Page 1

KF730 & SB730 LOUDSPEAKER

OWNER’S MANUAL

PRELIMINARY

Page 2

READ THIS FIRST

1.1 EC STATEMENT OF CONFORMITY

This document confirms that the range of products of Eastern Acoustic Works bearing the CE label meet all

the requirements in the EMC directive 89/336/EEC laid down by the Member States Council for adjustment

of legal requirements, furthermore the products comply to the rules and regulations referring to the

electromagnetic compatibility of devices from 30 August 1995.

The authorized declaration and compatibility certification resides with the manufacturer and can be viewed

upon request. The responsible manufacturer is the company:

Eastern Acoustic Works

One Main St.

Whitinsville, MA 01588 USA

Tel: 508-234-6158

Fax: 508-234-8251

E-mail: info@eaw.com

Whitinsville, MA USA 2003 April

1.2 SAFETY PRECAUTIONS

The terms “Caution,” “Warning,” and “Danger” are used throughout this manual to alert the reader to

important safety considerations. If you have any questions about any aspects of these precautions, contact

your local dealer, distributor, or EAW. The following are the descriptions of the safety precautions.

CAUTION: describes an operating condition or user action that may expose the equipment or user to

potential damage or danger.

WARNING: describes an operating condition or user action that will cause damage to the equipment or

injure the user.

DANGER: describes an operating condition or user action that will immediately damage the equipment or

be extremely dangerous or possibly life-threatening to the user.

1.3 GENERAL PRECAUTIONS

WARNING: Some aspects of rigging and other related fields for which EAW manufactures, sells, or

distributes equipment are potentially hazardous. Any person using this equipment is personally responsible

for their own safety. EAW transactions are made with the assumption that the purchaser is a qualified

individual or will have only qualified individuals perform work with the equipment. EAW will not be liable for

any damages arising from the use of equipment sold to purchaser.

DANGER: Only persons with the knowledge of proper hardware and safe rigging techniques should

attempt to suspend KF730 and SB730 loudspeaker systems overhead. Failure to follow this precaution

may result in damage to the equipment, injury, or death.

Page 2 of 16 EAW KF730 & SB730 PRELIMINARY OWNER’S MANUAL

Page 3

2. INTRODUCTION

The KF730 Line Array represents EAW’s latest technology for arrayable loudspeakers. The KF730 is a

small format line array system for venues with listener distances up to about 200 ft / 65 m. The KF730

Series is designed to provide the highest output possible from a compact line array format. The Series

includes the 3-way, bi-amplified KF730 full-range and the complementary dual 12 in SB730 subwoofer.

This manual provides information about the design, configuration, and operation of KF730 Line Arrays. It is

intended to be used in conjunction with the KF730 Wizard Windows®-based software. Please thoroughly

familiarize yourself with this manual. The more you learn and understand the KF730 Line Array the easier

you will find it to use. This is not so much because of any inherent complexities, but because it is actually

easier to use than most, if not all, array systems.

3. UNPACKING

3.1 CONTENTS

KF730

(1) KF730 loudspeaker

(6) Connecting Pins

(1) Owner’s Manual

SB730

(1) SB730 loudspeaker

(4) Connecting Pins

(1) Owner’s Manual

3.2 SHIPPING DAMAGE

After unpacking, if the loudspeaker is found to have shipping damage, save the packing materials for the

carrier’s inspection, notify the carrier immediately, and file a shipping damage claim.

Although EAW will help in any way possible, it is always the responsibility of the receiving party to file any

shipping damage claim. The carrier will help prepare and file this claim.

3.3 RETURNING PRODUCTS TO EAW

If the loudspeaker must be returned to EAW, contact the EAW Service Department for a Return

Authorization (See Chapter 7). Use the original shipping carton and packing materials. If the shipping

carton is damaged, contact EAW for a new carton, for which there will be a small charge. EAW will not be

responsible for damage caused by inadequate packing.

EAW KF730 & SB730 PRELIMINARY OWNER’S MANUAL Page 3 of 16

Page 4

4. KF730 ARRAY DESIGN

4.1 KF730 WIZARD

Use the KF730 Wizard for designing KF730 arrays. It can be found in the Downloads section of the EAW

website (www.eaw.com). The Wizard’s primary function is to determine the configuration that will provide

the best vertical coverage for a given application. Various venue dimensions are entered that allow the

Wizard to calculate the resultant array performance. Given this information, the Wizard works in either of

two basic ways. For complete instructions about operating the KF730 Wizard, click on the About/Help

menu when running the Wizard.

Automatic Mode: The Wizard will select the optimum number of enclosures, enclosure splays, array aiming

angle, and fly-bar pick point. This can also be done for a given inventory of SB730s and SB730s. There are

variable adjustments for application-specific output levels and for level consistency for near-to-far listeners.

Manual Mode: This provides complete control over the array’s configuration.

4.1.1 Computer Requirements

The Wizard requires an IBM compatible PC with the Windows® 98, Windows® 98SE, Windows® 2000,

Windows® ME, Windows® XP, and Windows NT® operating systems. It is not designed to work with

Windows® 3.x, Windows® 95, or Macintosh® operating systems.

4.1.2 Wizard Results

• Graphical representations of the array and the venue

• Aiming splay angle between each pair of enclosures

• How to set the enclosure-to-enclosure rigging

• On-axis aiming angle for each enclosure as a difference from 0° horizontal

• Various angles and throw distances calculated from the venue’s dimensions

• Difference between the array beamwidth angle and the needed coverage angles

• Length of the array and trim height to the bottom of the array from the floor

• Pick Point on the Fly-Bar to achieve the calculated array angle when suspended

• Weight of the array

4.2 FILL COVERAGE

4.2.1 Up-Fill

Some applications, such as theaters and small arenas, can require up-fill coverage from the array. In this

case, the array is designed to tilt back for up-firing coverage from the topmost enclosures.

4.2.2 Down-Fill

Many applications require extreme down-fill coverage. In this case, the array is designed to have enough

curvature for the bottom KF730 to provide coverage almost directly beneath the array.

4.2.3 Horizontal Coverage And Side-Fill Arrays

Regardless of the length of the array, a KF730 array has a horizontal beamwidth (-6 dB points) of

approximately 110°, with pattern control maintained to a very low frequency.

The horizontal pattern also features “soft shoulders” that provide consistent frequency response to well

beyond the nominal -6 dB points. These soft shoulders can provide up to 150° of “usable” horizontal

coverage, albeit at somewhat reduced level. This off-axis performance also provides good acoustic

integration with side-fill arrays. In some cases, these shoulders may be sufficient for side-fill purposes.

4.2.4 KF730 Series as Side-fill Arrays

KF730 side fill arrays can be hung adjacent to the mains, extending the coverage to over 180° for wraparound audience coverage.

Page 4 of 16 EAW KF730 & SB730 PRELIMINARY OWNER’S MANUAL

Page 5

4.3 GROUND STACKING

Normally, a ground-stacked KF730 main array is used where suspension is not possible, too difficult, or too

time consuming. Additional uses are as stage side fills and audience front fill.

Both KF730s and SB730s may be ground-stacked alone or in combination. In combination, always stack

the KF730s on top of the SB730s. The recommended minimum and maximum array quantities are:

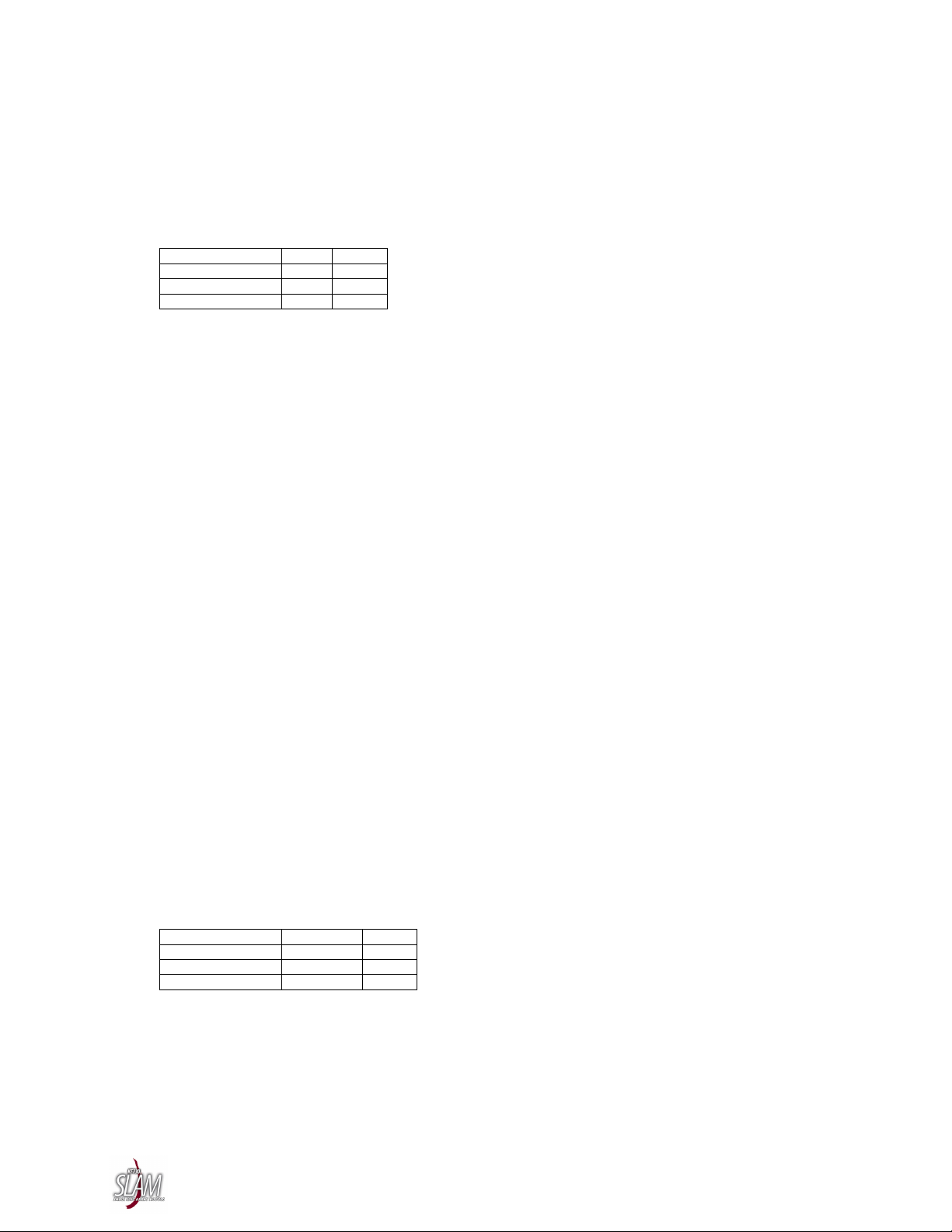

Array Min Max

KF730 alone 2 6

SB730 alone 1 4

KF730 / SB730 2/1 4 / 2

4.4 SUBWOOFERS

4.4.1 General Considerations

Although the impressive low frequency performance of KF730 Series arrays allows them to be used without

subwoofers for some events, subwoofers will normally be used for live musical performances. The

recommended subwoofers are EAW’s SB730, specifically designed to complement KF730 line arrays.

NOTE: Bass performance is often highly program or venue-dependent, as well as subjective as to quantity

and quality. For this reason the type, quantity, and disposition of subwoofers may vary considerably with

the application. The quantity recommendations below are for general purposes, providing a balanced

system for most music applications. Quantities may need to be adjusted up or down for specific situations.

4.4.2 SB730 Subwoofers

SB730 subwoofers are designed to complement the KF730 loudspeakers to both extend the low frequency

response and provide more output for the upper low frequencies. The SB730 subwoofers may either be

ground stacked, flown as part of a KF730 array, or flown separately alongside a KF730 array.

A general recommendation is to use KF730s and SB730s in a ratio of 3 KF730s to 2 SB730s.

4.4.3 Suspending SB730 Subwoofers

The SB730 enclosure rigging is designed to directly couple to a KF730 Fly-Bar and KF730 enclosures. As

such, the SB730 can be rigged seamlessly with KF730s.

When flown as part of a KF730 array, the SB730s should be the uppermost enclosures in the array. In this

application, the SB730s are suspended flat-fronted, with the KF730s suspended below in their curved line.

When flown separately, SB730s should be flown so that the spacing between the line of SB730 enclosures

and KF730 enclosures is about 1 ft / 0.3 m. The SB730 should be suspended in a flat-fronted configuration.

4.4.4 Other Subwoofers

Other subwoofers, such as the EAW’s SBX220, SB1000zRi, or BH760, can also be used with KF730s. For

Recommended quantities of KF730 for each subwoofer are:

Model Subwoofer KF730

SBX220 2 3

BH760 1 4

SB100zRi 1 2

4.4.5 Signal Delay on Subwoofers

If SB730 or other subwoofers are used with KF730s, it will usually be necessary to apply overall signal

delay to the either the processor’s subwoofer outputs or KF730 outputs in order to synchronize the outputs

of the subwoofers with the KF730s.

EAW KF730 & SB730 PRELIMINARY OWNER’S MANUAL Page 5 of 16

Page 6

5. ARRAY OPERATION

5.1 OVERVIEW

The operation of a KF730 Series system involves:

1. Understanding the principles on which it operates.

2. How to electronically configure it for a specific task.

5.2 ENGINEERING DESIGN

How a KF730 Array works: Divergence Shading

In almost any venue, there are significant differences in distance from the loudspeaker array to the nearest

and farthest audience members. The idea is to turn up the output level of the array aimed towards the

farthest audience members, then progressively turn it down for audience members closer to the array.

These differences in distance are accompanied by changes in the array’s vertical aiming angle.

Rather than use amplifier input levels, the volume controls for the KF730 is a combination of the shape of

its curvature and the quantity of KF730s that make up the array. If you understand this point, you

understand how a KF730 array works. Simply put, less curvature turns the volume up and more curvature

turns the volume down. Specifically:

1. More splay at the rear of the enclosures turns the volume up (adds less curvature to the array)

2. Less splay at the rear of the enclosures turns the volume down (adds more curvature to the array).

3. More enclosures provide a greater vertical coverage angle.

4. Fewer enclosures provide less vertical coverage angle.

5.3 SYSTEM BLOCK DIAGRAM

The block diagram shows the signal flow for a single KF730 and

SB730. A DSP (Digital Signal Processor) with three outputs is

required. Additional KF730s and SB730s would be connected in

parallel with the same processor outputs, pre or post amplifier.

5.4 SIGNAL PROCESSING

WARNING: Do not under any circumstances use “generic” or

your “favorite” crossover settings. Always use EAW’s

recommended processor settings. KF730 array performance, in

terms of frequency response, beamwidth consistency, output

level capability, and wavefront coherency is dependent on the

EAW engineered crossover and other processing settings.

5.4.1 Factory Signal Processing Settings

The signal processing adjustments determined by EAW for the KF730 Series Array should be fully

implemented “as is.” These settings are determined from extensive measurements in typical venues as well

as the theory of curved sources from the acoustical work of physicists Harry Olsen and Leo Beranak. As

such, they will normally provide excellent results in a variety of venues.

Factory signal processor settings can be found in the Downloads section of the EAW web site:

www.eaw.com.

5.4.2 Non-EAW Digital Signal Processors

Even though they can be set to numerically equal values, the transfer function (magnitude and phase) for

any equalization applied can vary for different digital processors. The factory settings were determined

using EAW’s MX8750 Digital Signal Processor. If in doubt about any other processor’s equalizer

implementation, contact EAW.

Page 6 of 16 EAW KF730 & SB730 PRELIMINARY OWNER’S MANUAL

Page 7

5.5 AMPLIFIER GAIN SETTINGS

In order for Divergence Shading to work properly, all amplifiers for all passbands must be set to the same

voltage gain, regardless of their power output ratings.

NOTE: This does NOT mean the same input sensitivity, but the same input to output voltage gain. Consult

your amplifier manufacturer if this cannot be readily determined. Do not selectively boost or attenuate

loudspeaker levels at the amplifiers in order to achieve consistent SPL at various distances. This is

achieved by adjusting the array curvature as described above. This will also maintain array coherence

throughout the venue.

5.6 USER ADJUSTEMENTS

5.6.1 Equalization

EAW recommends that 1/3 octave or careful use of parametric equalization be used to modify performance

to accommodate a particular program, venue characteristics, or personal taste.

5.6.2 Array Measurements

SMAART - The SmaartLive program from SIA Software Company is an ideal tool to use to measure and

optimize a KF730 array for a particular venue. This is a fast, yet sophisticated, process that will show up

problem areas due to particular venue characteristics. Usually it is a matter of applying small amounts of

1/3 octave or parametric equalization to adjust significant anomalies. A demo version of SmaartLive is

available at www.siasoft.com.

5.7 AMPLIFIER POWER REQUIREMENTS

As is true of all professional loudspeaker systems, the performance of the KF730s and SB730s depends on

amplifiers delivering an adequate supply of clean power. The selection of the appropriate power amplifier is

a subject of some debate. There is no exact answer to the question of what amplifier power you should use

for a particular loudspeaker or transducer. There are three separate and distinct issues regarding amplifier

power as discussed in the next sections.

For more information on selecting appropriate amplifiers, please consult EAW’s Technical Paper on

Amplifier Power, available on the EAW web site or by contacting EAW Applications Support Group.

5.7.1 Power Ratings

The KF730 is a bi-amplified loudspeaker, requiring one LF and one MF/HF amplifier channel. The SB730

can be either single amplified, requiring one amplifier channel for both drivers, or multi-amplified, requiring

a separate amplifier channel for each driver.

Model KF730 SB730

Input LF MF/HF SUB 1 / SUB 2 (paralleled) SUB 1 & SUB 2 (each)

Continuous 700 W / 106 V 350 W / 75 V 1400 W / 75 V 700 W / 75 V

Nominal Impedance 16 ohm 16 ohm 4 ohm 8 ohm

CAUTION: The ratings listed above are the published continuous (thermal) power ratings meaning that

they have passed EAW’s standard power handling test. In this test, transducers are “exercised” to a point

of damage or failure. A power rating for the loudspeaker is then determined based on these test results and

the transducer’s application in the system. The powers listed are calculated from the RMS voltage level of

an EIA-426A pink noise signal with a 6 dB peak to average ratio at each sub-system’s nominal impedance.

The listed power ratings are intended as a point of comparison with the power ratings of other

loudspeakers. In many applications, these ratings do not necessarily correspond to the best amplifier sizes

for optimizing loudspeaker reliability and performance. Proper amplifier selection requires a considered

analysis for the particular application.

EAW KF730 & SB730 PRELIMINARY OWNER’S MANUAL Page 7 of 16

Page 8

5.7.2 Selecting an Appropriate Amplifier Size

The amplifier for your loudspeaker should be sized according to both the sound levels required and the

type of audio signals that will be reproduced. If you are unsure of how to determine these parameters,

consult a qualified professional or contact EAW’s Application Support Group.

If a KF730 Line Array is used for professionally operated and controlled concert applications, a rule of

thumb can be applied. Where the full output capabilities of the loudspeakers are needed to achieve

appropriate acoustic output levels, EAW recommends amplifiers rated at twice the loudspeaker’s published

power ratings. This provides peak power capability 6 dB above the specified power handling without

exceeding the transducer’s thermal limits. This assumes that the audio signals will have peak to average

ratios in excess of 6 dB, which is usually, but not always, true. Under this condition, the thermal limits are

unlikely to be exceeded. This is consistent with the EAW’s power testing parameters. However, this

recommendation does NOT guarantee trouble-free operation. That is the next issue.

5.7.3 Operating Limits

It is the responsibility of the audio system operator to operate the system properly and within its

capabilities. This is the only way to ensure that loudspeakers are not stressed beyond their limits to the

point of damage or failure.

WARNING: The power amplifier sizes recommended by the above rule of thumb are capable of continuous

output levels that can cause damage to or failure of the transducers. Exercise caution in operation to avoid

exceeding both the maximum RMS and peak voltage ratings listed in the Power Ratings section above.

5.8 INPUT CONNECTIONS

5.8.1 KF730 Input Connections

There are two Neutrik NL4MP connectors on the rear of each KF730. The connectors mate with Neutrik

NL4FC in-line cable connectors.

KF730 INPUT NL4 (each of two)

PIN 1- LFPIN 1+ LF+

PIN 2- MF/HFPIN 2+ MF/HF+

1. Use as the input to the KF730

2. Use the second connector to loop the LF and MF/HF signals to the next KF730.

5.8.2 SB730 Connections

There are three Neutrik NL4MP and one NL8MP connectors on the rear of each SB730. The connectors

mate, respectively, with Neutrik NL4FC and NL8FC in-line cable connectors.

SUB INPUT/OUTPUT NL4MP (each of two)

PIN 1- SB730 SUB 1PIN 1+ SB730 SUB 1+

PIN 2- SB730 SUB 2PIN 2+ SB730 SUB 2+

1. Use as the input to the SB730.

2. Use the second connector to loop SUB signals to additional SB730s.

Page 8 of 16 EAW KF730 & SB730 PRELIMINARY OWNER’S MANUAL

Page 9

5.8.3 SB730 System Input Connections

The NL8MP connector on the SB730s can be used as the input for an entire array.

SYSTEM INPUT NL8MP

PIN 1- SB730 SUB 1PIN 1+ SB730 SUB 1+

PIN 2- SB730 SUB 2PIN 2+ SB730 SUB 2+

PIN 3- KF730 LFPIN 3+ KF730 LF+

PIN 4- KF730 MF/HFPIN 4+ KF730 MF/HF+

1. Connect the four different amplified signals needed to power a complete array of KF730s and SB730s.

2. Use the KF730 OUTPUT to loop the LF and MF/HF signals to the KF730s using NL4 cabling.

3. Use the SUB INPUT/OUTPUT to loop the Sub signals to the next SB730 using NL4 cabling.

4. Daisy-chain additional SB730s in a similar fashion.

NOTE: Using the SB730 SYSTEM INPUT on one SB730, an NL8 cable carries all amplified signals from

the array’s amplifiers to this SB730. Using NL4 cabling from this SB730, you can loop up to eight KF730s

and three additional SB730s. With the maximum combination, the nominal load for each of the four

amplified signals is 2 ohms.

KF730 OUTPUT NL4MP

PIN 1- KF730 LFPIN 1+ KF730 LF+

PIN 2- KF730 MF/HFPIN 2+ KF730 MF/HF+

1. Connect to a KF730 INPUT using NL4 cabling.

5.8.4 Wire Gauge

The following are minimum recommended wire sizes for loudspeaker cabling. The wire sizes are based on

maintaining an acceptable damping factor and minimizing power loss. The table includes nominal load

impedances where the passbands in multiple enclosures are paralleled off one amplifier channel.

Maximum Cable Length Nominal Input Z Wire Gauge

50 ft / 15 m 16 ohm 16 AWG / 16 MWG

100 ft / 30 m 16 ohm 14 AWG / 16 MWG

200 ft / 60 m 16 ohm 12 AWG / 20 MWG

300 ft / 90 m 16 ohm 10 AWG / 25 MWG

>300 ft / >90 m 16 ohm Not recommended

50 ft / 15 m 8 ohm 14 AWG / 16 MWG

100 ft / 30 m 8 ohm 12 AWG / 20 MWG

200 ft / 60 m 8 ohm 10 AWG / 25 MWG

>200 ft / >60 m 8 ohm Not recommended

50 ft / 15 m 4 ohm 12 AWG / 20 MWG

100 ft / 30 m 4 ohm 10 AWG / 25 MWG

>100 ft / >30 m 4 ohm Not recommended

50 ft / 15 m 2 ohm 10 AWG / 25 MWG

> 50 ft / > 15 m 2 ohm Not recommended

(AWG = American Wire Gauge; MWG = Metric Wire Gauge)

EAW KF730 & SB730 PRELIMINARY OWNER’S MANUAL Page 9 of 16

Page 10

6. RIGGING

WARNING: Suspending anything, especially overhead of people, should be done with extreme

caution. Always engage the services of a certified professional who is qualified to determine the

requirements for and to implement overhead rigging. Only persons with the knowledge of proper

hardware and safe rigging techniques should attempt to suspend KF730 Series loudspeaker systems

overhead. Failure to follow these precautions may result in damage to the equipment, injury, or death.

KF730 Series arrays are intended to be suspended or ground-stacked. This chapter details how to

physically configure a KF730 Series array.

6.1 RIGGING LOAD RATING (WLL)

The KF730, SB730 and Fly-Bar rigging has a WLL (Working Load Limit) for suspending a maximum of

eighteen KF730s or a maximum of 12 SB730s. The design factor for this rating is 8:1.

6.2 RIGGING RECOMMENDATIONS

6.2.1 Attachment to the Fly-Bar

The KF730 Fly-Bar design permits several methods of attachment.

1. Center Holes:

• Use one of these holes for single point attachment, the particular hole being dictated by the KF730

Wizard to result in the correct array tilt angle.

• Use one hole in the rear and one in the front for bridling to a single point.

• Use one hole in the rear and one in the front to attach two chain motors.

2. Corner Hoisting Points:

Use in pairs, side to side, to bridle to single front and rear points for attaching two chain motors.

6.2.2 Rigging Methods

The two recommended rigging methods are:

1. Employ one chain motor, attached to particular Center Hole dictated by the KF730 Wizard

• This will automatically result in the correct array tilt angle when all enclosures are flown.

• One motor may be easier to deploy than two.

2. Employ two chain motors, one attached to the front of the Fly-Bar and the second to the rear.

• The attachment can be to the Center Holes or the Corner Hoisting Points.

• The array will be easier to assemble because it allows tilting the enclosures already suspended to

better match the angle of the next enclosure(s) to be attached.

• Once assembled, the overall tilt angle for the array can be easily adjusted, if needed.

6.3 ENCLOSURE TO ENCLOSURE ATTACHMENT

6.3.1 Splay Angles

The splay angles required between each enclosure to achieve the desired array curvature are set by the

integral rigging hardware. The hardware consists of square Hinge Tubes each with a sliding Hinge on each

of the four enclosure corners.

6.3.2 Basic Attachment Procedure

With the enclosures near or in contact, slide the Hinges into the Hinge Tubes of the enclosure or the FlyBar above it. Connect the Hinges to each of the four Hinge tubes using the supplied connecting pins.

CAUTION: To avoid pin damage while moving or transporting the enclosures, always insert the pins from

the inside of the Hinge Tubes.

Page 10 of 16 EAW KF730 & SB730 PRELIMINARY OWNER’S MANUAL

Page 11

6.3.3 Hinge And Hinge Tube Holes

Each Hinge and Hinge Tube has several holes for inserting the supplied Connecting Pins to attach

enclosures together. The particular holes used determine the splay angles between the aiming axes of the

loudspeakers. The required splay angles are designated by the KF730 Wizard.

KF730 to Fly-Bar 1

Rear Hinge Hole Rear Hinge Tube Hole Front Hinge Hole Front Hinge Tube Hole

3 Upper 2 Upper

SB730 to Fly-Bar 1

Rear Hinge Hole Rear Hinge Tube Hole Front Hinge Hole Front Hinge Tube Hole

1 Upper 1 Upper

KF730 to KF7302

Front Splay Angle Rear Hinge Hole Rear Hinge Tube Hole Front Hinge Hole

1.5° 1 A 2

3.0° 2 B 2

6.0° 3 B 2

12.0° 4 B 2

18.0° 4 B 1

KF730 to SB7302

Front Splay Angle Rear Hinge Hole Front Hinge Hole

-7.2° 1 2

-3.0° 2 2

0.0° 3 2

6.0° 4 2

12.0° 4 1

NOTES: 1. This positions the front face of the enclosure so it is 90° to the plane of the KF730 Fly-Bar.

2. The front splay angle is the angle between the aiming axes of the loudspeakers. It is not the splay

angle between the top/bottom enclosure surfaces.

KF730 FLY-BAR HINGE TUBE HOLES

UPPER HOLES: USE THESE HOLES

FOR SUSPENSION

WARNING: USE LOWER HOLES

ONLY FOR GROUND STACKING

KF730 AND SB730 HINGE AND HINGE TUBE HOLES

Hole 1

Hole 2

FRONT

HINGE

REAR

HINGE

Hole 1

Hole 2

Hole 3

Hole 1

Hole 2

FRONT

REAR

HINGE

Hole 1

Hole 2

REAR

HINGE

TUBE

Hole A

Hole B

EAW KF730 & SB730 PRELIMINARY OWNER’S MANUAL Page 11 of 16

Page 12

6.3.4 LOCKING PINS

Certain array configurations and array tilts can collapse the splays between KF730 enclosures. This is

more likely to occur the more the array is curved relative to its length. The reason this happens is the

center of gravity for those enclosures ends up being forward or rearward of the suspension point(s). In

these cases, the Locking Pins should be used.

When ground-stacking, creating splays between enclosures requires the

use of locking pins.

Locking pins are inserted in the Hinge Tubes at the top of an enclosure

through the hole in the part of the Hinge captive to that tube and below

the hinge knuckle. This prevents the Hinge from receding down into its

LOCKING PIN

HOLE

own Hinge Tube, which is what happens when the splay between two

enclosures collapses. The KF730 Wizard will indicate when locking pins

are likely needed.

CAUTION: When tilting the array while rigging or unrigging enclosures,

unexpected collapse of the splays can occur because of shifts in the

array's center of gravity. To prevent this, It is recommended to always

use locking pins as described.

6.4 SETTING THE TILT ANGLE FOR THE ENTIRE ARRAY

Normally, the easiest method is to use a clinometer, such as a simple, bubble-type angle finder (pictured).

More sophisticated, albeit more expensive, electronic clinometers can also be used.

Place the angle finder against one of the rigging tubes on the face of the

uppermost enclosure in the array that can be physically reached. Using the

aiming angle for that enclosure listed in the KF730 Wizard, adjust the angle of the

entire array so that the face this enclosure is set at its prescribed aiming angle.

Page 12 of 16 EAW KF730 & SB730 PRELIMINARY OWNER’S MANUAL

Page 13

7. CONTACTING EAW

HOW TO CONTACT EAW

We have tried to answer any questions you may have about the KF730 and SB730 in this manual and the

associated guides. Should you need further assistance, please do not hesitate to contact us. You can

contact us in several different ways.

7.1 OPERATING QUESTIONS

For questions about configuring or operating the loudspeakers, contact:

EAW Applications Support Group

Tel 508-234-6158

Tel 800-992-5013 (USA only)

Fax 508-234-8251

e-mail asg@eaw.com

7.2 SERVICE INFORMATION

For questions about troubleshooting or servicing a KF730 or SB730, contact:

EAW Service Department

Shipping One Main Street

Whitinsville, MA 01588 USA

Tel 508-234-6001

Tel 800-992-6001 (USA only)

Fax 508-234-3776

e-mail service@eaw.com

7.3 LITERATURE AND SPECIFICATIONS

For literature and specifications on EAW products, contact:

EAW Literature Department

Tel 508-234-6158

Tel 800-992-5013 (USA only)

Fax 508-234-8251

Web Site http://www.eaw.com

e-mail litperson@eaw.com

7.4 GENERAL

For all other information:

Mail Eastern Acoustic Works

One Main Street

Whitinsville, MA 01588 USA

Tel 508-234-6158

Tel 800-992-5013 (USA only)

Fax 508-234-8251

Web Site http://www.eaw.com

e-mail info@eaw.com

EAW KF730 & SB730 PRELIMINARY OWNER’S MANUAL Page 13 of 16

Page 14

8. TROUBLESHOOTING AND SERVICE

8.1 SERVICE

For any faults that cannot be field-repaired as noted below, contact the EAW Service Department listed in

Chapter 7 to determine the appropriate action. This applies to both warranty and non-warranty faults.

8.2 RIGGING

Because of the potential, serious consequences and liabilities due to faulty rigging, contact EAW to

determine the appropriate service solution for any rigging hardware problems.

8.3 BASIC TROUBLESHOOTING

Each KF730 Series loudspeaker has an input panel, internal components and wiring, two or four

transducers, and an enclosure. Troubleshooting a KF730 or SB730 for various performance problems

usually involves isolating the problem to one of these areas:

1. Transducers

2. Input panel, internal components, and wiring

3. Enclosure and integral hardware

If no problems can be traced to any of these items, look for problems with external electronics or cabling.

Troubleshooting these items is beyond the scope of this manual.

8.3.1 Transducers

A faulty transducer will usually cause readily audible distortions or other unwanted noises. In other cases,

they may stop functioning. Use your ears and test signals or other sound source to determine which one is

at fault. Normally a faulty transducer requires service or replacement by EAW.

8.3.2 Input panel, Internal Components and Wiring

Faults with these items will usually cause transducers to stop working or possibly be intermittent. Check

that audio signals pass from the input jacks to the transducer terminals. Many faults with this area can be

field-repaired.

8.3.3 Enclosures

Enclosure problems, such as loose hardware, faulty joints, or other structural problems, will usually be

heard as distinct buzzes, rattles, or other unwanted noises. To test for enclosure problems, use a sine

wave signal manually swept on the LF sub-system. The input level should be no more than 6 dB below

rated power (equals no more than 1/2 rated voltage). It may be possible to field-repair some enclosure

problems.

§§§

Page 14 of 16 EAW KF730 & SB730 PRELIMINARY OWNER’S MANUAL

Page 15

EAW KF730 & SB730 PRELIMINARY OWNER’S MANUAL Page 15 of 16

Page 16

EASTERN ACOUSTIC WORKS

ONE MAIN STREET

WHITINSVILLE, MA 01588

2003 May 16 RD # xxxxxxxx

Page 16 of 16 EAW KF730 & SB730 PRELIMINARY OWNER’S MANUAL

Loading...

Loading...