Eberspächer Airtronic D2 24 V, Airtronic D3 12 V, Airtronic D2 Camper 12 V, Airtronic D4 12 V, Airtronic D4 24 V Troubleshooting And Repair Instructions

...

Airtronic M Order no.

Airtronic D3, 12 V 25 2317 05 00 00

Airtronic B4, 12 V 20 1812 05 00 00

Airtronic D4, 12 V 25 2113 05 00 00

Airtronic D4, 24 V 25 2114 05 00 00

Airtronic D4 Plus, 12 V 25 2484 05 00 00

Airtronic D4 Plus, 24 V 25 2498 05 00 00

Airtronic D4S, 12 V 25 2144 05 00 00

Airtronic D4S, 24 V 25 2145 05 00 00

Airtronic D3 Camper, 12 V

(see Airtronic D3)

Airtronic D4 Camper, 12 V 25 2318 05 00 00

Airtronic D4 Camper plus, 12 V 25 2327 05 00 00

AIRTRONIC / AIRTRONIC M

Troubleshooting and Repair Instructions

25 2115 95 19 01

12.2011

Airtronic Order no.

Airtronic D2, 12 V 25 2069 05 00 00

Airtronic D2, 24 V 25 2070 05 00 00

Airtronic D2 Camper, 12 V 25 2326 05 00 00

Complete package

Airtronic D2, 12 V 25 2115 05 00 00

Airtronic D2, 24 V 25 2116 05 00 00

Air heater for diesel and petrol

operating independently of the engine.

2

4

3

1

2

1

Contents

This list of contents gives you precise information about the

contents of the Troubleshooting and Repair Instructions.

Introduction

Use the index, list of abbreviations, etc, to look for a term,

technical word or an explanation for an abbreviation.

Chapter Title Contents Page

Introduction • Foreword .................................................................................................................. 4

• Accident prevention .................................................................................................. 4

• Special text structure, presentation and picture symbols ........................................... 4

• Important information before starting work ................................................................ 4

Function and use Cutaway view ............................................................................................................ 5

• Description of functions

– Switching on .......................................................................................................... 6

– Starting the Airtronic .............................................................................................. 6

– Starting the Airtronic M .......................................................................................... 6

– Temperature selection with the control element ...................................................... 6

– Control in heating mode ......................................................................................... 6

– Ventilating mode .................................................................................................... 6

– Switching off .......................................................................................................... 6

• Control and safety devices ........................................................................................ 7

– Forced shut-down for ADR operation..................................................................... 7

– Emergency shutdown – EMERGENCY OFF ........................................................... 7

Technical data • Airtronic (for diesel) ................................................................................................... 8

• Airtronic M (for petrol) ................................................................................................ 9

• Airtronic M (for diesel) ........................................................................................ 10, 11

• Check values

– Test speed for the blower ..................................................................................... 12

– Resistan\ce values ............................................................................................... 12

– Switching value .................................................................................................... 12

– Exhaust emission specification ............................................................................. 12

– Check “external temperature sensor” ................................................................... 12

– Table of values: “External temperature sensor” ..................................................... 12

Troubleshooting • What to check first in case of faults

– Check .................................................................................................................. 13

– Electrical components.......................................................................................... 13

– Measure battery voltage ....................................................................................... 13

– Measures voltage supply ..................................................................................... 13

– Check switch-on signal ........................................................................................ 13

– Check control unit ................................................................................................ 13

• Overview of the individual test equipment and control units ..................................... 14

• Locking the control box ........................................................................................... 14

• Cancel the control box lock ..................................................................................... 14

• Important notes (diagnosis of heaters with mini-controller) ....................................... 14

• Testing device for the control device ........................................................................ 15

• Fault diagnosis using the diagnostic unit ........................................................... 15, 16

• Fault diagnosis using the EDiTH diagnostics tool with ISO adapter .......................... 17

• Air pressure sensor diagnosis using EDiTH diagnostics tool and ISO adapter .......... 18

• Fault diagnosis using the EDiTH diagnostics tool with basic adapter ....................... 19

• Fault diagnosis using the module timer .................................................................... 20

• Fault diagnosis using the radio remote control TP5 ................................................. 21

• Fault diagnosis using the EasyStart R+ radio remote control or

the EasyStart T timer ............................................................................................... 22

• Fault code table ...............................................................................................23 – 27

3

Introduction

7

6

5

1

Chapter Title Contents Page

Repair instructions • Repair instructions .................................................................................................. 28

• Always observe the following safety instructions before working on the heater ........ 28

• Special tool, AMP release tool ................................................................................. 28

• Assembly drawing Airtronic / Airtronic M ................................................................. 29

• Repair step 1, remove the heater cover ................................................................... 30

• Repair step 2, dismantle control box, check control box ......................................... 30

• Repair step 3, dismantle glow plug .......................................................................... 31

• Repair step 4, renew lining ...................................................................................... 31

• Repair step 5, dismantle combination sensor (overheating / flame sensor ............... 32

• Repair step 6, install combination sensor (overheating / flame sensor) ..................... 33

• Repair step 7, dismantle heat exchanger /

dismantle combustion air fan ................................................................................... 34

• Repair step 8, dismantle combustion chamber ........................................................ 35

• Check fuel supply .................................................................................................... 36

• Measuring the fuel quantity...................................................................................... 36

Circuit diagrams Overview of the parts lists and circuit diagrams........................................................... 37

• Parts list circuit diagrams Airtronic / Airtronic M ....................................................... 38

• Circuit diagram Airtronic / Airtronic M ..................................................................... 39

This circuit diagram is valid for heaters with one diagnosis cable

and a control box cable loom wich is firmly encapsulated.

• Circuit diagram Airtronic / Airtronic M ..................................................................... 40

This circuit diagram is for heaters with 2 diagnostics cable and whose

control box cable loom is wound with cable tape.

• Parts list circuit diagrams, control units .................................................................... 41

• Circuit diagram control units – part 1 ....................................................................... 42

• Circuit diagram control units – part 2 ....................................................................... 43

• Circuit diagram control units – part 3 ....................................................................... 44

• Circuit diagram control units – part 4 ....................................................................... 45

• Circuit diagram control units – part 5 ....................................................................... 46

• Circuit diagram control units – part 6 ....................................................................... 47

• Circuit diagram control units – part 7 ....................................................................... 48

• Parts list circuit diagram control unit EasyStart R+ / R / T ........................................ 49

• Circuit diagram control unit EasyStart R+ (control box with 1 diagnostics cable) ...... 50

• Circuit diagram control unit EasyStart R+ (control box with 1 diagnostics cable) ...... 51

• Circuit diagram control unit EasyStart R+ (control box with 2 diagnostics cable) ...... 52

• Circuit diagram control unit EasyStart R (control box with 1 / 2 diagnostics cables) . 53

• Circuit diagram control unit EasyStart R (control box with 2 diagnostics cables) ...... 54

• Circuit diagram control unit EasyStart R (control box with 1 diagnostics cables) ...... 55

• Circuit diagram control unit EasyStart T (control box with 1 diagnostics cable) ........ 56

• Circuit diagram control unit EasyStart T (control box with 2 diagnostics cable) ........ 57

• Parts list circuit diagrams Airtronic / Airtronic M – ADR ............................................ 58

• Circuit diagram Airtronic / Airtronic M – ADR .......................................................... 59

1 encapsulated diagnostics cable and control box cable loom firmly encapsulated

• Circuit diagram Airtronic / Airtronic M – ADR .......................................................... 60

2 diagnostics cables and control box cable loom with cable tape

• Parts list circuit diagrams, control units – ADR ......................................................... 61

• Parts list circuit diagrams, control units – EasyStart T – ADR ................................... 61

• Circuit diagram control units – ADR ......................................................................... 62

• Circuit diagram control unit EasyStart T – ADR (control box with 1 diag. cable) ....... 63

• Circuit diagram control unit EasyStart T – ADR (control box with 2 diag. cable) ....... 64

Service • Certification ............................................................................................................. 65

• Disposal .................................................................................................................. 65

• EC Declaration of Conformity .................................................................................. 65

• List of key words ..................................................................................................... 66

• List of abbreviations ................................................................................................ 67

4

Special text structure, presentation and

picture symbols

Special text formats and picture symbols are used in these

instructions to emphasise different situations and subjects.

Please refer to the following examples for their meanings and

appropriate action.

Special text formats and presentations

• A dot (•) indicates a list, which is started by a heading.

– If an indented dash (–) follows a “dot”, this list is a sub-

section of the black dot.

Picture symbols

Danger!

This information points out a dangerous situation for a person

and / or the product. Failure to comply with these instructions

can result in injuries to people and / or damage to machinery.

Caution!

This information points out a dangerous situation for a person

and / or the product. Failure to comply with these instructions

can result in injuries to people and / or damage to machinery.

Important information before starting

work

Initial commissioning of the heater or functional test

after a repair

• After installing the heater, the whole fuel supply system must

be carefully vented: please refer to and follow the vehicle

manufacturer’s instructions.

• During the heater trial run, all fuel connections must be

checked for leaks and secure, tight fit.

• If faults occur while the heater is running, use a diagnostic

unit to determine and correct the cause of the fault.

1 Introduction

Foreword

These Troubleshooting and Repair Instructions are applicable

to the heaters listed on the title Page, to the exclusion of all

liability claims.

Depending on the version or revised status of the heater, there

may be differences between it and these troubleshooting and

repair instructions.

The user must check this before carrying out the repair work

and, if necessary, take the differences into account.

Caution!

Safety instructions for installation and repair!

Improper installation or repair of Eberspächer heaters can

cause a fire or result poisonous exhaust entering the inside of

the vehicle. This can cause serious and even fatal risks.

The heater may only be installed according to the specifications in the technical documents or repaired using original

spare parts by authorised and trained persons.

Installation and repairs by unauthorised and untrained persons, repairs using non-original spare parts and without the

technical documents required for installation and repair are

dangerous and therefore are not permitted.

A repair may only be carried out in connection with the respective unit-related technical description, installation instructions, operating instructions and maintenance instructions.

This document must be carefully read through before / during

installation and repair and followed throughout. Particular

attention is to be paid to the official regulations, the safety

instructions and the general information.

Please note!

The relevant rules of sound engineering practice and any

information provided by the vehicle manufacturer are to be

observed during the installation and repair.

Eberspächer does not accept any liability for defects and

damage, which are due to installation or repair by unauthorised and untrained persons.

Compliance with the official regulations and the safety instructions is prerequisite for liability claims. Failure to comply with

the official regulations and safety instructions leads to exclusion of any liability of the heater manufacturer.

Accident prevention

General accident prevention regulations and the corresponding workshop and operating safety instructions are to be

observed.

5

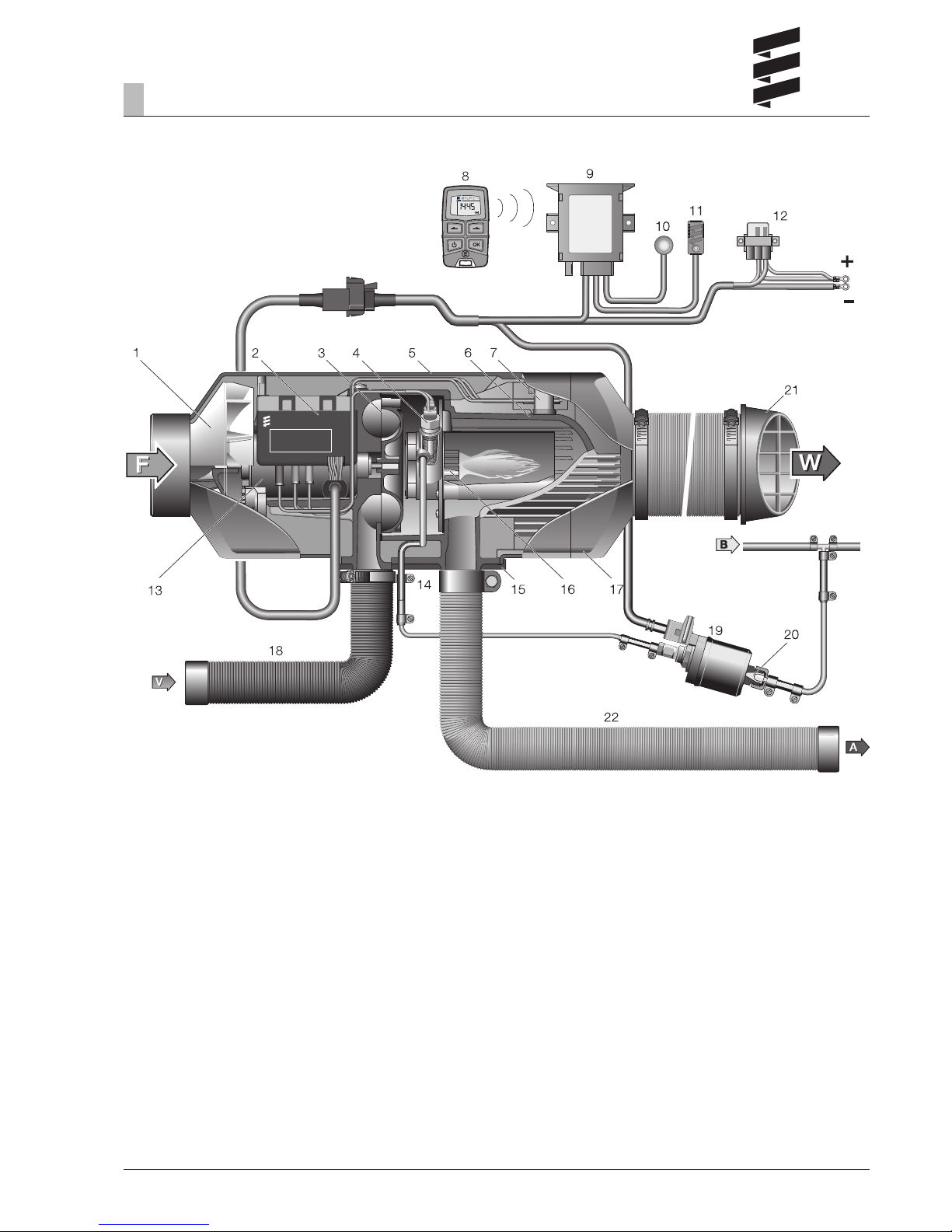

Cutaway view

1 Heater impeller

2 Control box

3 Combustion air fan impeller

4 Glow plug

5 Cover

6 Heat exchanger

7 Combination sensor (overheating / flame sensor)

8 Radio remote control (mobile unit)

9 Radio remote control (stationary unit)

10 Button

11 Temperature sensor (room temperature)

12 Fuse bracket with main fuse and “actuation” fuse

13 Electrical motor

14 Fuel connection

15 Flange seal

16 Combustion chamber

17 Outlet hood

18 Combustion air hose

19 Metering pump

20 Pot-type strainer, installed in the dosing pump

21 Outflow

22 Flexible exhaust pipe

F = Fresh air

W = Hot air

A = Exhaust

B = Fuel

V = Combustion air

Function and use2

6

Description of functions

Switching on

When the heater is switched on, the control lamp in the control unit lights up. The glow plug is switched on and the fan

starts at low speed.

f there is still too much residual heat in the heat exchanger

from when the heater was last used, firstly only the fan starts

up (cold blowing).

Once the residual heat has been cleared, the heater starts.

Starting Airtronic

After approx. 65 seconds the fuel supply starts and the fuel /

air mixture in the combustion chamber ignites.

Once the combined sensor (flame sensor) has detected the

flame, the glow plug is switched off after 60 seconds. The

heater is now in standard operation.

Starting Airtronic M

After approx. 60 seconds the fuel supply starts and the fuel /

air mixture in the combustion chamber ignites.

After the flame sensor has detected the flame, the glow plug

is switched off after approx. 90 sec. The heater is now in

standard operation.

After another 120 seconds, the heater has reached the

“POWER” stage (maximum fuel quantity, maximum fan

speed).

Temperature selection with the control element

The control can be used to preselect an interior temperature.

The resulting temperature can be within the range of +10 °C

to +30 °C and depends on the selected heater, on the size of

the space to be heated and on the prevailing outdoor temperature.

The setting to be selected at the control is an empirical value.

Control in the heating mode

During the heating mode, the room temperature or the temperature of the sucked in heating air is constantly measured.

If the temperature is higher than the temperature selected on

the control element, the heater starts to regulate its output.

There are 4 control stages so that the outflow of heat produced by the heater can be adjusted finely to the heating

requirements. Fan speed and fuel quantity correspond to the

particular control stage.

If the set temperature is still exceeded in the smallest control

stage, the heater goes to the “OFF” stage with the fan running

on for approx. 4 minutes to cool off.

The fan then continues running at minimum speed (circulation

mode) until the restart or is switched off (fresh air mode with

external temperature sensor).

Ventilating mode

The EasyStart R+ and EasyStart T control units and the minicontroller can be used to activate the „Ventilate“ function.

The „Heat / Ventilate“ switch is also required for the modular

timer and control device whereby, for fan mode, the „Heat /

Ventilate“ switch must be pressed first and then the heater

switched on.

The blower runs at maximum speed in fan mode.

Switching off

When the heater is switched off, the control lamp goes off and

the fuel supply is switched off.

The fan runs on for approx. 4 minutes to cool down.

While the fan is running on, the glow plug is switched on for

approx. 40 seconds to clean.

Special case:

If no fuel has been supplied or if the heater is in the “OFF”

stage until it is switched off, the heater is stopped without any

after running.

Function and use2

Please note!

7

Forced shut-down for ADR operation

In vehicles for the transport of dangerous goods (e.g. tanker

trucks), the heater must be switched off before the truck

drives into a danger area (refinery, petrol station, etc.).

Failure to comply results in the heater automatically switching

off if:

• the vehicle engine is switched off,

• an additional unit is started up (auxiliary drive for unloading

pump, etc.),

• a vehicle door is opened (ADR99 regulation, only in France).

The fan then runs on for max. 40 seconds.

Function and use2

Emergency shutdown – EMERGENCY OFF

If an emergency shutdown –EMERGENCY OFF – is required during operation, execute the following:

• Switch the heater off at the control element or

• remove the fuse or

• disconnect the heater from the battery.

Control and safety devices

• If the heater does not ignite within 90 seconds after starting

the fuel pump, the start is repeated. If the heater still does

not ignite after another 90 seconds of pumping fuel, the

heater is switched off, i.e. the fuel supply is off and the fan

runs on for approx. 4 minutes.

• If the flame goes off by itself during operation, the heater is

restarted. If the heater does not ignite within 90 seconds

after the fuel pump has started, or ignites and goes off

again within 15 minutes, the heater is switched off, i.e. the

fuel supply is off and the fan runs on for approx. 4 minutes.

This status can be remedied by briefly switching off and

on again. Do not repeat the switching off / on routine more

than twice.

• In the case of overheating, the combined sensor (flame

sensor / overheating sensor) triggers, the fuel supply is

interrupted and the heater switched off. Once the cause of

the overheating has been eliminated, the heater can be restarted by switching off and on again.

• If the lower or upper voltage limit is reached, the heater is

switched off after 20 seconds.

• The heater does not start up if the glow plug or blower motor is defective or if the electric lead to the metering pump is

interrupted.

• If the combined sensor (flame sensor / overheating sensor)

is defect or the electric lead interrupted, the heater starts up

and is then switched off again during the start phase.

• The speed of the fan motor is monitored continuously. If

the fan motor does not start up or if the speed deviates by

more than 10%, the heater is switched off after 30 sec.

• When the heater is switched off, the glow plug is

switched on for 40 seconds (after-glowing) while the

fan runs on to clean off any combustion residues.

Please note!

Do not repeat the switching off / on routine more than twice.

8

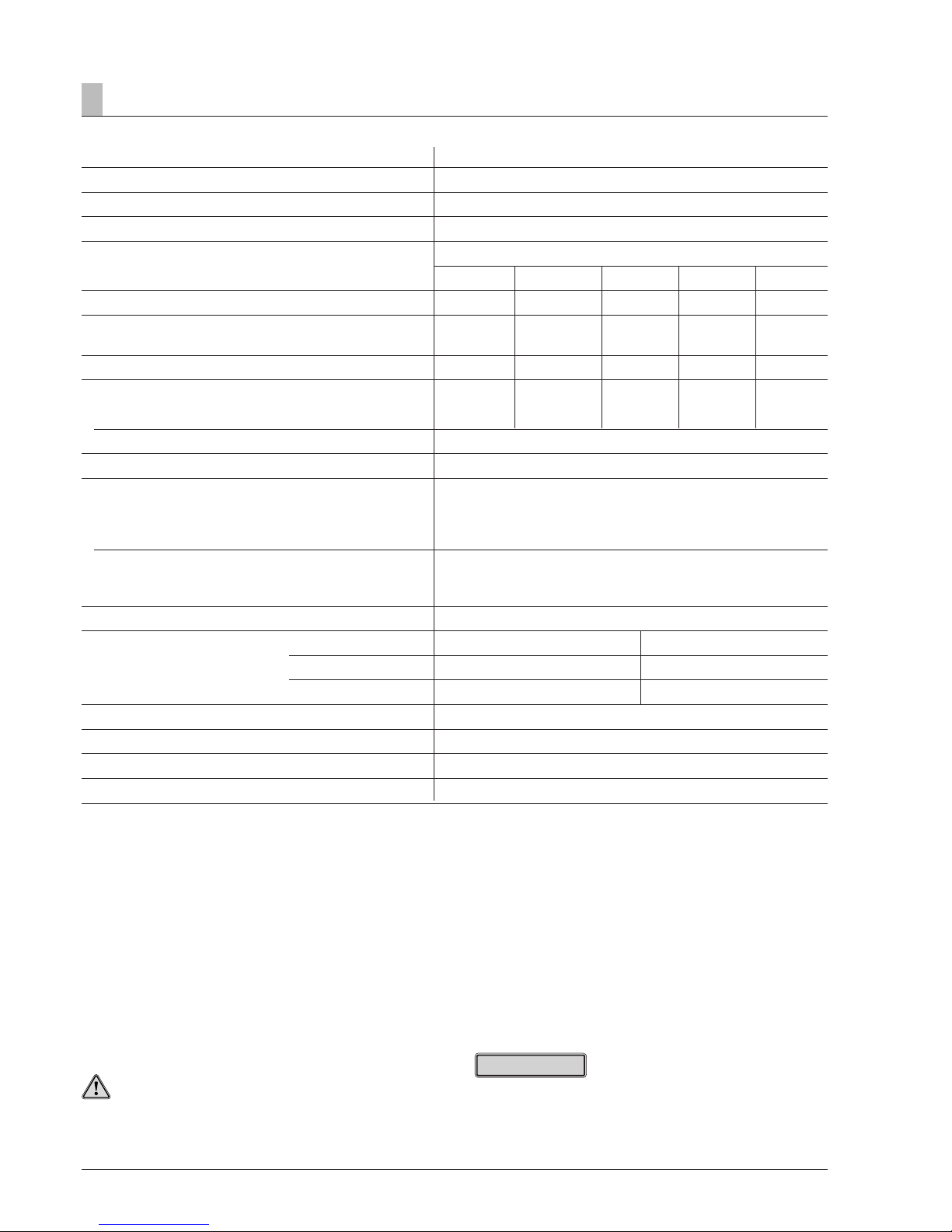

Technichal data3

Provided no limit values are given, the technical data listed

is subject to the tolerances usually applicable to heaters of

±10% for nominal voltage, ambient temperature 20 °C and

reference altitude Esslingen.

Caution!

Safety instructions for technical data!

Failure to comply with the technical data can result in malfunctions.

Technichal data

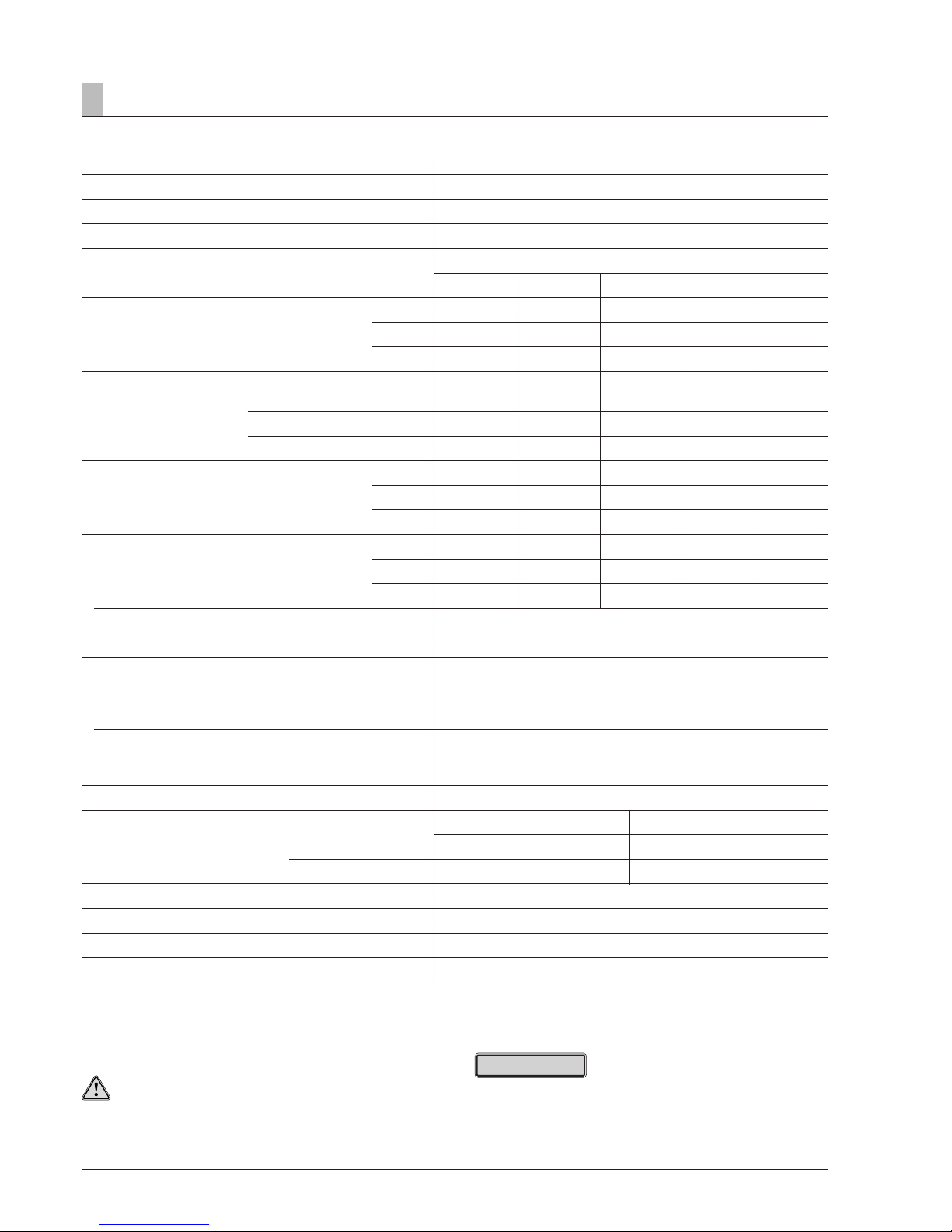

Heater type

Heater

Version

Heating medium

Control of the heat flow

Heat flow (watt)

Heater air flow rate without counterpressure (kg/h)

with hood Ø 60 mm

Fuel consumption (l/h)

Elektr. power consumption (watt)

in operation (12 and 24 volt)

at start (12 and 24 volt)

Rated voltage

Operating range

Lower voltage limit: An undervoltage protection in the

controller switches off the heater when the voltage limit is

reached.

Upper voltage limit:

An uppervoltage protection in the controller switches off the

heater when the voltage limit is reached.

Fuel

Tolarable ambient temperature

Heater

Dosing pump

Maximum air intake temperature

Interference suppression

Weight

Ventilation mode

Airtronic

Airtronic D2 / Airtronic D2 Camper

D2 / D2 Camper

Air

Stage

Power Large Medium Small Off

2200 1800 1200 850 –

105 90 60 40 13

0.28 0.23 0.15 0.10 –

34 22 12 8 5

#100

12 or 24 volt

approx. 10.5 volt resp. 21 volt

Undervoltage protection trigger time: 20 seconds

approx. 16 volt resp. 32 volt

Overvoltage protection trigger time: 20 seconds

Diesel DIN EN 590 (commercially available)

in operation no operation

–40 °C to +70 °C –40 °C to +85 °C

–40 °C to +50 °C –40 °C to +125 °C

max. +40 °C

Interference suppression class 5 to DIN EN 55 025

approx. 2.7 kg

possible

Please note!

9

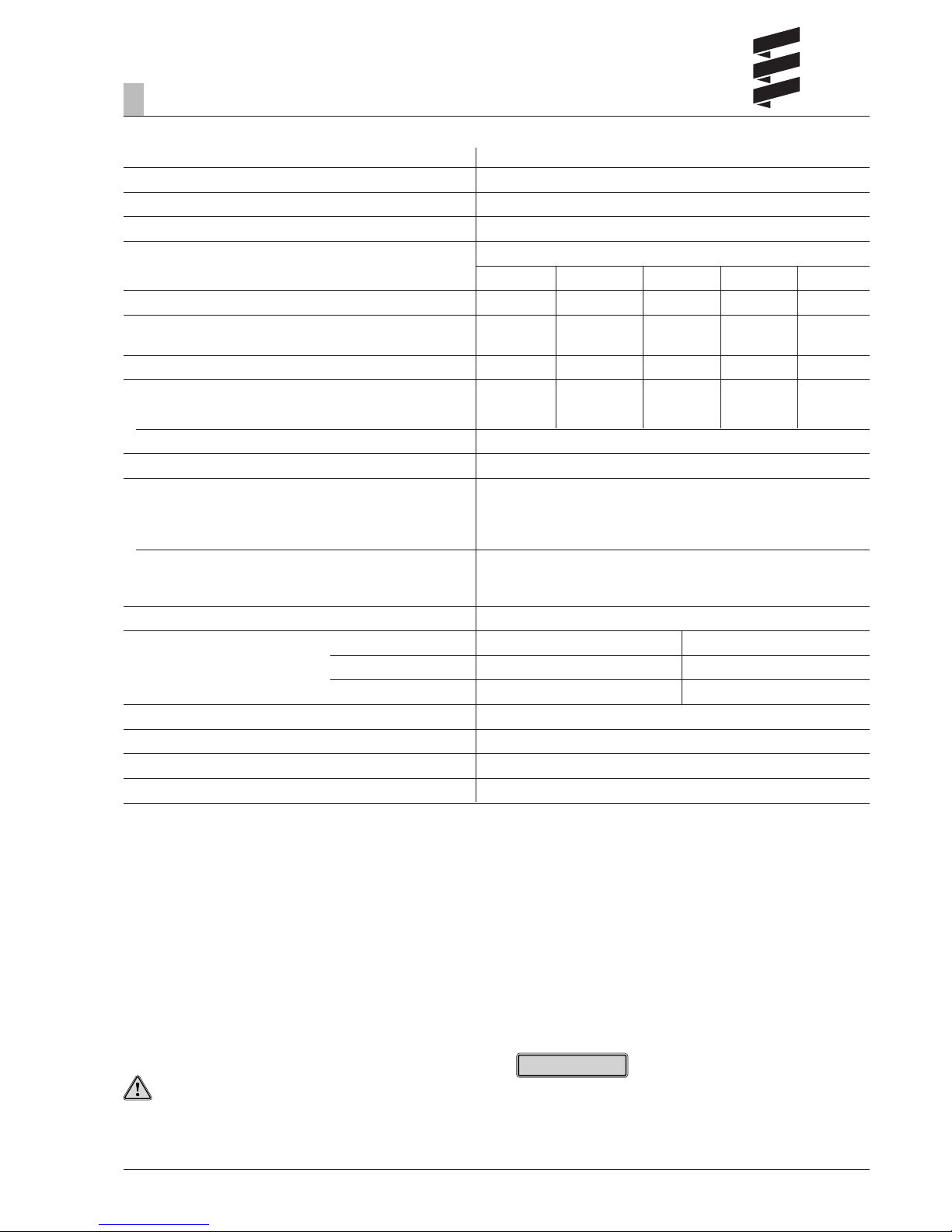

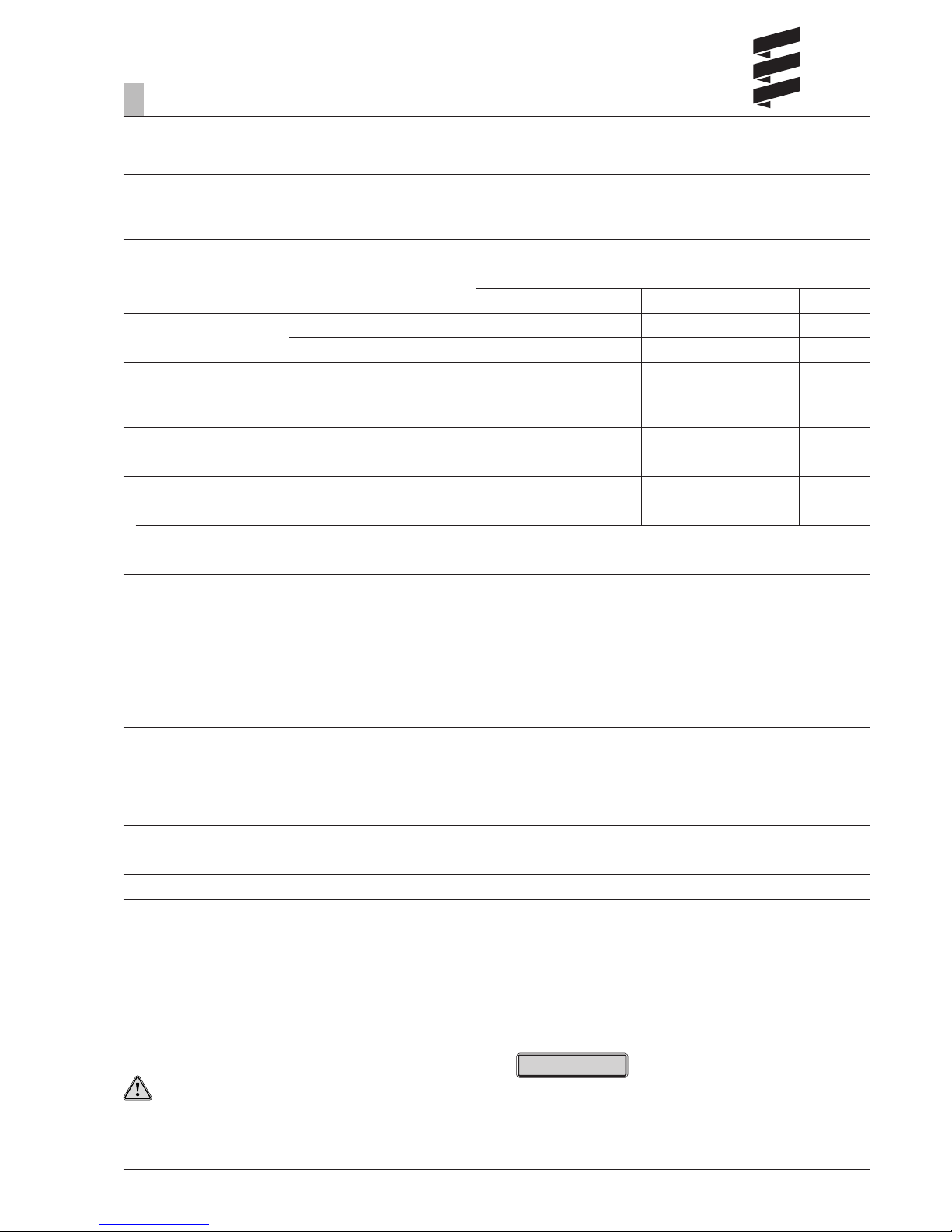

Technichal data3

Technichal data

Heater type

Heater

Version

Heating medium

Control of the heat flow

Heat flow (watt)

Heater air flow rate without counterpressure (kg/h)

with hood Ø 90 mm

Fuel consumption (l/h)

Elektr. power consumption (watt)

in operation (12 and 24 volt)

at start (12 and 24 volt)

Rated voltage

Operating range

Lower voltage limit: An undervoltage protection in the

controller switches off the heater when the voltage limit is

reached.

Upper voltage limit:

An uppervoltage protection in the controller switches off the

heater when the voltage limit is reached.

Fuel

Tolarable ambient temperature

Heater

Dosing pump

Maximum air intake temperature

Interference suppression

Weight

Ventilation mode

Airtronic M

Airtronic B4

B4

Air

Stage

Power Large Medium Small Off

3800 3200 2100 1300 –

185 160 120 85 24

0.54 0.46 0.29 0.18 –

40 29 15 9 5

#100

12 volt

approx. 10.5 volt

Undervoltage protection trigger time: 20 seconds

16 volt

Overvoltage protection trigger time: 20 seconds

Petrol DIN EN 228 (commercially available)

in operation no operation

–40 °C to +50 °C –40 °C to +85 °C

–40 °C to +20 °C –40 °C to +125 °C

max. +40 °C

Interference suppression class 5 to DIN EN 55 025

ca. 4.5 kg

possible

Provided no limit values are given, the technical data listed

is subject to the tolerances usually applicable to heaters of

±10% for nominal voltage, ambient temperature 20 °C and

reference altitude Esslingen.

Caution!

Safety instructions for technical data!

Failure to comply with the technical data can result in malfunctions.

Please note!

10

Technichal data3

Technichal data

Heater type

Heater

Version

Heating medium

Control of the heat flow

Heat flow (watt) D3

D4

D4 Plus

Heater air flow rate without counterpressure (kg/h)

D3 with hood Ø 90 mm

D4 with hood Ø 90 mm

D4 Plus with hood Ø 75 mm

Fuel consumption (l/h) D3

D4

D4 Plus

Elektr. power consumption (watt) D3

in operation (12 and 24 volt) D4

D4 Plus

at start (12 and 24 volt)

Rated voltage

Operating range

Lower voltage limit: An undervoltage protection in the

controller switches off the heater when the voltage limit is

reached.

Upper voltage limit:

An uppervoltage protection in the controller switches off the

heater when the voltage limit is reached.

Fuel

Tolarable ambient temperature

Heater

Dosing pump

Maximum air intake temperature

Interference suppression

Weight

Ventilation mode

Airtronic M

Airtronic D3 / Airtronic D4 / Airtronic D4 Plus

D3 / D4 / D4 Plus

Air

Stage

Power Large Medium Small Off

3000 2200 1600 900 –

4000 3000 2000 900 –

4000 3000 2000 900 –

150 120 90 60 24

185 150 110 60 24

175 140 100 55 22

0.38 0.28 0.2 0.11 –

0.51 0.38 0.25 0.11 –

0.51 0.38 0.25 0.11 –

24 16 10 7 5

40 24 13 7 5

55 30 16 7 5

#100

12 or 24 volt

approx. 10.5 volt resp. 21 volt

Undervoltage protection trigger time: 20 seconds

approx. 16 volt resp. 32 volt

Overvoltage protection trigger time: 20 seconds

Diesel DIN EN 590 (commercially available)

in operation no operation

–40 °C to +70 °C –40 °C to +85 °C

–40 °C to +50 °C –40 °C to +125 °C

max. +40 °C

Interference suppression class 5 to DIN EN 55 025

approx. 4.5 kg

possible

Provided no limit values are given, the technical data listed

is subject to the tolerances usually applicable to heaters of

±10% for nominal voltage, ambient temperature 20 °C and

reference altitude Esslingen.

Caution!

Safety instructions for technical data!

Failure to comply with the technical data can result in malfunctions.

Please note!

11

Technichal data3

Technichal data

Heater type

Heater

Version

Heating medium

Control of the heat flow

Heat flow (watt) D4S

D4 Camper / D4 Camper Plus

Heater air flow rate without counterpressure (kg/h)

D4S

D4 Camper / D4 Camper Plus

Fuel consumption (l/h)) D4S

D4 Camper / D4 Camper Plus

Elektr. power consumption (watt) D4S

in operation (12 and 24 v) D4 Camper / D4 Camper Plus

at start (12 and 24 v)

Rated voltage

Operating range

Lower voltage limit: An undervoltage protection in the

controller switches off the heater when the voltage limit is

reached.

Upper voltage limit:

An uppervoltage protection in the controller switches off the

heater when the voltage limit is reached.

Fuel

Tolarable ambient temperature

Heater

Dosing pump

Maximum air intake temperature

Interference suppression

Weight

Ventilation mode

Airtronic M

Airtronic D4S / Airtronic D4 Camper /

Airtronic D4 Camper Plus

D4S / D4 Camper / D4 Camper Plus

Air

Stage

Power Large Medium Small Off

3500 3000 2000 1000 –

4000 / 3500 3000 2000 900 –

160 140 100 60 22

185 / 160 150 / 140 110 / 100 60 / 55 24 / 22

0.44 0.38 0.25 0.13 –

0.51 / 0.44 0.38 0.25 0.11 –

40 30 16 8 5

40 24 / 30 13 / 16 7 / 8 5

#100

12 or 24 volt

approx. 10.5 volt resp. 21 volt

Undervoltage protection trigger time: 20 seconds

approx. 16 volt resp. 32 volt

Overvoltage protection trigger time: 20 seconds

Diesel DIN EN 590 (commercially available)

in operation no operation

–40 °C to +70 °C –40 °C to +85 °C

–40 °C to +50 °C –40 °C to +125 °C

max. +40 °C

Interference suppression class 5 to DIN EN 55 025

approx. 4.5 kg

possible

Provided no limit values are given, the technical data listed

is subject to the tolerances usually applicable to heaters of

±10% for nominal voltage, ambient temperature 20 °C and

reference altitude Esslingen.

Caution!

Safety instructions for technical data!

Failure to comply with the technical data can result in malfunctions.

Please note!

12

Check values

Test speed for the blower

Airtronic D2 / D2 Camper (12 volt / 24 volt)

• 12 volt 5000 rpm ±25 % at U = 10,0 volt

• 24 volt 5000 rpm ±25 % at U = 18,0 volt

Airtronic B4 (12 volt)

Airtronic D3 / D3 Camper (12 volt)

Airtronic D4 (12 volt / 24 volt)

Airtronic D4 Camper (12 volt)

• 12 volt 4400 rpm ±25 % at U = 10,0 volt

• 24 volt 4400 rpm ±25 % at U = 18,5 volt

Airtronic D4S / Airtronic D4 Plus (12 volt / 24 volt)

Airtronic D4 Camper Plus (12 volt)

• 12 volt 4400 rpm ±25 % at U = 10,5 volt

• 24 volt 4400 rpm ±25 % at U = 19,0 volt

Resistance values

at 20 °C

12 volt 24 volt

Glow plug 0.42 – 0.70 1.2 – 2.0

Dosing pump 9.5 ±0.50 36.0 ±1.8

Control unit

resistance values

Switch position,

left limit stop

Switch position,

right limit stop

Control device

12 volt / 24 volt

min. 1720

max. 1760

min. 2096

max. 2216

Modular timer and

mini-controller

12 volt / 24 volt

min. 1730

max. 1780

min. 2120

max. 2240

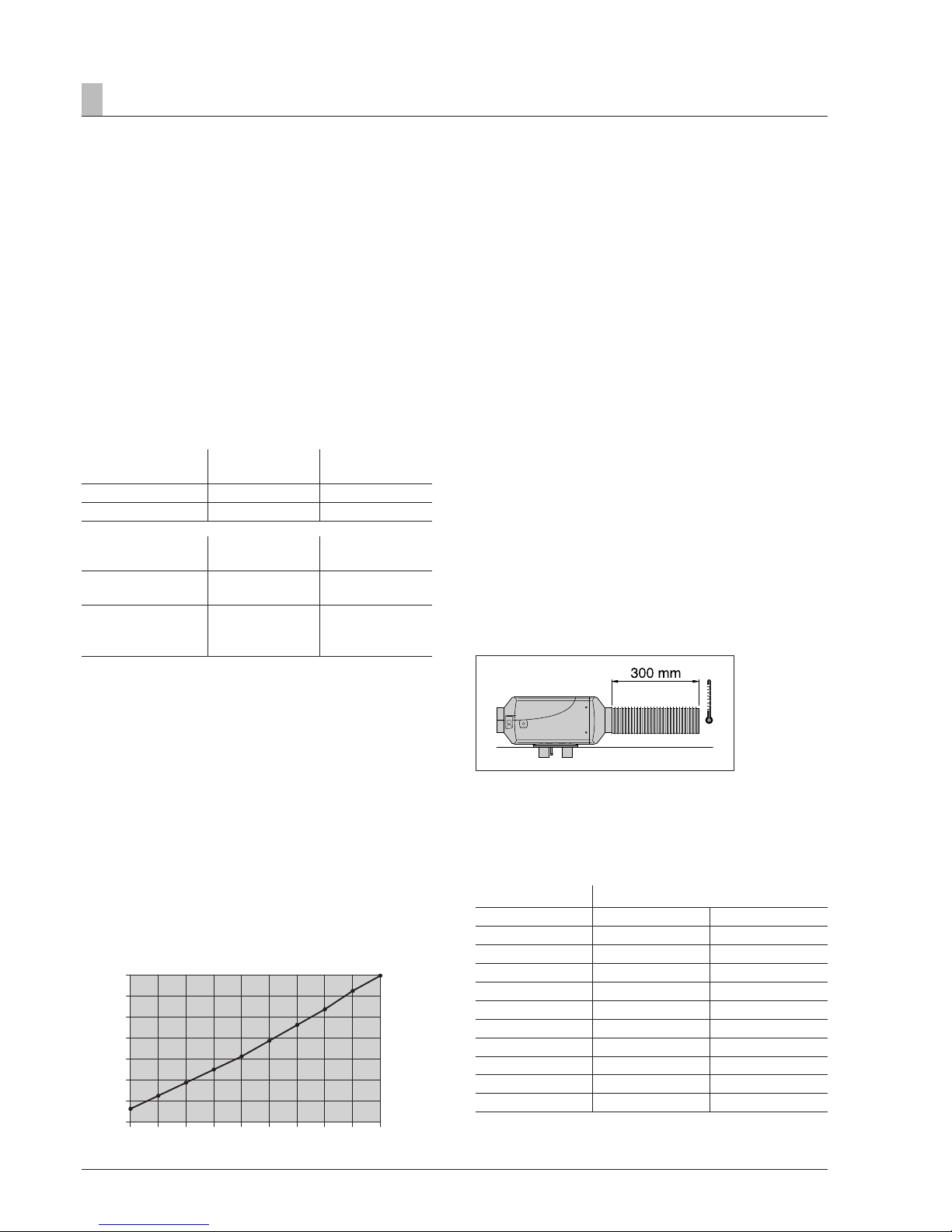

Switching value

Overheating sensor 140 °C – 170 °C

measured in the “High” control stage

and at a distance of 300 mm downstream

from the hot air outlet

Exhaust emission specification

CO

2

in exhaust

in control stage “high” 7,5 – 12,5 Vol. %

Smoke spot number according to Bacharach < 4

Temperature (°C)

Resistance (ohm)

2200

2000

1800

1600

1400

1200

1000

±40

±20

02040±10

±30

10 30

2400

50

Technical data3

Check “external” temperature sensor

(Order No.: 25 1774 89 03 00)

The “external” temperature sensor test must be carried out

using a digital multimeter. If the resistance value is not the

same as the curve in the diagram or the table of values, replace the temperature sensor.

Table of values – “external” temperature sensor

Temperature °C Resistance

min. max.

0 1600 1660

5 1670 1730

10 1745 1800

15 1820 1870

20 1895 1950

25 1970 2030

30 2050 2110

35 2130 2190

40 2210 2280

45 2295 2370

13

Troubleshooting4

What to check first in case of faults

• Check

– Fuel in the tank?

– Fuel pipes leaking? (visual check)

– Summer diesel in the fuel pipe?

– Combustion air system or exhaust system damaged or

blocked?

– Hot air system blocked?

– Air pressure sensor installed? If yes, refer to „What to do

if…?“ chapter of the „Altitude Kit“ installation instructions.

– New generation control box installed?

Features:

> Cable loom of control box wound with cable tie

> Temperature sensor mounted on the side of the control

box (visible when cover removed)

• Electrical components

– Cables, connections damaged?

– Contacts corroded?

– Fuses defective?

– Incorrect wiring? (short circuits, interrupted / broken)

• Measure battery voltage

– Battery voltage < 10.5 volt, the undervoltage protection of

the 12 volt heater has triggered.

– Battery voltage < 21 volt, the un

• Measure voltage supply (Cl 30)

Disconnect the 16-pin connector S1 / B1 and measure the

voltage applied at connector B1 between chamber 1 (cable

2.5

2

rt) and chamber 10 (cable 2.52 br).

If it differs from the battery voltage, check the fuses, the

supply cables, the negative connection and the positive

support point on the battery for voltage drop (corrosion /

interruption).

• Check switch-on signal

Disconnect the 16-pin connector S1 / B1 and then switch

on the heater at the control unit.

Check whether voltage is applied in the connector B1

between chamber 4 (cable 0.5

2

ge) and chamber 10 (cable

2.5

2

br).

If no voltage is measured, then check the supply cable (ca-

ble 0.5

2

ge), the 5 A fuse (item 2.7.1 in the circuit diagram)

and the control unit.

• Check control unit

Control device, mini-timer, mini-controller

and modular timer

Disconnect the connector at the control unit; install a jumper

between the red 0.5² rt cable and the yellow 0.5² ge cable.

If a voltage is measured in connector B1 between cham-

ber 4 (cable 0.5² ge) and chamber 10 (cable 2.5² br), then

replace the control unit.

EasyStart R+ / EasyStart R / EasyStart T

Disconnect the connector at the control unit; install a jumper

between the yellow 0.5² ge cable and the red 0.5² rt cable.

If a voltage is measured in connector B1 between cham-

ber 8 (cable 0.5² ge) and chamber 10 (cable 2.5² br), then

replace the control unit.

14

Troubleshooting4

Overview of the test equipment and

control units suitable for diagnosis

The electronic control box can store up to 5 faults, which can

be read out and displayed. The following test equipment and/

or control units can be used to query the fault memory in

the control box and if necessary to delete the locking of the

control box:

Test equipment Order No.:

• Testing device

for the control device 22 1509 89 00 00

• Diagnostic unit 22 1529 89 00 00

additionally required:

Adapter cable 22 1000 31 86 00

• EDiTH diagnostic tool

– Basic adapter with software 22 1542 89 00 00

additionally required:

Airtronic extension 22 1537 89 00 00

– ISO-adapter 22 1541 89 00 00

additionally required:

Adapter cable 22 1000 31 86 00

– „Air pressure sensor“ adapter cable 22 1000 33 31 00

Only for heaters with connected air pressure sensor for

reading out the „air pressure sensor“ fault memory.

If a diagnostics cable is connected, the following control units

can also be used:

Control units Order No.:

• Module timer 22 1000 30 34 00

• TP5 radio remote control 22 1000 32 01 00

• EasyStart T 22 1000 32 88 00

• EasyStart R+ 22 1000 32 80 00

Please note!

If the fault memory cannot be read out, check the diagnostics

cable for correct laying and possible damage.

Important notes on diagnosis of heaters

with mini-controller control unit

Caution!

When checking the heater with the diagnostics unit or the

EDiTH diagnostics tool the order given in the following notes

must always be followed as otherwise the heater detects Error

62 (control unit – interruption) and switches to emergency

operation.

Mini-controller in stand-alone operation

• Connect adapter cable 22 1000 31 86 00 as described in

the operating instruction.

• Select operating mode (Heat / Ventilate) at the mini-controller

• Perform diagnosis using the diagnostics unit or the EDiTH

diagnostics tool.

• Switch off the mini-controller after finishing the diagnosis

• Remove the adapter cable

Mini-controller in combination with mini-timer

• Connect adapter cable 22 1000 31 86 00 as described in

the operating instruction.

• Press the m button of the mini-timer

• Select operating mode (see mini-timer operating instructions)

• Perform diagnosis using the diagnostics unit or the EDiTH

diagnostics tool.

• Switch off the mini-timer after finishing the diagnosis

• Remove the adapter cable

Mini-controller in combination with TP5

• Connect adapter cable 22 1000 31 86 00 as described in

the operating instruction.

• Press the

button of the TP5 radio remote control

• Select operating mode (see TP5 radio remote control operating instruction)

• Perform diagnosis.

• Switch off TP5 radio remote control after finishing the diagnosis

• Remove the adapter cable

Please note!

If the operating mode is to be changed during the test the

heater must be switched off first using the diagnostics unit or

the EDiTH diagnostics tool, otherwise the heater detects Error

62 (control unit – interruption) and switches to emergency

operation.

Test mini controller

The mini-controller must be connected to the heater for testing. The setpoint value can be displayed using the EDiTH

diagnostics tool. If the rotary knob is at the left limit stop the

setpoint value is 8 °C, at the right limit stop it is 34 °C.

Please note!

The resistance of the setpoint value potentiometer cannot be

measured directly. The measured values are not meaningful.

15

Troubleshooting4

Testing device for the control device

(Order No.: 22 1509 89 00 00)

Prepare for test

Connect the correct operating voltage (12 or 24 volt) to the testing device, with plus at the red connector socket and minus

at the blue connector socket.

• Disconnect socket from the control unit.

• Connect cable loom from testing device with the control

unit.

• Set the rotary knob of the control unit to “Heat”, the corresponding red LED in the testing device must light up.

• Set control unit to “0”, then press the “LED – red” button,

the red control lamp in the control unit must light up.

• Set control unit to “Heat”, then press the “LED – green”

button, corresponding red control lamp in the testing device

and the green control lamp in the control unit must light up.

Caution!

Safety instructions for checking the control unit!

Ensure you use the correct operating voltage, otherwise the

connected components can be severely damaged.

Check the setpoint potentiometer of the control unit

Set the “Temperature sensor / Potentiometer” switch in the

testing device to the “Potentiometer” setting and slowly turn

the rotary knob of the control unit.

The green LED – temperature sensor / potentiometer must

light up continuously.

In case of a fault, replace the control unit.

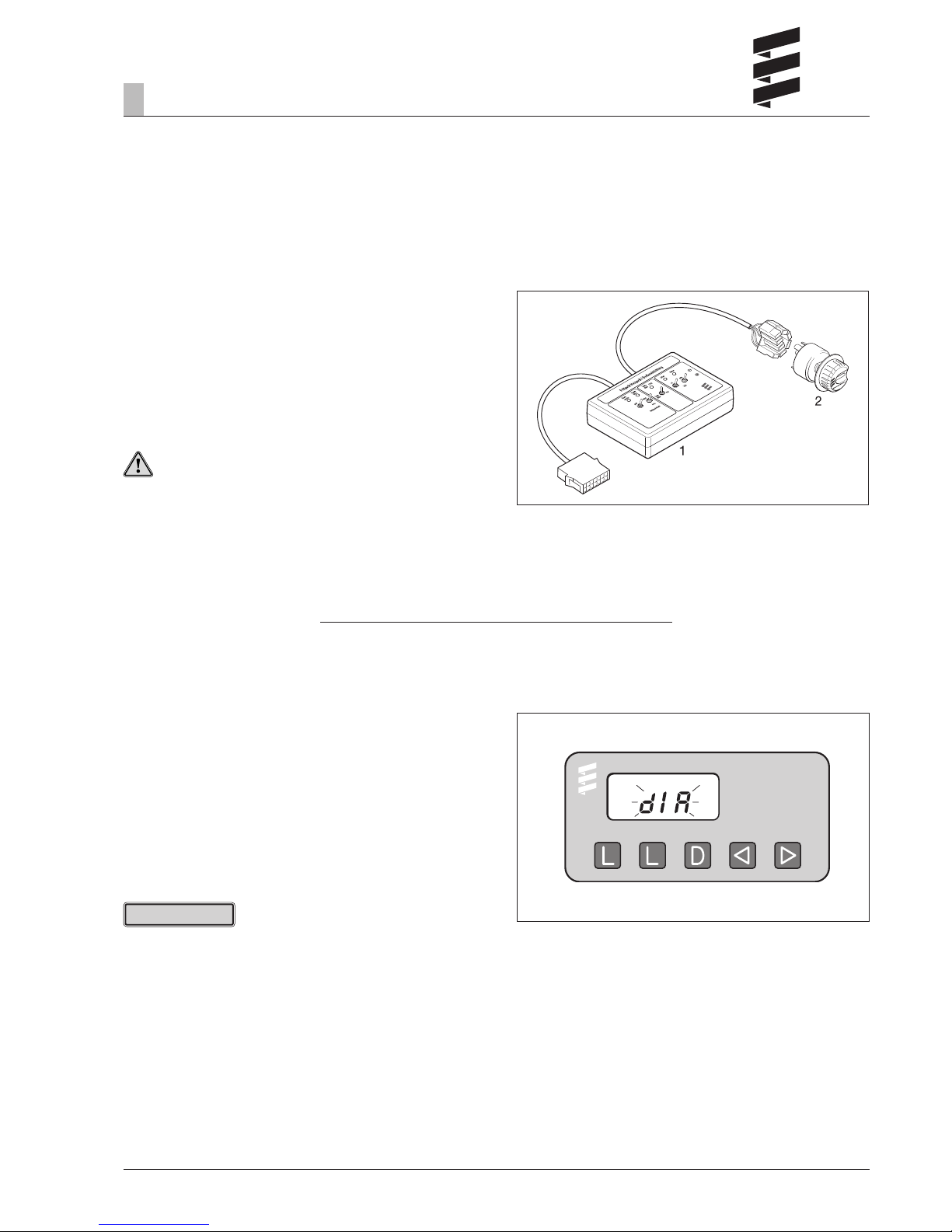

1 Testing device

2 Control device

Diagnostic unit

(Order No.: 22 1529 89 00 00)

An additional adapter cable is required to connect the diag-

nostic unit (Order No.: 22 1000 31 86 00).

The current fault is displayed as “AF” and a 2-digit number

and is always written in the memory position F1.

Preceding faults are moved to the memory locations F2 – F5,

if necessary the contents of memory position F5 is overwritten.

• Not only the defective component, but also a defective current circuit results in a fault being displayed.

• In heaters with connected air pressure sensor the diagnostics unit can be used to read out the fault memory of the

heater only.

The fault memory of the „air pressure sensor“ can be read

out using the EDiTH diagnostics tool only.

• Fault code, fault description, cause / remedial action are

described on Pages 23 – 27.

l

–Delete fault memory

l

– Delete fault memory

d

– Switch heater on / off, request diagnosis

e

– Reverse, F5 – F1

f

– Forward, F1 – F5, current fault (AF)

Connect diagnostics unit, see page 16.

Please note!

16

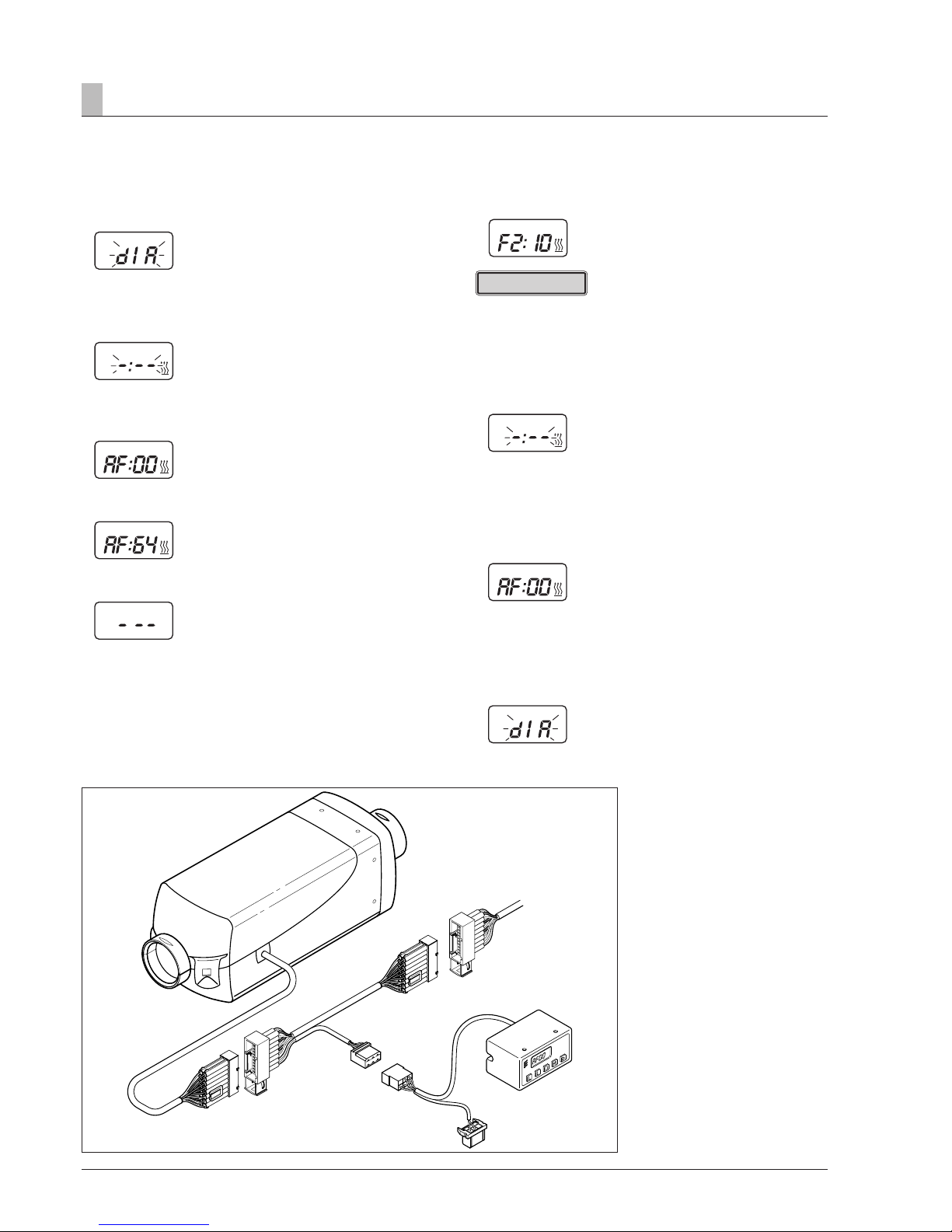

Connect diagnostic unit

• Disconnect the 8-pin connector of the heater’s cable harness and connect the adapter cable.

• Connect the diagnostic unit to the adapter cable.

Display is as follows:

Query fault memory

• Use the D key to switch on the heater.

Display is as follows:

• After 8 sec the following is displayed:

Display is as follows:

Heater has no malfunction

or

e.g. current error / fault code 64

or

Fault diagnosis not possible

Possible causes:

– Adapter cable is not properly connected.

– Control box is defective or is not capable of diagnosing

(not a universal control box).

Display of the fault memory F1 – F5 or F5 – F1

• Press the e or f button, or press several times, to display

the fault memory.

Display is as follows:

e.g. fault memory 2 / fault code 10

Only the fault memory positions with an error assigned to

them are displayed.

Delete fault memory

• Press both L buttons simultaneously until the following appears in the display:

Display is as follows:

• If the fault memory has been deleted the most recent current fault is displayed. The current fault is not reset to 00

until the heater is restarted – provided there is no new, more

recent fault.

Display is as follows:

Heater has no malfunction

Cancel the control box lock

• Delete the fault memory as described and switch off the

heater using the d key.

• The control box lock is cancelled and the diagnosis closed.

Display is as follows:

Troubleshooting4

1 Heater

2 Adapter cable

3 Diagnostic unit

1

2

3

Please note!

17

Troubleshooting4

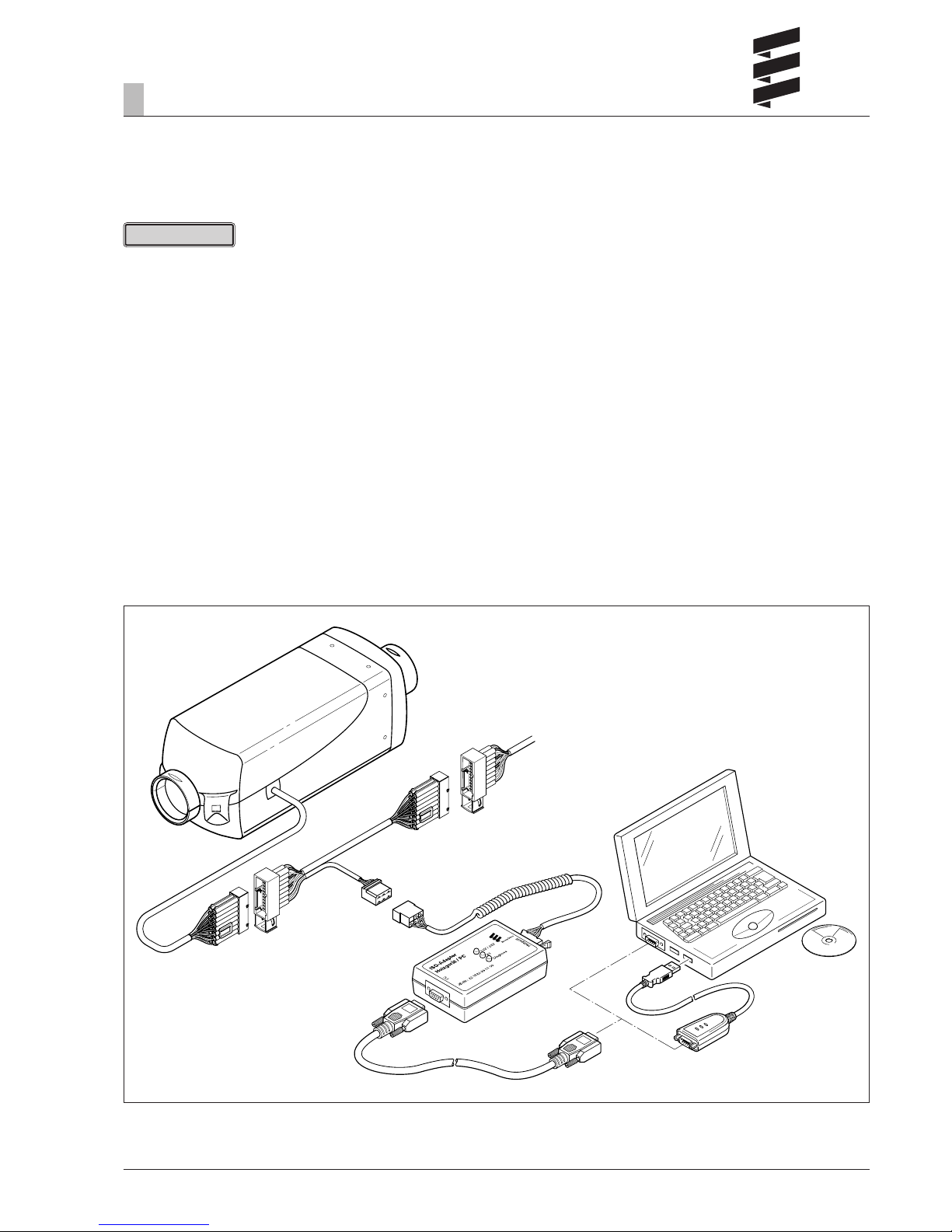

EDiTH diagnostic tool with ISO adapter

(Order No.: 22 1541 89 00 00)

An additional adapter cable is required to connect the ISO

adapter (Order No.: 22 1000 31 86 00).

• It is very important to always install in the given order.

• Not only the defective component, but also a defective current circuit results in a fault being displayed.

• Fault code, fault description, cause / remedial action are

described on Pages 23 – 27.

• The EDiTH diagnostics tool scope of supply does not

include the software; this must be downloaded from the

Service Portal.

Connect ISO adapter

• Disconnect the heater’s cable harness.

• Connect the adapter cable to the cable harness – as shown

in the sketch.

• Connect the adapter cable to the ISO adapter.

• Connect the SUB-D connection cable with the PC and the

ISO adapter.

Installing the software on your PC

• Double click the “setup.exe” file to start the installation and

following the SETUP program instructions.

Query / delete fault memory F1 – F5

or cancel the control box lock

• Start the software on your PC:

– on the desktop —> double click the “EDiTH” icon

– Select heater type

– Press the “GO” button.

• Delete fault memory or cancel the control box lock:

– press the “Delete fault memory” button

—> the stored faults F1 – F5 are deleted and the control

box is unlocked.

Quit diagnosis

• Press the “STOP” button —> fault memory query is ended.

1 Heater

2 Adapter cable

3 ISO adapter

4 SUB-D connection cable

5 USB to Serial RS-232 adapter

Please note!

18

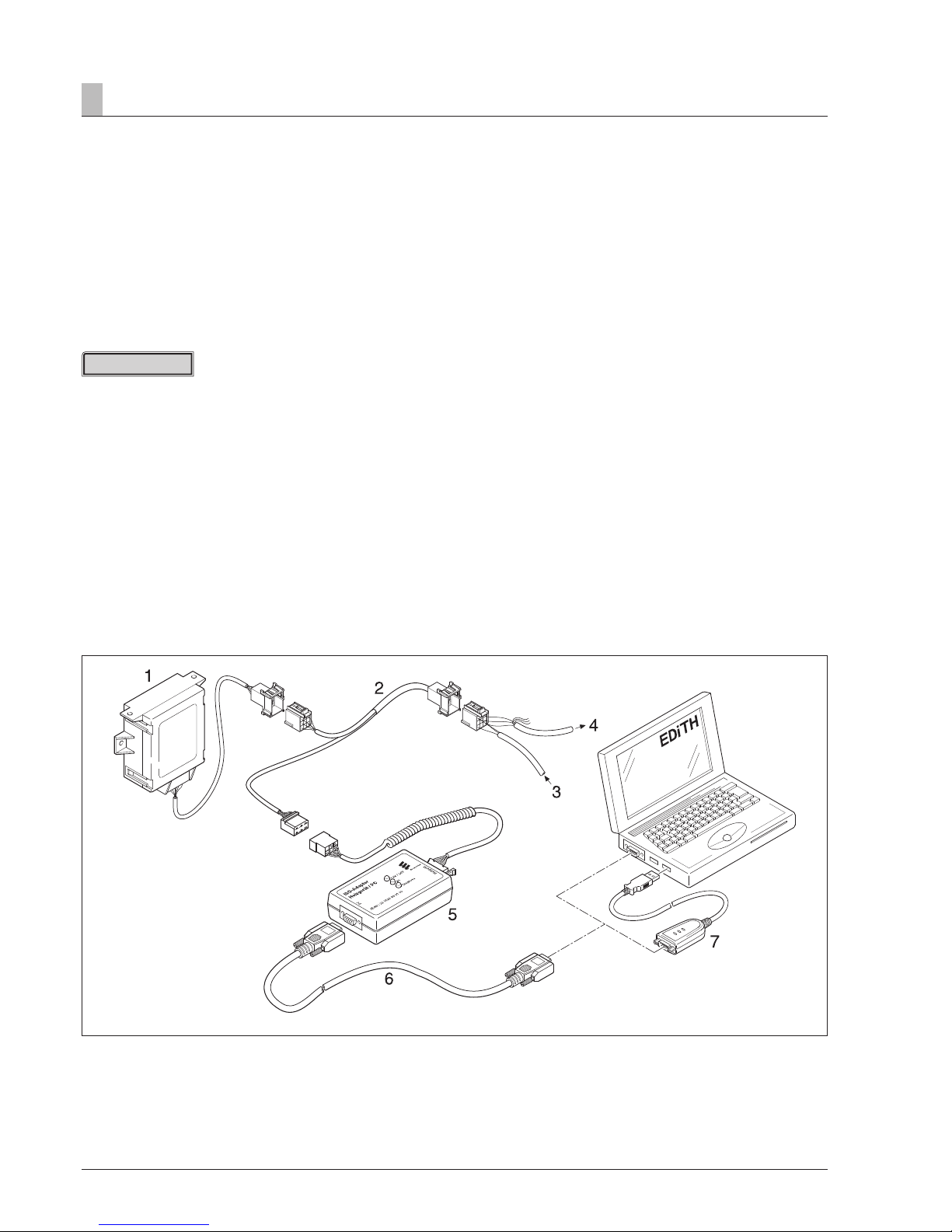

Troubleshooting4

Air pressure sensor diagnosis using

EDiTH diagnostics tool and ISO adapter

(Order No. 22 1524 89 00 00)

An additional adapter cable is required to connect the

ISO adapter (Order No.: 22 1000 33 31 00).

The air pressure sensor connected to the heater can be diagnosed. If faults occur during the altitude adjustment they are

stored in the air pressure sensor. If necessary, faults can be

read out using the ISO adapter in conjunction with the EDiTH

diagnostics tool – from Version S3V7-F – and the additionally

necessary adapter cable.

Please note!

• It is very important to always install in the given order.

• Not only the defective component, but also a defective current circuit results in a fault being displayed.

• Fault code, fault description, cause / remedial action are

described on pages 27.

• The EDiTH diagnostics tool scope of supply does not

include the software; this must be downloaded from the

Service Portal.

Perform diagnosis of the air pressure sensor

Disconnect the connector between the air pressure sensor /

heater, control unit, connect the ISO adapter with the adapter

cable (see sketch).

Start the diagnosis of the air pressure sensor.

• Double-click the >>EDiTH<< icon on the desktop.

• Select the air pressure sensor in the »Heater and Test Selection«.

The following actions are possible:

– Read out the current fault and the fault memory.

– Delete the fault memory.

– Query the current measured air pressure.

– Query the operating state.

– Query the general data.

– Print out the fault memory and / or the general data

• Exit the diagnosis with the »Stop« button or by closing all

windows.

– Selection: Save analysis / Do not save analysis

• Remove ISO adapter and adapter cable from the lead harness and reconnect the air pressure sensor / heater, control

unit connector.

1 Air pressure sensor

2 Adapter cable

3 Cable loom from heater

4 Cable loom to control unit

5 ISO adapter

6 SUB-D connection cable

7 USB to Serial RS-232 adapter

19

Caution!

Magnetic field!

During the test operation a magnetic field develops at the

adapter. Therefore, do not place any objects such as data

media, credit cards, etc. on the adapter or in its immediate

vicinity.

Troubleshooting4

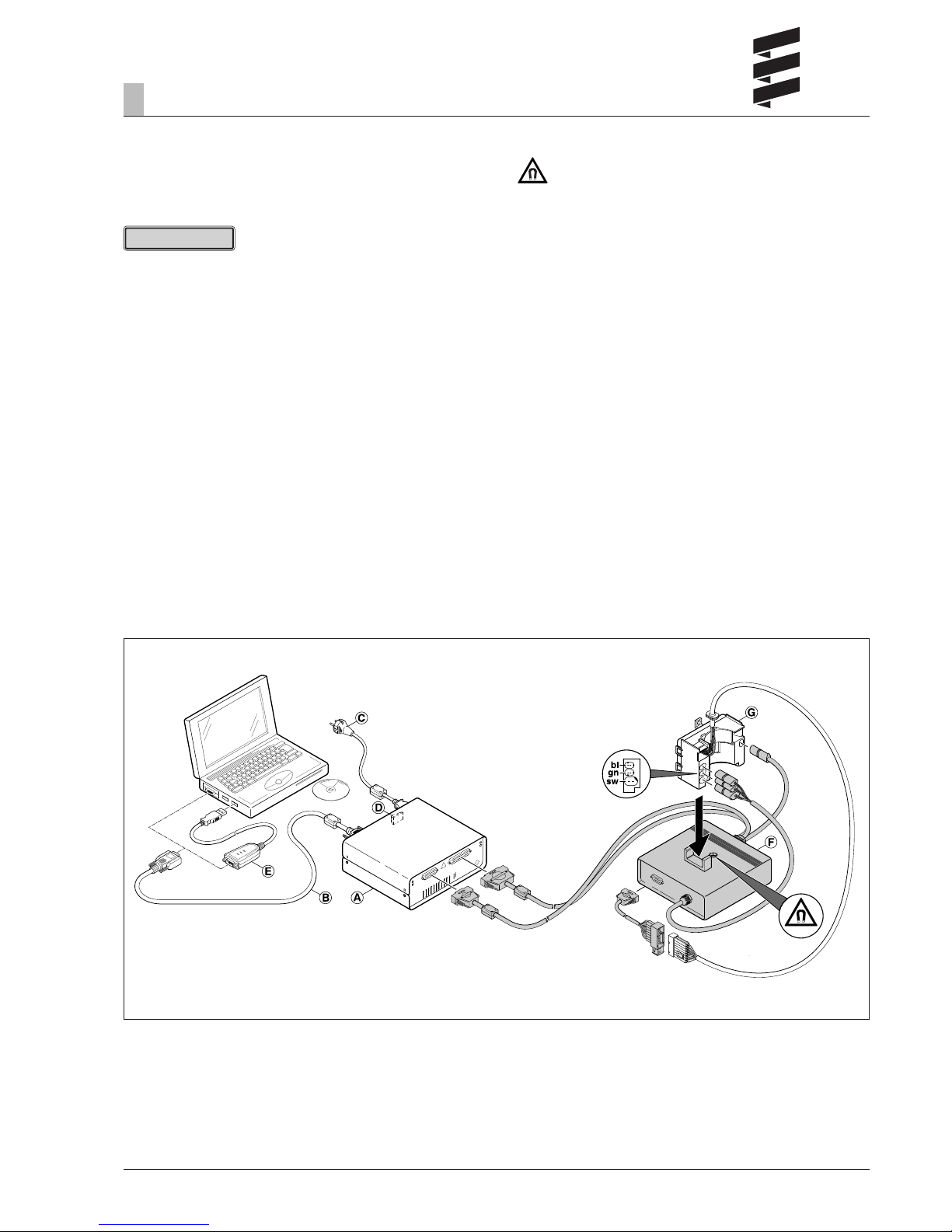

(A) Basic adapter

(B) SUB-D connection cable

(C) Mains connection

(D) Mains switch

(E) USB to Serial RS-232 adapter

(F) Adapter

(G) Control box

Cable colours

sw = black

gn = green

bl = blue

EDiTH diagnostic tool with basic adapter

EDiTH basic adapter (Order No.: 22 1542 89 00 00)

An additional extension is required to check the control box

(Order No.: 22 1537 89 00 00).

• It is important to always follow the precise connection order

as given below!

• The Hall sensor integrated in the control box can only be

properly tested in the control box is correctly placed on the

extension.

• Only push or pull on the connectors, not on the cables!

• Only use the network cable and RS232 cable with snap

ferrites included in the scope of supply. Use original accessories with snap ferrites only to connect the test equipment.

• Not only the defective component, but also a defective

current circuit results in a fault being displayed.

• Fault code, fault description, cause / remedial action are

described on Pages 23 – 27.

Connect basic adapter

• Start computer and wait until the system has successfully

booted.

• Start PC software.

• Insert the unit connector of the mains cable in the basic

adapter (A) and connect the mains connection (C) to the

mains.

• Connect the SUB-D connection cable (B) with the PC and

basic adapter (A).

Connect extension and test control box

• Connect the extension to the basic adapter (A).

• Connect the control box (E) to the extension and the adapter (F).

• Switch on the basic adapter (A) at the mains switch (D).

• Select the control box version and operating voltage

(12 V / 24 V) in the PC software.

• Start the control box test with the PC software. A more detailed description of how to operate the basic adapters (A) is

given in the EDiTH online help.

Please note!

20

Troubleshooting4

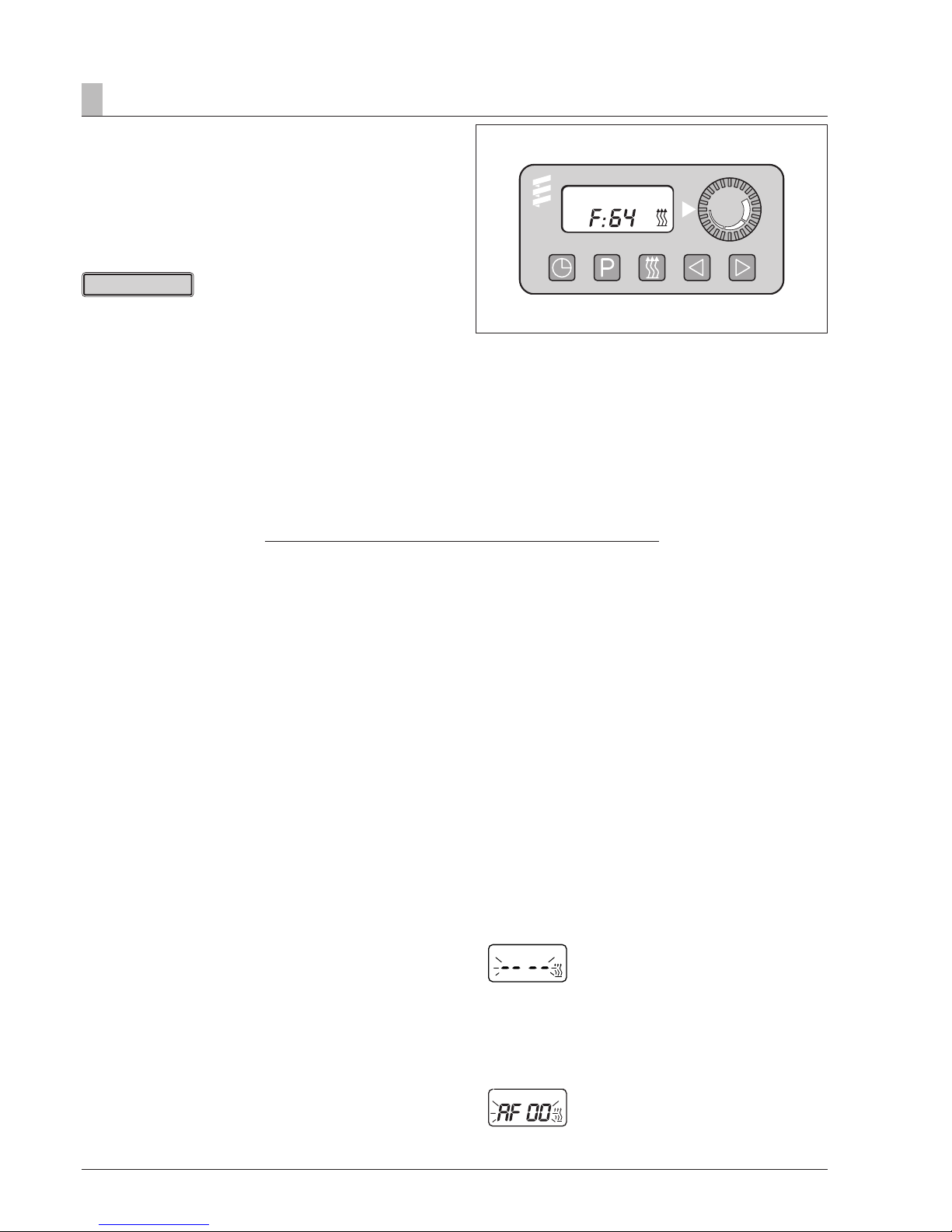

Module timer

(Order No.: 22 1000 30 34 00)

The current fault is displayed as “AF” and is always written in

memory position F1.

Preceding faults are moved to the memory locations F2 – F5,

if necessary the contents of memory position F5 is overwritten.

• Not only the defective component, but also a defective current circuit results in a fault being displayed.

• In heaters with connected air pressure sensor the modular

timer cannot be used to perform diagnoses. The diagnostics unit or the EDiTH diagnostics tool must be used to

perform the diagnosis.

The fault memory of the „air pressure sensor“ can be read

out using the EDiTH diagnostics tool only.

• Fault code, fault description, cause / remedial action are

described on Pages 23 – 27.

Query fault memory F1 – F5

Condition:

The heater is switched off.

• Press c key –> the heater is switched on.

• Press a key and keep pressed,

then press p key within 2 seconds.

Display is as follows:

AF = current fault

3 digit number = fault code

c flashes.

• Press f key once or several times,

fault memory positions F1 – F5 are displayed.

Cancel the control box lock and simultaneously delete

the fault memory

Condition:

An electrical connection exists from terminal 15 (ignition) to

the module timer, 12-pin connector, chamber 10.

• Press c key

Display is as follows:

the current fault F15 or F50.

• Press button a, keep it depressed and then press button p

within 2 seconds.

The module timer is now in the “Query fault memory” pro-

gram.

• Switch off ignition (terminal 15).

• Simultaneously press button a and button p, in addition,

switch on the ignition (terminal 15) and wait until the following appears in the display.

After ignition “ON” the following appears in the display:

Display flashes,

Heater symbol does not flash

• Switch the heater off and on –> the control box is unlocked,

the heater restarts.

After switching the heater off and on and renewed query of

the fault memory, the following appears in the display:

Display flashes,

Heater symbol does not flash

a

– Time

p

– Preset

c

– Heat

e

– Reverse

f

– Forward

Please note!

21

Troubleshooting4

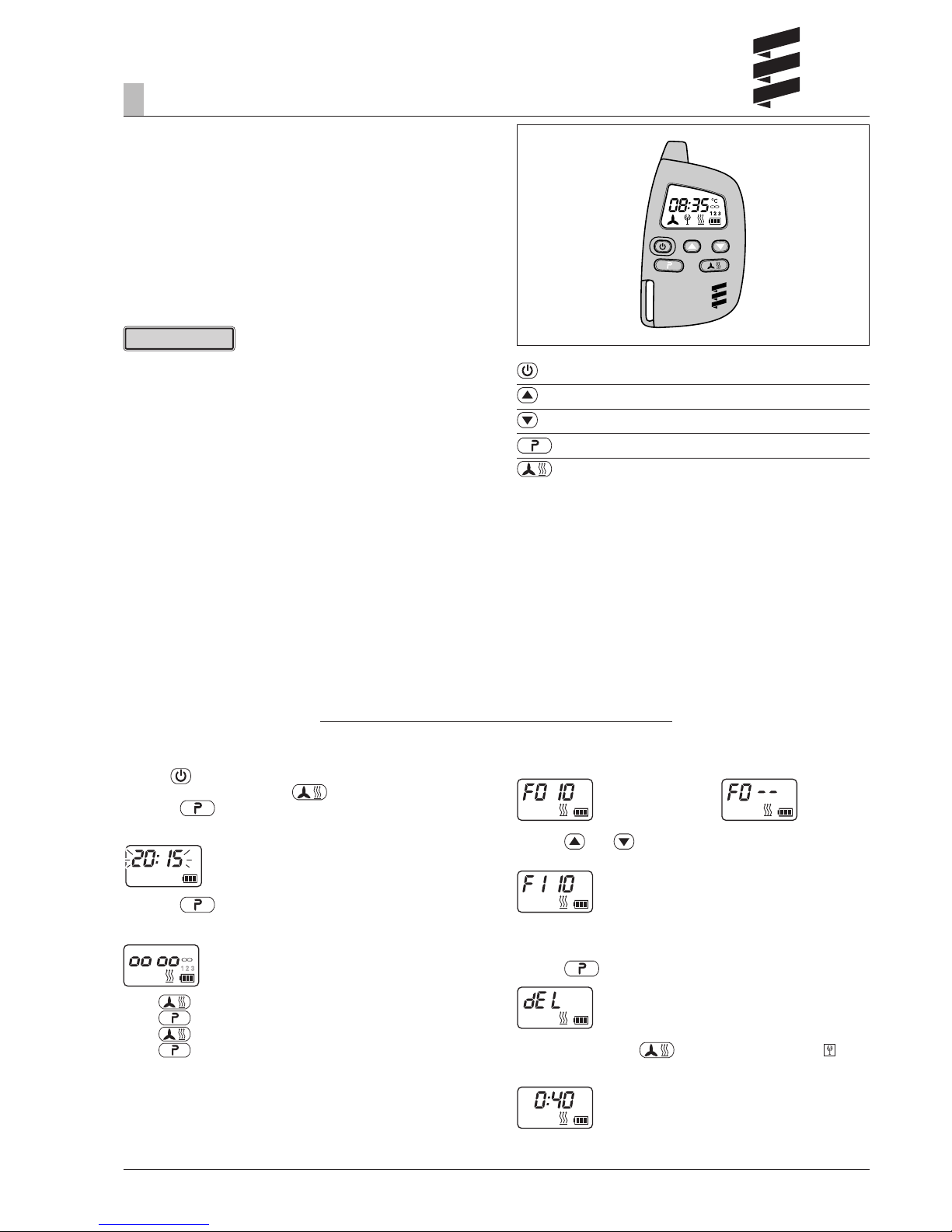

TP5 radio remote control

(Order No: 22 1000 32 01 00)

If faults occur while the heater is running, they are displayed

with “Err” after the mobile unit is activated.

After the diagnostics cable (bl/ws) has been connected and

the first logs have arrived at the stationary unit, the diagnose

can be carried out using the mobile unit of the TP5 radio

remote control.

The current fault “F0” is displayed. The stored faults “F1” to

“F5” can be queried.

• In order to carry out the diagnosis, the diagnostics cable

(bl/ws) must be connected to the stationary unit and the

heater cable harness. To this end, please refer to and follow

the circuit diagram for the TP5 radio remote control and the

heater.

• If the diagnostics cable (bl/ws) is not connected, the “Diagnosis” menu is blocked.

• Not only the defective component, but also a defective current circuit results in a fault being displayed.

• In heaters with connected air pressure sensor the TP5 radio

remote control cannot be used to perform diagnoses. The

diagnostics unit or the EDiTH diagnostics tool must be used

to perform the diagnosis.

The fault memory of the „air pressure sensor“ can be read

out using the EDiTH diagnostics tool only.

• Fault code, fault description, cause / remedial action are

described on Pages 23 – 27.

Button to activate / deactivate the mobile unit

Button for forward time setting

Button for backward time setting

Button for activating the possible settings

Button for switching heat / ventilate ON / OFF;

Activate / deactivate preselected time

Enquire / delete fault memory

Use the

key to activate the mobile unit.

Switch on the heater with the

key.

Press the

key twice to open the Time setting menu –

the time flashes in the display.

Press the

key for approx 2 sec – until the following ap-

pears in the display:

Press

key.

Press

key.

Press

key twice.

Press

key.

Malfunction in heater: Heater has no malfunction:

Use the

and buttons to call up the fault memory posi-

tions 1 to 5.

Delete fault memory /

Cancel the control box lock

Use the

key to delete the fault memory.

To confirm, press the

key for approx 2 sec until lights

up in the display – fault memory is deleted.

Please note!

22

The following actions are possible

• Call up fault memory.

Call up the fault memory positions F1 – F5 with

or .

• Call up fault memory again.

Briefly press and simultaneously.

• Delete fault memory

(display dEL)

Press .

Press again.

The diagnosis is completed.

Switch off heater.

Enquire / delete fault memory

Activate mobile part / timer

(see EasyStart R+ / EasyStart T operating instructions)

Confirm symbol

with .

Heater is switched on.

Confirm operating time with

.

Briefly press

and simultaneously.

Troubleshooting4

EasyStart R+ radio remote control

(Order-No.: 22 1000 32 80 00)

EasyStart T timer

(Order-No.: 22 1000 32 88 00)

If faults occur while the heater is running, they are displayed

with “Err” after the mobile unit or timer is activated.

The current fault is displayed. The stored faults “F1” to “F5”

can be queried.

• In order to carry out the diagnosis, the diagnostics cable (bl/

ge at heater connector, bl/ws at cable harness connector)

must be connected to the stationary unit and the heater

cable harness. To this end, please refer to and follow the

circuit diagram for the radio remote control and the heater.

• If the diagnostics cable is not connected, the “Diagnosis”

menu is blocked.

• Not only the defective component, but also a defective current circuit results in a fault being displayed.

• The heater diagnosis can also be performed if the air pressure sensor is connected.

The fault memory of the „air pressure sensor“ can be read

out using the EDiTH diagnostics tool only.

• Fault code, fault description, cause / remedial action are

described on Pages 23 – 27.

Back control key

Next control key

ON / OFF activation key mobile unit / timer

OK key (symbol selection / confirm input)

Please note!

23

Troubleshooting4

Fault code

Display

Fault description Comments

• Remedial action

000

No faults — —

004

Warning:

Short circuit in control box,

fresh air output

• Disconnect connector S1 / B1 at the heater and at the connector B1, PIN

16 check the cable up to the fresh air fan relay for short circuit to negative,

if ok —> replace control box.

005

Warning:

Short circuit in control box,

car alarm output

• Disconnect connector S1 / B1 at the heater and at the connector B1, PIN

15 check the cable up to the relay isolating switch or burglar alarm system

input for short circuit to negative, if ok —> replace control box.

006

Warning:

Inexplicable atmospheric altitude

information

(Display only if heaters labelled “H-Kit”

on the nameplate.)

Control box has not received any explicable altitude information.

• Read out fault memory in the air pressure sensor using the EDiTH diagnostics tool and correct fault.

009

Cut-off ADR ADR shutdown due to signal change from (+) to (–) at connector S1, PIN 13

(D+) or plus signal at connector S1, PIN 14 (HA+).

010

Overvoltage – cut-off Overvoltage applied to control box for at least 20 seconds without interruption

– heater not working.

• Disconnect connector S1 / B1 at the heater, start the vehicle’s engine,

measure the voltage at connector B1 between PIN 1 (cable 2.5

2

rt) and PIN

10 (cable 2.52 br).

Airtronic 12 volt – voltage >16 volt —> check generator regulator

Airtronic 24 volt – voltage >32 volt —> check generator regulator

011

Undervoltage – cut-off Undervoltage applied to control box for at least 20 seconds without interrup-

tion – heater not working.

• Disconnect connector S1 / B1 at the heater, the vehicle’s engine is switched

off, measure the voltage at connector B1 between PIN 1 (cable 2.5

2

rt) and

PIN 10 (cable 2.52 br).

The measured value and the voltage at the battery should be the same.

In case of a voltage drop, check the fuses, the supply cables, the negative

connections and the positive support point on the battery for corrosion and

correct contact.

012

Overheating at the overheating sensor Temperature of the overheating sensor too high.

• Check hot air pipes for blockage —> remove blockage.

• Sum of the component ratings of air-conducting parts is too large —>

Check air system, if necessary re-lay – for component ratings, please refer

to additional parts catalogue.

• Check overheating sensor, for diagram and table of values please refer to

Page 32, if ok —> measure fuel quantity, see Page 36.

013

Overheating at the flame sensor Flame sensor signals temperature at heat exchanger is too high.

• Check hot air pipes for blockage —> remove blockage.

• Sum of the component ratings of air-conducting parts is too large —>

Check air system, if necessary re-lay – for component ratings, please refer

to additional parts catalogue.

• Check flame sensor, if ok —> check overheating sensor, if overheating

sensor defective —> replace combination sensor, if overheating sensor ok

—> measure fuel quantity, see Page 36, for diagram and table of values for

flame sensor and overheating sensor please refer to Page 32.

014

Temperature difference between

flame sensor and overheating sensor

too large

Temperature difference between flame sensor and overheating sensor too

large

• Check hot air pipes for blockage —> remove blockage.

• Sum of the component ratings of air-conducting parts is too large —>

Check air system, if necessary re-lay – for component ratings, please refer

to additional parts catalogue.

• Check flame sensor, if ok —> check overheating sensor, if overheating sensor defective —> replace combination sensor, if overheating sensor ok —>

measure fuel quantity, see Page 36, if fuel quantity ok — > replace control

box. For diagram and table of values for flame sensor and overheating sensor, see Page 32.

24

Troubleshooting4

Fault code

Display

Fault description Comments

• Remedial action

015

Operating lock-out The fault code 015 is displayed, if the heater was switched back on after the

fault code display 017.

The hardware threshold value for the overheating sensor has been exceeded

—> the control box is locked.

• Replace control box.

017

Overheating The hardware threshold value for the overheating sensor has been exceeded,

because the control box failed to recognise the fault code 012 or 013 –> the

control box is locked.

If the heater is switched on again, the fault code 015 is displayed.

• Replace control box.

018

Starting energy of the glow plug is

too low

(Display only if heaters labelled “H-Kit”

on the nameplate.)

• Check glow plug (see fault code 020 and 021), if ok

• Check glow plug cable harness for correct laying and damage, if ok —>

check cable harness for continuity, if ok —> replace control box.

019

Ignition energy too low • Check glow plug (see fault code 020 and 021), if ok

• Check glow plug cable harness for correct laying and damage, if ok —>

check cable harness for continuity, if ok —> replace control box.

020

021

Glow plug – interruption

Glow plug – short circuit, overload or

short circuit after negative

• Check glow plug for function and continuity at ambient temperature 20 °C.

12 volt heater – 0.42 up to ± 0.7

24 volt heater – 1.2 up to ± 2.0

• If the values are ok —> check glow plug lead harness for damage and continuity, if ok —> replace control box.

022

*

Glow plug, output (+) – short circuit

after U

B

(battery voltage)

• Check glow plug lead harness for correct laying and damage, if ok —>

check lead harness for continuity, if ok —> replace control box.

025

*

Diagnostics cable bl/ws – short circuit

– after U

B

(battery voltage)

Fault code display is not possible. This fault code cannot be read out from the

fault memory until the fault has been corrected.

• Check diagnostics cable for correct laying and possible damage.

031

Blower – interruption • Check that the lead harness of the blower motor has been correctly laid

and check for damage, if ok —> remove lead harness at control box and

check for continuity, if ok —> replace control box.

032

Blower motor – short circuit after

negative

Please note!

Ensure compliance with the test voltage (see page 12). The component

is destroyed if the voltage value is

exceeded.

Ensure the power pack has adequate short-circuit resistance

– min 20 A.

• Carry out functional test on the blower motor, to do this remove the connector from the control box. Apply a test voltage (see page 12) to the blower motor and measure the current intensity after 40 sec.

Current intensity < 6.5 A – blower motor ok –> replace control box.

Current intensity > 6.5 A —> replace blower.

• Check wiring for short circuit.

033

Blower motor won’t rotate or short

circuit after negative

Please note!

Ensure compliance with the test voltage (see page 12). The component

is destroyed if the voltage value is

exceeded.

Ensure the power pack has adequate short-circuit resistance

– min 20 A.

Speed deviation > 10 % from setpoint value for longer than 30 seconds.

Use a non-contact r.p.m. counter to measure the speed of the combustion air

fan (see page 12 for test speed and test voltage).

• Speed too low:

Blower blocks – check blower for free running, if necessary remove foreign

body, if ok —> check blower (see fault code 032).

• Speed too high:

– Magnet missing from blower impeller —> replace blower.

– Speed sensor in control box is defective —> replace control box.

• Check wiring for short circuit.

* This fault code or ohmic value is valid for a new generation control box only. This differs from the control box to date by its cable loom wrapped in cable tape and by a

temperature sensor mounted on the side, which becomes visible when the cover is removed.

25

Troubleshooting4

Fault code

Display

Fault description Comments

• Remedial action

034

*

Blower motor, outlet (+) short circuit

after U

B

(battery voltage)

• Check that the lead harness of the blower motor has been correctly laid

and check for damage, if ok —> remove lead harness at control box and

check for continuity, if ok —> replace control box.

047

Metering pump – short circuit or

overload

• Remove connector from the metering pump, if the fault code 048 (interruption) is displayed the metering pump is defective —> replace metering

pump.

• If the fault code 047 continues to be displayed, disconnect connector S1 /

B1 at the heater, and at the connector B1, PIN 5 check the cable 1

2

gn/rt

up to the metering pump for short circuit to negative (PIN 10),

if ok –> replace control box.

048

Metering pump – interruption • Disconnect connector from metering pump and measure the resistance

value of the metering pump (see Page 12 for values), if resistance value ok,

re-connect the cable loom to the metering pump.

• Disconnect connector S1 / B1 at the heater and measure the resistance

value (see Page 12) between PIN 5 and PIN 10, if ok —> replace control

box.

049

*

Metering pump outlet (+) Short circuit

– after U

B

(battery voltage)

• Check that the lead harness of the metering pump has been correctly laid

and check for damage, if ok —> remove lead harness and check for continuity, if ok —> replace control box.

050

Too many failed start attempts (operating lock-out)

The control box locks after too many failed start attempts (max. 255 start attempts).

• Unlock the control box by deleting the fault memory with the timer, the diagnostic unit, EDiTH diagnostic tool, the TP5 radio remote control / EasyStart R+ and the EasyStart T timer.

051

Flame detected when switching on If, after being switched on, the resistance value of the flame sensor is 1274

(> 70 °C) the heater’s fan runs for approx 15 min to cool down, if the resistance does not fall below the aforementioned value within 15 min the heater

is switched off.

• Check flame sensor, see Page 32 for diagram and table of values,

if ok —> replace control box.

052

Safety time exceeded No flame detected within the start phase.

• Check exhaust and combustion air system.

• Check fuel supply / measure fuel quantity, see Page 36.

• Check spark plug (see fault code 020 and 021)

• Check flame sensor, diagram and table of values, see Page 32,

if ok —> replace control box.

053

054

055

056

Flame cutout in the

“POWER” control stage

“HIGH” control stage

“MEDIUM” control stage

“LOW” control stage

The heater has ignited (flame detected) and signals flame cutout during a

power stage.

• Check exhaust and combustion air system.

• Check fuel supply / measure fuel quantity, see Page 36.

• Check flame sensor, diagram and table of values, see Page 32,

if ok —> replace control box.

057

Flame cutout from start phase

(Display only if heaters labelled “H-Kit”

on the nameplate.)

A flame cutout was detected during the start phase..

• Check exhaust and combustion air system.

• Check fuel supply / measure fuel quantity, see Page 36.

• Check glow plug (see fault code 020 and 021).

• Check flame sensor, diagram and values table, see page 32,

if ok —> replace control box.

060

External temperature sensor –

interruption

• Disconnect the connector S4 / B4 of the external temperature sensor and

measure the resistance value at connector B2, for diagram and table of values see Page 12, if temperature sensor ok, reassemble connector S4 / B4.

• Disconnect connector S1 / B1 at the heater and measure the resistance

value in connector housing B1 between PIN 6 and PIN 12. If interrupted the

ohmic value is > 7175 / 3 k*.

If resistance value ok —> replace control box.

* This fault code or ohmic value is valid for a new generation control box only. This differs from the control box to date by its cable loom wrapped in cable tape and by a

temperature sensor mounted on the side, which becomes visible when the cover is removed.

26

Troubleshooting4

Fault code

Display

Fault description Comments

• Remedial action

061

External temperature sensor –

short circuit

• Disconnect connector S4 / B4 of the external temperature sensor, if fault

code 060 is displayed —> check external temperature sensor, diagram and

table of values, see Page 32. If temperature sensor ok —> check connection cables 0.5 gr and 0.5 br/ws for short circuit, if ok, reassemble the connector S2 / B2.

• Disconnect connector S1 / B1 at the heater and measure the resistance

value in connector housing B1 between PIN 6 and PIN 12.

In case of short circuit the ohmic value is < 486 / < 800 *.

If error 061 continues to be displayed —> replace control box.

062

Control unit – interruption

Please note!

Refer to notes on diagnosis with minicontroller on page 14.

Heater runs in „High“ control stage only

• Remove connector at the control unit and measure the resistance value of

the setpoint potentiometer, for connector pins see Page 42 onwards. If the

resistance value is ok, reconnect connector at the control unit.

• Disconnect connector S1 / B1 at the heater, measure the resistance value

between PIN 6 and PIN 7 in connector housing B1, if resistance value ok

—> replace control box. Resistance value in case of interruption

> 7175 / > 3 k *. Normal values: see page 12.

063

Control unit – short circuit

Fault recognition only works in heating mode. If, on the other hand, the

short circuit has already occurred and

then the heater is switched on, „Ventilation“ is active (not a fault code).

• If the “Ventilate” switch is installed, disconnect it and check it works. If not

ok —> replace switch.

• Disconnect connector at control unit, if error code 062 is displayed, replace

the control unit. If control unit ok, check connection cables 0.5 gr/rt and 0.5

br/ws for short circuit, if ok —> reconnect connector at control unit.

• Disconnect connector S1 / B1 at the heater, if the error 063 continues to be

displayed —> replace control box. Resistance value in case of short-circuit

< 486 / < 800 *. Normal values: see page 12.

064

Flame sensor – interruption • Dismantle control box and disconnect green connector from control box.

Check flame sensor, diagram and table of values, see Page 32, if flame sensor ok —> replace control box. Resistance value in case of interruption >

7175 / > 3 k *.

065

Flame sensor – short circuit Dismantle control box, remove green connector from control box, if error 064

is displayed —> replace combination sensor.

If error 065 continues to be displayed —> replace control box.

Resistance value in case of short circuit < 486 / < 500 *, see also dia-

gram on Page 32.

071

Overheating sensor – interruption • Dismantle control box, disconnect blue and green connectors from control

box. Measure resistance value at blue connector PIN 1 (cable 0.52 bl) and

at green connector PIN 2 (cable 0.52 br/ws), if ok, —> replace control box.

Resistance value in case of interruption >223 k / > 1600 k *, see also

diagram on Page 32.

072

Overheating sensor – short circuit • Dismantle control box, remove blue connector from control box, if error 071

is displayed —> replace combination sensor.

If error 072 continues to be displayed —> replace control box.

Resistance value in case of short circuit < 183 / < 95 *, see also dia-

gram on Page 32.

074

*

Control box defective • Overheating threshold value is not detected by control box —> replace con-

trol box.

090

Control box defective (internal fault) • Replace control box.

091

External interference voltage • Control box fault due to interference voltages from the vehicle’s electrical

system. Possible causes:

Poor battery, charger — > remove interference voltage.

092

Control box is defective (ROM error) • Replace control box.

093

*

Control box defective • Replace control box.

* This fault code or ohmic value is valid for a new generation control box only. This differs from the control box to date by its cable loom wrapped in cable tape and by a

temperature sensor mounted on the side, which becomes visible when the cover is removed.

27

Troubleshooting4

Fault code

Display

Fault description Comments

• Remedial action

094

Control box defective

(EEPROM-Fehler)

• Replace control box.

095

*

Control box defective • Replace control box.

096

Internal temperature sensor defective • Replace control box or use an external room temperature sensor..

097

Control box defective • SReplace control box.

098

*

Control box defective • Replace control box.

099

*

Too many resets in sequence

Transistor error in control box

• Voltage short-term < 5 – 6 volt (for 12 volt) or < 7 – 8 volt (for 24 volt).

In case of a voltage drop, check the fuses, the supply cables, the negative

connections and the positive support point on the battery for corrosion and

correct contact.

Test control box with testing device, if ok —> check lead harness of the ex-

ternal components has been correctly laid and check for damage, if ok —>

check lead harness for continuity, if ok —> replace control box.

Air pressure sensor fault code display

Fault code

display

Fault description Comments

• Remedial action

0

No faults —

11

Communication loss Interruption of the diagnostics cable between the control box (heater) and the

air pressure sensor

• Check wiring and plug-in connections

12

No altitude adjustment Control box (heater) does not support altitude operation with the air pressure

sensor

• Use a control box (heater) which supports altitude adjustment

13

Air pressure sensor fault The air pressure sensor is defective

• Replace the air pressure sensor