OEM Heater, 12 V

AIRTRONIC M D4S, 12 V

AIRTRONIC M D4

Camper Plus 12 V

AIRTRONIC M B4, 12 V

25 2113 05

25 2114 05

25 2441 05

25 2144 05

25 2327 05

20 1812 05

20 2900 81 01 03 0H

05.2015

1

Chapter Title Contents Page

Introduction • Heater Warnings .......................................................................... 3

1

• Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

• Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2

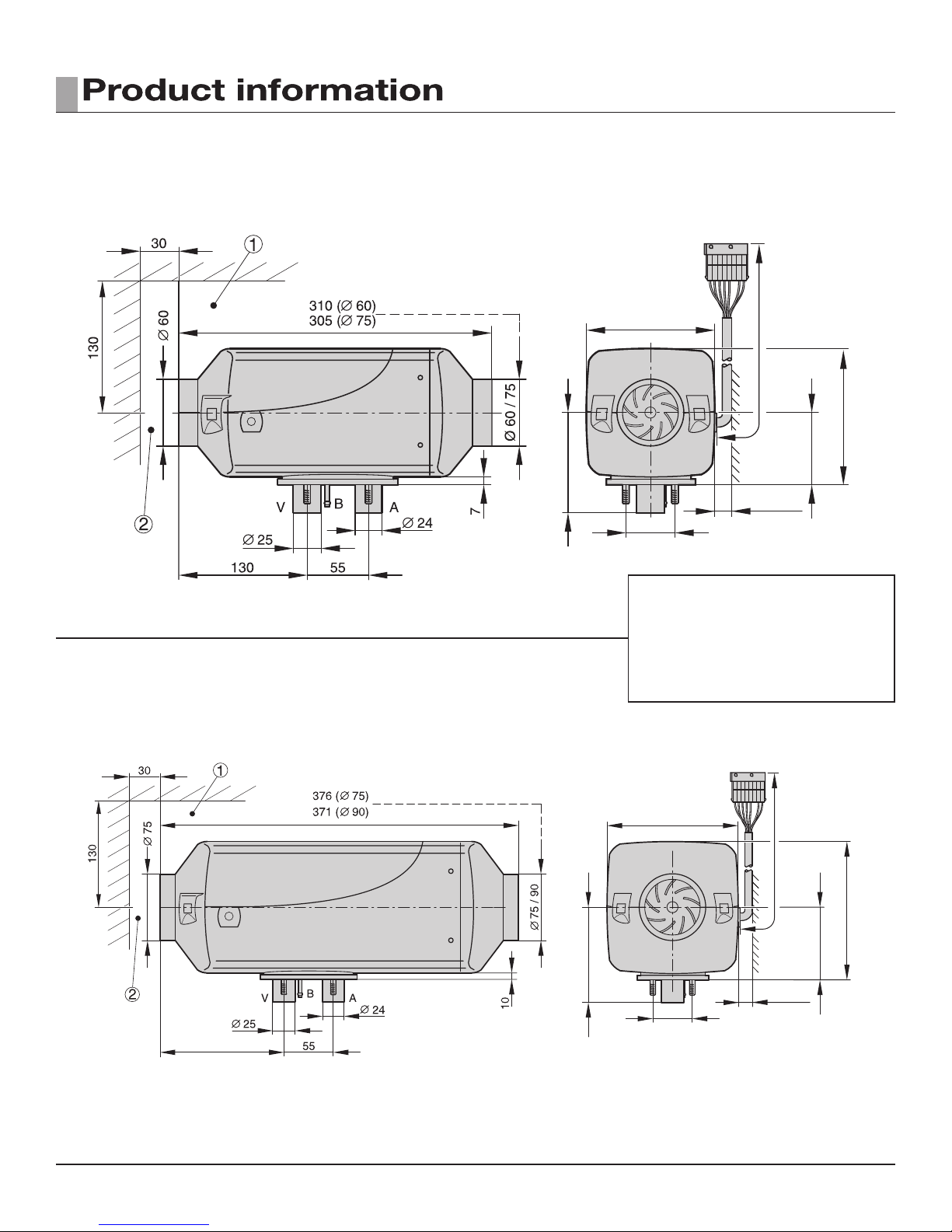

• Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

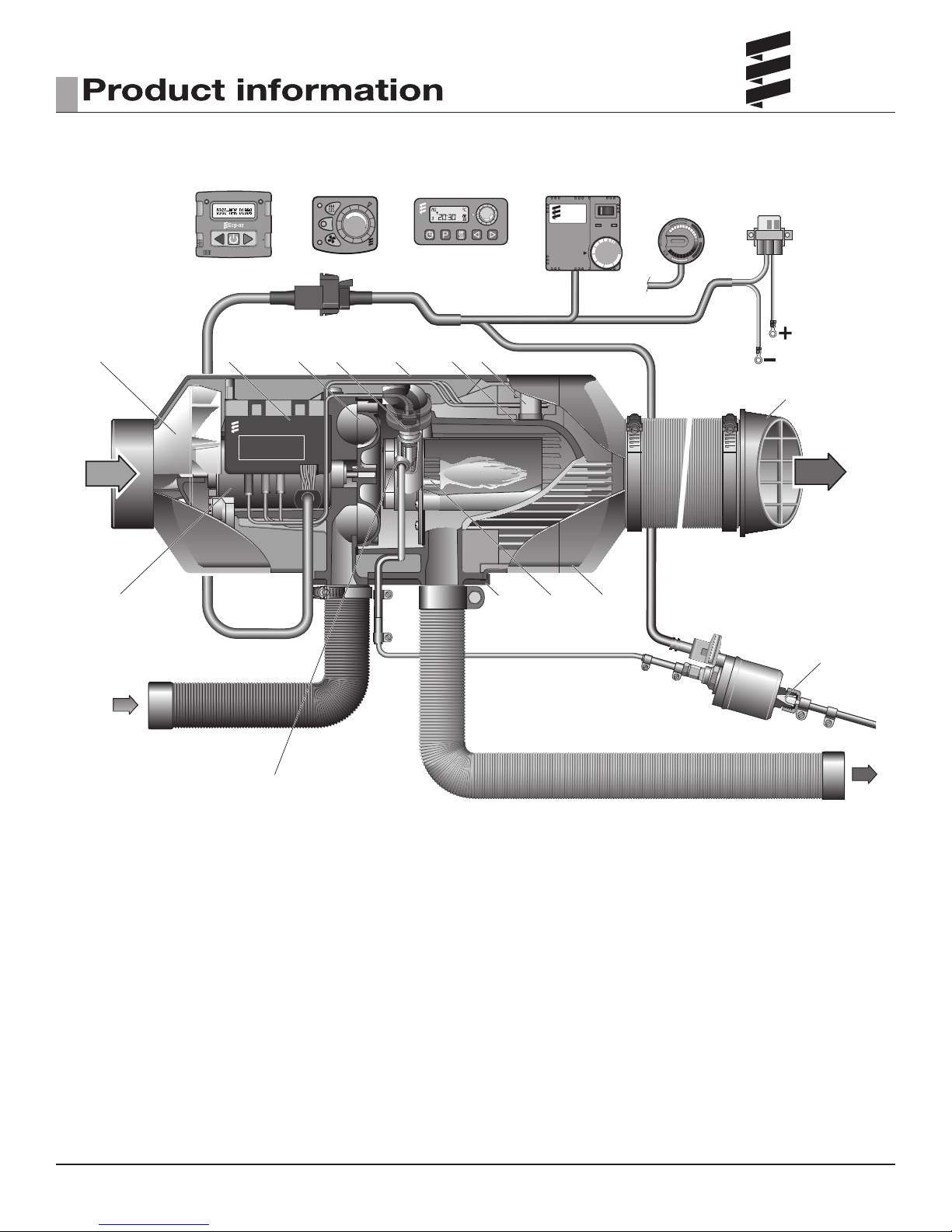

• Heater Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

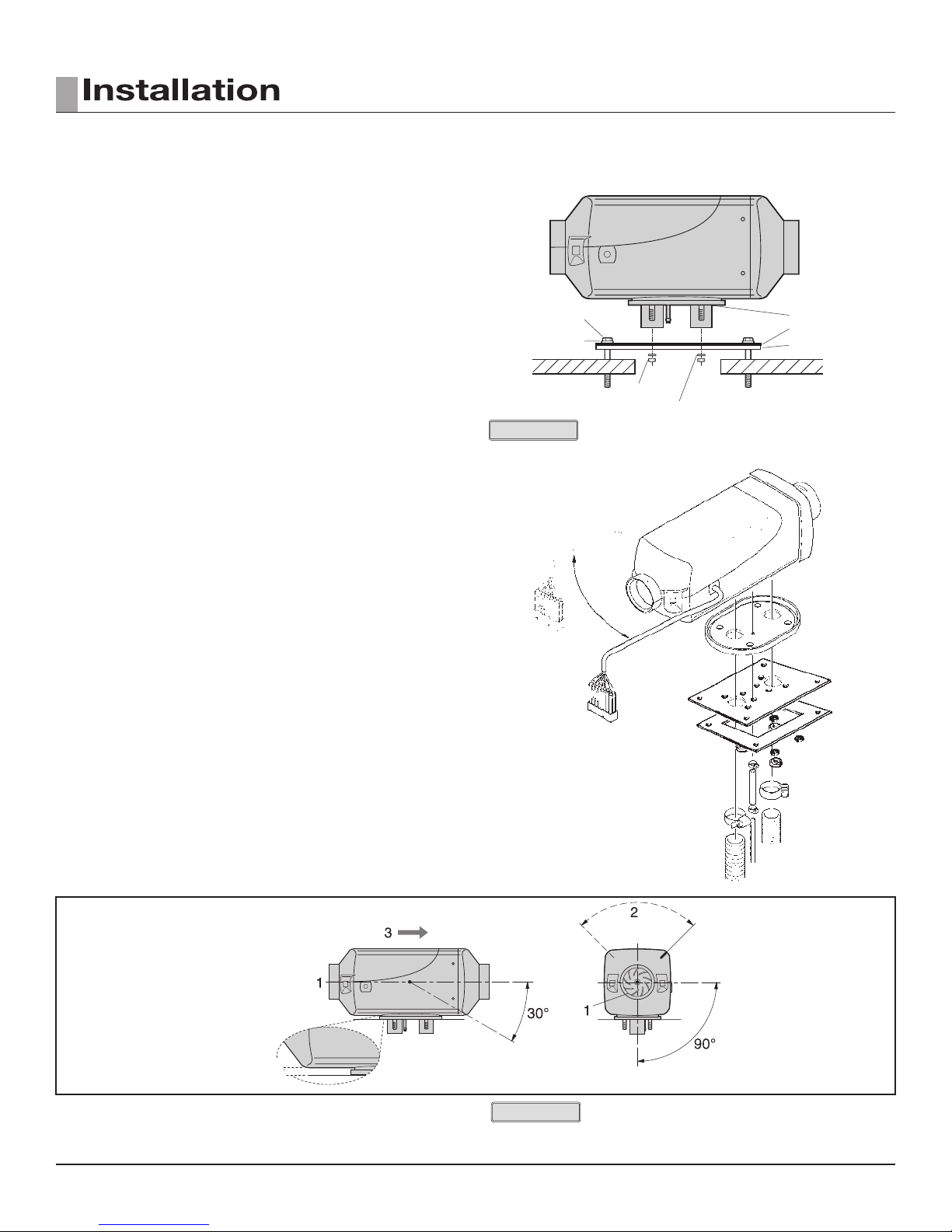

Installation Procedures • Heater Location .......................................................................... 8

3

• Heater Mounting .......................................................................... 8

• Heater Plate installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

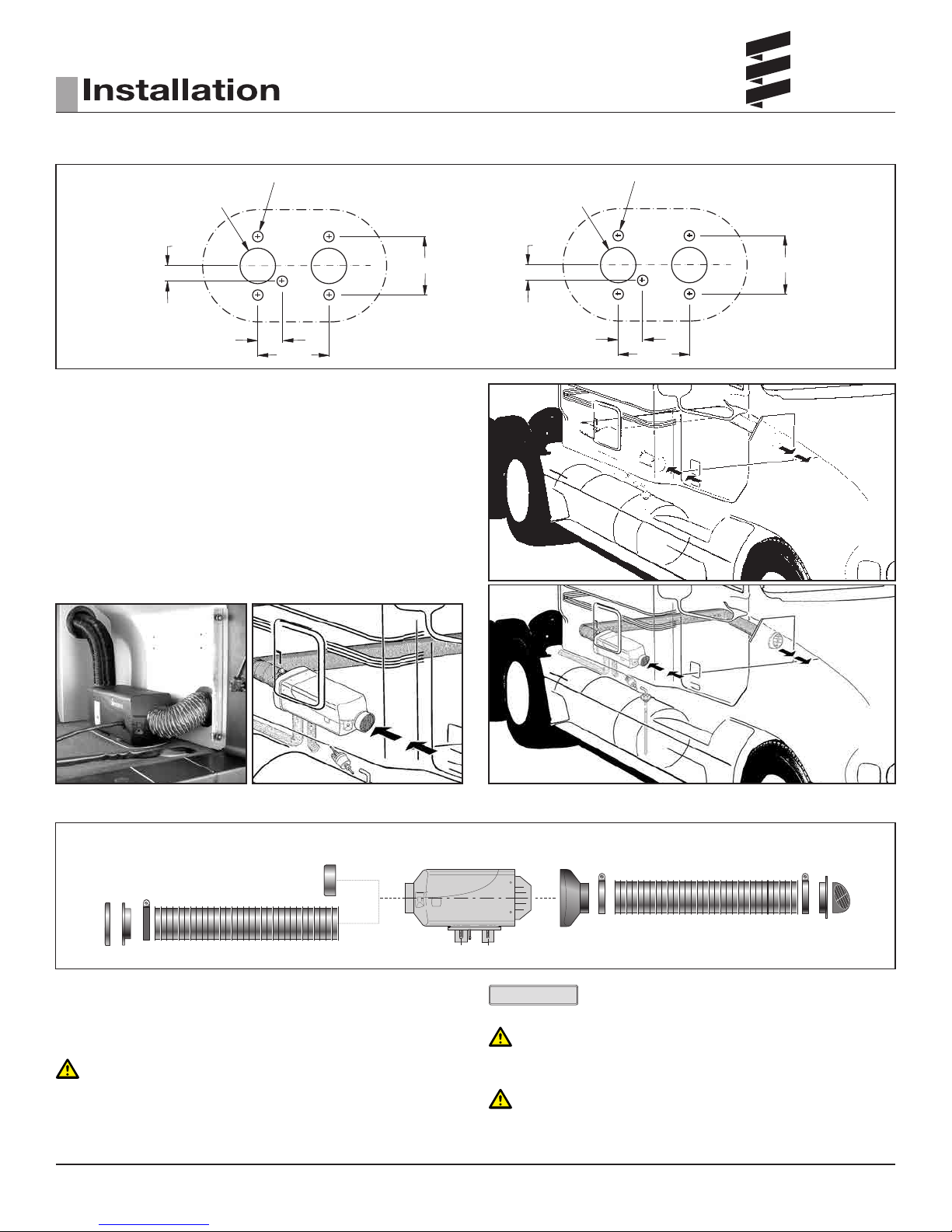

• Mounting Pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

• Heater Air Ducting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

• Ducting Components....................................................................... 9

• Fuel System ............................................................................ 10

• Electrical Connections..................................................................... 12

• Exhaust/Intake Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

• Operating Switches....................................................................... 13

Heater Operation • Switch on .............................................................................. 14

3

• Start-Up ............................................................................... 14

• Temperature s

• Temperature Control ...................................................................... 16

• Switching Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

• Controls & Safety Equipment................................................................ 16

• Operational Flow Chart .................................................................... 16

• Function Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

• Schematic AIRTRONIC D2/D4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

etting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . 15

Maintenance, • Periodic Maintenance ..................................................................... 21

4

Troubleshooting & • Basic Troubleshooting..................................................................... 21

Repairs • Self Diagnostic Troubleshooting ............................................................. 21

• Before beginning repairs - Installation review / inspection .......................................... 22

• Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

• Fuel Quantity Test ........................................................................ 29

• Overheat/Flame sensor values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

• Control and Resistance values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

• Repair Steps............................................................................

He

5

- Service Parts Diagram................................................................... 36

- Service Parts List....................................................................... 37

- Parts List Diagram ...................................................................... 38

- Parts List............................................................................. 39

PLEASE NOTE!

CAUTION:

DANGER:

This document aims to support service technicians and end users in North America. This does not replace documentation produced by J. Eberspächer.

The installation instructions and standards described in this document are NOT APPLICABLE TO MARINE INSTALLATIONS.

Please consult a certified Eberspaecher Marine dealer for marine installation.

ater Parts • AIRTRONIC D2/D4

31

This publication was correct at the time of going to print. However, Eberspaecher Inc. has a policy of continuous improvement and reserves the right to amend

2

1

CONCEPT OF THIS MANUAL

This manual aims to support the service company installing the heater and to

provide the user with all important information about the heater.

The manual has been divided into 5 chapters to make it easier to nd the

corresponding information quickly.

INTRODUCTION

1

Here you will nd important introductory information about installation

of the heater and about the structure of the manual.

Product information Here you will nd information about the scope of

supply, the technical data and the dimensions of the heater.

PRODUCT INFORMATION

2

Here you will nd information about the scope of supply, the technical

data and the dimensions of the heater.

HEATER WARNINGS

WARNING TO INSTALLER:

Correct installation of this heater is necessary to ensure safe and proper

operation.

Read and understand this manual before attempting to install a heater.

WARINING - EXPLOSION HAZARD

1. Heater must be turned off while re-fueling.

2. Do not install heater in enclosed areas where combustible fumes may

be present.

3. Do not install heaters in engine compartments of marine vessels.

WARINING - FIRE HAZARD

1. Install heater so it will maintain a minimum distance of 2” from any

ammable or heat sensitive material.

2. Install the exhaust system so it will maintain a minimum distance of

2” from any ammable or heat sensitive material.

3. Ensure that the fuel system is intact and there are no leaks.

Failure to follow these instructions could cause re resulting in serious

or fatal injury.

INSTALLATION PROCEDURES

3

Here you will nd important information and instructions referring to

installation of the heater.

HEATER OPERATION

4

Here you will nd information about the operation and function of the

heater.

MAINTENANCE / TROUBLESHOOTING / REPAIRS

5

This section contains information on possible faults and malfunctions,

troubleshooting, maintenance and the service hotline.

HEATER PARTS

6

Here you will nd the service parts diagrams and parts list.

PLEASE NOTE!

OPERATION WITH BIO-DIESEL

AIRTRONIC D2

The diesel heater is not approved for 100% Bio-Diesel. Mixtures up to 10%

bio fuel (FAME) may be used.

AIRTRONIC M (D4)

The diesel heater is approved for up to 100% Bio-Diesel according to the

following conditions:

- Bio-Diesel (FAME) according to Standard CAS NO. 67784-80-9 (or similar)

in free owing state (reduced at tempera tures below 0°C (32°F);

- Operation of heater with mixtures greater then 10% is restriced during

periods of temperatures below 0°C (32°F)

- Maintenance schedule for Bio-Diesel mixtures greater then 10%

- Heater must be run for 30min on high heat with regular diesel fuel once

every 500h if mixtures above 20% are used;

- Vent hole must be cleaned every 500h (twice a heating season assuming

1000h of operation annually);

- Atomizing Screen must be replaced every 500h (twice a heating season

assuming 1000h of operation annually).

WARINING - ASPHYXIATION HAZARD

1. Route the heater exhaust so that exhaust fumes can not enter any

passenger compartments.

2. Ensure an air tight seal is maintained between the heater and mounting

surface and at any exhaust connection points.

3. Ensure that heating air supply is taken from an area where poisonous

gases will not be present.

4. If running exhaust components through an enclosed compartment,

ensure that it is vented to the outside.

Failure to follow these instructions could cause oxygen depletion

resulting in serious or fatal injury.

Direct questions to Eberspaecher:

Canada & U.S.A. 1-800-387-4800

All maintenance procedures may be performed without removing heater from vehicle.

PLEASE NOTE!

Only one kit from the listed below is needed.

HEATING AT HIGH ALTITUDES

Up to 1500 meters (4920’) - unrestricted heating operation is possible.

Above 1500 meters (4920’) - heating operation is in principle possible for

short periods, e.g. when crossing a mountain pass or during a brief stop. In

cases of extended stays, the fuel supply at the fuel metering pump has to be

adapted to high altitude conditions.

The following high altitude kits are available:

P/N: 24 0222 00 00 00 - 12V only (Contains high altitude fuel pump)

P/N: 20 2900 70 00 07 - 12V or 24V (Contains high altitude compensator,

no extra fuel pump needed)

P/N: 22 1000 33 22 00 - 12V or 24V (Only works with Airtronic Heaters that

have “H-Kit” on the factory label)

MARINE CONCIDERATIONS

• Follow marine manual for installation requirements (separete document)

• Gasoline (B4) heaters must not be installed in ingene compartment.

• Diesel or Gasoline (petrol) heaters must not be installed in engine

compartment of gasoline (petrol) boats.

or

or

3

1

EBERSPAECHER’S

This manual aims to support the service company installing the heater and to

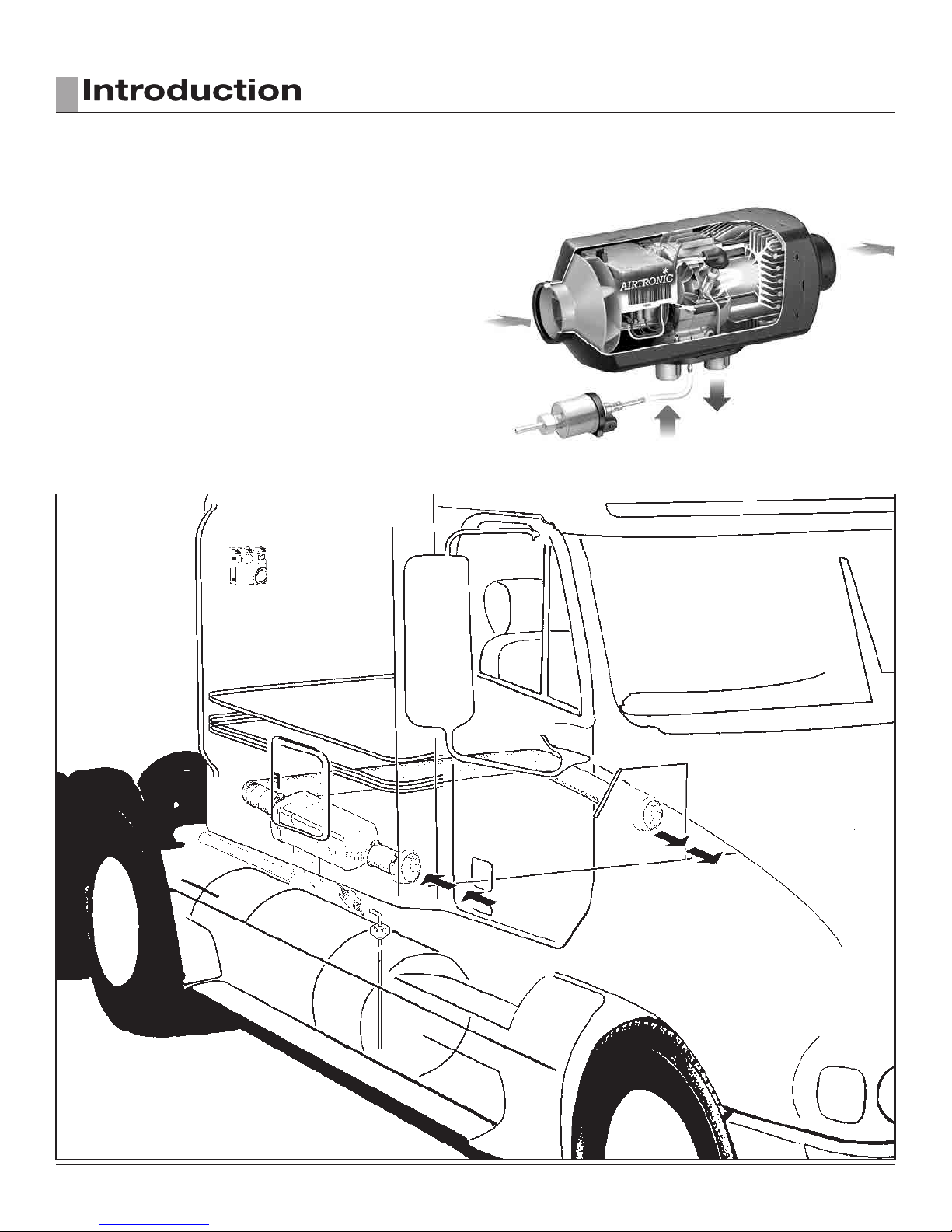

The AIRTRONIC D2 is a compact diesel-red 7,500 BTU/hr air heater, quality

engineered to provide a dependable means of space heating.

This heater is uniquely designed for inside mounting and ease of installation.

The AIRTRONIC D4 is a 13,650 BTU/hr air heater for larger bunks.

These heaters provide hot air to the interior of vehicles for passenger comfort.

Since the heater runs on diesel fuel and are available in 12 or 24 volt versions,

it is able to provide space heat completely independently of the vehicle engine.

Various control options are available to operate the heater. It cycles through

four heat output modes (boost-high-medium-low) in order to maintain the

desired temperature.

In special cases where the heat output required is less then what the “low”

power mode provides the heater switches to “stand-by” mode. Temperature

and overheat sensors, and a specially designed heat exchanger are among

the safety features which make this heater a safe and dependable unit.

AIRTRONIC

BUNK HEATERS

For illustration purposes only

4

2

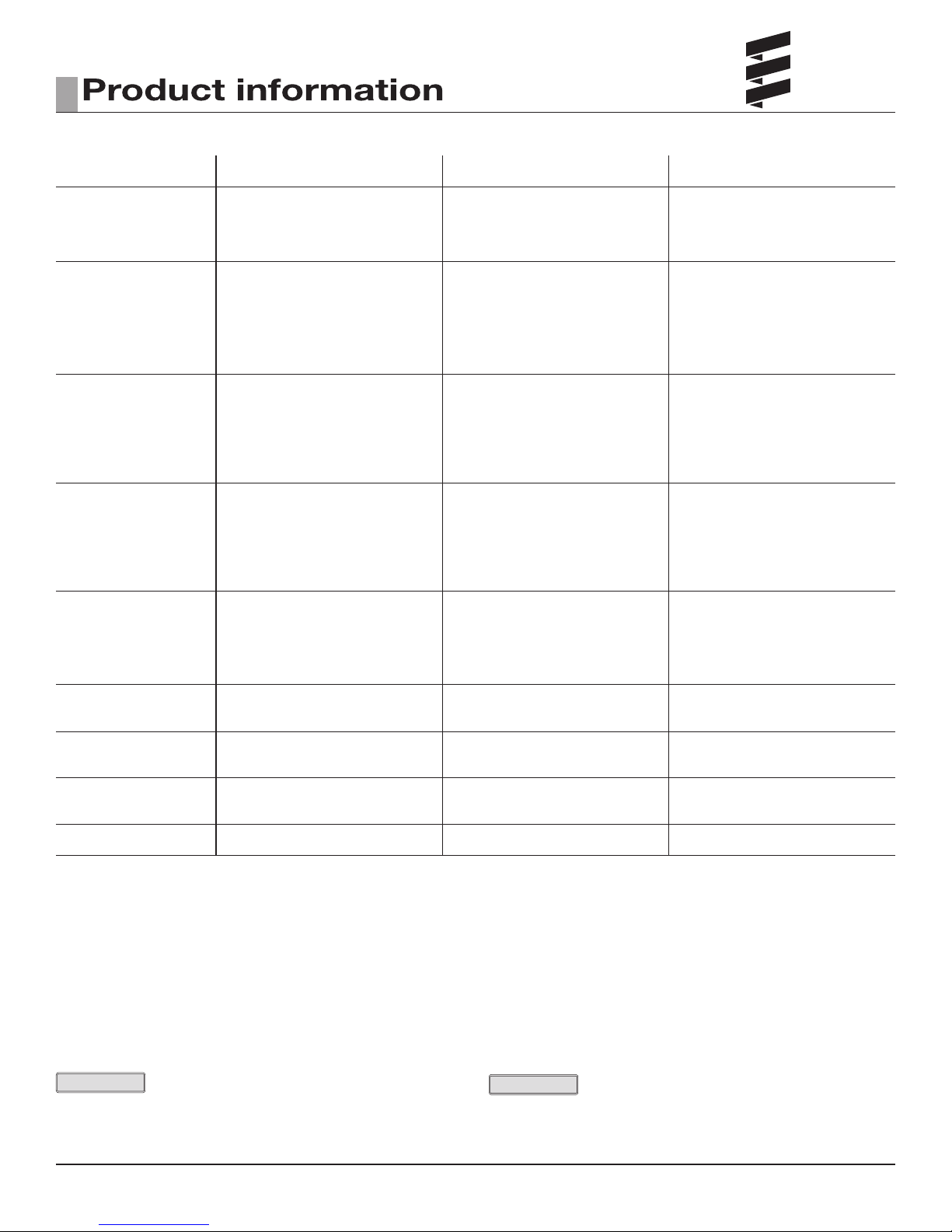

TECHNICAL DATA

HEATER

Heat Output (±10%) 7,500 BTU/hr Boost (2.2 kW) 13,650 BTU/hr Boost (4.0 kW) 12,950 BTU/hr Boost (3.8 kW)

6,150 BTU/hr High (1.8 kW) 10,200 BTU/hr High (3.0 kW) 10,910 BTU/hr High (3.2 kW)

4,100 BTU/hr Medium (1.2 kW) 6,800 BTU/hr Medium (2.0 kW) 7,160 BTU/hr Medium (2.1 kW)

2,900 BTU/hr Low (0.85 kW) 3,500 BTU/hr Low (1.0 kW) 4,430 BTU/hr Boost (1.3 kW)

Current at 12v (±10%) 8.3 amps - Start 8.3 amps - Start 8.3 amps - Start

2.8 amps - Boost 3.3 amps - Boost 3.3 amps - Boost

1.8 amps - High 2.0 amps - High 2.4 amps - High

1.0 amps - Medium 1.1 amps - Medium 1.3 amps - Medium

0.7 amps - Low 0.6 amps - Low 0.8 amps - Low

0.4 amps - Stand by 0.4 amps - Stand by 0.4 amps - Stand by

Current at 24v (±10%) 4.2 amps - Start 4.2 amps - Start

1.4 amps - Boost 1.7 amps - Boost

0.92 amps - High 1.0 amps - High (No 24V version available)

0.5 amps - Medium 0.5 amps - Medium

0.3 amps - Low 0.3 amps - Low

0.2 amps - Stand by 0.2 amps - Stand by

Fuel Consumption (±10%) U.S. Litre/hr U.S. Litre/hr U.S. Litre/hr

Gal/hr Gal/hr Gal/hr

Boost 0.07 0.28 Boost 0.13 0.51 Boost 0.14 0.54

High 0.06 0.23 High 0.10 0.38 High 0.12 0.46

Medium 0.04 0.15 Medium 0.07 0.25 Medium 0.08 0.29

Low 0.03 0.10 Low 0.03 0.11 Low 0.05 0.18

Air Flow (±10%) 48 cfm Boost 85 cfm Boost 85 cfm Boost

40 cfm High 69 cfm High 74 cfm High

27 cfm Medium 50 cfm Medium 55 cfm Medium

19 cfm Low 30 cfm Low 43 cfm Low

6 cfm Stand by 11 cfm Stand by 11 cfm Stand by

AIRTRONIC

D2

AIRTRONIC

D4

AIRTRONIC

B4

Operating Voltage Range 10.5 - 16 vdc at 12 vdc 10.5 - 16 vdc at 12 vdc 10.5 - 16 vdc at 12 vdc

21 - 32 vdc at 24 vdc 21 - 32 vdc at 24 vdc 21 - 32 vdc at 24 vdc

Overheat Temperature 240°F (115°C) 240°F (116°C) 240°F (116°C)

Shutdown (±10%)

Ambient Operating -40°F to 158°F (-40°C to 70°C) -40°F to 158°F (-40°C to 70°C) -40°F to 122°F (-40°C to 50°C)

Temperature

Weight 5.9 lbs. (2.7 kg) 9.9 lbs. (4.5 kg) 9.9 lbs. (4.5 kg)

PLEASE NOTE!

The heater control unit is equipped with a low voltage cutout to prevent vehicle

battery drain and a high voltage cutout to protect heaterelectrical parts.

PLEASE NOTE!

The terms “Boost” and “Power” are used interchangeably through out this

manual. The terms refer to the highest level of heat output.

5

(12.2 inches)

(4.8 inches)

64.5

89.5

325

122

(4.5 inches)

115

44

min. 17

4 x M6

(14.8 inches)

(5.9 inches)

80

105

325

150

(4.5 inches)

140

44

132.5

min. 17

4 x M6

2

HEATER DIMENSIONS

Principal Dimensions

Principal Dimensions

AIRTRONIC

AIRTRONIC

D2

D4

* All measurements in millimeters 25.4 mm = 1”

a Minimum installation distance (clearance)

to open the lid and to dismount the glow

pin and the control unit.

b Minimum installation distance (clearance)

to take in heating air.

6

2

12 11 89

Espar

10

2

1

3

0

4

23

1

F

F

13

32

4

567

21

H

H

14

15 16 17

19

20

18

C

C

22

E

24

E

1 Hot Air Blower Wheel

2 ECU

3 Combustion Air Blower Wheel

4 Glow Pin

5 Cover

6 Heat Exchanger

7 Overheat/Flame sensor

8 7 Day Timer with Thermostat (optional)

9 Operating Unit (Thermostat)

10 Operating Unit (Rheostat)

11 Mini Controller

12 Digi Max

13 Blower Motor

14 Fuel Connection

15 Flange Seal

16 Combustion Chamber (Burner)

17 Hot Air Outlet Hood

18 Combustion Air Intake Hose

19 Fuel Metering Pump

20 Fuel Filter built into FMP

21 Hot Air Output Deector

22 Flexible Exhaust Pipe

23 Main Fuse: AIRTRONIC 12 V - 20 A Fuse

AIRTRONIC 24 V - 10 A Fuse

24 Vent Hole

C = Combustion Air

D = Fuel Intake from Tank

E = Exhaust

F = Fresh Air Intake

H = Hot Air Output

7

10

mm

minimum

10

mm

minimum

3

HEATER LOCATION

Depending on the type of vehicle, the best location for mounting the heater will

vary. Typically, air heaters are mounted inside tool or luggage compartments.

However, the heater may be mounted anywhere inside the vehicle provided

you adhere to the following conditions:

• Combustion air intake, exhaust and fuel inlet must be located outside of the

vehicle.

• Heater must be mounted on at horizontal surface providing an air tight

seal between heater and vehicle.

• Do not mount the heater outside the vehicle, unless care is taken to protect

the heater from the weather. When selecting the location, consider the

following:

• Combustion air and exhaust connections.

• Ducting.

• Fuel line connections.

• Electrical connections.

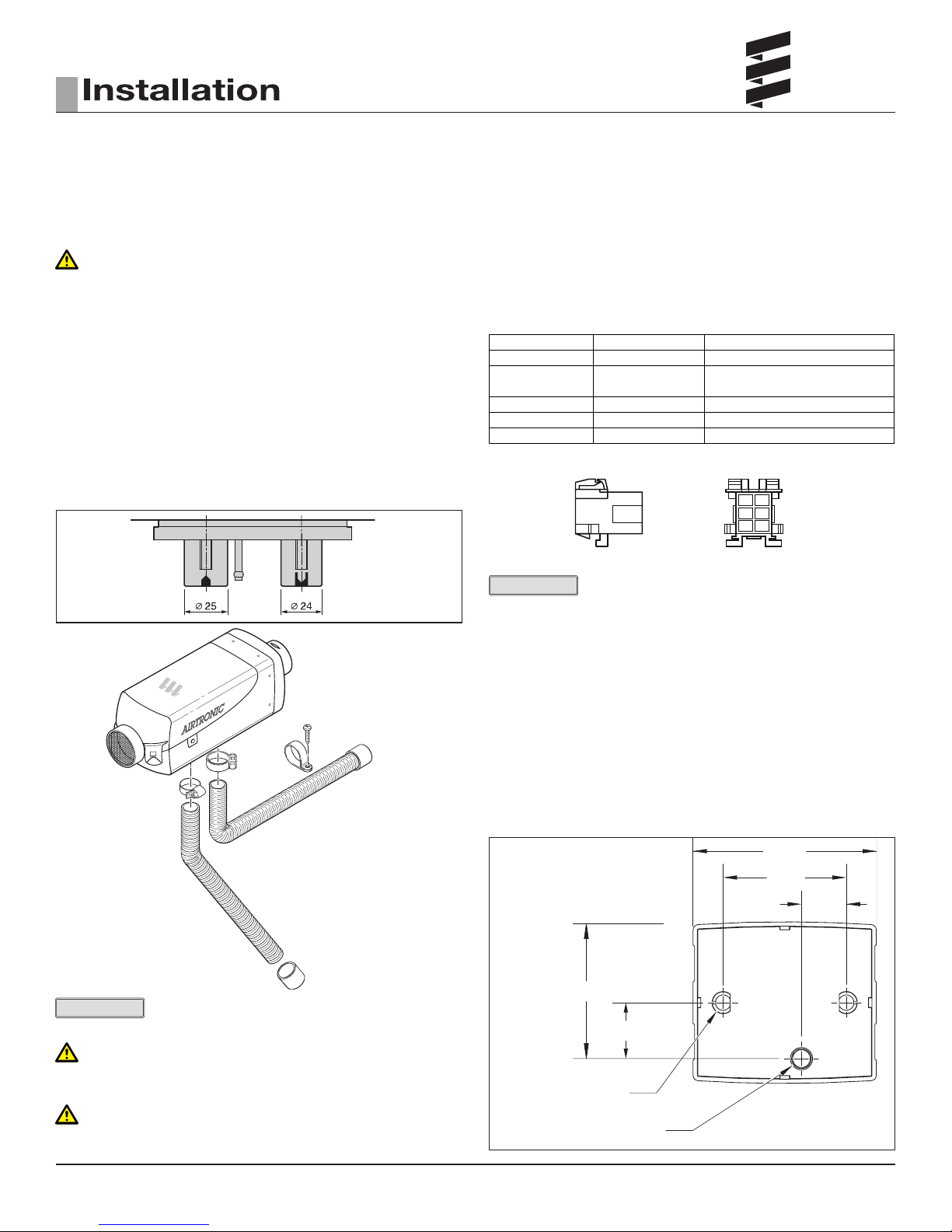

HEATER MOUNTING

A mounting plate and hardware are provided with the truck heater kit.

• Choose heater location.

• Cut a 4-½” hole or a rectangular opening 4”x 5” to accommodate

mounting plate and seal. Secure mounting plate to vehicle with provided

“Tek” screws.

• Mount heater on mounting plate with nuts and spring washers provided.

• If the mounting plate will not be used, the heater ange can be used as a

template to mark where the individual components openings should be

made. (A diagram of the ange is on the fallowing page.)

• For ease of installation make the exhaust, combustion air intake and fuel

connections at the base of the heater before mounting the heater. See the

fallowing pages for instructions and restrictions on the exhaust, combustion

air intake and fuel connections.

HEATER MOUNTING PLATE INSTALLATION

Hex Head Tek Screw

Flat washer

Nut

Spring Washer

Silicon gasket (flange)

Stainless Steel Plate

Plate seal

Cab Floor

PLEASE NOTE!

Tighten screws sufciently to ensure positive seal between mounting plate

and mounting surface.

Do not over tighten.

WIRING HARNESS MOUNTING

For convenient installation and maintenance purposes the wiring harness can

be mounted on the left or right side of the heater housing. To do this the ECU

must be removed from the heater. The bottom of the ECU has is a plastic ap

that holds the wiring in place. Unlatch the plastic ap and position the harness

in the direction that you desire. Before relatching the plastic ap ensure, that

the wiring is laid neatly so that the latch can closed without excessive force.

When mounting the harness to the housing remove the grommet from one

side of the housing and replace on the opposite side.

8

ALLOWABLE MOUNTING ANGLE

PLEASE NOTE!

The following pages refer to a standard installation kit.

Components included with different kits may vary.

3

MOUNTING PLATE

INCHES MILLIMETERS

Ø 1.024 (2 HOLES)

0.472

0.709

Ø 0.295 (5 HOLES)

Ø 26.0 (2 HOLES)

12.0

1.732

18.0

2.165

Ø 7.5 (5 HOLES)

44.0

55.0

HEATER WARNINGS

A 60mm exible duct 40 inches long, hot air outlet and clamps are provided

with the heater kit. In routing and installing the ducting the following criteria

must be observed:

• Route ducting with smooth bends. Avoid crushing duct.

• Position hot air outlet so that it cannot be obstructed.

• When not using return ducting. Use a protective air intake grille on air inlet

side of heater to prevent objects from being sucked in.

• Ensure provisions are made for proper air return ventilation.

• Use return air ducting for best heating efciency.

• For exact ducting design specications please refer to Product Catalogue.

DUCTING COMPONENTS

7634

1. Protective Grill 5. Air Outlet - Rotatable

2. Air Outlet Hood 6. Connection Piece

3. Hose Clamp 7. Protective Grill

4. Flex Duct

WARNING

Do not use existing vehicle ducting or outlets.

Ducts and outlets must be capable of withstanding a minimum of 300°F

operating temperatures.

1

PLEASE NOTE!

For exact ducting design specications please refer to

2

3

354

Product Catalogue.

WARNING

Do not over tighten duct clamps. May damage heater and result in a

costly repair.

CAUTION

Do not position outlet so that it will blow hot air directly at operator, at

room thermostat, or return air inlet.

9

3

Ø

1.0”

Ø

1 / 4” (2 HOLES)

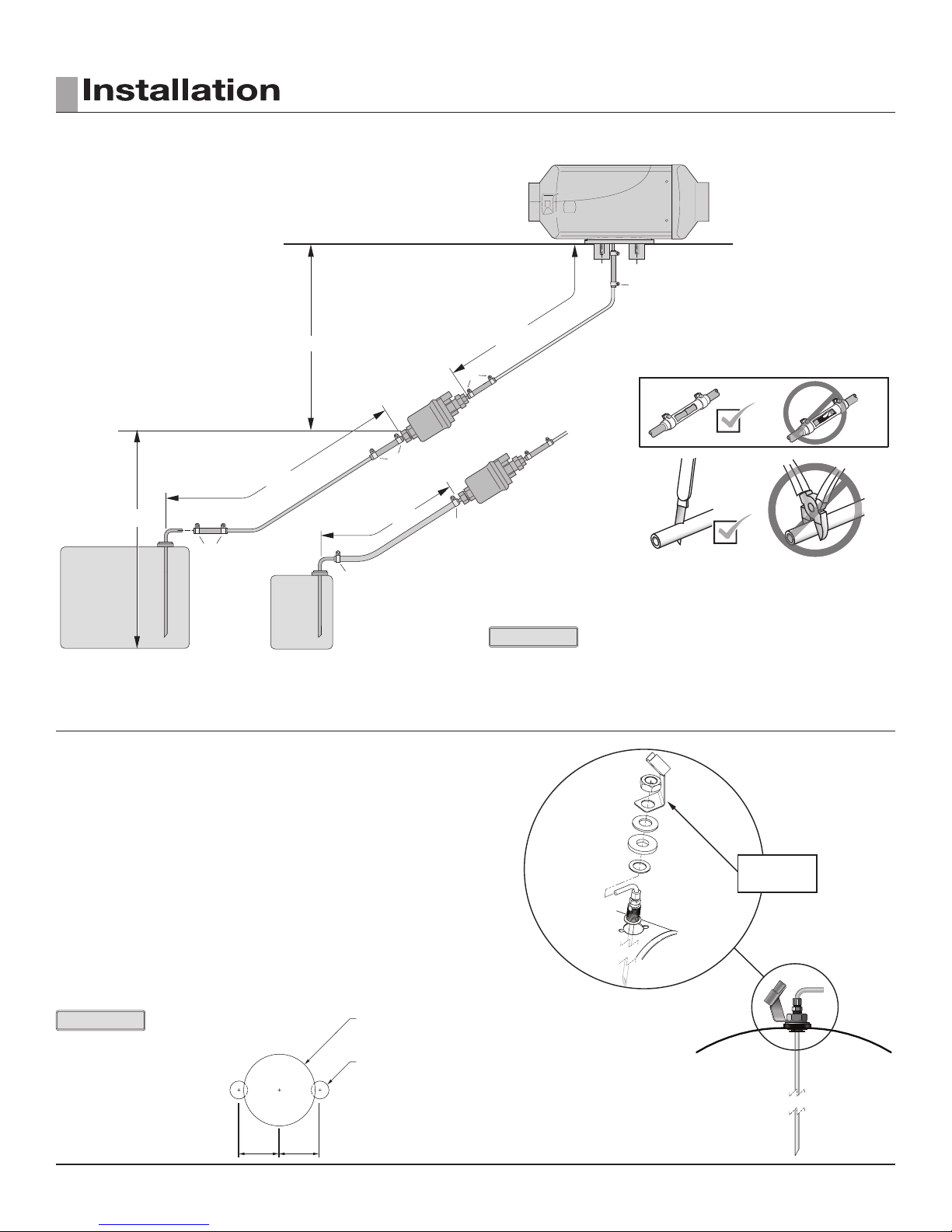

FUEL SYSTEM

The fuel metering pump is the heart of the system and must be

installed properly to ensure successful heater operation.

FUEL SYSTEM OVERVIEW

7

6

Max. 6’6”

2

5

3

Max. 6.6”

4

Max. 2’6”

2

3

Max. 2”

9

3

Fuel

Tank

1

Fuel

Tank

1

Optional

1. Fuel Pick-Up Pipe 4. 2.0mm Black Plastic Fuel Line

2. 5.0mm Rubber Connector 5. Fuel Metering Pump

3. 11mm Clamp 6. 9mm Clamp

FUEL PICK-UP PIPE INSTALLATION (DRILL OPTION)

The fuel metering pump is the heart of the system and must be installed properly to ensure successful heater operation.

Max. 20”

8

6

7

Right Wrong

5

3

Correct

PLEASE NOTE!

Use butt joints and clamps on all connections.

7. 3.5mm Rubber Connector 9. 5mm Rubber Fuel Line

8. 1.5mm or 2.0mm White

Plastic Fuel Line

Bubble

Wrong

• Choose a protected mounting location close to the fuel pump and heater.

A spare fuel sender gauge plate provides an ideal mounting location.

• Drill the mounting holes as shown.

• Tighten Ferrule nut to pick-up pipe at desired height.

• Cut the fuel pick-up pipe to length.

• Mount the fuel pick-up pipe as shown.

• Lower the fuel pick-up pipe (with reinforcing washer) into the tank using

the slot created by the two 1/4” holes.

• Lift the assembly into position through the 1” hole.

• Assemble the rubber washer, fuel metering pump bracket, metal cup

washer and nut.

PLEASE NOTE!

Drill the two 1/4” holes rst.

10

FMP Bracket

Optional

3

FMP

Fuel Pick-up Pipe

Ferrule Nut (Tighten before installing)

FMP bracket

Fuel Tank

Nut

Sheet Metal Washer

(raised center to top)

Reinforcing Washer

Holding Tabs

Allow 4" from Fuel

Pick-up to tank bottom.

Allow only 1" for flat

bottom tanks.

CUSTOM PICK-UP PIPE WITH 1/4” NTP FITTING - OPTION

Standard pick-up pipe can be installed as a drill type installation

or 1/4 NPT type installation.

• Remove an existing NPT plug from the top of the fuel tank.

• Cut the fuel pick-up pipe to length.

• Secure the fuel pick-up pipe into position using the combined NPT

compression tting.

FUEL LINE

• Route fuel lines from the fuel pick-up pipe to the fuel metering pump then

to the heater.

• Use fuel lines provided.

• Other sizes or types of fuel lines may inhibit proper fuel ow.

• Make proper butt joints using clamps and connector pieces as shown on

previous page.

• Use a sharp utility knife to cut plastic fuel lines to avoid burrs and pinching

fuel line shut.

To Pin 5 (of 16 pin connector)

Green / Red

Brown

Green / Red

Brown

To Pin 10 (of 16 pin connector)

Normal FMP

High Altitude FMP

PLEASE NOTE!

FMP bracket is not compatible with NPT pick up option.

Refer to product catalogue for other pick-up pipe options.

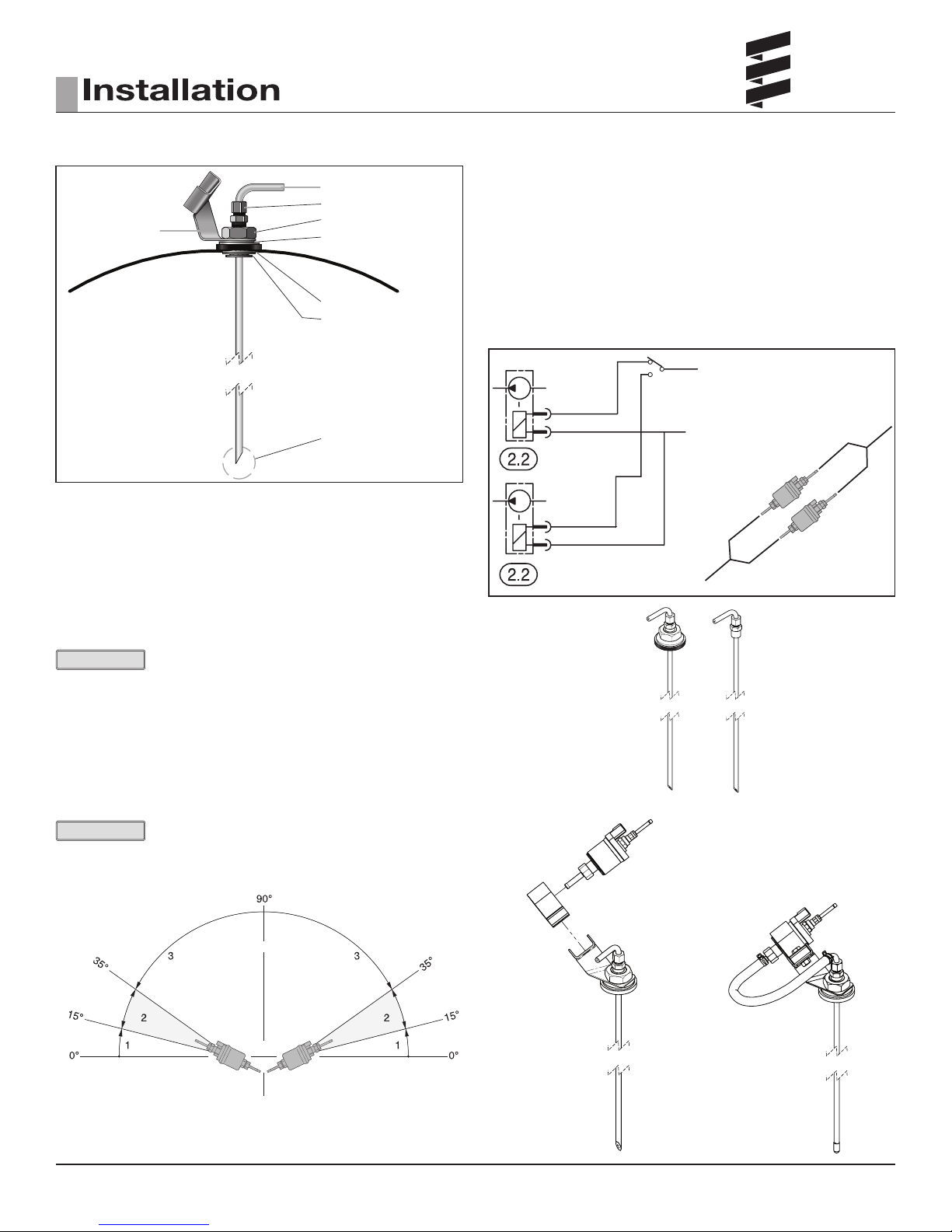

FUEL METERING PUMP

• Choose a protected mounting location close to the fuel pick- up pipe and

heater if not using standard assembly as shown on right.

• Using the bracket and rubber mount provided, install fuel pump as shown.

PLEASE NOTE!

Proper mounting angle of the fuel pump is necessary to allow any air or vapor

in the fuel lines to pass through the pump rather than cause a blockage.

Permissible

preferable

preferable

not permissiblenot permissible

1 Installation position between 0° and 15° is not allowed.

2 Preferred installation position in range 15° to 35°.

3 Installation position in range 35° to 90° is allowed.

Typical standard

assembly, if not

using this format

please adhere to

specications on

pg.10

11

Espar

Main Harness

Fuel Metering Pump Harness

Connector for Diagnostics

Switch Harness

Thermostat

Power Harness

Fuel and holder

3

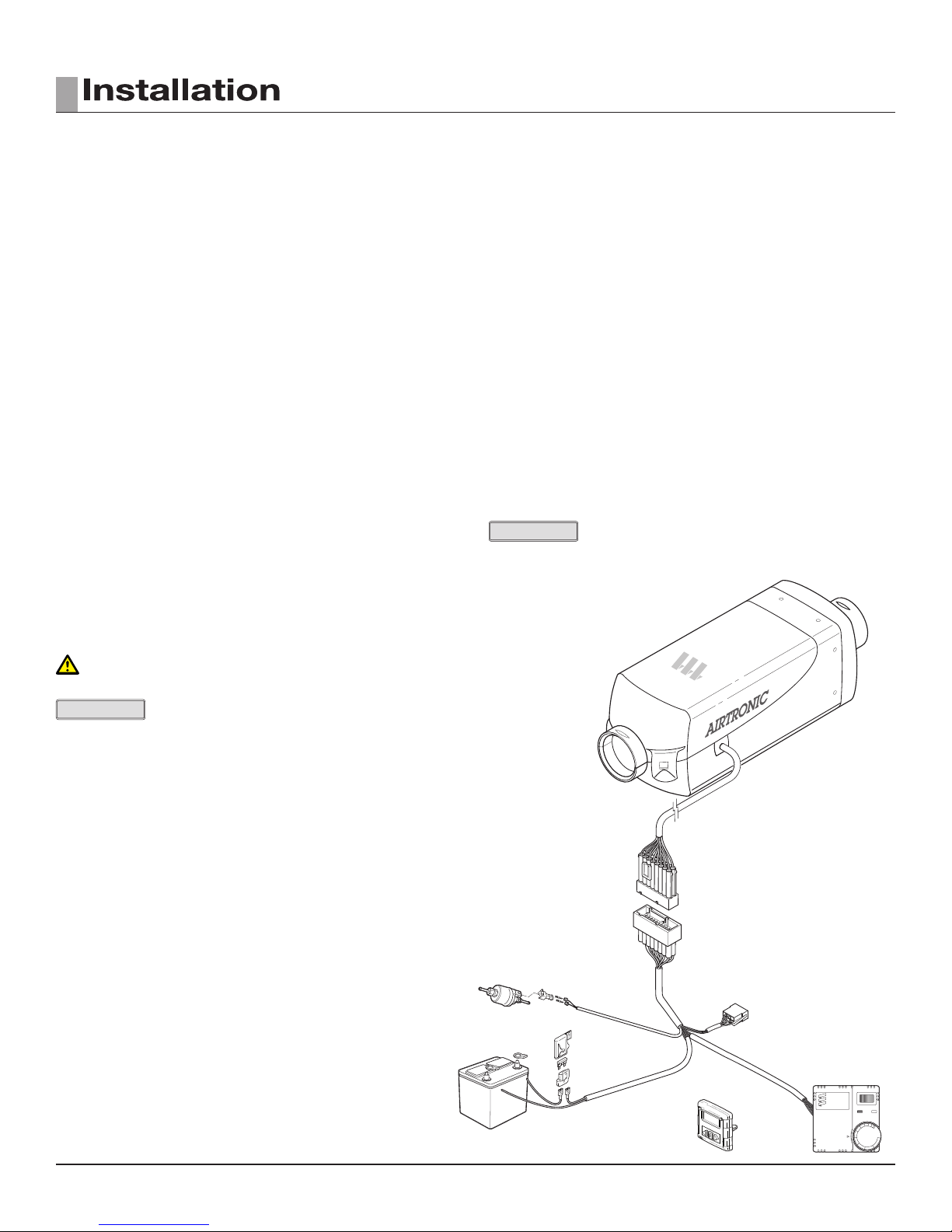

ELECTRICAL CONNECTIONS

Main Harness ..............................................................................................

Power Harness .........................................................................

Switch Harness ........................................................................

Fuel Metering Pump Harness ....................................................

Diagnostic Harness ..................................................................

16 pin connector with 10 terminated wires at 8 terminals (green/red, blue/

white (2), red, grey/red, grey, brown, brown/white and yellow (2)). Connect to

the heater’s 16 pin connector. Main harness branches off to sub harness’s

described below.

2 core harness (red and brown). Route power harness to batteries, cut to

length and terminate. Install 20 amp fuse last (10 amp on 24V). Connect red

wire to fuse holder near battery.

Connect fuse link wire directly to battery positive post using ring terminal.

Connect brown wire directly to battery negative post using ring terminal.

7 core harness (red, brown/white, yellow, grey, brown, grey/red and blue/

white). Route this harness to the control option mounted in the cab. Do

not cut this harness, wires have been soldered at ends for convenience of

terminating to terminals of the control option.

Coil up excess harness and secure in safe location.

Connect to control option (refer to switch connection section).

2 core harness (green/red and brown).

Route this harness from heater to fuel metering pump. Cut to length and

connect to fuel metering pump using single terminals and connector provided

with kit.

PLEASE NOTE!

Polarity does not matter for FMP connection.

8 pin connector (red, brown, yellow, blue/white). For diagnostic purposes only.

CAUTION: Install power 20 amp fuse only after all electrical connections

are complete. (10 amp fuse on 24V.)

PLEASE NOTE!

All exposed electrical connections should be coated with protective grease,

(petroleum gel, Vaseline, etc.).

12

3

OPERATION AND FUNCTION

EXHAUST AND COMBUSTION AIR INTAKE CONNECTIONS

A 24mm exible stainless steel exhaust pipe (40” long) and a 25mm exible

plastic tube (40” long) for combustion air intake are included with the heater

kit. Exhaust clamps and holders are also provided.

CAUTION!

Route exhaust and combustion air intakes so they cannot be plugged by dirt,

water or snow. Ensure the outlets do not face into the vehicle slip stream.

Keep exhaust and combustion air intake a minimum of 12” apart.

Drill 1/8” holes in exhaust pipe if necessary to allow water drainage.

Combustion air intake and exhaust lengths can be shortened to a minimum of 8”.

• Attach the exhaust pipe to the exhaust outlet of the heat exchanger.

• Route exhaust pipe to an open area to the rear or side of the vehicle so

that fumes cannot build up and enter the cab or the combustion air inlet to

the heater.

• Install protective cap.

• Attach the combustion air intake tube to the combustion air inlet of the

heater.

• Once secure to the heater inlet, the intake pipe must be routed to the

underside of the vehicle where it will pick up clean, fresh, moisture free air.

OPERATING SWITCHES

The heater can be controlled using a Digi-Max D1000, Thermostat or Rheostat

type switch. It can also be controlled by a 7 day timer with thermostat. See

schematic pg. 19.

WIRING

PIN CONNECTIONS

CONTROLLER HARNESS

Red Connect to pin 1 Red,+ Power

Yellow Connect to pin 2 Yellow, ON/OFF

Brown/White

Brown/White Connect to pin 3

Ground Reference

Grey/Red Connect to pin 4 Grey/Red Temperature setpoint

Grey* Connect to pin 5 Grey Temperature sensor

Blue/White Connect to pin 6 Blue/White Diagnostic

* The grey cable is an optional connection for temperature sensor.

12

34

56

Side View Cable Entry View

(Rear View)

PLEASE NOTE!

Insulate any cable ends not used.

The connectors and socket housing are shown from the cable entry side.

End Cap

End Cap

Exhaust ( min 8” - max 6.5’ )

Exhaust ( min.8” - max. 6.5’ )

Combustion Air Intake

( min 8” - max 6.5’ )

PLEASE NOTE!

Bends in both the intake and exhaust pipes should be kept to

Combustion Air Intake

( min.8” - max. 6.5’ )

End Cap

End Cap

a minimal. For every 90° bend it is recommended to shorten pipe by 16” (40cm).

WARINING!

The exhaust is hot, keep a minimum of 2” clearance from any heat

sensitive material.

WARINING!

Route exhaust so that the exhaust fumes cannot enter the passenger

compartment.

THERMOSTAT

• Select a mounting location which will be representative of the average

temperature of the area being heated. Avoid mounting near heater outlets,

windows, doors, electrical appliances or in areas receiving direct sunlight.

• Route the switch harness from the heater to the thermostat mounting

location.

• Mount the thermostat as shown using proper mounting hardware and the

slots provided on the thermostat base. Pull the switch harness through the

thermostat base access hole.

• Connect the six core switch harness to the thermostat as shown.

DRILLING TEMPLATE

( 65.5 mm )

(2.58”)

( 44 mm )

(1.73”)

( 16 mm )

(0.63”)

57.66 mm

(2.27”)

20 mm

(0.79”)

2 x Ø 7.74 (19/64”) FIXING S FOR

CONTROLLER LUGS

Ø 9.5 (3/8”) FIXING

FOR CABLE ENTRY HOLE

SECTION A-A

SCALE 1 : 1

13

Loading...

Loading...