Page 1

DSA250 & DSA230 LOUDSPEAKER

OWNER’S MANUAL

Page 2

DSA Owner’s Manual

TABLE OF CONTENTS

Introduction

Chapter 1 Safety

1.1 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.1 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Chapter 2 Unpacking

2.1 Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Shipping Damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Returning Products to EAW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 3 Quick Start

3.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Audio Signal Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.3 Computer Control Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.4 Daisy Chaining Audio and Computer Signal Between Loudspeakers. . . . . . . . . . . . 8

3.5 AC Mains Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.5.1 AC Mains Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.5.2 AC Mains Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.6 Physical Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.6.1 Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.6.2 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.7 Signal Processing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Chapter 4 Description

4.1 System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1.1 DSA Series Models. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1.2 Acoustical Benefits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1.3 Physical Benefits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1.4 Electrical Benefits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2.1 Acoustical. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2.2 Electronic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2.3 Computer Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2.4 Networking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2.5 Physical. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.3 Applications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.4 Engineering Design. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.5 DSAPilot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.6 Low Frequency Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.7 Comparison To Traditional Products. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.8 Designing DSA Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Chapter 5 Installation

5.1 Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.1.1 Cable Routing Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.1.2 Audio Signal Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1.3 Computer Control Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1.4 Daisy Chaining Computer and Audio Signals Within Clusters with Multiple Loudspeakers. . . 1 7

5.1.5 Daisy Chaining Computer and Audio Signals Between Clusters. . . . . . . . . . . . . . . . . 18

5.1.6 EIA-485 Terminate Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2 CobraNet™ Network Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2.2 CobraNet™ is Usually Desirable To Use When . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2.3 Additional Equipment You Must Supply For CobraNet™:. . . . . . . . . . . . . . . . . . . . . . . 19

5.2.4 Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2.5 Audio/Computer Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2.6 Loudspeaker Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2.7 Multiple Loudspeakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2.8 Support For CobraNet™/Ethernet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2

Page 3

5.3 AC Mains Power Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.3.1 AC Mains Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.3.2 AC Mains Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.3.3 Power On / Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.3.4 AC Mains Fuse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.4 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.4.1 Electrical Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.4.2 Audio Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.5 Physical Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.5.1 Installation Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.5.2 Physical Orientation - Signal End / Power End. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.5.3 Multiple Loudspeakers and Cluster Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.5.4 Installation Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.5.5 Angling Enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.5.6 Mounting Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.5.7 Wall Bracket Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.5.8 Enclosure Bracket Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.5.9 Enclosure Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.6 Initial Set-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.6.1 Verify Loudspeaker Orientation and Position. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.7 Acoustical Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Chapter 6 Operation

6.1 Operational Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.1.1 Power Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.1.2 LED Indicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.1.3 Signal Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.2 Operational Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.3 Normal Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.3.1 Powering Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.3.2 Signal Processing Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.3.3 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.4 Operational `DOS’and `DONTS’ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.4.1 Equalization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.4.2 Maximum Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.4.3 Low Frequency Content. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.4.4 Input Limiting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.4.5 DSAPilot Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Chapter 7 Maintenance and Service

7.1 Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.2 Service Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.3 How to Contact EAW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.3.1 Operating Questions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.3.2 Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.3.3 Literature and Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.3.4 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Chapter 8 Appendices

8.1 Inspections And Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8.1.1 Periodic Physical Inspections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8.1.2 Performance Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8.1.3 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8.2 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

8.3 EIA-485 Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

8.3.1 Cabling Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

8.3.2 Termination Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

8.4 Support For Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

8.5 Support For CobraNet™. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Chapter 9 Mechanical Drawings

9.1 DSA230 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

9.2 DSA250 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

9.3 WALL BRACKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3

Page 4

Introduction

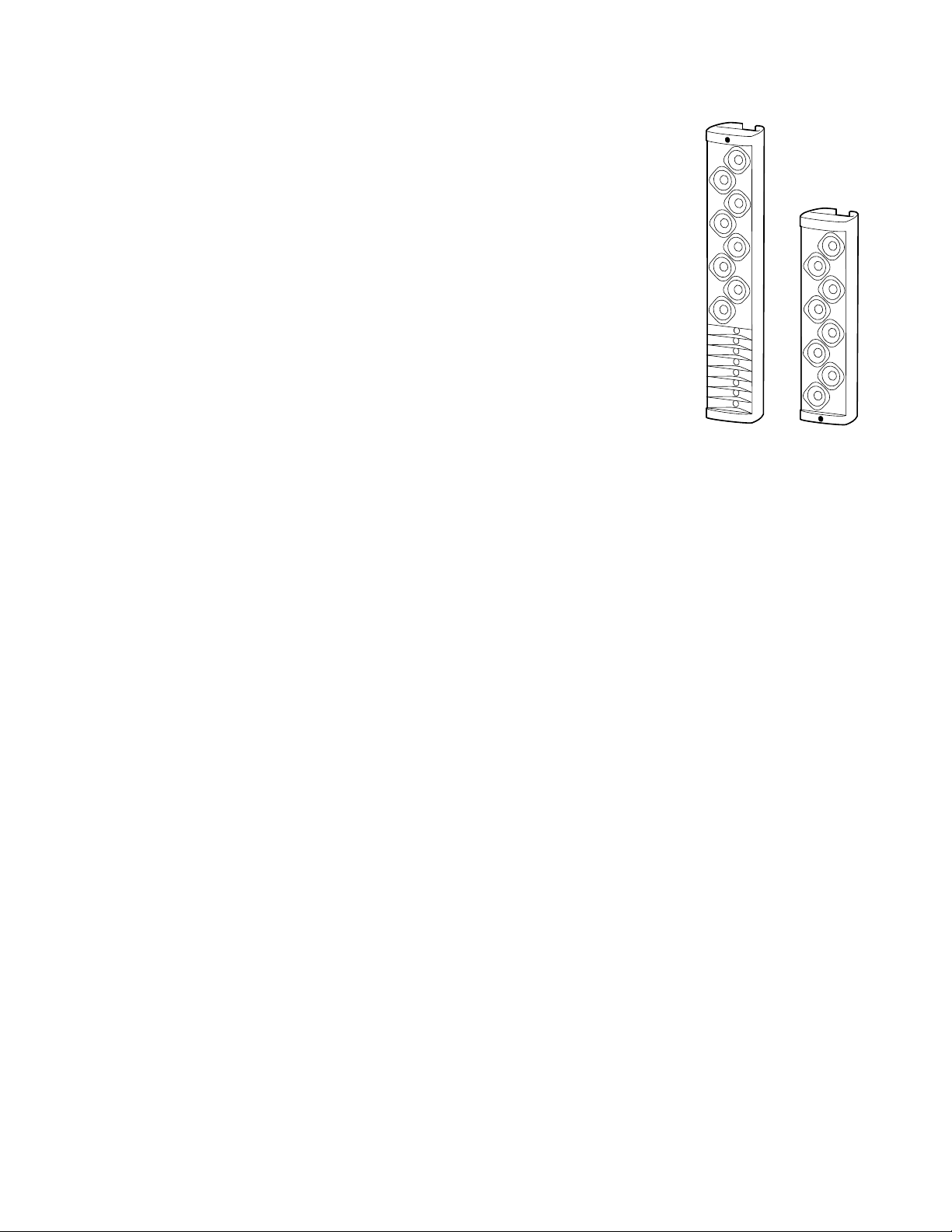

The Digitally Steerable DSA Series Arrays represents EAW’s latest innovation in

advanced, acoustic modeling and applied technology in designing loudspeakers.

The DSA250 full-range and DSA230 voice-only or low frequency system are small

format, column-type loudspeaker systems with a user-variable vertical beamwidth.

The easy-to-use DSAPilot software allows accurate adjustment of the loudspeaker’s

coverage area from a fixed, vertical mounting location. In addition to excellent

vocal performance, the DSA Series is fully capable of full-range music applications.

With integral signal processing and amplification, DSA loudspeakers are

economical and simple to use.

This manual provides information about the design, configuration, and operation

of DSA Series loudspeakers. It is intended to be used in conjunction with the

DSAPilot Windows®-based software.

Please thoroughly familiarize yourself with this manual. The more you learn and

understand about the DSA Series the easier you will find it to use. This is not so

much because of any inherent complexities, but because it is actually easier to use

than most. As such, it can take some experience with the system to establish

comfort with and appreciation of both its versatility and inherent simplicity.

***

4

Page 5

Chapter 1 Safety

1.1 Safety Precautions

The terms “Caution,” “Warning,” and “Danger” are used throughout this manual to

alert the reader to important safety precautions. If you have any questions about

any aspects of these precautions, contact your local dealer, distributor, or EAW. The

following are the descriptions of the safety precautions.

CAUTION: describes an operating condition or user action that may expose the

equipment or user to potential damage or danger.

WARNING: describes an operating condition or user action that will cause damage

to the equipment or injure the user.

DANGER: describes an operating condition or user action that will immediately

damage the equipment or be extremely dangerous or life threatening to the user.

1.2 Safety Instructions

CAUTION: To reduce the risk of electric shock, do not remove cover (or back). No

user-serviceable parts inside. Refer servicing to qualified personnel.

WARNING: To reduce risk of fire or electric shock do not expose this appliance to

rain or moisture.

The lightning flash with arrowhead symbol within an equilateral triangle is

intended to alert the user to the presence of uninsulated “dangerous voltage” within

the product’s enclosure that may be of sufficient magnitude to constitute a risk of

electric shock to persons.

The exclamation point within an equilateral triangle is intended to alert the user of

the presence of important operating and maintenance (servicing) instructions in

the literature accompanying the appliance.

This apparatus does not exceed the Class A/Class B (whichever is applicable) limits

for radio noise emissions from digital apparatus as set out in the radio interference

regulations of the Canadian Department of Communications.

WARNING: Some aspects of installation, rigging, electrical power, and other fields

related to using equipment, which EAW manufactures, sells, or distributes, are

potentially hazardous. Any person using this equipment is personally responsible

for his or her own safety. EAW transactions are made with the assumption that the

purchaser is a qualified individual or will have only qualified individuals perform

work with the equipment. EAW will not be liable for any damages arising from the

use of equipment sold to purchaser.

DANGER: Only persons with the knowledge of proper hardware and installation

techniques required should attempt to install DSA Series loudspeaker systems

overhead. Failure to follow this precaution may result in damage to the equipment,

injury, or death.

5

Page 6

1.2.1 GENERAL PRECAUTIONS

1. Read and Follow Instructions — Before installing and operating this loudspeaker,

read and follow all instructions and safety precautions in this manual and on

the loudspeaker. Retain them for future reference.

2. Ventilation — The sides and rear of the enclosure form the heat sink for the

internal amplifiers and may reach high temperatures during use. As such,

adequate ventilation is required to ensure proper operation. Allow a minimum

of 2 inches of clearance between the enclosure and adjacent surfaces so as not

to impede the flow of air past the sides and rear surfaces. Also, locate the

loudspeaker away from heat sources such as radiators or other devices that

produce heat. If the enclosure is in a grille-covered recess, forced air ventilation

may be required.

3. AC Mains — Connect this loudspeaker only to a nominal 115 V or 230 V AC

Mains supply as described in this manual. Before applying AC power, ensure

the AC Mains voltage rating on the loudspeaker matches the nominal AC Mains

voltage being supplied: 115 V or 230 V, 50 Hz or 60 Hz.

DANGER: DO NOT APPLY 230 V MAINS POWER IF THE VOLTAGE RATING

ON THE LOUDSPEAKER IS 115 V. IMMEDIATE AND CATASTROPHIC

DAMAGE TO THE LOUDSPEAKER WILL RESULT AND MAY CAUSE A FIRE

HAZARD, SERIOUS PERSONAL INJURY, OR DEATH.

4. Object and Liquid Entry — Take care that objects do not fall into and liquids

are not spilled into the loudspeaker.

5. Servicing — Do not attempt to service this loudspeaker. All service or repair

should be referred to the EAW Service Department or your EAW Distributor.

6. Damage Requiring Service — Only qualified service personnel should service

this loudspeaker if one or more of these conditions occur:

A. The power-supply cord or the plug has been damaged.

B. Objects have fallen, or liquid has spilled into the loudspeaker.

C. The loudspeaker has been exposed to rain.

D. The loudspeaker does not appear to operate normally or exhibits a marked

change in performance.

E. The loudspeaker has been dropped, or its chassis damaged.

7. Grounding or Polarization — Do not defeat the electrical grounding means

provided for this loudspeaker.

6

Page 7

Chapter 2 Unpacking

2.1 Contents

QTY PART # DESCRIPTION

(1) 0005483 DSA230 or

0005480 DSA250 loudspeaker

(1) 0005901 Instruction Manual

(1) 0005854 1 ft Cat-5 Signal Link Cable RJ-45 to RJ-45 (wired as a crossover cable)

(1) 005085 Neutrik® PowerCon™ NAC3FA in-line plug

(3) 0005850 Phoenix Contact MSTB 2,5/3-STZ-5,08 3-pin in-line plug

(2) 0006118 Enclosure Bracket

(2) 102195 3/8-16 x 2 in Enclosure Bracket Bolt

(2) 102035 1/4-20 x 3 in Retainer Bolt

(2) 105011 3/8 in Lockwasher

(2) 105004 1/4 in Lockwasher

(2) 0006119 Wall Bracket

(1) 0006103 DSA CD-ROM containing DSAPilot and other documentation

(1) RD0084 DSA230 or

RD0085 DSA250 Wall Bracket Mounting Template (Printed on

Shipping-Carton)

2.2 Shipping Damage

After unpacking, if the loudspeaker is found to have shipping damage, save the

packing materials for the carrier’s inspection, notify the carrier immediately, and file

a shipping damage claim.

Although EAW will help in any way possible, it is always the responsibility of the

receiving party to file any shipping damage claim. The carrier will help prepare and

file this claim.

2.3 Returning Products to EAW

If the loudspeaker must be returned to EAW, contact the EAW Service Department

for a Return Authorization (See Chapter 7). Use the original shipping carton and

packing materials. If the shipping carton is lost or damaged, contact EAW for a new

carton, for which there will be a small charge. EAW will not be responsible for

damage caused by inadequate packing when returning the loudspeaker for service.

All units returned must have a factory return authorization number. Any units

received without an Return Authorization Number assigned and written

prominently on the outside of the carton will be refused.

7

Page 8

Chapter 3 Quick Start

This section provides basic installation requirements. Refer to Chapter 5 for

detailed instructions.

Loudspeaker refers to either a DSA230 or DSA250.

Cluster refers to any of the permissible arrangements of single or multiple

DSA230s or DSA250s as defined in DSAPilot. Whether they consist of a single

or multiple loudspeakers, all DSA clusters function as a single loudspeaker.

3.1 Description

The EAW DSA Series loudspeakers are variable directivity, self-powered line

arrays. EAW’s easy-to-use DSAPilot provides computer control for the

loudspeaker’s vertical beamwidth pattern. This allows customizing the

coverage on-site to fit the application. Loudspeakers are controlled via

standard EIA-485* or optional CobraNet™/Ethernet networking.

*Also known as RS-485 (Recommended Standard 485)

Model DSA250 is a full range loudspeaker. Model DSA230 can be

employed as a voice-only loudspeaker or as low frequency loudspeaker to

supplement a DSA250’s low frequency output and pattern control.

3.2 Audio Signal Connection

NOTE: Using the DSAPilot, the two input channels may be summed to mono,

used separately, or set up for a priority override function: Audio B overrides

Audio A. Equalization, compression, and level are separately adjustable for

each input. Overall signal delay for each loudspeaker cluster is also provided.

Audio A and B (each): 2-conductor shielded audio cable/supplied

Phoenix Contact terminal block plug

3.3 Computer Control Connection

NOTE: Set the EIA-485 Terminate Switch to “ON”. For multiple

loudspeakers, see Chapter 5.

EIA-485: 2-conductor shielded audio cable/supplied

Phoenix Contact terminal block plug

3.4 Daisy Chaining Audio and Computer Signal

Between Loudspeakers

Distances up to 2 ft / 0.6 m are for connecting multiple loudspeakers in a

single cluster while distances over 2 ft / 0.6 m are for connecting physically

distributed clusters.

Up to 1 ft / 0.3 m: Supplied Cat-5 Signal Link Cable

Connect between Signal Link jacks (Neutrik® EtherCon®) on vertically

adjacent loudspeakers within a multi-loudspeaker cluster.

Up to 2 ft / 0.6 m: User-supplied, Cat-5 Ethernet crossover cable

Connect between Signal Link jacks (Neutrik® EtherCon®) on horizontally

adjacent loudspeakers within a multi-loudspeaker cluster.

8

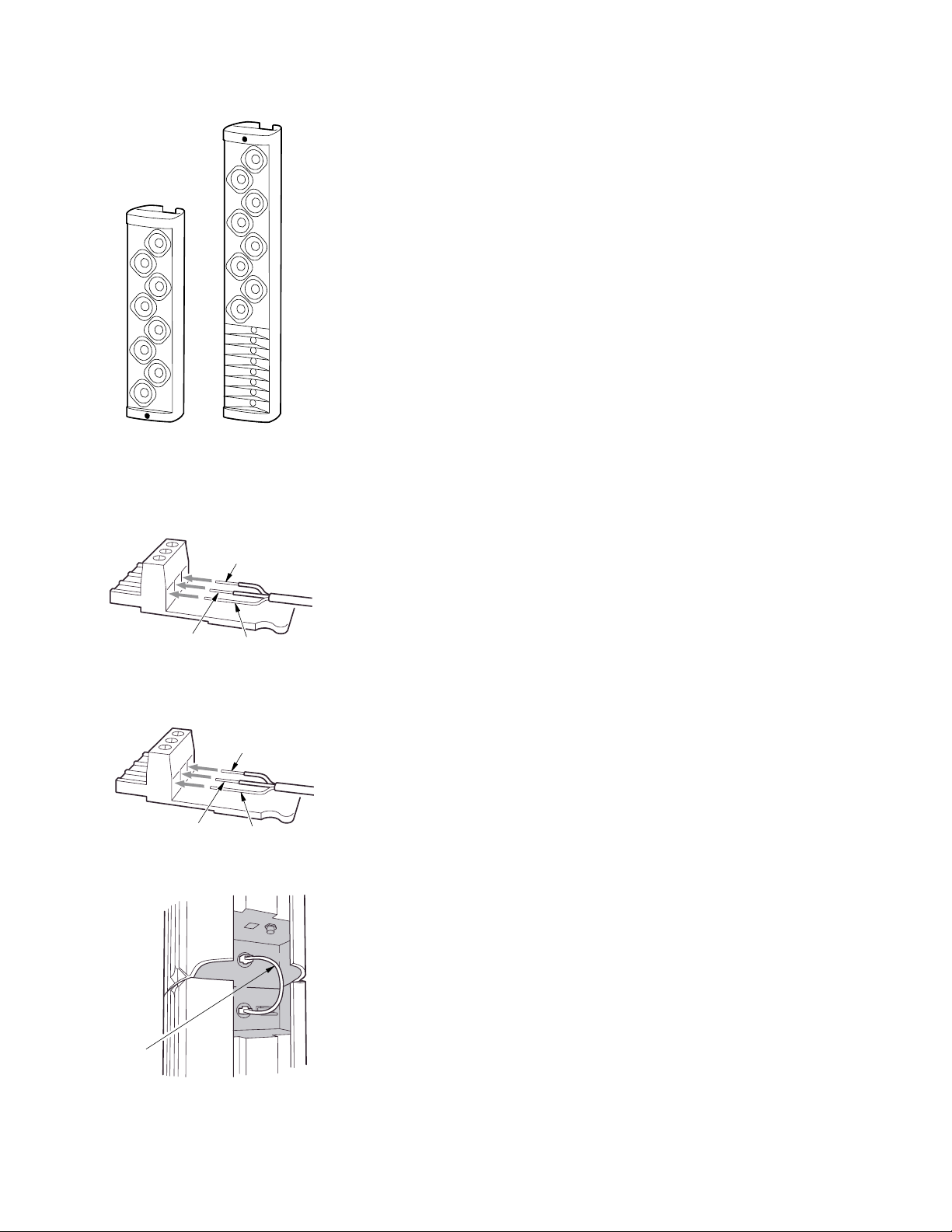

Figure 3.2 Audio Connector

Figure 3.1 DSA230 & DSA250

Figure 3.3 EIA-485 Connector

Figure 3.4a Signal Links < 1 ft / 0.3

AUDIO –

AUDIO +

SIGNAL +

LINK

CABLE

P/N

0005854

SHIELD

SIGNAL–

SHIELD

Page 9

Over 2 ft / 0.6 m: 2-conductor shielded audio cable / supplied Phoenix

Contact terminal block plugs

Connect Audio A, Audio B (if used), and EIA-485 in parallel daisy-chain

fashion between clusters.

3.5 AC Mains Installation

3.5.1 AC MAINS SUPPLY

Provide the loudspeaker with a 50 Hz or 60 Hz AC Mains circuit

capable of:

100 V to 120 V 220 V to 240 V

DSA230 4 A 2 A

DSA250 8 A 4 A

Before applying power, ensure that the AC Mains voltage matches the

voltage rating on the loudspeaker.

DANGER: DO NOT APPLY 230 V MAINS POWER IF THE VOLTAGE

RATING ON THE LOUDSPEAKER IS 115 V. IMMEDIATE AND CATASTROPHIC DAMAGE TO THE LOUDSPEAKER WILL RESULT AND

MAY CAUSE A FIRE HAZARD, SERIOUS PERSONAL INJURY, OR DEATH.

3.5.2 AC MAINS CABLE

Supply and connect #14 AWG / 2.5 mm power cable and appropriate

AC Mains plug to the supplied Neutrik/PowerCon® connector.

3.6 Physical Installation

3.6.1 ORIENTATION

1. When installing the enclosure, there is a

correct “top” and “bottom”. This cannot

be assumed from the physical appearance.

Instead, orientation depends on application

and desired acoustical performance

determined using the DSAPilot.

2. Ensure the enclosure is oriented correctly by

verifying which ends are supposed to be the

top and bottom for the intended application.

The Signal End is the end with the

identification LED, visible on one end

of the front of the enclosure. The Power

End has the AC Mains connector.

Note: The desired coverage cannot be gained

if the enclosure is incorrectly oriented.

3.6.2 MOUNTING

WARNING: Comply with all installation warnings in Section 5.5.1.

The DSA Series loudspeakers are normally intended to be flushmounted against a vertical surface capable of supporting their weight.

1. Using the template printed on the shipping box, locate and

position the supplied Wall Brackets to structure.

9

Figure 3.4b Signal Links >2 ft / 0.6 m

Figure 3.5 Connecting AC Mains

LED INDICATOR

ON FRONT SURFACE

POWER END

SIGNAL END

AC MAINS CONNECTOR

Figure 3.6 Signal End / Power End

EIA-485

AUDIO A

AUDIO B

Page 10

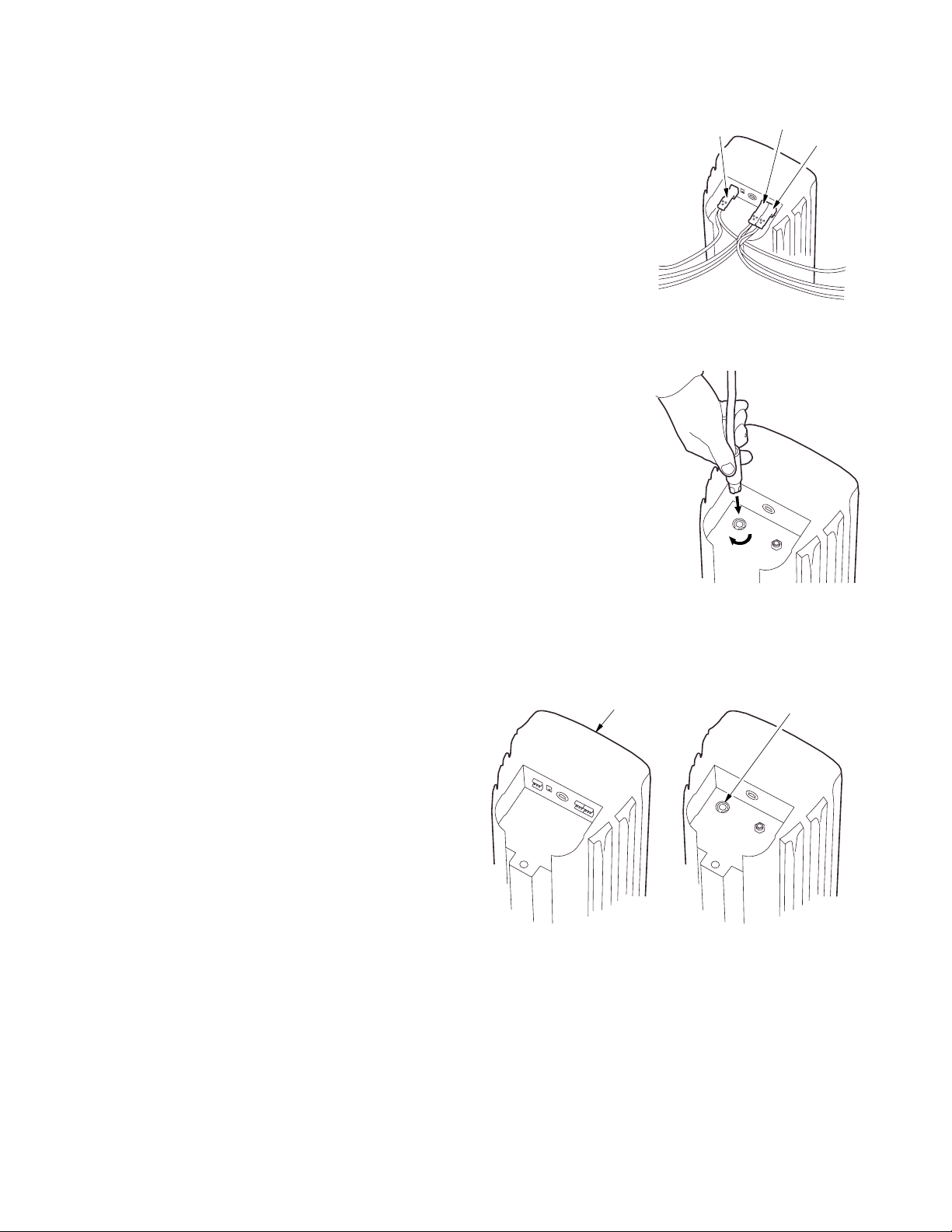

2. Attach the Wall Brackets to structure. You must provide attachment

hardware and ensure the attachment method and structure are

capable of supporting the intended load. Position the Wall Bracket

weld nuts left or right to allow clearance for later insertion of the

Retainer Bolt.

3. Ensuring they are oriented properly, install the two Enclosure

Brackets on the loudspeaker. Insert and hand-tighten the supplied 3/8-16

Enclosure Bracket Bolt and Lock Washer for each Enclosure Bracket.

4. Lift the enclosure onto the installed Wall Brackets.

WARNING: Use at least two people for lifting enclosure onto the

brackets.

5. Insert and snugly tighten at least one of the supplied 1/4-20 Retainer

Bolt and Lock Washer through the side of either of the Wall and

Enclosure Brackets. This prevents the enclosure from being lifted off

the Wall Brackets.

6. Securely tighten each 3/8-16 Enclosure Bracket Bolt to lock the

enclosure at the desired horizontal angle.

3.7 Signal Processing

The vertical coverage is determined by programming the loudspeaker’s

digital signal processing.

Use the DSAPilot to determine the desired coverage. The DSAPilot calculates

and optimizes the signal processing required to achieve the desired results.

High pass/low pass filters, parametric EQ, delay, and gain are user adjustable

for each of the two inputs.

10

2X 3/8-16 X 2 LG

Figure 3.6.2a Bracket Installation

Figure 3.6.2b Installed Bracket

Figure 3.7 DSAPilot Main Screen

BLACK HEX HEAD

ENCLOSURE BRACKET

BOLT & LOCK WASHER

2X ENCLOSURE

BRACKET P/N 0006118

1/4-20 X 3 LG

HEX HEAD

RETAINER BOLT

& LOCK WASHER

2X WALL BRACKET

P/N 0006119

Page 11

Chapter 4 Description

4.1 System Overview

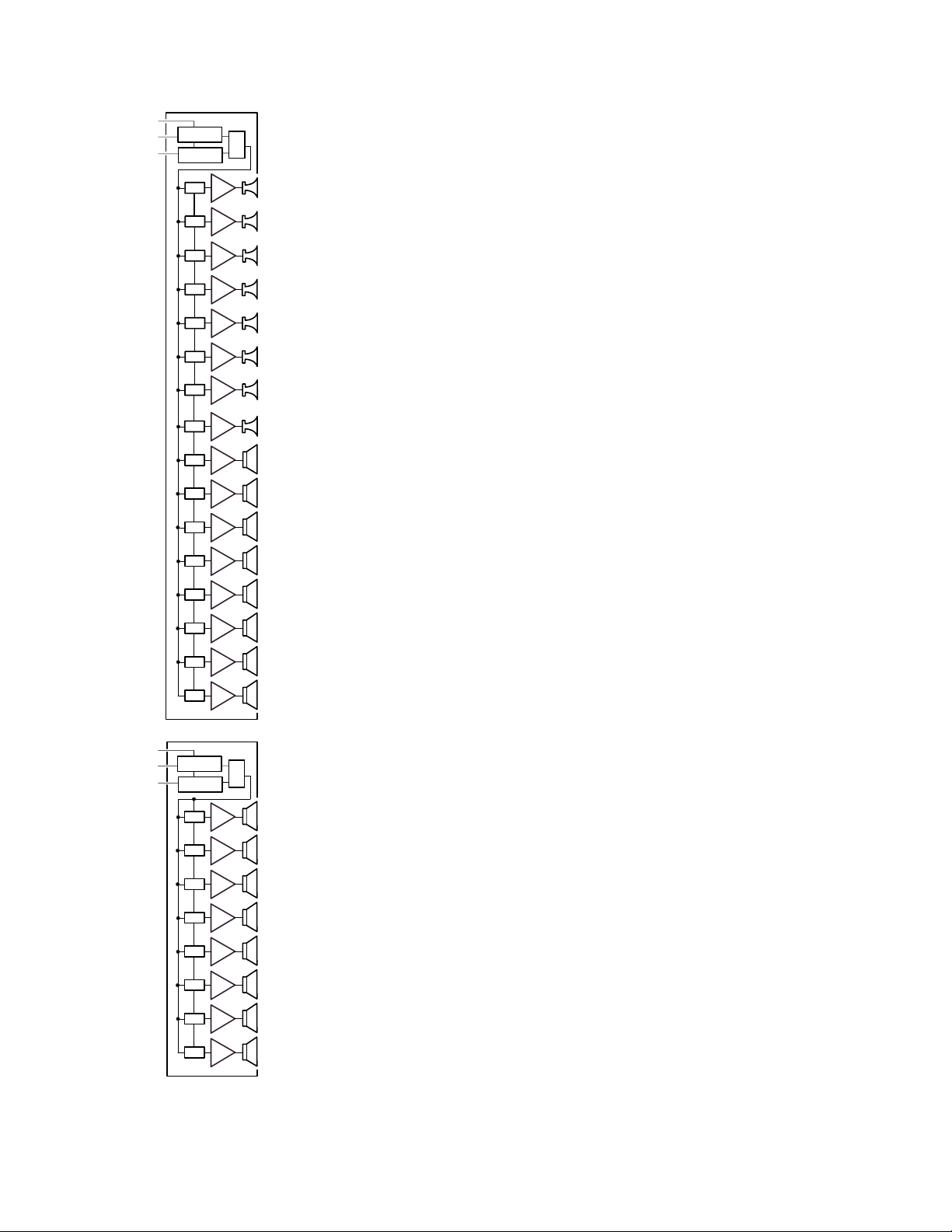

DSA Series loudspeakers are variable directivity, self-powered line arrays. Each

loudspeaker’s vertical beamwidth is determined by the settings of an internal

DSP (digital signal processor) and power amplifier for each transducer. This

provides complete, on-site control over the range of possible vertical

beamwidth patterns.

EAW’s Windows-based DSAPilot is used to set the coverage required for each

loudspeaker or loudspeaker cluster. The user-friendly DSAPilot optimizes the

required signal processing for the design. This data is then uploaded to the DSA

Series loudspeakers in the system. The DSAPilot normally communicates with the

loudspeakers using EIA-485*. An optional CobraNet™ network interface is available.

*Formerly known as RS-485 (Recommended Standard 485)

4.1.1 DSA SERIES MODELS

DSA250: Full range, 2-way, loudspeaker system

DSA230: Low frequency and voice-only loudspeaker system

4.1.2 ACOUSTICAL BENEFITS

Each loudspeaker can be electronically adjusted on-site to direct sound

primarily where needed. Unwanted sound reflections from room

surfaces can be reduced, improving the direct to reverberant sound

ratio. This, in turn, can significantly increase speech intelligibility.

Asymmetrical pattern control can provide consistent SPL in situations

with HIGH near-to-far listener distance ratios. User adjustable level

control, equalization, and compression, are provided on each of the

two audio inputs. For situations with multiple locations, overall signal

delay for each loudspeaker cluster is also provided.

4.1.3 PHYSICAL BENEFITS

The DSA Series loudspeakers are physically narrow and quite shallow,

providing a low profile to reduce their impact on architecture. Their

normal mounting position is specifically designed to be flat against a

vertical surface. This considerably reduces installation complexity. The

DSA Series design permits several loudspeakers to be easily arrayed in

one location as a cluster. This affords additional capabilities including

higher output and extremely narrow vertical coverage, as well as extended

pattern control, and output at lower frequencies.

DSA Series enclosures are constructed of a powder-coated, extruded

aluminum body (also used as the amplifier heat sink), high-impact

polystyrene end caps, a thick PVC baffle, and a finely perforated

steel grille. This construction is designed for years of trouble-free

use. The appearance is designed to blend attractively with a variety

of architecture. The enclosure finish is a neutral white. The grille is

powder-coated steel, with a perforation style that appears similar to a

cloth grille at typical in-use distances. Installation hardware is included to

facilitate installation in most applications.

11

Figure 4.1.1 DSA250 & DSA230

Page 12

4.1.4 ELECTRICAL BENEFITS

Built in digital signal processing, power amplification, and protective

limiting significantly reduces equipment costs, space, installation,

and set-up adjustments. Cabling is limited to providing AC mains, line

level audio, and computer control signals. EIA-485 or optional

CobraNet™/Ethernet networking technology allows all loudspeakers in a

project to be adjusted and controlled from one computer. EIA-485

network topology was chosen as the supplied default because it is easy

to implement. It is also unique in allowing multiple network nodes to

communicate bi-directionally over a single pair of twisted wires. No

other network standard combines this capability with equivalent noise

rejection, data rate, cable length, and general robustness.

4.2 Features

4.2.1 ACOUSTICAL

·Vertical beamwidth is software controlled on-site to fit the application

·Wide 120 degree fixed horizontal beamwidth

·Pre-determined templates for loudspeaker clusters provide a wide

range of capabilities

·DSA250 full-range loudspeaker has eight 4 in LF drivers, eight 1 in

horn-loaded HF drivers

·DSA230 low frequency or voice-only loudspeaker has eight 4 in LF drivers

·Full frequency response and high output for music applications

·Extended pattern control and higher outputs at lower frequencies

using additional DSA230’s

·Exceptional intelligibility for reverberant rooms

4.2.2 ELECTRONIC

· Self-powered requiring wiring for AC power, line level audio, and

computer control

· No amplifier or processing racks needed, reducing space and cost

· Individual amplifier and DSP for each transducer

· Convection cooled electronics eliminates noisy cooling fans

· Built-in driver protection provides high reliability

· Two audio inputs allow summed stereo or priority announcement

override capability

· Electronically balanced inputs maximize the signal to noise ratio

4.2.3 COMPUTER CONTROL

· User-friendly DSAPilot software easily creates desired vertical

coverage patterns

· DSP adjusted and optimized by DSAPilot for plug and play setup

· User adjustable input EQ, signal delay, level, HPF/LPF, and

compression for each loudspeaker cluster

· Computer can be disconnected for no-tamper operation

· Computer can be left connected for monitoring purposes

4.2.4 NETWORKING

· EIA-485 network for remote PC operation and computer control

· Analog audio and control signals can be daisy-chained to multiple

loudspeakers

12

EIA-485

Figure 4.1.4 DSA Block Diagrams

AUDIO A

AUDIO B

INPUT DSP

INPUT DSP

DSP

DSP

DSP

DSP

DSP

DSP

AMP

AMP

AMP

AMP

AMP

AMP

DSA250

∑

EIA-485

AUDIO A

AUDIO B

DSP

DSP

DSP

DSP

DSP

DSP

DSP

DSP

DSP

DSP

INPUT DSP

INPUT DSP

DSP

DSP

AMP

AMP

AMP

AMP

AMP

AMP

AMP

AMP

AMP

AMP

DSA230

AMP

AMP

∑

DSP

AMP

DSP

AMP

DSP

AMP

DSP

AMP

DSP

AMP

DSP

AMP

Page 13

·Cat-5 Link Cable links adjacent loudspeakers.

·Optional CobraNet™ interface for digital distribution of audio and

computer control via Ethernet

·Provision for back up audio/computer communications using a

redundant Ethernet network, when using CobraNet™.

4.2.5 PHYSICAL

· Phoenix Contact and Neutrik EtherCon and PowerCon connectors

for reliable connections

· Low weight (<100 lb / 45 kg) reduces structural mounting requirements

· Mount vertically while providing asymmetrical down-angle coverage

· Brackets supplied for mounting to vertical surfaces

· Mounting allows +/-15 degree horizontal rotation of the enclosure.

· Optional hardware for suspending enclosures

· Elegant enclosure design and neutral color blends with a variety of

architecture

· Rear enclosure extrusion channels can be used to route cabling

4.3 Applications

The DSA Series provides a significant advance for cost-effective

implementation of line array technology in a variety of applications. As is

typical for line arrays, the DSA Series is an excellent choice for voice-only

applications. However, unlike typical voice-only line arrays, the DSA Series

can also provide the wide frequency range, fidelity, and output levels

needed for excellent music reproduction. This significantly extends its

range of applications to a wide range of venue types including theaters,

theme parks, retail spaces, and government facilities. Its unique

capabilities, however, make it particularly well suited to applications that

present a challenging acoustical, physical, or aesthetic environment.

The DSA Series is ideal for a variety of venues where achieving good vocal

intelligibility is critical. These include theatres, auditoria, houses of

worship, theme parks, retail spaces, government facilities, lecture halls,

large conference rooms, museums, and shopping malls. It can solve

acoustically difficult challenges in reverberant environments such as

cathedrals, concert halls, ballrooms, rail/air/sea terminals, large lobbies,

and athletic buildings. Its low profile further enhances its applicability in

aesthetically sensitive environments.

Designers can use DSA loudspeakers in a variety of factory-supported DSA

cluster configurations to meet specific output or directivity needs. For

voice-only applications, single DSA250 loudspeakers can be placed to

provide adequate output and horizontal coverage. In these cases, designers

enjoy control of the vertical pattern throughout the vocal range. For

broadband music reproduction, the addition of a DSA230 to each DSA250

will extend pattern control well into the LF range and provide additional

LF output.

Although the DSA Series is not specifically outfitted for outdoor

installations, its exterior components are inherently weather-resistant. If

suitably protected from direct exposure to weather, permanent outdoor

installation is possible, though is not recommended.

13

Page 14

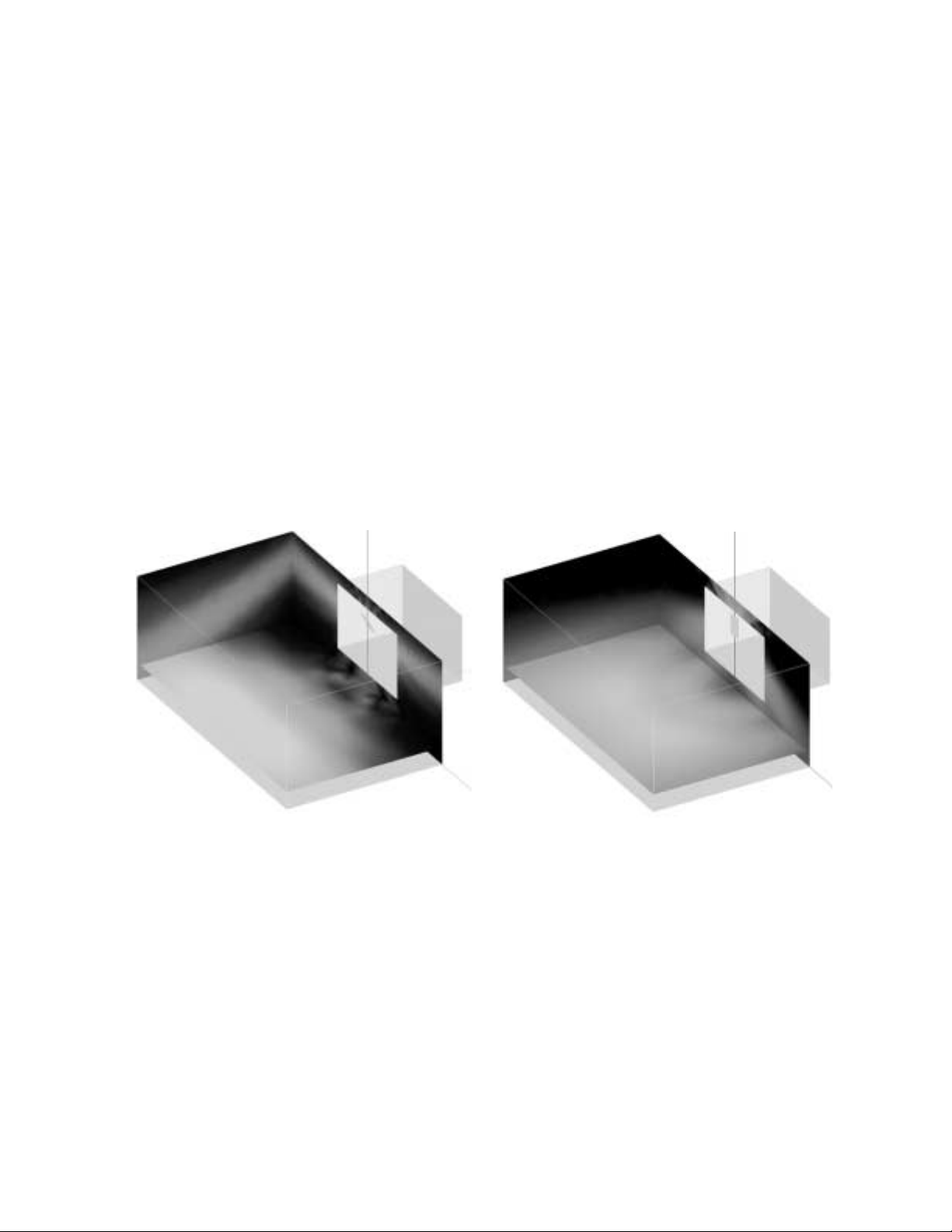

4.4 Engineering Design

The core acoustical design of the DSA Series dates back to the late 1930s in

Harry Olson’s book, “Acoustical Engineering”. He showed that, by using

different signal delays on the input to each transducer in a simple line array,

the array’s main output lobe could be effectively “steered”. While this

concept has certainly been used before, the design of the DSA Series goes far

beyond this simple concept.

The engineering design for the DSA Series is certainly capable of “steering”

the main output lobe, as per Olson. However, the shape of the lobe in the

vertical plane is also variable. This allows changing the depth of the

coverage to precisely fit the listening area thereby reducing troublesome

near-to-far SPL differences.

A major advantage of DSA is the character of its radiation pattern. Contrary to

what might be intuitively assumed, the DSA’s radiation pattern is not the same

as simply down-tilting a loudspeaker that has the same horizontal and vertical

beamwidths. The example EASE plots illustrate this difference.

The radiation pattern of the conventionally, down-tilted loudspeaker has at

least two problems. The geometry of the pattern results in inadequate

coverage across the front area of the room. It also focuses a distinct line of

energy along the side wall. This energy is nearly at the same loudness as the

floor seating area. The sound reflections off the upper part of the wall will

arrive at many listeners late enough to impair intelligibility. These

reflections add to the direct sound and cause the higher intensity sound

seen at the rear , even though these areas are further from the loudspeaker.

By contrast, the radiation pattern of the DSA loudspeaker is far more consistent

across the entire floor area. The energy it directs to the sidewalls is not only

lower in level, but creates a very different reflection pattern. The sound reflected

off the wall will be largely directed down into the floor or nearby listeners along

the sides, arriving early enough to actually enhance intelligibility.

14

Ver: 30° Hor: 120°

Lspk: S1

Project: DSAMultipurpose-Tilt

Map: Direct SPL

Freq: 5000 Hz

[Third Octave Average]

Shadow Cast: No

Resolution = 1.0 m

Ver: 30° Hor: 120°

Lspk: S1

Project: DSAMultipurpose-Steer

Map: Direct SPL

Freq: 5000 Hz

[Third Octave Average]

Shadow Cast: No

Resolution = 1.0 m

Figure 4.4a Angled Radiation Pattern

Figure 4.4b DSA Steered Radiation Pattern

Page 15

The required signal processing, accomplished by DSP (digital signal

processing), involves parametric equalization, signal delay, frequency

filtering, gain, and limiting. These parameters are individually adjusted by

the DSAPilot for each transducer in each loudspeaker. The available DSP

resources provide a broad range of possible coverage patterns and SPL

control over distance as well as the “voicing” required for exceptional

music reproduction.

The DSA allows multiple loudspeakers to be arrayed as a cluster at a single

location. This allows a greater range of beamwidths, SPL, pattern control,

and low frequency output than a single DSA loudspeaker can provide. The

DSAPilot treats the cluster as if it were a single loudspeaker, precluding the

complexities normally associated with designing clusters.

4.5 DSAPilot

The DSAPilot, used to set the loudspeaker signal processing parameters, is

based on software originally developed by EAW engineers for the KF750,

KF760, and, in particular, the KF900 Series products. These products

require precise but variable pattern control and a high degree of fidelity for

speech and music in projects that range from small houses of worship to

the newest super-stadiums. Sophisticated mathematical algorithms were

developed to determine the necessary adjustments to achieve these results

for both multiple transducers and multiple loudspeaker clusters. This math

was incorporated into highly user-friendly software. Thoroughly tested and

refined in successful, real-world applications, these techniques have been

applied to the DSA Series to achieve the same high degree of pattern

control, musicality, and ease of setup.

Though highly complex, the DSAPilot’s mathematics work behind the

scenes. Because of this, the DSAPilot makes adjusting the signal processing

deceptively simple. In fact, no acoustical knowledge is required to set up

and adjust one or multiple DSA Series loudspeakers. The only information

needed for the DSAPilot to perform its magic is the physical layout of the

listening area, loudspeaker mounting location, and desired coverage area.

4.6 Low Frequency Performance

While the DSA250 is designed as a full-range loudspeaker, addition of the

companion DSA230 increases directionality, and output at lower frequencies.

DSA230s extend directional control to lower frequencies using classical line

array theory by extending the length of the overall array. This is done by

mounting the DSA230 directly below or above a DSA250 to form a longer line

of low frequency transducers. In addition, the increased number of low

frequency transducers couple to increase the low frequency output capability.

4.7 Comparison to Traditional Products

A major benefit of the DSA Series is achieving desired down angle coverage

from a line source that is mounted flat to a vertical surface. The inclusion

of power amplifiers and dedicated signal processing to each transducer

provide the DSA Series with performance and capabilities well beyond

those of typical multi-way loudspeakers and traditional, voice-range line

arrays. The DSA Series can provide much better directional control, higher

output, and wider frequency response at less cost. Significantly smaller

sizes and weights, plus straightforward mounting and wiring options pay

15

Page 16

additional benefits in reduced installation costs and operation. The

flexibility of the DSAPilot to automatically optimize the acoustical

performance for multiple DSA Series loudspeakers in a single larger space

further enhances their advantage over traditional solutions.

4.8 Designing DSA Systems

DSA loudspeakers can be used individually, in multiples, or in various

cluster configurations to satisfy a wide range of design requirements. By

using different configurations, DSA performance can be varied according to

the type of audio program, the frequency range for the vertical control

desired, the maximum output levels, the audience location relative to the

loudspeaker, and for meeting the requirements for special applications.

Chapter 5 Installation

This chapter details the requirements for installing the loudspeaker.

Specific details may require some variation depending on the particular

situation. However, the basic requirements are the same in all cases.

Loudspeaker refers to either a DSA230 or DSA250.

Cluster refers to any of the permissible arrangements of single or multiple

DSA230s or DSA250s as defined in DSAPilot. Whether they consist of a single

or multiple loudspeakers, all DSA clusters function as a single loudspeaker.

5.1 Electrical Installation

This section details the electrical requirements for installing

the loudspeaker. Specific cabling details may require some

variation depending on the particular situation. However, the

basic requirements are the same in all cases.

Basic electrical installation tasks include:

Audio signal connection

Computer control connection

AC mains connection

5.1.1 CABLE ROUTING CONSIDERATIONS

The configuration and orientation of the loudspeakers will determine

where signal, computer, and AC mains cabling must be connected to

the loudspeakers. For certain cluster configurations it may be necessary

to route cabling from one end of a loudspeaker to another.

The main cable routing method is to use the channels in the heat sink

extrusion that forms the rear of the DSA250 and DSA230 enclosures.

These channels are intended to be used to route and conceal cabling

the length of the enclosure as required. In this way, single wall outlet

locations for audio, computer, and AC mains can easily service a single

loudspeaker or loudspeaker cluster.

To facilitate cable routing, clusters have been arranged, where possible,

so the Power Ends of the enclosures are adjacent. This minimizes the

routing of AC mains cables, which are heavier and more difficult to

thread into the extrusion than signal cables.

16

O

A

S

N

A

S

Figure 5.1 Electrical Block Diagram

Figure 5.1.1 Cable Channels

LINE LEVEL

AUDIO

SOURCE(S)*

PC*

*SUPPLIED BY THE USER

AC MAINS*

(115V OR 230V)

AUDIO A CABLE*

AUDIO B CABLE (IF USED)*

RS-232

TO EIA-485

CONVERTER*

EIA-485*

CABLE

CABLE CHANNELS

SIGNAL LINK CABLE T

ADJACENT DS

LOUDSPEAKER

DAISY-CHAI

CABLE TO DS

LOUDSPEAKER

DSA

SIGNAL LINK

CABLE TO

ADJACENT DSA

LOUDSPEAKERS

Page 17

5.1.2 AUDIO SIGNAL CONNECTION

CobraNet™: Skip to Section 5.2 if using CobraNet™ for distribution of

the audio and control signals.

Audio A

or

Audio B: 2-conductor twisted pair, shielded, audio cable connected

to supplied 3-pin Phoenix Contact Terminal Plug and to

the line level audio signal source.

Nominal level: 0 dBu / 0.775 V rms.

Recommended Conductor Gauge:

24 AWG to 18 AWG / 0.2 mm to 1 mm

Audio A

and

Audio B: As above but 4-conductor twisted pairs

5.1.3 COMPUTER CONTROL CONNECTION

CobraNet™: Skip to Section 5.2 if using CobraNet™ for distribution

of the audio and control signals.

EIA-485

(formerly

RS-485): 2-conductor twisted pair, shielded, cable connected to supplied

3-pin Phoenix Contact Terminal Plug and to EIA-485 port

for the computer.

Recommended Conductor Gauge:

24 AWG to 18 AWG / 0.2 mm to 1 mm

NOTES:

1. Do not combine EIA-485 and audio signals in the same cable.

2. An EIA-485 converter is required to convert a PC’s RS-232 or USB

port to a 2-wire EIA-485 port. While there are many converter

products available, contact EAW’s Application Support Group (See

Section 7.3) for recommendations about suitable models.

3. EIA-485 cabling has special requirements and limitations. See

Appendix 8.3 for details.

5.1.4 DAISY CHAINING COMPUTER AND AUDIO SIGNALS WITHIN CLUSTERS

WITH MULTIPLE LOUDSPEAKERS

NOTE: The Signal Link jacks carry both computer and audio

signals. The cable between the Signal Link jacks must be

wired as a standard Ethernet crossover cable. A cable wired as

a standard Ethernet straight through cable will not work.

1. Up to 1 ft / 0.3 m between adjacent over/under loudspeakers in a cluster:

Supplied Cat-5 Signal Link Cable

Connect between unused Signal Link jacks (Neutrik EtherCon) on

vertically adjacent ends of the loudspeakers.

2. Up to 2 ft / 0.6 m between adjacent side-by-side loudspeakers in a cluster:

User-supplied Cat-5 crossover cable.

Connect between unused Signal Link jacks (Neutrik EtherCon)

on horizontally adjacent ends of the loudspeakers.

17

LINK CABLE

P/N 0005854

Figure 5.1.4 Linking < 1 ft / 0.3 m

Figure 5.1.2 Audio A & Audio B

Figure 5.1.3 EIA-485 Connector

AUDIO –

AUDIO +

SHIELD

EIA-485

SIGNAL+

SHIELD

Crossover Cable Wiring

STANDARD END PINS 1 2 3 4 5 6 7 8

CROSSOVER END PINS 3 6 1 4 5 2 7 8

Page 18

5.1.5 DAISY CHAINING COMPUTER AND AUDIO SIGNALS BETWEEN CLUSTERS

Any distance (within EIA-485 limitations) between clusters:

2-conductor shielded cable

Audio A, Audio B, and EIA-485

Connect in parallel to the incoming signal cables on one loudspeaker

in the first cluster and connect to the same signal ports on one

loudspeaker in the next cluster. Use the supplied 3-pin Phoenix

Contact terminal plugs.

Recommended Conductor Gauge:

24 AWG to 18 AWG / 0.2 mm to 1 mm

5.1.6 EIA-485 TERMINATE SWITCH

EIA-485 termination has special requirements and limitations. See

Appendix 8.3 for details.

Single Cluster:

Set the EIA-485 Terminate Switch on the loudspeaker

(connected via the Phoenix connector) to “ON”.

Multiple Clusters:

Set the EIA-485 Terminate Switch to “ON” ONLY on the

loudspeaker (connected via the Phoenix connector) at the end of the

EIA-485 cable run furthest from the computer. Set all other Terminate

Switches to “OFF”.

CAUTION: Engaging the EIA-485 Terminate Switch on more than

one loudspeaker on the EIA-485 cable run can cause intermittent

or non-existent communications.

5.2 CobraNet™ Network Connections

This section provides details about using the optional CobraNet™

technology for distribution of audio and computer control signals.

5.2.1 DESCRIPTION

CobraNet™ is a combination software, hardware, and network protocol

that replaces the audio and computer connections described in Section

5.1. Digitized audio and computer control is distributed by a CAT-5

(or better) cable to each loudspeaker. The network infrastructure must

be designed using standard IEEE 802.3u 100BASE-T Fast Ethernet

hardware. The network will not function properly using 10BASE-T

technology.

5.2.2 COBRANET™ IS USUALLY DESIRABLE TO USE WHEN:

· A star cable configuration is easier to implement for multiple loudspeakers

· A high degree of noise immunity is needed for the audio

· Future system expansion is likely

· Long cable runs that permit fiber optic cabling

· Other CobraNet™-capable products are used in the same installation

· The number of loudspeakers and clusters exceeds 32

· The audio source(s) have digital outputs

18

EIA-485

Figure 5.1.5 Linking > 2 ft / 0.6 m

Figure 5.1.6b EIA-485 Network Diagram

Figure 5.1.6a EIA-485 Terminate Switch

AUDIO A

AUDIO B

EIA-485 TERMINATE SWITCH

ON

EIA-485

TERMIN

A

AUDIO

GROUND

LIFT

OFF

TE

LIFT

DSA

CLUSTERS

PC

RS-232

OR USB

TO EIA-485

CONVERTER

TERMINATE

SWITCH "OFF"

TERMINATE

SWITCH "OFF"

TERMINATE

SWITCH "ON"

Page 19

5.2.3 ADDITIONAL EQUIPMENT YOU MUST SUPPLY FOR COBRANET™ :

· Loudspeaker interface:

EAW CM-1 CobraNet™ Interface Card (P/N 0005987)

for each DSA Series loudspeaker

· Audio/Computer interface:

Converts signals to CobraNet™ protocol

· Ethernet switch or hub:

For networking multiple loudspeakers over Ethernet

5.2.4 CABLING:

A CAT-5 or better cable with RJ-45-compatible connectors is required

for each loudspeaker.

NOTE: Ethernet cable length is limited by specification to 328 ft / 100 m.

Longer runs are possible using network hubs or switches as repeaters or

by conversion to fiber optic cable.

5.2.5 AUDIO/COMPUTER INTERFACE:

Audio and RS-232 (for the DSAPilot control signals) must be converted to

the CobraNet™ protocol and connected to the network via an RJ-45 Ethernet

port. Products that do this are available from several manufacturers. Your

choice will depend, in part, on how many and what form of audio signals

(digital or analog) you need to distribute.

Manufacturers of converters include:

Peavey, QSC, Rane, Symetrix, Whirlwind, and Yamaha.

5.2.6 LOUDSPEAKER INTERFACE:

An optional EAW CM-1 CobraNet™ Interface Card must be installed in

the slot provided in loudspeaker. To do this, see installation instructions that accompany the CM-1.

Connect the PRIMARY RJ-45 Ethernet connector to the Ethernet cable.

The SECONDARY RJ-45 Ethernet connector on the CM-1 is for connecting to a second, redundant Ethernet network. This would be designed

as a back-up network that automatically takes over in the event of

failure in the primary network.

The digital audio received by the CM-1 connects directly to the loudspeaker’s digital signal processing. It is converted back to analog at the

inputs to the internal power amplifiers.

5.2.7 MULTIPLE LOUDSPEAKERS:

To connect multiple loudspeakers to the network, the Ethernet output

on the audio/computer interface must connect to a network switch or

hub. A network switch is normally recommended. The switch must

have an Ethernet port for each loudspeaker.

A CAT-5 cable is required from the Ethernet port on the CM-1 Interface

Card in each loudspeaker to its port on the network switch. For networks requiring cable runs longer than 328 ft / 100 m, a repeater

network or fiber optic cabling is recommended. Do NOT mix hubs and

switches on a repeater network. Network switches and hubs are available through most computer retailers.

5.2.8 SUPPORT FOR COBRANET™ / ETHERNET

See Sections 8.4 and 8.5 for support information for Ethernet and CobraNet™.

19

Figure 5.2.6 CM-1 Interface Card

(See Installation Instructions with Card)

CAT-5

CABLES

MAX 328

ft/100 m

100BASE-T

NETWORK

SWITCH

DSA

LOUDSPEAKERS

WITH

OPTIONAL

CM-1 CARD

AUDIO/COMPUTER

INTERFACE

PC

LINE LEVEL

AUDIO

SOURCE(S)

Figure 5.2.3 Basic CobraNet™ Diagram

4X FLAT

HEAD

SCREWS

CM-1 INTERFACE CARD

Page 20

5.3 AC Mains Power Connection

This section details the requirements for the AC mains which is the AC

power connection required by each DSA loudspeaker.

5.3.1 AC MAINS SUPPLY

CAUTION: Read all cautionary notes concerning electrical power in

Chapter 1.

Each DSA Series loudspeaker is rated for a particular nominal AC Mains

voltage: 115 V or 230 V. Provide the loudspeaker with 50 Hz or 60

Hz AC Mains circuit capable of:

100 V to 120 V 220 V to 240 V

DSA230 4 A 2 A

DSA250 8 A 4 A

Before applying power, ensure that the AC Mains voltage matches the

voltage rating on the loudspeaker.

DANGER: DO NOT APPLY 230 V MAINS POWER IF THE VOLTAGE

RATING ON THE LOUDSPEAKER IS 115 V. IMMEDIATE AND CATASTROPHIC DAMAGE TO THE LOUDSPEAKER WILL RESULT AND MAY

CAUSE A FIRE HAZARD, SERIOUS PERSONAL INJURY, OR DEATH.

5.3.2 AC MAINS CABLE

The supplied Neutrik PowerCon NAC3FCA plug mates with the Neutrik

PowerCon NAC3MPA AC MAINS jack on the loudspeaker. Because of

both varying installation and electrical code requirements, neither an

AC Mains cable nor AC mains supply connection are supplied.

1. Supply and connect a 3-conductor power cable to the supplied

PowerCon plug, ensuring a proper ground connection.

2. Supply and attach an appropriate connector for the AC Mains

connection at the other end.

Recommended Power Cable

Conductor Gauge: 14 AWG / 2.5 mm (limited by PowerCon design)

Cable O.D.: 5 mm to 15 mm (limited by PowerCon design)

Recommended

length: Maximum 25 ft / 8 m (for <2% voltage drop at

peak input power)

NOTE: If the power cable is longer than 25 ft / 8 m the voltage drop

will increase.

5.3.3 POWER ON / OFF

There is NO power on/off switch on DSA Series loudspeakers. The

loudspeaker will be powered on (energized) when connected to an AC

mains supply. The LED on the “Signal End” will flash rapidly for about

3 seconds when first powered on. This is normal and indicates the

electronics are being initialized.

20

Figure 5.3.2 PowerCon Plug

GROUND

L

N

NEUTRIK

POWERCON

PLUG NAC3FA

Page 21

The LED should then go off. See Section 6.1.2 for other LED indications.

If it is desired to completely power off (de-energize) the loudspeaker,

a conveniently located AC mains disconnect must be supplied or

the power cable must be unplugged from the loudspeaker or the AC

mains supply.

The PowerCon connector is a locking connecter. To lock, twist 1/4 turn

clockwise after fully inserting into the jack. It is recommended the

connection be made at the loudspeaker before connection to the AC

mains supply.

5.3.4 AC MAIN FUSE:

If excessive AC mains input current is detected, the replaceable fuse will

blow. This can occur for a variety of reasons, such as internal failure,

excessive AC mains voltage, or excessive amplifier output levels.

If the fuse blows, replace it only with a fuse of the correct type and

rating as listed below. In the unlikely event the fuse blows again, internal failure is indicated. This will require troubleshooting and repair

by a qualified service technician. Do not attempt further use of the

loudspeaker until such repairs are made. See Section 8.2 “Troubleshooting”.

Fuse Type: AGC (0.25 in x 1.25 in) slow-blow

Rating: 115 V AC 230 V AC

DSA230 4 A 2 A

DSA250 8 A 4 A

5.4 Grounding

5.4.1 ELECTRICAL GROUND

Ensure that the AC mains grounding conductor in the power cable is

properly grounded in accordance with applicable electrical codes.

5.4.2 AUDIO GROUND

The Audio Ground Lift switch may help isolate audio ground loops.

This dip switch disconnects the shield pins on all the audio connectors

from the internal audio ground. This affects the audio shield pins on

the Audio A and Audio B connectors. Use this switch as needed for

reducing ground loop noise.

21

Figure 5.3.4 Fuse

Figure 5.3.3 Connecting AC Mains

H

Figure 5.4.2a Ground Lift Switch

Figure 5.4.2b Ground Lift Function

CAP

FUSE

HOUSING

POWER END

GROUND LIFT SWITC

ON

EIA-485

AUDIO

GROUND

LIFT

OFF

LIFT

TERMINATE

SIGNAL END

2X

AUDIO

SHIELD

PINS

AUDIO A

PHOENIX

CONNECTORS

AUDIO B

EMI

FILTER

EMI

FILTER

CHASSIS/MAINS

GROUND

AUDIO

GROUND

LIFT

SWITCH

LIFT

AUDIO

GROUND

Page 22

5.5 Physical Installation

This section details the physical requirements and methods for installing

the loudspeaker. Specific mounting procedures detailed herein may require

some variation depending on the particular situation. However, the basic

methodology is the same in all cases.

Basic installation tasks include:

Installing the Enclosure and Wall Brackets

Mounting the loudspeaker

5.5.1 INSTALLATION WARNINGS

DANGER: DSA Series loudspeakers must be securely mounted to structure capable of supporting their weight. The user is responsible for

providing properly engineered attachment of the supplied Wall Brackets

to structure, using hardware rated for the load. Failure to follow this

warning may result in failure of the mounting causing the loudspeaker to fall down, with possible equipment damage, injury, or death.

DANGER: Only persons with the knowledge of proper hardware and

installation techniques required should attempt to install DSA

Series loudspeaker systems overhead. Failure to follow this precaution may result in damage to the equipment, injury, or death.

CAUTION: The actual coverage provided by a DSA Series loudspeaker

will be largely determined by the DSAPilot adjusting its signal processing

settings. However, the loudspeaker must still be positioned in a location that is within the possible adjustment range for the desired coverage.

CAUTION: It is physically possible to mount a DSA Series loudspeaker

either end up. Because of the transducer-specific signal processing, it

will NOT provide the desired performance if installed upside down in

its intended application.

CAUTION: For DSA Clusters with two or more loudspeakers mounted

one over the other, it is recommended to make all cable connections

before lifting each loudspeaker onto the wall brackets. See Sections 5.2

through 5.6. Once the loudspeakers are mounted, access to the

connectors may be difficult.

5.5.2 PHYSICAL ORIENTATION – SIGNAL END / POWER END

The directionality of the DSA Series loudspeakers partly depends on

using specific signal delays to each transducer to control its sound

arrival to the listeners. As such, the DSAPilot makes assumptions about

the physical location of each transducer in the enclosure. This means

there is a correct “top” and “bottom” to each enclosure that is specific

to each application.

The two ends of DSA loudspeakers are referred to as the Signal End and

Power End. In addition to this physical difference, there is a built-in LED

indicator on the front of the Signal End of each loudspeaker. The orientations are shown in the DSAPilot graphics. When activated by the DSAPilot

software, this LED can be used to verify both the correct up-down

orientation and, when multiple loudspeakers are used, the correct

location of each. For the DSA250, the Power End is the end with the

HF subsystem and Signal End is the end with the LF subsystem.

22

LED INDICATOR

Figure 5.5.2 Signal End / Power End

ON FRONT SURFACE

SIGNAL END

AC MAINS CONNECTOR

POWER END

Page 23

5.5.3 MULTIPLE LOUDSPEAKERS AND CLUSTER CONFIGURATIONS

CAUTION: Only clusters defined by the DSAPilot or pictured herein may

be used. Any other configurations will result in poor to unusable performance. In the future other configurations may be added to the DSAPilot.

In some applications, tighter MF/HF pattern control, higher output, or

narrower vertical coverage may be desirable. Where higher LF output

capability is desired, height restrictions may not permit the ideal overunder mounting of the DSA250 and DSA230 models. Because of these

and other possible requirements, the DSAPilot allows several cluster

configurations to be used in a single or in multiple locations to

achieve various coverage and output results. See the DSA Application

Guide for details.

NOTE: Where aesthetics or other

considerations warrant, side-by-side

configurations can be mirrored

without affecting the results.

23

1A

1B

1C

2A

2B

2C

2D

2G

2F

3A

2E

Figure 5.5.3 DSA Cluster Configurations

Page 24

5.5.4 INSTALLATION OPTIONS

Normal Method: This method is for installing DSA loudspeakers

flush-mounted to a vertical wall surface using the supplied brackets. The

installation instructions herein apply to this installation method.

Optional Normal Method: This method is for suspending DSA

loudspeakers. The optional DSA Fly-Bar Kit is required for suspension. For

suspending more than one loudspeaker from a single Fly-Bar, the

optional Enclosure Connecting Kit is also required. These accessories are

supplied with complete instructions for their use.

Alternate Methods: In some applications, the DSA loudspeakers may

require suspension or other methods of installation. Please contact EAW

for assistance when the normal method cannot be used. (See Section 7.3)

Orient each enclosure in the cluster as shown in the DSAPilot diagrams

according to the location of the Signal End with the LED.

5.5.5 ANGLING ENCLOSURES

1. Vertical Angle: Normally, the DSA Series enclosures are designed to

be mounted flat to a vertical surface.

2. Horizontal Angle Single Loudspeakers: When mounted flat to a

vertical surface, the mounting hardware allows the enclosures to be

rotated up to +/-15° degrees horizontally, 0° being perpendicular to

the wall surface. This allows directing its fixed 120° horizontal

coverage anywhere within a 150° arc around the front of theloudspeaker.

3. Horizontal Angle Over/Under Loudspeakers: Always align over/under

enclosures so they are aimed in the same direction.

4. Horizontal Angle Side-by-Side Loudspeakers: These clusters cannot

be rotated horizontally. Always position the DSA250 and DSA230

loudspeakers for these clusters so that their aiming axes are

perpendicular to the mounting surface.

24

Figure 5.5.5a Horizontal Rotation

Single Enclosure

WALL

Figure 5.5.4a Wall Mounted

Figure 5.5.4b Suspended

DSA

SUPPLIED

WALL

BRACKETS

USER-SUPPLIED

SUSPENSION

HARDWARE

OPTIONAL

FLY-BAR KIT

DSA

OPTIONAL

ENCLOSURE

CONNECTING

KIT

DSA

15°

0°

15°

WALL

Page 25

5.5.6 MOUNTING HEIGHT

The acoustical reference point for the DSAPilot is the geometric

center of the cluster, which is halfway between the top of the top

enclosure to the bottom of the bottom enclosure. That means for a

steering angle of 0 degrees “on-axis” is the physical center of the cluster.

The elevation entered into DSAPilot refers to this point. This means

that if an elevation is entered that is less than half the height of the

cluster, it will go “through the floor” in the software.

For installation purposes, the mounting height of the bottom

enclosure in a cluster will be the cluster elevation as entered in

DSAPilot minus one-half the total physical height of the cluster

5.5.7 WALL BRACKET INSTALLATION

DANGER: Only persons with the knowledge of proper hardware and

installation techniques required should attempt to install DSA Series

loudspeaker systems overhead. Failure to follow this precaution may

result in damage to the equipment, injury, or death.

The supplied Wall Brackets are designed for attachment of the loudspeaker enclosure to a wall or other vertical surface. Ensure both the

attachment hardware and the architectural structure are capable of supporting the load with a design factor that meets applicable building codes.

Weights:

DSA230 63 lb / 28.6 kg

DSA250 90 lb / 40.0 kg

1. Using the supplied Wall Bracket Mounting Template or exact

measurements, locate the four mounting points required to attach

each supplied Wall Bracket to the supporting structure. Mounting

templates are provided on the shipping-carton and CD-ROM. A

bracket template is shown in chapter 9. Ensure that these mounting

points are plumb and square to each other so the enclosure will be

exactly vertical when installed. Being out of plumb and/or square

can prevent them from properly engaging the Enclosure Brackets

attached to the enclosure.

25

GOOD

Figure 5.5.5b Horizontal Rotation

Over / Under Enclosures

Figure 5.5.5c Horizontal Rotation

Side-by-Side Enclosures

Figure 5.5.6 Mounting Height

BAD

GOOD

BAD

ACOUSTICAL

REFERRENCE

POINT

("ON AXIS" )

MOUNTING

HEIGHT

FLOOR

C

L

Page 26

Critical Dimensions:

1. Spacing between the Wall Brackets for a single loudspeaker must be

within 0.1 in / 3 mm of the dimensions in Figure 5.5.7a.

In order to lift a loudspeaker onto its wall brackets, spacing between

the top wall bracket and ceiling, or other overhead obstruction,

must be 8.5 inches minimum. NOTE: 8.5 inches allows only 0.25

inches extra clearance.

2. Spacing between the Wall Brackets for loudspeakers mounted overunder fashion must be 4.9 inches.

3. Spacing between the Wall Brackets for loudspeakers mounted side

by side must be 5.4 inches.

4. Provide attachment hardware and secure the supplied Wall Brackets

to the mounting structure, complying with all Caution and Warning

notes in Section 5.5.1.

NOTE: The Wall Brackets have a weld nut on one side. Be sure to locate

this weld nut to the right or left such that the Retainer Bolt can be

inserted into the opposite side of the Wall Bracket after the loudspeaker

is mounted.

26

Figure 5.5.7b Over-Under Spacing

Figure 5.5.7c Side-By-Side Spacing

Figure 5.5.7d Wall Bracket Attachment

(For illustration purpose only. Attachment

hardware selection is installer’s responsibility.)

8.5 in MINIMUM TO CEILING

Figure 5.5.7a Wall Bracket Spacing

DSA250

38.1 in

968.3 mm

DSA230

23.9 in

606.3 mm

4.9 in

123.9 mm

5.4 in

136.6 mm

USER SUPPLIED

ATTACHMENT

HARDWARE

Ø 0.39 in

Ø 9.9 mm

Page 27

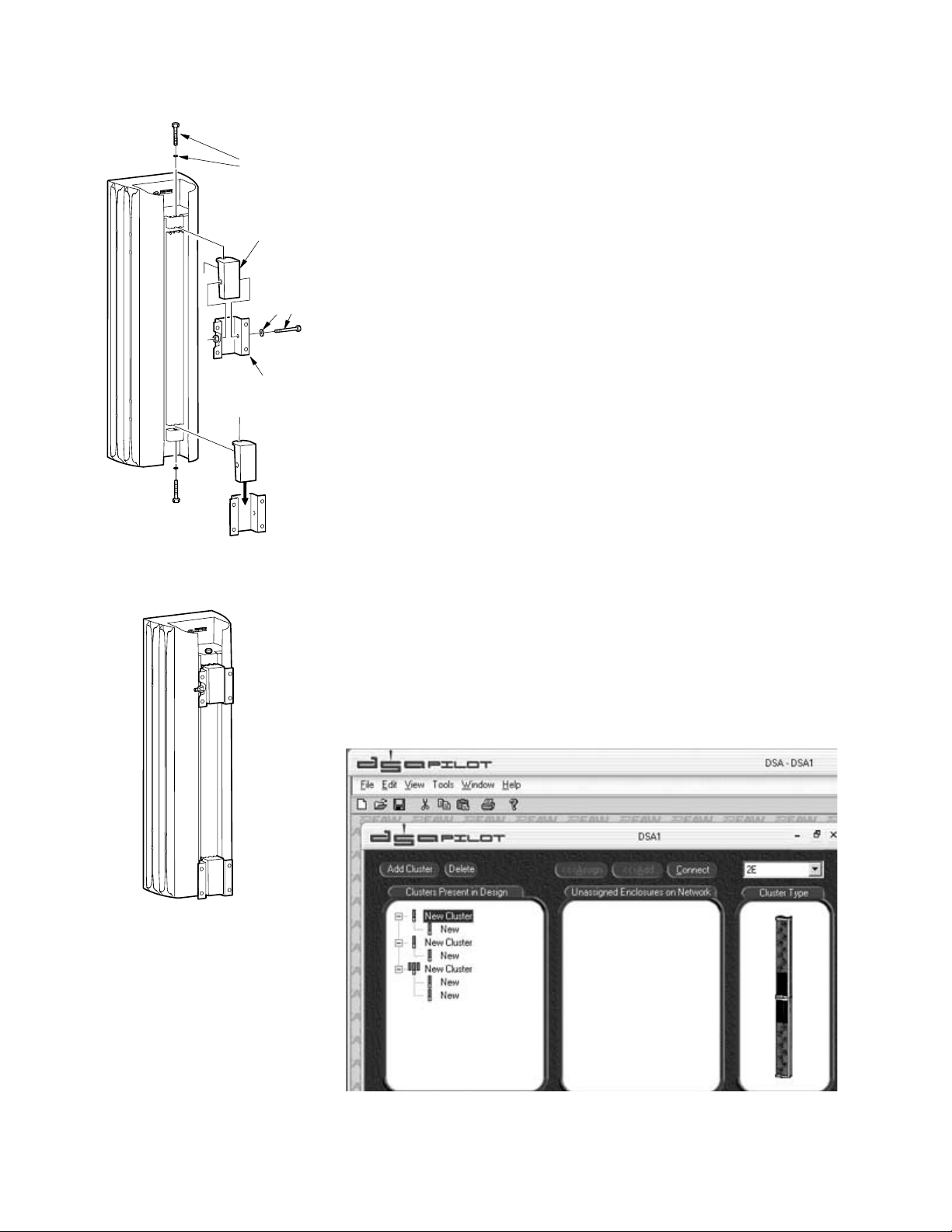

5.5.8 ENCLOSURE BRACKET INSTALLATION

Insert each supplied Enclosure Bracket into its slot near each end of the

enclosure, verifying the proper orientation of the enclosure. Insert a

supplied 3/8-16 x 2 in Enclosure Bracket Bolt with its lock washer into

each bracket bolt hole in the enclosure. Thread each bolt into the weld

nut on its Enclosure Bracket and hand-tighten.

CAUTION: Make sure the brackets are installed so the enclosure

orientation will be correct when the enclosure is mounted.

5.5.9 ENCLOSURE INSTALLATION

Lift the enclosure onto the structure-mounted Wall Brackets

DANGER: It is recommended that lifting the enclosure in place be

performed by at least two people to prevent it from falling during its

installation and causing possible equipment damage, injury, or death.

CAUTION: For DSA Clusters with two or more loudspeakers mounted

one over the other, it is recommended to make all cable connections

before lifting the loudspeakers onto the wall brackets. See Sections

5.2 through 5.6. Once the loudspeakers are mounted, access to the

connectors may be difficult.

IMPORTANT: When installing loudspeakers mounted vertically end to

end, install the lower loudspeaker first.

27

Figure 5.5.8 Enclosure Bracket Installation

Figure 5.5.9a Enclosure Installation

2X 3/8-16 X 2 LG

HEX HEAD SCREWS

& LOCK WASHERS

2X ENCLOSURE

MOUNTING

BRACKET

P/N 0006118

2X WALL

MOUNTING

BRACKET

P/N 0006119

Page 28

1. Install at least one of the supplied 1/4-20 X 3 in Retainer Bolt

with its lock washer through the side of either the top or bottom

Wall/Enclosure Bracket and snugly tighten. The bolt threads into a

weld nut on the side of the Wall Bracket. This Retainer Bolt prevents

the enclosure from being lifted off the Wall Brackets without first

removing the bolt. Note that the Retainer Bolt does not “clamp”

or support anything. It serves only to retain the enclosure on the

wall brackets, not to lock it into position.

2. Route cabling as required using the rear channels in the enclosures

extrusion.

3. Rotate the enclosure to the desired horizontal angle. Firmly tighten

each Enclosure Bracket Bolt to secure the enclosure in the desired

position.

28

1/4-20 X 3 L

G

W

R

Figure 5.5.9b Retainer Bolt Installation

Figure 5.5.9c Cable Routing

Figure 5.5.9d Secure the Enclosure Position

HEX HEAD SCRE

& LOCK WASHE

1/4-20 WELD NUT

CABLE CHANNELS

ENCLOSURE BRACKET BOLT

Page 29

5.6 Initial Set-Up

5.6.1 VERIFY LOUDSPEAKER ORIENTATION AND POSITION

Using the DSAPilot, and with communications established with the

loudspeakers, click on each loudspeaker in DSAPilot. The LED in

both the DSAPilot graphic and on the actual loudspeaker will

illuminate. Ensure that the physical orientation and position of

each loudspeaker corresponds to that shown in the DSAPilot graphic.

See the DSAPilot help file for further information.

CAUTION: Incorrect orientation or cluster position will result in poor

to unusable performance.

5.7 Acoustical Installation

Adjustment of the signal processing and thus the acoustical performance

for each DSA Cluster is accomplished using the DSAPilot program.

Complete instructions for its use can be found in the DSAPilot Help file.

These are the basic tasks that need to be done using the DSAPilot:

1. Select each cluster configuration used in the system design

2. Assign the installed clusters to those selected in the DSAPilot

3. Set the Steering parameters for each cluster

4. Configure the audio input routing for each cluster

5. Set the user-adjustable gain, EQ, compression, or signal delay for

the inputs

6. Set the desired Power Saving operation

7. Save the final signal processing settings for the system to a file

29

Figure 5.6 Identification LED

LED INDICATOR

Page 30

Chapter 6 Operation

The general operation of a DSA loudspeaker is similar to the operation of

most loudspeakers. Initial system set-up and overall tuning adjustments