EBAA Iron 1700 User Manual

Series 1700

MEGALUG® Restraint Harness

for Push On Joints on Ductile Iron Pipe

Features and Applications:

• Restraint harness for ductile iron pipe to

pipe push on joints

• Restraint harness meets or exceeds

ANSI/AWWA C151A21.51 and ANSI/

AWWA C150/A21.50 standards

• Minimum 2 to 1 safety factor

• MEGALUG Restraint Ring on spigot side

of joint

• Split Bell Ring design for ease of

installation

Series 1706 restraining 6 inch ductile iron pipe to pipe push on joint.

PSI Ratings

Nominal

Pipe Size

Series

Number

Approximate

Shipping Weight

4 1704 19.96 350

6 1706 28.92 350

8 1708 37.92 350

10 1710 56.34 350

12 1712 74.02 350

14 1714 119.62 350

16 1716 134.40 350

18 1718 138.40 250

20 1720 161.88 250

24 1724 242.36 250

30 1730 312.00 250

36 1736 475.00 250

42 1742* 1,131.00 250

48 1748* 1,345.00 250

NOTES: For applications for pressure other than those shown, please contact EBAA for assistance.

* Series 1742 and 1748 consist of two MEGALUGS, one on the spigot and one behind the bell.

Rated Pressure

(PSI)

• Constructed of ASTM A536 ductile iron

• MEGA-BOND® Restraint Coating System

For use on water or wastewater pipelines

subject to hydrostatic pressure and tested

in accordance with either AWWA C600 or

ASTM D2774.

Sample Specication

Ductile iron pipe bell restraint shall consist of a

wedge action restraint ring on the spigot joined to a

split ductile iron ring behind the bell. The restraint

ring shall have individually actuated wedges that

increase their resistance to pull-out as pressure or

external forces increase. The restraint ring and its

wedging components shall be made of ductile iron

conforming to ASTM A536. The wedges shall be

heat treated to a minimum hardness of 370 BHN.

Torque limiting twist off nuts shall be used to insure

proper actuation of the restraining wedges. The

split ring shall be made of ductile iron conforming to

ASTM A536. The restraint devices shall be coated

using MEGA-BOND®. (For complete specications on

MEGA-BOND visit www.ebaa.com.) The connecting tie

rods that join the two rings shall be made of low alloy

steel that conforms to ANSI/AWWA C111/A21.11.

The assembly shall have a rated pressure with a

minimum two to one safety factor of 350 PSI in the

sixteen inch size and below 250 PSI in the eighteen

through thirty-six inch sizes. The product shall be

the Series 1700 MEGALUG® restraint harness,

manufactured by EBAA Iron, Inc., or approved equal.

1008-3-I Copyright 2006 © EBAA Iron, Inc.

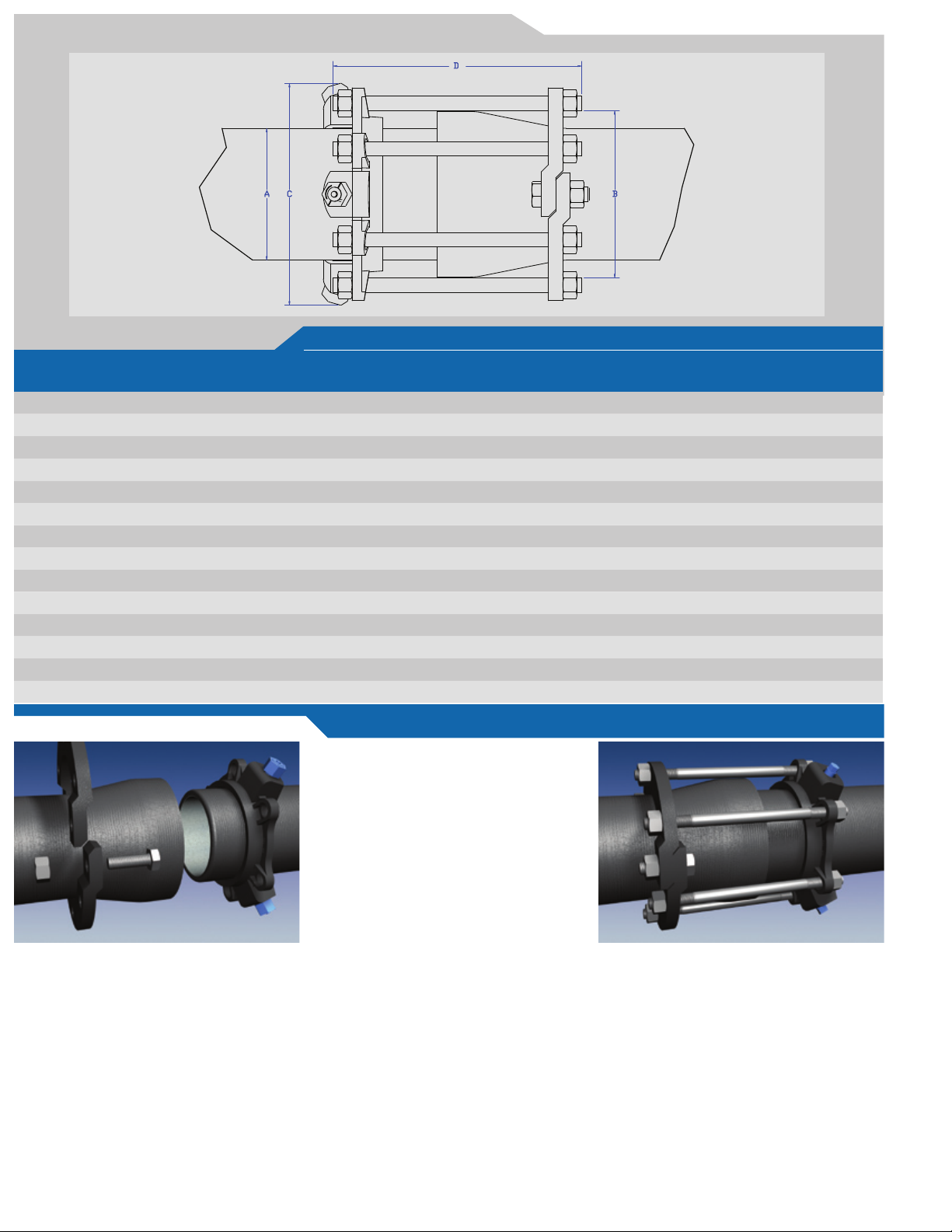

Series 1700 Submittal Reference Drawing

EBAA IRON

Nominal

Pipe Size

4 1704 4.80 6.60 9.90 4 - ¾ x 13

6 1706 6.90 8.60 12.00 6 - ¾ x 13

8 1708 9.05 10.9 14.15 6 - ¾ x 13

10 1710 11.10 13.1 16.20 8 - ¾ x 18

12 1712 13.20 15.4 18.30 8 - ¾ x 18

14 1714 15.30 17.9 21.88 8 - ¾ x 18

16 1716 17.40 20.1 24.13 10 - ¾ x 18

18 1718 19.50 22.4 26.50 10 - ¾ x 18

20 1720 21.60 24.6 28.50 12 - ¾ x 18

24 1724 25.80 29.1 33.38 14 - ¾ x 18

30 1730 32.00 35.8 40.25 16 - 1 x 18

36 1736 38.30 42.6 46.75 20 - 1 x 18

42 1742* 44.50 49.2 55.57 24 - 1¼ x 28

48 1748* 50.80 56.1 61.87 28 - 1¼ x 28

Series

Number

*Series 1742 and 1748 are comprised of two MEGALUGS ; one on the spigot and the other behind the bell.

Installation Instructions

4. Position the Series 1100 MEGALUG®

restraint on the spigot such that the

bolts are in alignment and the distance

between the rings is suitable for the tie

bolt length. Allow enough room on the tie

bolt to fully engage the nuts with several

threads showing.

5. Install the tie bolts in each available bolt

hole for maximum distribution of operating forces. Place nuts on the end of the

tie bolts. Allow room on the tie bolt to

fully engage the nut with several threads

The Series 1700 is designed for restraining

ductile iron pipe, conforming to ANSI/AWWA

C151/A21.51 (all thickness classes) push-on

pipe bells. It has a restraint ring on the spigot

and a split ring behind the bell.

1. Install the split ring behind the bell in the

direction indicated on the casting. Tighten

the clamp bolts to 90 ft-lbs.

2. Place the Series 1100 MEGALUG®

restraint gland on the spigot with the lip

extension toward the bell.

3. Assemble the push-on joint per the pipe

manufacturer’s instructions.

showing.

6. Pull the restraint ring away from the joint

until the slack is removed from the tie

bolts.

7. Tighten the torque limiting twist-off nuts in

a clockwise direction (direction indicated

by arrow on top of nut) until all wedges

are in rm contact with the pipe surface.

Continue tightening in an alternate manner until all of the nuts have been twisted

off.

For Sizes 42 inch and 48 inch, two solid ring MEGALUGS are provided. One MEGALUG will be

placed on the spigot with the lip extension toward the bell. The second will slide along the barrel

of the second pipe and placed behind the bell (lip extension toward the bell). Then proceed with

steps 3 - 8.

A B C D

Pipe

O.D.

Maximum Bell

O.D. Cleared

NOTES: Dimension are in inches and are subject to change without notice.

Casing Clearance

(w/Nuts Off)

8. Tighten the tie bolt nuts until the ring

behind the bell is in rm contact with the

back of the bell. Do not tighten these

bolts enough to force the spigot further

into the bell.

9. If removal is necessary; use the ⅝ inch

hex heads provided. If reassembly is required, assemble the product in the same

manner as indicated in the previous steps

and tighten the wedge bolts to 90 ft-lbs.

Thrust Rod

(Quantity - Size)

MADE IN USA

Loading...

Loading...