Series 1000

E-Z Flange™

Flange Adapter For Ductile Iron and Steel Pipe

Features and Applications:

• Adapts a plain end of ductile iron or

steel pipe to a tting, valve, or other

appurtenances equipped with anges

meeting ANSI/AWWA C110

• When used on Ductile Iron Pipe at anged

joints, sizes 3 inch through 12 inch, use the

E-Z Flange Gasket supplied.

• When used on Steel Pipe at anged joints,

sizes 3 inch through 12 inch, a transition

gasket is required.

• Minimum 2 to 1 Safety Factor

• MEGA-BOND® Restraint Coating System

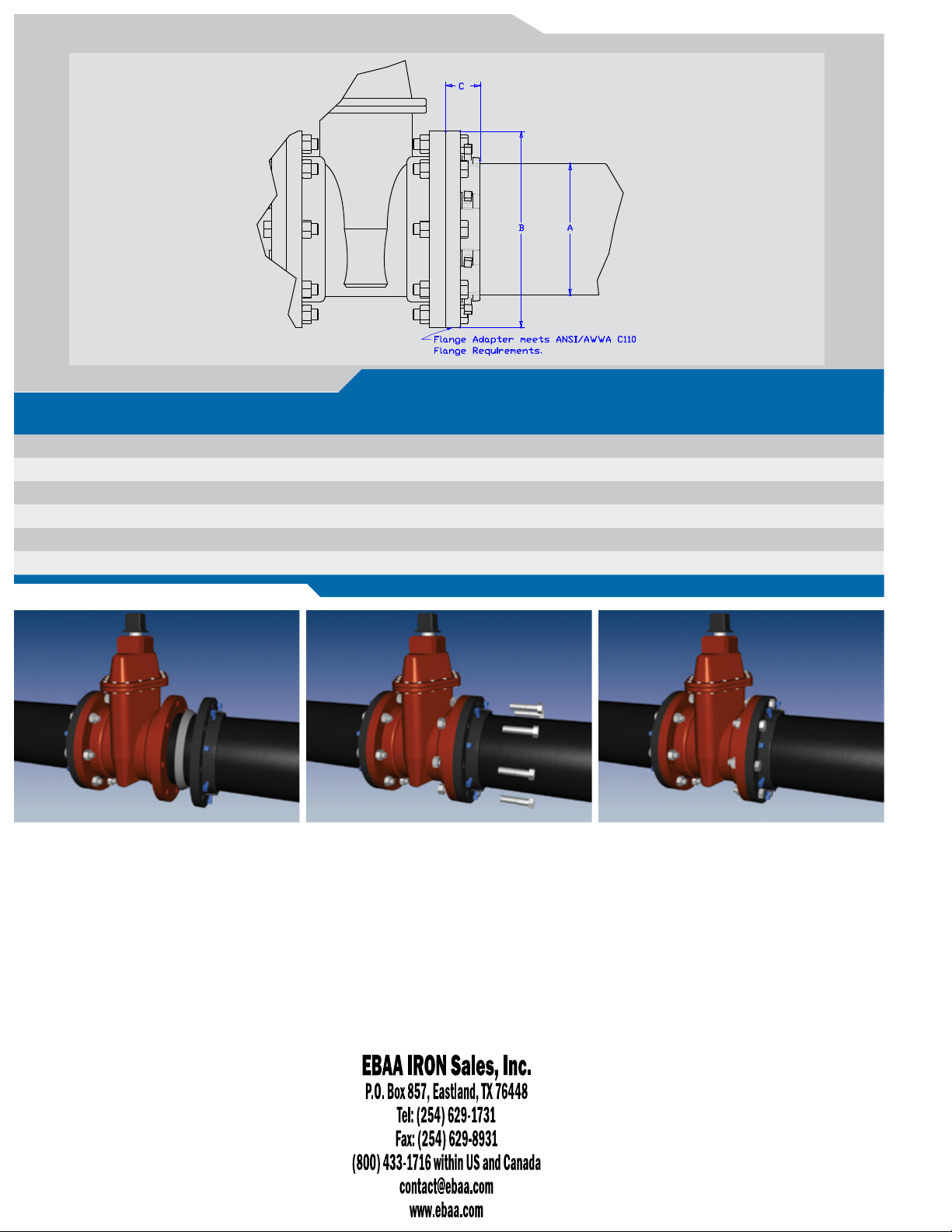

Series 1008 E-Z Flange on 8 inch DIP, adapting to a anged gate valve.

• Set Screw Design

Pressure Ratings Table

Nominal

Pipe Size

3 1003 4.00 250

4 1004 6.30 250

6 1006 8.80 250

8 1008 12.99 250

10 1010 23.10 200

Series

Number

Approximate

Weight

Pressure

(PSI)

• Constructed of ASTM A536 Ductile Iron

• This product is Listed to applicable UL

Standards and requirements by Underwriters

Laboratories Inc.

Sizes 3 inch through 12 inch

• Available with Accessory Packages

12 1012 29.50 200

NOTE: For applications or pressures other than those shown, please contact EBAA for assistance.

For Higher Pressures and or Larger Size Applications

Series 2100 MEGAFLANGE® Restrained Flange Adapter

Available in sizes 3 inch through 48 inch for Ductile Iron and PVC Pipe and

sizes 3 inch through 12 inch for Steel and HDPE Pipe

www.ebaa.com

0912-O Copyright 2005 © EBAA Iron, Inc.

For use on water or wastewater pipelines

subject to hydrostatic pressure and tested in

accordance with either AWWA C600 or ASTM

D2774.

Sample Specication

Flange adapters shall be used in lieu of threaded

or welded anges on plain end ductile and carbon

steel pipe. The restraints shall be manufactured of

ductile iron conforming to ASTM A536. The restraint

devices shall be coated using MEGA-BOND®. (For

complete specications on MEGA-BOND visit www.

ebaa.com.) The bolt circles and bolt holes shall

conform to ANSI/AWWA C110/A21.10. The screws

shall have a Rockwell hardness of C40-45 converted

from Brinnell. The ange adapter shall have a

minimum working pressure rating as shown in the

adjacent table. The restraint shall be the Series 1000

E-Z Flange, as manufactured by EBAA Iron, Inc., or

approved equal.

Submittal Reference Drawing

EBAA IRON

Nominal

Pipe Size

3 1003 3.96 7.50 2.14

4 1004 4.80 9.00 2.33

6 1006 6.90 11.00 2.39

8 1008 9.05 13.50 2.76

10 1010 11.10 16.00 2.83

12 1012 13.20 19.00 2.89

Number

Installation Instructions

Series

A B C

Pipe

O.D.

NOTE: Dimensions are in inches ± 1% and are subject to change without notice.

Flange

O.D.

Flanged Adapter

Length

MADE IN USA

The Series 1000 E-Z Flange is

designed for joining plain end ductile

iron pipe, conforming to ANSI/AWWA

C151/A21.51 (class 50-56 thickness)

to standard AWWA C110 (class 150

dimensions) flanges.

1.

The pipe ends must be cut

smooth and square. (The E-Z

Flange adapter should not be

used on beveled end of the pipe.)

All surfaces must be cleaned.

Back the set screws out of the

ange to clear the pipe and slide

onto the pipe. Install E-Z Flange

gasket on the pipe with the bevel

of the gasket facing the E-Z

Flange.

2.

Position the pipe end square

against the adjacent ange. Slide

the gasket and E-Z Flange toward

the adjacent ange.

3.

Install and hand tighten the

ange bolts keeping an equal gap

around the ange.

4.

Tighten the ange bolts evenly to

the proper range of torque.

(45-60 ft-lbs for 3 inch and 4

inch and 75-90 ft-lbs for 6 inch

through 12 inch)

5.

Tighten the set screws in a

Alternating Manner until all are in

rm contact with the pipe surface.

After all set screws are in rm

contact with the pipe, continue

tightening in an alternating

manner until all are tightened to

the proper range of torque. (45

ft-lbs for 3 inch through 6 inch

and 70 ft-lbs for 8 inch through

12 inch.)

Loading...

Loading...