Page 1

MMU-16LE Series

SmartMonitor

NEMA TS-2

Enhanced Malfunction Management Unit

Operations Manual

THIS MANUAL CONTAINS TECHNICAL INFORMATION FOR THE MMU-16LE and

MMU16LEip SmartMonitor

®

SERIES MALFUNCTION MANAGEMENT UNIT.

REVISION: APRIL 2012

pn 888-0116-001

®

Page 2

THE MMU-16LE SERIES IS DESIGNED AND MANUFACTURED IN THE USA BY

AN ISO 9001 :2008 REGISTERED COMPANY

INFORMATION CONTAINED HEREIN IS PROPRIETARY TECHNICAL INFORMATION

OF EBERLE DESIGN INC. PUBLICATION, REPRODUCTION OR USE IN WHOLE OR

PART IS NOT PERMITTED EXCEPT UNDER TERMS AGREED UPON IN WRITING.

EBERLE DESIGN INC.

PHOENIX, ARIZONA

© COPYRIGHT 2004-2012 EDI

Canadian Patent No. 2,574,101

U.S. Pat. No. 7,246,037

MAINTENANCE NOTE

THIS EBERLE DESIGN INC. MALFUNCTION MANAGEMENT UNIT

HAS BEEN CAREFULLY INSPECTED AND TESTED TO ENSURE

PROPER OPERATION. IT IS RECOMMENDED THAT THE

MALFUNCTION MANAGEMENT UNIT BE TESTED AT LEAST

ANNUALLY TO ENSURE PROPER OPE RATION AND COMPLIANCE

WITH FA C TOR Y SP EC IFICATIONS.

.

Page 3

Table of Contents

Section 1 General.................................................................................................................... 1

1.1 Description.................................................................................................................... 1

1.2 Advanced Feature Overview ....................................................................................... 1

1.2.1 Liquid Crystal Status and Field Display ............................................................. 1

1.2.2 Menu Driven Operation ...................................................................................... 1

1.2.3 Context Sensitive Help System ......................................................................... 1

1.2.3.1 Set-up Wizard ........................................................................................... 1

1.2.3.2 Diagnostic Wizard ..................................................................................... 1

1.2.4 Pr ogram Card M em ory ....................................................................................... 2

1.2.5 RMS Voltage Reporting ..................................................................................... 2

1.2.6 ECcom Software Interface ................................................................................. 2

1.2.7 Nema TS-1 Operation With SDLC Mode .......................................................... 2

1.2.8 Flashing Yellow Arrow (FYA) Protected-Permis s ive Mo vem ent ...................... 2

1.2.9 Five Secti on Arr ow Su ppression Protected-Permissive Movement (PPLT5) .. 3

1.3 General ......................................................................................................................... 3

1.4 Field Signal Terminals ................................................................................................. 4

1.4.1 LEDguard® LED Field Signal Sensing ............................................................... 4

1.4.2 Type Select Input ............................................................................................... 4

1.4.2.1 Type 12 With SDLC Mode........................................................................ 5

1.4.2.2 Force T ype 16 M od e ................................................................................ 6

Section 2 Standard Functions ............................................................................................... 7

2.1 Conflict Monitoring ....................................................................................................... 7

2.2 Red Fail M onit or i n g ...................................................................................................... 7

2.2.1 Red Enable Input ................................................................................................ 7

2.2.2 Walk Disable Option ........................................................................................... 7

2.3 Voltage Monitoring ....................................................................................................... 8

2.3.1 +24Vdc Supply Monitoring ................................................................................. 8

2.3.1.1 +24Vdc Monitor Inhibit Input .................................................................... 8

2.3.1.2 +24Vdc Monitor Latch Input ..................................................................... 8

2.3.1.3 +24Vdc M on it or II 12V dc M od e ................................................................ 8

2.3.2 Controller Voltage / Fault Monitor Input ............................................................. 8

2.3.2.1 CVM Monitor Latch Input.......................................................................... 9

2.3.2.2 CVM Log Disable ...................................................................................... 9

2.4 Local Flash Status Input .............................................................................................. 9

2.5 Minimum Yellow Change / Red Clearance Monitoring ............................................... 9

2.5.1 Mini m u m Y ell ow Change Interval ...................................................................... 9

2.5.1.1 Minimum Yellow Clearance Disable ........................................................ 9

2.5.2 Minimum Yellow Plus Red Interval .................................................................... 9

2.5.2.1 Minimum Yellow Plus Red Clearance Disable ...................................... 10

2.6 MMU Power Failure Detection ................................................................................... 10

2.7 Port 1 Communications.............................................................................................. 10

2.7.1 Port 1 Timeout .................................................................................................. 11

2.7.2 Port 1 Disable Input .......................................................................................... 11

2.8 Type 129 Response Frame ....................................................................................... 11

2.9 Output Relay Recovery .............................................................................................. 12

2.10 Internal Diagnostics ................................................................................................. 12

2.10.1 Memory Diagnostics ....................................................................................... 12

2.10.2 Mic roproc essor Monitor.................................................................................. 12

2.10.3 Internal Hardware Monitor ............................................................................. 12

Section 3 Enhanced Features ............................................................................................. 13

3.1 Har d w ar e F eat ures .................................................................................................... 13

3.2 Dual In dication M on itoring ......................................................................................... 13

3.2.1 Walk Disable Option ......................................................................................... 14

.

Page 4

3.3 External Watchdog Monitoring .................................................................................. 14

3.4 Program Card Absent Indication ............................................................................... 14

3.5 Reset Input Detection ................................................................................................ 14

3.6 Display LED Test ....................................................................................................... 14

3.7 Recurrent Pulse Detection ......................................................................................... 15

3.8 Type Fault................................................................................................................... 15

3.9 Field Check Monitoring .............................................................................................. 16

3.9.1 Field Check Fault ............................................................................................. 16

3.9.2 Field Check Status ........................................................................................... 16

3.10 Diagnostic Wizard .................................................................................................... 17

3.11 Flashing Yellow Arrow Protected-Permissive Monitoring (FYA) ............................ 18

3.11.1 Basic FYA MODE ........................................................................................... 18

3.11.2 Compact FYAc MODE ................................................................................... 19

3.11.2.1 FYAc Type 16 Mode ............................................................................. 19

3.11.2.2 FYAc Type 12 Mode ............................................................................. 20

3.11.3 FYA Channel Assignment Diagrams ............................................................. 21

3.12 Five Section Arrow Suppression Protected-Permissive Monitoring (PPLT5) ........ 22

3.12.1 Basic PPLT5 Arrow Suppression Mode ........................................................ 22

3.12.2 PPLT5 Arrow Suppression Channel Assignment Diagrams......................... 24

Section 4 ECcom Interface .................................................................................................. 25

4.1 EDI ECcom Monitor Reports ..................................................................................... 25

4.1.1 General Data .................................................................................................... 25

4.1.2 Current Status (S) ............................................................................................ 25

4.1.3 Pr evious Fault (PF) Event Log ......................................................................... 25

4.1.4 AC Line (AC) Event Log ................................................................................... 25

4.1.5 Manual Reset (MR) Event Log ........................................................................ 26

4.1.6 Configuration (CF) Event Log .......................................................................... 26

4.1.7 Si gn al S equence E ven t L og............................................................................. 26

4.2 Configuration Programming ....................................................................................... 26

4.2.1 ECcom Configurati on Set-up Wizard............................................................... 26

4.3 Ethernet LAN Port ...................................................................................................... 26

Section 5 Menu Operation ................................................................................................... 27

5.1 Main Status Menu ...................................................................................................... 27

5.2 Top Lev el M en u ......................................................................................................... 27

5.2.1 St atus ................................................................................................................ 27

5.2.2 Men u ................................................................................................................. 28

5.2.2.1 View Logs ............................................................................................... 28

5.2.2.2 View and Set Configuration .................................................................... 28

5.2.2.3 Set-up Wizard ......................................................................................... 28

5.2.2.4 Clear Logs ............................................................................................... 29

5.2.2.5 Set Clock ................................................................................................. 29

Section 6 Installation ............................................................................................................ 30

6.1 General ....................................................................................................................... 30

6.2 Program Card Programming...................................................................................... 30

6.2.1 Per mis s i ve C h an n el Pr ogram mi ng .................................................................. 30

6.2.2 Minimum Flash Time Programming ................................................................. 31

6.2.3 Minimum Yellow Change Disable Programming ............................................. 31

6.2.4 Voltage Monitor Latch Programming ............................................................... 31

6.3 Enhanced Function Programming ............................................................................. 32

6.3.1 Field Check Enable Programming ................................................................... 32

6.3.2 Dual Indication Enable Programming .............................................................. 32

6.3.3 Red Fail Enable Programming ......................................................................... 32

6.3.4 Unit Option Programming................................................................................. 33

6.3.4.1 Recurrent Pulse Option .......................................................................... 33

6.3.4.2 Walk Disable Option ............................................................................... 33

6.3.4.3 Log CVM FAULTS Option ...................................................................... 33

.

Page 5

6.3.4.4 External Watchdog Enable Option ......................................................... 33

6.3.4.5 +24V-II = 12 Vdc Enable Option ............................................................ 33

6.3.4.6 Program Card Memory Enable Option .................................................. 33

6.3.4.7 LEDguard® Enable Option ...................................................................... 33

6.3.4.8 Force Type 16 Mode Enable Option ...................................................... 33

6.3.4.9 Type 12 With SDLC Mode Enable Option ............................................. 33

6.3.5 View Permissives ............................................................................................. 33

6.3.6 View program card options .............................................................................. 34

6.3.7 Yellow Plus Red Clearance Disable Programming ......................................... 34

6.3.8 Vi ew M onitor ID and Nam e .............................................................................. 34

6.3.9 View Firmware Version .................................................................................... 34

6.3.10 Run the Setup Wizard .................................................................................... 34

6.3.11 Set Factory Default Programming ................................................................. 34

6.3.12 Set ATSI Default Programming ..................................................................... 35

6.3.13 View Configuration Check Value ................................................................... 35

6.3.14 Flashing Yellow Arrow Monitor ...................................................................... 35

6.3.15 PPLT5 Arrow Suppression Monitor ............................................................... 35

6.4 Set-up Wizard............................................................................................................. 36

6.4.1 Unused Channels ............................................................................................. 36

6.4.2 Pedestrian Channels ........................................................................................ 36

6.4.3 Pr ot ected-Permissive Turn Channels .............................................................. 37

6.4.4 Review Channel Assignments ......................................................................... 37

Section 7 Front Pane l Des cription ...................................................................................... 38

7.1 Main Status Display ................................................................................................... 38

7.2 Channel Status Display.............................................................................................. 38

7.3 Front Panel LED Indicators........................................................................................ 38

7.3.1 Power Indicator................................................................................................. 38

7.3.2 Fault Indicator ................................................................................................... 38

7.3.3 Diagnostic Indicator .......................................................................................... 38

7.3.4 Receive Indicator .............................................................................................. 38

7.3.5 Transmit Indicator ............................................................................................. 38

7.3.6 COMM Indicator ............................................................................................... 38

7.4 Front Panel Buttons ................................................................................................... 39

7.4.1 Reset Button ..................................................................................................... 39

7.4.2 Menu Control Buttons ...................................................................................... 39

7.4.2.1 Next Button ............................................................................................. 39

7.4.2.2 Select Button........................................................................................... 39

7.4.2.3 Exit Button ............................................................................................... 39

7.4.2.4 Help Button ............................................................................................. 39

Section 8 Specifications ...................................................................................................... 40

8.1 Electrical ..................................................................................................................... 40

8.1.1 Power Requirements ........................................................................................ 40

8.1.2 AC Voltage Monitors ........................................................................................ 40

8.1.3 Power Fail Monitor ........................................................................................... 40

8.1.4 DC Voltage Monitor .......................................................................................... 40

8.1.5 Logic Inputs ...................................................................................................... 40

8.2 Mechanical ................................................................................................................. 40

8.3 Environmental ............................................................................................................ 41

Section 9 Timing Functions................................................................................................. 42

Section 10 Wiring Assignments.......................................................................................... 43

10.1 Harnessing Connectors ........................................................................................... 43

10.2 Type 16 Terminations .............................................................................................. 43

10.2.1 Type 16 Connector MS-A Pin Terminations .................................................. 43

10.2.2 Type 16 Connector MS-B Pin Terminations .................................................. 44

10.3 Type 12 Terminations .............................................................................................. 45

10.3.1 Type 12 Connector MS-A Pin Terminations .................................................. 45

.

Page 6

10.3.2 Type 12 Connector MS-B Pin Terminations .................................................. 46

10.4 MMU1 6LE-RM & MMU16LEip-RM Rack Mount Connector ................................... 46

10.5 Programming Card Pin Connections ....................................................................... 47

10.5.1 Programming Card P1 Connector ................................................................. 47

10.5.2 Programming Card P2 Connector ................................................................. 48

10.6 Port 1 Connector ...................................................................................................... 49

10.7 EIA-232 Connector .................................................................................................. 49

10.7.1 EIA-232 Cable to a PC ................................................................................... 50

10.8 Ethernet LAN Port (J2)............................................................................................. 50

10.8.1 Ethernet LAN Cable ....................................................................................... 50

.

Page 7

MMU-16LE SmartMonitor

Operati ons M an ual

Section 1

General

1.1 DESCRIPTION

The MMU-16LE SmartMonitor

used in a Traffic Controller Assembly to accomplish the detection of, and response to,

improp er and conf licti ng sign als and i mprop er operat ing vol tages i n a Contr oller As sembl y

caused b y malf unctions of the Controller Unit (CU), load switches , or mis-wiring of the

cabinet . The MMU-16LE SmartMonitor

suppli es and the contr oller pow er supplies via +24V MONIT OR I, +24V MON ITOR II, an d

Controller Voltage Monitor (CVM) inputs respectively. The Eberle Design MMU-16LE

SmartMonitor

®

is direc tly i nter ch ang eabl e with a st andar d NE MA Malf uncti on Man agem ent

Unit and meets with or exceeds all specifications outlined in Section 4 (Malfunction

Manag em en t U ni t) of the N at i onal Elect r ical Manufactur er s As s oci ation (NEMA) Standards

Publication TS2-2003 v02.06, Traffic Controller Assemblies With NTCIP

Requirements.

1.2 ADVANCED FEATURE OVERVIEW

1.2.1 LIQUID CRYSTAL STATUS AND FIELD DISPLAY

The MMU-16LE SmartMonitor

(LCD) t o sh ow monit or st atus and t wo icon based LCDs to s how fi eld s ignal c hann el and

fault st atus. This versatile back-lighted displ ay system pr ovides a ser vic e tech nici an with

both detail ed informat ion regard ing c abinet voltag es, config uration , and st atus, and at the

same time an easily read field signal status display showing full intersection status.

1.2.2 MENU DRIVEN OPERATION

The Displ ay, Program, and Help modes of the MMU-16LE SmartMonitor

using a simpl e menu dri ven us er interf ace. Th e menu pr ovides an organ ized sch eme f or

displ aying both curr ent st atus as well as r evi ewin g hist oric al f ault s tatus . I t als o p r ovid es a

mechani sm for setti ng and revi ewing the m onitor enhanced-f eature pr ogramming wit hout

the need for a laptop computer.

1.2.3 CONTEXT SENSITIVE HELP SYSTEM

The built-in Help s ystem provi des operational guid ance as well as troubl e shooting ad vice

to both the novice and expert technician. The front panel HELP button presents the

requested information on the main LCD depending on the display page and context

currently selected.

From start to finish, a technician can use the Set-up W izard t o accurately and quickly

configure the monitor, and then use the Diagnostic W izard to analyze the cause of a

malfunction without the need for understanding complex monitor terminology and theory.

1.2.3.1 SET-UP W I ZARD

The built-in Set-u p W izard (se e Sect ion 6.3.14) c onfigures the monitor enh anced-feature

program ming usi ng a simp le ser ies of int ers ection rel ated qu estions . It all ows a tech nician

to accur ately and comp letely progr am the MMU-16LE SmartMonitor

without the need for understanding the complexities of monitor enhanced configuration

parameters.

1.2.3.2 DIAGNOSTIC WIZARD

The built-in Diagn os tic Wizard (see Section 3.10) is an in tegral p art of t he Help Syst em t h at

provides detailed diagnostic information regarding the fault being analyzed. The Wizard

provid es a conc ise view of th e signal states involved in th e fault, pinp oints faulty sig nal

®

series Malfunction Management Unit (MMU) is a devic e

®

also pr ovid es err or s ensin g of t wo +24V dc c abi net

®

uses a pr ogr amm able al pha-numeric Liquid Crystal Display

®

are controlled

®

en hanced f unctions

Eberle Design Inc. Page 1

Page 8

MMU-16LE SmartMonitor

Operati ons M an ual

inputs, and provides guidance on how the technician should isolate the cause of the

malfunction.

1.2.4 PROGRAM CARD MEMORY

All monit or enhanc ed-f eatur e progr am min g is s tor ed in a n onvol atil e m emor y cont ai ned on

the EDI P rogram C ard. W hen repl acing th e MMU-16LE SmartMonitor

®

for s erv ic e or tes t

purposes, all Nema standard and enhanced-feature programming is automatically

transferred to the replacement unit when the EDI Program Card is inserted. The EDI

Program Card is c ompletel y com patibl e with other MMU mod els c ompliant with t he Nema

TS2-2003 Standard.

The Program Card Memory fun ct i on must b e enabled bef ore us e. The factor y default

setting is Off. See S ect ion 6.3.4.6.

1.2.5 RMS VOLTAGE REPORTING

Input voltages are measured using a true Root Mean Squared (RMS) technique. A

dedicated D igital Sign al Processor (DSP) RMS-Engine

hardware which samples each AC input voltage a minimum of 32 times per cycle. The

RMS-Engine

®

th en calc ulat es the tr ue RMS vol tag e valu e produc in g accur ate res ults which

®

c ontr ols th e anal og to di git al (A/D )

are very insensitive to changes in frequency, phase, wave shape, and distortion.

1.2.6 ECCOM SOFTWARE INTERFACE

The field proven EDI ECcom Signal Monitor Comm unicati ons softwar e pr ovides a lapt op

computer or system interface to all information contained in the monitor. This includes

detailed status, voltages, configuration, as well as historical event logs, and five thirty

second Signal Sequence logs.

Event logs provid e a historical r ecord of previous fault data, ac line ev ent data, moni tor

reset events, and c onfiguration programming change events. These logs are invaluable

when anal yz ing fault d at a t o diag n os e c abinet equ ip m ent malfunct i on s .

The Signal Sequenc e logs provide a graphical display of the signal states of all sixteen

chann els f or up t o thirt y sec onds pri or to t he f ault tr igg er poi nt at 50 mi llis econ d r esolu tion.

The MMU-16LE SmartMonitor

®

stores these signal records for the last five fault events.

Th e E D I E C com s oft w ar e (Ver sion 3. 5.8 or gr eat er is requ ired) is av ailabl e at no charg e

from the EDI web site at www.EDItraffic.com.

1.2.7 NEMA TS-1 O PE RAT ION WI TH S DL C MODE

Th e M MU -16LE SmartMonitor

advantages of the Port 1 SDLC communications to the Controller Unit including Field

Check m onitoring and the Diagnostic Wizard. In this mod e th e MMU-16LE SmartMonitor

®

can operate in a N em a TS-1 c onf igured cabinet wit h th e full

®

channel displays operate in the twelve channel configuration displaying the Walk input

status dir ectl y on the ass ociat ed veh icl e chann els. Cer tai n programming requ ir ements exist

but typically n o c abin et w ir i ng m odifications are necessar y. See Secti on 1.4.2.1.

1.2.8 FLASHING YELLOW ARROW (FYA) PROTECTED-PERMISSIVE MOVEMENT

®

The MMU-16LE SmartMonitor

is designed to monitor an intersection with up to four

approac hes usi ng th e f our s ecti on Flas hing Yel low A rrow ( FYA) movement outlined b y the

NCHRP Research Project 3-54 on Protected/Permissive signal displays with Flashing

Yellow Arrows. T wo cabin et config urations are supp orted for both the MMU Type 16 and

Ty p e 1 2 modes depending on the number of load switches provided and the capabilities of

the Controller U nit. In both modes the MMU-16LE SmartMonitor

®

has been designed to

provid e the s ame b r oad f ault c over age f or t he FYA app roac hes as it d oes f or con venti on al

protected left turn phases incl udin g Confl ict, R ed F ail, D ual Ind icati on, and both Minim um

Yellow and Minimum Yellow Plus Red Clearance monitoring. See section 3.11 for

programming information.

Eberle Design Inc. Page 2

Page 9

MMU-16LE SmartMonitor

Operati ons M an ual

1.2.9 FIVE SECTION ARROW SUPPRESSI ON PR OTECT ED-PERMISSIVE MOVEMENT

(PPLT5)

®

The MMU-16LE SmartMonitor

approac hes usin g the five section PPLT5 Arrow Suppression movement. Th e MMU -16LE

SmartMonitor

®

has been designed to pr o vi de the same br o ad fault c ov er age f or th e PPLT5

is designed to monitor an intersection with up to four

Arrow Suppression approaches as it does for conventional protected left turn phases

including Conflict, Red Fail, Dual Indication, and both Minimum Yellow and Minimum

Yellow Pl us Red Clear ance monit oring. N ote that this mode is n ot intended f or a basic

Protec t ed / Permis s i ve “doghouse” s t yl e s ig nal approach where th e Ball sect i on is i ntended

for the thru vehicle phase. See section 3.12 for programming information.

1.3 GENERAL

®

The MMU-16LE SmartMonitor

is nor mally c onfigured as a 16 chann el (Type 16) m onitor

when oper ated in a TS2 type c abinet ass embly. Th e Type 16 MM U mode is in tended for

those applications in which there are thr ee circuits per channel and the MMU channels

have been wired in a one-to-one correspondenc e with the load switches, as defined in

Section 5. 5.3 par agraph 9 of th e NEMA Standar ds Pu blication T S2-2003 v02.06, Traffic

Controller As semblies With NTCIP Requir ements. Each c hannel has the c apability of

monitor ing a Green (W alk), a Yell ow, and a Red ( Don’t Walk) f ield signal output at the

Terminals and Facilities field terminals.

®

The MMU-16LE SmartMonitor

c an al s o be c onf igur ed as a 12 c ha nnel (T ype 12) m onit or

when operated in a NEMA TS1 type cabinet assembly. The Type 12 MMU mode is

intend ed to provi de downw ard compat ibilit y with 12 chan nel Confl ict Monit or Units (C MU)

conf orming t o NE MA T raf fic Contr ol S yst ems P ublic at ion T S1-1989. Each channel has the

capability of mon itoring a Green, a Yel low, a Red, and a W alk field sign al output at the

Terminals and Facilities field terminals.

A Program Card is provided for assigning permissive channels. The MMU-16LE

SmartMonitor

®

det ects the presenc e of conflict ing Green or Yel low ( or Walk) field si gnal

inputs b etween an y two or more ch annels n ot assigned t o be perm issive on th e Program

Card. Th e RED ENA BLE inp ut, wh en activat ed, enables th e Red Fa il Monit oring f unctions

of the un it causing t h e m onitor to trigg er w h en i t d et ects the absence of vol t ag e on all thr e e

(four) of the field signal inputs of a channel. It also enables the Minimum Yellow

Change/Red Cl e arance M onitoring f u nc t i on wh ic h verifi es th at the Yell ow C hange plus Red

Clear anc e interval b etween th e end of an active Gr een sign al and the begi nnin g of the next

conflic ti ng G reen s ig n al is proper. The m oni t or in g c ir c u itry is capabl e of det ect ing eit h er full

wave or positive and negative half-wave sinusoidal field signal inputs at the specified

voltage levels.

When tri ggered b y the det ecti on of a fault condit ion whic h exist s long er than th e minim um

period defined by the NEMA Standards Publication TS2-2003 v02.06 the MMU-16LE

SmartMonitor

®

will enter the f ault mode causing the OUTPUT relay to de-energi ze and t wo

sets of cont acts on the OU TPUT rel ay to tr ansf er. Th e cabi net ass embl y shou ld be wired

such th at the clos ure of th e OUTPUT relay cont acts wil l cause an automat ic switc hing of

the field signal outputs from normal operation to flashing operation. The MMU-16LE

SmartMonitor

reset the fau l t mode of t he OUTP UT r ela y co n ta cts. I n the e vent of AC LI NE los s t he MMU16LE SmartMonitor

®

will th en display th e appropriat e fault status. The los s of AC LINE will not

®

will ret ain the st atus of al l f ault and chan nel in di cators and w ill dis pl ay

the correct fault and channel status upon restoration of AC LINE.

When op erating in t he Type 16 m ode and c onnected t o a TS2 Con troller U nit, the MMU-

16LE SmartMonitor

the Con troller Unit i n real tim e using Port 1. Messages are define d in the TS2 St andard

which all ows t he Contr oller Un it and th e MMU-16LE SmartMonitor

checks on each other. The Controller Unit has access to all MMU-16LE SmartMonitor

®

has t he abi lity to exc hange inf ormation in a st andardi zed format with

®

to perf orm redu ndant

®

inform ation including fi eld signal inp ut status, p ermissive pr ogramming, and fault st atus.

This gi ves the Con troller Unit t he capab ility to pr ovide a bac kup monit oring funct ion and

Eberle Design Inc. Page 3

Page 10

MMU-16LE SmartMonitor

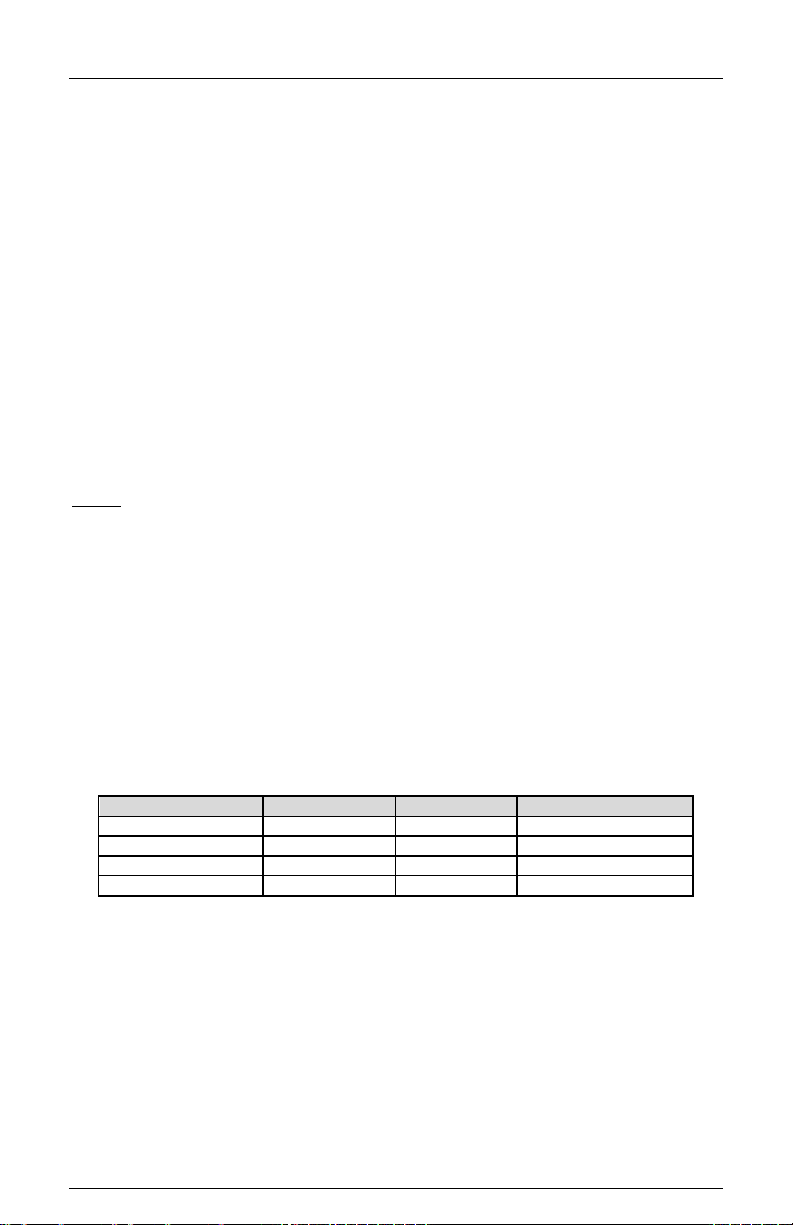

LEDguard

®

Green/Walk

Yellow

Red/Don’t Walk

Conflict

Low

Low

---

Red Fail

High

High

High

Dual Indicati on

Low

Low

Low

Clearance

Low

Low

High

Operati ons M an ual

make enhanced event logging, remote intersection monitoring, and remote diagnostics

feasible. Similarly, the MMU-16LE SmartMonitor

Unit whic h corr esponds to the C ontroll er Uni t output c omman ds to t he load s witches. T his

allows the MMU-16LE SmartMonitor

The TS2 St andar d als o provides f or mess ages t o be gener ated b y the Contr oller U nit and

the MMU-16LE SmartMonitor

®

to better respond to and diagnose fault situations.

®

which ext end th e c ommun ic ati ons cap abil ities of a st andar d

assembl y. T he Eber le Des ign MMU-16LE SmartMonitor

®

rec eives inf ormation f rom the Contr oller

®

us es t hes e m ess a ge f aci li ti es t o

provid e enh anced appl icati on sp ec if ic diagnostic r ep or ti ng an d m onitori ng.

1.4 FIELD SIGNAL TERMINALS

A GREEN , YE LLOW, or W ALK f ield sig n al inpu t wil l be s ens ed as acti ve by th e MMU -16E

SmartMonitor

®

wh en it exceeds t h e G reen, Yell ow , or Walk Signal D etect voltage t hreshold

(Section 8.1.2) and a field signal input will be sensed as inactive when it is less than the

Green, Yellow, or W alk Signal N o-Detect voltag e thresh old (Section 8.1.2). Both p ositive

and negative half wave rectified inputs will be sensed.

A RED (DO N’T W ALK) f i eld sig nal i nput will be s ens ed as acti ve b y t he M MU-16E when it

exceeds the Red Signal D etect voltage thr es hold (Section 8.1.2) and a field signal input will

be sensed as inactive when it is less than the Red Signal No-Detect voltage threshold

(Section 8.1.2). B ot h p ositive and n egative h alf w ave r ectifi ed inp uts wi ll be s ensed.

NOTE:

When the circuit connected to the sensing input of an MMU exhibits high

impedance char acteristics such as caused by dimmers, burned out lamps, low wattage

equipm en t, or n o load , it m ay b e necess ary to pl ace a low imp ed ance devic e ext ernal to th e

unit betw een the M MU input and AC NEUT RAL (See S ecti ons 5.5.3 .9 and 6.2 .4 of NEMA

Standards Publication TS2-2003 v02.06, Traffic Controller Assemblies With NTCIP

Requirements).

1.4.1 LEDGUARD® LED FIELD SIGNAL SENSING

®

The Eberl e Design MMU-16LE SmartMonitor

LEDguard

®

that is designed to better monitor the characteristics of LED based signal loads

c an be configured t o us e a t ec h niq u e called

(See S ection 6.3.4.7). E ach field si gnal inpu t is measur ed and co mpared to both a high

threshold and a low threshold value to determine On / Off status. This differs from

conventional stand ard Nema op eration wher e the active thr eshold is picked accor ding to

th e color of t he f ield signal. Once the high and low On / Off thresholds (Section 8.1.2) have

been det ermined us ing th e inp ut RMS vol t age, the in di vi dual f ault m onitor func ti ons use th e

appropriate threshold to determine if a fault condition exists.

1.4.2 TYPE SELECT INPUT

®

The MMU-16LE SmartMonitor

will op erate as a Type 16 mon itor with sixt een channels

when th e TYPE SE LECT input is a logic True (low ). The MMU-16LE SmartMonitor

operat e as a T ype 12 monit or with tw elve chan nels when t he TYPE SE LECT inp ut is a

logic False (high) or open circuit.

Type 16 - Each channel has three inputs: RED (DON’T WALK), YELLOW, and

GREEN (WALK).

Type 12 - Each channel has four inputs: RED, YELLOW, GREEN, and WALK.

®

The MMU-16LE SmartMonitor

is nor mally c onfigured as a 16 chann el (Type 1 6) monit or

when op er ated in a T S 2 typ e c abin et ass embl y. T he T ype 12 mod e is int end ed to pr ovid e

downw ard c ompati bi lity wit h 12 c han nel C onflic t M onitor Unit s (CMU ) c onf ormin g to NE MA

Eberle Design Inc. Page 4

®

will

Page 11

MMU-16LE SmartMonitor

Ped Phas e

MMU Channel

Phase 2 Ped

13

Phase 6 Ped

15

Phase 8 Ped

16

Operati ons M an ual

Traff ic Control S ystems Pu blicati on TS1-198 9. Wh en operatin g in the T ype 12 mode, the

MMU-16LE SmartMonitor

®

monitor ing f unct ions are th e sam e as the T ype 16 m ode exc ept

that Por t 1 com munic ations are dis abl ed and Fiel d Ch eck Mon itori n g is dis abled. See als o

TYPE 12 MODE WITH SDLC Option, section 1.4.2.1.

1.4.2.1 TYPE 12 WITH SDLC MODE

®

Th e M MU -16LE SmartMonitor

advantages of the Port 1 SDLC communications to the Controller Unit including Field

Check mon itori ng. In this mod e the MMU-16LE SmartMonitor

can operate in a N em a TS -1 config ured cabinet with t h e f ull

®

ch ann el displays op erate in

the Type 12 configuration displaying the Walk input status directly on the associated

vehicle channels (2, 4, 6, and 8). Certain requirements exist for this mode to operate

correctly:

1. T hi s m od e is li mi te d t o a ma xi mu m of f ou r P ed ph as es which mus t be assigned

to vehicl e phases 2, 4, 6, and 8. Th e Walk field t erminals must be wi red to th e

MMU-16LE SmartMonitor

®

channel inputs 2W, 4W, 6W, and 8W on MMU

connector pins MSA-y, MSA-FF, MSA-EE, and MSA-u respectively. This is

conventional wiring for a standard Nema TS-1 cabinet. MMU input TYPE

SELECT (pin #HH) must be “open circuit” (False).

2. The C ontrol ler Unit (CU) must be TS-2 Type 2 capabl e and provi de th e Port 1

EIA-485 c ommunic ations port. T he C ontroller Unit must b e config ured f or MM U

operation in the following areas (terminology and procedure may vary with

different brands of CU):

a. Enable the MMU in the CU Port 1 setup.

b. Add the Ped channels to the CU ring structure with the following

assignments:

See Section 6.3.4.9 for the T ype 12 wit h SD LC op tion setti n g.

Eberle Design Inc. Page 5

Phase 4 Ped 14

c. The CU Signal Driver Output mapping may need to be modified to

ensure that the CU is still driving the Ped load switches from the

correct output pins: MSA-J (2W), MSB-d (4W), MSC-LL (6W), and

MSC-d (8W).

3. TS-2 Controller Units provide an MMU utilization diagnostic that verifies the MMU

Program Card c hannel comp atibility to th e CU Driver Group U tilization (Nema

TS-2 clause 3. 9.3.1. 3). Depen din g on the CU capab iliti es, jum pers m ay need t o

be add ed t o t h e MM U -16LE SmartMonitor

®

Program C ar d p ermissi v e m atrix as i f

the Walk inputs were actually assigned to MMU channels 13 (2P), 14 (4P), 15

(6P), and 16 (8P).

®

Not e t h at t h e MMU -16LE SmartMonitor

will only use th e chann el 2, 4, 6, and 8

jumper pr ogramm ing for act ual conf lict detecti on. Pr ogram Card j umpers added

to channels 13, 14, 15, and 16 i n t h e Type 12 With SDLC m ode are only used by

the MM U -16LE SmartMonitor

®

t o s atis fy the ut i li z ation diagnost ic of the controll er

unit desc rib ed above.

4. A pr oper Port 1 EIA-485 r ated cable must b e connec ted b etween t he CU Por t 1

and the MMU-16LE SmartMonitor

®

Port 1.

Page 12

MMU-16LE SmartMonitor

Operati ons M an ual

1.4.2.2 FORCE TYPE 16 MODE

If the cab inet is alr eady wir ed for 16 channel operati on but the T YPE SELE CT inpu t is not

acces s i b l e du e t o c a bi n e t w ir i n g is s u es , t h e MM U -16LE SmartMonitor

®

can be forced t o the

Type 16 m od e by sett in g t h e F O RC E TYPE 1 6 opt ion in U nit Options. See Sect ion 6.3.4.8.

The FORCE TYPE 16 mode is not compatible with the TYPE 12 WITH SDLC mode

(section 1.4.2.1).

Eberle Design Inc. Page 6

Page 13

MMU-16LE SmartMonitor

Operati ons M an ual

Section 2

Standard Functions

2.1 CONFLICT MONITORING

When volt ages on any conf licting ch annels are sensed as acti ve for more th an the C onflic t

Fau l t t i m e ( S ection 9), th e MMU-16LE SmartMonitor

OUTPU T relay cont acts to t he Fault position, and display t he CONFLICT status s creen.

The MMU-16LE SmartMonitor

®

will remain in the fault mode until the unit is reset by the

RESET but t on or the EXT ER N A L R ESET input. When volt ag es on any conflicting channels

are sensed as active for less than the Conflict No-F ault ti m e, the MMU-16LE SmartMonitor

will not transfer the OUTPUT relay contacts to the Fault position.

®

The MMU-16LE SmartMonitor

is f ull y pr ogramm ab l e an d requir es the us e of soldered w ire

jumpers on an int erc h angeable Programming Card to defi n e p ermissive chan nel pair s . The

Program m in g Card is used wit h b oth Type 16 and T yp e 12 op er at i on. See Sec t i on 6.2.1 for

Programming Card details.

2.2 RED FAIL MONITORING

When volt ages on all inputs (G, Y, R, (W )) to a chann el are sens ed as in active f or more

than the R ed Fail F ault ti me (S ection 9), t he MMU-16LE SmartMonitor

mode, transfer the O UTPUT r elay contacts to th e F au lt p osi tion, and display the R ED F AIL

status s cr een. T h e MMU-16LE SmartMonitor

reset by t he RESET button or t h e EXT ER NAL RE SE T inp ut . When v oltages on all inputs t o

a chan nel are s ens ed as in act ive f or l ess th an t he R ed Fail N o-Faul t ti me, th e MMU-16LE

SmartMonitor

®

will not transfer the OUTPUT relay contacts to the Fault position.

Red Fail M on it or i ng wi ll b e d isabled when th e R ED EN ABLE inp ut is n ot ac t i ve. In the T yp e

16 mode, R ed Fail M onitori ng will also be dis abled if the LOAD S WIT CH FLAS H bit is s et

to "1" in the Type 0 message from the Controller Unit.

Programming is provided in the SET / VIEW CONFIG menu item to enable Red Fail

Monitor ing on a per ch ann el b as is . See Section 6.3.3 for the program mi ng pr oc edure.

2.2.1 RED ENABLE INPUT

The RED ENA BLE in put will be sens ed as activ e by the MMU-16LE SmartMonitor

exceeds the Red Enable Input threshold (Section 8.1.2). The presence of the proper

operatin g voltag e at this input enab les Red Fai l Monitori ng, Minimu m Yellow Ch ange/Red

Clear ance Monitorin g, and Dual Ind icati on Monitori ng. I n the T ype 16 mod e, if the LO AD

SWITCH FLASH bit is set t o "1" in the T ype 0 mess age fr om the Contr oll er Unit, R ed Fail

Monitor ing will be disabled.

The main status screen will display “RED ENAB LE IS OFF” if the RED ENABLE input is not

active. I n the Typ e 16 mode, if the LOAD SWIT CH FLASH bit is set t o "1 " in t h e Ty pe 0

message fr om the Controll er Unit, the main status screen will display “CU LS-FL ASH i s

SET”.

2.2.2 WALK DIS A BLE O PTIO N

This opti on wi ll mod if y the oper ati on of R ed Fail an d Du al Indic at ion M onitor in g in the TS -1

Type 12 mode onl y. When en abled, t he Red F ail and D ual Indic ation Moni toring f unction

will not monitor t he W alk field outputs. Absenc e of sig nals on th e Gr een, Yell ow, and R ed

field outp uts of a channel will pl ace the MMU-16LE SmartMonitor

mode causing t h e O u tp ut r elay con tacts t o tr ansf er. Pr esenc e of active si gnals on t h e Walk

outputs will n ot caus e a Dual In dic ation w hen c oncur rent with acti ve Red or Yel low sign als.

This f unction is en abled by th e Unit Opti on called "W ALK DISABLE" in the SET / VIEW

CONFIG m enu. See Section 6.3.4.2.

®

will enter the faul t mod e, tr ansf er th e

®

will ent er the f ault

®

will r emain in t he f ault mod e un til th e un it is

®

when it

®

int o the Red Fail f ault

®

Eberle Design Inc. Page 7

Page 14

MMU-16LE SmartMonitor

Operati ons M an ual

2.3 VOLTAGE MONITORING

2.3.1 +24VDC SUP PLY MONITORING

The +24V MONITOR I and +24V MONITOR II inputs are provided for monitoring two

+24Vdc su pplies in the c abinet assem bly. Shou ld loss of proper voltage occur at ei ther of

these inputs , th e MMU-16LE SmartMonitor

relay contacts to the Fault position, and display the appropriate 24V-1 or 24V-2 status

screen. The MMU-16LE SmartMonitor

correct inp ut voltages are restored to both of thes e inputs. The MMU-16LE SmartMonitor

®

will enter th e fault m od e, transf er the OUTPUT

®

will automatically reset the OUTPUT relay when the

®

will remain in the fault mode for at least the time determined by the Minimum Flash

programming.

A voltage gr eater than th e +24V M onit or input t hres hold (S ection 8.1.4) appli ed to bot h of

the +24V MON ITOR in puts will b e sens ed b y the MMU-16LE SmartMonitor

®

as adequ ate

for operation of the cabinet assembly. A vol tage less than t he +24V M onit or input thres hol d

applied t o either of the +2 4V MONITOR inp uts will be sens ed as inadequ ate for pr oper

operati on. W h en a +24V MON ITO R inp ut is s ens ed as inad equ at e for mor e th an the +24V

Monitor F aul t tim e (S ecti on 9), th e MMU-16LE SmartMonitor

®

will ent er the f ault mod e and

transfer the O UTPUT r elay cont ac t s t o t h e F aul t p os ition. When a + 24V MON ITOR i np ut is

sensed as inadequate for less than the +24V Monitor No-Fault time, the MMU-16LE

SmartMonitor

®

will not t rans fer t he OUT PUT r elay c ontac ts t o th e Fault p ositi on. A + 24Vdc

failure dur ing the progr ammed Minimu m Flash time or duri ng an MMU Power Fail ure will

not cause a fault condition.

2.3.1.1 +24VDC MONITOR INHIBIT INPUT

A +24V MON ITOR INH IBIT inp ut is pr ovi d ed t o inhib it t he oper ati on of t h e + 2 4Vdc M onitor.

Applic ation of a l ogic T R U E ( l ow) s t at e t o th i s in pu t will disable th e op erati on of th e +24Vdc

Monitor.

2.3.1.2 +24VDC MONITOR LATCH INPUT

A jumper p osit ion is supp lied on the Pr ogr ammi ng C ard t o allow +2 4 Vdc f ailur es to l atch in

the fault condition until the unit is reset by the activation of the RESET button or the

EXTERNA L RESET input. See Section 6.2.4 for the programm ing procedure. A +24Vdc

failure dur ing the progr ammed Minimu m Flash time or duri ng an MMU Power Fail ure will

not cause a latched fault condition.

2.3.1.3 +24VDC MONITOR II 12VDC MODE

®

The MMU-16LE SmartMonitor

offers th e capabilit y of setting t he threshol d for the +24V

MONITO R II inpu t to l evels suit able f or monitor ing a 12 V dc pow er sup ply. This mode is

enabled by the Unit Option call ed " 24V-2 = 12 V dc " in the SET / V IE W CONFIG menu. See

Section 6.3.4.5.

2.3.2 CONTROLLER VOLTAGE / FAULT MON ITOR INPUT

This input is to be connected to the CONTROLLER UNIT VOLTAGE MONITOR (CVM) or

FAULT MONITOR (FM) output from the Controller Unit. W hen the TRUE (low) state is

absent for more than the C VM Fau lt tim e (Section 9), the MMU-16LE SmartMonitor

®

will

enter the f ault mod e, tr ansf er the OUT PUT r elay c ontacts t o the Fau lt p ositi on, and display

the CVM status screen. When the T RUE (low) s tate is abs ent for less than t he C VM NoFault time, t he MMU-16LE SmartMonitor

the Fault position. The MMU-16LE SmartMonitor

relay wh en th e Tru e (low ) st ate is r estor ed t o the in put. The MMU-16LE SmartMonitor

®

wil l not tr ansfer t he OUTP UT relay c ontacts to

®

will automatically reset the OUTPUT

®

will

remain in the fault mode for at least the time determined by the Minimum Flash

programming. A CVM failure during the programmed Minimum Flash time or during an

MMU Power Failure will not cause a fault condition.

Eberle Design Inc. Page 8

Page 15

MMU-16LE SmartMonitor

Operati ons M an ual

2.3.2.1 CVM MONITOR LATCH INPUT

A jumper position is supplied on the Programming Card to allow CVM failures to latch in the

fault condition until the unit is reset by the activation of the RESET button or the

EXTERNAL RESET input. See Section 6.2.4 for the programming procedure. A CVM

failure d uring th e progr ammed Minimum F lash time or duri ng an MMU Power Failur e will

not cause a latched fault condition.

2.3.2.2 CVM LOG DISABLE

If CVM even ts ar e not relat ed to a malf unc ti on con diti on an d occur on a reg ular basis suc h

as Time of Day flash, the logging of these events can be disabled. See Section 6.3.4.3.

2.4 LOCAL FLASH STATUS INPUT

This inp ut is to be c on n ect ed to th e Auto/Fl as h s w itc h in t h e cabinet. When th e TR U E (low)

state is present for more than the Local Flash Fault time (Section 9), the MMU-16LE

SmartMonitor

position, and display the LOCAL FLASH status screen. W hen the TRUE (low) state is

present f or less th an th e L oc al Fl as h No-Fault tim e, the MMU-16LE SmartMonitor

tr ansf er the OUTPUT relay contacts to the Fault position. The MMU-16LE SmartMonitor

will aut omaticall y r eset th e OUTPUT relay when th e False (hig h) state is r estored to th e

input. The MMU-16LE SmartMonitor

®

wil l enter th e fault mode, tr ansfer th e OUTPUT relay c ontacts t o the Fault

®

will not

®

will r emain in the fault mode f or at least th e time

®

determined by the Minimum Flash programming. A Local Flash condition during the

Minimum Flash time or during an MMU Power Failure will not cause a fault condition.

2.5 MINIMUM YELLOW CHANGE / RED CLEARANCE MONITORING

2.5.1 MINIMUM YELLOW CHANGE INTERVAL

®

The MMU-16LE SmartMonitor

will verif y that the Yellow C hange interv al is at least the

Clear ance Fail F ault ti me (S ection 9). The Y ellow Ch ange int erval c onsis ts of th e durati on

of time in which the Yellow field signal input is active in a sequence from Green to Yellow to

Red. W hen this min imum int erval is not satisfi ed the MMU-16LE SmartMonitor

®

will ent er

the fault m ode, trans fer the O UTPUT relay contac ts to the F ault positi on, and display the

SKIPPED Y CLEARANCE or SHORT Y CLEARANCE status screen. The MMU-16LE

SmartMonitor

®

will r emai n in th e fault mode u ntil th e unit is res et by th e RESET butt on or

the EXTERNAL RESET input.

Minimum Yellow Change Monitoring will be disabled when the RED ENABLE input is not

active.

2.5.1.1 MINIMUM YELLOW CLEARANCE DISABLE

A set of s older ed wir e jum pers is pr ovided on the P rogr amming C ar d to dis able Minimum

Yellow Ch ange Mon itorin g on a per ch annel bas is. See Sect ion 6.2.3 for th e pr ogram min g

procedure.

2.5.2 MINIMUM YELLOW PLUS RED INTERVAL

®

The MMU-16LE SmartMonitor

will verify that the Yellow Change plus Red Clearance

interval bet ween t h e end of an ac tive G reen ( or W alk) si gnal and th e b eginn ing of th e next

conflic ting G reen ( or W alk) sig nal is at leas t t he Clear anc e F ail F ault t i m e ( S ecti on 9). This

ensures a minimu m clearance int erval for channels without a true yellow sign al such as

pedestrian channels. When this minimum interval is not satisfied the MMU-16LE

SmartMonitor

position, and display the SHORT Y+R CLEARANCE status screen. The MMU-16LE

SmartMonitor

®

wil l enter th e fault mode, tr ansfer th e OUTPUT relay c ontacts t o the Fault

®

will r emai n in th e fault mode u ntil th e unit is res et by t he RESET butt on or

the EXTERNAL RESET input.

Yellow C hange plus Red Clear ance Monit oring will be disabl ed when the R ED ENABL E

input is not active.

Eberle Design Inc. Page 9

Page 16

MMU-16LE SmartMonitor

Operati ons M an ual

2.5.2.1 MINIMUM YELLOW PLUS RED CLEARANCE DISABLE

The Red + Yell ow Clear anc e Disabl e Conf igur ation sc reen is provi ded in t he SET / VIEW

CONFIG menu to disable Minimum Yellow Plus R ed Chang e Monitori ng on a per channel

basis. Provision to disable this function is not provided for in the NEMA Standards

Publication TS2-20 03 v 02. 06.

The MUTCD Sectio n 4D.10 Yell ow Change a nd Red Clear ance Inter vals requirement

states, “ A yellow s ig nal indication s h all b e display ed foll owing every CIR CU LA R G R EE N or

GREEN A RROW s ignal indic ation”. I n some leg acy inters ection cas es this requir ement is

not met due t o th e lac k of a Yell ow s ign al head on an overl ap phase (ch annel) , and signal

timing th at precludes what would nor mally be the over lap clearanc e interval. I n this c ase

the Minimum Yellow Plus Red Clearance monitoring function can be disabled for that

channel. It should be noted that the Minimum Yellow Plus Red Clearance monitoring

function is only intended to be disabled under these special conditions.

See Sect i on 6.3.7 for t he pr ogr amm ing proc edur e. The default setting for Minimum Yellow

Plus Red Clearance monitoring is Enabled.

2.6 MMU POWER FAILURE DETECTION

W h en the AC LINE voltage is below the minimum AC Line drop-out l ev el (Section 8.1.3) for

the MMU Power F ail Respond t i m e (S ecti on 9), the MMU-16LE SmartMonitor

®

will s us p end

all fault m onitor ing func tions, de-en ergize t he OUTPU T rel ay, and d e-en er gi z e th e S TA RT

relay. Th e POW ER indicator on t he front p an el will fl ash at a rate of 2Hz t o indicate the low

voltag e status. The main st atus displ ay will indicat e “AC LI NE BROWN OUT” and displ ay

the curr ent AC Li n e input volt ag e.

When th e AC LINE vol tage returns above the maximu m AC Line r estor e lev el (Section

8.1.3) for t he MMU Pow er Fail Rest ore time (S ection 9), the monitor will r esume nor mal

operation and the POWER ind ic ator on th e fr ont pan el will rem ain il lum inat ed. Aft er a 2.0 +_

0.5 second delay the START relay will be energized. After a programmable delay

determined by the Minimum Flash programming, the OUTPUT relay will be energized (see

Section 6.2.2).

This expanded operating voltage range for cabinet components allows the MMU-16LE

SmartMonitor

orderly manner when th e AC LINE volt age is suff icient for proper operation. The MMU16LE SmartMonitor

®

to place the intersection into flash and return to normal operation i n an

®

sh ould be t he first c ompon ent in the c abinet t o sens e a low volt age

conditi on and th e l ast c om p onent to sense a proper AC LIN E op erating vol t ag e.

The AC LINE an d AC NEUT RA L inp uts ar e us ed t o gen erat e th e int ern al voltag e s uppl i es

requir ed t o oper at e the moni tor . AC N EU TR AL als o s erves as t he r etur n f or al l AC s ign als

including RED ENABLE. EARTH GROUND provides an independent connection to the

chassis of the unit and is isolated from AC NEUTRAL and LOGIC GROUND. LOGIC

GROUN D is provi d ed for in puts w hich are isolat ed f rom AC N EU T RAL ( i. e. +24V M onit or s ,

CVM, CONTROLLER W ATCHDOG, EXTERNAL RESET, and 24V MONITOR INHIBIT).

LOGIC GROUND may be tied to AC NEUTRAL if desired.

2.7 PORT 1 COMMUNICATIONS

When op erating in t he Type 16 m ode and c onnected t o a TS2 Con troller U nit, the MMU16LE SmartMonitor

®

has th e ability to exch ange infor mation in a stan dardiz ed format with

the Controller Un it using Port 1. For details on mess age formats refer to Secti on 3.3.1,

NEMA Standards Publication TS2-2003 v02.06, Traffic Controller Assemblies With

NTCIP Requirements.

The information transmitted from the Controller Unit to the MMU-16LE SmartMonitor

consist s of th e follow ing m essag e types : load s witch dri ver com mands (T ype 0), time and

date (Type 9). The information transmitted from the MMU-16LE SmartMonitor

®

to the

Control ler Uni t consis ts of t he foll owing m essag e types : field si gnal s tatus and fault s tatus

Eberle Design Inc. Page 10

®

Page 17

MMU-16LE SmartMonitor

Fault Type

Bit #

Nema Desi gnation

Field Ch ec k F ault / St at us

67

Spare Bit #1

RP Detection Status

69

Spare Bit #3

External Watchdog Fault

70

Spare Bit #4

Operati ons M an ual

(Type 129), channel compatibility programming (Type 131). The load switch driver

command (Type 0) and field signal status (Type 129) messages are exchanged

approxi m ately ever y 1 00 msec.

The electrical interface used for Port 1 conforms to the requirements of the Electronic

Industri es As soci ation EIA -485 Standard. It is designed for balanced digital multipoint bus

systems an d provides fu lly different ial signal oper ation. The baud r ate used is 153. 6K bit

per second. The Port 1 connector intermates with a 15 pin D type connector, AMP

Incorp orated part nu mber 205206-1 or equivalent. The Port 1 connect or pin assign ments

are shown in Section 10.6.

The data and clock communications protocol used for Port 1 is a subset of the

Synchr onous Data Link C ontrol (SDLC) Protoc ol, as defined by Internatio nal Busine ss

Machines Corporation Document GA27-3093-3 (June 1986). This protocol utilizes

sophisticated error checking computations to verify message integrity. In addition, the

Eberle Design MMU-16LE SmartMonitor

®

ad ds enh anc ed c ommunic at ions diag nost ics and

error handling capabilities to ensure proper communications occur.

2.7.1 PORT 1 TIMEOUT

When a T ype 0 messag e from the Con troller U nit has not b een corr ectly recei ved for the

Port 1 Timeout Fau lt time (Section 9 ), the MMU-16LE SmartMonitor

®

will enter t he f ault

mode, tr ansfer the O UTPUT relay contacts to the Faul t positi on, and display the PORT 1

FAIL status screen. When receipt of a Type 0 message again occurs, the MMU-16LE

SmartMonitor

®

will exit the fault state and transfer the OUTPUT relay contacts to the norm al

positi on, e xc ep t when three Por t 1 f aul ts h ave oc c urred in a c alen d ar d ay.

®

After t he thir d Por t 1 f ault i n a c alendar day, the MMU-16LE SmartMonitor

will remain in

the fault m ode unt il the unit is r eset b y the RESE T but ton or the EX T ERN AL RES ET inp ut.

Loss of AC Li ne after the th ird P ort 1 f ault wi ll exit the f ault st ate and res et the P ort 1 f ail

count to 2.

A PORT 1 timeou t failure dur ing the progr ammed Min imum Flash t ime or durin g an MMU

Power Failure will not cause a latched fault condition.

2.7.2 PORT 1 DISABLE INPUT

Port 1 communications will b e disabled when th e P O RT 1 DIS A B LE input is at a logic True

(low) st ate OR the TYPE S ELECT input is at a logic Fals e (high) stat e (Type 12 mode) .

Port 1 communic ations will be enabled wh en th e P O RT 1 DISA B LE i nput is at a l ogic F alse

(high) state AND the TYPE SELECT input is True (low) (Type 16 mode).

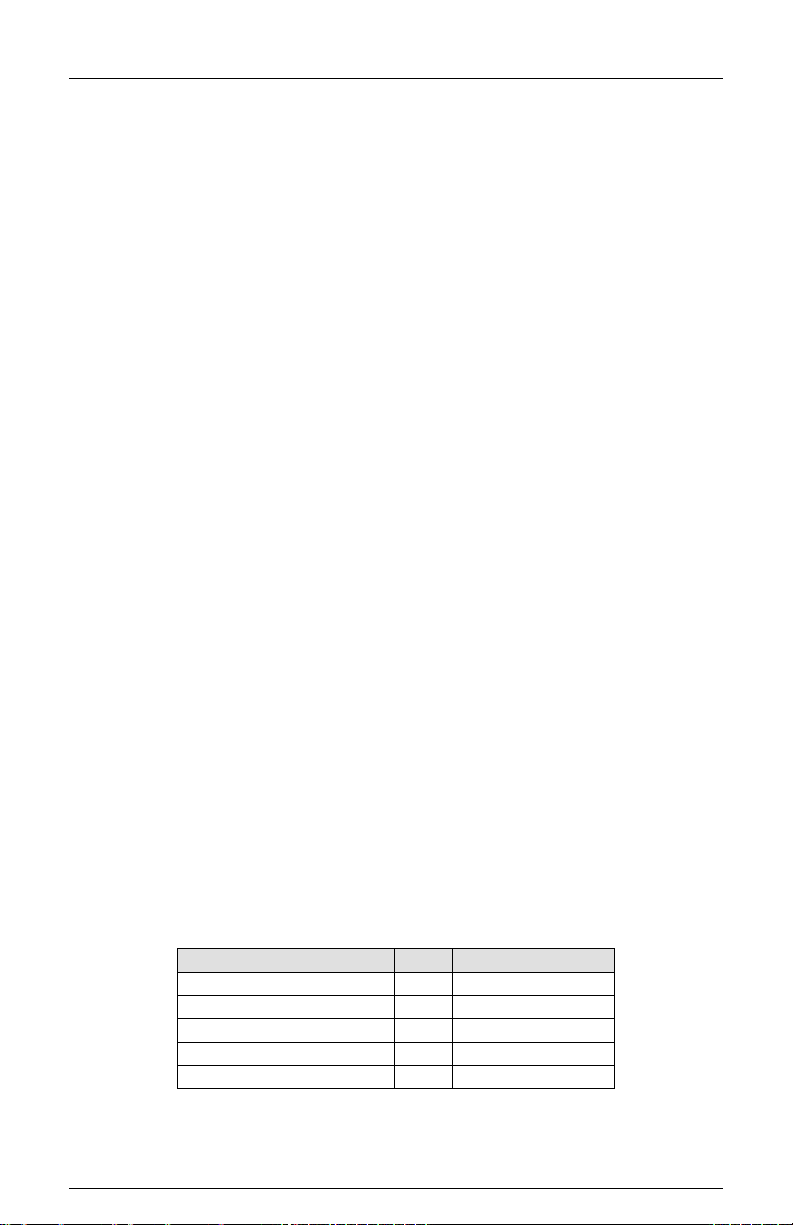

2.8 TYPE 12 9 RESPONSE FRAME

Five bits desi gnat ed as S p are Bi t #1 thr ou gh Sp are bi t #5 of the T ype 129 r espons e f ram e

to the Controller Unit are used by the MMU-16LE SmartMonitor

failure detected for enhanced fault monitoring capabilities of the MMU-16LE. Refer to

sections 3.9, 3.2, 3.7, 3.2.1, and 2.5.2 of this manual for further information.

Eberle Design Inc. Page 11

®

to i ndic ate t he ty pe of

Dual Indication Fault 68 Spare Bit #2

Yellow Plus Red Clearance 71 Spare Bit #5

Page 18

MMU-16LE SmartMonitor

Operati ons M an ual

2.9 OUTPUT RELAY RECOVERY

®

Prior to the MMU-16LE SmartMonitor

trans ferring the Output Rel ay c ontacts f r om the f ault

stat e to th e no-fault st ate, a tr ansition state w ith duration of 50 0 milliseconds will occur.

During t he transit ion state th e Output Relay wil l remain in t he fault s tate and th e Start-up

Flash Call bit in the Type 129 frame will be set to 1.

2.10 INTERNAL DIAGNO S TICS

®

The MMU-16LE SmartMonitor

capabilities whic h monitor for c orrect operati on of the MMU-16LE SmartMonitor

is su pplied with a r esident s eries of self ch eck diagn ostic

®

both at

power-up and continuously during operation. Should an internal diagnostic error occur,

other f ault indicat ors that may b e concurrent ly displayed with the DIAGNOSTIC indicator

may not be val i d du e to t h e nature of thes e h ar d w are an d/or firm w ar e failures.

2.10.1 MEMORY DIAGNOSTICS

®

On power-up, the MMU-16LE SmartMonitor

components including RAM, EPROM, and non-volatile EEPROM. During operation the

MMU-16LE SmartMonitor

volatile memory components. When either diagnostic test fails, the MMU-16LE

SmartMonitor

®

wil l enter th e fault mode, tr ansfer th e OUTPUT relay c ontacts t o the Fault

®

continuously performs a check sum verification of the non-

verifies the operation of all memory

positi on, and ill uminat e the DIAG NOSTIC i ndic ator. An MMU Power Failure will reset the

Diagnostic fault state of the monitor (see Section 2.6). Due to the nature of these

har dw are/ fir mwar e f ailu res, ot her f aul t ind ic ators th at may be c oncurrently d isplayed with

the DIAGNO STIC indicat or may n ot b e val id.

2.10.2 MICROPROCESSOR MONITOR

®

The MMU-16LE SmartMonitor

contains circuitry which monitors the operation of the

internal microproc essor. This monitoring c ircuit rec eives a logic transition s ignal fr om the

micropr ocess or ever y 5 msec. When th is logic trans ition is not rec eived f or 300 ms ec, th e

MMU-16LE SmartMonitor

®

will enter th e fault m od e, t r ans fer th e OUTPU T relay contac t s t o

th e Fault position, and illuminate the DIAGNOSTIC indicator. Due to the nature of these

hardw are/f irmware f ailures, oth er fault ind icators that may be conc urrently dis played wit h

the DIAGNO STIC indicat or may n ot b e val id.

This t ype of f ailur e is c onfigur ed as latch ing. I f the micropr ocessor resumes op eration th e

unit wil l not ret urn to nor mal op eration. With l atchin g operat ion, only a loss of AC Li ne will

restore operati on. I f non-latch ing operat ion is desir ed, internal jumper E1 ( Latching MPU

Fault) may b e r em o ved .

2.10.3 INTERNAL HARDWARE MONITOR

®

The MMU-16LE SmartMonitor

sections of the internal circuitry. Should a malfunction be detected, the MMU-16LE

SmartMonitor

®

wil l enter th e fault mode, tr ansfer th e OUTPUT relay c ontacts t o the Fault

cont ains circuitr y which verifies the oper ation of the many

position, and illuminate the DIAGNOSTIC indicator. An MMU Power Failure will reset the

Diagnos tic f ault st ate of the m onitor (s ee Sec tion 2.6). D ue to t he n ature of this hard ware

failure, other f ault indicators that may be c oncurrently displayed with the DIAGNOSTIC

indic ator m ay n ot b e vali d.

Eberle Design Inc. Page 12

Page 19

MMU-16LE SmartMonitor

Operati ons M an ual

Section 3

Enhanced Features

The following enhanced features are provided on the Eberle Design MMU-16LE

SmartMonitor

16LE SmartMonitor

3.1 HARDWARE FEATURES

The MMU-16LE SmartMonitor

functions and features are firmware programmable which permits upgrades or

modific ations b y simply reprogramming the Flash mem ory devic e contai ning th e firmwar e

with the upgraded version. Thus, most changes to the MMU-16LE SmartMonitor

specif ications m ay b e accommodated without modifying th e har d ware.

Since all critical timing functions are accomplished by the microprocessor, the quartz

crystal based accuracy results in very precise and repeatable measurements. This

accurac y is mai ntai ned on f uncti ons f rom timi ng faul t c onditions to imp lement ing a uniqu e

firmw are based digi tal sampli ng and filt ering alg orithm. This algorit hm is appli ed to all AC

field signals to help eliminate false detection in a "noisy" AC line environment.

Input voltages are measured using a true Root Mean Squared (RMS) technique. A

dedic ated mic rocontrol ler RMS-Engine

samples each AC input voltage at least 32 times per cycle. The RMS-Engine

calculates the true RMS voltage value, producing accurate results which are very

insensit i v e t o c hanges in frequ ency, ph as e, wav e s hape, an d d is tortion. V ol t a g e r efer e nces

are tem per atur e c ompens at ed f or c onst ant vol tag e lev els wit hin t h e op eratin g temper atur e

range.

A nonvol atile E EPROM device is utiliz ed to ret ain fault s tatus informat ion and event l ogs

through an A C Line pow er interr upti on. The corr ect fault indic ations wi ll be displ ayed up on

restor ation of A C Lin e pow er . This EE PROM d evic e requir es no batter y back-up. The time

of day in the MMU-16LE SmartMonitor

Should this battery fail, only current time of day and date information will be lost. No

monitor configuration programming is stored under battery power.

®

for additional monitoring functions and to increase the reliability of the MMU-

®

monit or op eration.

®

is a dual microprocessor based unit. All monitoring

®

cont rols th e analog t o digit al (A/D) hardwar e that

®

is stored in a b attery-backed real time clock circuit.

®

then

®

3.2 DUAL INDICATION MONITORING

In Type 16 m od e t his m on itoring f unc tion det ec ts s im ultaneous input c omb in at ions of act i v e

Green (Walk), Yellow, or R ed ( Don’t Walk) field sign al in pu ts on th e s am e c h ann el. In Type

12 mod e this m onit ori ng fu ncti on d et ects s im ultan eous in put c ombin ations of act iv e Gr een

and Yellow, Green and Red, Yellow and Red, Walk and Yellow, or Walk and Red field

signal inputs on the same channel. When voltages on any two inputs of a channel are

sensed as act ive for mor e than the Du al Indic ation F ault time ( Secti on 9), the MMU-16LE

SmartMonitor

®

wil l enter th e fault mode, tr ansfer th e OUTPUT relay contacts to the Fault

positi on, and display the DUAL INDICATION status screen. When operating in the Type 16

mode with Port 1 communications enabled, Bit #68 (Spare Bit #2) of the Type #129

response fram e w il l be set to indicate a Dual In dication fault h as been detect ed . The MMU16LE SmartMonitor

button or the EXT ERNAL RES ET input. W hen voltages on an y two inputs of a channel ar e

se n sed as acti ve for les s than the Dual Indication Fault time, the MMU-16LE SmartMonitor

®

will remain in the fault mode until the unit is reset by the RESET

®

will not transfer the OUTPUT relay contacts to the Fault position.

Dual In dicati on Monit orin g may an ticip ate and pr even t a poss ible c onflictin g sign al dis play

in the inters ecti on in the event that a pr oceed sig nal on th e curr ent ph ase h angs up and is

const antly det ected as active. A n open or no load c ondit ion (i. e., bur ned-out b ulb) m ay be

also det ected as an acti ve sign al dep endi ng on th e outp ut imp edanc e ch ar acteris tics of th e

load switch (i.e. load switch le ak ag e current), and may cause a Dual I ndication Fau lt .

Eberle Design Inc. Page 13

Page 20

MMU-16LE SmartMonitor

Operati ons M an ual

Programming f or Dual Indic ation is provided in th e SET / VIEW CONFIG menu item to

enable Dual Indication Monitoring on a per channel basis. See Section 6.3.2 for the

programming procedure.

Dual Indication Moni toring will be disabled when the RED ENABLE input is not a c tive.

3.2.1 WALK DIS A BLE O PTIO N

This option will modify the operation of Red Fai l and Du al Indic at i on M onitorin g i n t h e T S -1

Type 12 mode onl y. When en abled, t he Red F ail and D ual Indic ation Moni toring f unction

will not monitor t he W alk field outputs. Absenc e of sig nals on th e Gr een, Yell ow, and R ed

field outp uts of a channel will plac e the MMU-16LE SmartMonitor

®

int o the Red Fail fault

mode causing t h e O u tp ut r elay con tacts t o tr ansf er. Pr esenc e of active si gnals on t h e Walk

outputs will n ot caus e a Dual In dic ation w hen c oncur rent with acti ve Red or Yel low sign als.

This f unction is en abled by th e Unit Opti on called "W ALK DISAB LE" in the SET / VIEW

CONFIG m enu. See Section 6.3.4.2.

3.3 EXTERNAL WATCHDOG MONITORING

This func tion monit ors an option al exter nal watchd og outpu t from a Control ler Unit or oth er

extern al c abin et c ircu itr y. Th e ext er nal s ourc e s houl d togg le th e E XT ER NAL W AT CH DOG

input l og ic s tate once ev er y 1 00 msec . If th e MMU-16LE SmartMonitor

change in stat e on the EXTER NAL WATCH DOG input for t he External W atchdog Fault

time (Section 9), the MMU-16LE SmartMonitor

®

will enter the fault mode, transfer the

®

d oes n ot recei ve a

OUTPUT relay contacts to the Fault position, and display the EXT W ATCHDOG status

screen. When operati ng in th e Type 16 m od e w ith Port 1 comm un ic at i ons en abled, Bit #70

(Spare Bit #4) of the Type #129 response frame will be set to indicate an External

W atchdog fault has been d etect ed. Th e MMU-16LE SmartMonitor

®

will r emain in th e fault

mode un til t he unit is r es et b y th e R ES ET butt on or t h e EXTERNAL RESET input. A n MMU

Power F ailur e will als o res et t he External Watchdog f ault st ate of t he m onit or (s ee S ec tion

2.6).

This f unc tion is enabled by a UNIT Option called EXTERN W AT C HDOG in the SET / VIEW

CONFIG men u ( see Sect ion 6.3.4.4). The EXT ERNAL W AT CHDOG inp ut is har nessed t o

spare pin MSB-S on the front panel B connector by the factory.

3.4 PROGRAM CARD ABSENT INDICATION

If the Pr ogram Card is abs ent or n ot seated pr operly i n th e edge connector, t he MMU-16LE

SmartMonitor

®

wil l enter th e fault mode, tr ansfer th e OUTPUT relay c ontacts t o the Fault

positi on, and display the PGM CARD AJAR status screen. The MMU-16LE SmartMonitor

will r em ain i n the fault m od e u ntil th e Program Card is correc tl y seated an d the MMU-16LE

SmartMonitor

®

is reset by the RESET button or the EXTERNAL RESET input.

3.5 RESET INPUT DETECTION

Activati on of the front pan el RESET button or th e EXTERNA L RESET input will r eset th e

MMU-16LE SmartMonitor

®

from th e fault mod e an d c ause the START relay t o energiz e an d

th e O UTP U T r el a y t o tra ns fer t o t h e n o-f ault s tat e. E ach activat i on o f the R ESET but ton or

EXTERNAL RESET input will cause a one time reset input to the unit. A continuously

activat ed R ESET inp ut w ill n ot prev ent th e MMU-16LE SmartMonitor

®

f rom monit oring an y

fault condition and/or transferring the OUTPUT relay contacts to the fault position. This

functi on pr events the Cab in et Ass embl y fr om bein g oper at ed with t he m onitor unit dis abled

due to a faulty RESET button or EXTERNAL RESET input.

3.6 DISPLAY LED TEST

The monitor will illuminate all front panel LED and LCD in dic ators f or 500 ms w hen a Reset

command is issu ed by the f ront panel RESET b utton or E XTERNAL R ESET inp ut. This

functi on provides a m eans to check the operati on of all front pan el in dicators.

Eberle Design Inc. Page 14

®

Page 21

MMU-16LE SmartMonitor

Operati ons M an ual

3.7 RECURRENT PULSE DETECTION

This err or detect ion funct i on s u pp lements t h e n ormal Conf lic t, Dual Indic ati on , and Red F ail

monitoring algorithms for sensing faults which are intermittent or pulsing in nature. The

RMS-Engine

®

is designed to filter out short term transients commonly found on the

electrical service and pr ovi de nois e i mmunity ag ai ns t f alse signal detect i ons . The Recu rr e nt

Pulse det ection fu nction is d esigned t o respond t o fault conditi ons whic h are inter mittent in

nature and do not meet the continuous timing requirements of the normal detection

algorithms, yet may still produce improper signal displays. These input conditions are

differentiated by their longer time constant and fault response times.

The f igure bel ow s hows a simple examp le of a Rec urrent Conflic t fault. Channel 2 G reen is

detect ed act ive d ue t o a m alfu ncti on of the l oad s witc h whic h c aus ed the out put t o “flic k er”

On for 100 ms appr oximat ely ever y 200 ms. Because norm al Conf lict d etecti on requir es a

continu ous f ault of at least 350 ms t ypic al, this event c ould g o unde tected. Th e R ecur re nt

Pulse det ection algorith m will process th ese pulses i nto one even t and trig ger a Conf lict

fault once the longer recurrent timing threshold is exceeded.

®

When triggered by a recurrent pulse fault condition, the MMU-16LE SmartMonitor

will

enter th e fault mode, tr ansfer t he Output relay c ontacts t o the Fau lt pos ition, and display

the approp riate RP CONFLICT, RP DUAL INDICATION, or RP RED FAIL status scr een.

The unit wil l rem ain i n t he f ault mod e un til r eset b y the R es et but ton or the E xt ernal R es et

input. Faul t respons e times will vary dep ending on the pulse widt h and frequency of the

recurrent inputs, but typically range from 1000 ms minimum to 10 seconds maximum.

This f unction c an be dis abled by a UNIT Option called REC URRENT PU LSE in the SET /

VIEW CONFIG menu. See Secti on 6.3.4.1.

3.8 TYPE FAULT

®

The TYP E SE LECT inp ut is us ed b y th e MMU-16LE SmartMonitor

to spec ify whether the

monitor is to be c onfig ured as a Type 16 unit with 16 c hannels or a T S1 comp atible T ype

12 unit with 12 channels (see Section 1.4.2). This input is read by the MMU-16LE

SmartMonitor

button or EXTERNAL RESET input. The Type Select configuration of the MMU-16LE

SmartMonitor

®

on ly during power-up initial ization or when th e unit is reset by th e RESET