Page 1

Steering Catalog

Steering Control Units

Torque Generators

Steering Columns

Page 2

2 EATON Char-Lynn Steering Catalog C-STOV-MC001-E1 July 2006

Literature Referenced in this Catalog:

• Eaton Technical Bulletin 3-401

• Eaton Flow Divider Catalog E-VLFL-MC001-E

• Eaton Relief Valve Catalog 11-510

• Eaton Gear Pumps Series 26 Model 26000 Catalog 11-609

• Eaton Char-Lynn Low Speed High Torque Motors Catalog E-MOLO-MC001-E2

• Vick ers

®

Screw in Cartridge Values Catalog V-VLOV-MC001-E2

• Vick ers

®

Proportional Valves Catalog 539

• Vickers Solenoid Operated Directional Valves Catalog GB-C-2015

Page 3

EATON Char-Lynn Steering Catalog C-STOV-MC001-E1 July 2006 3

Table of

Contents

Description and Technologies About Power Steering

Description and Advantages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Hydraulic Circuit Explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Neutral Circuits

Open Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Open Center Power Beyond . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Closed Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Load Sensing (static and dynamic signal) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Work Circuits

Non-Load Reaction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Load Reaction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Steering Units with Integral Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Special Features and Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-18

Manual Steering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2 Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Dual Displacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Eaton Patented Technologies

Q-Amp (Flow Amplification) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Wide Angle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Cylinder Damping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

VersaSteer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

STC Direct Porting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Steering Control Units and Torque Generators

Series 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Series 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Series 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Series 25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Series 40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Torque Generator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Steering System Components and System Accessories

Antijerk Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Priority Valves VLC, VLE, VLH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Check Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Relief Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Columns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Steering Wheels and Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

EH Proportional Steer Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Four Wheel Steer Switching Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Flow Divider Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Brake Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

T Series Hydraulic Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Sizing and Application

Ackermann Type Steering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Articulated Type Steering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Articulated Vehicle Steering Analysis Form. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Articulated Vehicle Steering Analysis Form. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Information contained in this publication is accurate as of the publication date and is subject to change without notice. Performance values are typical values. Customers are responsible for selecting

products for their applications using normal engineering methods.

Page 4

4 EATON Char-Lynn Steering Catalog C-STOV-MC001-E1 July 2006

Description and

Advantages

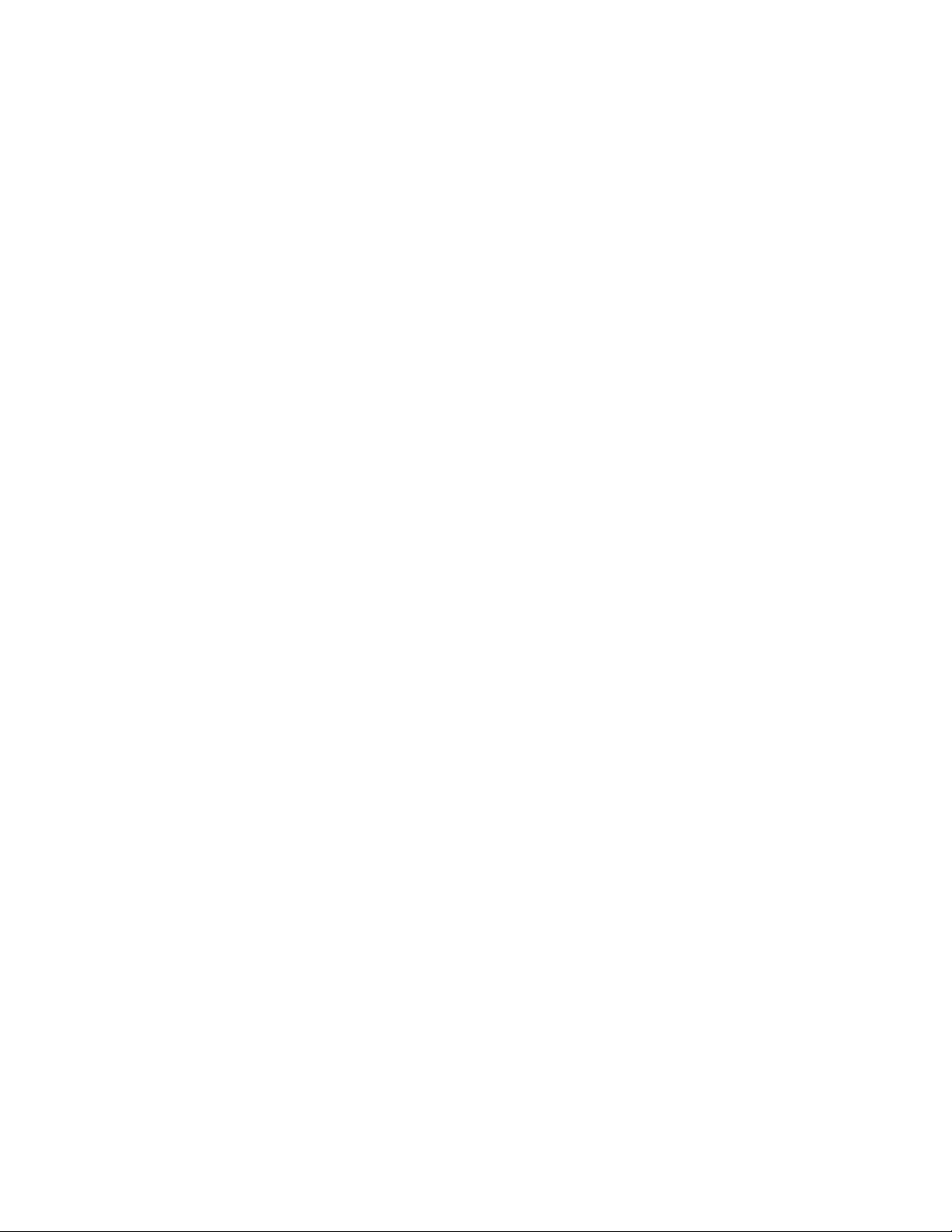

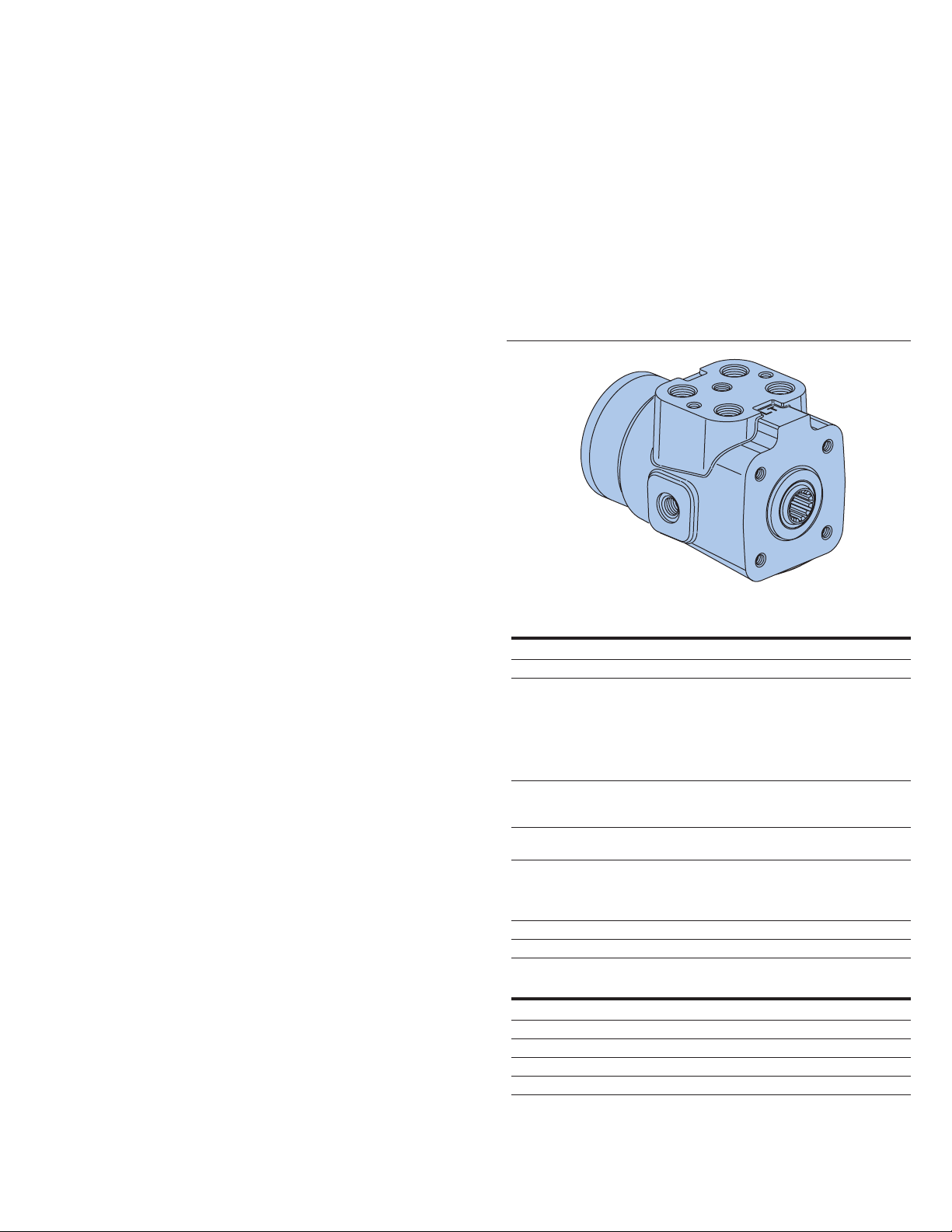

Steering Control Units

The Char-Lynn®steering control unit (SCU) is fully

fluid linked. This means there is no mechanical

connection between the steering unit, the pump

and the steering cylinders. The unit consists of a

manually operated directional control servo valve

and feedback meter element in a single body. It is

used principally for fluid linked power steering

systems but it can be used for some servo-type

applications or any application where visual

positioning is required. The close coupled, rotary

action valve performs all necessary fluid directing

functions with a small number of moving parts.

The manually actuated valve is coupled with the

mechanical drive to the meter gear. The control is

lubricated and protected by the power fluid in the

system and can operate in many environments.

Char-Lynn power steering control units offer the

following advantages:

• Minimizes steering linkage—reduces cost, provides

flexibility in design.

• Provides complete isolation of load forces from the

control station—provides operator comfort.

• Provides continuous, unlimited control action with

very low input torque.

• Provides a wide selection of control circuits and

meter sizes.

• Can work with many kinds of power steering pumps

or fluid supply.

SERIES 5 (291-XXXX-XXX, 292-XXXX-XXX, 293-XXXX-XXX, 294-XXXX-XXX)

Displacement 31.5 - 146 cm3/r 1.92 - 8.9 in3/r

Flow 11 - 19 l/min 3 - 5 GPM

Pressure 140 bar 2030 PSI

SERIES 10 (200-XXXX-XXX, 220-XXXX-XXX)

Displacement 58.7 - 739 cm3/r 3.58 - 45.1 in3/r

Flow 11 - 76 l/min 3 - 20 GPM

Pressure 275 bar 4000 PSI

SERIES 20 (236-XXXX-XXX)

Displacement 60 - 985 cm3/r 3.6 - 60 in3/r

Flow 38 - 114 l/min 10 - 30 GPM

Pressure 241 bar 3500 PSI

SERIES 25 (251-XXXX-XXX, 252-XXXX-XXX, 253-XXXX-XXX)

Displacement 490 - 1230 cm3/r 30 - 75 in3/r

Flow 95 - 151 l/min 25 - 40 GPM

Pressure 241 bar 3500 PSI

SERIES 40 (281-XXXX-XXX, 282-XXXX-XXX, 283-XXXX-XXX)*

Displacement 1230 - 3030 cm3/r 75 - 185 in3/r

Flow 151 - 227 l/min 40 - 60 GPM

Pressure 241 bar 3500 PSI

* For all other product numbers consult steering website.

Page 5

EATON Char-Lynn Steering Catalog C-STOV-MC001-E1 July 2006 5

Description and

Advantages

Torque Generator

Char-Lynn torque generators have been completely

redesigned to meet the needs of the changing

marketplace. These torque generators have served

the industry well, providing:

• Power assist for vehicle steering

• Power assist on gates and valves, eliminating the

large hand wheels

• Powerful rotary motion with effortless manual rotary

input on numerous other applications

Today’s market includes power steering on electric lift

trucks. These new torque generators have been designed

with features that greatly improve the operator’s comfort as

well as the vehicle’s performance.

Use the Torque Generator as rotary power assist for:

• Large indexing tables

• Manually operated gates and valves

• Manual positioning devices

• Mechanical steering systems

• T urntables

SERIES 217, 227

Displacement 76 - 160 cm3/r 4.7 - 9.6 in3/r

Flow 15 l/min 4 GPM

Pressure 69 and 172 bar 1000 and 2500 PSI

STEERING COLUMNS (204-XXXX-XXX)

Jacket Length 56 - 836 mm 2.2 - 33 inch

Horn Wire with and without with and without

Upper Ends 10 Upper End Types 10 Upper End Types

Customized Steering Columns

Char-Lynn columns can be custom built to your

exact specifications. The column and mounting

flange is of a sturdy single weldment design. These

columns have high thrust and side load capacity

with low shaft torsional friction. A tilt column is

also available.

Page 6

6 EATON Char-Lynn Steering Catalog C-STOV-MC001-E1 July 2006

Hydraulic Circuit

Explanation

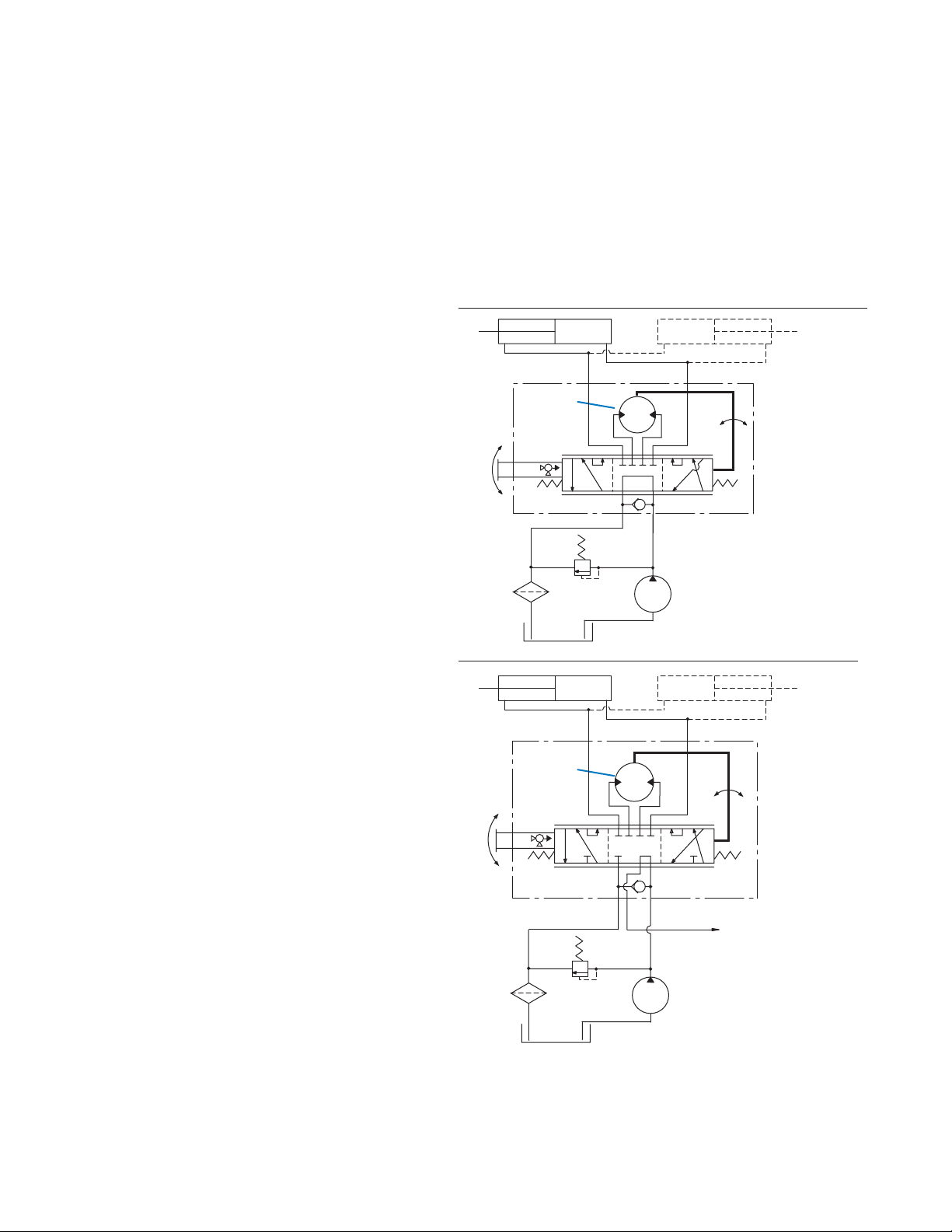

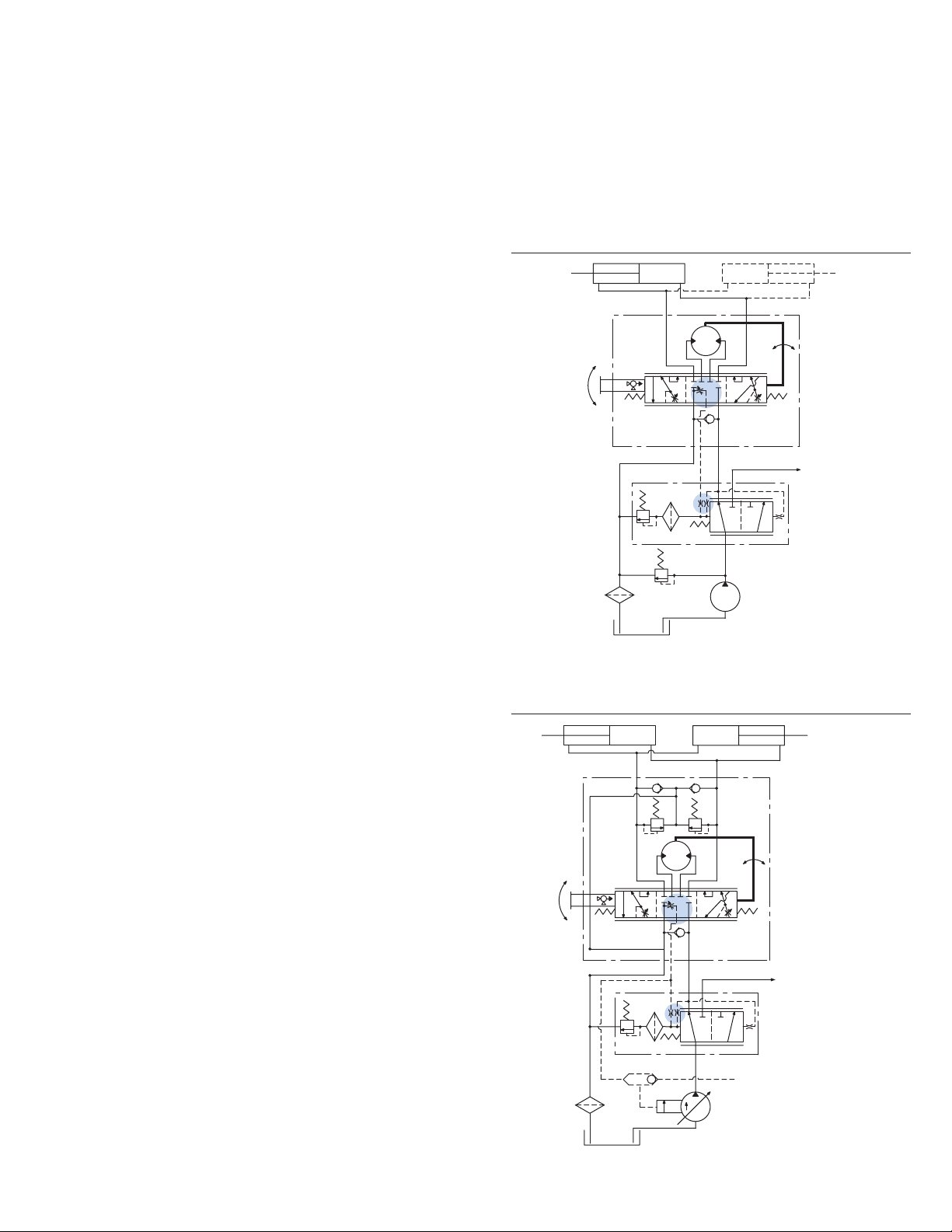

Neutral Circuits:

Open Center

and Open Center

Power Beyond

Open Center

• Simplest, most

economical system

• Uses a fixed

displacement pump

• In neutral position

pump and tank are

connected

• Most suitable on

smaller type vehicles

Open Center Power Beyond

The power beyond steering

control unit supplies steering

and auxiliary valve functions.

The power beyond unit is

used on medium pressure,

open center (fixed

displacement pump) systems.

When not steering, the power

beyond unit directs all inlet

flow to the auxiliary circuit.

However once steering is

initiated, part of the auxiliary

flow is diverted to steering.

Since steering has priority, all

flow, if required, will be

diverted to steering. The tank

port of the steering unit has

flow only when steering is

operated. Thus, flow out of

the auxiliary (“PB”) port and

the tank port will fluctuate or

stop depending on steering

input.

The following special

considerations should be

addressed when applying

power beyond steering:

• Auxiliary valves

(connected to PB) must

be open center type.

Slight bump or kick may

be felt in steering

wheel when auxiliary

functions are activated

during steering

operations.

• Pump flow not used for

steering is available at

power beyond (PB)

outlet, except at

steering stops where

total pump flow goes

over the system relief

valve. Avoid auxiliary

functions that require

constant flow while

steering.

• Flow is only directed to

the tank port when

steering is operated.

Avoid systems where

return flow from tank

port is used for auxiliary

functions.

• Inlet pressure to the

steering unit will be the

higher of steering

system pressure or

auxiliary valve pressure.

• Generally avoid

systems where heavy

use of auxiliary

functions occur while

steering.

Applications

• Lawn and Garden

Equipment

• Utility Vehicles

LR

Gerotor

T

LR

Gerotor

T

PB

P

Fixed

Displacement

Pump

P

To Auxilliary Circuit

Open Center Valves

Fixed

Displacement

Pump

Page 7

EATON Char-Lynn Steering Catalog C-STOV-MC001-E1 July 2006 7

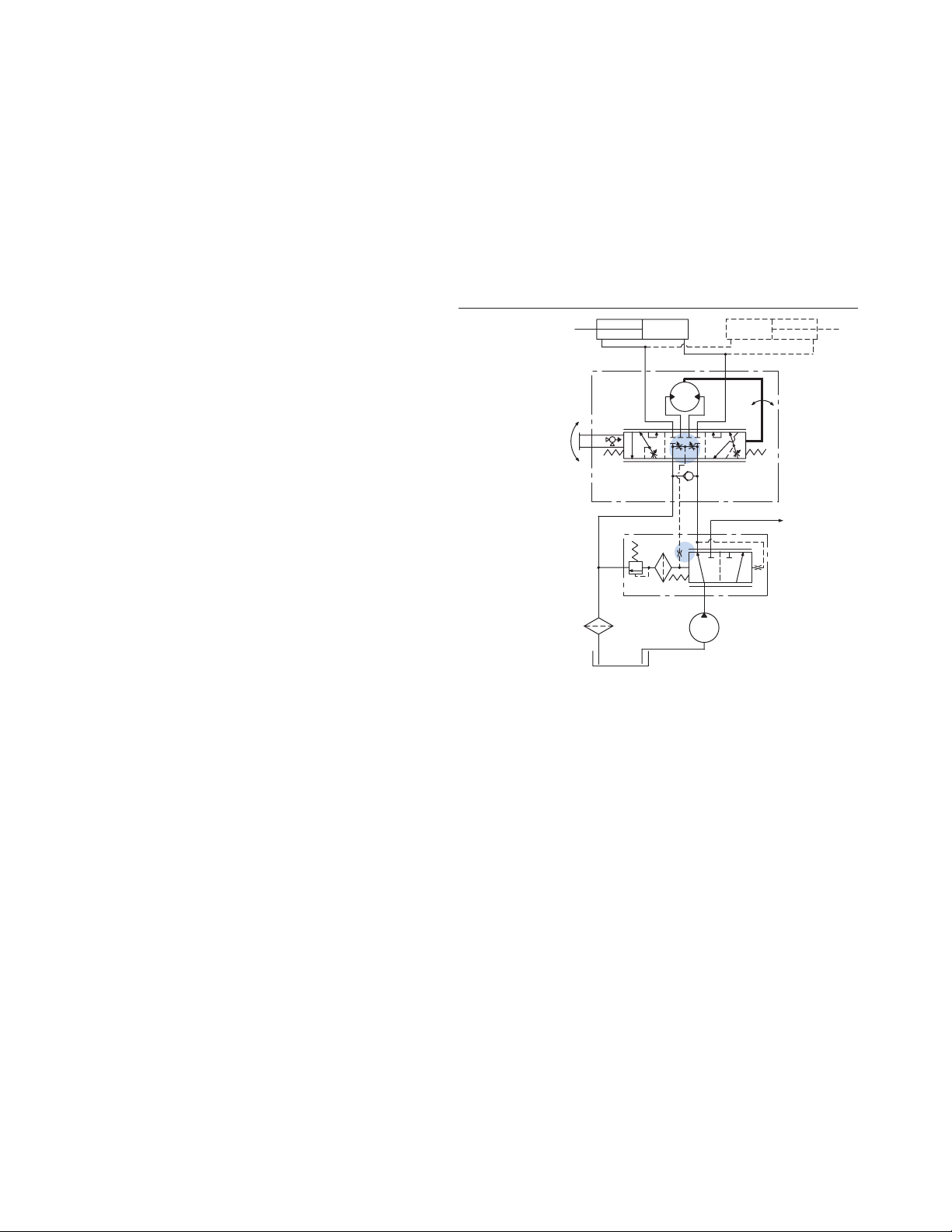

Hydraulic Circuit

Explanation

Neutral Circuits:

Closed Center

Closed Center

• Uses a pressure

compensated variable

displacement pump

• In neutral position

pump and tank are

disconnected

• Most suitable on large

construction equipment

Valve Option A

Closed Center System

Pressure

Compensated

Pump

P

RL

T

Closed Center with

Neutral Bleed

Neutral Bleed Feature

Closed Center Steering

Control Units are available

with and without neutral

bleed feature. Most

applications may not require

the bleed feature, however,

the maximum temperature

differential between

components within the

steering circuit must not

exceed specification (50° F or

28° C). Order unit with the

bleed feature if the

temperature differential may

exceed this limit. The neutral

bleed feature allows a small

flow of fluid to pass through

the unit when in neutral to

reduce the thermal

diff erential.

Typical applications where

neutral bleed is required are:

• Remote steering

position from power

source.

• Extended engine idle

operation when vehicle

is parked.

• High duty cycle

operation sharing a

common reservoir with

the steering circuit.

Applications

• Construction Industry

RL

Gerotor

Metering

Mechanism

T

P

with

Neutral

Bleed

Direct

Mechanical

Link

Steering

Control

Unit

Page 8

8 EATON Char-Lynn Steering Catalog C-STOV-MC001-E1 July 2006

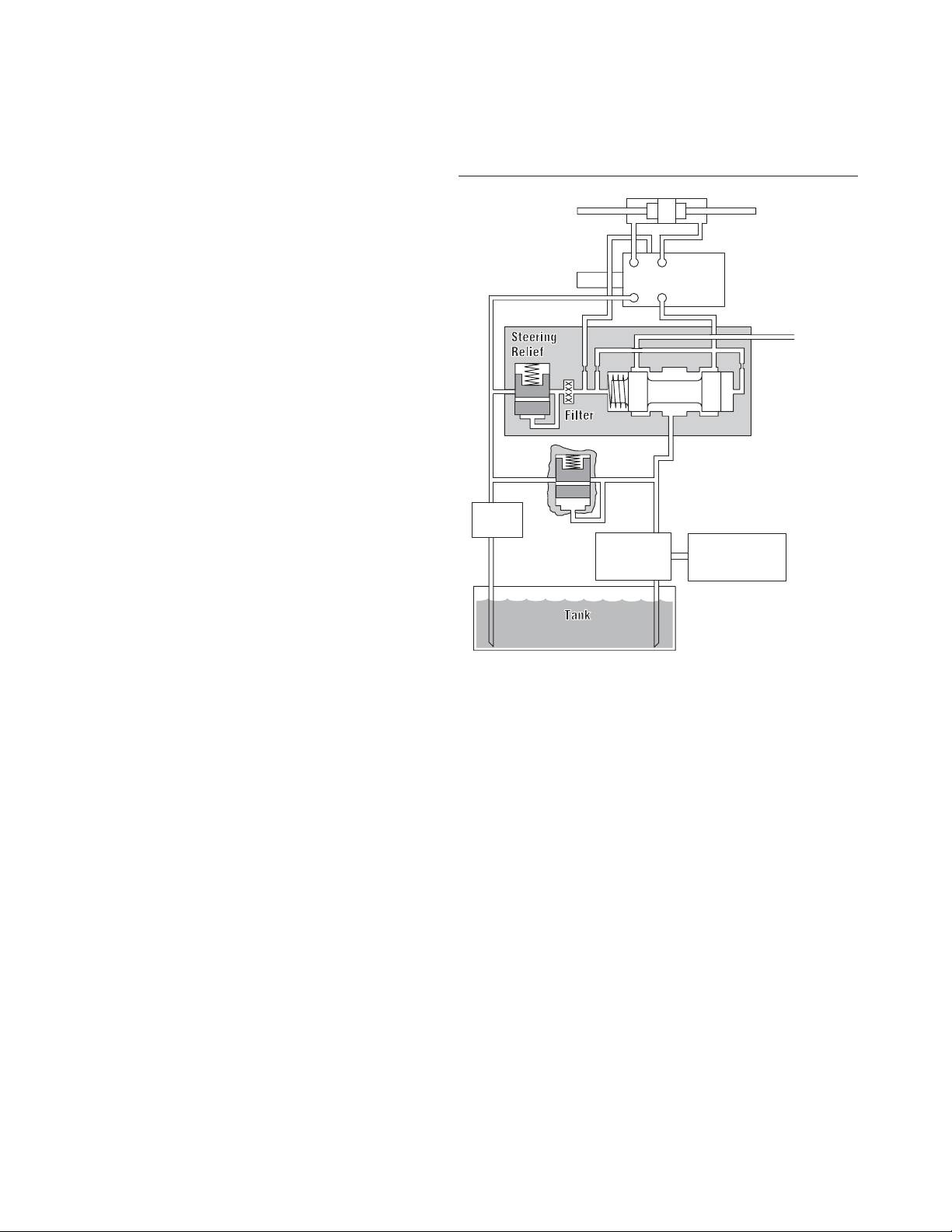

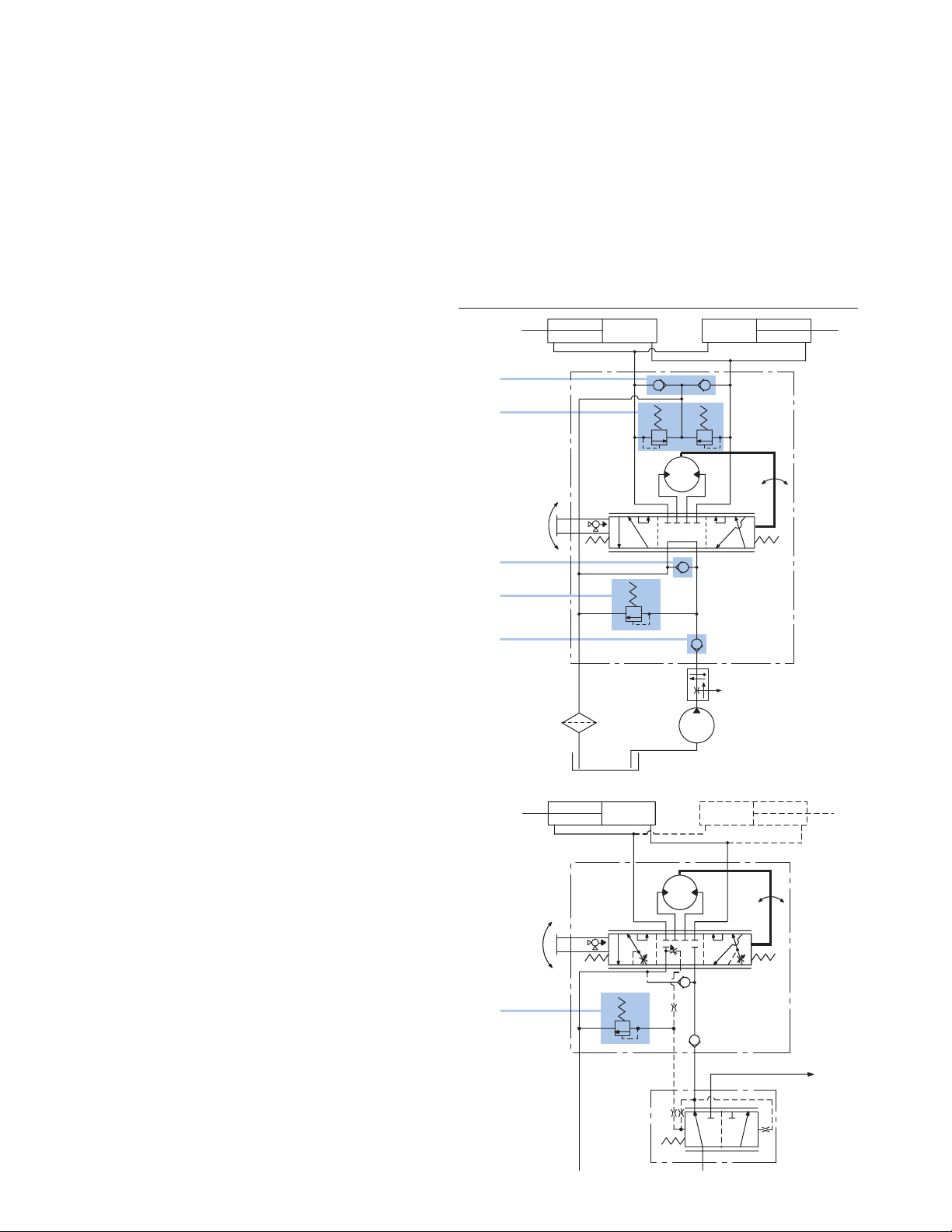

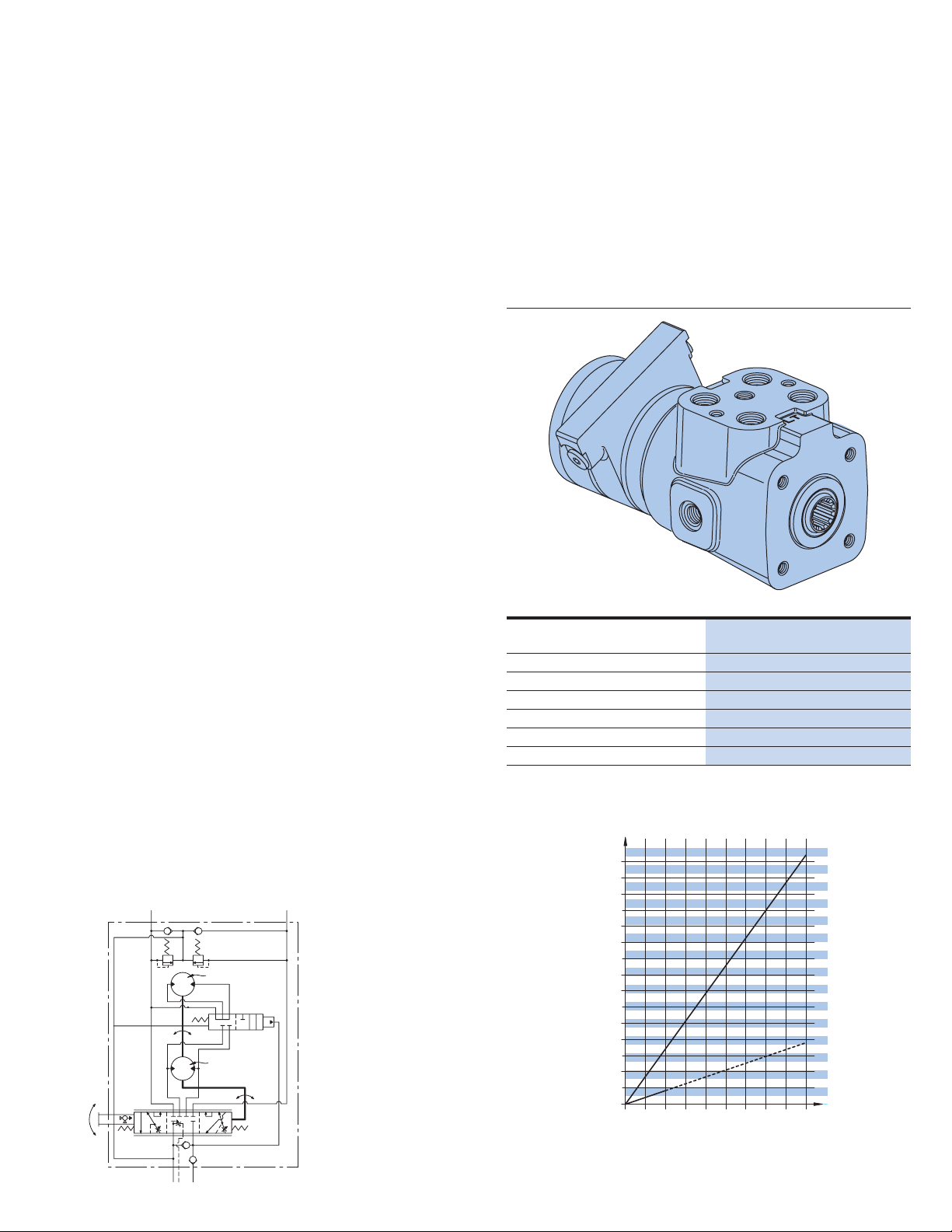

Hydraulic Circuit

Explanation

Neutral Circuits:

Load Sensing

Load Sensing Circuits

Char-Lynn load sensing

power steering uses

conventional or load sensing

power supplies to achieve

load sensing steering. The

use of a load sensing

steering unit and a priority

valve in a normal power

steering circuit offers the

following advantages:

• Provides smooth

pressure compensated

steering because load

variations in the

steering circuit do not

affect axle response or

maximum steering rate.

• Provides true power

beyond system

capability by splitting

the system into two

independent circuits.

Pressure transients are

isolated in each circuit.

Only the flow required

by the steering

maneuver goes to the

steering circuit. Flow

not required for

steering is available for

use in the auxiliary

circuits.

• Provides reliable operation

because the steering

circuit always has flow

and pressure priority.

Char-Lynn load sensing

steering control units and

priority valves can be used with

open center , closed center or

load sensing systems. Use in

an open center system with a

fixed displacement pump or a

closed center system with a

pressure compensated pump,

offers many of the features of a

load sensing system. Excess

flow is available f or auxiliary

circuits.

Listed below are the

components of a typical load

sensing control circuit and a

brief application description.

Pump—May be fixed

displacement, pressure

compensated,

or flow and pressure

compensated design.

Prior ity V alve—Sized for

design pressure drop at

maximum pump output flow

rate and priority flow

requirements. The minimum

control pressure must assure

adequate steering flow rate

and must be matched with

the steering control unit.

A dynamic signal priority

valve must be used with a

dynamic signal steering

control unit.

Steering Control Unit—

Designed for specific rated

flows and control pressures.

It must be matched with a

control pressure in the

priority valve to obtain

maximum steering rates.

Higher flow rates require

higher control pressures.

Neutral internal bleed

assures component

temperature equalization.

LS Line—A LS line is always

needed to sense pressure

downstream from the

variable control orifice in the

steering control unit. This is

balanced by an internal

passage to the opposite side

of the priority control spool.

The total system

performance depends on

careful consideration of the

control pressure chosen and

pressure drop in the CF line.

Steering Relief Valve—

Must be factory set at least

10 bar [145 PSl] above the

maximum steering cylinder

pressure requirement. Most

of the flow will be directed

to the auxiliary circuit (EF)

when the relief setting is

exceeded.

System Main Relief

Valve—A pressure relief

valve for the auxiliary circuit

and/or a main safety valve for

the protection of the pump is

recommended and sized for

the maximum pump output

flow rate. If a main relief valve

is used, it must be set above

the priority circuit steering

relief valve pressure setting.

LS— Load Sensing

DS— Dynamic Signal

PP— Pilot Pressure

CF— Control Flow

EF — Excess Flow

Manual

Input

LS

T

Filter

Steering Cylinder

LR

TP

DSLS

Main

Relief

P

Pump Prime Mover

Load Sensing

Steering Unit

CF

PP

Priority Valve

Dynamic Signal

High Pressure

Carryover

EF

Page 9

EATON Char-Lynn Steering Catalog C-STOV-MC001-E1 July 2006 9

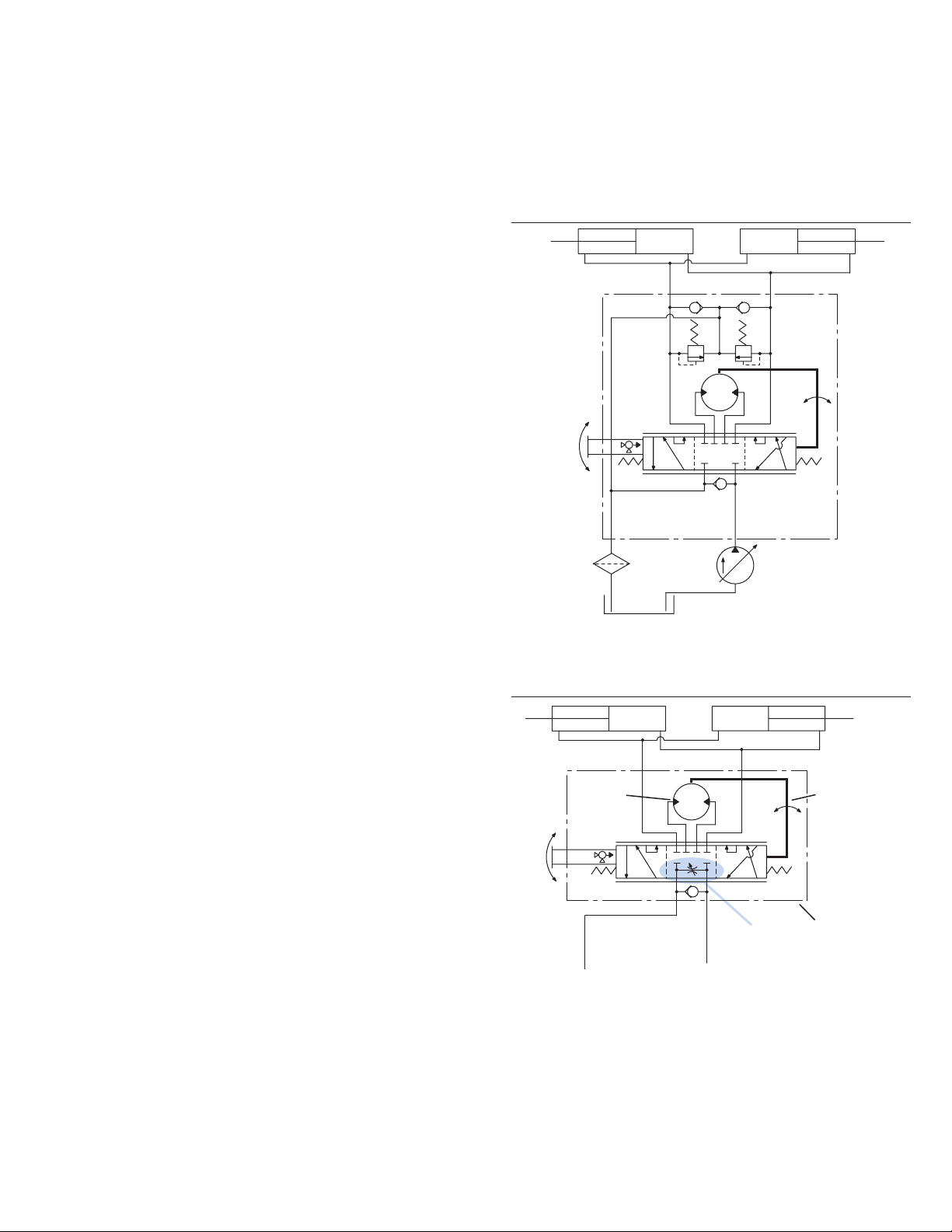

Hydraulic Circuit

Explanation

Neutral Circuits:

Load Sensing

Dynamic Signal—

Open Center Pump

Dynamic Signal—

Load Sensing Pump

Load Sensing Circuits—

Signal Systems

Two types of load sensing

signal systems are

available—Dynamic and

Static.

Dynamic Signal—Used for

more difficult applications.

The dynamic signal systems

offer the following benefits:

• Faster steering

response.

• Improved cold weather

start-up performance.

• Increased flexibility to

solve problems related

to system performance

and stability.

Dynamic

Signal

RL

Load

Sensing

(Dynamic

Signal)

Steering

Control Unit

(non-load

LS P

T

LS CF EF

T

P

Fixed Displacement Pump

Load Sensing Steering System with Fixed

Displacement Pump (Open Center Circuit)

reaction)

High Pressure

Carryover to

Auxiliary Circuit with

Open Center Valve(s)

Priority Valve

(Dynamic Signal)

Dynamic

Signal

T

Shuttle Valve

RL

Load

Sensing

(Dynamic

Signal)

Steering

Control Unit

(non-load

TLSP

LS CFEF

P

Pressure and Flow

Compensated Pump

Load Sensing Steering System with Pressure and Flow

Compensated Pump (Closed Center, Load Sensing Circuit)

reaction)

Auxiliary

Circuit with

Load Sensing

Valve(s)

Priority Valve

(Dynamic Signal)

Pilot Signal

from Auxiliary

Circuit

Page 10

10 EATON Char-Lynn Steering Catalog C-STOV-MC0 01-E1 July 2006

Static Signal—

Open Center Pump

Static Signal—Used for

conventional applications

where response or circuit

stability is not a problem.

The load sensing pilot line

should not exceed 2 meters

[6 feet] in length.

Hydraulic Circuit

Explanation

Neutral Circuits:

Load Sensing

Static Signal

RL

Load

Sensing

(Static

Signal)

Steering

Control Unit

(non-load

TLS P

LS CF EF

T

P

Fixed Displacement Pump

Load Sensing Steering System with

Fixed Displacement Pump

(Open Center Circuit)

reaction)

Auxiliary

Circuit with

Open Center

Valve(s)

Priority Valve

(Static Signal)

Page 11

EATON Char-Lynn Steering Catalog C-STOV-MC001-E1 July 2006 11

Hydraulic Circuit

Explanation

Work Circuits:

Non-Load Reaction

and Load Reaction

Non-Load Reaction

A non-load reaction steering

unit blocks the cylinder ports

in neutral, holding the axle

position whenever the

operator releases the

steering wheel.

Load Reaction

A load reaction steering unit

couples the cylinder ports

internally (in the neutral

position) with the meter

gear set. Axle forces are

then allowed to return the

steering wheel to its

approximate original

position. Comparable to

automobile steering,

gradually releasing the

wheel mid turn will allow

the steering wheel to spin

back as the vehicle

straightens.

The cylinder system used

with load reaction units

must have equal oil

volume displaced in both

directions. The cylinders

should be a parallel pair (as

shown) or one double rod

end unit. Do not use with a

single unequal area

cylinder system.

Gerotor

Metering

Mechanism

RL

Direct

Mechanical

Link

Gerotor

Metering

Mechanism

T

Closed Center System

Non-Load Reaction Circuit

P

Steering

Control

Unit

Pressure and Flow

Compensated Pump

RL

T

P

Fixed

Displacement

Pump

Direct

Mechanical

Link

Steering

Control

Unit

Open Center System

Load Reaction Circuit

Page 12

12 EATON Char-Lynn Steering Catalog C-STOV-MC0 01-E1 July 2006

Steering Units

with Integral

Valves

Integral valves are available

for the Char-Lynn steering

control unit. Included are:

Inlet Relief Valve, Cylinder

Port Shock Valves, LS-Relief

Valve, and Anti-Cavitation

Valves for cylinder ports. In

addition, a Manual Steering

Check V alv e for limited

manual steering is included.

The integral valves eliminate

the need for a separate

valve block, and provides

versatility to meet any

steering circuit standard.

Valve Description:

1 Anti-cavitation check

valve for cylinder ports—

(R & L) protects steering

circuit against vacuum

(cavitation) conditions.

2 Cylinder Port Relief

Valves—(R & L) protects

hoses against pressure

surge created by ground

forces on the steered axle.

3 Manual Steering Check

Valve—converts unit to a

hand operated pump for

limited manual steering.

Included in all units except

Series 20, 25, and 40.**

4 Inlet Relief Valve—limits

maximum pressure drop

across the steering unit

protecting the steering

circuit.

5 Inlet Check Valve—

prevents oil from returning

through the steering unit

when pressure on the

cylinder side is greater

than pressure on the inlet

side to prevent steering

wheel kick.

6 LS-Relief Valve—Limits

maximum pressure in the

steering circuit (LS units

only)

**Steering units with displacements larger than

185 cm

3

/r [11.3 in3/r] may require a separate

power source for limited operation.

1

2

3

4

5

EF

6

Page 13

EATON Char-Lynn Steering Catalog C-STOV-MC001-E1 July 2006 13

Special Features

and Application

Manual Steering

96

[5.9]

74

[4.5]

59

[3.6]

46

[2.8]

185

[11.3]

146

[8.9]

160

[9.7]

230

[14.1]

295

[17.9]

370

[22.6]

120

[7.3]

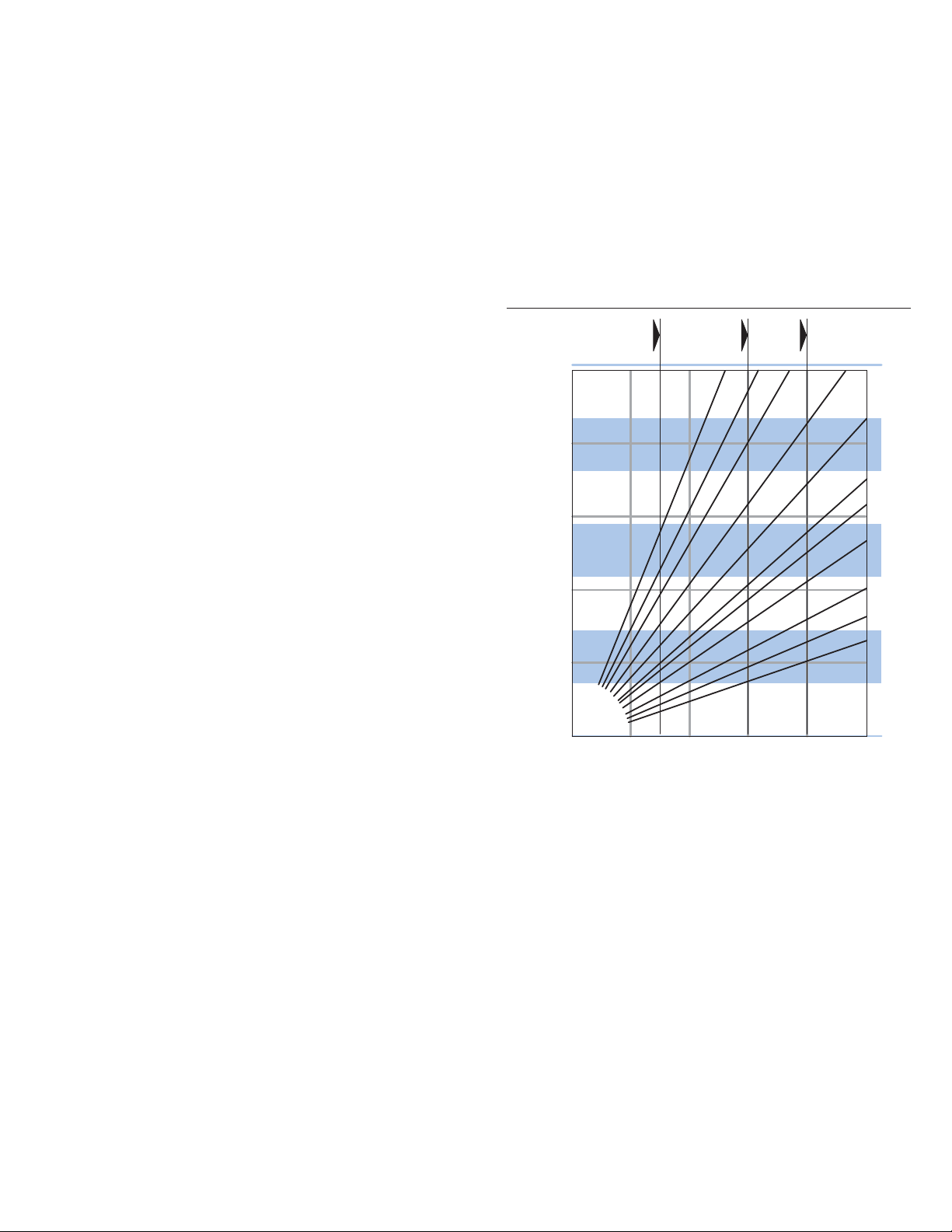

Description

The steering control unit can

provide steering flow when

the pump or engine fails. It

will pump oil through the

meter (gerotor) as the

operator applies input or

torque to the steering wheel

which provides limited

manual steering.

This feature is available in all

steering models except for

Series 25 and 40.

Use of Graph

1. Determine steering work

port pressure required to

preform the desired

steering maneuver from

vehicle test data. This

defines the approximate

manual steering pressure

level required. Find this

value on the vertical axis

and construct a horizontal

line on the graph.

2. Find the input torque limit

on the horizontal axis.

Follow this vertically until

it crosses the required

pressure line of step 1.

3. The maximum steering

unit displacement is

identified by the first

angled line to the left of

this intersection.

[PSI]

[1000]

[ 800]

[ 600]

[ 400]

[ 200]

30-60

RPM

0

0

27

[20]

1) Maximum flow less than 7,6 l/min [2 GPM].

2) Actual steering pressures required and manual

steering capabilities must be verified with vehicle

testing.

The above curves are intended as a design guide only.

10-15

RPM

46

46

[2.8]

[2.8]

74

74

[4.5]

[4.5]

54

[40]

Manual Input Torque

Nm [lb-ft]

59

59

[3.6]

[3.6]

81

[60]

1-3

RPM

96

96

[5.9]

[5.9]

185

185

[11.3]

[11.3]

108

[80]

120

120

[7.3]

[7.3]

295

295

[17.9]

[17.9]

370

370

[22.6]

[22.6]

Displacement

3

cm

/r [in3/r]

146

146

[8.9]

[8.9]

160

160

[9.7]

[9.7]

230

230

[14.1]

[14.1]

136

[100]

70

60

50

40

bar

30

20

10

0

Page 14

14 EATON Char-Lynn Steering Catalog C-STOV-MC0 01-E1 July 2006

Description

Eaton’s 2-Speed technology

offers two operatorselectable metered modes

at any time, with the touch

of a button or the flip of a

switch, and provides the

operator flexibility to

significantly improve the

overall steering experience.

2-Speed technology is

available on the Series 10

Steering Control Unit (SCU).

Dual Steering Modes

Typically, the gerotor

between the SCU housing

and the shift valve is the

smaller gerotor (first

gerotor). The shift valve is

activated by the operator,

which allows or prevents

flow to the second gerotor.

A separate solenoid valve

provides the pressure pilot

signal to shift the

aforementioned valve. The

OEM will define and provide

the operator switch to

activate the solenoid valve.

Metered Steering Mode 1

– The steering unit operates

the same as a traditional

hydrostatic steering control

unit. Steering (flow) is a

function of steering wheel

rotations (rpm). Metered

(gerotor) steering provides

precise, responsive, and

smooth steering. All the

flow is metered by the first

gerotor, resulting in a

greater number of turns

lock-to-lock. In case of

pressure loss, the shift valve

automatically prevents flow

to the second gerotor and

emergency steering is

available via the first gerotor.

Metered Steering Mode 2

–The steering unit operates

the same as a traditional

hydrostatic steering control

unit, except the flow is

metered for a combined

displacement of two

gerotors. As with Mode 1,

steering (flow) is a function

of steering wheel rotations.

As the total displacement

per rotation is the sum of

the two gerotor

displacements, the number

of turns lock-to-lock may be

significantly decreased.

Operator effort is greatly

reduced during the work

cycle. The number of turns

lock-to-lock could go down

to 0.5, where the ratio of

the two gerotor

displacements could vary

from 1:1 to as high as 5:1,

providing great flexibility in

the design.

Benefits

• Manual steering

capability in unpowered

mode (“emergency

steering”)

• Steering flow is always

proportional to steering

speed

• Allows for excellent

roadability and operator

selectable quick-steer

for work cycles

Features

• Open Center, Load

Sense

• All Integral Valves

• Wide Angle

• Max System pressure:

241 Bar [3500 psi]

Applications

• All Ackerman Steering

• T ractors, T elehandlers,

Sweepers, Forestry

Equipment, Backhoes,

Loaders

• Sprayers, Combines,

Motor Graders

Special Features

and Application

2-Speed

Page 15

EATON Char-Lynn Steering Catalog C-STOV-MC001-E1 July 2006 15

Special Features

and Application

Dual

Displacement

Description

The dual displacement

steering control unit allows

manufacturers of off road

vehicles to retain manual

steering capabilities while

reducing the number of

components in their system.

By using two displacements

in one unit we offer a better

solution to manually steer a

vehicle in an unpowered

mode without the need of a

back-up power system—

resulting in a more

economical machine.

The dual displacement

steering unit uses two

gerotors and a pressure

controlled logic valve. The

logic valve switches bet ween

two displacements, one

displacement for manual

steering and the total of both

displacements for powered

operation. The logic valve is

spring returned to the

smaller manual

displacement when inlet

pressure falls below 8 bar

[120 psi]. Above 8 bar [120

psi] the logic valve connects

both gerotors to provide full

powered displacement.

Manual steering capabilities

in unpowered mode

• Eliminates the need of

a back-up emergency

system.

• Engages the small

displacement in an

unpowered mode and

allows manual steering.

• Allows vehicles to meet

ISO/TUV road regulations

without the need of the

currently used

emergency system.

Performance in powered mode

• Both gerotors are

engaged to steer the

vehicle.

• Same performance as

other Char-Lynn

steering units.

Additional Features

• Steering circuit: Load

Sensing Dynamic Signal

• Max. system pressure:

241 bar [3500 psi].

• Valve options and other

features: same as those

available on Series 10

(single displacement)

units

DISPLACEMENT CHART:

Gerotor 1 Gerotor 1 and 2 Gerotor 1 Gerotor 1 and 2

Manual displ. Powered displ. Manual displ. Powered displ.

in3/rev in3/rev cm3/rev cm3/rev

3.6 9.5 60 156

3.6 10.9 60 179

3.6 12.5 60 205

3.6 13.3 60 218

3.6 14.9 60 244

For any other displacement please see your Eaton Representative.

Powered Mode

Manual Mode

Added Gerotor

Logic Valve

Manual Gerotor

TLS P

RL

Manual 60 cm

Powered 244 cm

7.5

7.0

6.5

6.0

5.5

5.0

4.5

4.0

3.5

3.0

2.5

Steering Flow GPM

2.0

1.5

1.0

0.5

0

Flow vs RPM (for each operating mode)

3

/r [3.6 in3/r]

3

/r [14.9 in3/r]

Powered Mode

Powered Mode

Manual Mode

Manual Mode

30 45 60 75 90 60 105 120

015

Input Speed RPM

30

28

26

24

22

20

18

16

14

12

10

8

6

4

2

0

Steering Flow l/min

Page 16

• Manual Steering

Steering a vehicle with

loss of engine power may

not be possible with a

large displacement

steering control unit (SCU).

Q-Amp with manual

feature has the smaller

displacement required for

manual steering and has

the additional flow

requirement of the larger

displacement SCU for

power steering.

• Single Cylinder

(Unequal area)

On vehicles with one single

unequal area cylinder the

steering wheel turns lock to

lock are more in one

direction than the other.

When extending the rod one

would get more turns than

when retracting it. A

different Q-Amp ratio while

turning in one direction

versus the other can be

used to give an equal

number of turns lock to lock

in each direction.

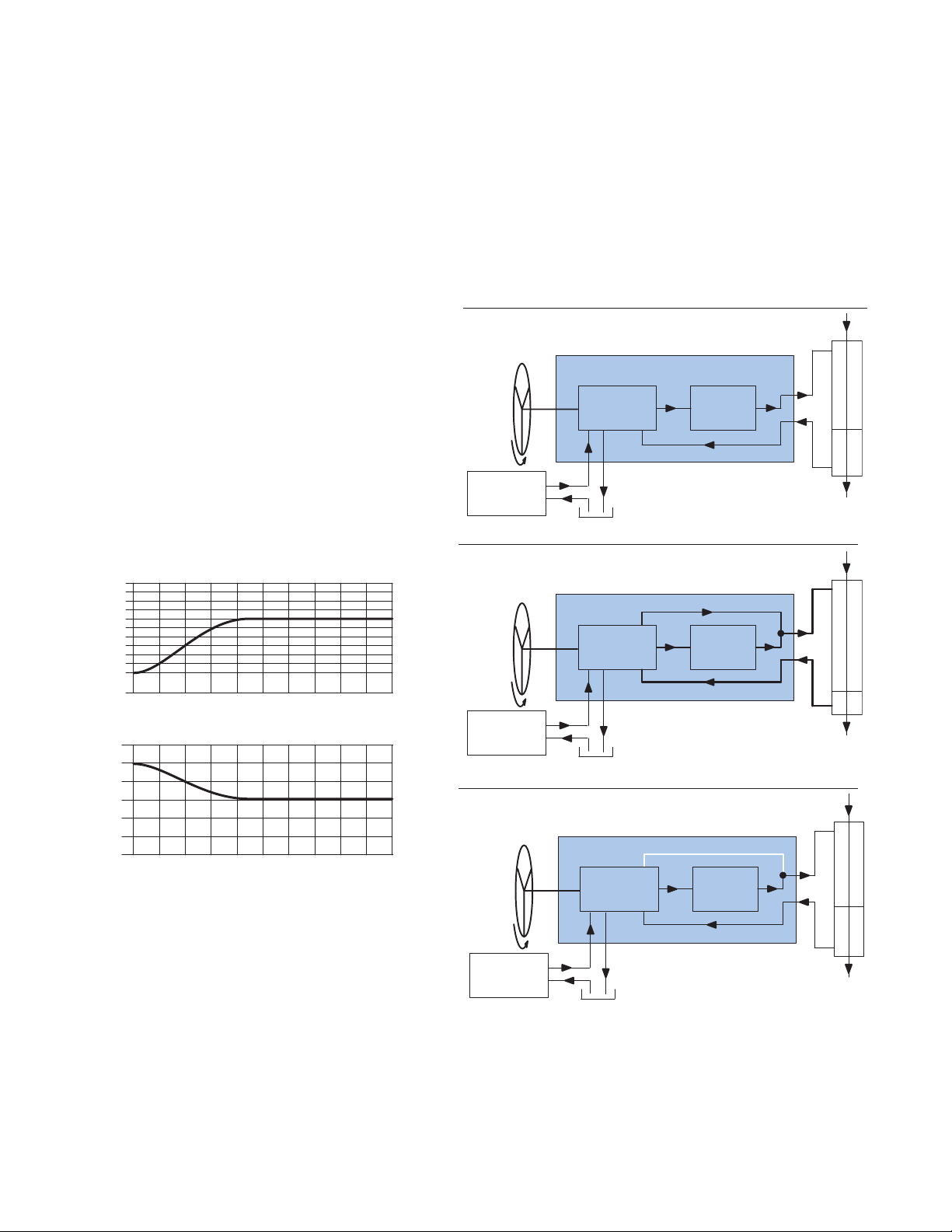

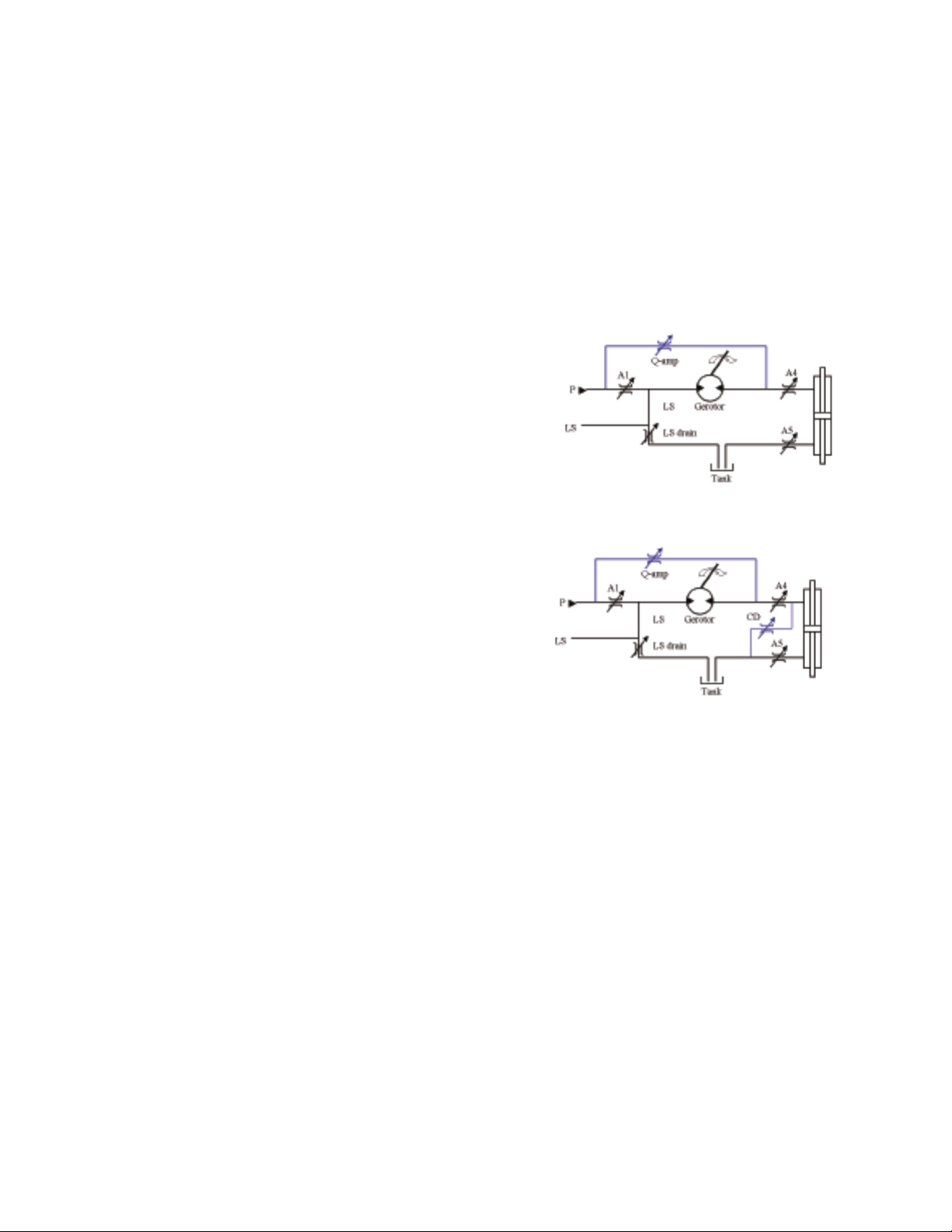

Eaton Patented

Technologies

Q-Amp (Flow

Amplification)

for Load Sensing

Circuits

Description

Q-Amp steering units have

built in variable orifices

that provide flow directly to

the cylinder without going

through the gerotor section.

The orifices do not open

until after the gerotor begins

to rotate and then gradually

open until the desired flow

is achieved which is

proportional to the flow

going through the gerotor. A

typical Q-Amp unit has a

ratio of 1.6 : 1 which means

the flow of the cylinder is

1.6 times the flow going

through the gerotor when

turning the steering wheel

at medium to fast speeds.

(See model code for

available ratios.)

Covered by one or more of the following U.S.

and foreign Patents: 4759182, 4862690,

4781219. Unequal area Q-Amp.

Q-Amp Steering Control Unit—Slow Turn

Features

• Variable Ratio

Q-Amp Steering Control Unit—Fast Turn

Conventional Steering Control Unit

16 EATON Char-Lynn Steering Catalog C-STOV-MC0 01-E1 July 2006

2:1

1.6:1

Ratio

1:1

10 20 30 40 50

6

5

4

Turns

3

Lock

to

2

Lock

1

10

20 30 40 50

60 70 80 90 100

RPM

60 70 80 90 100

RPM

Fast

Turn

Pump

Fast

Turn

Pump

Slow

Turn

Pump

Rotary

Valve

Rotary

Valve

No Flow

Rotary

Valve

Meter

Cylinder

Meter

Cylinder

Meter

Cylinder

Page 17

EATON Char-Lynn Steering Catalog C-STOV-MC001-E1 July 2006 17

Eaton Patented

Technologies

Q-Amp (Flow

Amplification)

for Load Sensing

Circuits

Applications

Articulated vehicles such as

wheel loaders, log skidders,

scrapers, trucks, and similar

vehicles can benefit from

this feature.

While roading, a slow

movement of the steering

wheel (input speed), will not

overcorrect steering.

Increasing input speed will

produce the additional

steering flow required to

quickly change the vehicle’s

direction.

For example, operating log

skidders in the woods

requires very quick steering.

This same log skidder on

the road would be extremely

difficult to steer a straight

normal course. The variable

ratio feature provides good

steering in both conditions.

Combines, row crop tractors,

and large articulated

agricultural tractors also can

benefit from this feature

when traveling down

a field. It will be easier to

follow rows or furrows, and

still be able to make fast

turns at the end of the rows.

Variable Ratio

• Wheel Loaders

• Scrapers

• Articulated AG Tractors

• Articulated Dumpers

• Mine T ruc ks

• Forestry Equipment

• Rough T errain Lift T r ucks

Variable Ratio with

Manual Steering

• AG T ractors

• Small Wheel Loaders

• Rubber Tired Excavators

• Sprayers

• Site Handlers

• Graders

• Combines

Page 18

18 EATON Char-Lynn Steering Catalog C-STOV-MC0 01-E1 July 2006

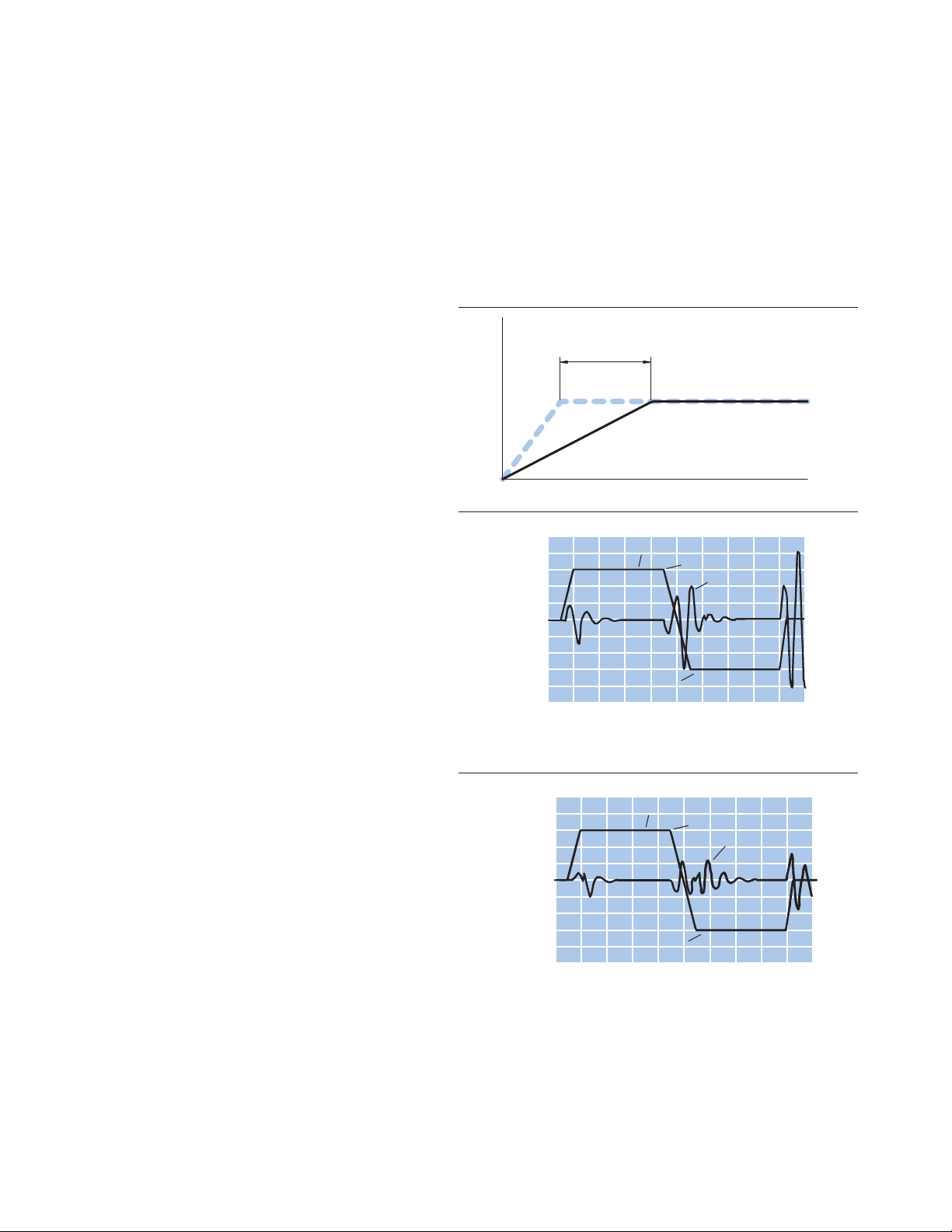

Eaton Patented

Technologies

Wide Angle

Description

Steering units with wide

angle features have been

developed to significantly

reduce or eliminate the jerky

motion of vehicles with

articulated steering systems.

This has been accomplished

by increasing the maximum

deflection of the spool

relative to the

sleeve. Increasing the

deflection reduces the gain.

This in turn reduces

acceleration and jerk levels

and provides overall

smoother vehicle

performance. The steering

still responds fast enough so

the operator does not notice

the reduced gain.

Benefits

• Minimizes jerking

motion on medium and

large articulated

vehicles.

• Jerk reducing valves and

accumulators can be

eliminated on most

vehicles.

• Avaliable on Series 10,

Series 20 (standard),

and Series 25.

• Eliminates need for

cushion valves

Applications

• Articulated Vehicles

Wide Angle Steering Control Units Patent No. 5080135

These graphs show a computer simulation of the jerk levels and have been verified by

actual vehicle tests.

Flow

60 RPM

125 ms

Wide Angle

Standard

Time

Jerk (g/sec)

8

4

0

-4

-8

012346

Steering Input (RPM)

60 RPM CCW

Time (Seconds)

Standard Steering on a 25 Ton Loader

Computer Simulation

60 RPM CW

Jerk (g/sec)

Jerk (g/sec)

8

4

0

-4

-8

012346

Steering Input (RPM)

60 RPM CW

Jerk (g/sec)

60 RPM CCW

Time (Seconds)

Wide Angle Steering on a 25 Ton Loader

Page 19

Eaton Patented

Technologies

Cylinder Damping

Description

Cylinder damping can help

smooth the steering action

of large articulated vehicles

such as loaders, scrapers,

and skidders. These vehicles

have overhanging weight

with high inertial loads. This

energy is dissipated by the

cylinder damping orifices

which bleed a small amount

of flow from the cylinder

port to tank.

Cylinder Damping has 3

different levels of

application. The number of

levels equal to the number

of Cylinder Damping (CD)

orifices. This technology is

available on Series 10,

Series 20, Series 25, and

Series 40. Not all SCUs

come with all 3 levels.

Features

Three levels engineered to

fit your application.

Benefits

• Reduces jerking motion

on medium and large

articulated vehicles.

• Available on the

following steering

control units (Series 10,

20, 25, 40).

• Damps or stabilizes

unstable systems.

Applications—

Large Articulated Vehicles

• Wheel Loaders

• Skidders

• Scrapers

Flow Amplification without Cylinder Damping

Flow Amplification with Cylinder Damping

Steering Control Units with Cylinder Damping

Patent No. 5080135

EATON Char-Lynn Steering Catalog C-STOV-MC001-E1 July 2006 19

Page 20

20 EATON Char-Lynn Steering Catalog C-STOV-MC0 01-E1 July 2006

Eaton Patented

Technologies

VersaSteer

Description

Eaton’s patented

VersaSteer™ technology

offers operator-selectable

Metered or Quick Steering

modes at any time, with the

touch of a button or the flip

of a switch, and provides

the operator flexibility to

significantly improve the

overall steering experience.

Dual Steering Modes

Metered Steering –The

steering unit operates the

same as a traditional

hydrostatic steering control

unit. Steering (flow) is a

function of steering wheel

rotations (rpm). Metered

(gerotor) steering provides

precise, responsive, and

smooth steering.

Quick Steering –

Gerotorless (quick) steering

provides a much different

effect, enabling the operator

to put the vehicle in full lock

while only turning the

steering wheel a few

degrees. This is achieved by

hydraulically blocking the

flow of oil to the gerotor

with a shift valve. Full

steering flow can be

obtained by deflecting the

steering wheel ±45° for a

Series 10 and ±50° for a

Series 20. Operator effort is

greatly reduced during the

work cycle.

Benefits

• Provides steering

system cost savings by

eliminating the need for

a separate joystick

• Available on Load Sense

steering systems

• Compatible with

Integral Valv es, Bolt-On

Priority Valv es, Q-Amp

and Cylinder Damping

• Emergency manual

steering capability

• Minor size increase –

can retrofit to existing

vehicles

• Smoother steering with

Eaton Patented W ide

Angle technology.

Features

• Dual steering modes in

one integrated Steering

Control Unit (SCU)

• High pressure rating

and flow capabilities

• Compatible with current

steering options

• Easily retrofit to existing

vehicles

• Proven base technology

• Easy one-touch switch

(OEM defined)

VersaSteer System

Components

• Steering Control Unit

• Solenoid Shift Valve

• Four –04 hoses

• Electric Switch

Series 10 VersaSteer

Traditional Metered Steering Series 10 Quick Steering

Series 20 VersaSteer

SPECIFICATIONS

1. System Pressure Rating a. 241 Bar [3500 psi] - Series 10

b. 241 Bar [3500 psi] - Series 20

2. Back Pressure Rating - 21 Bar [305 psi]

3. Flow Rating

a. 15 gpm - Series 10

b. 25 gpm - Series 20

VersaSteer is covered under

US Patent No. 6,318,078

Page 21

EATON Char-Lynn Steering Catalog C-STOV-MC001-E1 July 2006 21

Eaton Patented

Technologies

STC Direct Porting

With the Snap-To-Connect

(STC) Direct Porting option,

the fitting profile is

machined into the SCU

housing, eliminating the

need for extra STC fittings.

This revolutionary and

patented porting technology

provides leak-proof sealing

and has operating pressure

capability exceeding

4500PSI (310bar).

STC Direct Porting is

available with Series 5 and

Series 10 Steering Control

Units.

Benefits

• STC Direct Ports

provide a great

opportunity for

significant cost savings

compared to threaded

fittings

• Eliminates the need for

assembly tools during

installation

• Eliminates installation

variability

• Improves ergonomics reduces installer effort

to connect

• Improves serviceability

• High quality, leak-proof

seal

• Eliminates connector

leakage

• Compact design and

overall lighter weight

Page 22

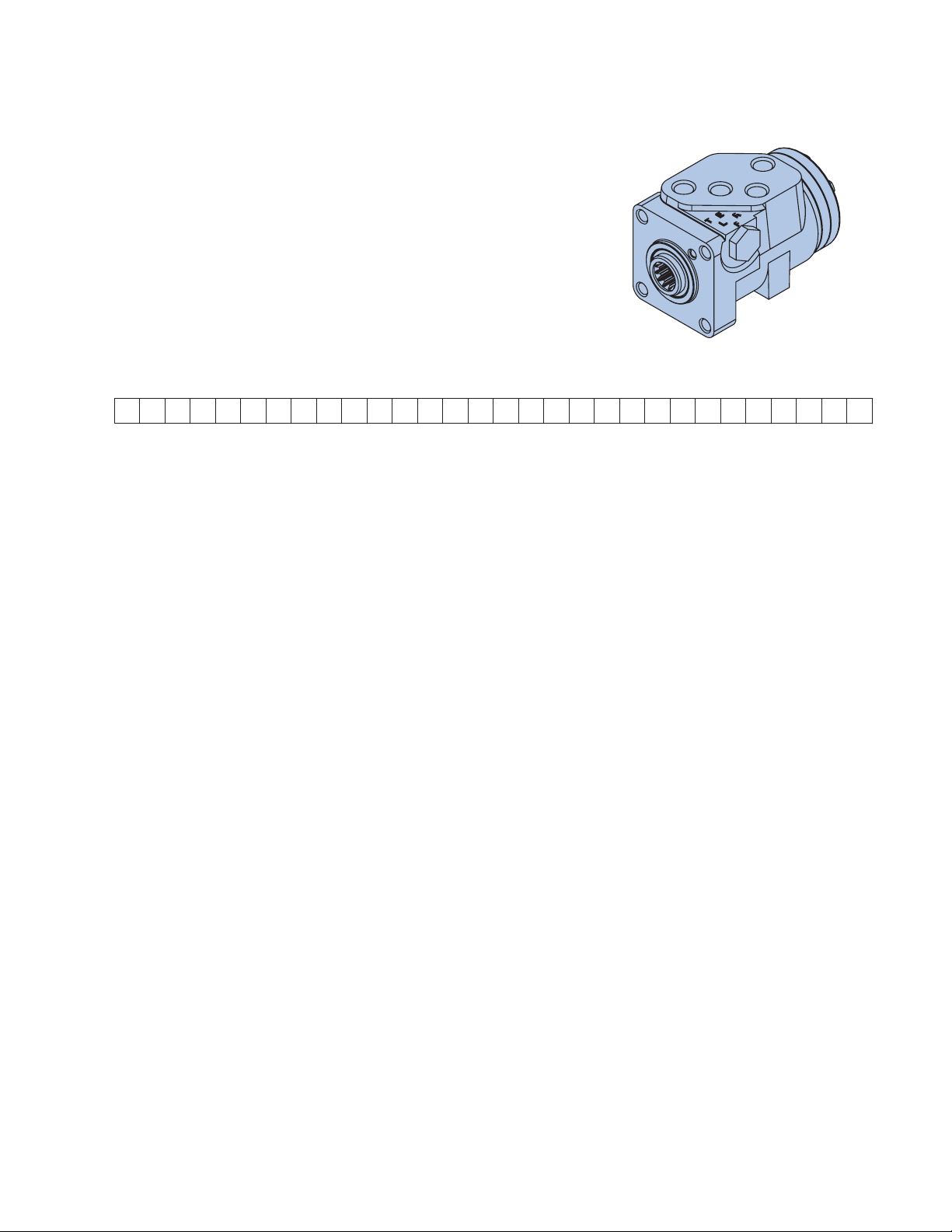

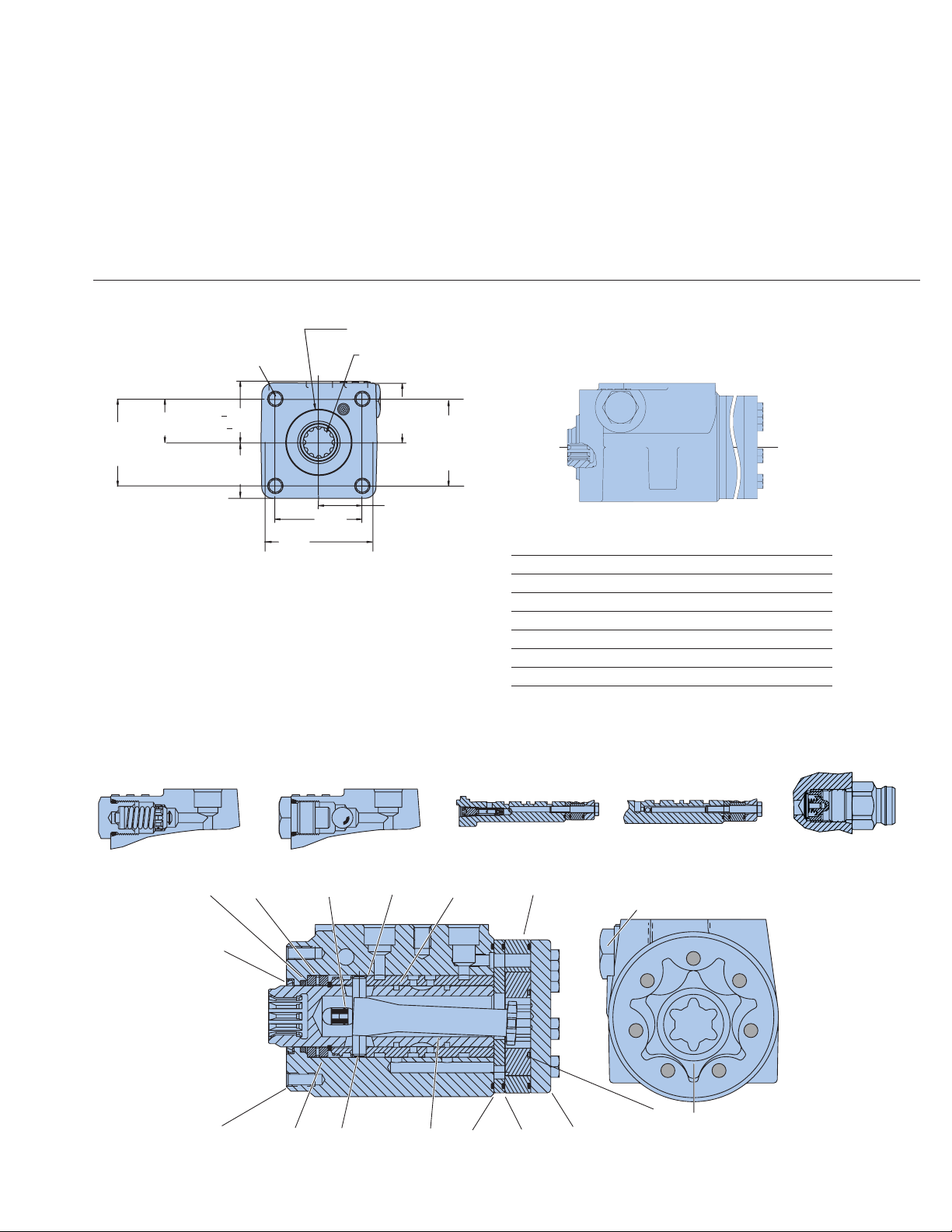

22 EATON Steering Catalog C-STOV-MC0 01-E1 May 2006

Steering Control

Units—Series 5

Product

Description

The new Series 5 steering

control units (SCU) are

exciting new products

designed for low flow, low

pressure applications.

The Series 5 units are

available in two compact

designs:

Option 1:

Square Housing (Mount)

Unit with Side Ports

Option 2:

Round Housing (Mount) Unit

with End Ports

In addition to the installation

flexibility provided by the

two options above, this new

family of products has bestin-class steering feel and

provides crisp centering.

These units also have better

efficiency (lower pressure

drop) than competitive units.

Power Beyond Models—

Optional power beyond

steering control units supply

steering and flow to auxiliary

valve functions. The power

beyond unit is used in open

center (fixed displacement

pump) systems in the

medium pressure range.

When not steering, the

power beyond unit directs all

inlet flow to the excess flow

port (power beyond) for use

in the auxiliary circuit. Once

steering is initiated, and

since steering has priority,

inlet flow will be diverted to

the steering circuit as

required. Flow out the

excess flow port (power

beyond) and tank port will

vary or stop depending upon

the steering requirement.

The tank port of the steering

unit has flow only when

steering is operating.

SPECIFICATIONS

Max. System Pressure 140 bar [2030 PSI]

Max. Back Pressure 21 bar [ 300 PSI]

Max. Flow 19 l/min [5 GPM]

Max. Differential

Between Steering Unit 28°C

and System Temperature 50°F

Max. System Operating Temperature 93°C [200° F]

Input Torque

Powered -Standard 1,7 - 2,8 Nm @ 6,9 bar tank pressure

[15 - 25 lb-in @ 100 PSI tank pressure]

Low 1,1 - 2,0 Nm @ 6,9 bar tank pressure

[10 - 17.5 lb-in @ 100 PSI tank pressure]

Max. Non Powered 81,4 Nm [60 lb-ft]

Fluid Petroleum Based Fluids

Recommended Filtration ISO 18/13 cleanliness level

Port Options 9/16-18 SAE O-ring

– 06 STC

3/8 BSP Straight thread ports

Check Valve for Manual Steering Yes

Optional Relief Valve Settings

bar [PSI] 40 [ 580]

50 [ 725]

63 [ 914]

70 [1015]

80 [1160]

90 [1305]

100 [1450]

125 [1812]

Option 1: Square Housing

with Side Ports

refer to Model Code, page 23

Option 2: Round Housing

with End Ports

refer to Model Code, page 24

Features

• Open Center

• Load Sensing

• Open Center

Power Beyond

• Integral Column

• Manual Steering

Check V alv e

• Inlet Relief Valve

• Load Sense Relief Valve

• Cylinder Relief Valve

• Anti-Cavitation Valve

Applications

• Lawn and Garden

Equipment

• T urf Equipment

• Golf Course

Maintenance

Equipment

• Lift Trucks

• Compact Utility Tractors

Page 23

EATON Steering Catalog C-STOV-MC001-E1 May 2006 23

Steering Control

Units—Series 5

Model Code –

Ordering

Information

The following 30-digit coding system has been developed to

identify all of the configuration options for the Series 5

steering control units. Use this model code to specify a unit

with the desired features. All 30-digits of the code must be

present when ordering. You may want to photocopy the

matrix below to ensure that each number is entered in the

correct box.

Nos Feature Code Description Nos Feature Code Description

1,2,3 Product Series ABR Series 5 Steering Control Unit

4 Nominal Flow 1 11 l/min [3 GPM]

Rating B 19 l/min [5 GPM]

5 Inlet Pressure C 140 bar [2030 PSI]

Rating

6 Tank Pressure A 10 bar [150 PSI]

Rating B 21 bar [30 0 PSI]

7-8 Displacement 35 31.5 cm3/r [1.92 in3/r]

37 39.5 cm3/r [2.41 in3/r]

39 50.8 cm3/r [3.10 in3/r]

41 63.1 cm3/r [3.85 in3/r]

43 73.8 cm3/r [4.50 in3/r]

46 100 cm3/r [6.10 in3/r]

48 120 cm3/r [7.33 in3/r]

9 Flow Amplification 0 None

10 Neutral Circuit A Open Center

B Open Center, Power Beyond

F Load Sensing, Dynamic signal

11 Load Circuit A Non-Load Reaction

12,13 Valve Options 01 Manual Steering Check Valve

04 Inlet Check Valve, Manual

Steering Check Valve

05 Inlet Relief Valve,

Manual Steering Check Valve

12 Cylinder Relief Valve,

Anti-Cavitation Valve,

Inlet Relief Valve,

Inlet Check Valve,

Manual Steering Check Valve.

13 Cylinder Relief Valve,

Anti-cavitation Valve, Inlet Check

Valve, Load Sensing Relief Valve,

Manual Steering Check Valve

14,15 Integral Inlet 0 0 None

Relief Valve 18 40 bar [580 PSI]

Setting 1J 50 bar [725 PSI]

1Z 63 bar [914 PSI]

26 70 bar [1015 PSI]

2G 80 bar [1160 PSI]

2T 90 bar [1305 PSI]

34 100 bar [1450 PSI]

3W 125 bar [1812 PSI]

16,17 Cylinder Relief 00 None

Setting 37 103 bar [1490 PSI]

42 130 bar [1890 PSI]

55 185 bar [2680 PSI]

68 200 bar [2900 PSI]

18,1 9,20,21 Ports and 4AAN Square 4 x 9/16 SAE Ports,

Mounting Threads M10 x 1,5 Column Mounting

Threads (Use with Open Center)

4AKN Square 5 x 9/16 SAE Ports,

M10 x 1,5 Column Mounting

Threads (Use with Excess Flow)

4AEN Square 5 x 9/16 SAE Ports,

M10 x 1,5 Column Mounting

Threads (Use with Load Sense)

UAAN Square 4 x -06 STC Direct

Ports, M10 x 1,5 Column

Mounting Threads (Use with

Open Center)

UBNN Square 5 x -06 STC Direct

Ports, M10 x 1,5 Column

Mounting Threads

(Use with Excess Flow)

UBPN Square 5 x -06 STC Direct

Ports, M10 x 1,5 Column

Mounting Threads

(Use with Load Sense)

YAAN Square 4 x G .375 BSP Striaght

Thd. Ports, M10 x 1,5 Column

Mounting Threads

(Use with Open Center)

YBRN Square 5 x G .375 BSP Striaght

Thd. Ports, M10 x 1,5 Column

Mounting Threads

(Use with Load Sense)

22 Input Torque 1 Low*

3 Standard

23 Fluid Type A See Eaton Tec hnical

Bulletin 3-401

24 Special Application 0 None

25,26 Special Feature AA None

27 Paint 1 Black Primer

28 Identification 0 Eaton Product Number on

Nameplate

29 Mechanical A Tapered 17.919mm (.7055in)

Interface diameter, .083:1 and serrated

17.5 (.688) diameter, 40 tooth,

M16x1.5-6g, Extension length

65.02 (2.56)

D Internal involute spline12 tooth,

16/32 DP, 30 degree PA

30 Eaton Assigned B Assigned Design Code

Design Code

* All low torque units need approval from an Eaton Steering Engineer.

Square Housing with Side Ports - Option 1

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

A B R 0 A A 0 1 0 B

C A

Page 24

24 EATON Char-Lynn Steering Catalog C-STOV-MC001-E1 July 2006

Steering Control

Units—Series 5

Model Code –

Ordering

Information

The following 30-digit coding system has been developed to

identify all of the configuration options for the Series 5 steering

control units. Use this model code to specify a unit with the

desired features. All 30-digits of the code must be present when

ordering. You may want to photocopy the matrix below to ensure

that each number is entered in the correct box.

Nos Feature Code Description Nos Feature Code Description

1,2,3 Product Series ABR Series 5 Steering Control Unit

4 Nominal Flow 1 11 l/min [3 GPM]

Rating B 19 l/min [5 GPM]

5 Inlet Pressure

Rating C 140 bar [2030 PSI]

6 Tank Pressure A 10 bar [150 PSI]

Rating

7-8 Displacement 35 31.5 cm3/r [1.92 in3/r]

37 39.5 cm3/r [2.41 in3/r]

39 50.8 cm3/r [3.10 in3/r]

41 63.1 cm3/r [3.85 in3/r]

43 73.8 cm3/r [4.50 in3/r]

46 100 cm3/r [6.10 in3/r]

48 120 cm3/r [7.33 in3/r]

9 Flow Amplification 0 None

10 Neutral Circuit A Open Center

B Open Center, Power Beyond

C Closed Center

F Load Sensing, Dynamic signal

11 Load Circuit A Non-Load Reaction

12,13 Valve Options 01 Manual Steering Check Valve

04 Inlet Check Valve, Manual

Steering Check Valve

05 Inlet Relief Valve,

Manual Steering Check Valve

12 Cylinder Relief Valve,

Anti-cavitation Valve,

Inlet Relief Valve,

Inlet Check Valve,

Manual Steering Check Valve.

14,15 Integral Inlet 0 0 None

Relief Valve 18 40 bar [580 PSI]

Setting 1J 50 bar [725 PSI]

1Z 63 bar [914 PSI]

26 70 bar [1020 PSI]

2G 80 bar [1160 PSI]

2T 90 bar [1310 PSI]

34 100 bar [1450 PSI]

3W 125 bar [1812 PSI]

4C 140 Bar [2030 PSI]

16,17 Cylinder Relief 00 None

Setting

18,1 9,20,21 Ports and VAAH Round 4 x 9/16 SAE Ports,

Mounting Threads M6 x 1,0 Column Mounting

Threads (Use with Open Center)

VAKH Round 5 x 9/16 SAE Ports,

M6 x 1,0 Column Mounting

Threads (Use with Excess Flow)

VAEH Round 5 x 9/16 SAE Ports,

M6 x 1,0 Column Mounting

WAAH Round 4 x -06 STC Direct Ports,

M6 x 1,0 Column Mounting

Threads (Use with Open Center)

WBNH Round 5 x -06 STC Direct Ports,

M6 x 1,0 Column Mounting

Threads (Use with Excess Flow)

WBPH Round 5 x -06 STC Direct Ports,

M6 x 1,0 Column Mounting

Threads (Use with Load Sense)

22 Input Torque 1 Low*

3 Standard

23 Fluid Type A See Eaton Tec hnical

Bulletin 3-401

24 Special Application 0 None

25,26 Special Feature AA None

27 Paint 1 Black Primer

28 Identification 0 Eaton Product Number on

Nameplate

29 Mechanical A Tapered 17.919mm (.7055in)

Interface diameter, .083:1 and serrated

17.5 (.688) diameter, 40 tooth,

M16x1.5-6g, Extension length

65.02 (2.56)

D Internal involute spline12 tooth,

16/32 DP, 30 degree PA

30 Eaton Assigned B Assigned Design Code

Design Code

* All low torque units need approval from an Eaton Steering Engineer.

** Plug-O ports rated to 103 bar [1500PSI]

Round Housing with End Ports - Option 2

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

A B R 0 A 0 0 A 0 1 0 B

A

Page 25

Option 1: Square Housing with Side Ports

refer to Model Code, page 23

Steering Control

Units—Series 5

Installation

Drawing

Relief Valve/Check

or Manual Check

Relief Valve/Check Manual Check

View of Gerotor Section

Gerotor Seal

Cylinder Relief Valve Anti-Cavitation Valve

Inlet Check Valve

Housing

PinBearing, Ball Drive Spacer Plate End Cap

O-ring

Bearing

Race

Shaft

Seal

Dust Seal

Centering Springs Sleeve Spool Gerotor

Sectional Drawing

EATON Steering Catalog C-STOV-MC001-E1 May 2006 25

Side View

Displacement Dim. A Max.

Code cm3/r [in3/r] mm [inch]

35 31.5 [1.92] 123.4 [4.86]

37 39.5 [2.41] 125.2 [4.93]

39 50.8 [3.10] 124.2 [4.89]

41 63.1 [3.85] 126.2 [4.97]

43 73.8 [4.50] 128.0 [5.04]

46 100.0 [6.10] 132.3 [5.21]

48 120.0 [7.33] 135.4 [5.33]

4X M10 x 1.5-6H

15,2 [.60] Min

44,4 [1.75] Dia.

Involute Spline

12 Tooth 16/32 D.P.

30° P.A. PER SPC DS-023-2

48.26+0.13

29,18

58.37

[1.149]

[1.900+.005]

[2.298]

38,4

[1.51]MAX

58,37

[2.298]

78,5

[3.09]MAX

40,6

[1.60] MAX

58,37

[2.298]

29,18

[1.149]

Page 26

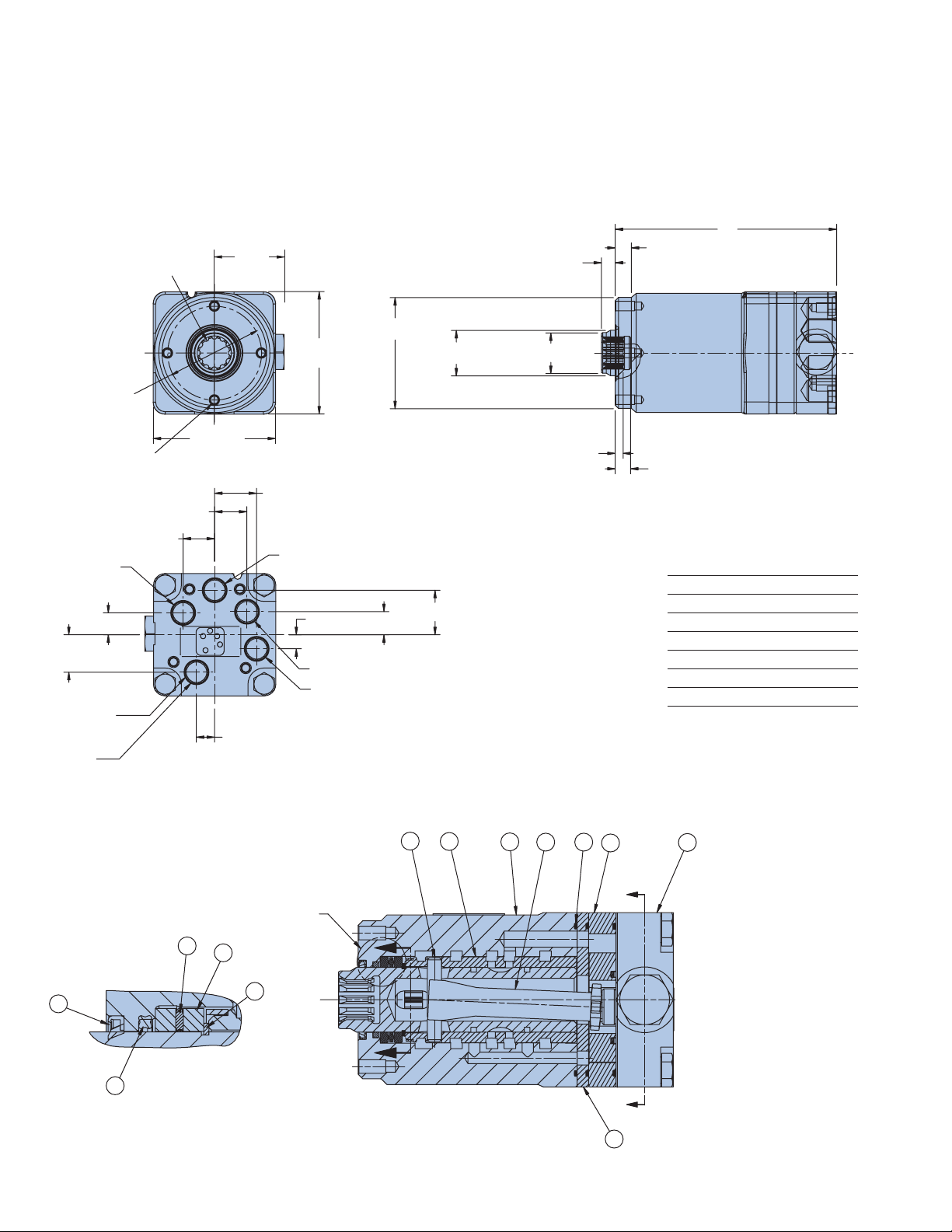

26 EATON Char-Lynn Steering Catalog C-STOV-MC001-E1 July 2006

Option 3: Square Housing with End Ports

refer to Model Code, page 24

Steering Control

Units—Series 5

Installation

Drawing

Option 2: Round Housing with End Ports

Sectional Drawing

11 Pin

10 Sleeve

8 Drive

3 O-ring

5 Gerotor

2 End cap

22 Dust seal

16 Bearing

15 Race

21 Quad seal

23 Retaining ring

7 Wear plate

6 housing

Displacement Dim. A Max.

cm3/r [in3/r] mm [inch]

31.5 [1.92] 135.1 [5.32]

39.5 [2.41] 137.2 [5.40]

50.8 [3.10] 136.1 [5.36]

63.1 [3.85] 137.9 [5.43]

73.8 [4.50] 139.7 [5.50]

100 [6.10] 144 [5.67]

120 [7.33] 147.3 [5.80]

Involute Spline

12 Tooth 16/32 D.P.

30° P.A.

59,00

[2.323] Dia.

[3.17] MAX

4 x M6 x 1.0-6H

12,2 [.48] Min. Depth

20,3±0,5

[.80±.02]

19,8±0,5

[.78±.02]

Pressure Port

13,7±0,5

[.54±.02]

23,6±0,5

[.93±.02]

5X .5625-18

UNF-2B SAE

O-Ring Port

Left Port

[1.75] MAX

80,5

11,4±0,5

[.45±.02]

44,4

26,4±0,5

[1.04±.02]

[2.750±.002] Dia.

80,5

[3.17] MAX

Additional Port

8,9±0,5

[.35±.02]

Right Port

Tank Port

69,85±0,05

[.57±.02]

14,5±0,5

28,6

[1.126] MAX Dia.

27,9±0,5

[1.10±.02]

9,1

[.36] MAX

25,7

[1.01] MAX Dia.

5,1±0.8

[.20±.03]

A

9,9

[.39] MIN

8,9

[.35] MIN

11

10

VIEW B

16

15

22

23

D

D

VIEW B

21

6

3

8

5

C

C

7

2

Page 27

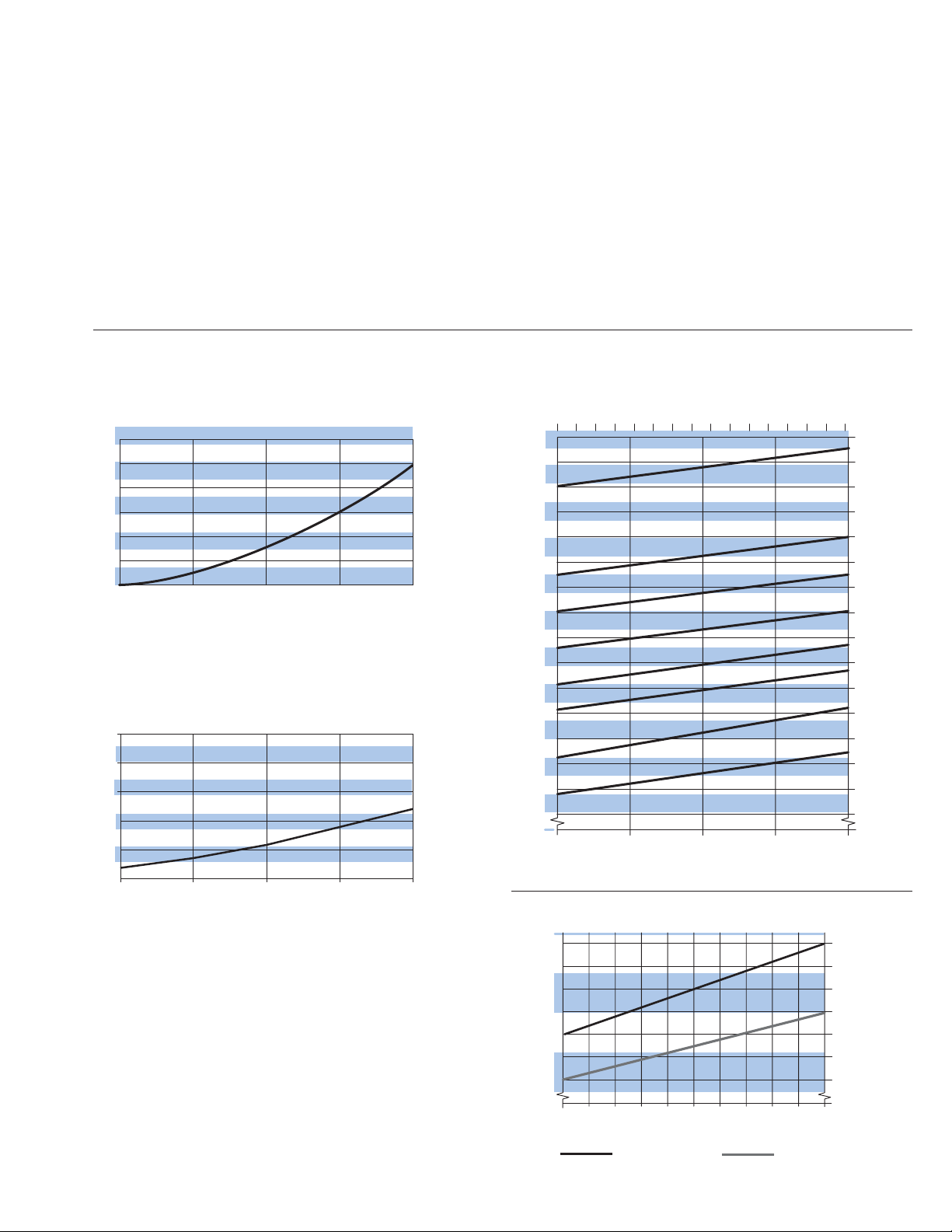

EATON Steering Catalog C-STOV-MC001-E1 May 2006 27

Steering Control

Units—Series 5

Performance Data

Neutral Pressure Drop

Inlet to Auxiliary

Relief V alve Curve

Input T orque Curve

bar

8

6

4

2

0

0

bar

14

10

6

2

8

[2]

11 L/min [3 GPM] Rated Round Unit

4

[1]

19 L/Min (5 GPM) Rated Unit

11

[3]

7

[2]

L/min [GPM]

15

[4]

L/min [GPM]

11

[3]

19

[5]

23

[6]

15

[4]

[PSI]

[120]

[ 80]

[ 40]

[ 0]

[PSI]

[250]

[200]

[150]

[100]

[ 50]

[ 0]

1 3 5 7 9 11 13 15

135

125

115

105

95

85

bar

75

65

55

45

35

0

0

3

L/min

2000

1900

1800

1700

1600

1500

1400

1300

1200

PSI

1100

1000

900

800

700

600

500

1234

GPM

0

25

20

2

1

0 102030405060708090100

Percent Deflection

Standard torque

Low torque

in-lbNm

15

10

Page 28

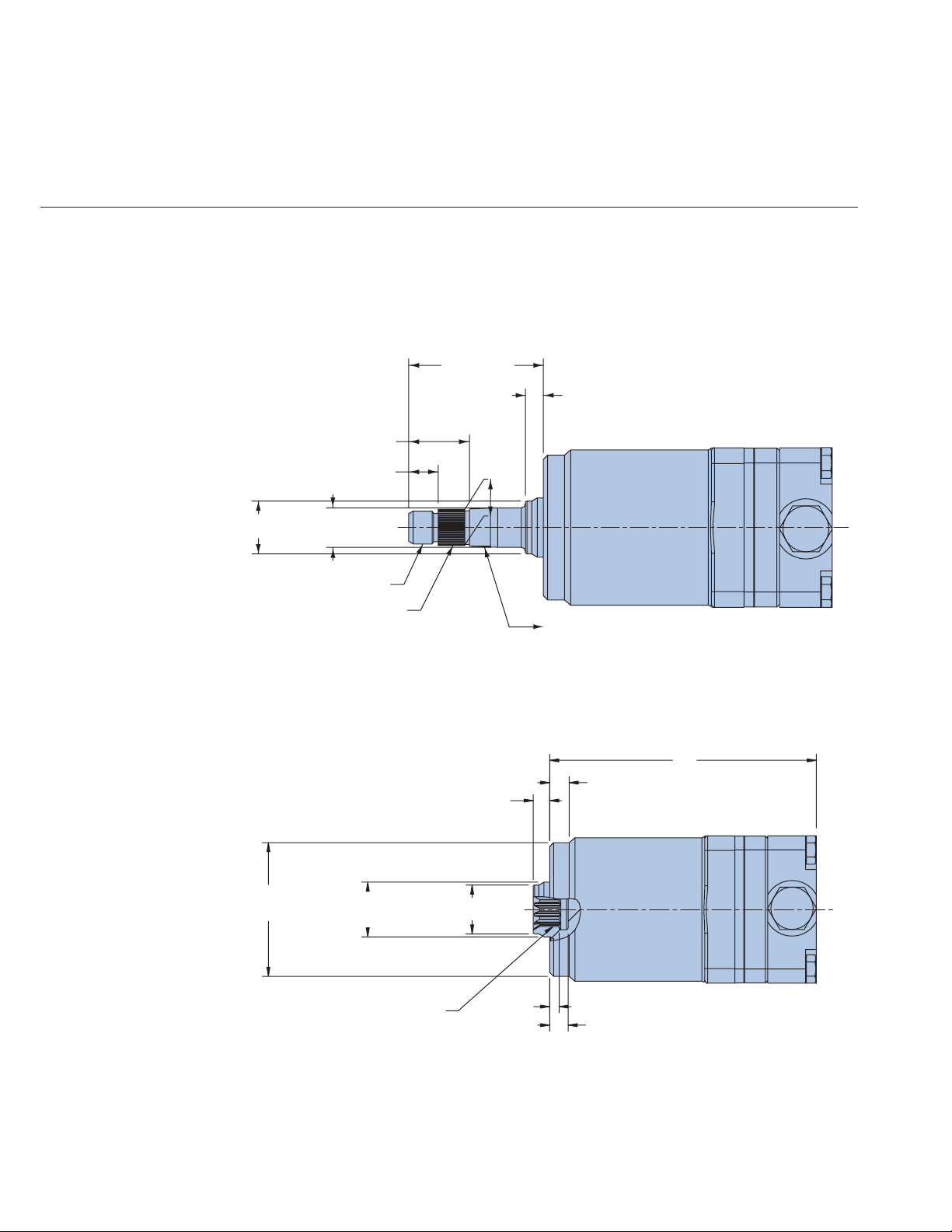

28 EATON Char-Lynn Steering Catalog C-STOV-MC001-E1 July 2006

Tapered 17.919mm (.7055in)

diameter, .083:1 and serrated

17.5 (.688) diameter, 40 tooth,

M16x1.5-6g, Extension length

65.02 (2.56)

M16 x 1.5-6g

.0831:1

65.0 ± 0.5

[2.56 ± .02]

9.1

[.36] MAX

25.7

[1.01] MAX

19.2

[.755] MAX

14.27 ± 0.25

[.562 ± .010]

29.36 ± 0.25

[1.156 ± .010]

17.919

[.7055]

Steering Control

Units—Series 5

Integral Column

Option

Integral Column

Option Av ailable in

Square Housing with

Side Ports, and Round

Housing with End

Ports

40 T ooth Serrated Integral

Column Option (Shown on

Round Housing with End

Ports)

12 Tooth Internal Spline

Standard Mechanical Interface

(Shown on Round Housing

with End Ports)

69,85±0,05

[2.750±.002] Dia.

28,6

[1.126] MAX Dia.

Internal Involute Spline

12 Tooth 16/32 D.P.

30° P.A.

9,1

[.36] MAX

25,7

[1.01] MAX Dia.

5,1±0,8

[.20±.03]

A

9,9

[.39] MIN

8,9

[.35] MIN

Page 29

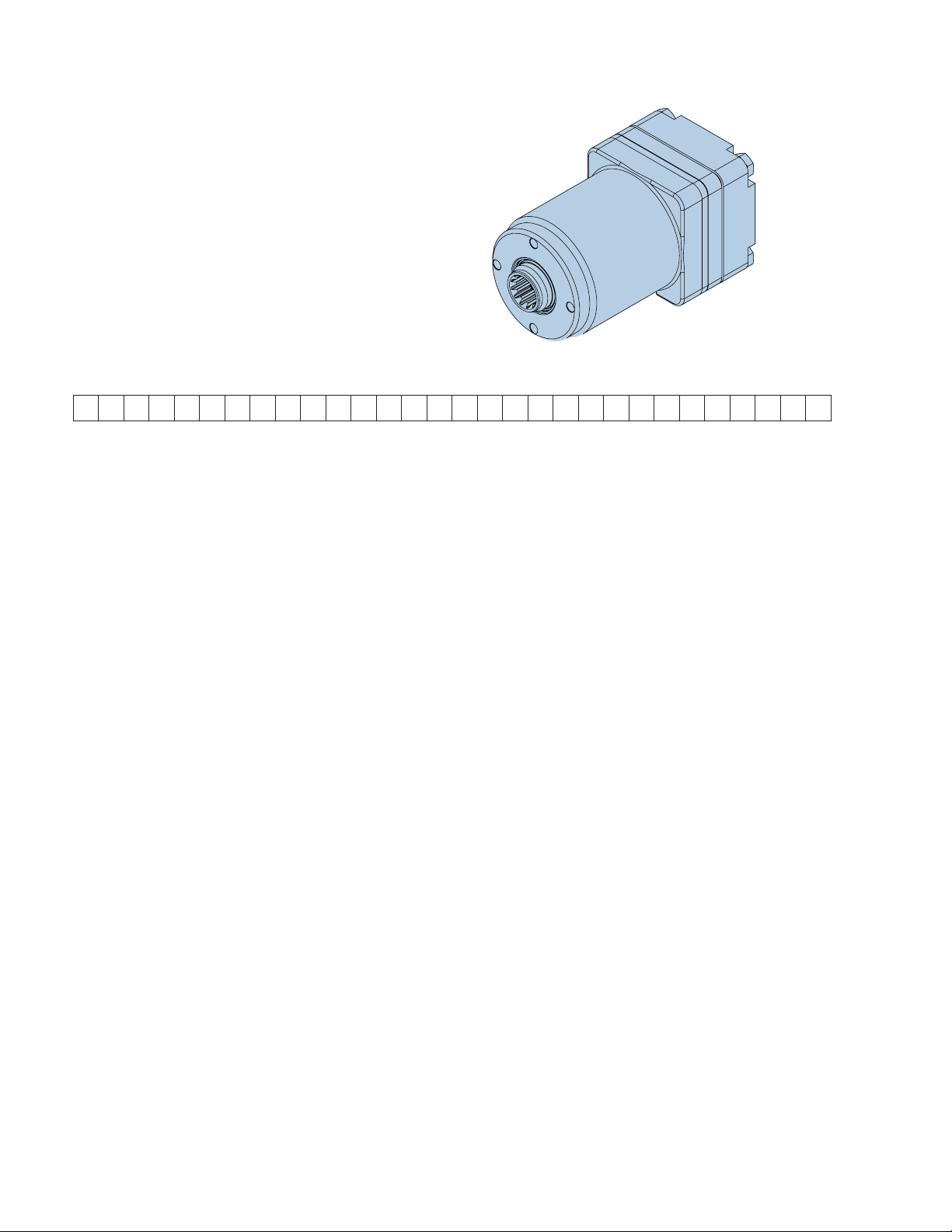

Steering Control

Units—Series 10

Product Description

Eaton’s Series 10 Steering

Control Unit (SCU) facilitates

hydraulic fluid flow like no

other unit on the market.

This highly-engineered product

is the ultimate SCU for

mid-range flow applications.

Benefits

• The new Series 10 SCU

has an unprecedented,

continuous pressure

rating of 275 bar (4000

psi), making it ideal for

heavy-duty equipment,

such as construction

and agricultural

machinery.

• Its high-pressure

rating reduces overall

equipment costs, since

smaller cylinder sizes

can be assigned into

the system.

• The new Series 10

incorporates proven

Eaton technologies. An

internal, balanced

architecture and a widewalled sleeve that is

40% thicker than

standard designs offer

increased performance

during transient

pressure conditions.

Features

• Open Center

• Power Beyond

• Closed Center

• Load Sensing

• Integral Valves

• Q-Amp

• 2-Speed

• Dual Displacement

• V ersa Steer

• Wide Angle

• Cylinder Damping

Applications

• Construction Machinery

• Agriculture Machinery

• Heavy-Duty Equipment

• Marine

• Forestry Machinery

• Mining Equipment

SPECIFICATIONS

Max. System Pressure 275 bar [4000 PSI]

Max. Back Pressure 21 bar [305 PSI]

Rated Flow

– Low 7,6 - 15 l/min [ 2 - 4 GPM]

– Medium 15 - 30 l/min [ 4 - 8 GPM]

– High 30 - 61 l/min [ 8 - 16 GPM]

– Low (with Q-Amp) 8 - 19 l/min [ 2 - 5 GPM]

– Medium (with Q-Amp) 19 - 38 l/min [ 5 - 10 GPM]

– High (with Q-Amp) 38 - 76 l/min [10 - 20 GPM]

Max. Differential

Between Steering Unit

and System Temperature 28° C [50° F]

Max. System

Operating Temperature 93°C [200° F]

Input Torque

Powered 1,1-2,8 Nm @ 6,9 bar back pressure

[10-25 lb-in @ 100 PSI back pressure]

Non-Powered 136 Nm [100 lb-ft]

Fluid See Eaton Technical Bulletin 3-401

Recommended Filtration ISO 18/13 cleanliness level

PORT SIZES:

Work Ports (4) Load Sense (LS) Port (1)*

3/4-16 (SAE) 7/16-20

M18 x 1,5 - 6H M12 x 1,5 - 6H

G 1/2 (BSP) Straight Thread G 1/4 (BSP) Straight Thread

STC Dash 08** STC Dash 06**

*Top or side when applicable

**STC

®

Ports, Aeroquip patented, feature snap to connect technology

EATON Steering Catalog C-STOV-MC001-E1 May 2006 29

Page 30

Steering Control

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29

30 31 32

A D R AAAAA01AA

Model Code — Series 10 Steering Control Units

Units—Series 10

Model Code—

Ordering

Information

The following 32-digit coding system has been developed to

identify all of the configuration options for the Series 10

steering control units. Use this model code to specify a unit

with the desired features. All 32-digits of the code must be

present when ordering. You may want to photocopy the

matrix below to ensure that each number is entered in the

correct box.

Nos Feature Code Description Nos Feature Code Description

1,2,3 Product Series ADR Series 10 Steering Control

4 Unit Type A Standard

5 Nominal Flow Rating 1 11 l/min [3 GPM]

6 Inlet Pressure Rating 1 276 bar [4000 PSI]—(Load

7 Return Pressure A 21 bar [305 PSI] Max.—

Rating (standard rating*)

8-9 Displacement 01 352 [21.5] / 60 [3.6]

cm3/r [in3/r] — 02 218 [13.3] / 60 [3.6]

Dual Displacement 03 290 [17.7] / 60 [ 3.6]

Combined/Manual 04 440 [26.8] / 146 [8.9]

8-9 Displacement 40 60 [3.6]

cm3/r [in3/r] 43 75 [4.5]

Unit

B Dual Displacement

C Wide Angle

D 2-Speed

E 2-Speed with Wide Angle

G Dual Displacement with Wide

Angle

V Versa Steer, Wide Angle

(Open Center)

2 23 l/min [6 GPM]

(Closed Center and LS)

3 45 l/min [12 GPM]

(OC, CC, and LS)

4 19 l/min [5 GPM]

(Q-Amp)

5 38 l/min [10 GPM]

(Q-Amp)

6 76 l/min [20 GPM]

(Q-Amp)

7 23 l/min [6 GPM]

(Open Center)

sensing and closed center)

2 207 bar [3000 PSI]—

(Open center)

B 10 bar [145 PSI] Max.

05 231 [14.1] / 85 [5.2]

45 95 [5.9]

48 120 [7.3]

50 145 [8.9]

51 160 [9.7]

52 185 [11.3]

54 230 [14.1]

57 295 [17.9]

59 370 [22.6]

61 460 [28.2]

64 590 [35.9]

66 740 [45.1]

1-8 GPM

8-16 GPM

10 Flow Amplification** A None (No Q-Amp)

B 1.6 : 1.0 Ratio†

C 1.6 : 1.0 Ratio

(with Manual Steering)†

E 2.0 : 1.0 Ratio

(with Manual Steering)†

G 1.3 : 1.0 Ratio

(with Manual Steering)†

†Use with closed center or

load sensing only.

11 Neutral Circuit A Open Center

C Closed Center

D Load Sensing, Static Signal

E Load Sensing, Dynamic Signal

F Open center with

Power Beyond

12 Load Circuit A Non-Load Reaction

B Load Reaction (Open Center

3,8 - 30 l/min [1 - 8 GPM] Only

D Non-Load Reaction,

Cylinder Damped

13,14 Special Spool/Sleeve 00 None

Modification

15,16 Valve Options

Manual Load Inlet Cylinder Anti- Inlet

Steering Sensing Check Relief Cavitation Relief

Check Relief Valve Valve Valve Valve

01 •

02 • •

03 • •

04 • • •

05 • •

06 • • •

07 • • •

08 • • • •

09 • • • • •

10• ••• •

11 • • •

* 12 GPM open center requires 145psi back pressure

** All Q-amp applications need approval from an Eaton Applications Engineer

30 EATON Char-Lynn Steering Catalog C-STOV-MC0 01-E1 July 2006

Continued on next page

Page 31

EATON Steering Catalog C-STOV-MC001-E1 May 2006 31

Steering Control

Units—Series 10

Model Code—

Ordering

Information—

Continued

17 ,18 Inlet or Load Sense 00 None

Relief Valv e — 18 124 [1800]

bar [PSI] 19 131 [1900]

20 138 [2000]

21 145 [2100]

22 152 [2200]

23 158 [2290]

24 165 [2390]

25 172 [2490]

26 179 [2600]

27 186 [2700]

28 193 [2800]

29 200 [2900]

30 207 [3000]

31 214 [3100]

32 220 [3190]

33 227 [3290]

34 234 [3390]

35 241 [3500]

36 248 [3600]

37 255 [3700]

38 262 [3800]

39 269 [3900]

40 276 [4000]

99 136 [1970]

19,20 Cylinder Relief Valve 0 0 None

— bar [PSI] 23 158 [2290]

** Cylinder Relief 24 165 [2390]

setting recommen- 25 172 [2490]

dation is 870 PSI 26 179 [2600]

(60 bar) above 27 186 [2700]

steering inlet/load 28 193 [2800]

sense pressure. 29 200 [2900]

30 207 [3000]

31 214 [3100]

32 220 [3190]

33 227 [3290]

34 234 [3390]]

35 241 [3500]

36 248 [3600]

37 255 [3700]

38 262 [3800]

39 269 [3900]

40 276 [4000]

41 283 [4100]

42 289 [4190]

43 296 [4290]

44 303 [4390

45 310 [4500]

46 317 [4600]

47 324 [4700]

48 331 [4800]

49 338 [4900]

21,22,23,24 Ports and AAAA 4 x 3/4-16 (SAE) Ports

Mounting None (No Additional Port)

Threads 2 x M12 Mounting Threads

Port Face

4 x M10 Mounting Threads

Mounting Face

AABA 4 x 3/4-16 (SAE) Ports

7/16-20 Load Sensing Port on Side

2 x M12 Mounting Threads

Port Face

4 x M10 Mounting Threads

Mounting Face

AACA 4 x 3/4-16 (SAE) Ports

7/16-20 Load Sensing Port Port

Face

2 x M12 Mounting Threads

Port Face

4 x M10 Mounting Threads

Mounting Face

BAAA 4 x M18 x 1,5 - 6H Metric

O-ring Ports

None (No Additional Port)

2 x M12 Mounting Threads

Port Face

4 x M10 Mounting Threads

Mounting Face

BADA 4 x M18 x 1,5 - 6H Metric

O-ring Ports

M12 x 1,5 - 6H Load Sensing Port

on Side

2 x M12 Mounting Threads

Port Face

4 x M10 Mounting Threads

Mounting Face

BAEA 4 x M18 x 1,5 - 6H Metric

O-ring Ports

M12 x 1,5 - 6H Load Sensing Port

Port Face

2 x M12 Mounting Threads

Port Face

4 x M10 Mounting Threads

Mounting Face

CAAA

4 x G 1/2 (BSP) Straight Thread

Ports

None (No Additional Port)

2 x M12 Mounting Threads

Port Face

4 x M10 Mounting Threads

Mounting Face

Continued on next page

Nos Feature Code Description Nos Feature Code Description

Page 32

32 EATON Char-Lynn Steering Catalog C-STOV-MC001-E1 July 2006

21,22,23,24 Ports and CAFA 4 x G 1/2 (BSP) Straight Thread

Mounting Ports

Threads G 1/4 (BSP) LS Straight Thread Port

(continued) on Side

2 x M12 Mounting Threads Port

Face

4 x M10 Mounting Threads

Mounting Face

CAGA 4 x G 1/2 (BSP) Straight Thread

Ports

G 1/4 (BSP) LS Straight Thread Port

on Port Face

2 x M12 Mounting Threads Port

Face

4 x M10 Mounting Threads

Mounting Face

DAAA Dash 08 STC® Ports ***

None (No Additional Port)

2 x M10 Mounting Threads Port

Face

4 x M10 Mounting Threads

Mounting Face

DAHA Dash 08 STC® Ports ***

Dash 06 STC® Port on Side

2 x M10 Mounting Threads Port

Face

4 x M10 Mounting Threads

Mounting Face

DAJA Dash 08 STC® Ports ***

Dash 06 STC® Port Face

2 x M10 Mounting Threads Port

Face

4 x M10 Mounting Threads

Mounting Face

25 Mechanical A Internal Involute Spline,

Interface 12 Tooth 16/32 DP 30° PA

26 Input Torque 3 Standard

27 Fluid Type A See Eaton T echnical

Bulletin 3-401

28,29 Special Features AA None

30 Paints and Packaging 1 Black Primer

31 Identification 0 Eaton Product Number on

Nameplate

32 Eaton Assigned B Assigned Design Code

Design Code

STC®—Aeroquip

Patent numbers: 5,553,895

5,226,682

5,570,910

Steering Control

Units—Series 10

Model Code—

Ordering

Information—

Continued

*** STC with inlet check requires threaded adapter. Contact your Eaton Account Representative for assistance.

Nos Feature Code Description

STC Hose/Connector

Dash 08 Port Face (4)

Dash 06 LS Port Side (1)

STC Port

Release Sleeve

Housing

Retaining Ring

Backup Washer

O-ring

Page 33

EATON Steering Catalog C-STOV-MC001-E1 May 2006 33

PORT AND MOUNTING THREAD COMBINATIONS

Column Load Port

PortMounting Sensing* Mounting

Thread PortThread

3/4 -16 M10 x 1,5-6H 7/16 - 20 M12 x 1,75-6H

M18 x 1,5-6H M10 x 1,5-6H M12 x 1,5-6H M12 x 1,75-6H

STC M10 x 1,5-6H STC M12 x 1,75-6H

G 1/2 (BSP) M10 x 1,5-6H G 1/4 (BSP) M12 x 1,75-6H

*Load Sensing Units Only.

Displacement

cm3/r Dimension C Dimension D

[in3/r] mm [in.] mm [in.]

60 [ 3.6] 10,2 [ .40] 138,1 [5.44]

75 [ 4.5] 10,2 [ .40] 138,1 [5.44]

95 [ 5.9] 13,2 [ .52] 141,1 [5.56]

120 [ 7.3] 16,5 [ .65] 144,4 [5.69]

146 [ 8.9] 20,1 [ .79] 148,0 [5.83]

159 [ 9.7] 21,8 [ .86] 149,9 [5.90]

185 [11.3] 25,4 [1.00] 153,3 [6.04]

231 [14.1] 31,7 [1.25] 159,7 [6.29]

293 [17.9] 40,4 [1.59] 168,3 [6.63]

370 [22.6] 50,8 [2.00] 178,7 [7.04]

462 [28.2] 63,5 [2.50] 191,4 [7.54]

588 [35.9] 80,8 [3.18] 208,8 [8.22]

739 [45.1] 101,6 [4.00] 229,6 [9.04]

Steering Control

Units—Series 10

Installation Drawing

Load Sensing Side Port

44,45/44,34

[1.750/1.746]

Dia.

* LS side port

location changes

with a LSR

83,8

[3.30]

Dia. Max.

8,89/8,39

[.350/.330]

94,0 [3.70] Max.

56,1[2.21]

47,8

2,05/3,36 [.081/.132]

*

8,2 [.32] Max.

[1.88]

37,08/36,32 [1.460/1.430]

63,12/62,62 [2.485/2.465]

48,8

56,13/55,37 [2.210/2.180]

[1.92]

Max.

12 Tooth Involute Spline

16/32 D.P. 30° P.A.

14,2 [.56] Deep

Column Mounting

Thread x 15,2 [.60]

Deep on 82,5 [3.25]

45°

Dia. Bolt Circle

7,4/5,4 [.29/.21] Spline

63,25/62,49

[2.490/2.460]

D

38,61/38,41

[1.52/1.480]

Load Sensing

Side Port

Load Sensing

Port Face

Left

Right

C

44,96/43,94

[1.770/1.730]

22,48/21,98

Tank Pressure

[.885/.865]

Port Mounting Thread x 24,1 [.95] Min. Deep (2)

10,2 [.40] Min. Depth (7,1 [.28] Max.

Mating Spline Depth)

60,51/59,49

[2.382/2.342]

103,6

[4.08]

58,67/58,17

Max.

[2.310/2.290]

45,0/44,0

[1.77/1.73]

Max.

94,0

[3.70]

Max.

83,8

[3.30]

Dia.

Max.

Page 34

34 EATON Char-Lynn Steering Catalog C-STOV-MC001-E1 July 2006

Steering Control

Units—Series 10

Sectional Drawing

and Integral Valves

AA

DD

FF

BB

EE

CC

AA

Inlet Check Valve

DD

Cylinder Port

EE

Anti-Cavitation Valves for Cylinder Ports

Shock Valves

BB

Inlet

Relief

Valve

CC

Internal

Check

Valve for

Limited

Manual