USER MANUAL

for

KF860 ARRAYS

Juno Awards

GM Place, Vancouver, BC, Canada

Application: Live Sound

Devices Used: KF860, KF850, JF260, KF940, SM200, MX8600

Touring Company: Rocky Mountain Sound

The Laws of Physics / The Art of Listening

EASTERN ACOUSTIC WORKS

PRODUCT USAGE GUIDE:

AN INTRODUCTION

This is the fourth installment in the Eastern Acoustic W orks

Product Usage Guide series. The goal of this series is to offer

concise, accurate guidance on the use EA W loudspeaker

products.

Each guide will offer a concise overview of a particular

product series and illustrate the most common methods

of use. This chapter will focus on the application of the

six most common KF860 Series Virtual Line Array

configurations.

KF860 SERIES

The KF860/VLA Series comprises two

high-output modules optimized to

create vertical line arrays. The Series

comprises two modules – the KF860

which features a 60°horizontal

coverage pattern, and the KF861

which features a 90°pattern for

nearfield coverage . Nominal vertical

coverage is 30°but the each arra y's true

vertical pattern is determined by the size and

configuration of the array as well as by digital signal

processor settings.

Each module contains 2x 15-in woofers, 2x horn-loaded

1 0-in mid frequency cone drivers , and 2x 2-in exit/75mm

voice coil compression drivers on constant directivity horns.

KF860 SERIES BACKGROUND

AND DESCRIPTION

The KF860/VLA Series was originally developed to help

solve specific problems for high-end entertainment industry

events that featured both live and broadcast audiences.

The key design parameters were minimal array size , high

output and broadband pattern control.

Part of the KF860 Series solution was the application

of configuration-specific digital signal processing (DSP)

to maintain pattern control over an exceptionally wide

bandwidth. Settings vary depending on the number of

modules in the array and the angle between adjacent

modules.Thus two crucial elements of any KF860 Series

application are accurately splaying the enclosures and

applying the correct DSP settings.

BUILDING AND PROCESSING

KF860 SERIES ARRAYS

To maintain accurate and repeatable arra y angles, EA W

developed a unique, all-steel rigging s ystem for the KF860

Series that eliminates guesswork. The steel rigging plates that

link modules together fit into steel-tubing brackets on each

end of the module and are secured with quick-release pins.

The reader will find a complete explanation of this rigging

system on pages 7 and 8 of this guide as well as in the

companion publication, KF860 Hardware Instructions.

EA W has developed appropriate settings for the MX8600

Close Coupled Digital Processor to control each of the

KF860 array configurations discussed in this guide. These

settings are available from the ftp (file transfer protocol)

section of EA W's website (www .ea w .com) or can be faxed as

text files for manual entry . These settings are appropriate to

the MX8600 and only the MX8600. Do not attempt to use

these settings in any other DSP unit. Contact EA W's

Application Support Group for more information.

HANGING AND AIMING

KF860 SERIES ARRAYS

Hanging KF860 arrays requires the use of a dedicated

"bumper bar" developed for EA W by A TM, Inc. The bumper

bar accepts the top portion of the rigging plates at twelve

pre-configured locations.

The top module of any array will be aimed at an angle

determined by the bumper bar location selected and the size

and configuration of the array . As most application require

the array to be hung above the intended co verage area, the

bar has been designed to aim the array's output down.

However , the bar can be rev ersed to aim the array's output in

an upward direction. A chart indicating all possible angles

that can be obtained from the rigging system can be found

on page 8 of this guide.

EA W has developed a specially modified hand truck to

assist in rigging KF860 Series arrays. Specific instruction on

its use can be found at EA W's website or by contacting EAW

and requesting the KF860 Rigging Hardware Instructions.

15°

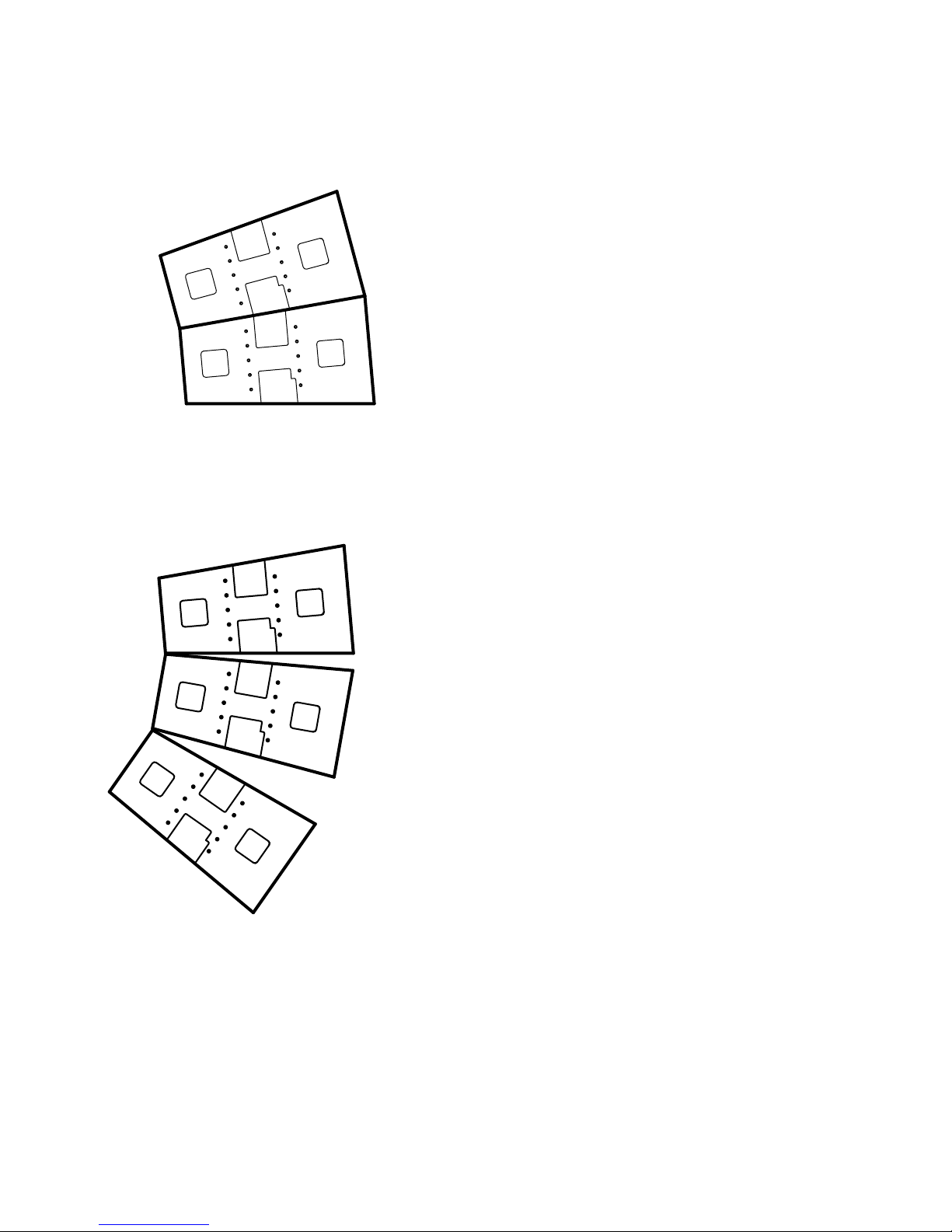

TWO-HIGH KF860 CONFIGURATION

Typical Uses: Distributed ground-stacked clusters, delay

clusters on lifts or scaffolds.

Coverage: 20 degrees (specific angles determined b y aiming)

Bumper Bar Trim Height (nominal): N/A

Splay: The boxes are nominally splayed 10 degrees, which is

the tight-packed configuration. The coverage angle can be

opened up or tightened by splaying more or less than the

nominal 1 0 degrees. Ground-stacking note???

Ground-Stacked Application Shown

5°

-10°

5°

Aiming: The cluster should be aimed so that the seam

between the two boxes points at the farthest seat. This

configuration is tuned for a 200 ft throw .

Processors: Only one EA W MX8600 processor is required.

• For manual entry – use file2xKF860.TXT which may be

found at ftp://ftp.eaw .com/PPSTfiles/KF860.

• For ECORE – use file 2xKF860.EACwhich ma y be found

at ftp://ftp.eaw .com/Process/MX8600

THREE-HIGH KF860 CONFIGURATION

Typical Uses: Theatres

Coverage: +10 degrees to -60 degrees

Bumper Bar Trim Height (nominal): 22 ft

Splay: The three boxes are aimed +5, -1 0, & -35 degrees , so the

boxes should be rigged with 15 degree (upper to middle box),

and 25 degree (middle to downfill box) splays.

Aiming: The cluster should be aimed so that the top box

points at the highest seating area. This configuration is tuned

for a 1 00 ft throw to the farthest seat.

-35°

Processors: One processor should drive the upper two boxes.

This processor is referred to as “main” in the settings.

A second processor should drive the lowest box. This

processor is referred to as “downfill” in the settings.

• For manual entry – use file3xKF860.TXT which may be

found at ftp://ftp.eaw .com/PPSTfiles/KF860.

• For ECORE – use file 3xKF860.EACwhich ma y be found

at ftp://ftp.eaw .com/Process/MX8600

Loading...

Loading...