®

MEGALUG

Series 1100

Mechanical Joint Restraint for Ductile Iron Pipe

Features and Applications:

• Sizes 3 inch through 48 inch

• Constructed of ASTM A536 Ductile Iron

• Torque Limiting Twist-Off Nuts

• MEGA-BOND

Restraint Coating System

For more information on MEGA-BOND,

refer to www.ebaa.com

• The Mechanical Joint Follower Gland is

incorporated into the restraint

• Heavy Duty thick wall design

Post

Nominal

Pipe Size

3 1103 6.1 3° 350

4 1104 7. 7 3° 350

6 1106 11.9 3° 350

8 1108 14.8 3° 350

10 1110 23.9 3° 350

12 1112 31.2 3° 350

14 1114 48.5 2° 350

16 1116 56.4 2° 350

18 1118 63.1 1½° 250

20 1120 72.3 1½° 250

24 1124 133.1 1½° 250

30 1130 194.6 1° 250

36 1136 234.0 1° 250

42 1142 536.0 1° 250

48 1148 653.0 1° 250

NOTE: For applications or pressures other than those shown please

Made In

The USA

0914-2.5-H Copyright © 2007. EBAA Iron, Inc. All Rights Reserved.

Series

Number

4092036, 4627774, 4779900, 4896903, 5544922

Shipping

Weights

U.S. Patent Nos.

Assembly

Deection

contact EBAA for assistance.

Pressure

Rating

(PSI)

• Support Products Available:

Split repair style available 3 inch

through 48 inch.

EBAA Series 1100SD

Solid restraint harness available for

push-on pipe bells.

EBAA Series 1700

Split restraint harness available for

existing push-on bells.

EBAA Series 1100HD

• All MEGALUG and related restraint

products can be furnished as packaged

accessories complete with appropriate

restraint, gasket, lubrication, and bolting hardware

• For use on water or wastewater pipelines subject to hydrostatic pressure

and tested in accordance with either

AWWA C600 or ASTM D2774

®

PRESURE OR EXTERNAL FORCE

MEGALUG: THE PRODUCT OF PREFERENCE SINCE 1984

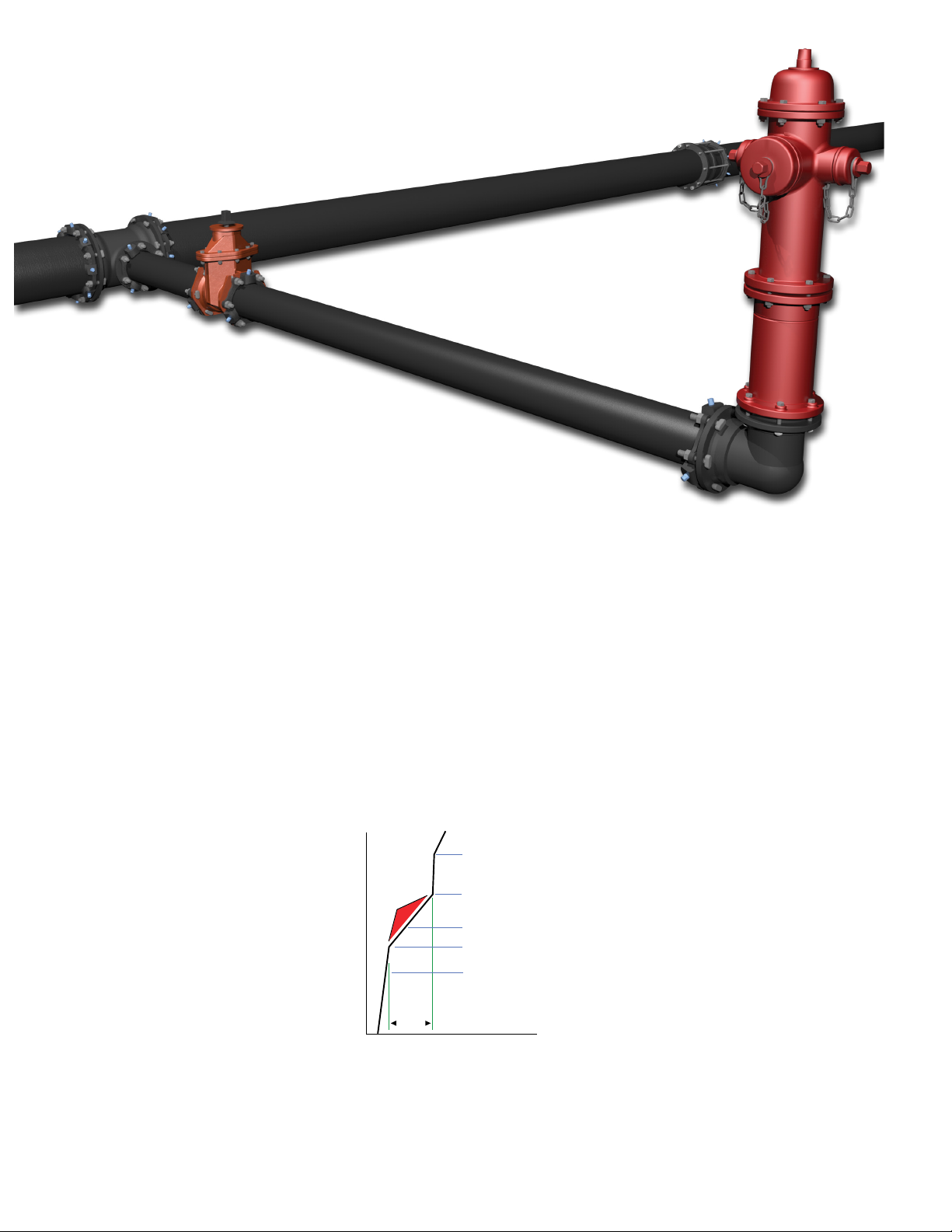

Since 1984, engineers and contractors designing and installing

water and wastewater pipelines and systems have come to rely

on the EBAA Series 1100 MEGALUG Mechanical Joint Restraint

as the “Product of Preference” for effectively and economically

restraining ductile iron pipe connections above or below ground.

MEGALUG Mechanical Joint Restraints replace external restraints such as cumbersome concrete thrust blocks and corrodible metal tie rods creating a quicker, safer and more economical

installation.

THE MEGALUG GRIPPING WEDGE... PERFORMANCE PROVEN

The wedge style MEGALUG design reacts

to the amount of force acting on the joint.

When each wedge is set, the wedge teeth

penetrate the pipe’s outer surface, and

the wedge does not move on the pipe.

There is very little change in this interface

until the wedge movement begins inside

the pocket of the main casting. Once the

wedge starts moving, the formation of the

buttress begins.

This “dam” of material (the wedge

impression) is cold formed as the wedging

action continues. If the force of pressure

acting on the joint is released, the wedge

moves back to near its original position.

This engages the reserve-controlled movement or “RCM”. The wedge is then ready

for another round.

After the wedge has moved to the back

of the pocket at the maximum pressure or

load, the wedge buttress are in shear. The

maximum movement is about 0.3 inch

through the thirty-six inch size and 0.4

inch for forty-two and forty-eight inch.

The RCM is available even with severe

Movement

causes

wedges to

increase

grip

RCM

MOVEMENT

Major testing laboratories agree as the 3” through 24” sizes

are Underwriters Laboratories (UL) listed, and the 3” through 12”

sizes are Factory Mutual (FM) approved.

For use on all classes of ductile iron pipe (PC350 through

PC150 and CL56 through CL50), for practically any application

including valves, hydrants and pipe, the MEGALUG Mechanical

Joint Restraint effectively and safely performs without damage to

the pipe or cement linings.

cyclic loads. This has been tested to very

Max pressure

high-pressure differentials and the wedge

impressions look the same as if a single

Max movement

Rated pressure

Wedge movement

begins

Normal operating

pressure

test had been performed.

Typically, the depth of pipe wall penetration, or wedge impression at around

25,000 pounds of force per wedge (200

PSI on a six inch and 150 PSI on a twelve

inch) is 0.03”. Finally, at roughly twice that

force the penetration is around 0.05” At

these high pressures, there is no affect on

the design thickness of ductile iron pipe

made according to AWWA C150. The lack

of damage to the cement lining clearly

indicates that the thrust load is primarily

longitudinal.

This ability to move in the pocket allows

for angular exibility as well as longitudinal exibility.

Loading...

Loading...