Eaton Motor Insight C441 Product Installation Leaflet

Installation Leafl et IL04209007E-HVR

Supersedes March 2011

C441 Motor Insight™ Overload Relay (120V

Control Powered) Product Installation Leafl et

Effective May 2011

DANGER

HAZARDOUS VOLTAGE CAN CAUSE ELECTRIC SHOCK AND

BURNS. TO AVOID SHOCK HAZARD, DISCONNECT ALL POWER

BEFORE ANY WORK IS PERFORMED ON THIS DEVICE. FAILURE

TO DO SO WILL RESULT IN PERSONAL INJURY, DEATH OR

SUBSTANTIAL PROPERTY DAMAGE

AVERTISSEMENT

UNE TENSION ÉLECTRIQUE DANGEREUSE PEUT CAUSER DES

CHOCS ÉLECTRIQUES ET DES BRÛLURES. POUR ÉVITER DES

CHOCS ÉLECTRIQUES, DÉBRANCHER L’ALIMENTATION AVANT

D’Y EFFECTUER DU TRAVAIL. L’INOBSERVATION DE CES

INSTRUCTIONS ENTRAÎNERA DES BLESSURES CORPORELLES

GRAVES, LA MORT OU DES DÉGÂTS MATÉRIELS SUBSTANTIELS.

Voltage Ratings

Motor Insight overload relay is powered by 120V control

power between X1 - X2. This voltage range for the various models is given in the following table.

Table 1. Voltage Range

Nominal Rating Catalog

Number

CONTROL POWER

INPUT

C441P3309NOUI-HVR

C441059ONOUI-HVR

110 - 120V

Line Voltage C441P3309NOUI-HVR

C441059ONOUI-HVR

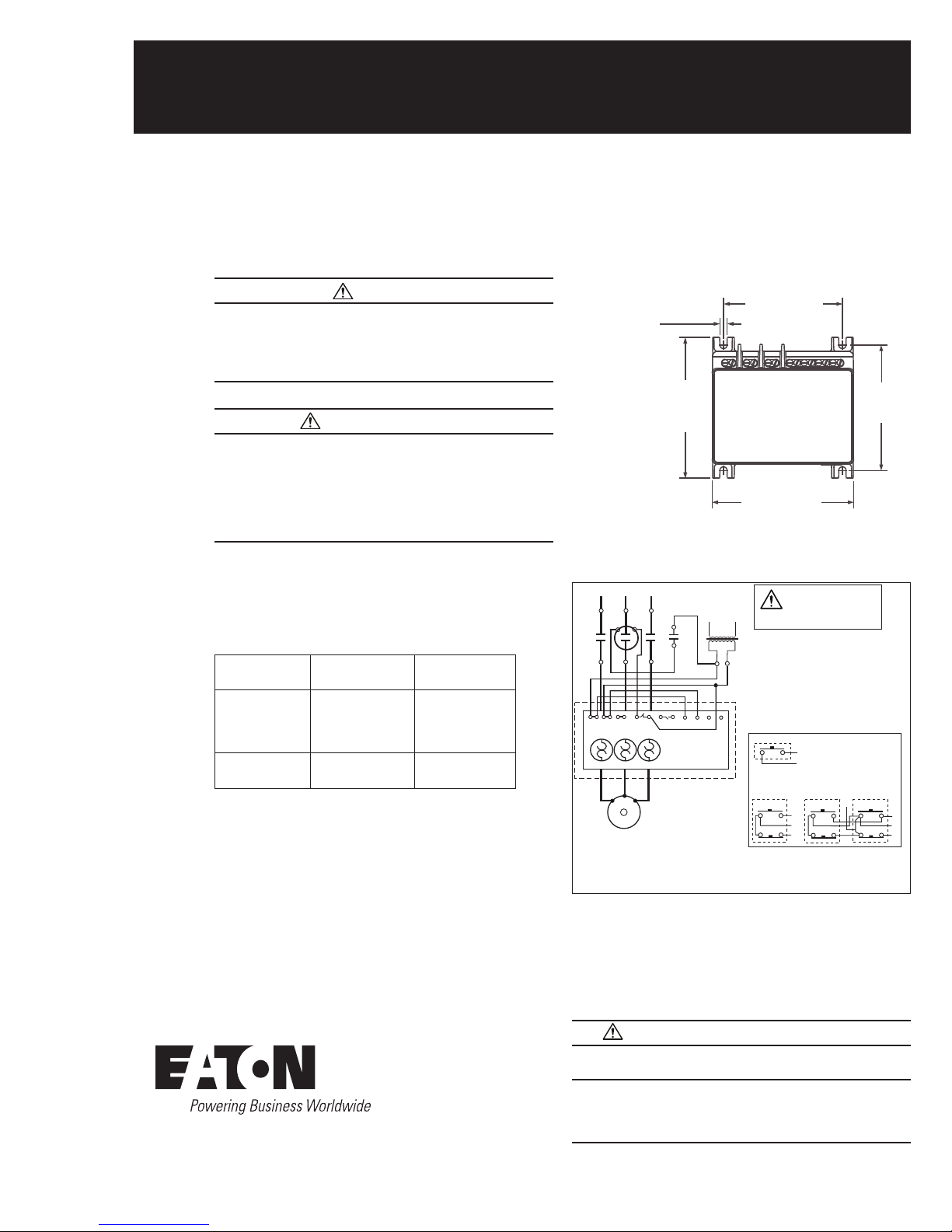

Wiring

Pass motor leads through Motor Insight overload relay

CT pass through. If multiple passes of the motor leads

are required, make sure that the current flow is from

top to bottom through Motor Insight overload relay. If

external CTs are used, pass the 5 amp secondary of the

external CTs through Motor Insight overload relay internal CTs. See Table 3A for wrap and CT multiplier.

Voltage

110 - 120 Vac;

(50/60 Hz)

+10% - 15%

0 - 1200Vac

0.20

3.31 (84.1)

(5.1)

4 Places

3.90

(99.1)

3.50

(88.9)

3.90 (99.1)

Figure 1. Mount with 10-32 Hardware Torque to 25

in-lb.

1 / L1 3 / L2 5 / L3

A1 A2

M

2/T1 4/T2

L X1 N X2 95 96 97 98 X1 X2 R1 R2

T2

T1

3 PHASE

AC MOTOR

NOTE:

X1, X2 - 120V Control Power Input.

R1, R2 - 120V RESET INPUT

2/13

3/14

6/T3

T3

CPT

120V

ATTENTION

CONTROL CIRCUITS ARE B300 RATED USE A

CPT AND SEPRATATE CONTROL WHEN LINE

VOLTAGE IS ABOVE 240VAC.

REMOTE PILOT DEVICES

2 WIRE CONTROL

NOT FOR USE

WITH AUTO RESET

OL RELAYS.

3 WIRE CONTROL

START

STOP

3

1

WHEN MORE THAN ONE

PUSH BUTTON STATION IS

USED OMIT CONNECTOR

A AND CONNECT PER

SKETCH BELOW.

START

3

2

STOP

1

A

START

STOP

Figure 2. Typical Starter Application Sample Wiring

Diagram

Motor Insight overload relay is factory set for manual

reset operation. See Table 5 for automatic reset opera-

tion.

3

2

1

WARNING AVERTISSEMENT

AUTOMATIC RESET IS NOT INTENDED FOR TWO-WIRE CONTROL DEVICES.

CE DISPOSITIF DE REENCLENCHEMENT AUTOMATIQUE NE

CONVIENT PAS AUX COMMANDES À DEUX

CONDUCTEURS.

Installation Lea et IL04209007E-HVR

Effective May 2011

C441 Motor Insight™ Overload Relay (120V

Control Powered) Product Installation Leafl et

Terminal Connections

Motor Insight overload relay provides the following terminal connections. NC 95/96 contact is open when the device is unenergized.

USE 75°C CU WIRE ONLY

* No Motor Loads, 9A Max

120VAC Control Power 50/60 Hz

L

N

X1

X2

18-12 AWG Torque 0.6 Nm/5.3 lb-in.

B300 PILOT DUTY ONLY

NC NO CTRL PWR RESET

95 96 97 98 X1 X2 R1

120VAC

120VAC

120VAC

R2

Figure 3. Terminal Connection Diagram

Table 2. Terminal Connection Specifications

Name Designation Input Description

L1, L2

Control Power

L, N

Fault Relay 95/96 UL® 508

Programable

97/98 UL® 508

Auxiliary Relay*

Reset

Input

R1

R2

* See section 6.7 of Users Manual MN04209001E for instructions to configure the programmable auxiliary relay, which changes the behavior of the relay

from the default and allows for greater flexibility and alarming.

93.5 - 132Vac Voltage input

- X1*, X2*, = 120V

- Tie X1 to X1

- Tie X2 to X2

- Inputs should have short circuit

protection

- Terminal provided for wiring

control power transformer

(9A maximum capacity).

- 95/96 Contact opens when the unit

B300

is faulted or unpowered.

-97/98 Contact closes when the unit

B300

120 Vac

is faulted or unpowered.

Fault Reset Input.

+10%/-15%

CAUTION!

THE OPENING OF BRANCH-CIRCUIT PROTECTIVE DEVICE MAY BE AN INDICATION THAT A FAULT HAS BEEN INTERRUPTED. TO REDUCE THE RISK OF

FIRE OR ELECTRIC SHOCK, CURRENT-CARRYING PARTS AND OTHER COMPONENTS OF THE CONTROLLER SHOULD BE EXAMINED AND REPLACED

IF DAMAGED. IF BURNOUT OF THE ELEMENT OF AN OVERLOAD RELAY

OCCURS, THE COMPLETE OVERLOAD RELAY SHOULD BE REPLACED.

ATTENTION

LE DÉCLENCHEMENT DU DISPOSITIF DE PROTECTION DES DÉRIVATIONS

PEUT SIGNIFIER QU’UN COURANT DE DÉFAUT A ÉTÉ INTERROMPU. POUR

RÉDUIRE LE RISQUE D’INCENDIE OU DE CHOC ÉLECTRIQUE, LES PIÈCES

PORTEUSES DE COURANT ET LES AUTRES COMPOSANTS DE LA COMMANDE DOIVENT ÊTRE VÉRIFIÉS ET REMPLACÉS S’ILS SONT ENDOMMAGÉS. SI L’ÉLÉMENT PORTEUR DE COURANT DU RELAIS DE SURCHARGE

GRILLE, LE RELAIS DE SURCHARGE ENTIER DOIT ÊTRE REMPLACÉ.

Initial Configuration

On initial power-up, Motor Insight overload relay displays a “rOF”

message. This indicates that the fault relay is OFF. Configure the

device for the application prior to resetting the device.

To turn the fault relay OFF, press the Trip button.

Programming Set Points

Motor Insight overload relay is easy to configure. Viewing and

editing protection set points can be performed in the Protection

and Operation Mode. The following steps outline the procedure

for modifying any of the set points.

Step 1: Press Mode button until Protection or Operation

Mode Led is lit.

Mode

Step 2: Press Up or Down button until the desired O/P LED

is lit. Display shows the current parameter value.

110

Step 3: Press the Edit/Save button. The display now shows

the parameter value but is now flashing.

Edit/Save

Step 4: Use the Up/Down button to adjust the parameter

to the desired value.

Step 5: Press the Edit/Save button. The Display now shows

the new parameter value that has been saved by the device.

Edit/Save

110

120

120

Configuring the Thermal Overload Protection Feature

Motor Insight overload relay features electronic motor overload protection. This feature protects the motor and power wiring against

overheating caused by excessive current for extended periods

of time.

The trip current is programmed by entering the motor full load

amperes (FLA) using the Motor FLA parameter. The trip class

(5 to 30) is set using the Trip Class parameter.

The FLA range of the overload relay can be modified with the use

of multiple turns through the CTs or with the use of external CTs.

Use the following tables to appropriately configure the device for the

application. If the application requires the FLA range to be extended,

program the CT multiplier first.

Table 3A. FLA Range

Current

Range

Catalog

Number

Motor

FLA

.33 – 9 C441P3309NOUI-HVR .33 - 1.5

.4 - 1.8

.5 - 2.25

.67 - 3.0

1 – 5

2 – 9

60 – 135

120 – 270

240 – 540

5 – 90 C441059ONOUI-HVRI 5 – 22.5

6.67 – 30

10 – 45

20 – 90

Conductors

Through CT

6

5

4

3

2

1

1

1

1

4

3

2

1

CT

Multiplier

6

5

4

3

2

1

150 - (150:5)

300 - (300:5)

600 - (600:5)

4

3

2

1

Important Note: After an overload trip, Motor Insight relay cannot be reset

until the thermal model decays to a thermal capacity that is thermally safe for

a motor restart. Cycling the power does not reset the thermal model.

Table 3B. Service Factor FLA Setting

Number of

Service Factor Motor FLA Setting

>1.15 Enter the motor nameplate FLA

=1.10 Enter the FLA as (1.1* nameplate FLA/1.15)

2

EATON CORPORATION www.eaton.com

Loading...

Loading...