Page 1

Power-Sure 700

Instruction manual

Effective September 2015

Supersedes September 2013

Page 2

Power-Sure 700

DISCLAIMER OF WARRANTIES AND LIMITATION OF LIABILITY

The information, recommendations, descriptions and safety notations in this document are based on Eaton Corporation’s

(“Eaton”) experience and judgment and may not cover all contingencies. If further information is required, an Eaton sales

office should be consulted. Sale of the product shown in this literature is subject to the terms and conditions outlined in

appropriate Eaton selling policies or other contractual agreement between Eaton and the purchaser.

THERE ARE NO UNDERSTANDINGS, AGREEMENTS, WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING WARRANTIES

OF FITNESS FOR A PARTICULAR PURPOSE OR MERCHANTABILITY, OTHER THAN THOSE SPECIFICALLY SET OUT IN ANY

EXISTING CONTRACT BETWEEN THE PARTIES. ANY SUCH CONTRACT STATES THE ENTIRE OBLIGATION OF EATON. THE

CONTENTS OF THIS DOCUMENT SHALL NOT BECOME PART OF OR MODIFY ANY CONTRACT BETWEEN THE PARTIES.

In no event will Eaton be responsible to the purchaser or user in contract, in tort (including negligence), strict liability or

other-wise for any special, indirect, incidental or consequential damage or loss whatsoever, including but not limited to

damage or loss of use of equipment, plant or power system, cost of capital, loss of power, additional expenses in the

use of existing power facilities, or claims against the purchaser or user by its customers resulting from the use of

the information, recommendations and descriptions contained herein. The information contained in this manual is

subject to change without notice.

ii

Instruction manual IM1002004E September 2015 www.powerquality.eaton.com

Page 3

Contents

Power-Sure 700

General description ..........................1

Monitor ....................................1

Protection ..................................1

Operation ...................................2

Benefits of owning and using

the Power-Sure 700 ...........................2

Specifications ...............................2

Main transformer .............................3

Cabinet ....................................3

Input breaker ................................3

Industry standards ............................3

Theory of operation ...........................3

Sizing the Power-Sure 700 .....................4

Installation considerations ......................4

Inspection and installation ......................5

Unpacking ..................................5

Storing .....................................5

Choice of location ............................5

Inspection ..................................5

Installation procedure .........................5

Input wire size, grounding, and output wiring .......5

Startup sequence ............................7

Preventive maintenance .......................7

General troubleshooting guide ..................7

Troubleshooting ..............................7

Equipment required ...........................8

Power modules (SCRs) ........................8

Check the SCR snubber card ...................9

Check control card and filter card ................9

Final testing and adjustment ...................10

Control board measurements ..................22

Adjustment procedure ........................22

Parts kits ..................................22

Replacement parts ..........................22

Technical diagrams ..........................22

Cabinet dimensions ..........................36

Manual bypass switch ........................36

Normal mode ...............................36

Bypass mode ...............................36

Metering option .............................37

Warranty ..................................37

Instruction manual IM1002004E September 2015 www.powerquality.eaton.com

iii

Page 4

Power-Sure 700

iv

Instruction manual IM1002004E September 2015 www.powerquality.eaton.com

Page 5

General description

IMPORTANT

Save these instructions. Please read this manual before

using equipment.

General description

The Power-Sure™ 700 is a continuous duty electronic

voltage regulator designed to supply reliable, clean

regulated power to critical loads. An efficient design with

state-of-the-art microprocessor controlled solid-state devices

provide immunity to all line disturbances.

The basic design consists of a three-phase triple-shielded

isolation transformer with seven separate voltage taps per

phase. Output regulation is achieved by monitoring the

input and automatically switching taps anytime the input

line sags or surges. The special process of triple-shielded

isolation transformers provide superior common mode and

transverse mode noise attenuation. Automatic switching

occurs during current zero, allowing noise-free switches

for both leading and lagging power factor loads that are

connected to the Power-Sure 700.

Monitor

Monitoring of the Power-Sure 700 is simple, clean, and

effective. Three green light indicators are utilized to

display“POWER ON” (output line to neutral for each

phase) and one red light indicator to display “ALERT.” The

“POWERON” display is connected directly to the output

that indicates the Power-Sure 700 is operating properly

with just a quick glance. The “ALERT” display represents

an overtemp problem when illuminated, and will shut down

the output, but cooling fans remain on. Overtemp thermal

sensors are strategically located at critical points on the

regulator assemblies and transformer. The main AC input

circuit breaker must be turned off in order to reset the

“ALERT” light.

Protection

Protection is accomplished very effectively to minimize

failures and the cost of repairs. A total of four major devices

protect the Power-Sure 700.

1. The input is protected with an integrally mounted

AC circuit breaker for abnormal current overloads

and provides a convenient means of disconnecting

utility power.

2. The electronic regulating devices are protected

with fast-acting semi-conductor fuses. These fuses

are designed to clear before damage occurs to the

more expensive SCR regulating devices. The main

transformer is protected by fuse links connecting the

SCR regulators together, and are designed to clear in

the event that two or more SCRs should fail. This will

prevent a transformer tap short and the possibility of

transformer failure.

3. Overtemp sensing devices are mounted at critical

points on the SCR regulating assembly and the main

transformer. When an overtemp condition exists,

the “ALERT” light will illuminate and hold until the

overtemp is corrected. There are no automatic shutoff

circuits for the “ALERT” condition. The main AC input

breaker must be turned off in order to reset the

“ALERT” light.

4. Optional dedicated surge protective device can be

installed internally if requested at time of order. This

surge suppression device (SPD) is a CVX 50 kA SPD

forPower-Sure 700 units 50 kVA and below, and

CVX100 kA SPD for Power-Sure 700 units 75 kVA

andabove. This unit provides effective transient voltage

surge suppression and will help to prolong the life of

the Power-Sure 700.

Instruction manual IM1002004E September 2015 www.powerquality.eaton.com

1

Page 6

Operation

Operation

The Power-Sure 700 is operated by simply turning on the

main AC input circuit breaker. All units 50 kVA and larger are

equipped with a bypass switch as a standard feature. For

units 45 kVA and smaller, the bypass switch is optional. This

is a no load switch and MUST only be operated when the

unit is OFF. The bypass switch should be in the “NORMAL”

position unless a problem occurs with the system. If a

problem occurs, turn OFF the main AC circuit breaker

and turn the bypass switch to the “BYPASS” position.

Re-energize the system by turning on the AC circuit breaker

and contact the Customer Support Department for repairs.

Any “ALERT” condition requires the main AC input breaker

to be turned off in order to reset the “ALERT” light.

FOR ASSISTANCE, CALL 1-800-809-2772, option 4, and

then option 2.

Bene ts of owning and using the

Power-Sure 700

Line harmonic filtering

Small physical size

Simple and inexpensive installation

Highly efficient

Quiet operation

Low BTU output

Low failure rate

Seven-tap, microprocessor control and diagnostics

UL® Listed to 1012 standards

Priced to be affordable

Conservatively rated

Extremely high surge capability

Simple operation

Input electronic circuit breakers

Nationwide customer support service

Load regulation: output maintained within 3% from no

load to full load

Response time: <1/2 cycle

Correction time: output will correct to within ±3% of

nominal in 1.5 cycles or less

Harmonic distortion: Less than 1.0% THD added to

the output waveform under any dynamic linear loading

conditions presented to the line regulator

Transverse-mode noise attenuation: 3 dB down at 1000 Hz,

40 dB/decade to below 50 dB with resistive load

Common-mode noise attenuation: 146 dB

Audible noise: 45 dB or less

Turn on characteristics: when energized, voltage

overshoot will be less than 5% of nominal for 1 cycle

or less

Overload rating: 1000% for 1 cycle and 200% for

10 seconds

Ambient rating: –10º to +40º Celsius

Integral manual rotary maintenance bypass switch

standard on 50 to 500 kVA units and optional on

smaller units

ote: N 50 Hz models available.

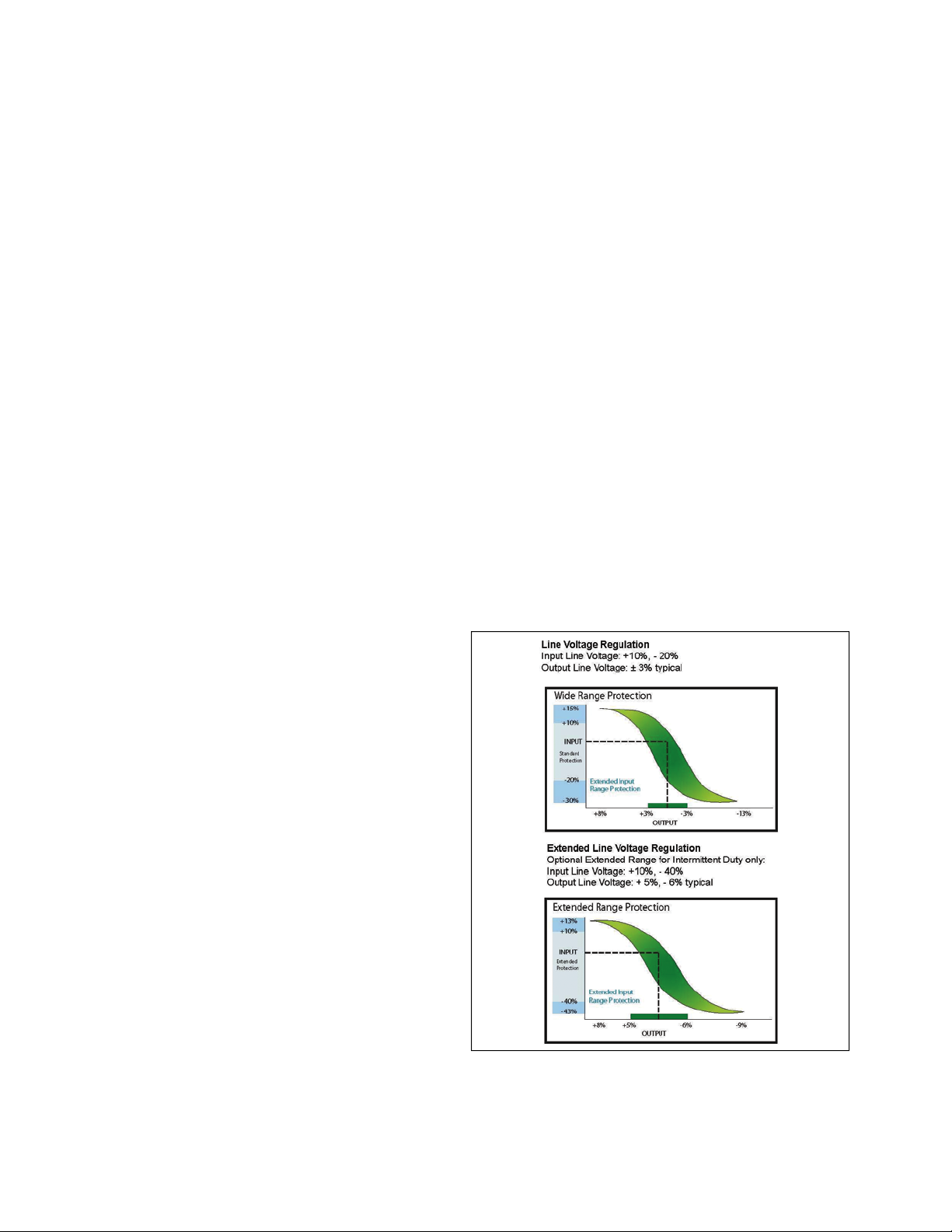

Figure 1. Regulation graphs

Speci cations

Dynamic electrical specifications

Output: maintained to within ±3% of nominal

Input: +10% to –23% of the nominal rated input

Frequency: 60 Hz ±3 Hz

Input power factor: >0.99 PF with resistive load

Line regulation: output is ±3% of nominal for input

variations of +10% to –23% of nominal

2

Instruction manual IM1002004E September 2015 www.powerquality.eaton.com

a

a

ab

a

Optional extended input regulation range provided on some units.

If provided, reference the description next to the units specification tag.

b

Between 160 V and 229 V at 208 V nominal. Between 369 V and 528 V

at 480 V nominal.

Page 7

Main transformer

Main transformer

Windings: all copper

Magnetics: grain orientated, M6 grade, stress-relieved

transformer steel is utilized for minimum losses and

maximum efficiency

Insulation: Class (N) 200 all sizes

Shielding: multiple triple copper shield to minimize

interwinding capacitance, transient, and noise coupling

between primary and secondary windings

Cooling: convection, operating temp is 130 degrees

Celsius maximum rise above ambient

Isolation: output is fully isolated from input

Cabinet

Heavy-gauge industrial steel throughout. Metal is

anti-corrosive phosphate treated prior to paint. Paint

is a baked finish.

Input breaker

Main input molded-case circuit breaker, rated at 125% of full

load input current.

Industry standards

Listed to UL 1012, standard for “power units other than

Class 2.”

Theory of operation

The Power-Sure 700 provides the triple function of isolation,

noise attenuation and voltage regulation. The first two

functions are provided by the power transformer, where as

the third function of voltage regulation is achieved through

solid-state thyristors (SCRs) connected to taps on the power

transformer. A microprocessor monitors and controls the

overall function of regulating the system.

The power transformer is manufactured with a unique

method of shielding which produces very low capacitive

coupling between the primary and secondary. This low

coupling provides excellent attenuation of the commonmode noise. In addition, special care is taken in the design

of the transformer to attenuate transverse-mode noise

above 1000 Hz.

The power transformer has taps to which solid-state

switches (SCRs) are connected.

The voltage regulator incorporated in the Power-Sure 700

is microprocessor controlled to achieve optimum correction

time of input voltage sags and surges. The response time is

typically one half (1/2) cycle for 100% correction, therefore,

a very smooth switch takes place undetected by computer

equipment.

As the input voltage (building power) varies, the voltage

available at each tap of the transformer will also change.

The amount of variation is dependent upon the input sag

or surge, turns ratio, and transformer losses.

By selecting a particular tap voltage, the output can be kept

within a tight range. The way in which this is accomplished

is that an electronic control card using a microprocessor

continually monitors the input voltage. When a voltage

fluctuation occurs, which exceeds the limit of rated regulation

(typically ±3%), the output is switched to another tap, that

is within the required range. This “switch” will be made at

the next current zero crossing to allow for both leading and

lagging power loads to be connected to the conditioner.

Instruction manual IM1002004E September 2015 www.powerquality.eaton.com

3

Page 8

Sizing the Power-Sure 700

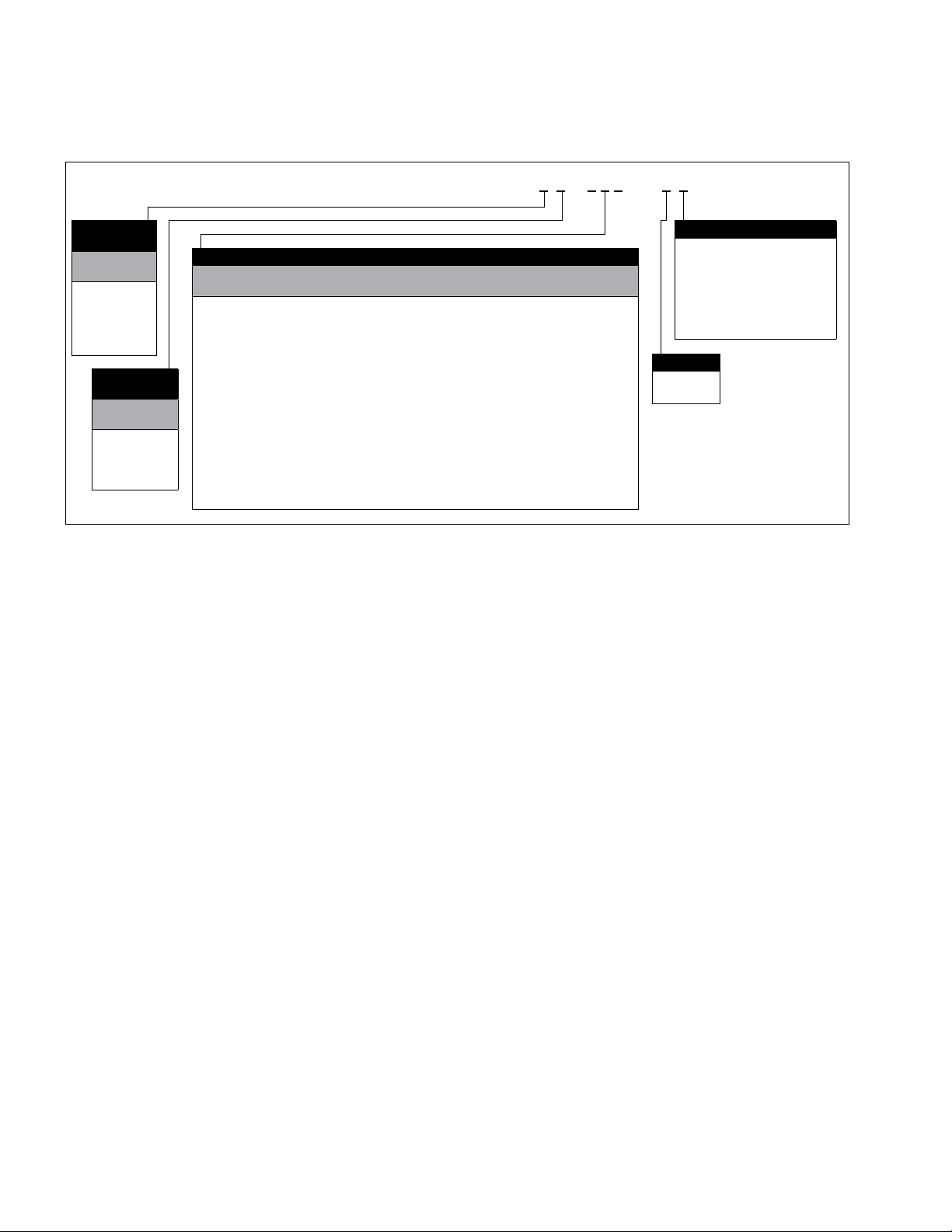

Table 1. Eaton Power-Sure 700 ordering guidelines

Nominal

input voltage

Delta input:

L, L, L, G

B = 208

C = 240

H = 400

D = 480

E = 600

Nominal

output voltage

Wye output:

L, L, L, N, G

L = 120/208

M = 230/400

N = 277/480

P = 347/600

kVA

010

010

015

015

025

030

045

050

075

100

125

150

225

300

500

Weight

(lbs)

440

520

520

600

870

890

950

1,176

1,575

2,014

2,137

2,240

3,300

4,000

5,500

BTUs/ hr

1,025

1,205

1,540

1,540

2,560

3,090

4,600

7,332

9,514

11,833

14,748

17,698

23,000

30,750

51,250

kVA ratings and dimensions

Bypass Metering

Optional

Optional

Optional

Optional

Optional

Optional

Optional

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

No

Yes

No

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

T - k -

Cabinet size

Dimensions H x W x D in inches (mm)

30.20 x 22.20 x 29.00 (767.1 x 563.9 x 736.6)

44.20 x 22.20 x 29.00 (1122.7 x 563.9 x 736.6)

30.20 x 22.20 x 29.00 (767.1 x 563.9 x 736.6)

44.20 x 22.20 x 29.00 (1122.7 x 563.9 x 736.6)

44.20 x 22.20 x 29.00 (1122.7 x 563.9 x 736.6)

44.20 x 22.20 x 29.00 (1122.7 x 563.9 x 736.6)

44.30 x 45.90 x 29.00 (1125.2 x 1165.9 x 736.6)

66.00 x 29.00 x 35.50 (1676.4 x 736.6 x 901.7)

76.00 x 34.40 x 35.50 (1930.4 x 873.8 x 901.7)

76.00 x 34.40 x 35.50 (1930.4 x 873.8 x 901.7)

76.00 x 34.40 x 35.50 (1930.4 x 873.8 x 901.7)

76.00 x 34.40 x 35.50 (1930.4 x 873.8 x 901.7)

77.40 x 56.00 x 41.50 (1966.0 x 1422.4 x 1054.1)

77.40 x 56.00 x 41.50 (1966.0 x 1422.4 x 1054.1)

77.00 x 72.40 x 48.40 (1955.8 x 1839.0 x 1229.4)

Options

Blank = No options

B = Bypass switch

M1 = Standard metering

(IQ 130)

M2 = Premium metering

(IQ 150)

S = Surge

Frequency

6 = 60 Hz

5 = 50 Hz

A

2

A

Units with no surge protection option, bypass option or metering will have blanks in the last three spaces in the catalog number.

B

Bypass is standard on 50 kVA and larger units and an option on 45 kVA and smaller units.

otes:N Listings—UL Listed, CSA Certified, except for 600 V: no UL, CSAon 600 V units.

For output distribution, call factory. K factor rated units availableon request.

Sizing the Power-Sure 700

When sizing the Power-Sure 700, be sure to take into

consideration all loads and circuits the unit is to supply.

A good way to ensure that the Power-Sure 700 is sized

properly is to use the following guidelines:

List each piece of equipment, include model, voltage,

current, and kVA

Calculate kVA of load plus a safety margin

When this is not possible, gather the data by reading

the specification plate of the equipment you plan on

backing up

One method is to ask the vendor of the equipment to

supply you with the information you need

Be sure to verify the input supply voltage and the output

requirements of the Power-Sure 700

Installation considerations

Prior to installing the Power-Sure 700, be sure to take into

consideration the site you have selected. Power Conditioners

produce heat and therefore require ventilation, as well as

accessibility.

Consider these factors:

Ventilation

Size of the Power-Sure 700

Weight load

Audible noise requirements

Monitors

Options

Clean environment

Proper ground techniques

Input source voltage

Receiving facilities

Distribution of power

Room temperature

Clearances

Accessibility

Excessively long power runs

4

Instruction manual IM1002004E September 2015 www.powerquality.eaton.com

Page 9

Inspection and installation

Inspection and installation

WARNING

There are dangerously high voltages present within

the enclosure of the power supply system. Under no

circumstances should any person reach within the

enclosure of this equipment. All service to this piece

of equipment should be performed by qualified

personnel only.

Unpacking

Upon receipt of the unit, visually inspect for shipping

damage. If any damage is found, the Purchaser must

contact the Carrier immediately and file a shipping

damage claim.

ote:N Be sure to remove top and side panels and inspect

inside unit for shipping damage.

Eaton should be notified if the nature of damage is such

that operation of the equipment has been impaired. Please

call 1-800-809-2772, option 4, and then option 2.

Storing

If it is necessary to store the unit for a period of time

before it is installed, be sure to place the unit in a clean,

dry area. To prevent excessive dust from accumulating on

the unit, it is advisable to protect it by replacing it in the

original container. The unit must be handled at all times with

the same care you would give to any piece of precision

industrial equipment.

Choice of location

The unit has been completely inspected and extensively

tested under various load conditions prior to shipment.

Care to install it at a proper location will ensure long

trouble-free operation.

The unit is air cooled with the air intake at the bottom

and exhausts at the top, front or at the sides. Therefore,

it should be installed in a clean, dry place with enough

clearance to allow a free flow of air. Allow at least

4.00 inches (101.6 mm) of space between the unit and

the wall or other equipment. Allow enough space for

maintenance on all four sides of larger units.

Inspection

A. Remove top and side panels (not applicable on 225 kVA

and larger).

B. Check all electrical connections to be sure none have

loosened during shipment. Tighten if necessary. Check

for any internal damage.

C. Check the spec. plate on the front of the unit to be

sure that the voltage and frequency match the available

power supply. Under no circumstances should the

unit be connected to a power source which does not

conform to the spec. plate rating.

Installation procedure

A. Verify that the input voltage to the unit matches the

unit’s specification plate.

B. Refer to installation diagrams on page 27–page 35

for input and output connection recommendations and

conduit locations.

Input wire size, grounding, and output wiring

A. Conduit should be used for both input and

output wiring.

B. Minimum ground wire size is based on 2011 National

Electrical Code® Table 250.122.

®

C. Input wire size is based on 2011 NEC

specifying not more than three conductors in a raceway

based on ambient of 30 degrees Celsius, and wire rated

at 75 degrees Celsius.

D. Output neutral to ground is already bonded during

manufacturing of the Power-Sure 700.

E. Output requires four (five including ground wire)

conductors in a raceway assuming neutral as a

current carrying conductor. This requires conductors

to be derated by using a multiplier of .8, reference

2011 NEC Article 310.15(B)(3)(a).

Example

1. Assume #10 wire maximum current = 25 A.

2. Multiply 25 x .8 = 20.

3. 20 A is maximum current for #10 wire in a raceway

with four conductors.

ote:N Installation is subject to local codes—verify with a

local electrical inspector.

Table 310.15(B)(16)

Instruction manual IM1002004E September 2015 www.powerquality.eaton.com

5

Page 10

Input wire size, grounding, and output wiring

Table 3. Wire size chart

Unit size

in kVA

Input breaker

size (amperes)

Input

wire size

Minimum ground

wire size

208 Vac input

10 40 #8 #10

15 60 #6 #10

25 110 #2 #6

30 110 #2 #6

45 175 2/0 #6

50 175 3/0 #6

75 300 #350 #4

100 400 3/0

a

125 500 250 kcmil

150 600 350 kcmil

225 800 500 kcmil

300 1200 500 kcmil

500 2000 500 kcmil

a

a

a

b

d

#3

#2

#1

1/0

3/0

250 kcmil

240 Vac input

10 30 #10 #10

15 50 #8 #10

25 100 #3 #8

30 100 #3 #8

45 150 1/0 #6

50 150 2/0 #6

75 250 #250 #4

100 350 500 #3

125 400 3/0

a

150 500 250 kcmil

225 800 500 kcmil

300 1000 500 kcmil

500 1600 500 kcmil

a

2 pcs.

b

3 pcs.

c

4 pcs.

d

5 pcs.

a

a

b

c

#3

#2

1/0

2/0

4/0

Unit size

in kVA

Input breaker

size (amperes)

Input

wire size

Minimum ground

wire size

480 Vac input

10 15 #10 #14

15 25 #10 #10

25 50 #6 #10

30 50 #6 #10

45 80 #4 #8

50 80 #4 #8

75 125 #1 #6

100 175 2/0 #6

125 200 3/0 #6

150 250 250 kcmil #4

225 350 500 kcmil #3

300 500 250 kcmil

500 800 500 kcmil

a

a

#2

1/0

600 Vac input

10 15 #10 #14

15 20 #10 #12

25 40 #8 #10

30 40 #8 #10

45 60 #6 #10

50 70 #4 #8

75 100 #3 #8

100 150 1/0 #6

125 175 2/0 #6

150 200 3/0 #6

225 300 350 kcmil #4

300 400 500 kcmil #3

500 700 400 kcmil

a

1/0

ote:N Refer to NEC for output wire size based on

output breaker size as mentioned in Step E

on the previous page.

6

Instruction manual IM1002004E September 2015 www.powerquality.eaton.com

Page 11

Startup sequence

Startup sequence

WARNING

There are dangerously high voltages present within

the enclosure of the power supply system. Caution

must be taken when working with the enclosure. It is

recommended that all work be performed by qualified

electrical personnel only.

ote:N Initial startup should be performed with no-load

on system.

1. Re-install all panels that may have been removed

during installation.

2. Make sure the input circuit breaker is in the OFF position.

3. Energize the primary building power.

4. Turn on the main AC input breaker.

5. Verify that the output voltage is within the

specified range.

6. Verify output phase rotation is correct.

7. Turn the system off.

8. Connect the loads one at a time and repeat Step 5.

General troubleshooting guide

Table 4. General Troubleshooting Guide

Symptom Probable causes

1. No output on one or

more phases

2. Output is too high or too low A. Control card adjustment

3. Input breaker tripping off A. Defective breaker

4. Blowing semi-conductor fuses A. Shorted SCRs or power modules

5. No output voltage A. Defective over/under output

A. Blown fuse

B. Defective SCR or power module

C. Defective control card

D. Defective sense card

E. No input

B. Defective control card

C. Defective sense card

D. Defective SCR or power module

E. Input out of range

B. System overloaded

C. Over/undervoltage detection is shutting

down system (see symptom #2)

D. Defective over/under detection card

E. Shorted taps

B. Output loads shorted

detection PCB

Preventive maintenance

WARNING

Danger of electrical shock. Turn off all power supplying

this equipment prior to maintenance.

To ensure longer component life and trouble-free operation,

minor preventive maintenance procedures should be

performed at regular intervals, for example once every

year. More frequent inspection intervals would be needed

for more severe operating conditions and larger number of

hours of continuous operation.

A. Remove top and side panels and at each service

inspection any accumulated dust, dirt or foreign particles

should be carefully removed. Special care should be

exercised in cleaning the thyristors, heat sinks, and the

control assembly.

B. Inverse parallel silicon rectifiers (SCRs) or thyristors:

The silicon controlled rectifiers (SCRs) usually fail in the

shorted mode. When this happens, normally the fusible

link in series with the SCR will be blown open to clear

the short and prevent damage to the transformers. The

individual SCR can be checked with an ohmmeter. Refer

to page 8 for resistance checking procedures.

C. Replace top and side panels. Turn unit on with no load.

D. Turn on loads.

E. Check to verify all fans are operational.

ote:N Preventive maintenance plans are included on

page 38 of the manual.

WARNING

There are dangerously high voltages present within

the enclosure of the power supply system. Under no

circumstances should any person reach within the

enclosure of this equipment. All service to this piece

of equipment should be performed by qualified

personnel only.

Troubleshooting

ote:N Circuit diagrams in this manual are for reference only.

Always refer to the actual circuit diagrams received

with the system.

Introduction

This procedure is written in a specific order and must be

used from start to finish when troubleshooting. Any steps

skipped over may cause serious damage to the system.

Instruction manual IM1002004E September 2015 www.powerquality.eaton.com

7

Page 12

Equipment required

Equipment required

True rms digital multimeter, SCR tester, common hand tools.

Step 1: Disassembling the power line conditioner

A. Turn off the power to the conditioner at its source.

B. Turn off the input circuit breaker on the unit and the

output circuit breakers to all loads (remove all loads

from unit).

C. Remove the top and side covers to the conditioner.

Step 2: Electrical connections, fuses

Refer to diagrams on page 11–page 16 for component

locations.

A. Inspect the unit for proper tightness of all electrical

connections, burnt, frayed, broken, or loose connections

and components in these areas.

Input and output connections, SCR assembly, SCR

snubber, output filter assembly, MOVs (metal oxide

varistors), circuit boards, bypass switch, and

transformer connections.

B. Correct and tighten any loose connections, replace

any physically burned or broken components.

C. Check all fuses in system.

ote:N Remove fuses from circuit when checking to avoid

false readings.

D. Time delay fuses, semi-conductor fuses, fan fuses,

circuit board fuses, SCR fusible Link wire.

Power modules (SCRs)

Refer to diagram on page 17 for 10–30 kVA SCR

assembly, page 18 for 45–150 kVA SCR assembly,

page 19 for 225–300 kVA SCR assembly, and page 20

for 500 kVA SCR assembly.

1. Unplug the connections to the control cards

Part # 49120/407415 labeled TB1, TB2, and TB3.

2. Disconnect any cooling fans in the unit so your SCR

resistance checks are not interfered by fan motor coils.

Also, remove main semi-conductor fuse located on

all three SCR assemblies and any wires attached to

the fuse. Each power module contains two inverse

parallel SCRs.

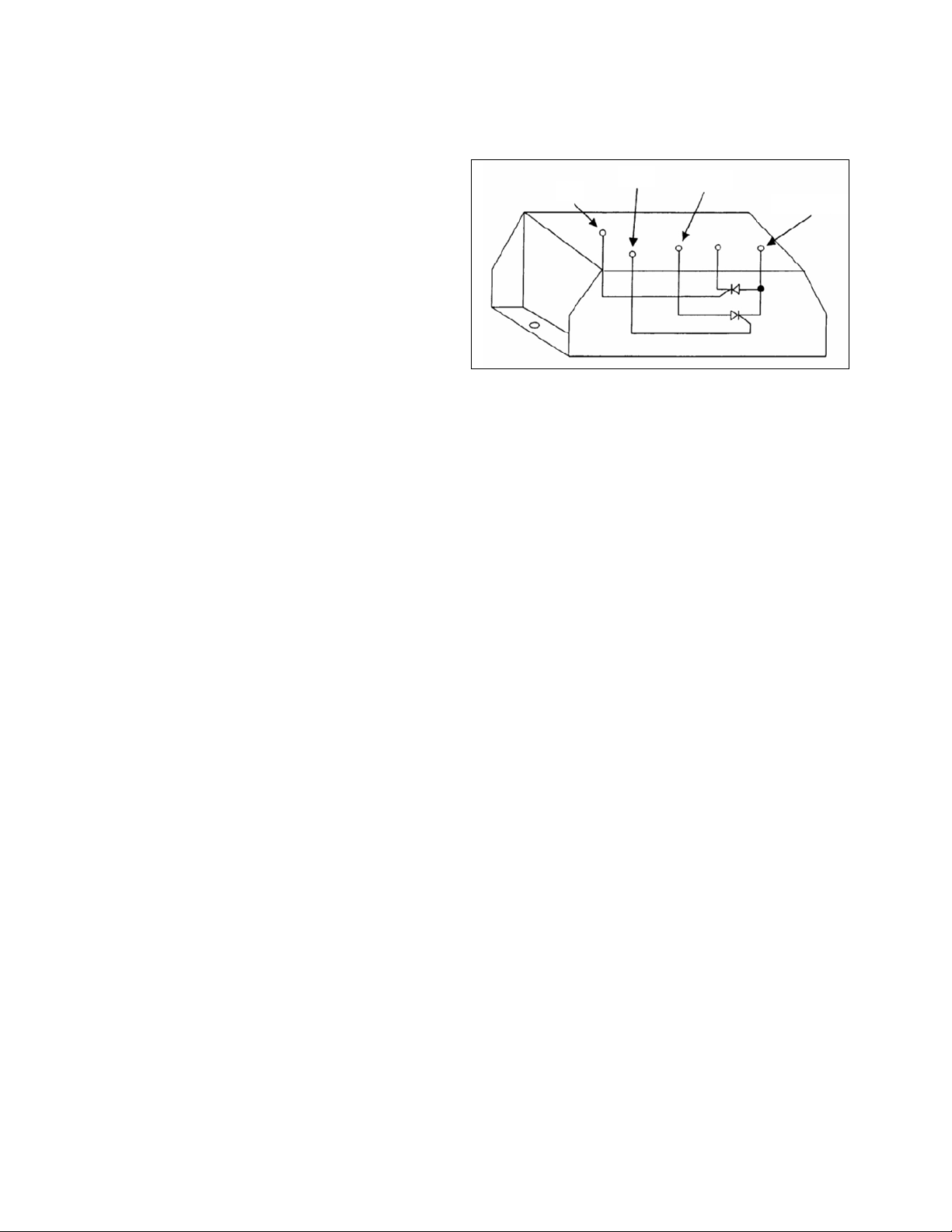

Figure 2. Power module

G2

G1

Shunt

Transformer

3. Measure the following resistance on each power

module. There are seven per phase or 21 for all three

phases. Refer to the circuit diagrams received with

your unit.

ote:N When checking the power module assembly, if more

than one defective power module is present it will

appear as if all the power modules are defective. If

this is the case, the individual power module must be

isolated from the power transformer.

a. K1-1 to K2-1 through K1-7 to K2-7 = High resistance,

1 megohm.

b. K1-1 to G1-1 through K1-7 to G1-7 = 10 to 90 ohms.

c. K1-1 to G2-1 through K1-7 to G2-7 = 1 megohm.

d. K2-1 to G2-2 through K2-7 to G2-7 = 10 to 90 ohms.

e. K2-1 to G1-1 through K2-7 to G1-7 = 1 megohm.

f. G1-1 to G2-1 through G1-7 to G2-7 = 1 megohm.

4. Replace any defective power modules. This may require

removing the shunt and loosening the K1 bus from all

the power modules to get the defective power module

out. Use only equivalent hardware and heat sink grease

when replacing power modules.

5. If a resistance measure is questionable, a more

thorough test will ensure an SCR is good or bad by

using the following test procedure.

a. Completely isolate SCR under test by removing all

connections to the device.

b. Hook up the following test circuit to each individual SCR.

c. Plug in SCR tester. With switch #1 open light bulb

should be off. If not, replace SCR.

d. Close switch #1. Light bulb should illuminate to about

3/4 brilliance. If not, replace SCR. See Figure 3.

8

Instruction manual IM1002004E September 2015 www.powerquality.eaton.com

Page 13

Check the SCR snubber card

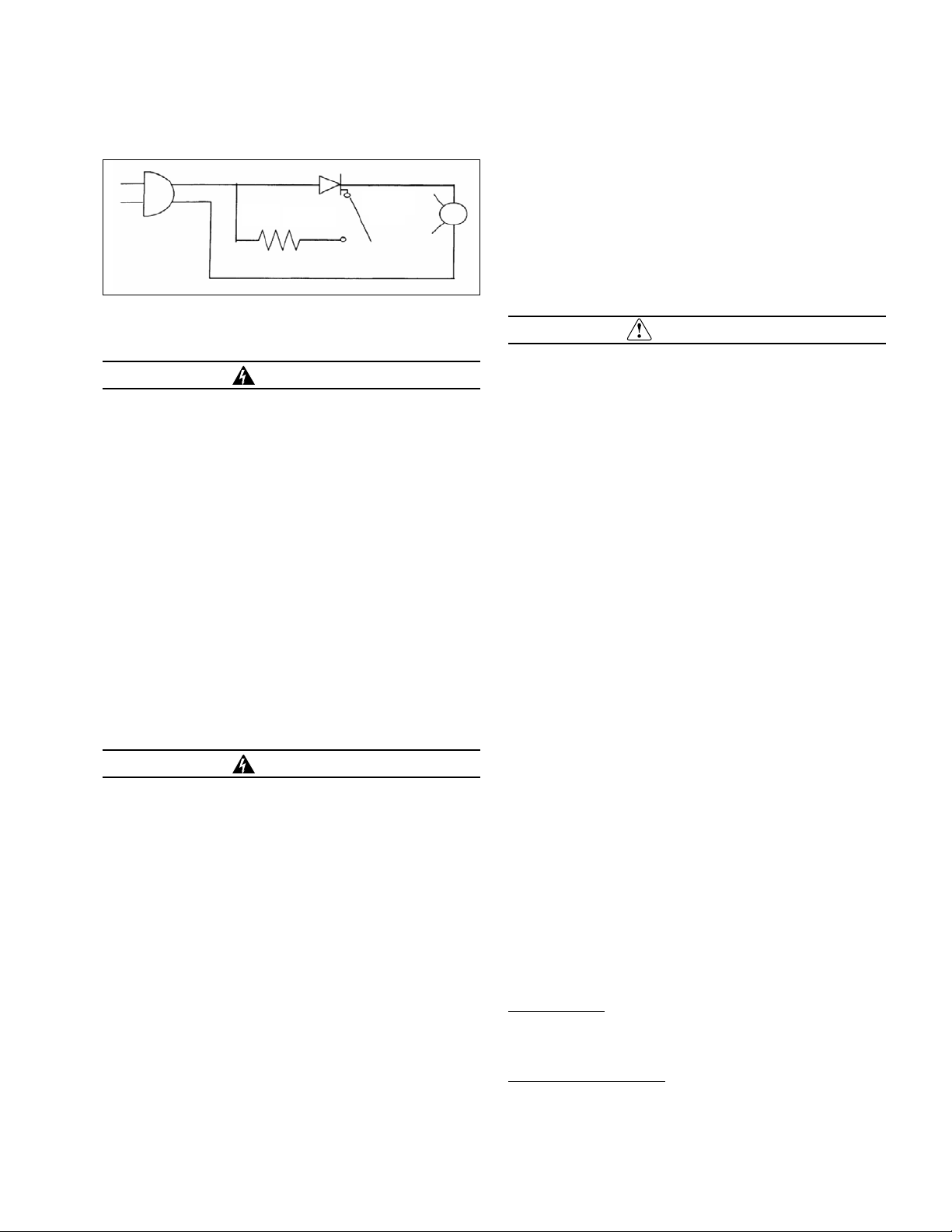

Figure 3. SCR tester

1K Ω 1 Watt

6. Re-assemble the power module assembly, make sure

all connections are tight.

Swi tch 1

WARNING

Do not connect the semi-conductor fuse, wires or fan

wires at this point.

Check the SCR snubber card

1. Three components make up the SCR snubber—

resistors, MOVs, and capacitors. Check for open

resistors. Check MOVs for shorts, they should read

high resistance when ohmmeter is placed across them.

Resistance check each capacitor. The DC resistance

across the snubber capacitor-should look capacitivethat is high resistance after the meter charges the

capacitor. If it measures open or shorted, replace the

snubber card.

2. RE-CONNECT SEMI-CONDUCTOR FUSE, ALL

WIRES, AND FANS. DOUBLE CHECK THAT ALL

CONNECTIONS ARE SECURE.

ote:N Control board # 49120 is for 10 kVA to 50 kVA units.

Control board # 407415 is for 75 kVA and larger.

WARNING

Do not connect TB1, TB2, and TB3 connectors from the

control cards #49120/407415 yet.

Check control card and lter card

1. Verify input to the conditioner matches the unit’s

specification. Also verify correct control board

#49120/407415 jumper setup on page 21.

2. Disable the over/undervoltage shutdown card #35867

(optional card) by removing connectors K1 and K2 on

the card.

3. Turn on AC input breaker to unit.

IMPORTANT

Extreme caution must be taken when measuring voltages

on Molex connectors. Do not press meter leads into

connectors or bend connectors back.

4. Measure the following voltages on wires feeding

the TB1 Molex connector to the control card on all

three phases.

Pins 1 and 3 = 4–6 Vac.

ote:N When the connector is plugged in, this voltage is

around 3 Vac.

Pins 7 and 8 = 120 Vac

If this voltage is incorrect or not present, then check

the fuses associated with the filter card or replace filter

card and re-check voltages.

5. Turn main AC circuit breaker off. Plug in connectors TB1

and TB3 only. On the control card #49120 / 407415 on

all three phases.

6. Turn main AC on. With DC voltmeter on the millivolt

scale, check between TP1 and TP GND of the control

card and adjust pot P2 so meter reads “0” millivolts or

close as possible.

ote:N This step does not apply to control board # 407415.

ote:N Refer to page 21 for test points and pot locations

on control card.

7. Use the following formula to calculate the next

adjustments. You must calculate each input phase for

each control card or a total of three calculations.

a. For phase 1 control card, measure AC input at Line 1

to Line 2.

b. For phase 2 control card, measure AC input at Line 2

to Line 3.

c. For phase 3 control card, measure AC input at Line 1

to Line 3.

Formula

AC Input x 2.47 = Volts DC at TP2

480 (Nominal)

Example

475 Volts AC Input x 2.47 = 2.44 Volts DC at TP2

480 (Nominal)

Instruction manual IM1002004E September 2015 www.powerquality.eaton.com

9

Page 14

Final testing and adjustment

8. After calculations are complete, place DC voltmeter

on the 20 V scale and check between TP2 and TP GND

on control card. Adjust pot P1 so meter reads DC level

calculated in Step 7 for all three phases.

ote:N If adjustments in Steps 6 and 7 are not possible,

replace control card # 49120/407415 and repeat Steps

6 and 8.

ote:N Be sure to turn power off when replacing circuit

boards.

ote:N Be sure AC input is stable when making this

adjustment. If the input changes, you must

re-calculate.

ote:N Output voltage correction is a “stepped correction”,

adjusting P1 will not cause a smooth change in

output voltage as it is adjusted.

9. Turn the unit off. Plug in TB2 Molex connectors to all

the control cards #49120 / 407415.

10. Replace connectors K1 and K2 on over/under detect

#35867.

ote:N P1 pot turned clockwise = decrease in output voltage

and counter-clockwise = increase in output voltage.

By changing this adjustment on phase 1, you may

see the output voltage change from line to neutral

on two phases. It is best to use procedures in

Steps 1–9 adjusting.

Final testing and adjustment

1. Connect AC voltmeter to output of system with proper

meter scale selected.

ote:N On three-phase systems, connect your AC voltmeter

across the output phase to neutral.

2. Disconnect customer’s loads.

3. Energize system.

4. Verify the output is within specifications. If not, adjust

P1 on control board, for the appropriate phase. See

adjustment procedure on page 22.

ote:N On three-phase systems, be sure and check all

three phases.

ote:N If the main AC breaker trips or there is no output

voltage, disable the over/under detect circuit #35867

by disconnecting K1 and K2 connectors, then

calibrate the control boards if the output voltage is

out of spec. See control card adjustment procedure

on page 22.

5. Turn the input circuit breaker off.

6. Connect customer’s equipment.

7. Energize system.

8. Repeat Step 4 and adjust as needed.

9. Be sure over/under detect is connected and if input

breaker trips or there is no output voltage, re-calibrate

the detect board or replace board if defective (see

adjustment procedure on page 22).

10

Instruction manual IM1002004E September 2015 www.powerquality.eaton.com

Page 15

Figure 4. Unit component location diagram

10–15 kVA, 60 Hz, all input voltages

Final testing and adjustment

10–15 kVA, 50 Hz, all input voltages and 25–30 kVA, 60 Hz, all input voltages

Instruction manual IM1002004E September 2015 www.powerquality.eaton.com

11

Page 16

Final testing and adjustment

Figure 5. Unit component location diagram (45–150 kVA, 60 Hz / 30–100 kVA, 50 Hz)

12

Instruction manual IM1002004E September 2015 www.powerquality.eaton.com

Page 17

Figure 6. Power-Sure 700 50K component location

Final testing and adjustment

Instruction manual IM1002004E September 2015 www.powerquality.eaton.com

13

Page 18

Final testing and adjustment

Figure 7. Power-Sure 700 75–150K component location

14

Instruction manual IM1002004E September 2015 www.powerquality.eaton.com

Page 19

Figure 8. Unit component location diagram (225–300 kVA 50/60 Hz, all voltages)

Output

Semi-

Conductor

Output Filtering

Fuses

Multi -

Shielded

Isolation

Transformer

Final testing and adjustment

Rear View

Cabinet Cooling Fan

Output Terminals

Input

Breaker &

Optional

Bypass

Heatsink

Assembly

With Snubber

Card

Heatsink

Assembly

Cooling Fan

Power

Supply

Card

Control

Card

Right Side View

Left Side View Front View

Instruction manual IM1002004E September 2015 www.powerquality.eaton.com

15

Page 20

Final testing and adjustment

Figure 9. Unit component location diagram (500 kVA, 50 Hz and 60 Hz, all voltages)

16

Instruction manual IM1002004E September 2015 www.powerquality.eaton.com

Page 21

Final testing and adjustment

Figure 10. 10–30 kVA heat sink layout

a

a

Heat sink layout does not necessarily follow kVA size shown. Input voltage is also a factor in heat sink layout.

Instruction manual IM1002004E September 2015 www.powerquality.eaton.com

17

Page 22

Final testing and adjustment

Figure 11. 45–150 kVA heat sink layout

a

a

Heat sink layout does not necessarily follow kVA size shown. Input voltage is also a factor in heat sink layout.

18

Instruction manual IM1002004E September 2015 www.powerquality.eaton.com

Page 23

Final testing and adjustment

Figure 12. 225–300 kVA heat sink layout

a

a

Heat sink layout does not necessarily follow kVA size shown. Input voltage is also a factor in heat sink layout.

Instruction manual IM1002004E September 2015 www.powerquality.eaton.com

19

Page 24

Final testing and adjustment

Figure 13. 500 kVA heat sink layout

a

a

Heat sink layout does not necessarily follow kVA size shown. Input voltage is also a factor in heat sink layout.

20

Instruction manual IM1002004E September 2015 www.powerquality.eaton.com

Page 25

Figure 14. Control board #49120/407415

Final testing and adjustment

Instruction manual IM1002004E September 2015 www.powerquality.eaton.com

21

Page 26

Control board measurements

Control board measurements

WARNING

All service to this piece of equipment must be

performed by qualified personnel.

CAUTION

The control board (#49120/407415) is electrically referenced

to high voltage, not earth or chassis ground. Extreme care

must be used when taking measurements on the control

board. Any AC powered instruments must be ground

isolated prior to taking measurements. A ground isolated

instrument case will be at the high voltage line potential.

Measurement procedure

Verify the L–N for each phase is ±3% of the nominal

voltage. If the voltage measurement is out of range,

consult factory.

Parts kits

Table 5. 50 and 60 Hz, all voltages

kVA size Kit price (U.S. funds)

10 kVA Consult factory

15 kVA Consult factory

25–50 kVA Consult factory

75 kVA Consult factory

100–125 kVA Consult factory

150 kVA Consult factory

225 kVA Consult factory

300 kVA Consult factory

500 kVA Consult factory

ote:N Each parts kit includes the following:

(7) Power modules (SCRs)

(3) Semiconductor Fuses

(1) Fusible link (for one full phase)

(2–4) Fan motors (depending on unit size)

(1) SCR snubber board

(3) Sense fuses

(1) Main control board

Replacement parts

Individual components are also available upon request.

Please contact the factory for specific part numbers

and prices. See “Unit component location diagrams”

on page 11–page 16 for component location and

description. When contacting Application Support, please

have the unit’s full model number and serial or system

number. Call 1-800-809-2772, option 4, and then option 2.

22

Instruction manual IM1002004E September 2015 www.powerquality.eaton.com

Page 27

Technical diagrams

Figure 15. Generic circuit diagram—primary SCR—no bypass

Technical diagrams

Instruction manual IM1002004E September 2015 www.powerquality.eaton.com

23

Page 28

Technical diagrams

Figure 16. Generic circuit diagram—primary SCR—with bypass

24

Instruction manual IM1002004E September 2015 www.powerquality.eaton.com

Page 29

Figure 17. Generic circuit diagram—secondary SCR—no bypass

Technical diagrams

Instruction manual IM1002004E September 2015 www.powerquality.eaton.com

25

Page 30

Technical diagrams

Figure 18. Generic circuit diagram—secondary SCR—with bypass

26

Instruction manual IM1002004E September 2015 www.powerquality.eaton.com

Page 31

Figure 19. Installation diagram—Power-Sure 700 10–15 kVA with optional bypass

Technical diagrams

Instruction manual IM1002004E September 2015 www.powerquality.eaton.com

27

Page 32

Technical diagrams

Figure 20. Installation diagram—Power-Sure 700 10–30 kVA with optional meter and bypass

28

Instruction manual IM1002004E September 2015 www.powerquality.eaton.com

Page 33

Figure 21. Installation diagram—Power-Sure 700 45K with optional meter and bypass

Technical diagrams

Instruction manual IM1002004E September 2015 www.powerquality.eaton.com

29

Page 34

Technical diagrams

Figure 22. Installation diagram—Power-Sure 700 50K with bypass and optional meter

30

Instruction manual IM1002004E September 2015 www.powerquality.eaton.com

Page 35

Technical diagrams

Figure 23. Installation diagram—Power-Sure 700 50K with bypass and optional meter (top and bottom view)

Instruction manual IM1002004E September 2015 www.powerquality.eaton.com

31

Page 36

Technical diagrams

Figure 24. Installation diagram—Power-Sure 700 75–150K with bypass and optional meter

32

Instruction manual IM1002004E September 2015 www.powerquality.eaton.com

Page 37

Technical diagrams

Figure 25. Installation diagram—Power-Sure 700 75–150K with bypass and optional meter (top and bottom view)

Instruction manual IM1002004E September 2015 www.powerquality.eaton.com

33

Page 38

Technical diagrams

Figure 26. Installation diagram—Power-Sure 700 225–300K with bypass and optional meter

34

Instruction manual IM1002004E September 2015 www.powerquality.eaton.com

Page 39

Figure 27. Installation diagram—Power-Sure 700 500K with bypass and optional meter

Technical diagrams

Instruction manual IM1002004E September 2015 www.powerquality.eaton.com

35

Page 40

Cabinet dimensions

Cabinet dimensions

Table 6. Power-Sure 700 unit cabinet sizes

kVA

rating Bypass Metering

10 Yes No 30.2 x 22.2 x 29.0 1,025 440

10 Yes Ye s 44.2 x 22.2 x 29.0 1,205 520

15 Yes No 30.2 x 22.2 x 29.0 1,540 465

15 Yes Ye s 44.2 x 22.2 x 29.0 1,540 700

25 Yes Ye s 44.2 x 22.2 x 29.0 2,560 700

30 Yes Ye s 44.2 x 22.2 x 29.0 3,090 720

45 Yes Ye s 44.3 x 45.9 x 29.0 4,600 950

50 Yes Ye s 66.0 x 29.0 x 35.5 7,332 1,176

75 Yes Ye s 76.0 x 34.4 x 35.5 9,514 1,575

100 Yes Yes 76.0 x 34.4 x 35.5 11,833 2,014

125 Yes Yes 76.0 x 34.4 x 35.5 14,748 2,137

150 Yes Yes 76.0 x 34.4 x 35.5 17,698 2,240

225 Yes Yes 77.4 x 56.0 x 41.5 23,000 3,300

300 Yes Yes 77.4 x 56.0 x 41.5 30,750 4,000

500 Yes Yes 77.0 x 72.4 x 48.4 51,250 5,500

Manual bypass switch

The manual bypass switch is a break-before-make switch

located on the Power-Sure 700. The manual bypass switch

is used to bypass all power electronics in case of failure.

Bypass is standard on 50 kVA and larger units and an option

on 45 kVA and smaller units.

ote:N This switch may be added in the field.

Cabinet size

H x W x D (in) BTUs/Hr Weight (Lb)

Normal mode

With the switch in the normal position, the Power-Sure 700

will provide clean and regulated power to the critical loads.

The Power-Sure 700 should have the switch in the normal

position unless a failure has occurred.

These units are sold in accordance to Eaton

Selling Policy 25-000.

36

Instruction manual IM1002004E September 2015 www.powerquality.eaton.com

Page 41

Bypass mode

Bypass mode

With the switch in the bypass position, the Power-Sure 700

will provide clean power to the critical loads. In the bypass

position, the unit will not regulate the incoming voltage. The

transformer and suppression circuitry remains in the circuit

when in the bypass mode. The Power-Sure 700 should be

placed in the bypass position when a failure of the system

has occurred. This provides the user with some protection

until a service technician arrives.

CAUTION

Prior to switching from one position to another, turn off the

AC input breaker. Some systems are equipped with pushto-turn switches. With these switches, the switch will shunt

trip the input breaker when pressed in.

Standard monitoring

Overtemp sensing devices are mounted at critical points on

the SCR regulating assembly and the main transformer. If

an overtemp condition exists, the unit will electronically shut

off; however, the cooling fans will continue to operate. The

“ALERT” light will illuminate and hold until the overtemp is

corrected. The main AC input breaker must be turned off in

order to reset the “ALERT” light.

Alert light—An indicator light indicates if the output has

been disabled by one of the following conditions:

(1) Transformer over-temperature

(2) SCR thermal over-temperature

Indicating lamps—Output ON indicating lamps are

provided for each phase.

Metering option

The Power-Sure 700 offers two metering options. The IQ 130

meter is the standard option on the Power-Sure 700. The

IQ 130 has programmable voltage, current transformer

ratios, and true rms indication for accurate measurement

of distorted waveforms, which can be viewed through

four screens via a high visibility LED display. Installation

and operation instructions for this meter can be found in

Instructional Leaflet IL02601002E. The premium metering

option is the IQ 150—which offers all the features of the

IQ 130, along with energy, power, communications ability,

and many other enhanced features. Please refer to Technical

Data TD02601025E for additional information.

Warranty

Eaton warrants the Power-Sure 700 to be free from defects

in material and workmanship for a period of one year from

the shipment date. The warranty includes parts only during

this time.

These units are sold in accordance to Eaton Selling

Policy 25-000.

Instruction manual IM1002004E September 2015 www.powerquality.eaton.com

37

Page 42

Warranty

Figure 28. Performance Checklist

38

Instruction manual IM1002004E September 2015 www.powerquality.eaton.com

Page 43

Instruction manual IM01002002E September 2015 www.eaton.com

39

Page 44

At Eaton, we’re energized by

the challenge of powering a

world that demands more. With

over 100 years experience in

electrical power management,

we have the expertise to see

beyond today. From groundbreaking products to turnkey

design and engineering services,

critical industries around the

globe count on Eaton.

We power businesses with

reliable, efcient and safe

electrical power management

solutions. Combined with our

personal service, support and

bold thinking, we are answering

tomorrow’s needs today.

Follow the charge with Eaton.

Visit eaton.com/electrical.

Eaton

1000 Eaton Boulevard

Cleveland, OH 44122

United States

Eaton.com

© 2015 Eaton

All Rights Reserved

Printed in USA

Publication No. IM1002004E / Z17152

September 2015

Eaton is a registered trademark.

All trademarks are property

of their respective owners.

Loading...

Loading...