Series 1500

Bell Restraint Harness for C900 PVC Pipe

Features and Applications:

• For use on AWWA C900 PVC pipe bells

• Minimum 2 to 1 Safety Factor

Series 1512 on 12 inch PVC Pipe.

Pressure Ratings (C900)

Nominal

Pipe Size

Series

Number

Approximate

Shipping Weight

DR 14

Class 200

DR 18

Class 150

4 1504 15.0 200 150 100

6 1506 22.0 200 150 100

8 1508 28.0 200 150 100

10 1510 51.8 200 150 100

12 1512 56.2 200 150 100

NOTE: For applications or pressures other than those shown, please contact EBAA for assistance.

Packaged Items.

DR 25

Class 100

• MEGA-BOND

®

Restraint Coating System

For more information regarding MEGABOND refer to www.ebaa.com

• Split design for ease of installation

• Constructed of ASTM A536 ductile iron

• Available in accessory packages

• For use on water or wastewater pipelines subject to hydrostatic pressure

and tested in accordance with either

AWWA C600 or ASTM D2774

Sample Specication

Restraint for PVC pipe bell (AWWA C900)

shall consist of the following: The restraint shall be manufactured of ductile

iron conforming to ASTM A536. The

restraint devices shall be coated with

MEGA-BOND. (For complete specications on MEGA-BOND visit www.ebaa.

com.) A split serrated ring shall be used

behind the pipe bell. A split serrated ring

shall also be used to grip the pipe, and a

sufcient number of bolts shall be used

to connect the bell ring and the gripping

ring. The combination shall have a pressure rating as shown in the adjacent

table. The restraint shall be the Series

1500, as manufactured by EBAA Iron,

Inc., or approved equal.

0810-3-F Copyright 2007 © EBAA Iron, Inc. All Rights Reserved.

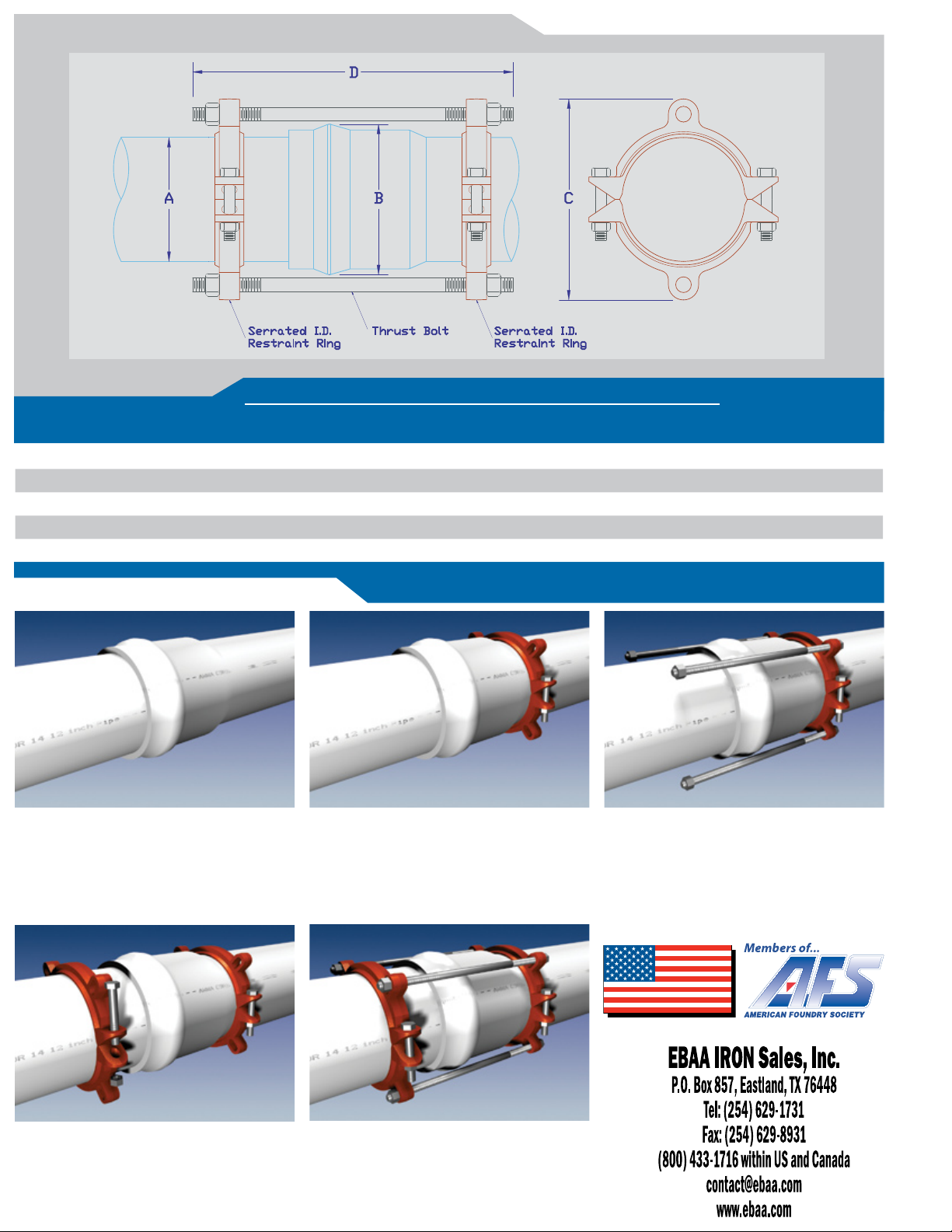

Series 1500 Submittal Reference Drawing

EBAA IRON

MADE IN USA

Nominal

Pipe Size

Series

Number

A

Pipe

O.D.

B

Maximum Bell

O.D. Cleared

C

Max. Restraint O.D.

(Casing Clearance)

D

Overall

Length

4 1504 4.80 6.75 9.25 13 2 - ¾ x 13

6 1506 6.90 8.75 11.25 18 2 - ¾ x 18

8 1508 9.05 12.25 14.75 18 2 - ¾ x 18

10 1510 11.10 14.20 16.85 22 4 - ¾ x 22

12 1512 13.20 16.90 19.45 22 4 - ¾ x 22

Installation Instructions

1. The Series 1500 is designed for restraining

push-on PVC pipe bells. It has a split, serrated restraint ring on the spigot and a split

serrated ring behind the bell.

2. Assemble the push-on joint per the pipe

manufacturer’s instructions.

3. Install both halves of the serrated ring

around the pipe behind the bell, tapping

each half into place. Make sure that the

complete ID of the ring is touching the pipe

before installing the side bolts. Install the

side bolts and tighten evenly to 110 ft-lbs.

of torque. (60 ft-lbs on 4 inch and 6 inch)

NOTE: Dimensions are in inches and are subject to change without notice.

4. Remove the side bolts from the second

serrated restraint ring. Use the Thrust Bolts

to determine the proper location of the

restraint ring on the spigot. Allow enough

room on the thrust bolt to fully engage the

nuts.

Thrust Bolt

(Number-Size)

5. Install both halves of the restraint ring at

the proper location, tapping each half into

place. Make sure that the complete ID of

the ring is touching the pipe before installing the side bolts. Tighten the side bolts

evenly to 110 ft-lbs. (60 ft-lbs on 4” and 6”)

6. Place nuts on the thrust bolts and tighten

until they are snug. Allow enough room on

the thrust bolts to fully engage the nuts. Do

not tighten these bolts enough to force the spigot

further into the bell of the joint.

Loading...

Loading...