Page 1

Instructions/Installing the KF850z

NL8 and AP6 Upgrade Kits

The KF850z AP6 Upgrade Kit P/N 0006241 and the KF850z NL8 Upgrade Kit P/N 0006242 are available for the

KF850e loudspeaker. These two kits are the same but for the Electrical Assemblies.

Warning: Installation should only be done by an experienced technician. Improper installation may result

in damage to the equipment, injury or death.

1. Inventory the kit against the following bill of materials insuring the kit is complete.

EAW P/N Qty Description

804116 1 Driver-Cone (LC-1536)

102021 4 Screw 1/4-20 X 1-1/2 LG SHCS Blk

0005848 1 Horn/URE/H4532

0008726 1 Driver/Compression [DN20/3004-8]

102165 4 Screw/M6 X 14mm LG HHCS

105005 4 Washer/Flat 1/4

105004 8 Washer/Lock 1/4

0006004 2 Bracket/Horn [KF850z Upgrade Kit]

102016 6 Screw 1/4-20 X 1 LG PH PHMS Blk

105007 10 Washer/Flat 1/4 Blk

105008 10 Washer/Lock 1/4 Blk

102017 4 Screw 1/4-20 X1 SHCS Blk

804097 1 Driver-Cone [LC-1075]

0006008 1 Assembly/Phase Plug/Housing

0006005 1 Ring/Aperture/Wood/10” Mid [KF850z]

0006007 4 Screw 1/4-20 X 4-1/2 LG SHCS Blk

105033 4 Washer/Flat/M6

0006011 1 Instruction/Kit/KF850z/Upgrade

102087 4 Screw #8 X 1 LG PH PHSMS

102048 8 Screw #10 X 16 X 3/4 PH PHSMS

102102 23 Screw #8 X 5/8 PH PHSMS Blk

0006239 1 Electrical Assembly KF850z [NL8]

or

0006240 1 Electrical Assembly KF850z [AP6]

2. Overview

KF850z Kit installation requires the technician to remove and replace all transducer components. The HF

horn assembly is accessed from the front and the 15” woofer, 10” mid range, and electrical assembly from

the back.

To do this the enclosure will first be rested on its back, the grille

removed, and the HF horn assembly disconnected, removed, and disassembled. Its rear bracket will be re-installed into the new KF850z

HF horn assembly, which will then be installed into the enclosure.

After this is complete the enclosure should be repositioned onto its

front, and the 2 access lids, polyfill, input and crossover removed, the

new crossover installed, and its leads routed to the appropriate chambers. Then the new 15” woofer and the new mid assembly will be

installed. The old polyfill should be restapled into both chambers and

the new electrical assembly installed.

Finally the enclosure will be stood upright, HF leads connected, tested for continuity, and access lids and grille reinstalled.

3. Instructions: Tip the enclosure on its back and remove the 23

Phillips head screws that mount the grille to the enclosure.

S

REMOVE AND DISCARD

23 #8 X 5/8 LG PHILLIPS

HEAD SHEET METAL SCREW

10X GRILL

FOAM RETAINERS

(DO NOT REMOVE)

Page 2

T

Y

6

)

)

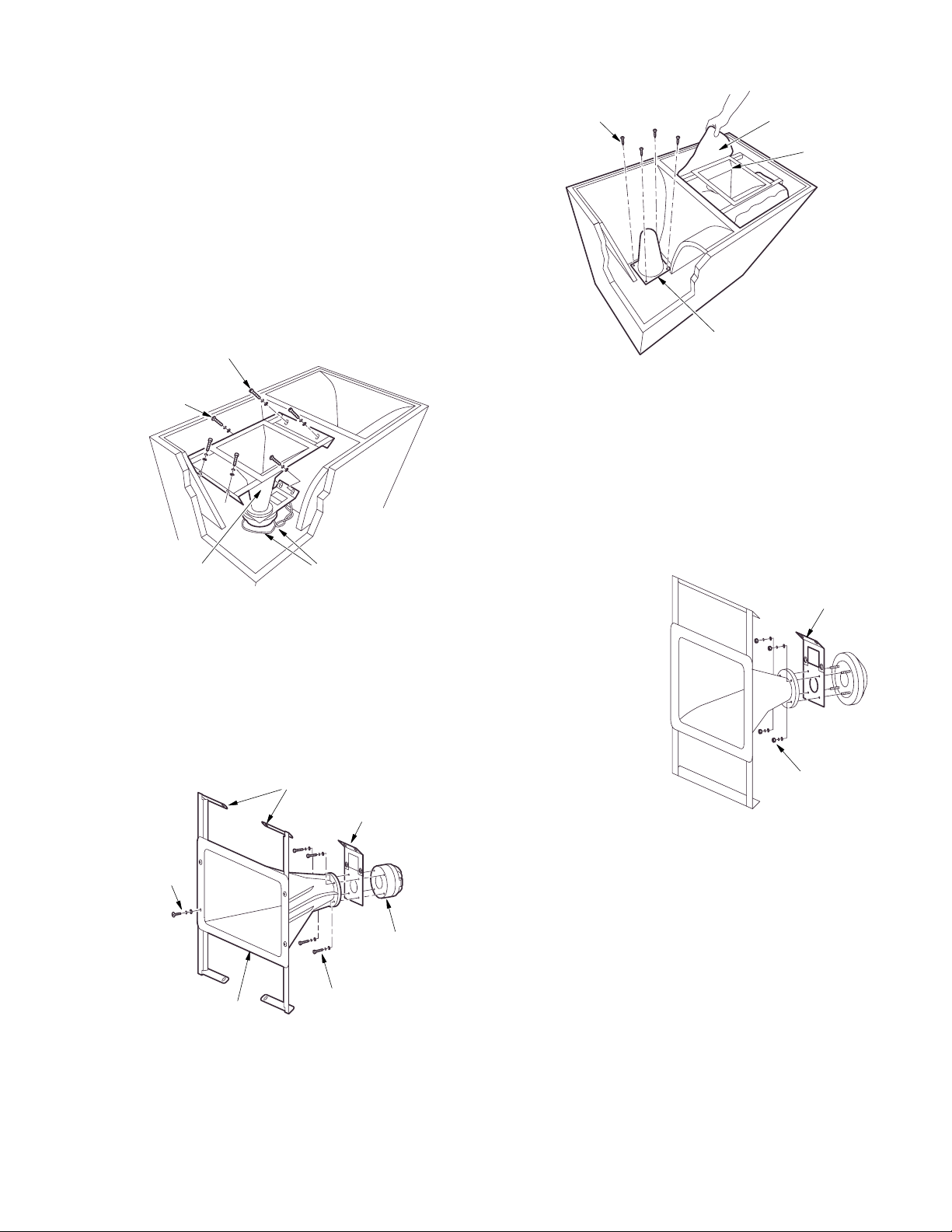

5. Removing the High Frequency Assembly

a. Disconnect the two leads.

b. Remove and discard the 2 Phillips head screws, lock

and flat washers that hold the back bracket to the enclosure.

c. Remove and discard the 4 socket head cap screws, lock

and flat washers that attach the front metal bracket to

the enclosure.

d. Lift the HF assembly from the enclosure.

4. Removing the Pillow and Wave Guide

The pillow is beneath the HF horn assembly and held to

the side walls of the enclosure by hook-and-loop tape.

Tug the sides of the pillow free and lift it out.

The waveguide/grille is attached by 4 Phillips head screws.

Remove the screws and remove the waveguide.

The pillow and waveguide will not be reused.

6. Dissassembling the High Frequency Assembly

a. Remove the 4 M6 nuts, lock and flat washers.

b. Separate the driver from the horn and remove the rear bracket. DO NOT

remove the 2 Phillips head screws that hold the two halves of the rear

bracket together.

c. The HF assembly may be discarded except for the rear bracket.

7. Building up the new the High Frequency Assembly

a. Assemble the driver and rear bracket to the round horn

flange using the 4 M6 bolts, lock and flat washers.

b. Attach the 2 brackets to the front horn flange as shown

using 4 black 1/4-20 x 1 lg Phillips head screws, 4 black

lock washers and 4 black flat washers.

8. Attaching the new the High Frequency Assembly to the Enclosure

a. Place the new HF assembly into the enclosure aligning the 4 slots in the front bracket and the 2 slots in the rear

bracket with the threaded holes in the HF chamber. Attach the front bracket to the enclosure with 4 black 1/4-20

x 1 lg socket head cap screws, lock and flat washers. Use 2 black 1/4-20 x 1 lg Phillips head screws, lock and flat

washers to attach the rear bracket to the enclosure. The 2 elecrical leads are attached in Step 12b.

4X PHILLIPS HEAD SCREWS

(REMOVE AND DISCARD)

PILLOW (REMOVE AND DISCARD

HIGH FREQUENCY

HORN ASSEMBLY

4X SOCKET HEAD CAP SCREWS

LOCK AND FLAT WASHERS

(REMOVE & DISCARD)

2X PHILLIPS HEAD

SCREWS LOCK

AND FLAT WASHERS

(REMOVE AND

DISCARD)

DISCONNECT

HIGH FREQUENCY

HORN ASSEMBLY

RED AND BLACK

WIRE ELECTRICAL LEADS

4X NEW 1/4-20

X 1" LG BLACK

SOCKET HEAD

CAP SCREWS,

LOCK AND

FLAT WASHERS

2X NEW HORN BRACKET

P/N 0006004

REUSED REAR BRACKE

NEW H4532

HORN P/N 0005848

NEW HIGH FREQUENC

DRIVER P/N 000872

4X NEW 6mm HEX HEAD

SCREWS, LOCKWASHER & FLAT

WASHER (USING 10mm WRENCH

WAVE GUIDE (REMOVE AND DISCARD)

REAR BRACKET

REMOVE NUTS, LOCK

WASHER & FLAT WASHER

USING 10mm WRENCH

Page 3

9. Reposition the Enclosure on its face.

With the grille still removed,

a. Reposition the enclosure front down.

b. Remove the 18 hex head screws and flat

washers that attach the two lids.

c. Lift the the two lids from the enclosure.

Retain the hardware and lids.

d. Remove all the polyfill fiber that surounds

the 10” and 15” drivers. Retain the polyfill.

e. Disconnect the 2 electrical leads from both

drivers.

f. Remove the 8 socket head screws that hold

both drivers into the enclosure and lift the

drivers away. Do not retain hardware or

drivers.

g. Remove and discard the 8 input Phillips

head mounting screws and dangle the input to the side of the enclosure as shown.

h. Free the electrical leads that pass thru partitions inside the enclosure.

i. Remove and discard the 4 crossover mounting screws and lift the electrical assembly from the enclosure.

S

)

10. Installing the new Electrical Assembly

a. Attach the new crossover as shown

with the 4 supplied #8 x 1” long

Phillips head screws.

b. Insert the blue and black leads from

the input board thru the partition

into the 15” woofer chamber.

c. Insert the red and black leads from

the crossover board, thru the partition, down thru the rectangular hole

into the HF chamber.

d. Seal the hole in the partition with

user supplied putty or silicone.

11. Installing the new Mid Driver and Woofer

a. Place the wooden aperture and new phase

plug into the mid chamber.

b. Position the new 10” driver onto the phase

plug.

c. Insert the 4 supplied 4-1/2 lg screws, lock

washers and M6 flat washers thru the

driver, phase plug and aperture into the

threaded holes in the baffle and tighten.

d. Install the input with the 8 supplied #10

Phillips head screws.

e. Connect the yellow and black leads from

the input board to the 10” mid driver. The

black lead to the black terminal.

f. Attach the new 15” woofer using 4 supplied

1/4-20 x 1-1/2 long screws.

g. Connect the blue and black leads from

the input board to the 15” woofer. The black

lead to the black terminal.

h. Restaple the polyfill into both chambers.

8X 1/4-20 X 1 HEX HEAD CAP

SCREWS & FLAT WASHERS

(DO NOT DISCARD HARDWARE)

SMALL LID

4X 1/4-20 X 1 LG

SOCKET HEAD

CAP SCREWS

(DISCARD

HARDWARE)

10 INCH MID DRIVER

(YELLOW AND BLACK

LEADS DISCONNECTED)

10X 1/4-20 X 1 HEX HEAD CAP

SCREWS & FLAT WASHERS

(DO NOT DISCARD HARDWARE)

LARGE LID

4X 1/4-20 X 1 LG SOCKET

HEAD CAP SCREW

(DISCARD HARDWARE

LEADS DISCONNECTED)

15 INCH WOOFER

(BLUE AND BLACK

REMOVED INPUT

(EIGHT #8 X PHILLIPS HEAD

SCREWS NOT SHOWN DISCARD HARDWARE)

RED AND BLACK LEADS FROM

CROSSOVER THRU PARTITION

& THRU RECTANGULAR CUTOUT

TO HIGH FREQUENCY ASSEMBLY

ELECTRICAL ASS'Y

INCLUDES THE

CROSSOVER BOARD

AND INPUT

(AP6 OR NL8)

BLUE AND BLACK LEADS FROM

INPUT THRU PARTITION

TO 15 INCH WOOFER

YELLOW AND BLACK

TO 10 INCH MID DRIVER

4X #8 X 1 LG PHILLIPS

LEADS FROM INPUT

4X 1/4-20 X 1-1/2 LG SOCKET

HEAD CAP SCREWS

BLK P/N 102021

NEW 15 INCH

WOOFER P/N 804016

(CONNECT BLUE

AND BLACK LEADS )

NEW INPUT HARD WIRED

TO INSTALLED CROSS OVER

HEAD SCREWS

INPUT OPENING MAY BE USED

TO ACCESS 10 INCH WOOFER

MOUNTING SCREWS

4X 1/4-20 X 4-1/2 LG

SOCKET HEAD

CAP SCREWS,

LOCK WASHERS

& M6 FLAT

WASHERS

NEW 10 INCH MID

DRIVER P/N 804097

PHASE PLUG ASS'Y

P/N 0006008

WOODEN APERTURE

RING P/N 0006005

Page 4

If you have questions about the KF850z kit installation please contact the EAW Application Support Group:

Tel 800-992-5013 (USA only)

Tel 508-234-6158

Fax 508-234-8251

E-mail asg@eaw.com

Thank you for purchasing

EAW products

One Main Street, Whitinsville, MA 01588 tel 800 992 5013 / 508 234 6158 fax 508 234 8251 web www.eaw.com

The Laws of Physics | The Art of Listening

EAW is the worldwide technological and market leader in the design and manufacture of high-performance, professional loudspeaker systems.

EAW P/N 0006011 (A) 6NOV03

12. Finishing the Kit Installation

a. Stand the enclosure upright.

b. Connect the red and black leads to the high frequency driver. The black lead to the black terminal.

c. Continuity check the low frequency, mid and high frequency drivers.

g. Re-attach the two access lids.

h. Re-attach the grille.

ATTACH RED AND BLACK LEADS

FROM NEW CROSSOVER BOARD

RE-ATTACH BOTH ACCESS

LIDS WITH THE 18 OLD

1/4-20 X 1 LG HEX HEAD

CAP SCREWS AND

FLAT WASHERS

RE-ATTACH GRILLE AND GRILLE FOAM

WITH THE 23 SUPPLIED #8 X 5/8 LG

PHILLIPS HEAD SHEET METAL SCREWS

Loading...

Loading...