Page 1

Thank you for purchasing an Eastern Acoustic Works Weather-Protected Loudspeaker System. Eastern Acoustic

Works designs and manufacturers features into Weather-Protected Loudspeaker Systems to maximize their

durability for outdoor use. Some of these features include:

Installation and Maintenance

of Weather-Protected

Loudspeaker Systems

Page 1

Installation and Maintenance

EAW Weather-Protected Loudspeaker Systems

are intended to withstand direct exposure to

the weather. However, any steps which can be

taken to minimize this exposure will maximize

the life of the loudspeaker system. These include:

• Select mounting locations that provide some level of

shielding from the weather. Examples include balcony

overhangs, etc.

• If a dedicated loudspeaker system support structure is

to be provided, a simple roof construction can help

reduce exposure of the loudspeakers to direct moisture.

• Aim loudspeaker systems in a manner consistent with

EAW’s recommended use. This will assure that weatherprotection features are properly oriented.

NOTE: The warranty on Weather-Protected loudspeakers will

be voided if reasonable care is not taken in selecting mounting locations. Locations which channel or direct water onto

installed loudspeaker systems will void the warranty.

Maintaining Weather-Protection Features

Care must be taken during installation or maintenance

to avoid any measures that could compromise weatherprotection features. Of particular concern are:

Mounting hardware

Each product is shipped with a bolt in each available mounting

point. Each bolt is sealed with a non-hardening, waterproof,

non-locking thread

sealant. Any bolts removed during the

installation process must be replaced, as an exposed bolt

hole provides an

opening into the interior of the loud-

speaker enclosure.

Any bolts removed and replaced during

installation must be re-sealed.

In no case should any type of hardware be used to mount

the loudspeaker system except for structurally approved

stainless-steel hardware which mates into factory-installed

mounting points integral to the loudspeaker system.

Fiberglass shell

Each loudspeaker system must be handled carefully during

installation to avoid cracking or perforating the exterior

fiberglass shell.

In no case should anything be attached to the loudspeaker

shell, except using structurally approved stainless-steel

hardware which mates into the factory-installed mounting

points integral to the loudspeaker system.

Grilles

Grilles may be factory attached using screws of varying

lengths. Use care when re-attaching grille to ensure that all

hardware is returned to the correct locations.

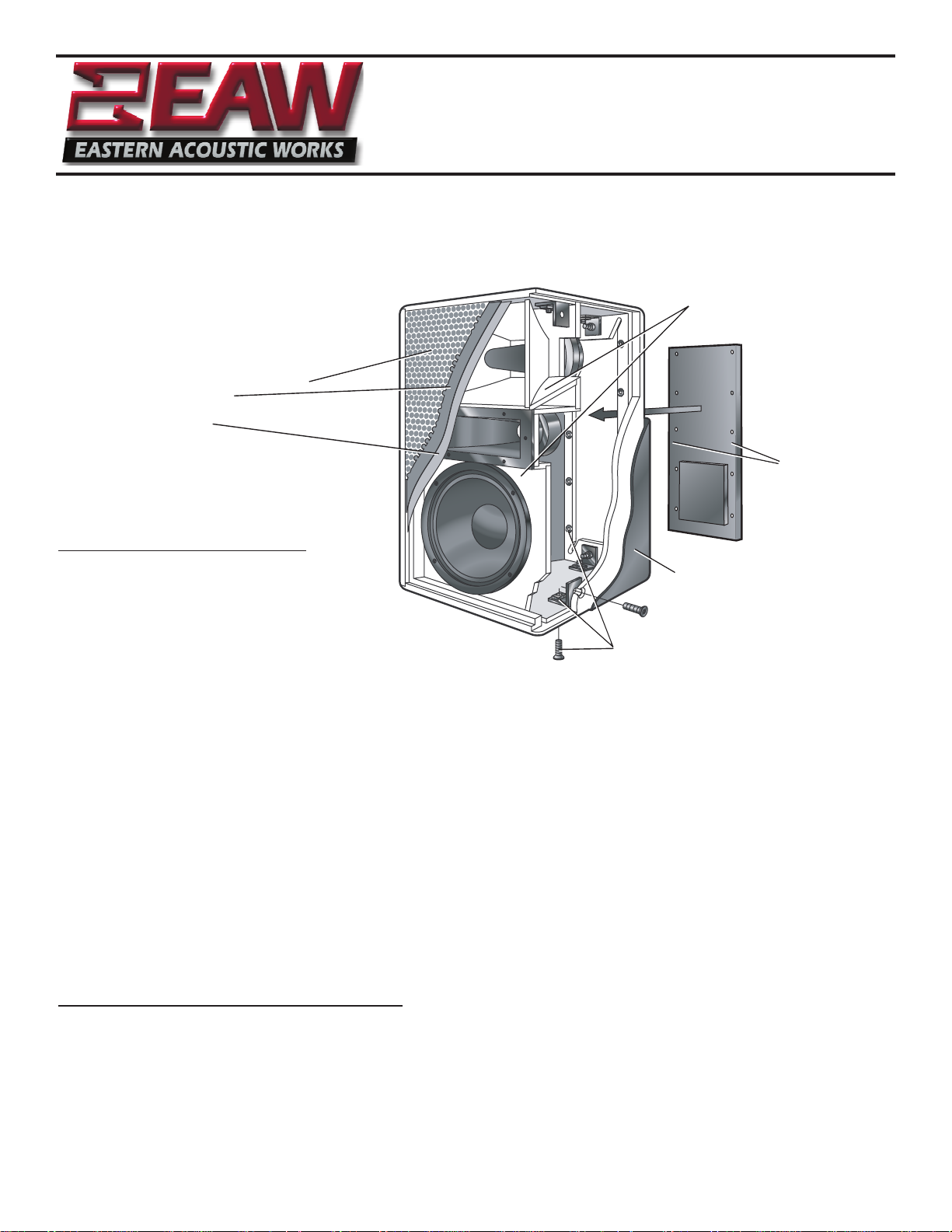

ENCLOSURE CONSTRUCTED OF

EXTERIOR-GRADE PLYWOOD.

MULTI-LAYER GRILLE ASSEMBLY COMPRISED

OF ANY OR ALL OF THE FOLLOWING:

• STAINLESS STEEL

PERFORATED EXTERIOR GRILLE

• SYNTHETIC FOAM

• 100 X 100 STAINLESS

STEEL MESH

INTERIOR AND BAFFLE COATED

WITH STYRENE RESIN

ACCESS HATCH

TO CABINET

SEALED WITH NON-

HARDENING SEALANT

FIBERGLASS SHELL

STAINLESS-STEEL MOUNTING HARDWARE

Page 2

Acoustical Performance

Loudspeakers should be individually checked by an

experienced sound system professional to verify that all

drivers are operational.

Please contact the system installer or EAW for further

assistance or guidance with testing.

Structural Integrity

Loudspeakers should be periodically examined for signs of

physical damage. Specifically, the following should be

checked:

• Damage to loudspeaker due to vandalism.

• Deterioration of mounting hardware due to rust or

corrosion.

• Damage to weather-protection features due to

improper installation or maintenance.

• Any other deterioration of the loudspeaker system

including loosening of parts, accessories or attachments

which could fall or cause injury.

Failure of any type should be immediately reported to the

system installer or Eastern Acoustic Works Service Department.

If you need assistance, please contact Eastern Acoustic Works

Service Department at 1-800-992-5013. We will be happy to

provide more detailed information on testing, maintenance,

installation, or any other aspect of your loudspeaker system.

PN 0000696(A) One Main Street, Whitinsville, MA 01588 tel 800 992 5013 / 508 234 6158 fax 508 234 8251 web www.eaw.com

The Laws of Physics | The Art of Listening

EAW is the worldwide technological and market leader in the design and manufacture of high-performance, professional loudspeaker systems.

Page 2

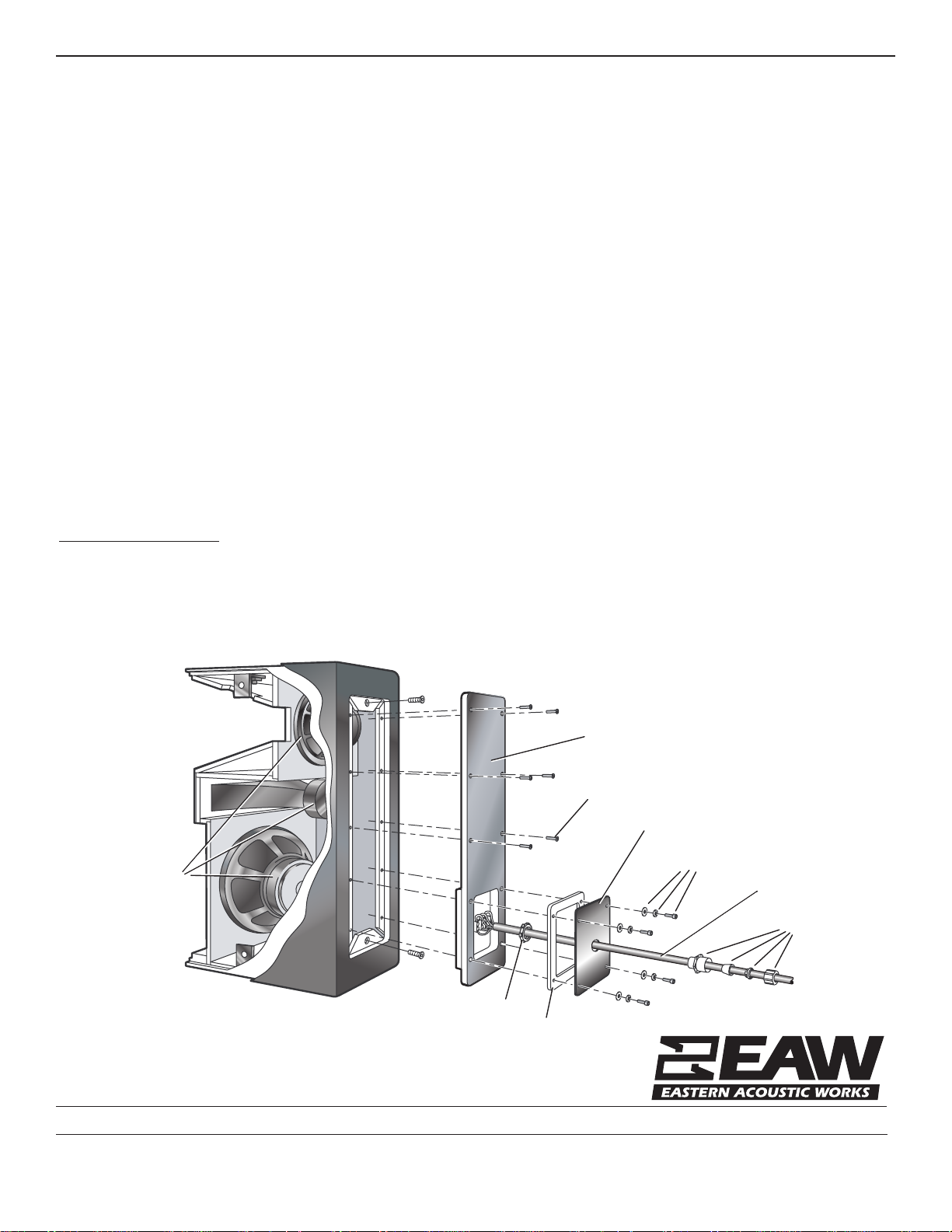

Access Hatches

Hatches that are removed for any reason must be replaced

and sealed with a non-hardening, waterproof, UV-stable

sealant suitable for use over the temperature range typical

for your geographical location. Sealant must be compatible

with the surface being sealed to ensure proper adhesion.

Hardware used to secure hatches must be sealed with a

non-hardening, non-locking thread sealant.

Input Cover Plates

All cover plates must be in place after connections to the

loudspeaker system have been made. Conduit should be

connected to cover plates using waterproof fittings. Bolts

securing cover plates must be sealed with a non-hardening,

non-locking thread sealant.

Drivers/Transducers

EAW drivers/transducers intended for use in WeatherProtected systems are designed specifically for outdoor

applications. Failed units should only be repaired/replaced

with factory-authorized parts. When contacting the EAW

Service Department, be sure to notify service personnel that

the replacement part is for use in a Weather-Protected system.

Routine Inspection

While installed, loudspeakers should be periodically examined and tested to maintain performance and safety. Two

main areas for inspection are Acoustical Performance and

Structural Integrity. Some of the main inspection points are

as follows:

ACCESS HATCH

ACCESS HATCH HARDWARE

INPUT COVER PLATE

DRIVERS AND

TRANSDUCERS

WEATHERPROOF FITTING

COVER PLATE GASKET

COVER PLATE HARDWARE

CONDUIT

WEATHERPROOF

FITTINGS

Loading...

Loading...