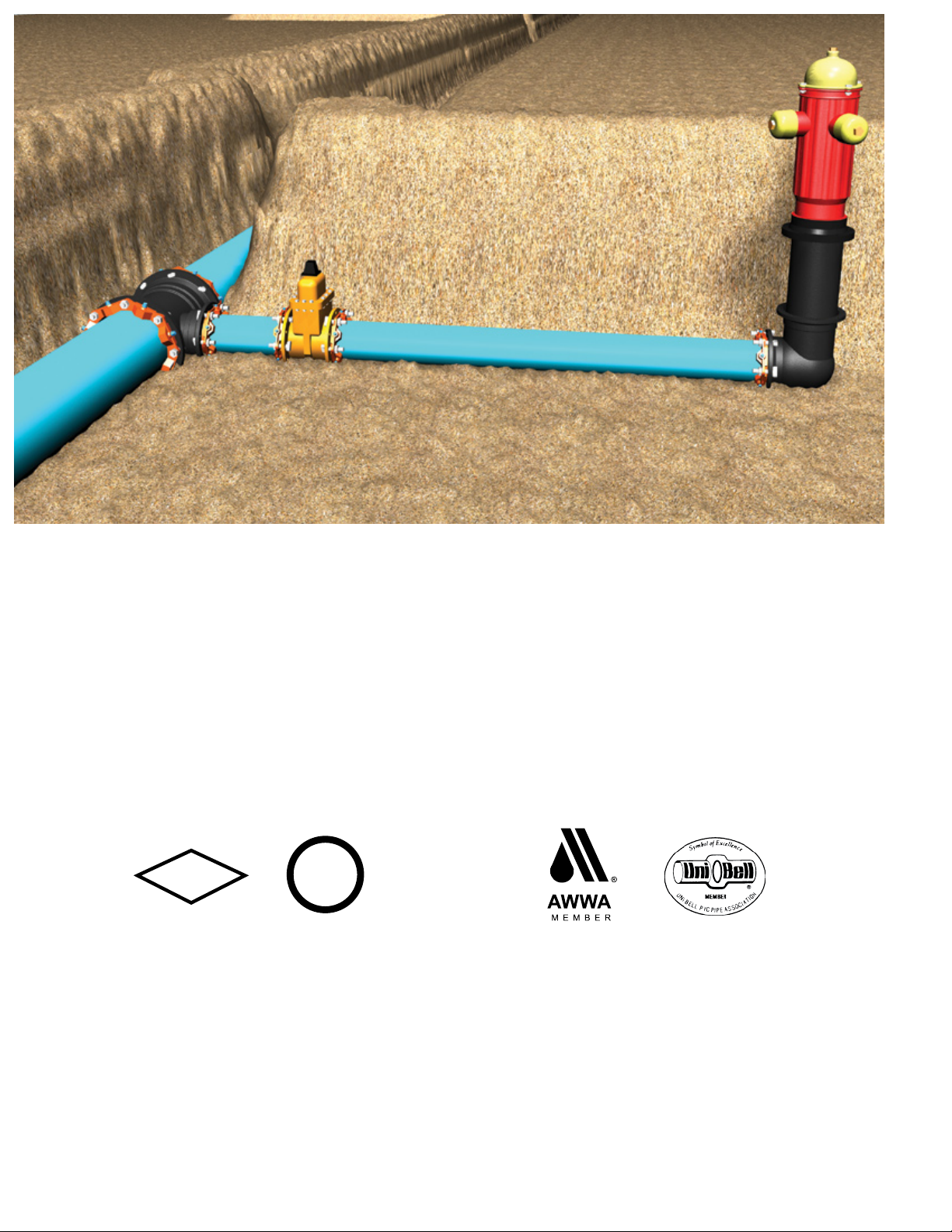

EBAA Iron 2000PV User Manual

Series 2000PV

Mechanical Joint Restraint for PVC Pipe

Features and Applications:

• For restraining plain end PVC pipe

at mechanical joint ttings and

appurtenances

• Sizes 3 inch through 36 inch

Sizes 42 inch through 48 inch

accommodated by Series 2200

• MEGA-BOND® Restraint Coating System

For more information on MEGA-BOND,

refer to www.ebaa.com

• Constructed of ASTM A536 Ductile Iron

Series 2012PV on 12inch C900 PVC pipe at a ductile iron tting.

Nominal Pipe Size Series Number Shipping Weight

3 2003PV 7.0

4 2004PV 8.8

6 2006PV 12.1

8 2008PV 16.3

10 2010PV 26.0

12 2012PV 31.4

14 2014PV 47.6

16 2016PV 52.8

18 2018PV 61.8

20 2020PV 70.9

24 2024PV 92.9

30 2030PV 128.5

36 2036PV 161.3

42 2242* 652.0

48 2248* 711.1

*Restraint for pipe size 42 inch and greater, please refer to Series 2200 Brochure

found at www.ebaa.com.

• The mechanical joint follower gland is

incorporated into the restraint

• Heavy duty thick wall design

• Support Products Available:

◦ Split mechanical Joint style available

for 3 inch through 12 inch

EBAA Series 2000SV

◦ Solid restraint ring harness available

for C905 PVC pipe bells

EBAA Series 2800

◦ Split restraint ring harness available

for C900 and C905 PVC pipe bells

and PVC ttings

EBAA Series 1500, 1600 and 2500

• All 2000PV and related restraint

products can be furnished as packaged

accessories complete with appropriate

restraint, gasket, lubrication and bolting

hardware

U.S. Patent No.

4627775 4896903 5071175

0208-J Copyright 2007 © EBAA Iron, Inc. All Rights Reserved.

For use on water or wastewater pipelines

subject to hydrostatic pressure and tested

in accordance with either AWWA C600 or

ASTM D2774.

FM

APPROVED

U

L

ASTM

F1674

Series 2000PV:

Mechanical Joint Restraint Gland for use With AWWA C900 or IPS Outside Diameter PVC Pipe

The 2000PV MEGALUG Mechanical Joint Restraint

is the fastest and most economical method of

restraining PVC pipe to mechanical joints. Now the

need for costly concrete thrust blocks and corrodible

steel tie rods is eliminated. It can be used in straight

alignment or at the preset deection recommended

for mechanical joints.

The 2000PV was the rst PVC joint restraint to be

tested to UNI-B-13, Underwriters Laboratories, and

Factory Mutual.

The 2000PV MEGALUG Concept

EBAA Iron started manufacturing joint restraint

products for PVC pipe in the early 1980s. The testing

of early prototypes of various congurations of

restraints on large diameter PVC pipe indicated that a

restraint device must be capable of consistently and

reliably gripping the pipe. If not, the restraint can slip

under pressure, resulting in a sudden impact, and

cause the pipe to burst. Armed with this background

knowledge and an appreciation for the capabilities of

PVC pipe, EBAA purposefully deviated from what many

in the industry once considered to be the ‘only’ way to

grip PVC pipe. This led to development of the Series

Tested to and meets the requirements of ASTM F

1674-96 ‘Standard’ Test Method for joint restraint

products use with PVC pipe through 24 inch size.

UL Listed in the four through twelve inch sizes for

joining UL Listed ductile iron ttings to UL Listed,

Class 150 PVC pressure pipe. The maximum allowable

joint deection is ve degrees.

Factory Mutual approved for use on DR18 PVC pipe in

four through twelve inch sizes.

2000PV MEGALUG Mechanical Joint Restraint for PVC

pipe.

The design of the 2000PV incorporates the gripping

mechanism into the design of the mechanical

joint gland and utilizes a simple two part assembly

process. The rst step involves assembling the

joint the same as any standard mechanical joint.

The assembly procedure we recommend is that

established in AWWA C600. The second is the

actuation of the restraint.

Loading...

Loading...