BACKGROUND AND TESTING OF THE

MEGAFLANGE

®

FLANGE ADAPTER

INTRODUCTION

EBAA Iron developed the Series 2100

MEGAFLANGE

®

flange adapter to make the

installation of flanged piping and fitting more

field adaptable. The Series 2100 utilizes wedges

rather than set screws to grip the pipe. The

MEGAFLANGE flanging system provides a

fully restrained joint with deflections

capabilities. It is availab l e in sizes 3 inch through

36 inch. The Series 2100 has been subjected to

several kinds of hydrostatic pressure tests on a

variety of piping material. This report details the

3 through 12 inc h si zes.

BACKGROUND

Although the installation proce dure for the

flanged joint is very simple and straight forward,

there are several problems associated with the

flanged joint that make it difficult to install in the

field. For example, the flanged joint requires an

excessive amount of torque on the bolts to

achieve a good seal. The pipe layout must be

precisely planned to avoid misalignment errors

due to deviations in appurtenances or pipe

fabrication.

Products such as the flange adapter and the

flanged coupling adapter were introduced to

make flanged joints easier to assemble in the

field. While these products have been helpful,

they are limited. Typical flange adapters use a

standard mechanical joint gasket for both the

pipe and the flange seal and are still prone to

leaks. The flanged coupling adapter separates the

pipe seal from the flange seal but most are not

restrained. In most cases, unrestrained flange

adapters and flange coupling adapters must be

restrained. In some cases, set screws are

incorporated to restrain these devices, but set

screw restraints are ineffective when compared

to the “pull out strength” of the standard flanged

joint. However, the MEGAFLANGE adapter

from EBAA Iron provides a field fabricated,

fully restrained flanging system for use on plain

end ductile iron, steel, and PVC pipe. The

MEGAFLANGE flange adapter not only

provides a way of connecting plain end pipe to a

flanged fitting, it also delivers flexibility, up to

5° in three through eight inch sizes and up to 3°

FL-2

9-94

in the ten and twelve inch sizes, both during and

after assembly.

SERIES 2100 MEGAFLANGE FLANGING

SYSTEM

For years, EBAA has produced flange adapters

similar in design to any other flange adapter.

Consequently, EBAA’s flange adapters

encountered the same problems as the others on

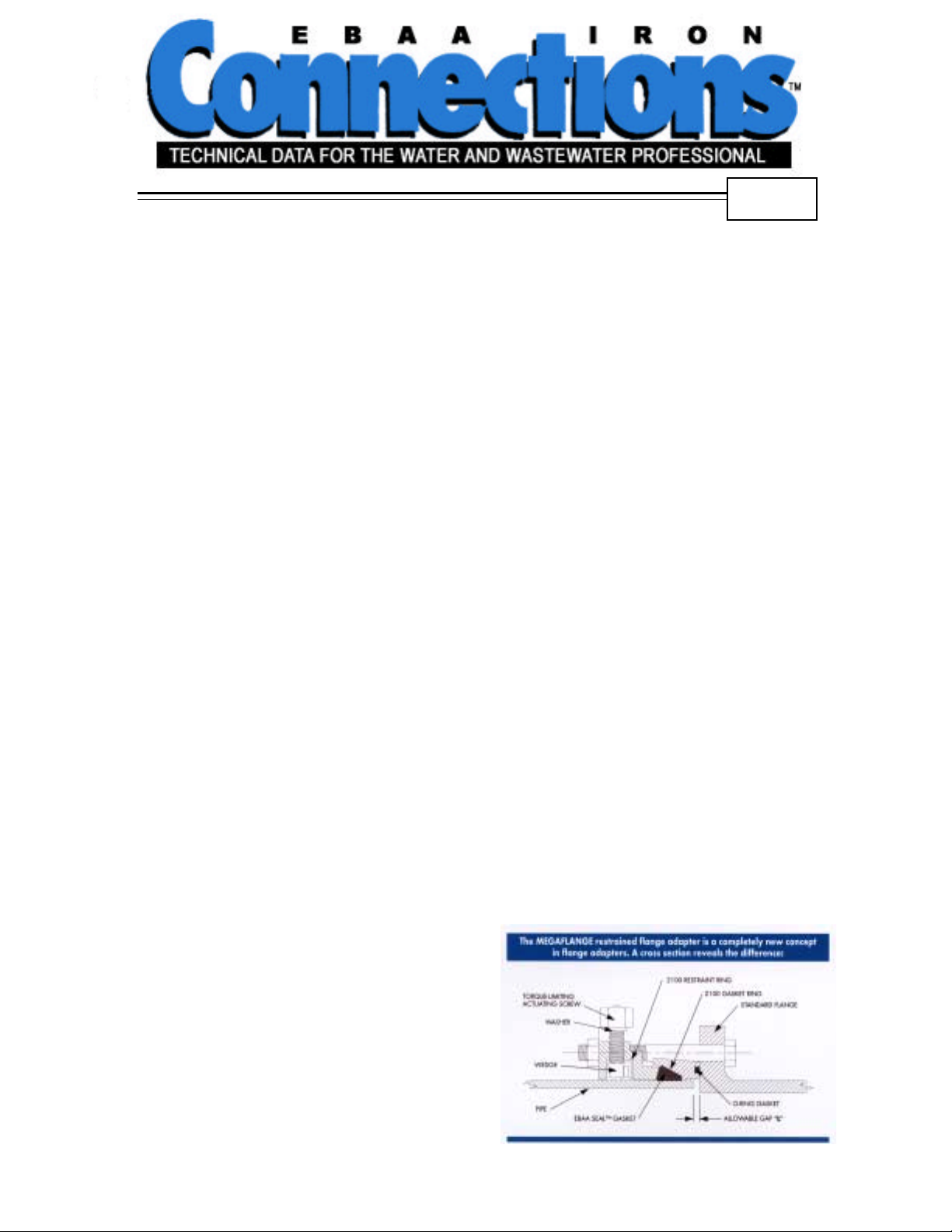

the market. The Series 2100 MEGAFLANGE

adapter from EBAA is a completely new

product. The cross section of the Series 2100 can

be seen in Fig. 1. As can be seen in the figure,

the Series 2100 is comprised of two rings. The

first is the restraint ring. Wedges, around the

circumference of the ring, grip the pipe. The

wedge style of restraint offers enormous pullout

strength when compared to that of the set screw

type restraint. The resiliency of the wedge style

restraint allows the Series 2100 to withstand

severe moment loads. The second ring, the

gasket ring, separates the seals dedicated to each

sealing surface. This ring allows the pipe to be

cut in the field at the tolerance of 0.6 inch or

more. The gasket ring also enables the joint to

deflect during assembly.

The MEGAFLANGE flange adapter can be

deflected five degrees d uring assembly through

the eight inch size and three degrees in the ten

and twelve inch sizes. The deflection capabilities

provided by the gasket ring allows offset of

almost nineteen inches of an eighteen foot length

of pipe through the eight inch size. The ten and

twelve inch sizes are capable of an eleven inch

offset or greater over an eighteen foot span.

However, the gap between the pipe end and the

flange face should never be greater than the

dimension “L”.

TESTING

The Series 2100 has been subjected to several

hydrostatic pressure tests. The testing procedure

was as follows:

1) A test section was made using a length of pipe

closed with the Series 2100 restraint and blind

flanges.

2) The test section was filled with water and

vented of all the air.

3) The section was pressurized to the specified

requirements.

The testing co nducted on PVC involved a quick

burst, high pressure test, and a long term test.

Our quick burst test requirement was that the test

section was to be pressurized to or beyond the

minimum burst pressure for various dimension

ratios (DR’S or SDR’s). For example, DR18

PVC pipe was tested to 755 psi and DR14 PVC

pipe was tested to 985 psi.

The long term pressure test consisted of the test

sections being pressurized to a specific pressure

for 1000 hours. The pressure is determined by a

stress regression line equation developed by

Robert T. Hucks. A DR18 sample should be able

to hold 615 psi for 1000 hours. The Series 2100

has been tested on DR18 PVC pipe at 615 psi for

1000 hours without failure.

The testing preformed on steel and ductile iron

pipe was conducted according to Underwriters

Laboratory standard UL213. This standard

required three separate tests: a leakage test, a

hydrostatic test, and a flexural test.

The leakage test required the test section to

withstand twice the rated pressure without

leaking for one minute. The hydrostatic test

required the test sample to withstand for one

minute a multiple of the rated pressure without

rupture. The three through six i nch sizes were

required to withstand a pressure five times the

rated pressure. The eight and ten inch sizes were

tested to four times the rated pressure and the

twelve inch size was subjected to a pressure

three times three times the rated pressure.

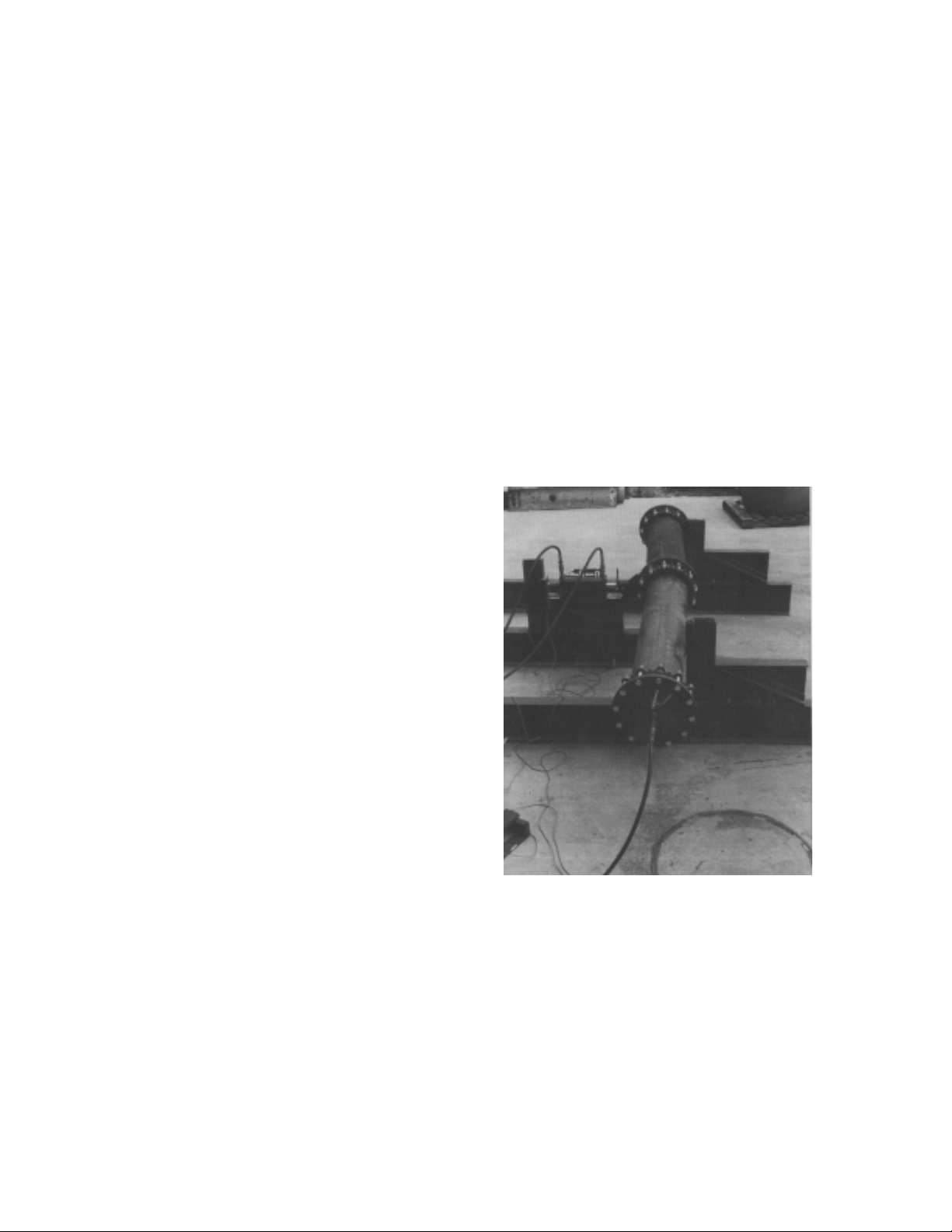

The final test was the flexural test. The pipe and

joint were required to withstand a bending

moment based on twice the weight of water

filled pipe over twice the maximum distance

between pipe supports as specified in the

“Standard for Installation of Sprinkler”, NFPA

13-1991. The test was conducted with the test

section at rated pressure. The photograph to the

right shows the test set up for the flexural test.

The moment requirements are listed below.

Nominal Fitting Size Moment Requirements

(Inches) (Ft-lbs.)

3 2426

4 3845

6 7085

8 11304

10 16785

12 22950

The tests were conducted on SCH40 steel and

PC350 ductile iron pipe. An additional pipe

damage test was conducted on the ductile iron

samples according to paragraph 9 of the

Underwriters Laboratories standard UL194. The

purpose of this test was to confirm the fact that

the Series 2100 does not damage the pipe wall or

the mortar lining.

SUMMARY

The Series 2100 MEGAFLANGE adapter

provides a strong, resilient and field adaptable

flanging system. The MEGAFLANGE adapter is

listed for above ground use by Underwriters

Laboratories in sizes three through twelve inch

for joining plain end Schedule 40 steel or ductile

iron pipe to flanged fittings. The Series 2100

may also be used on C900 and IPS PVC at the

full pressure rating of the pipe. The

MEGAFLANGE adapter is simple to install and

allows a greater tolerance in plant layout than

Loading...

Loading...