Eaton COOPER POWER Series, MN202002EN Installation, Operation, And Maintenance Instructions And Parts Replacement Information

COOPER POWER

SERIES

Substation

Transformers

MN202002EN

Effective June 2016

Supersedes S210-15-10 February 2013

Substation transformer installation, operation, and maintenance

instructions and parts replacement information

DISCLAIMER OF WARRANTIES AND LIMITATION OF LIABILITY

The information, recommendations, descriptions and safety notations in this document are based on Eaton Corporation’s

(“Eaton”) experience and judgment and may not cover all contingencies. If further information is required, an Eaton sales

office should be consulted. Sale of the product shown in this literature is subject to the terms and conditions outlined in

appropriate Eaton selling policies or other contractual agreement between Eaton and the purchaser.

THERE ARE NO UNDERSTANDINGS, AGREEMENTS, WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING WARRANTIES

OF FITNESS FOR A PARTICULAR PURPOSE OR MERCHANTABILITY, OTHER THAN THOSE SPECIFICALLY SET OUT IN ANY

EXISTING CONTRACT BETWEEN THE PARTIES. ANY SUCH CONTRACT STATES THE ENTIRE OBLIGATION OF EATON. THE

CONTENTS OF THIS DOCUMENT SHALL NOT BECOME PART OF OR MODIFY ANY CONTRACT BETWEEN THE PARTIES.

In no event will Eaton be responsible to the purchaser or user in contract, in tort (including negligence), strict liability or otherwise for any special, indirect, incidental or consequential damage or loss whatsoever, including but not limited to damage or

loss of use of equipment, plant or power system, cost of capital, loss of power, additional expenses in the use of existing

power facilities, or claims against the purchaser or user by its customers resulting from the use of the information, recommendations and descriptions contained herein. The information contained in this manual is subject to change without notice.

ii SubStation tranSformer inStallation and partS replacement information MN202002EN JUNE 2016

Contents

DISCLAIMER OF WARRANTIES AND LIMITATION OF LIABILITY ................................... II

SAFETY FOR LIFE .........................................................................IV

SAFETY INFORMATION ....................................................................IV

Safety instructions .............................................................................. iv

PRODUCT INFORMATION ................................................................... 1

Introduction ....................................................................................1

Acceptance and initial inspection ...................................................................1

Handling .......................................................................................1

Storage .......................................................................................1

Quality standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

INSTALLATION ............................................................................ 2

Installation location ..............................................................................2

Connections ....................................................................................2

Final inspection .................................................................................2

ACCESSORIES ............................................................................ 4

Liquid level gauge ...............................................................................4

Liquid temperature gauge .........................................................................4

Pressure-vacuum gauge ..........................................................................5

Pressure relief device ............................................................................5

Winding temperature gauge .......................................................................6

Transformer cooling fans ..........................................................................6

High voltage bushings ............................................................................7

Low voltage bushings ............................................................................7

De-energized tap-changer .........................................................................8

Insulating liquid .................................................................................8

Vacuum fault interrupter (VFI) ......................................................................9

MAINTENANCE ...........................................................................11

Periodic inspection .............................................................................11

Removing and replacing bushings ..................................................................11

Removing and replacing draw lead type bushings .....................................................11

Removing and replacing fixed stud or spade type bushings ..............................................12

Cover removal .................................................................................13

Insulating liquid maintenance .....................................................................14

APPLICABLE STANDARDS ................................................................. 14

R-TEMP FLUID-FILLED TRANSFORMERS ..................................................... 14

Dielectric strength ..............................................................................14

PEAK™ AND ENVIROTEMP™ FR3™ FLUID-FILLED TRANSFORMERS ............................. 15

Spare parts and service ..........................................................................15

PREVENTATIVE MAINTENANCE INSTRUCTIONS .............................................. 16

iiiSubStation tranSformer inStallation and partS replacement information MN202002EN JUNE 2016

!

SAFETY

FOR LIFE

Eaton meets or exceeds all applicable industry standards relating to product safety in its Cooper Power™ series products.

We actively promote safe practices in the use and maintenance of our products through our service literature, instructional

training programs, and the continuous efforts of all Eaton employees involved in product design, manufacture, marketing,

and service.

We strongly urge that you always follow all locally approved safety procedures and safety instructions when working around

high voltage lines and equipment, and support our “Safety For Life” mission.

Safety for life

!

SAFETY

FOR LIFE

Safety information

The instructions in this manual are not intended as a

substitute for proper training or adequate experience in the

safe operation of the equipment described. Only competent

technicians who are familiar with this equipment should

install, operate, and service it.

A competent technician has these qualifications:

• Is thoroughly familiar with these instructions.

• Is trained in industry-accepted high and low-voltage safe

operating practices and procedures.

• Is trained and authorized to energize, de-energize, clear,

and ground power distribution equipment.

• Is trained in the care and use of protective equipment

such as arc flash clothing, safety glasses, face shield, hard

hat, rubber gloves, clampstick, hotstick, etc.

Following is important safety information. For safe installation and operation of this equipment, be sure to read and

understand all cautions and warnings.

Hazard Statement Definitions

This manual may contain four types of hazard statements:

DANGER

Indicates an imminently hazardous situation which, if

not avoided, will result in death or serious injury.

WARNING

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

CAUTION

Indicates a potentially hazardous situation which, if not

avoided, may result in equipment damage only.

Safety instructions

Following are general caution and warning statements that

apply to this equipment. Additional statements, related to

specific tasks and procedures, are located throughout the

manual.

DANGER

Hazardous voltage. Contact with hazardous voltage will

cause death or severe personal injury. Follow all locally

approved safety procedures when working around highand low-voltage lines and equipment.

G103.3

WARNING

Before installing, operating, maintaining, or testing this

equipment, carefully read and understand the contents

of this manual. Improper operation, handling or

maintenance can result in death, severe personal injury,

and equipment damage.

G101.0

WARNING

This equipment is not intended to protect human

life. Follow all locally approved procedures and safety

practices when installing or operating this equipment.

Failure to comply can result in death, severe personal

injury and equipment damage.

G102.1

WARNING

Power distribution and transmission equipment must

be properly selected for the intended application. It

must be installed and serviced by competent personnel

who have been trained and understand proper safety

procedures. These instructions are written for such

personnel and are not a substitute for adequate training

and experience in safety procedures. Failure to properly

select, install or maintain power distribution and

transmission equipment can result in death, severe

personal injury, and equipment damage.

G122.3

iv SubStation tranSformer inStallation and partS replacement information MN202002EN JUNE 2016

Product information

CAUTION

Do not Exceed Transformer Ratings. Transformers

should be operated only at the ratings specified on the

transformer nameplate. Prolonged overload operation

will measurably shorten the projected service life of a

mineral oil-filled transformer. Eaton’s Cooper Power™

series PEAK™ transformers may help to extend

insulation life and can be operated at higher capacities

than traditional units while still exceeding ANSI

standard insulation life.

Introduction

This manual has been prepared to assist competent technicians in the installation, operation and service of primary or

secondary unit- or open-type substation trans-formers.

Substation transformers are designed for installation on

three-phase systems. All units are constructed for in-door

or outdoor mounting on a concrete pad with high and low

voltage cables entering operating compartments through

enclosed sidewall mounted bushings (unit-type transformers) or through cover or sidewall mounted bushings (opentype transformers).

Although every effort has been made to anticipate normal

installation, operation and servicing problems, these instructions do not cover all possible variations in equipment or

application conditions. All possible installation, operation or

service contingencies are not discussed. If additional information is required, contact a factory representative.

It is important that personnel using these instructions

be fully acquainted with industry accepted high and low

voltage safe operating practices and procedures. These

instructions are not intended as a substitute for proper

training or adequate experience in the safe operation of the

equipment described.

®

2. Before unloading the transformer, make an inspection to

detect any signs of damage or mishandling. Locate any

accessory parts that may have been shipped separately.

3. If any damage is detected or shortages are noticed,

write a brief description on the freight bill. Normally, the

transformer is shipped FOB point of manufacture, and

it is the customer's responsibility to file a claim against

the carrier. If the transformer was shipped FOB destination, notify your factory representative. He or she will,

with the inspector's report, take the necessary steps to

file a claim against the carrier.

Handling

For unloading, lifting hooks are provided near the top of the

transformer tank. Cable pull angles should not be over 30°

from vertical. Otherwise, spreaders should be used to hold

the lifting cables apart to avoid any bending of the structure

or lifting hooks.

WARNING

Do not attempt to lift the transformer by placing a continuous loop of cable or chain around the unit or lifting

lugs. Improper handling can result in death, severe personal injury and equipment damage.

If the transformer cannot be lifted by crane, it may be

skidded or moved with rollers. When jacking a transformer

to insert rollers underneath it, insure that at least two jacks

are used and that two adjacent corners are raised simultaneously and evenly to avoid warping the base. Jacks may be

placed only at the corners of the transformer base.

Do not place jacks under cooler assemblies, valves, or sheet

metal parts. When using rollers, use as many as necessary

to distribute the weight uniformly. To pull, attach pulling eyes

to the holes in the base at either end of the transformer.

Do not attach pulling lines to moldings or other sheet metal

parts of the transformer.

Read this manual first

Read and understand the contents of this manual and follow

all locally approved procedures and safety practices before

installing or operating this equipment.

Additional information

These instructions cannot cover all details or variations in

the equipment, procedures, or process described, nor to

provide directions for meeting every possible contingency

during installation, operation, or maintenance. For additional

information, contact your Eaton representative.

Acceptance and initial inspection

It is important that a thorough inspection of the transformer

be made before it is unloaded from the carrier.

1. Ensure that all parts listed on the bill of lading are

present.

Storage

Whenever possible, the transformer should be stored at its

permanent location.

The insulating liquid should be at its proper level and the

gas space pressurized with dry nitrogen to approximately

two psig. Then it should be tightly sealed so that no

moisture or air can enter the tank. Periodic inspection

should determine that the pressure gauge does not remain

at zero, and proper liquid level is maintained at all times.

The transformer should not be stored in the presence of

corrosive gases (e.g., chlorine). Exterior surfaces of the transformer should be maintained against rust and corrosion.

Before placing a transformer into service after an ex-tended

storage time, check fans, alarm and control circuits, and the

dielectric strength of the insulating liquid.

Quality standards

ISO 9001 certified quality management system

1SubStation tranSformer inStallation and partS replacement information MN202002EN JUNE 2016

Installation

Installation location

The transformer should be located on a concrete pad of

sufficient strength to support the weight of the unit. The

pad must be level. The location of the transformer, whether

indoor or outdoor, should provide for adequate accessibility,

ventilation and ease of inspection. The transformer should

be at least 24 inches from any obstruction. These are

the recommendations of the manufacturer for operation

purposes; see your local codes for additional guidelines.

Location in areas of corrosive chemicals should be avoided.

These substation transformers are built to operate at

altitudes up to 3300 feet at 30°C average and 40°C

maximum ambient, unless otherwise specified. Before

operating a standard transformer at higher altitudes, contact

your factory representative.

Adequate ventilation must be provided. For indoor

installations, room air inlets should be located at floor level;

the air outlets should be located as high as the room will

permit. The number and size of the air inlets depends upon

the rating of the transformer. In general, about 20 square

feet each of inlet and outlet area should be provided for

each 1000 kVA of transformer capacity. If the ventilation

system is adjustable, it should be locked permanently open

to avoid overheating of the transformer in case of operator

error.

Connections

Connections must be made without placing undue stress

on the bushing terminals. Conductors should be securely

fastened in place and supported properly, with allowance

for expansion and contraction. Make sure that the tap

connection is proper for the required voltage. Changes in

tap connections must be done ONLY with the transformer

high voltage and low voltage circuits completely

"DE-ENERGIZED". Safely verify that there is no voltage

present at the terminals.

WARNING

Do not change connections on a transformer that is

energized. Ground all circuits before making any transformer connection. Failure to observe precautions when

making connections can result in exposure to high voltages, which can cause death, severe personal injury or

damage to the equipment.

WARNING

Do not make any connections, except as authorized by

the nameplate or schematic. Improper connections

can result in severe personal injury and damage to the

equipment.

Transformers equipped with an internal terminal board are

normally shipped with the higher voltage connected, unless

otherwise specified by the customer.

A secure and effective low resistance ground is essential

for protection. The transformer must be grounded permanently by connecting a heavy ground cable to the ground

pad located at the bottom of the tank. If the transformer is

designed for operation in a solidly grounded neutral system,

the neutral connection should be solidly and permanently

grounded with minimum resistance.

WARNING

Improper grounding may result in personal injury or

damage to the equipment.

Lightning arresters are recommended for every trans-former

installation. Arresters of proper rating should be located as

close as possible to the transformer terminations.

When alarm contacts or controls are supplied with the

transformer accessories, a connection box may be provided

to facilitate termination of the customer's cable or conduit.

Final inspection

The final inspection can be done in three major steps:

Electrical, Internal and External.

WARNING

Do not tamper with interlocks, alarm or control circuits.

Doing so can produce unsafe conditions for operators or

result in damage to the equipment.

Electrical inspection should determine that:

1. All external connections have been made properly

(phasing of connections to terminal bushings, etc.).

2. All connections are tight and secure.

3. All accessory contact circuits are operational.

4. Current transformer circuits, if supplied, have secondaries either shorted or connected through their load.

5. Tap changer is operative and properly positioned.

6. The correct transformer ratio exists for units furnished

with internal terminal board.

7. There is no grounding of windings that are not

intended to be grounded. A 1000-volt megger test is

recommended.

8. There is continuity in all windings.

9. The dielectric strength of the insulating liquid is

30 kV minimum when new. (Refer to section for

"Testing Insulating Liquid" in this manual.)

10. The neutral and ground connections have been properly

made.

2 SubStation tranSformer inStallation and partS replacement information MN202002EN JUNE 2016

If an internal inspection is required, assure that:

1. There is no evidence of moisture.

2. All available bolted connections are tight.

3. There has been no shifting of any parts or any other

damage.

The external inspection should determine that:

1. All scratches have been painted.

2. The bushings are clean.

3. The accessories are operative.

4. There are no tools, or other objects, left on top of the

transformer or inside any enclosure.

5. The liquid level is correct.

6. The transformer holds positive pressure.

7. The manhole covers are tightly bolted.

8. All protective covers are closed and bolted tight.

9. The mechanical pressure relief device is reset.

CAUTION

Whenever it is necessary to open a liquid-filled transformer, insure that the liquid temperature is higher

than the outside air temperature. Otherwise, internal

moisture condensation may occur, which could lead to

failure of the transformer.

CAUTION

Before breaking the seal of any handhole, manhole or

bushing hole, bleed internal pressure to zero. Seals

should not be broken in the presence of fog, rain or

snow, or if there is any evidence of condensation on the

transformer tank. If even a very slight amount of such

moisture enters the transformer tank, it can decrease

the dielectric strength of the cooling liquid to dangerously low levels, which can result in damage to the

equipment.

CAUTION

Only authorized personnel should be permitted on top

of the transformer and every precaution should be taken

to avoid dropping objects into the transformer. Workers

should not have anything in their pockets (such as pens,

pencils, coins, etc.) and their clothing should not have

loose metal buttons, badges, buckles, etc. Wristwatches

should also be removed. When dropped into the

transformer tank, such objects can cause equipment

malfunction and damage.

3SubStation tranSformer inStallation and partS replacement information MN202002EN JUNE 2016

Accessories

Liquid level gauge

Liquid temperature gauge

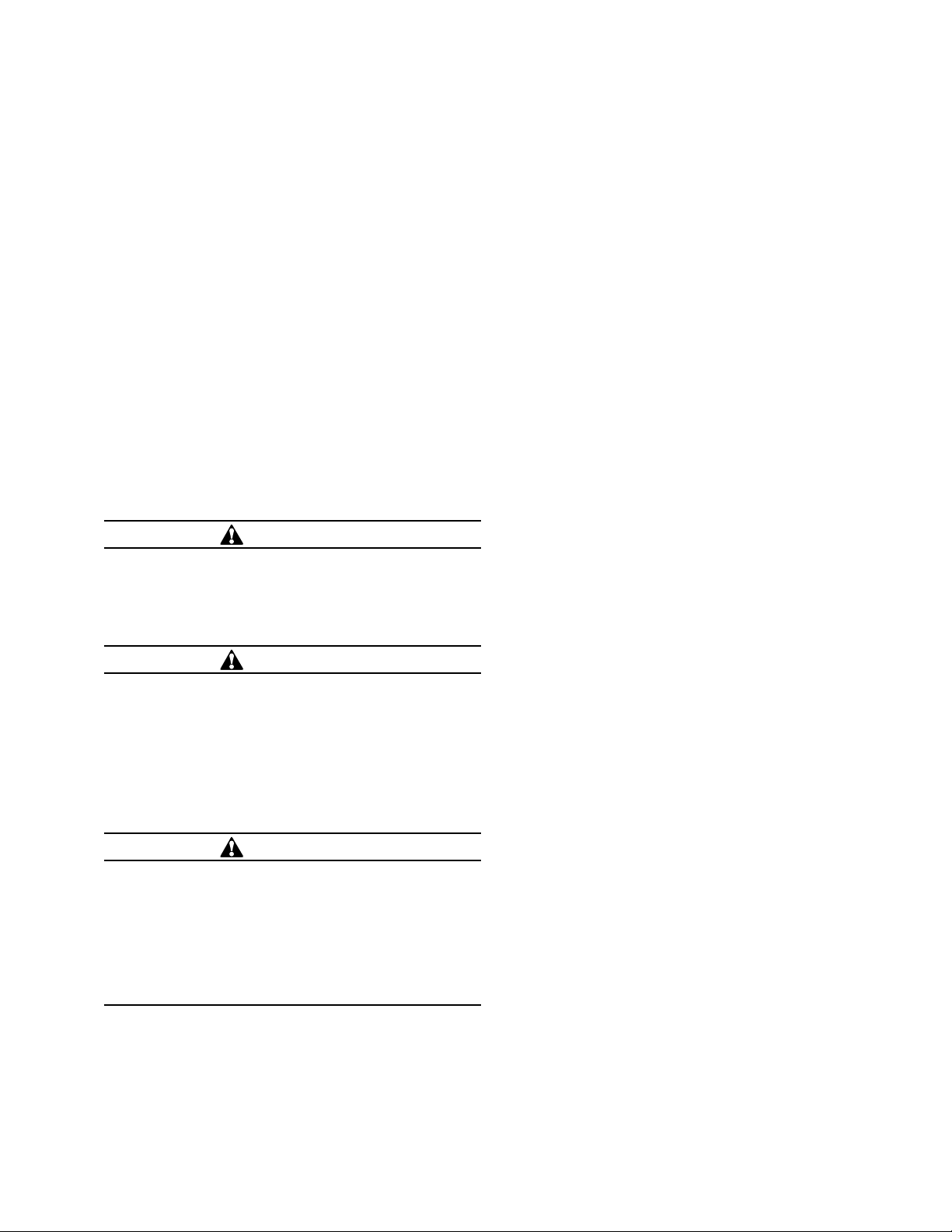

Figure 1. Liquid level gauge.

A liquid level indicator is provided to aid in the systematic

inspection of the transformer under load. It consists of

a float-arm inside the tank, an indicating pointer and a

magnetic coupling between the two across a liquid-tight

separation. Under normal operating conditions, the pointer

should be between the lo/min and hi/max level markings.

The gauge may be furnished with SPDT (Single Pole Double

Throw) alarm contacts to give a remote annunciation of

low liquid level. For contact wiring and terminal points,

see the accessory connection diagram furnished with the

transformer.

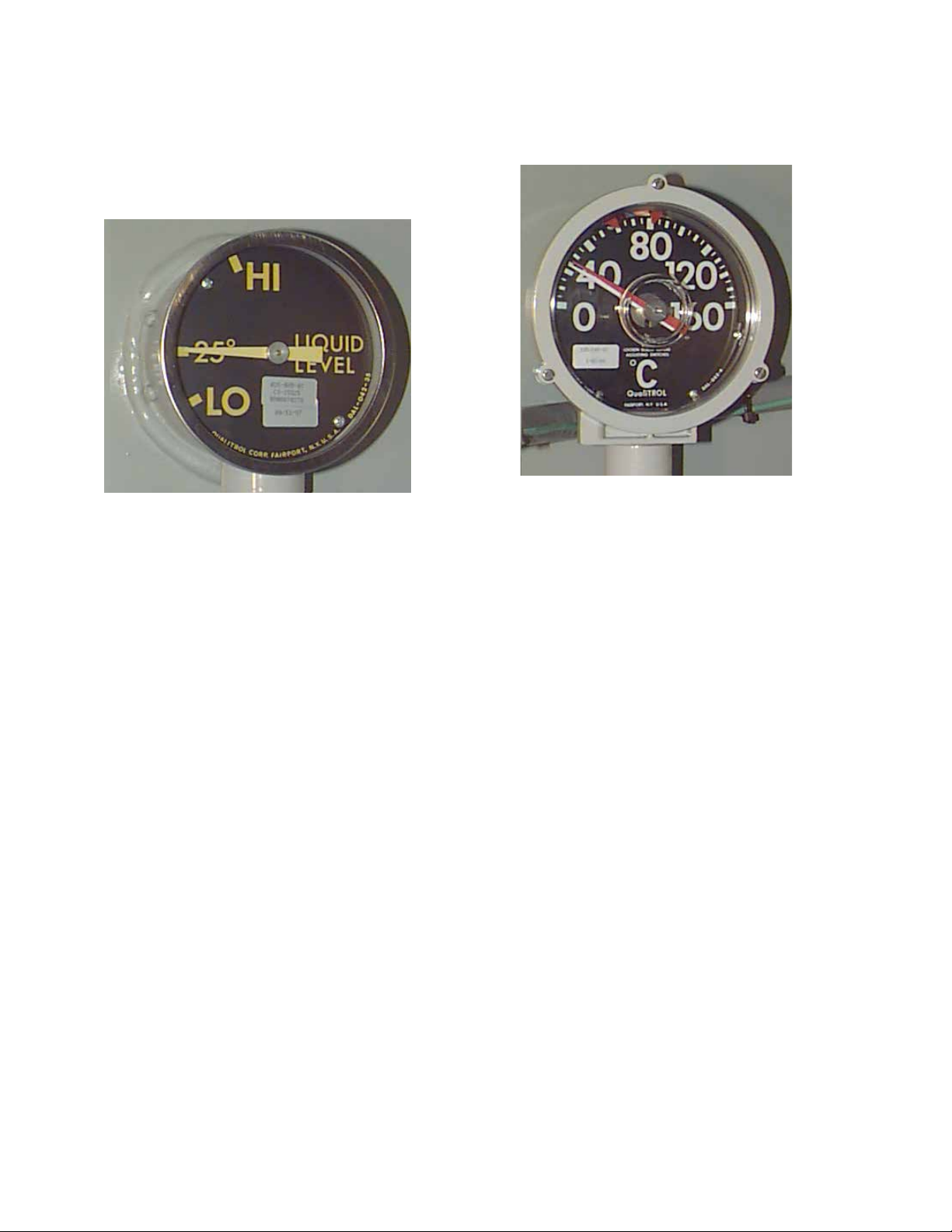

Figure 2. Liquid temperature gauge.

The temperature gauge is furnished to indicate the top

liquid temperature in the tank in degrees Centigrade. The

temperature-sensitive element is mounted in a leak-proof

well, permitting removal of the thermometer without lowering the oil level. The device is furnished with an additional

red pointer to show the highest temperature attained since

the last reset. To reset the maximum indicator, turn the knob

in the center of the dial.

The thermometer can be furnished with two SPDT contacts

for a high temperature alarm, for energizing a fan circuit or

for a low temperature alarm. The trip settings are indicated

by the red tick marks on the edges of the dial. For additional

wiring and contact settings, refer to the schematic furnished

with the transformer.

4 SubStation tranSformer inStallation and partS replacement information MN202002EN JUNE 2016

Loading...

Loading...