E aton Technical E nvironm ent Solutions

Installation G uide

Publication No: MN 212001E N r1.0

TechBench™ and TechOrganizer System

© Copyright 2013 Eaton Corporation, Worcester, MA, USA

All rights reserved.

Information in this document is subject to change without notice. No part of this document may

be reproduced or transmitted in any form or by any means, electronic or mechanical, for any

purpose, without the express written consent of Eaton Corporation.

Eaton is a registered trademark of Eaton Corporation or its subsidiaries and affiliates. Phillips is

a registered trademark of Phillips Screw Company. All other trademarks are the property of

their respective owners.

.

Table of Contents

About this Guide .............................................................................................................. 2

Intended Audience ................................................................................................................. 2

Technical Support .................................................................................................................. 2

Sales Representative and Contact Information ...................................................................... 2

Document History ................................................................................................................... 2

Document Conventions .......................................................................................................... 2

Before You Begin ............................................................................................................ 3

Tools Required ....................................................................................................................... 3

Safety Warnings and Precautions .......................................................................................... 3

Installation Kit Components ............................................................................................. 4

Hardware: Screws, Nuts, Washers, and Bolts ........................................................................ 6

Linear TechBench™ As sembly ....................................................................................... 8

TechBench™ Adjustable Height ............................................................................................. 8

TechBench™ With Leveling Glides Installed ..................................................................... 8

TechBench™ With Casters Installed ................................................................................. 8

Step 1: Separate Upper Side Frame from Lower Side Frame................................................. 9

Step 2: Attach Stiffeners to Upper Side Frames ....................................................................10

DETAIL A .........................................................................................................................10

Fully Assembled Corner ...................................................................................................10

Step 3: Attach Upper Side Frame and Stiffener Assembly to Worksurface ............................11

Place Laminate Worksurface Face Down .........................................................................11

Secure Side Frames and Stiffeners to Worksurface .........................................................11

Step 4: Attach Accessory Bracket and Two Drawer Pedestal (optional) ................................12

Secure Hanger Screws to Accessory Bracket ..................................................................12

Attach Two Drawer Pedestal to Accessory Bracket ..........................................................13

Step 5: Determine Worksurface Height and Re-Attach Lower Side Frames ..........................14

Determine Worksurface Height .........................................................................................14

Re-Attach Lower Side Frames ..........................................................................................15

Step 6: Adjust Height of Leveling Glides ...............................................................................16

Step 7: Attach Casters and Foot Rest to Bottom of TechBench™ (optional) .........................17

Remove Leveling Glide Feet ............................................................................................17

Attach Casters to TechBench™ .......................................................................................17

Attach Foot Rest to TechBench™ ....................................................................................18

Step 8: Attach Back Panel .....................................................................................................18

Step 9: Turn the TechBench™ Upright ..................................................................................19

Level TechBench™ Worksurface .....................................................................................19

Step 10: Attach TechOrganizer to Worksurface (optional) .....................................................20

Step11: Attach Mounting Channels and Bin Board to TechOrganizer (optional) ....................21

Attach Bin Board to Mounting Channels ...........................................................................22

Step 12: Attach Overhead Lighting to TechOrganizer (optional) ............................................23

Overhead Lighting Components .......................................................................................23

Attach Support Brackets to TechOrganizer .......................................................................24

Attach Mounting Spacers to Overhead Light ....................................................................25

Attach Overhead Light to Support Brackets ......................................................................25

Step 13: Attach Laminate Hook-On Shelf (optional) ..............................................................26

Attach Shelf Supports to Laminate Shelf ..........................................................................26

Attach Laminate Shelf to the TechOrganizer ....................................................................27

Step 14: Attach LH and RH Power Strip Brackets (optional) .................................................28

Installation Guide: TechBench™ / TechOrganizer - MN 212001EN r1.0

1

About this Guide

This document describes how to assemble Eaton’s A Series Linear TechBench™ and

TechOrganizer System, with a Laminate Worksurface.

Intended Audience

This document is intended for end-users responsible for assembling Eaton’s Linear

TechBench™ and TechOrganizer System. This includes optional components that may be

attached to the bench and organizer support structures.

Technical Support

If you encounter any problems with this installation, send an email and detailed description of

the problem, as well as contact information, to Technical Support at To.support@eaton.com.

Sales Representative and Contact Information

Contact your Eaton Sales representative using one of the methods below:

Phone

Mail

Call us toll free at 800.225.7348 (US Only) or 508.852.4300

Eaton

160 Gold Star Boulevard

Worcester, MA 01606

Email

Web

InfoESWorcesterMA@Eaton.com

Visit us at www.eaton.com/wrightline and click on “Contact Us.”

Simply complete and submit the form as directed.

Document History

The following table shows this document’s revision history:

Aug 2013 First Publication – MN 212001EN r1.0

Document Conventions

This document uses the following conventions:

• Links to other topics, email addresses, and Web sites are in blue.

• Acronyms are defined the first time they appear, with the acronym in parentheses.

• Color is sometimes used in illustrations to emphasize focus on key components.

• In illustrations, number callouts are used to identify component parts and letter callouts

points of interest.

NOTE

IMPORTANT

CAUTION Cautions draw special attention to anything that may cause damage to equipment.

WARNING

2

Notes point out something of special interest to the reader in direct context or

relationship to the immediate topic or step being performed.

Important notes provide information of interest to the reader of a more global or

general context.

Warnings draw special attention to any situation that may cause severe injury,

physical harm, or death, to the reader and/or person performing the task at hand.

Installation Guide: TechBench™ / TechOrganizer - MN 212001EN r1.0

Before You Begin

Before assembling Eaton’s Linear TechBench™ and TechOrganizer System, or attaching

optional components, it is recommended that you do the following:

• Ensure that you have the list of tools itemized in the Tools Required section, found on

page 3, or obtain them if necessary;

• Read and adhere to the statements found in the Safety Warnings and Precautions

section, found on page 3.

• Compare the illustrations found in the Installation Kit Components section, on page 4,

with the contents that arrived in your installation kit, and verify you received all

standard components, as well as all optional components ordered.

• Review the steps outlined in t he section titled, Linear TechBench™ Assembly, found

on page 8.

Tools Required

The list below identifies the tools required for assembling or attaching optional components to

Eaton’s Linear TechBench™ and TechOrganizer System:

• Cordless, Electric Drill/Wrench, with Torque Control

• Sockets: 3/8”, 1/2”, 9/16”

• Open End Wrenches: 3/8”, 1/2”, 9/16”, 1.0”

• Allen Wrenches (or Equivalent Bit for Drill/Wrench): 1/4”

• Hex Wrenches (or Equ ivalen t Bit for Drill/Wrench): 5/32” [provided]

• Drill Bit: #33 or 7/64” (.113 inch diameter)

• Plastic Mallet

• #2 Magnetic Tip Phillips Head Screwdriver (or Equivalent Bit for Drill/Wre nch)

• Flat Blade Screwdriver

• Level

Safety Warnings and Precautions

Due to the weight and size of the Linear TechBench™ and TechOrganizer

System, it is recommended that a minimum of two installers work together when

assembling the system. Attempting to assemble the Linear TechBench™ and

TechOrganizer System without assistance may result in serious injury.

A minimum of three people are required to adjust the height of the worksurface

once the Linear TechBench™ and TechOrganizer System is assembled and in

the upright position. Attempting to adjust the height of the worksurface without the

assistance of two additional installers may result in serious injury.

WARNING

WARNING

Installation Guide: TechBench™ / TechOrganizer - MN 212001EN r1.0

3

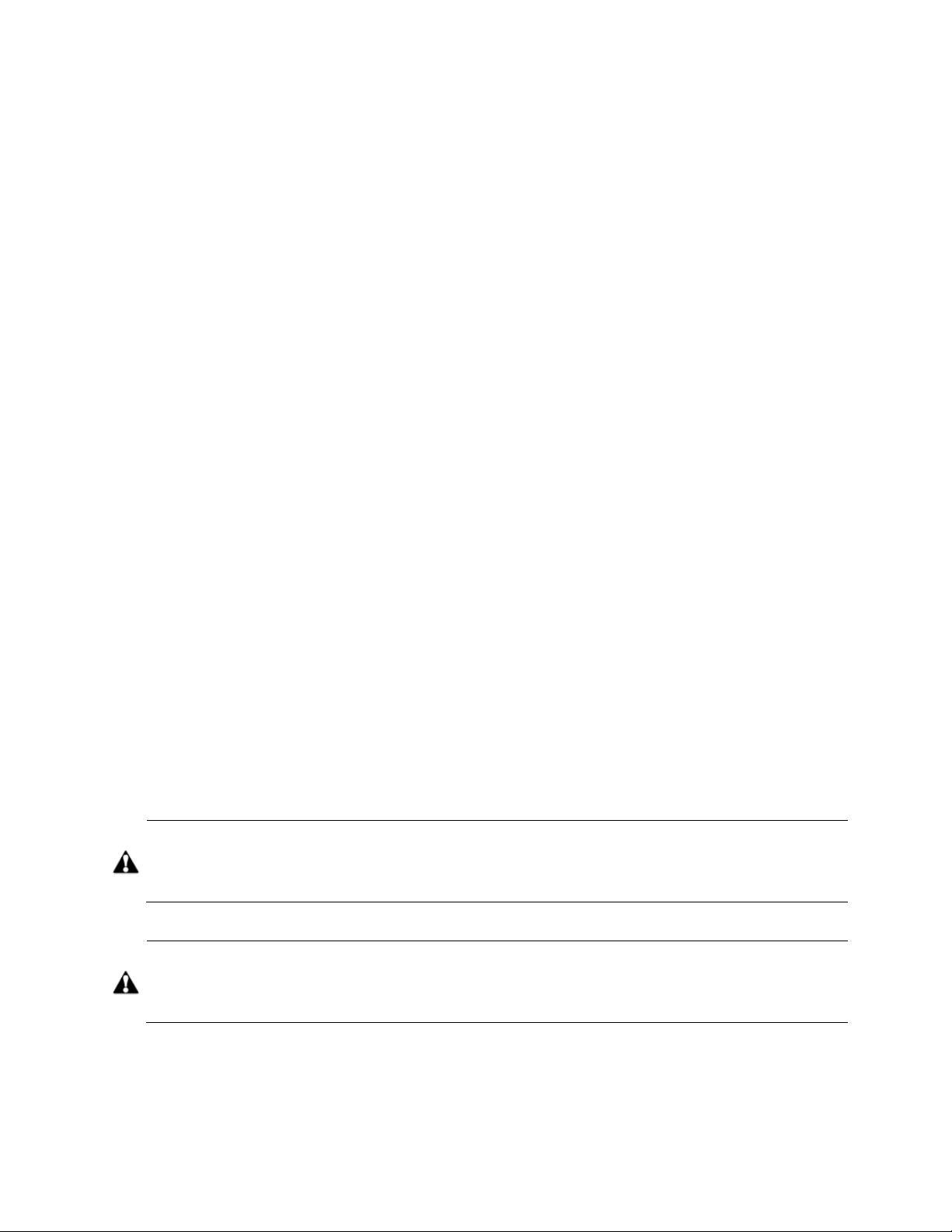

Installation Kit Components

Check the contents of your installation kit against the standard and optional components

shown in the following table. Optional components are marked (optional).

Side Frames

Frame Stiffeners

TechOrganizer (optional)

Back Panel

Laminate Worksurface (Top Surface)

Laminate Shelf (optional)

4

Installation Guide: TechBench™ / TechOrganizer - MN 212001EN r1.0

Two Drawer Pedestal and Accessory Bracket (optional)

Caster Wheels (optional)

Bin Board and Mounting Channels (optional)

Foot Rest (optional; included with Caster Wheels)

Installation Guide: TechBench™ / TechOrganizer - MN 212001EN r1.0

5

Overhead Lighting (optional)

Power Strip Brackets LH and RH (optional)

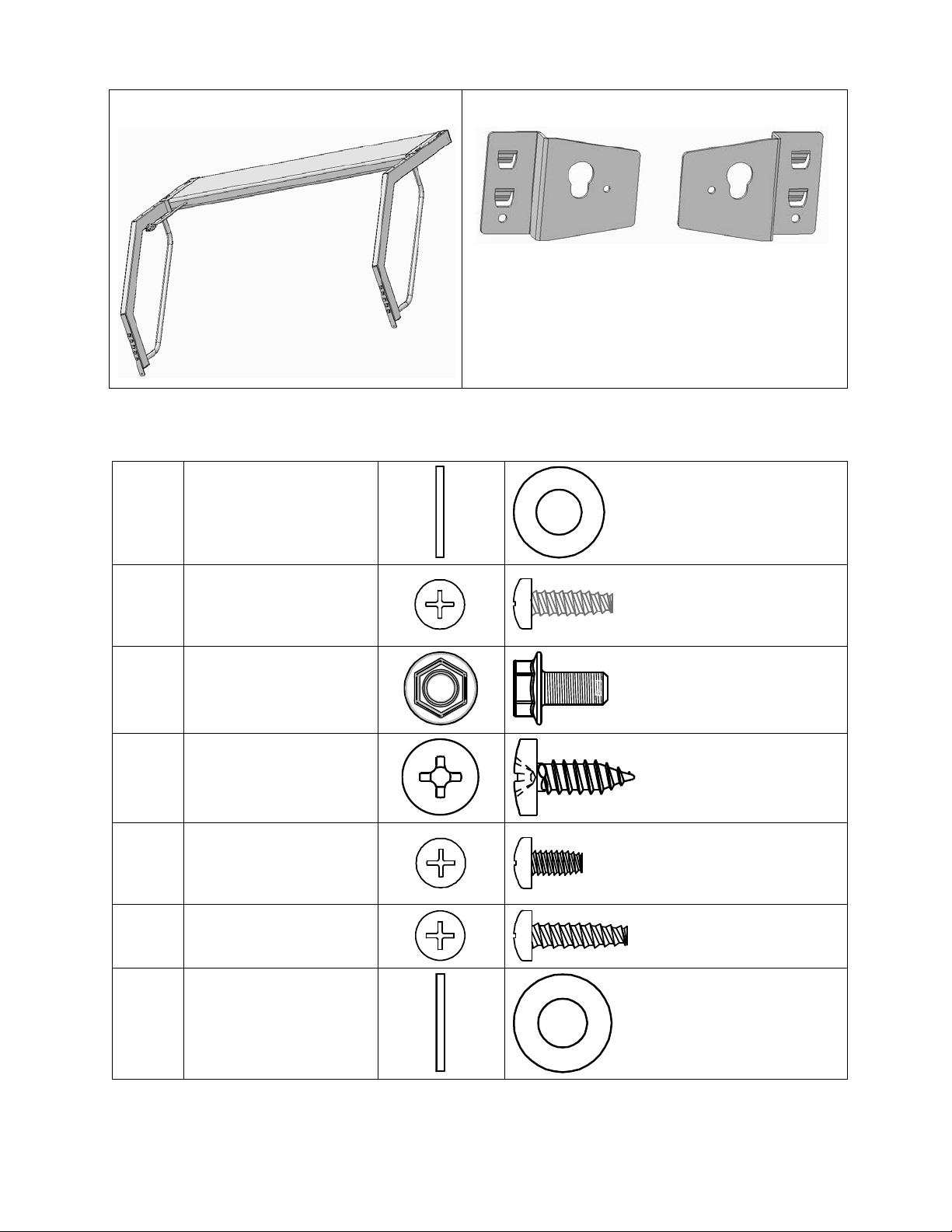

Hardware: Screws, Nuts, Washers, and Bolts

Washer, #10 Flat, Plain

Type A, Outside Dia. .5”

54225

(1.27 cm), Inside Dia.

.22” (.56 cm), .05” (.127

cm) Thick

54298

54348

59103

66714

80023

81710

Screw, #14B x 5/8”,

Phillips, Pan Head,

Thread Forming, Type B,

#3

Screw, 1/4 – 20 x 1/2”

Hex, Washer Head, SelfThreading

Screw, #10 - 3/4”,

Phillips, Pan Head,

Self-Tapping, Zinc

Screw, 10 -24 x 3/8”

Phillips, Pan Head,

Thread Forming, Black

Oxide

Screw, #10-24 x 3/4”

Phillips, Pan Head,

Thread-Forming

Washer, 5/16” SAE, Flat

Black, Plain Type A,

Outside Dia. ..69” (1.75

cm), Inside Dia. .34” (.86

cm), .06” (.15 cm) Thick

6

Installation Guide: TechBench™ / TechOrganizer - MN 212001EN r1.0

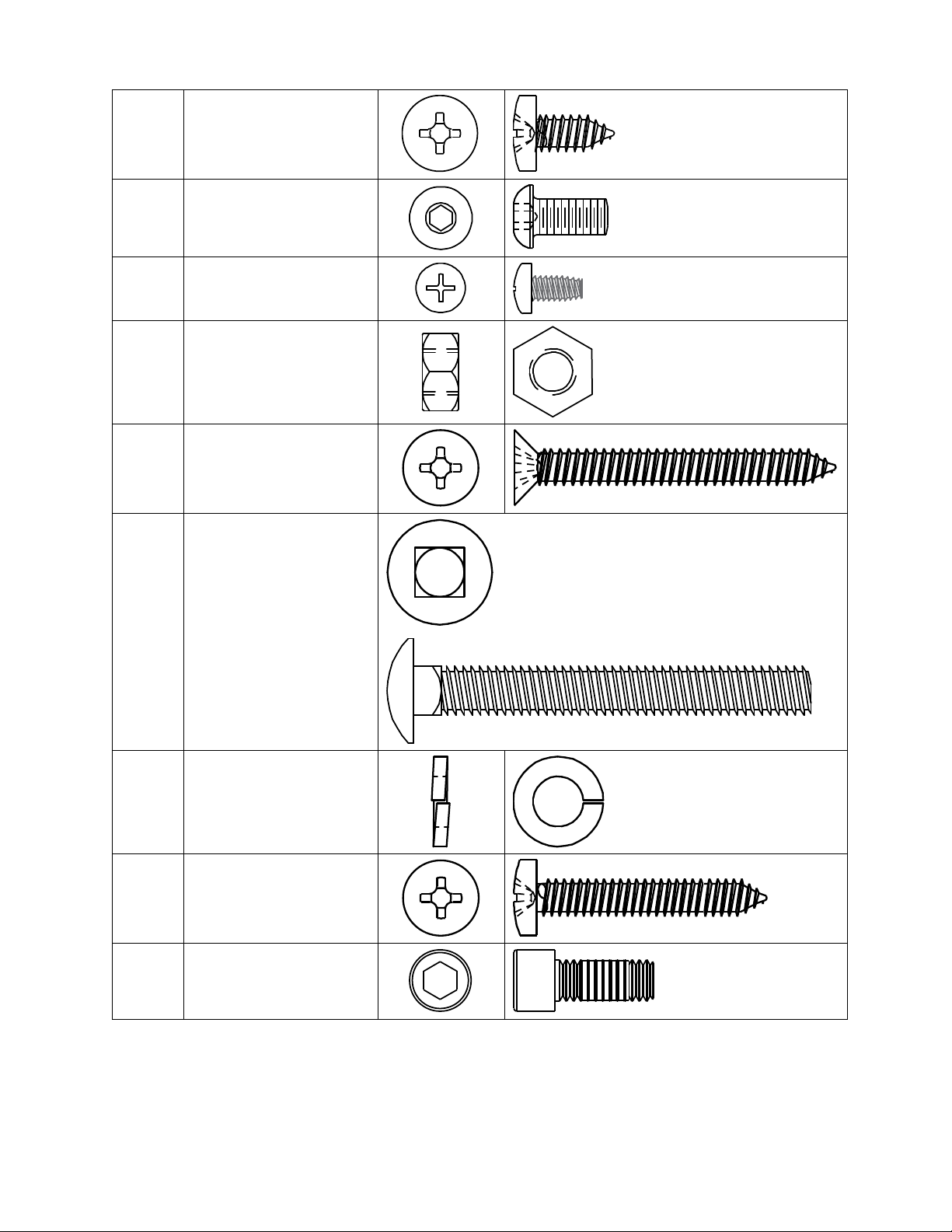

82287

Screw, #10-16 x 5/8”,

Phillips, Flat Head,

Self-Tapping, Zinc

82703

83645

84363

84742

85056

Screw, 1/4”-20 x 1/2”,

Button Head Cap, Black

Screw, 8-32 x 3/8”

Phillips, Pan Head,

Thread Forming

Nut, 3/8”-16

Screw, #10-16 x 2 1/4”,

Phillips, Flat Head,

Self-Tapping, Zinc

Carriage Bolt, 3/8”-16 x

3.00”

Washer, Split Lock, 3/8"

85057

Inside Dia., 11/16”

Outside Dia.

Screw, #10-16 x 1 3/4”,

85320

Phillips, Pan Head,

Self-Tapping, Zinc

91360

Screw, 5/16” x 3/4”,

Socket Head Cap

Installation Guide: TechBench™ / TechOrganizer - MN 212001EN r1.0

7

Linear TechBench™ Assembly

The following procedure applies to Linear Type A TechBench™ and T echOrganizer Systems

installed with the Laminate Worksurface in widths of 48 inches (121.9 cm), 60 inches (152.4

cm), and 72 inches (198.1.cm).

TechBench™ Adjustable Height

The base height of the TechBench™ Laminate Worksurface can be adjusted by removing the

eight Carriage Bolts along the Lower Side Frames and sliding the Upper Side Frames upward

(to raise) or downward (to lower) the height of the surface. The adjustable range for the

Lower and Upper Side Frame base structure is 30” (76.2 cm) to 35” (89.9 cm). To determine

the full height of the Worksurface, the Side Frame base measurement must be added to one

of the following; either the variable height set for the Leveling Glide Feet, which is between .5

(1.27 cm) to 2.5” (6.35 cm), or the fixed height of 5.625” (14.29 cm) if Casters are installed.

The Worksurface height level range varies slightly depending on whether the

TechBench™ is installed with Leveling Glides or Casters. Leveling Glides have

an adjustable range of .5” (1.27 cm) to 2.5” (6.35 cm). Casters are not

adjustable and have a fixed height of 5.625” (14.287 cm).

A minimum of three people are required to adjust the height of the worksurface

once the Linear TechBench™ and TechOrganizer System are assembled and in

the upright position. Attempting to adjust the height of an upright system without

the assistance of two additional installers may result in serious injury.

NOTE

WARNING

TechBench™ With Leveling Glides Installed

If Leveling Glides are attached to the bottom of the TechBench™, the height of the

Worksurface can be adjusted from a minimum of 30.5” (77.47 cm) to a maximum of 37.5”

(95.25 cm).

The minimum value above is calculated with the Leveling Glide feet fully

NOTE

retracted to a height of .5” (1.27 cm). The maximum value is calculated with the

Leveling Glide feet fully extended to a height of 2.5” (6.35 cm).

TechBench™ With Casters Installed

If Casters are attached to the bottom of the TechBench™, the height of the Worksurface can

be adjusted from a minimum of 35.625” (90.49 cm) to a maximum of 40.625” ( 103.19 cm).

The minimum and maximum values calculated for Caster-attached benches

includes 5.625” (14.29 cm), which is the a fixed height of each Caster.

NOTE

Before starting this procedure, identify/obtain the Worksurface height requirements

NOTE

for the TechBench™ to be assembled. It is much easier to adjust the height of the

Worksurface while the bench is face down on the floor, prior to turning the bench to

an upright position.

NOTE

8

Throughout the procedure, letter and number callouts within a figure only apply to

the figure in which they appear.

Installation Guide: TechBench™ / TechOrganizer - MN 212001EN r1.0

Step 1: Separate Upper Side Frame from Lower Side Frame

Locate the two Side Frames

within the installation kit.

Separate each Upper Side

Frame (5) from each Lower

Side Frame (4) by removing the

four Carriage Bolts (1),

Washers (2), and Nuts (3), on

both units. See Figure 1.

NOTE

Set the Lower Side Fram es and

hardware aside for r e-assembly

in a later step.

Carriage Bolt, 3/8-16 x

1

3.00” Long (85056)

Washer, Split Lock, 3/8"

2

Dia. (85057)

3

Nut, 3/8-16, (84363)

4

Lower Side Frame

Figure 1: Separate Upper and Lower Side Frames

5

Upper Side Frame

Installation Guide: TechBench™ / TechOrganizer - MN 212001EN r1.0

9

Step 2: Attach Stiffeners to Upper Side Frames

Locate the two Stiff eners (3) in

the installation kit. Attach the

Stiffeners to the Upper Side

Frames (2) as shown in Figure

2. See DETAIL A below.

Screw, 1/4”-20 x 1/2” Hex

1

Washer Head, SelfThreading [54348]

2

Upper Side Frames

3

Stiffeners

DETAIL A

A

Slot on Side Frame

B

Tongue Slides Into Slot

IMPORTANT! Flange Must Be

C

Positioned On Top as Shown

Figure 2: Attach Stiffeners to Upper Side Frames

DETAIL A

Screw, 1/4”-20 x 1/2” Hex Washer

1

Head, Self-Threading (54348)

2

Upper Side Frame

3

Stiffener End

4

Side Frame Post

At each corner, sl ide the tongue (B) at end

of Stiffener (3) into slot (A) on Side Frame

(2). Secure using six, Hex Washer Head,

Self-Threading screws (1).

Fully Assembled Corner

10

Installation Guide: TechBench™ / TechOrganizer - MN 212001EN r1.0

Step 3: Attach Upper Side Frame and Stiffener Assembly to Worksurface

Place Laminate Worksurface Face Down

Using two people, locate the Laminate

Worksurface in the installation kit. Carefully

unpack the W orksurface and place it finished

side down on the em pty carton or on a clea n

carpeted surface.

NOTE

The pre-drilled ho les locate d on the un dersid e

of the Laminate Worksurface should be facing

upward as shown in Figure 3.

Secure Side Frames and Stiffeners to Worksurface

Place the Upper Side Frame and

Stiffener assembly (B) on the

underside of the Worksurface (A),

as shown in Figure 4.

Secure Stiffeners to Worksurface

using ten, #10AB x 5/8” Ph i llips Pa n

Head screws (1).

Secure Upper Side Frames to

Worksurface using eight, #10 x 13/4” Phillips Pan Head screws (2),

with #10 Flat Washers (3).

Figure 4: Secure Side Frames and Stiffener to Worksurface

Figure 3: Laminate Worksurface Underside

A

Worksurface Underside

Upper Side Frame and

B

Stiffener Assy

Screw, #10AB x 5/8” Phillips

1

Pan Head, Black (82287)

Screw, #10 x 1-3/4”, Phillips

2

Pan Head (85320)

Washer, #10 flat

3

(54225)

Installation Guide: TechBench™ / TechOrganizer - MN 212001EN r1.0

11

Step 4: Attach Accessory Bracket and Two Drawer Pedestal (optional)

NOTE

If NOT attaching the optional Accessory

Bracket and Two Dra wer P edes ta l, the n GO

TO Step 5: Determine Worksurface Height

and Re-Attach Lower Side Frames, page

14.

With the Upper Side Frame and Stiffener

assembly firmly attached to the underside

of the Worksurface, secure the Accessory

Bracket (1) to the front and back Stiffeners

using four, #14B x 5/8”, Phillips, Pan Head

screws (2), as shown in Figure 5.

NOTE

The illustration shows the Accessory

Bracket centered along the front Stiffener.

Depending on user preference, the

Accessory Bracket and Two Drawer

Pedestal may also be attached to loc ations

left or right of center.

Point flange on front edge of

A

Accessory Bracket towards Laminate

Worksurface underside.

Figure 5: Attach Accessory Bracket to Stiffeners

Abut inside edge of flange to outside

B

edge of front Stiffener.

C

FRONT edge of Worksurface.

1

Accessory Bracket

Screw, #14B x 5/8”, Phillips, Pan

2

Head (54298)

Secure Hanger Screws to Accessory Bracket

After the Accessor y Bracket is fastened to

the front and back Stiffeners, secure the

four Pedestal Hanger screws (1) to the

bottom of the Accessory Bracket (2), as

shown in Figure 6.

CAUTION

Do NOT over-tighten Hanger screws.

Pedestal Hanger screws; Qty. 4

1

Shipped with Two Drawer Pedestal

Figure 6: Secure Hanger Screws to Accessory

Bracket

2

Accessory Bracket (bottom)

12

Installation Guide: TechBench™ / TechOrganizer - MN 212001EN r1.0

Attach Two Drawer Pedestal to Accessory Bracket

WARNING

To avoid injury, it is recommended that

two installers work together to lift the

Pedestal (1) onto the Accessory

Bracket (2).

As shown in Figure 7, to attach the

Two Drawer Pedestal (1), turn the

Pedestal upside down and place the

four key-slots in the top surface of the

Pedestal over the four Hanger screws

(A) on the Accessory Bracket (2). To

lock the Pedestal in place, push/slide

the Pedestal towards t he rear (B) until

the spring clips inside the Pedestal

holes lock into place.

A

Hanger Screws (4)

Sliding Pedestal Towards Rear

B

Locks Spring Clips in Place

C

FRONT of TechBench™

D

REAR of TechBench™

1

Two Drawer Pedestal

Figure 7: Attach Pedestal to Accessory Bracket

2

Accessory Bracket (bottom)

Installation Guide: TechBench™ / TechOrganizer - MN 212001EN r1.0

13

Step 5: Determine Worksurface Height and Re-Attach Lower Side Frames

Determine Worksurface Height

Figure 8 shows a view of the TechBench ™, up-side down, with the W orksurface flat on the flo or and

the Lower Side Fram es (2) separated from the Upp er Side Frames (1). As sho wn, when assembled,

the Upper Side Frames (1) slide inside the Lower Side Frames (2) and eight, Carriage Bolts (3),

Washers (4), and Nuts (5) are used to fasten the components together at a specific height.

Figure 8: Determine Worksurface Height

When adjusting the TechBench™ to set the Worksurface height, two factors (measurements ) must be

taken into consideratio n. T he firs t measur em ent (setti ng) is the height of the T echBenc h™ bas e, whic h

includes the Upper and Lower Side Frames along with the thick ness of the Lam inate W orksurface. As

shown in Figure 8, this ranges from 30” (76.2 cm) to 35” (89.9 c m). The second factor (m easurement)

is the height of the adjustable Leveling G lide Feet (range .5 (1.27 cm ) to 2.5” (6.35 cm), or the fixed

height of the Caster Wheels, 5.625” (14.29 cm), depending upon which are installed. To

obtain/achieve the full he ight of the Worksurface, the base measurement must be added to the

height of the Leveling Glides or Casters, depending upon which ones are to be attached.

To secure the base he ight, line up the holes and C arriage Bolts (A) located on the Lower Side Rails

with the d esired holes (items 30-35) on the Upper Side Rails. Once all bo lts are ins erted, sec ure using

the Washers (4) and Nuts (5) provided.

To determine the full height of the Worksurface, the Side Frame measurement,

30” (76.2 cm) to 35” (89.9 cm), must be added to the height set for the Leveling

Glides, .5 (1.27 cm) to 2.5” (6.35 cm), or Coasters, 5.625” (14.29 cm) fixed,

NOTE

depending upon which ones will be installed on the TechBench™.

14

Installation Guide: TechBench™ / TechOrganizer - MN 212001EN r1.0

Re-Attach Lower Side Frames

NOTE

When setting the height, remember to

add the height of the Leveling Glide

Feet, .5” (1.27 cm) to 2.5” (6.35 cm ), or

Coasters, 5.625” (14.29 cm) fixed, to

the base measurement, depending

upon which ones will be installed. For

details, see Determine Worksurface

Height, on page 14.

NOTE

Leveling Glide Feet will be adjusted in

the next step. If Leve ling Glide Fee t are

to remain on the TechBench™ (not

removed), select a measurement for

the Leveling Glide Feet (to be used in

the next step), and add that valu e to the

base measurement when determining

the full height of the Worksurface for

this step.

For Casters, add the fixed value of

5.625” ( cm).

As shown in Figure 9, re-attach the

Lower Side Frames (1) to the Upper

Side Frames (2) using the eight

Carriage Bolts (3), Washers (4), and

Nuts (5) removed in Step 1.

Figure 9: Re-Attach Lower Side Frames

1

Lower Side Frame

2

Upper Side Frame

Carriage Bolt, 3/8-16 x 3.00”

3

Long (85056)

Washer, Split Lock 3/8" Dia.

4

(85057)

5

Nut, 3/8-16 (84363)

Installation Guide: TechBench™ / TechOrganizer - MN 212001EN r1.0

15

Step 6: Adjust Height of Leveling Glides

e bottom of the

NOTE

If Casters and the Foot Rest are to be

attached to th

TechBench™, skip this step and GO TO

Step 7: Attach Casters and Foot Rest to

Bottom of TechBench™ (optional), on

page 16.

To adjust Leveling Glides, use a 1/2” open

end wrench at Notch position (3). Turn

Counter Clockwise (CCW) to increase

distance (A) and Clockwise (CW) to

decrease. Use a 1” open end wrench to

loosen/tighten Check Nut (2). Tighten

Check Nut once Levelin g Glid e Foot is set.

See Figure 10.

Leveling Glide range is 0.5” (12.7 mm)

A

minimum, to 2.5” (63.5 mm) maximum.

1

Leveling Glide Foot

2

Check Nut (1”)

3

Notch (1/2”)

Once Leveling Glide height adjustments

are complete, GO TO Step 8: Attach Back

Panel, on page 18.

Figure 10: Adjust Leveling Glide Height

NOTE

Set all four Leveling Glides to the same measurem ent

(A). Leveling Glide ra nge is .5” (12.7 m m ) to 2.5” (63.5

mm).

16

Installation Guide: TechBench™ / TechOrganizer - MN 212001EN r1.0

Step 7: Attach Casters and Foot Rest to Bottom of TechBench™ (optional)

NOTE

If Casters and Foot Rest are NOT to be installe d,

then skip this step an d GO TO Step 8: Attac h Bac k

Panel, on page 18.

Remove Leveling Glide Feet

Before Casters can b e attached, the four Leveling

Glide Feet (1) must be removed.

To remove the Leveling Glide Feet (Figure 11), use

a 1/2” open end wrench on the Notch point (see

Figure 10, on page 16 to view Notch location).

Turn Leveling Glide CCW to remove.

1

Four Leveling Glide Feet

Attach Casters to TechBench™

Figure 11: Remove Leveling Glide Feet

As shown in Figure 12, attach Locking

Casters (1) to the front (A) of the

Figure 12: Attach Casters to TechBench™

TechBench™, and Non-Lo cking Casters

(2) to the rear of the TechBench (B).

NOTE

When attaching Locking Casters (1),

make sure the Lock ing Me c hanism (C) is

pointing forwards, to wards the front, as

shown.

Secure each Caster to th e TechBench™

using four, 5/16” x 3/4” Long, Socket

Head Cap screws, and 5/16” Washers.

Tighten screws using 1/4” Allen wrench.

A

FRONT of TechBench™

B

REAR of TechBench™

C

Locking Mechanism

1

Locking Caster

2

Non-Locking Caster

Screw, 5/16” x 3/4” Long,

3

Socket Head Cap (91360)

Washer, 5/16” SAE, Flat Black

4

(81710)

NOTE

Casters add 5.65” (142.24 mm) to height of Worksurface.

Installation Guide: TechBench™ / TechOrganizer - MN 212001EN r1.0

17

Attach Foot Rest to TechBench™

As shown in Figure 13, attach the Foot Rest

(1) to the inside edges of both lower Side

Frames using four, 1/4”-20 x 1/2” Hex

Washer Head, Self-Threading screws (2).

NOTE

The Foot Rest (1) is typical ly attached to the

most forward location along the inside of the

lower Side Fram es (A), as shown. Additio nal

holes are available on both sides to

position/re-locate the Fo ot Rest further back

if necessary.

A

Front of TechBench™

1

Foot Rest

Screw, 1/4”-20 x 1/2” Hex Washer

2

Head, Self-Threading (54348)

Step 8: Attach Back Panel

Using six, 1/4”-20 x 1/2” Hex

Washer Head, Self-Threading

screws (3), attach the Back

Panel (1), to the rear of both

Side Frames (2), as shown in

Figure 14.

Figure 13: Attach Foot Rest to TechBe n ch

Figure 14: Attach Back Panel

1

Back Panel

2

Side Frames (rear)

Screw, 1/4”-20 x 1/2”

3

Hex Washer Head, SelfThreading (54348)

18

Installation Guide: TechBench™ / TechOrganizer - MN 212001EN r1.0

Step 9: Turn the TechBench™ Upright

WARNING

To avoid injury, it is recommended that

two or more installers work together to

turn the TechBench™ upright.

As shown in Figure 15, turn the

TechBench™ upright so it is resting on

either the Casters or Leveling Glides.

NOTE

If Casters were installed on the

TechBench™, there is no need for

leveling. GO TO Step 10: Attach

TechOrganizer to Worksurface, on page

20.

Level TechBench™ Worksurface

If Casters were NOT installed on the

TechBench™, then place a Leveling

device on the Worksurface (A) and level

the Worksurface by adjusting the height

of the four Leveling Glides (1).

To adjust the Le vel ers , us e a 1” o pe n end

wrench to loosen the Check Nut. Use a

1/2” open end wrench on the Leveler

Notch to adjust th e Leveler height (CCW

to raise a corner and CW to lower).

Tighten all four Check Nuts once final

adjustments are made. For a detailed

view of the Leveling Glide, see Figure 10,

on page 16.

Figure 15: Turn TechBench™ Upright

Installation Guide: TechBench™ / TechOrganizer - MN 212001EN r1.0

19

Step 10: Attach TechOrganizer to Worksurface (optional)

As shown in Figure 16, position the

TechOrganizer (1) along the rear of the

Worksurface (2).

Adjust the rear edge of the TechOrganizer

(1) so that it is .2” (5.08 mm) from the rear

edge of the Worksurface (A).

Using a plastic mallet, tap the en ds of the

TechOrganizer frame to ensure both feet

and frame are at a 90° a ngle in reference

to the corner of the Worksurface.

Using the holes along the frame bottom

crossbar (B) and both feet (C) as a

template, drill holes .113” (2.97 mm) in

diameter and .5” (12.7 mm) deep.

NOTE

Use a 7/64 drill bit to drill holes.

NOTE

It may be easier to m ark all drill loc ations

first, using the TechOrganizer as the

template, then rem ove the TechOrganizer,

drill the holes, and reposition the

TechOrganizer back along the

Worksurface edge.

Once all holes are drilled and the

TechOrganizer is repositioned, attach the

TechOrganizer bottom frame to the

Worksurface using four , #10 – 2 1/4” Long,

Phillips Flat Head, Self-Tapping screws

(4). Attach both feet to the Worksurface

using four (two per side), #10 - 3/4” Long,

Phillips Pan Head, Self-Tapping screws

(3).

Figure 16: Attach TechOrganizer to Worksurface

Position rear edge of TechOrganizer

A

.2” (5.08 mm) from rear edge of

Worksurface.

B

TechOrganizer Frame

C

TechOrganizer Feet

1

TechOrganizer

2

Worksurface

Screw, #10 - 3/4” Long, Phillip s Pa n

3

Head, Self-Tapping, Zinc (59103)

Screw, #10 – 2 1/4” Long, Phillips

4

Flat Head, Self-Tapping, Zinc

(84742)

20

Installation Guide: TechBench™ / TechOrganizer - MN 212001EN r1.0

Step11: Attach Mounting Channels and Bin Board to TechOrganize r (optional)

12: Attach Overhead Lighting to

NOTE

If Bin Board an d Mounting Channels are

NOT to be installed, then GO TO

TechOrganizer (optional), on page 23.

NOTE

Bin Board and Mounting Channels

MUST be installed BEFORE

components that might extend across

the face of the bo ard, such as a ho ok on

shelf.

NOTE

Figure 17 shows the Bin Board and

supporting Mounting Channels attached

to the lower right section of the

TechOrganizer. The Bin Board can be

installed at other locations along either

side of the TechOrganizer by relocating

the Mounting Channels accordingly.

Step

Figure 17: Mounting Channels and Bin Board

Assembly

1

Bin Board

2

Mounting Channels

Screw, #10-24 x 3/4” Phillips, Pan

3

Head, Thread-Forming (80023)

Screw, #8 -32 x 3/8” Phillips, Pan

4

Head, Thread-Forming, (83645)

A

TechBench™ Worksurface

TechOrganizer Frame with Slotted

B

Standards

Embossed Triangle on Mounting

C

Channels – MUST BE AT TOP,

when Installed.

As shown in Figure 17

, attach each

Mounting Channel (2) al ong the inside of

the Slotted Standards (B) using eight,

#8-32 x 3/8” Phillips, Pan Head, ThreadForming screws (4). Make sure to

position the Embossed Triangle at the

TOP (C) during installation.

Installation Guide: TechBench™ / TechOrganizer - MN 212001EN r1.0

21

Attach Bin Board to Mounting Channels

1

Bin Board

2

Mounting Channels

Screw, #10-24 x 3/4” Phillips, Pan

3

Head, Thread-Forming (80023)

Bin Board Panel Hooks (three on

A

each side)

To attach the Bin Board (1) to the Mounting

Channels (2), align the Panel Hook s (A) on the

back of the Bin board with the rectangular slots

on each Mounting Channel. See Figure 18.

Figure 18: Line Up Panel Hooks

Figure 19: Insert Panel Hooks Into Channel Slots

As shown in Figure 19, ins ert and firmly seat

the three Panel Hooks (A) along each side

into the slots on the Mounting Channels (2).

NOTE

Use a flat blade screwdriver as a lever or

plastic mallet as required.

Secure the Bin Panel to the Mounting

Channels using two, #10-24 x 3/4” Phillips,

Pan Head, Thread-Forming screws, as shown

in Figure 20.

Figure 20: Secure to Mounting Channe ls

22

Installation Guide: TechBench™ / TechOrganizer - MN 212001EN r1.0

Step 12: Attach Overhead Lighting to TechOrganizer (optional)

5

6

NOTE

If the Overhead Light is NOT t o be installed, then GO TO Step 13: Attach Lam inate Hook-On Shelf

(optional), on page 26.

Overhead Lighting Components

Figure 21: Overhead Lighting Components

Figure 21 shows the components com prising the

Overhead Lighting assembly. As illustrated, the

assembly consists of the Overhead Light (1), two

Support Brackets (2), two Mountin g Spacers (3),

and the hardware Screws (4, 5 and 6) , used for

interconnecting t he com ponents toge ther an d for

fastening the unit to the TechOrganizer.

NOTE

The Overhead Light (High Profile Model) hooks

onto the slotted standard (trapezoid shaped

holes) at the top of the TechOrganizer. If

attached to the very top, the light will sit 12”

above the top of the frame.

Installation Guide: TechBench™ / TechOrganizer - MN 212001EN r1.0

1

Overhead Light (High Profile Model)

2

Support Bracket

3

Mounting Spacers

4

Screw, 1/4”-20 x 1/2”, Button Head (82703)

Screw, 10 -24 x 3/8” Phillips, Pan Head,

+

Thread Forming, Black Oxide, (66714)

23

Attach Support Brackets to TechOrganizer

Brackets (1) will be attached to the

Figure 22: Hook Support Brackets onto TechOrganizer

Select the position (height) where the Support

TechOrganizer (3). Insert the Hooks (A) into the

Slotted Standard (B). Tap the brackets down

making sure the hook s are seated firml y into the

frame. As shown in

Figure 22, secure the

brackets to the standards using two, 10-24 x 3/8”

Phillips, Pan Head, T hr ead F orm ing, B lack Oxide,

screws (2).

24

1

Support Brackets

Screw, 10 -24 x 3/8” Phillips, Pan Head,

2

Thread Forming, Black Oxide, (66714)

3

TechOrganizer Frame

A

Hooks

B

Slotted Standard (trapezoid shaped holes)

Installation Guide: TechBench™ / TechOrganizer - MN 212001EN r1.0

Attach Mounting Spacers to Overhead Light

Figure 23: Attach Mounting Spacers to Overhead Light

The Mounting Spacers (2) must be attach ed to the ends of

the Overhead Light (1) b efore the light can be secured to

the Support Brackets.

As shown in Figure 23, secure the Mount ing Spacer s (2) t o

the Overhead Light (1) us ing six, 10-2 4 x 3/8” Phillips , Pan

Head, Thread Forming, Black Oxide, screws.

Attach Overhead Light to Support Brackets

Figure 24: Attach Overhead Light to Support Brackets

1

Overhead Light

2

Mounting Spacers

Screw, 10 -24 x 3/8” Phillips,

3

Pan Head, Thread Forming,

Black Oxide, (66714)

Once Mounting Spacers are attached to both ends of the

Overhead Light (1), it can be attached to the top of the

Support Brackets (2), using four, 1/4”-20 x 1/2”, Button

Head, screws, as shown in Figure 24.

NOTE

1

Overhead Light

2

Support Brackets

Screw, 1/4”-20 x 1/2”,

3

Button Head, (82703)

The Overhead Light can be mounted in three different

locations (front to back) along the top of the Support

Brackets.

Installation Guide: TechBench™ / TechOrganizer - MN 212001EN r1.0

25

Step 13: Attach Laminate Hook-On Shelf (optional)

are pointing inward towards one another.

NOTE

If Laminate Hook-O n Shelf is NOT to be installe d, then G o So Step 14: Attach LH and RH Power Str ip

Brackets (optional), on page 28.

Attach Shelf Supports to Laminate Shelf

Figure 25: Attach Shelf Supports to Laminate Shelf

Before the Laminate Hook-On Shelf can be

installed, the Shelf Support s (2 and 3) must first

be attached to the Laminate Shelf Underside (1).

As shown in Figure 25, lay the Laminate Shelf

(1) with the finished side down on an empty

carton or on a clean carpeted surface. Then

position the Left H and ( LH) and Right Hand ( RH)

Shelf Supports (2 and 3) on the underside as

shown and secure both Supports to the

Laminate Shelf using four, #10AB x 5/8” Phillips,

Pan Head, Black, screws.

A

Square Holes at Rear of Shelf

B

Hooks on Shelf Supports

1

Laminate Shelf Underside

2

LH Shelf Support

3

RH Shelf Support

Screw, #10AB x 5/8” Phillips, Pan Head,

4

Black, (82287)

NOTE

For proper positioning, make sure the hooks (B)

on both supports are pointing towards the s quare

holes at the rear of the s helf (A) and the flanges

26

Installation Guide: TechBench™ / TechOrganizer - MN 212001EN r1.0

Attach Laminate Shelf to the TechOrganizer

Figure 26: Attach Laminate Shelf to TechOrganizer

Identify the height a t which the Laminate HookOn Shelf will be ins talled. I nsert the ho oks at the

front of the LH and RH Shelf Supports (2 and 3)

into the corresponding holes along both

Standards (A).

As shown in Figure 26, secure the shelf to the

TechOrganizer using two, 10-24 x 3/8” Phillips,

Pan Head, Thread Forming, Black Oxide,

screws.

Installation Guide: TechBench™ / TechOrganizer - MN 212001EN r1.0

A

Standards with Trapezoid Shaped H o les

1

LH Shelf Support

2

RH Shelf Support

Screw, 10 -24 x 3/8” Phillips, Pan Head,

3

Thread Forming, Black Oxide, (66714)

NOTE

Use a flat blade screwdriver as a lever or a

plastic m allet to tap the brackets down m aking

sure the hooks are seated firmly into the frame.

27

Step 14: Attach LH and RH Power Strip Brackets (optional)

NOTE

If LH and RH Power Strip Brackets are NOT to be installed, then this procedure is complete.

Figure 27: Attach Power Strip Brackets to TechOrganizer

As shown in Figure 27, attach the LH and RH

Power Strip Brackets (1 and 2) to the Standards

(A) by inserting the hooks at the back of each

bracket into the Standard holes and securing

each bracket using one, 1/4”-20 x 1/2” Hex

Washer Head, Self-Threading, screw (3).

PROCEDURE COMPLETE.

A

Standards with Trapezoid Shaped H o les

1

LH Power Strip Bracket

2

RH Power Strip Bracket

Screw, 1/4”-20 x 1/2” Hex Washer Head,

3

Self-Threading (54348)

28

Installation Guide: TechBench™ / TechOrganizer - MN 212001EN r1.0

© Copyright 2013 Eaton Corporation, Worcester, MA, USA.

Eaton Corporation

To contact an Eaton salesperson

All rights reserved.

Information in this document is subject to change without notice. No part of this document may

be reproduced or transmitted in any form or by any means, electronic or mechanical, for any

purpose, without the express written consent of Eaton Corporation.

Eaton is a registered trademark of Eaton Corporation or its subsidiaries and affiliates. Phillips is

a registered trademark of Phillips Screw Company. All other trademarks are the property of

their respective owners.

Electrical Sector

1111 Superior Ave.

Cleveland, OH 44114

United States 877-ETN-CARE (877-386-2273)

Eaton.com © 2013

Eaton Corporation

All Rights Reserved

Publication No

MN 212001EN r1.0

or local distributor, please visit

www.eaton.com/wrightline or

call 800-225-7348.

Installation Guide: TechBench™ / TechOrganizer - MN 212001EN r1.0

29

Loading...

Loading...