Eaton MMX11AA1D7, MMX11AA2D4, MMX11AA3D7, MMX11AA2D8, MMX32 Operating Instructions Manual

...

Operating instructions

M-MaxTM Series

Adjustable Frequency Drive

04/10 MN04020001Z-EN

replaced 06/09 AWB8230-1603en

All brand and product names are trademarks or registered

trademarks of the owner concerned.

Emergency On Call Service

Please call your local representative:

http://www.eaton.com/moeller/aftersales

or

Hotline of the Moeller Field Service:

+49 (0) 180 5 223822 (de, en)

AfterSalesEGBonn@eaton.com

Original Operating Instructions.

The German-language edition of this document is the original

operating manual.

Translation of the original operating manual.

All editions of this document other than those in German language are translations of the original German manual.

1

st

edition 2009, edition date 06/09

2

nd

edition 2010, edition date 04/10

© 2009 by Eaton Industries GmbH, 53105 Bonn

Production: Thomas Kracht, Jutta Kremer

Translation: globaldocs GmbH

All rights reserved, including those of the translation.

No part of this manual may be reproduced in any form

(printed, photocopy, microfilm or any other process) or

processed, duplicated or distributed by means of

electronic systems without written permission of Eaton

Industries GmbH, Bonn.

Subject to alteration without notice.

Danger!

Dangerous electrical voltage!

Before commencing the installation

• Disconnect the power supply of the device.

• Ensure that devices cannot be accidentally restarted.

• Verify isolation from the supply.

• Earth and short circuit the device.

• Cover or enclose any adjacent live components.

• Follow the engineering instructions (IL04020001E) for the

device concerned.

• Only suitably qualified personnel in accordance with

EN 50110-1/-2 (VDE 0105 Part 100) may work on this

device/system.

• Before installation and before touching the device ensure

that you are free of electrostatic charge.

• The functional earth (FE, PES) must be connected to the

protective earth (PE) or the potential equalisation. The system

installer is responsible for implementing this connection.

• Connecting cables and signal lines should be installed so

that inductive or capacitive interference does not impair the

automation functions.

• Install automation devices and related operating elements in

such a way that they are well protected against unintentional

operation.

• Suitable safety hardware and software measures should be

implemented for the I/O interface so that an open circuit on the

signal side does not result in undefined states in the

automation devices.

• Ensure a reliable electrical isolation of the extra-low voltage of

the 24 V supply. Only use power supply units complying with

IEC 60364-4-41 (VDE 0100 Part 410) or HD384.4.41 S2.

• Deviations of the mains voltage from the rated value must

not exceed the tolerance limits given in the specifications,

otherwise this may cause malfunction and dangerous

operation.

• Emergency stop devices complying with IEC/EN 60204-1 must

be effective in all operating modes of the automation devices.

Unlatching the emergency-stop devices must not cause a

restart.

• Devices that are designed for mounting in housings or control

cabinets must only be operated and controlled after they have

been installed and with the housing closed. Desktop or

portable units must only be operated and controlled in

enclosed housings.

• Measures should be taken to ensure the proper restart of

programs interrupted after a voltage dip or failure. This should

not cause dangerous operating states even for a short time.

If necessary, emergency-stop devices should be implemented.

• Wherever faults in the automation system may cause injury or

material damage, external measures must be implemented to

ensure a safe operating state in the event of a fault or

malfunction (for example, by means of separate limit switches,

mechanical interlocks etc.).

• Depending on their degree of protection, adjustable frequency

drives may contain live bright metal parts, moving or rotating

components or hot surfaces during and immediately after

operation.

• Removal of the required covers, improper installation or

incorrect operation of motor or adjustable frequency drive may

cause the failure of the device and may lead to serious injury or

damage.

• The applicable national accident prevention and safety

regulations apply to all work carried on live adjustable

frequency drives.

• The electrical installation must be carried out in accordance

with the relevant regulations (e. g. with regard to cable cross

sections, fuses, PE).

• Transport, installation, commissioning and maintenance work

must be carried out only by qualified personnel (IEC 60364,

HD 384 and national occupational safety regulations).

• Installations containing adjustable frequency drives must be

provided with additional monitoring and protective devices in

accordance with the applicable safety regulations.

Modifications to the adjustable frequency drives using the

operating software are permitted.

Eaton Corp.

Safety instructions

I

• All covers and doors must be kept closed during operation.

• To reduce the hazards for people or equipment, the user must

include in the machine design measures that restrict the

consequences of a malfunction or failure of the drive

(increased motor speed or sudden standstill of motor).

These measures include:

– Other independent devices for monitoring safety-related

variables (speed, travel, end positions etc.).

– Electrical or non-electrical system-wide measures

(electrical or mechanical interlocks).

– Never touch live parts or cable connections of the adjustable

frequency drive after it has been disconnected from the

power supply. Due to the charge in the capacitors, these

parts may still be live after disconnection. Fit appropriate

warning signs.

II

04/10 MN04020001Z-EN

Contents

About This Manual 5

Notes on the second MMX upgrade 5

Writing conventions 6

Abbreviations and Symbols 7

– Mains supply voltages 7

–Units 7

1 M-MaxTM Series 9

System overview 9

Checking the Delivery 10

Rating data on the nameplate 11

– Key to part numbers 12

– General rated operational data 14

– Technical data 16

Description of the M-Max

Features 18

Selection criteria 20

Proper use 21

Maintenance and inspection 22

Storage 22

Charging DC link capacitors 22

Service and warranty 22

TM 18

2 Engineering 23

Introduction 23

Electrical power network 24

– Mains connection and configuration 24

– Mains voltage and frequency 24

– Voltage balance 24

– Idle power compensation devices 25

– Mains reactors 25

Safety and switching 26

– Fuses and cable cross-sections 26

– Cables and fuses 26

– Residual-current device (RCD) 26

– Mains contactor 27

EMC measures 27

Motor and Application 28

– Motor selection 28

– Connecting motors in parallel 28

– Motor and circuit type 29

– Bypass operation 30

– Connecting EX motors 30

3 Installation 31

Introduction 31

Installation instructions 31

– Mounting position 31

– Cooling measures 31

– Fixing 32

EMC installation 35

– EMC measures in the control panel 35

– Earthing 35

1

Contents

04/10 MN04020001Z-EN

– Screen earth kit 35

Electrical Installation 37

– Connection to power section 38

– Arrangement and connection of the power terminals 40

– Connection on control section 42

– Arrangement and connection of the control signal

terminals 43

– Microswitches and control signal terminals 43

– Function of the control signal terminals 44

–Block diagram 50

– Insulation testing 53

4Operation 55

Checklist for commissioning 55

Operational hazard warnings 56

Commissioning with control signal terminals (factory

setting) 57

– Brief Instructions 60

5 Error and Warning Messages 63

Introduction 63

– Error messages 63

– Acknowledge fault message (Reset) 63

– Fault log (FLT) 63

– Alarm messages 63

6 Parameters 67

Control unit 67

– Display unit 68

– General information on menu navigation 68

– Setting parameters 69

Parameter menu (PAR) 71

– Quickstart Wizard 72

– Parameter selection (P1) 73

– Analog input (P2) 75

– Digital input (P3) 78

– Analog output (P4) 83

– Digital output (P5) 84

– Drives control (P6) 88

– Motor (P7) 94

– Protective functions (P8) 95

– PID controller (P9) 100

– Fixed frequency setpoint value (P10) 104

– U/f-characteristic curve (P11) 111

– Braking (P12) 116

– Logic function (P13) 121

– Second parameter set (P14) 124

– System parameter 128

Operational data indicator (MON) 130

Setpoint input (REF) 132

2

04/10 MN04020001Z-EN

Contents

7 Serial interface (Modbus RTU) 135

General information about Modbus 135

Communications in a Modbus network 135

Modbus parameters 136

– Operating mode Modbus RTU 137

– Structure of the master request 138

– Data storage with Modbus 140

– Modbus-Register-Mapping 140

Modbus Process Data 141

– Explanation of function code 144

Appendix 147

Special technical data 147

– Device series MMX11 147

– Device series MMX12 148

– Device series MMX32 149

– Device series MMX34 150

Dimensions and frame size 151

MMX-COM-PC 153

– PC interface module 153

MMX-NET-XA 154

– Mounting frame for fieldbus connection 154

XMX-NET-CO-A 155

XMX-NET-PD-A, XMX-NET-PS-A 156

– PROFIBUS DP fieldbus interface card 156

Cables and fuses 157

Mains contactors 159

Radio interference suppression filters 161

– Special technical data for MMX-LZ... 163

Dimensions and sizes of the MMX-LZ... interference

suppression filters 164

Brake resistors 165

– Brake resistors BR1…-T-PF and BR3…-T-PF 166

– Brake resistors BR2… and BR2…-T-SAF 166

Mains chokes 169

Motor chokes 171

Sinusoidal filters 173

List of parameters 176

– Quick configuration (basis) 176

– All Parameters 179

Index 193

3

04/10 MN04020001Z-EN

4

04/10 MN04020001Z-EN

c

a

b

I

OK

BACK

RESET

LOC

REM

About This Manual

This manual provides a description of the frequency inverters of

TM

the M-Max

series. It provides special information required for

project planning, installation and for the operation of the MMX

frequency inverter. All information applies to the specified

hardware and software versions.

Please read the manual thoroughly before you install and operate

the frequency inverter.

We assume that you have a good knowledge of engineering

fundamentals and that you are familiar with handling electrical

systems and machines, as well as with reading technical drawings.

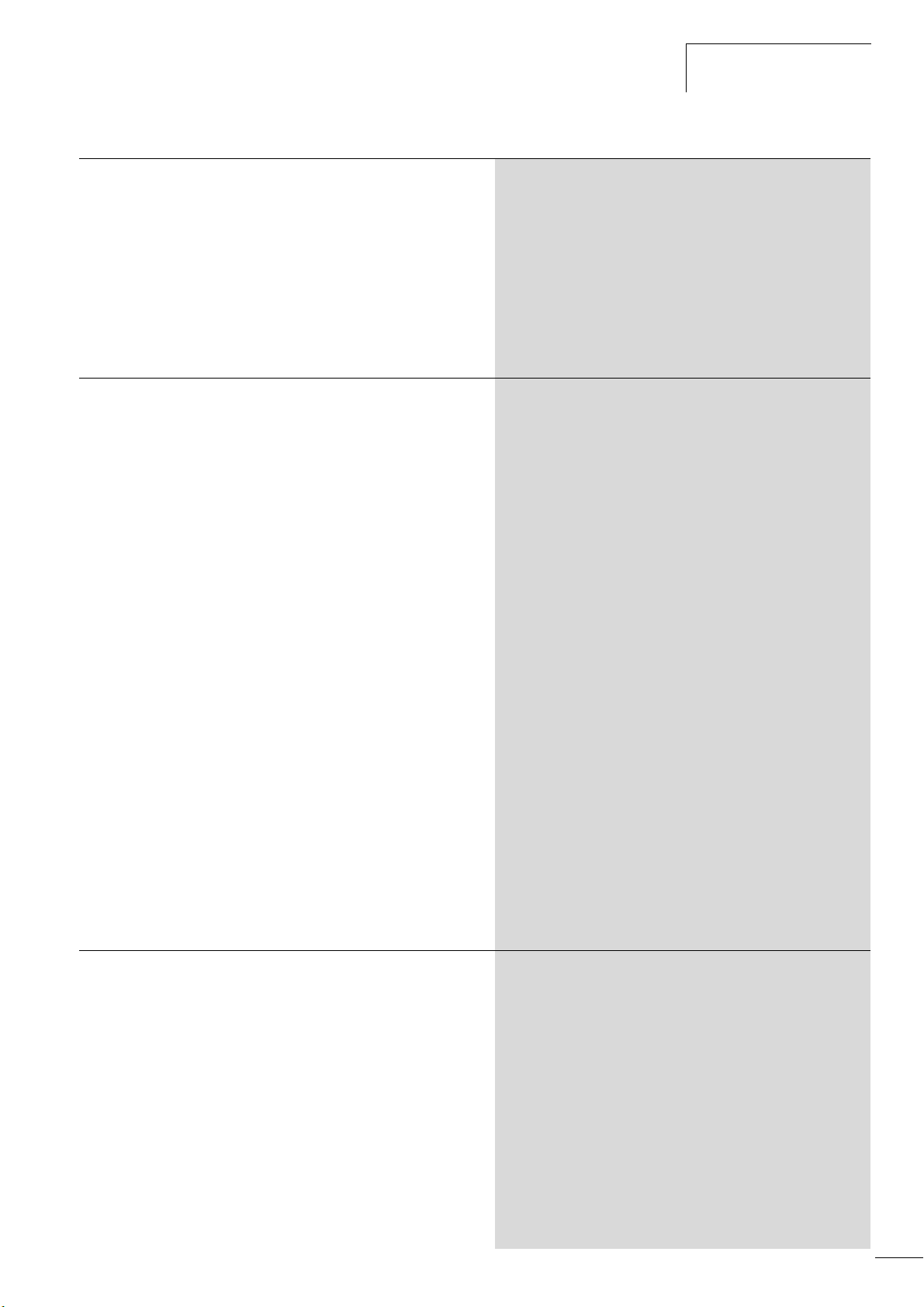

Notes on the second MMX upgrade

This second edition of the manual describes the extended functionality of the MMX. This applies to frequency inverters of the

TM

M-Max

series from production date 12W10 f S/N91275113,

see nameplate.

Essential features of this upgrade:

• New control circuit board with a more powerful microprocessor,

• Side mounted interface for fieldbus connections a,

• Two additional control buttons b,

• Extended functionality for digital and analog inputs and

outputs c.

AI2

DO-GND

4 5 13 14 15 16 18 20 22 23 26

+ 10V AI1 GND

DI4 DI5 DI6 AO DO+

12367

24V

DI-C

8

DI1 DI2 DI3 A B R21 R22

R13

R14 - R24

9

10 25 24

AI 1

LOGIC

- +

AI 2

V mA

Figure 2: Control signal terminals and microswitches

RS 485

V mA

- term.

Figure 1: Frequency inverters M-Max

TM

5

About This Manual

Writing conventions

Symbols used in this manual have the following meanings:

X indicates actions to be taken.

Indicates useful tips and additional information.

h

Caution!

h

Warns of the risk of material damage.

Warning!

i

Warns about the possibility of serious property damage

and minor injuries.

Danger!

j

Warns about the possibility of major property damage

and serious injuries or death.

04/10 MN04020001Z-EN

In order to make it easier to follow the manual, the name of the

current chapter is shown on the header of the left-hand page and

the name of the current section in shown on the header of the

right-hand page. This does not apply to pages at the start of a

chapter or to empty pages at the end of a chapter.

In order to make it easier to understand some of the

h

figures included in this manual, the housing of the

frequency inverter, as well as other safety-relevant parts,

have been left out. However, it is important to note that

the frequency inverter must always be operated with its

housing placed properly, as well as with all required

safety-relevant parts.

Please follow the installation instructions in the

h

AWA8230-2416 installation instructions document.

This manual was created in an electronic format. You can

h

also order a hard copy version of it.

All the specifications in this manual refer to the hardware

h

and software versions documented in it.

More information on the series described here can be

h

found on the Internet under:

www.moeller.net

6

A Support A Download Center

04/10 MN04020001Z-EN

Abbreviations and Symbols

Abbreviations and Symbols

The following symbols and abbreviations are used in this manual:

EMC

FS Frame size

GND Ground, 0 V potential

IGBT

PDS Power Drives System

LCD

PES

PNU Parameter number

UL Underwriters Laboratories

M-Max

Electromagnetic compatibility

Insulated-gate bipolar transistor

Liquid Crystal Display

EMC connection to PE for shielded lines

TM

frequency converters are divided into three voltage

categories:

• 100 V (MMX11)

• 200 V (MMX12…, MMX32…)

• 400 V (MMX34…)

Mains supply voltages

The rated operating voltages stated in the following table are

based on the standard values for networks with a grounded star

point.

In ring networks (as found in Europe) the rated voltage at the

transfer point of the power supply companies is the same as the

value in the consumer networks (e.g. 230 V, 400 V).

In star networks (as found in North America), the rated voltage at

the transfer point of the utility companies is higher than in the

consumer network. Example: 120 V l 115 V, 240 V l 230 V,

480 V l 460 V.

TM

The wide tolerance range of frequency inverter M-Max

takes

into account a permissible voltage drop of an additional 4 %

- 14 %) in load networks, while, in the 400 V category, it

(U

LN

takes into account the North American line voltage of

480 V +10 % (60 Hz).

TM

The permissible connection voltages for the M-Max

series are

listed in the Technical Specifications section in the appendix.

The rated operational data of the mains voltage is always based

on the mains frequencies 50/60 Hz (50 Hz -10 % - 60 Hz +10 %).

Units

Every physical dimension included in this manual uses international metric system units, otherwise known as SI (Système International d’Unités) units. For the purpose of the equipment's UL

certification, some of these dimensions are accompanied by their

equivalents in imperial units.

Table 1: Unit conversion examples

Designation US-American value SI value Conversion value US-American

designation

Length 1 inch (’’) 25.4 mm 0.0394 inch

Power

Torque 1 lbf in 0.113 Nm 8.851 pound-force inches

Temperature 1°F (TF) -17.222 °C (TC) TF=TCx9/5+32 Fahrenheit

Speed 1rpm 1min

Weight 1lb 0.4536 kg 2.205 pound

1 HP = 1.014 PS 0.7457 kW 1.341 horsepower

-1

1 Revolutions per minute

7

04/10 MN04020001Z-EN

8

04/10 MN04020001Z-EN

I

OK

BACK

RESET

LOC

REM

COMM

AC DRIVE

ERROR

a

d

e

f

b

c

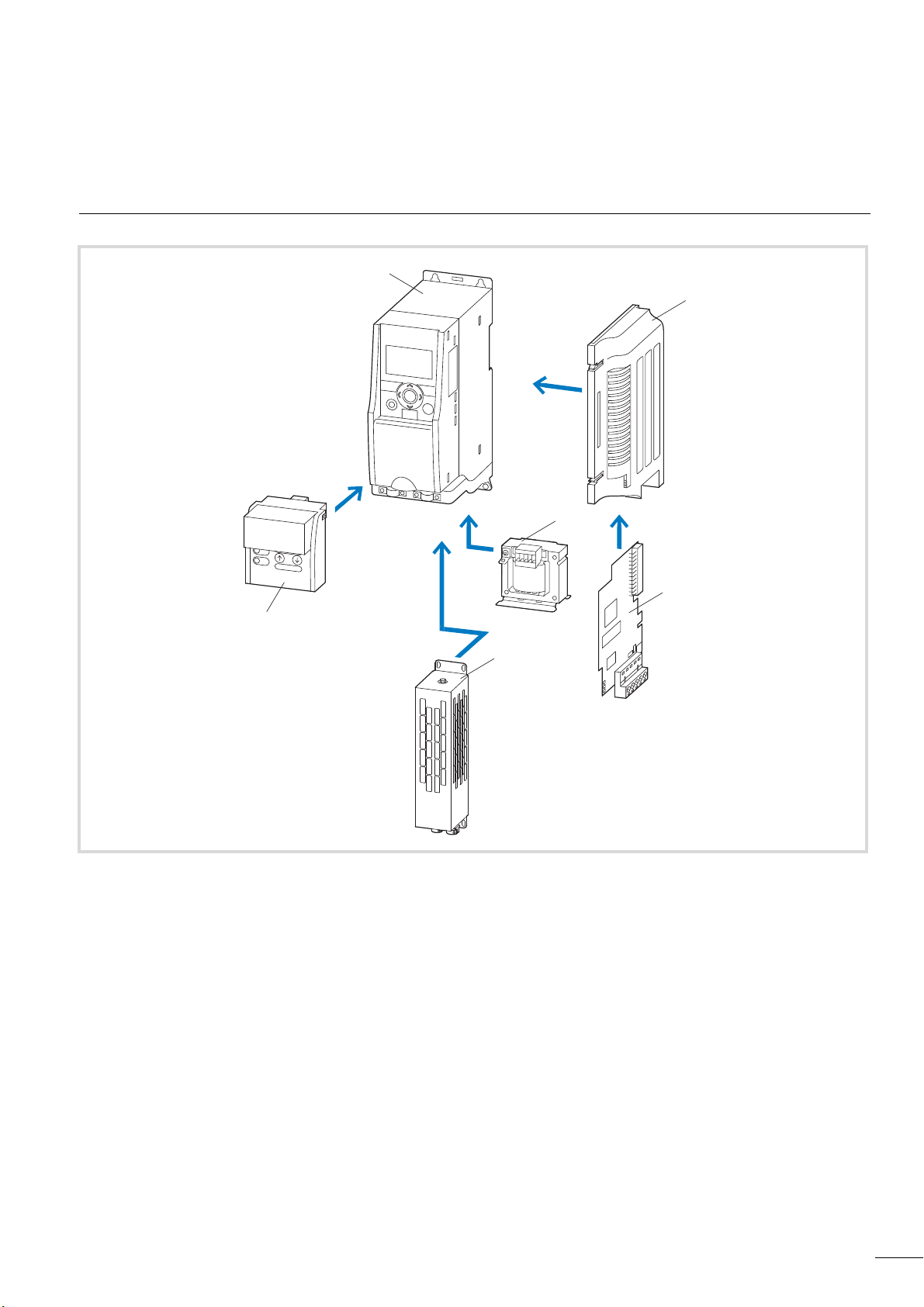

1M-MaxTM Series

System overview

Figure 3: System overview

a Frequency inverters MMX-…

b Mounting frame (for fieldbus connection) MMX-NET-XA

c Fieldbus connection

CANopen XMX-NET-CO-A

PROFIBUS DP with XMX-NET-PS-A screw terminals

PROFIBUS DP with XMX-NET-PD-A Sub-Dm connector

DeviceNet XMX-NET-DN-A

d DEX-LN… mains reactor, DEX-LM3… motor reactor, SFB400… sinusoidal filter

e BR… braking resistor

f Communication module MMX-COM-PC

9

M-MaxTM Series

I

OK

BACK

RESET

LOC

REM

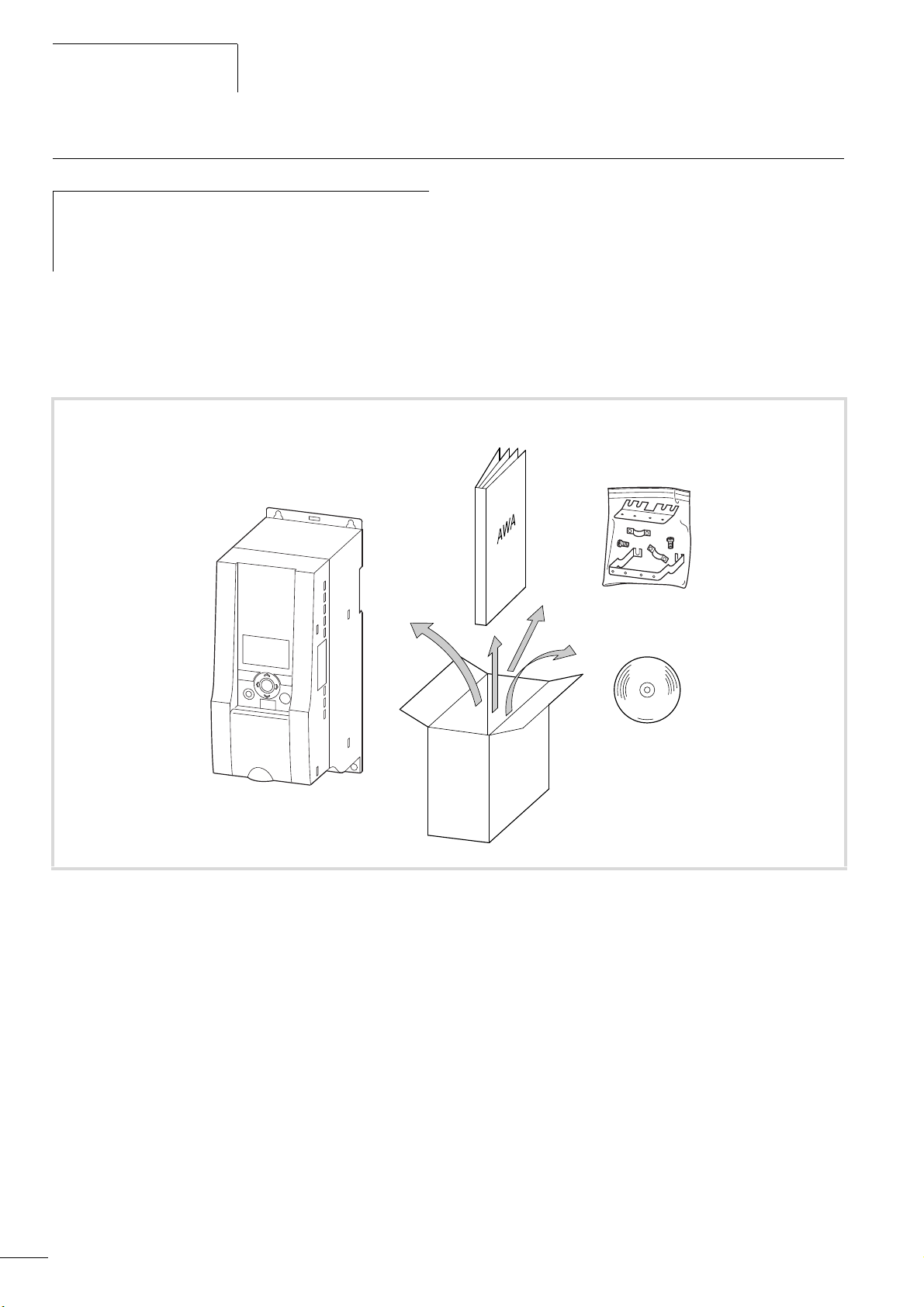

Checking the Delivery

04/10 MN04020001Z-EN

Before opening the packaging go over the ratings plate on

h

the packaging and check for whether the delivered

frequency inverter is the same type as the one you

ordered.

M-MAXTM frequency converters have been carefully packaged and

prepared for delivery. These devices should only be shipped in their

original packaging with suitable transportation materials. Please

take note of the labels and instructions on the packaging, as well

as of those meant for the unpacked device.

Open the packaging with adequate tools and inspect the contents

immediately after receipt in order to ensure that they are complete

and undamaged.

The packaging must contain the following parts:

TM

• a M-Max

frequency inverter,

• an accessory kit for EMC-suitable installation

• Installation instructions AWA8230-2416

TM

• a data carrier (CD-ROM) with documentation for M-Max

CD

.

Figure 4: Scope of supply

10

04/10 MN04020001Z-EN

a

Rating data on the nameplate

The device specific rating data of the M-Max

TM

is shown on the

nameplate on the side of the device and on the rear of the control

signal terminal cover.

The inscription of the nameplates has the following meaning

(example):

Label Meaning

Rating data on the nameplate

MMX34AA3D3F0-0 Part no.:

MMX = frequency inverter of the M-Max

series

3 = Three-phase power connection

4 = 400 V voltage category

AA = Instance (Software version A and

alphanumerical display)

3D3 = 3.3 A rated operational current

(3-decimal-3)

F = Integrated radio interference

suppression filter

0 = IP20 protection type

0 = No integrated optional assembly

Input

Output Load side (motor) rating:

Power Assigned motor rating.

S/N Serial number

IP 20/Open type

12W10

Power connection rating:

Three-phase AC voltage (U

380 - 480 V voltage, 50/60 Hz frequency,

input phase current (4.0 A)

Three-phase AC voltage (0 - U

phase current (3.3 A), output frequency

(0 - 320 Hz)

1.1 kW at 400 V/1.5 HP at 460 V for a

four-pole internally-cooled or surfacecooled three-phase asynchronous motor.

(1500 min

Frequency inverter is an electrical apparatus.

Read the manual (in this case

AWB8230-1603) before making any

electrical connections and commissioning.

Protection type of the housing: IP 20, UL

(cUL) Open type.

manufacturing date

Week 12 of 2010.

-1

at 50 Hz/ 1800 rpm at 60 Hz)

3~ AC),

e

), output

e

TM

11

M-MaxTM Series

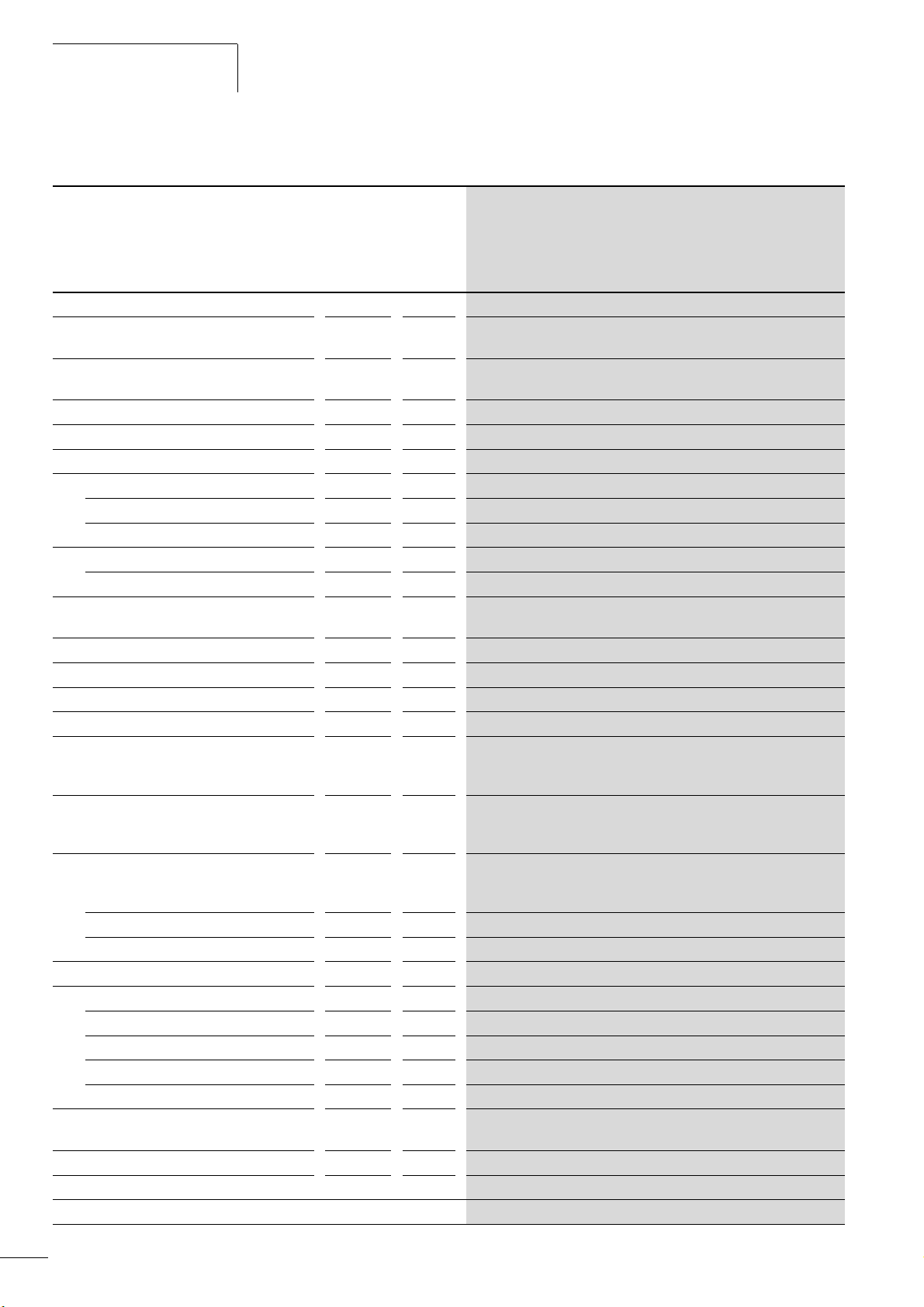

Key to part numbers

The type designation code and the part no. of the M-MAX

TM

frequency inverter series are in the following order:

MMX 3 4 AA 1D3 F 0 -0 Explanation

0 = No optional assembly integrated

1 = Optional assembly integrated

0 = IP20 protection type

1 = Protection type IP21, NEMA 1

F = Radio noise filter (internal)

N = Without internal radio noise filter (No filter)

04/10 MN04020001Z-EN

Voltage class

1 = 100 V (110 V -15 % - 115 V +10 %)

2 = 200 V (208 V -15 % - 240 V +10 %)

4 = 400 V (380 V -15 % - 480 V +10 %)

1 = Single-phase power supply

3 = Three-phase mains supply voltage

Figure 5: Type designation of the M-Max

Rated operational current

1D3 = 1.3 A (D = decimal)

011 = 11 A

AA = Specification (Software version, display unit)

MMX = frequency inverter of the M-Max

TM

frequency inverters

TM

series

12

04/10 MN04020001Z-EN

Rating data on the nameplate

Examples

Label Meaning

MMX11AA2D8N0-0 MMX = frequency inverter of the M-Max

series:

1 = Single-phase power supply

1 = Rated voltage 115 V

AA = Type of software version and display

unit

2D8 = 2.8 A (rated operational current)

N = No integrated interference suppression

filter (No filter)

0 = IP20 protection type

0 = No integrated optional assembly

MMX12AA1D7F0-0

MMX32AA2D4N0-0

MMX34AA012F0-0

MMX34AA5D6N0-0

MMX = frequency inverter of the M-Max

series:

1 = Single-phase power supply

2 = Rated voltage 230 V

AA = Type of software version and display

unit

1D7 = 1.7 A (rated operational current)

F = Integrated radio noise filter

0 = IP20 protection type

-0 = No integrated optional assembly

MMX = frequency inverter of the M-Max

series:

3 = Three-phase mains supply voltage

2 = Rated voltage 230 V

AA = Type of software version and display

unit

2D4 = 2.4 A (rated operational current)

N = No integrated interference suppression

filter (No filter)

0 = IP20 protection type

-0 = No integrated optional assembly

MMX = frequency inverter of the M-Max

series:

3 = Three-phase mains supply voltage

4 = Rated voltage 400 V

AA = Type of software version and display

unit

012 = 12 A (rated operational current)

F = Integrated radio noise filter

0 = IP20 protection type

-0 = No integrated optional assembly

MMX = frequency inverter of the M-Max

series:

3 = Three-phase mains supply voltage

4 = Rated voltage 400 V

AA = Type of software version and display

unit

5D6 = 5.6 A (rated operational current)

N = No integrated interference suppression

filter (No filter)

0 = IP20 protection type

-0 = No integrated optional assembly

TM

TM

TM

TM

TM

MMX… N…: An externally fitted interference suppres-

h

sion filter is required for operation in accordance with IEC/

EN 61800-3.

Example: MMX34AA5D6N0-0.

Assigned interference suppression filter: MMX-LZ3-009

(three-phase interference suppression filter up to 9 A, size FS2)

MMX11: The mains voltage of 115 V is raised to 230 V

h

(output voltage) through an internal voltage double

connection.

13

M-MaxTM Series

General rated operational data

04/10 MN04020001Z-EN

Technical data Symbols

Unit Value

used in

technical

data and

formulae

General

Standards EMC: IEC/EN 61800-3,

Safety: IEC/EN61800-5, UL508C

Certifications and manufacturer's declarations on

conformity

EMC: CE, CB, c-Tick

Safety: CE, CB, UL, cUL

Production quality RoHS, ISO 9001

Climatic proofing p

w

% < 95 %, average relative humidity, non-condensing (EN50178)

Air quality

Chemical vapors IEC721-3-3: Device in operation, Class 3C2

Mechanical particles IEC721-3-3: Device in operation, Class 3S2

Ambient temperature

Operation i °C -10 - +40 (+501))

Storage i °C -40 - +70

Installation altitude H m 0 – 1000 m above sea level, over 1000 m with 1% power reduction per

100 m, maximum 2000 m, at maximum +50 °C ambient temperature

Mounting position Vertical ±90

Protection type IP20

Busbar tag shroud BGV A3 (VBG4, finger and back-of-hand safe)

Overvoltage category/pollution degree -

Mechanical shock resistance IEC 68-2-27

Storage and transport: 15 g, 11 ms (in the packaging)

UPS drop test (for applicable UPS weights)

Vibration EN 60068-2-6

3 – 150 Hz, oscillation amplitude 1 mm (Peak) at 3 – 15.8 Hz,

maximum acceleration amplitude 1 g at 15.8 – 150 Hz

Emitted interference with internal EMC filter

(maximum motor cable length)

C2: Class A in 1st environment (residential area with commercial

utilization)

C3: Class A in 2nd environment (Industrial)

MMX11, MMX12

C2, C3

MMX32, MMX34 C2, C3

Power section

Rated operational voltage f

MMX11 U

MMX12 U

MMX32 U

MMX34 U

Mains network configuration (AC power supply

network)

LN

e

e

e

e

Hz at 50/60

VAC 1~115(110-15%-120 +10%)

VAC 1~230(208-15%-240 +10%)

VAC 3~230(208-15%-240 +10%)

VAC 3~400(380-15% - 480 +10%)

Center-point grounded star network (TN-S network)

Phase grounded AC networks are not permitted.

Mains switch-on frequency Maximum one time per minute

Mains current THD %

Short-circuit current I

K

kA maximum < 50

> 120

14

04/10 MN04020001Z-EN

Rating data on the nameplate

Technical data Symbols

Unit Value

used in

technical

data and

formulae

Mains frequency f

Pulse frequency (switching frequency of the

LN

f

PWM

Hz 50/60, (45 - 66 Hz ±0 %)

kHz 1-16 (FS: 6kHz)

1)

inverter)

Operating mode V/f characteristic curve control (FS), speed control with slip

compensation.

Output voltage U

Output frequency f

2

2

V 3 AC 230 (MMX11), 3 AC Ue (MMX12, MMX32, MMX34)

Hz 0 - 320 (FS: 0 - 50 Hz)

Frequency resolution (setpoint value) I Hz 0.01

Rated operational current I/I

Overload current I/I

Starting current I/I

e

e

e

Braking torque MB/M

N

% 100 % continuous current at maximum +50 °C ambient temperature

% 150 for 60 s every 600 s

% 200 for 2 s every 20 s

% F 30 for all sizes

up to maximum 100 % MN only as of size MMX34…4D3... with external

braking resistance

Control section

Control voltage (output) U

Reference voltage (output) U

c

s

VDC 24, max. 50 mA

VDC 10, max. 10 mA

Input, digital, parameter definable 6 x, max. +30 V DC, Ri > 12 kO

Permitted residual ripple with external

max. 5 % DUa/U

a

control voltage (+24 V)

Input, analog, parameterizable, selection via

2 x 0 (2) - +10 VDC, Ri> 200 kO or 0 (4) - 20 mA, RB~ 200 O

microswitches

Resolution Bit 10

Output, analog, parameter definable

1 x 0 (2) - 10 V, max. 10 mA

Resolution Bit 10

Output, digital, parameter definable 1 x Transistor: 48 V DC, max. 50 mA

Output relay, parameter definable

1 x N/O: 250 V AC, maximum 2 A or

250 V DC, max. 0.4 A

Output relay, parameter definable

1 x Changeover contact: 250 V AC, maximum 2 A or 250 V DC,

maximum 0.4 A

Serial interface RS485/Modbus RTU

1) +50 °C with lateral clearance of f 20 mm and reduced pulse frequency F 4kHz.

MMX34AA014… is only permissible for a maximum ambient temperature of +40 °C at a max. pulse frequency of F 4kHz.

15

M-MaxTM Series

Technical data

04/10 MN04020001Z-EN

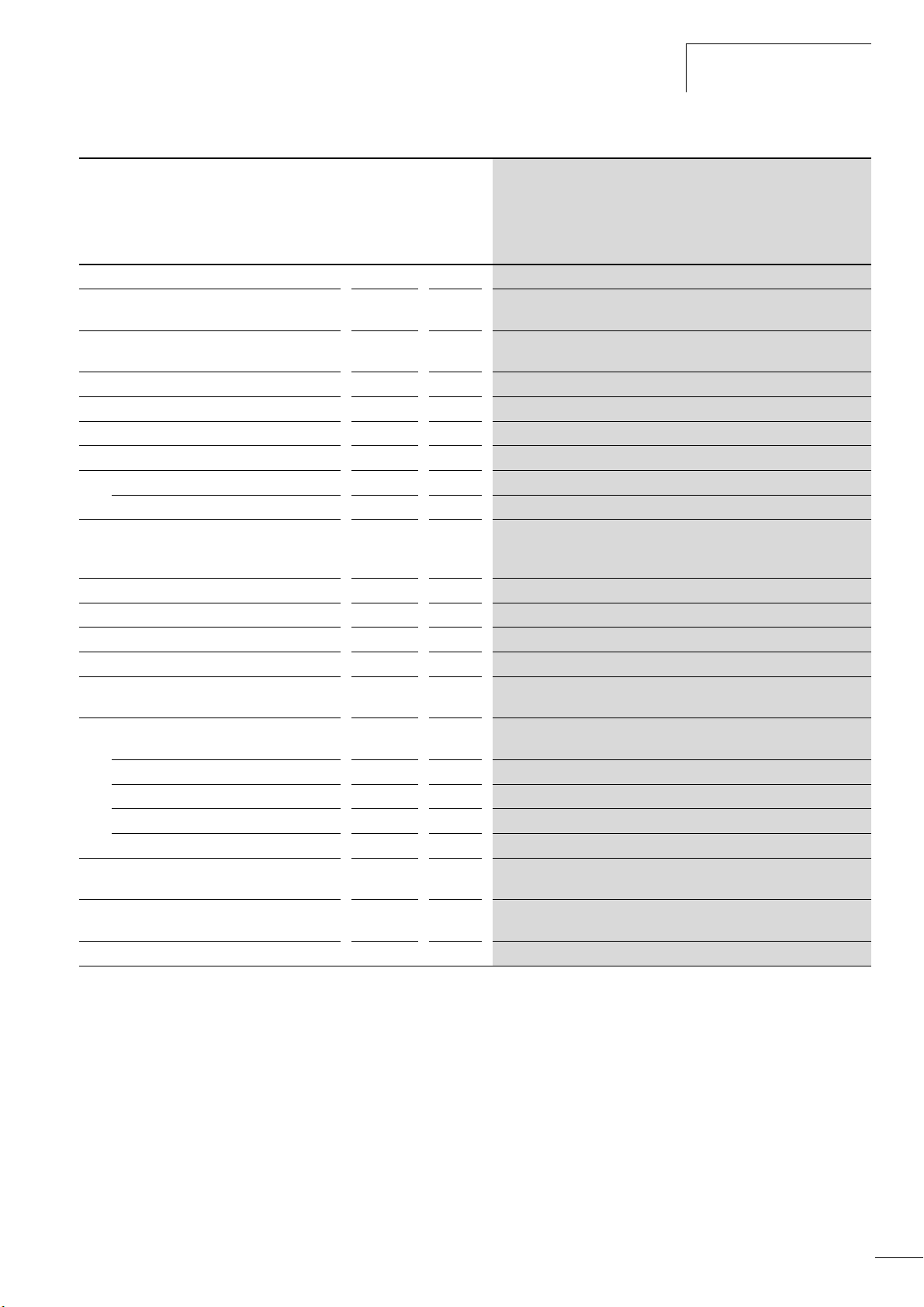

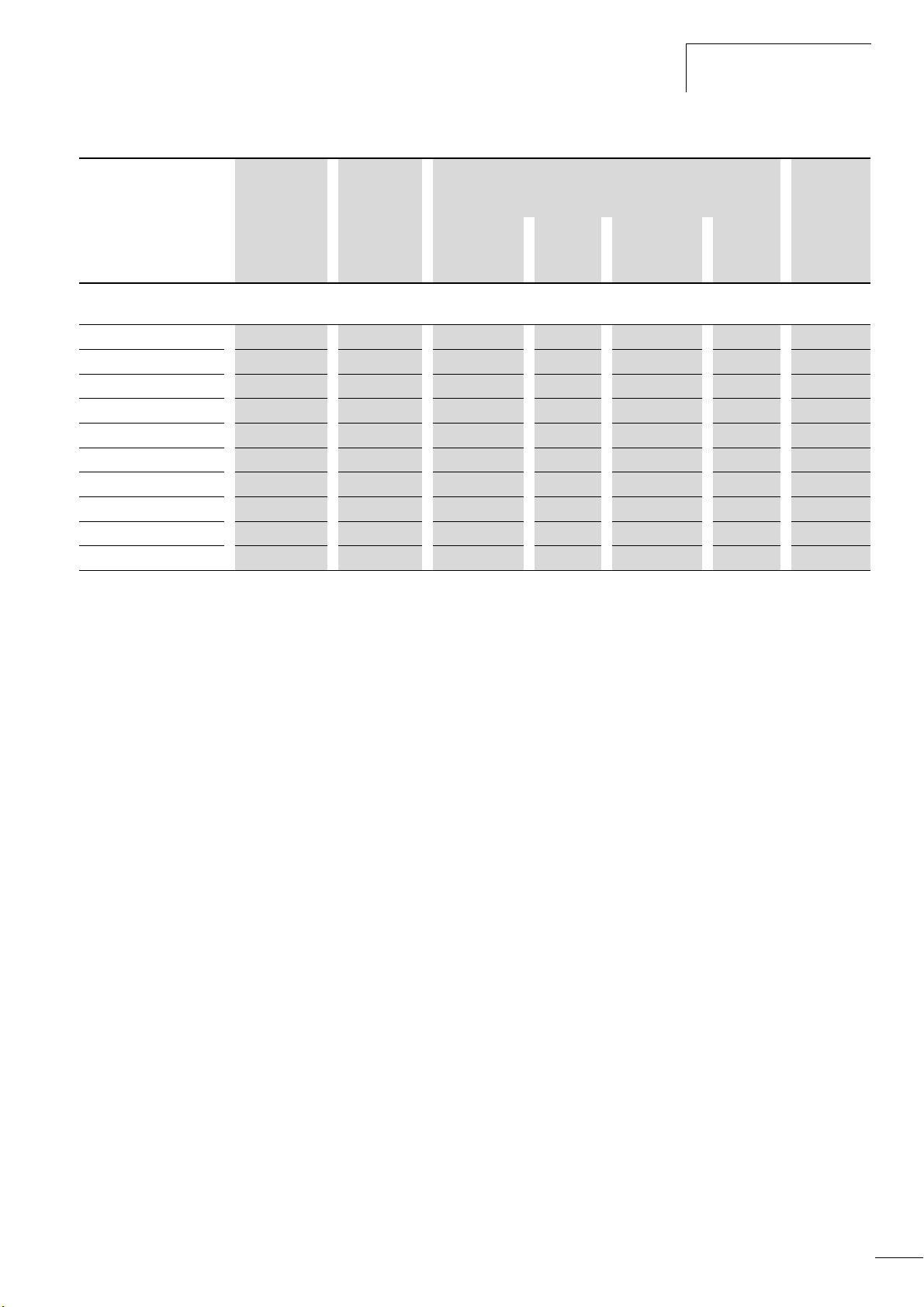

Part no. Rated current Overload

current

Assigned motor rating Installation

size

(150 %)

I

e

[A] [A] [kW] [A]

I

e150

P

(230 V, 50 Hz)

P

(230 V, 60 Hz)

1)

[HP] [A]

1)

Power connection voltage: 1 AC 115 V, 50/60 Hz

(94-132V

MMX11AA1D7… 1.7 2.6 0.25 1.4 1/3

MMX11AA2D4…

MMX11AA2D8…

MMX11AA3D7… 3.7 5.6 0.75 3.2 3/4 3.2 FS2

MMX11AA4D8… 4.8 7.2 1.1 4.6 1 4.2 FS3

1) Rated motor currents for normal four-pole internally and surface-cooled three-phase asynchronous motors (1500 rpm at 50 Hz, 1800rpm at 60 Hz).

2) Calculated motor output (no standard value).

g0%, 45-66Hz g0%)

2.4 3.6 0.37 2 1/2 2.2 FS2

2.8 4.2 0.55 2.7 1/2 2.2 FS2

2)

1.5

2)

FS2

The mains voltage of 115 V is raised to 230 V (output voltage) through an internal voltage double connection.

Part no. Rated current Overload

current

(150 %)

I

e

I

e150

[A] [A] [kW] [A]

Assigned motor rating Installation

size

P

(230 V, 50 Hz)

1)

P

(230 V, 60 Hz)

[HP] [A]

1)

Power connection voltage: 1 AC 230 V, 50/60 Hz

(177 - 264 V

MMX12AA1D7… 1.7 2.6 0.25 1.4 1/3

MMX12AA2D4…

MMX12AA2D8… 2.8 4.2 0.55 2.7 1/2 2.2 FS1

MMX12AA3D7…

MMX12AA4D8… 4.8 7.2 1.1 4.6 1 4.2 FS2

MMX12AA7D0… 7 10.5 1.5 6.3 2 6.8 FS2

MMX12AA9D6… 9.6 14.4 2.2 8.7 3 9.6 FS3

g0 %, 45 - 66 Hz g0 %)

2.4 3.6 0.37 2 1/2 2.2 FS1

3.7 5.6 0.75 3.2 3/4 3.2 FS2

2)

1.5

2)

FS1

Power connection voltage: 3AC 230 V, 50/60 Hz

(177 - 264 V

MMX32AA1D7… 1.7 2.6 0.25 1.4 1/3

MMX32AA2D4… 2.4 3.6 0.37 2 1/2 2.2 FS1

MMX32AA2D8… 2.8 4.2 0.55 2.7 1/2 2.2 FS1

MMX32AA3D7… 3.7 5.6 0.75 3.2 3/4 3.2 FS2

MMX32AA4D8… 4.8 7.2 1.1 4.6 1 4.2 FS2

MMX32AA7D0… 7 10.5 1.5 6.3 2 6.8 FS2

MMX32AA011… 11 14.4 2.2 8.7 3 9.6 FS3

1) Rated motor currents for normal four-pole internally and surface-cooled three-phase asynchronous motors (1500 rpm at 50 Hz, 1800 rpm

2) Calculated motor output (no standard value).

g0 %, 45 - 66 Hz g0 %)

2)

1.5

2)

FS1

at 60 Hz).

16

04/10 MN04020001Z-EN

Rating data on the nameplate

Part no. Rated current Overload

current

Assigned motor rating Installation

size

(150 %)

I

e

[A] [A] [kW] [A]

I

150

P

(400 V, 50 Hz)

P

(460 V, 60 Hz)

1)

[HP] [A]

1)

Power connection voltage: 3AC 400 V, 50/60 Hz

(323 - 528 V

MMX34AA1D3… 1.3 2 0.37 1.1 1/2 1.1 FS1

MMX34AA1D9… 1.9 2.9 0.55 1.5 3/4 1.6 FS1

MMX34AA2D4… 2.4 3.6 0.75 1.9 1 2.1 FS1

MMX34AA3D3… 3.3 5 1.1 2.6 1-1/2 3 FS2

MMX34AA4D3… 4.3 6.5 1.5 3.6 2 3.4 FS2

MMX34AA5D6… 5.6 8.4 2.2 5 3 4.8 FS2

MMX34AA7D6… 7.6 11.4 3 6.6 4

MMX34AA9D0…

MMX34AA012… 12 18 5.5 11.3 7-1/2 11 FS3

MMX34AA014… 14 21 7.5

1) Rated motor currents for normal four-pole internally-cooled and surface-cooled three-phase asynchronous motors (1500 min

at 60 Hz)

2) Calculated motor output (no standard value).

3) Operation with reduced load torque (about -10 % M

4) Allocated motor output at a maximum ambient temperature of +40 °C and a maximum pulse frequency of 4 kHz.

g0 %, 45 - 66 Hz g0 %)

9 13.5 4 8.5 5 7.6 FS3

2)

2)

)

N

(15.2)

3)

10

4)

2)

6.4

FS3

14 FS3

-1

at 50 Hz, 1800 min

-1

17

M-MaxTM Series

g

h

i

j

a

b

c

d

f

e

I

OK

BACK

RESET

LOC

REM

04/10 MN04020001Z-EN

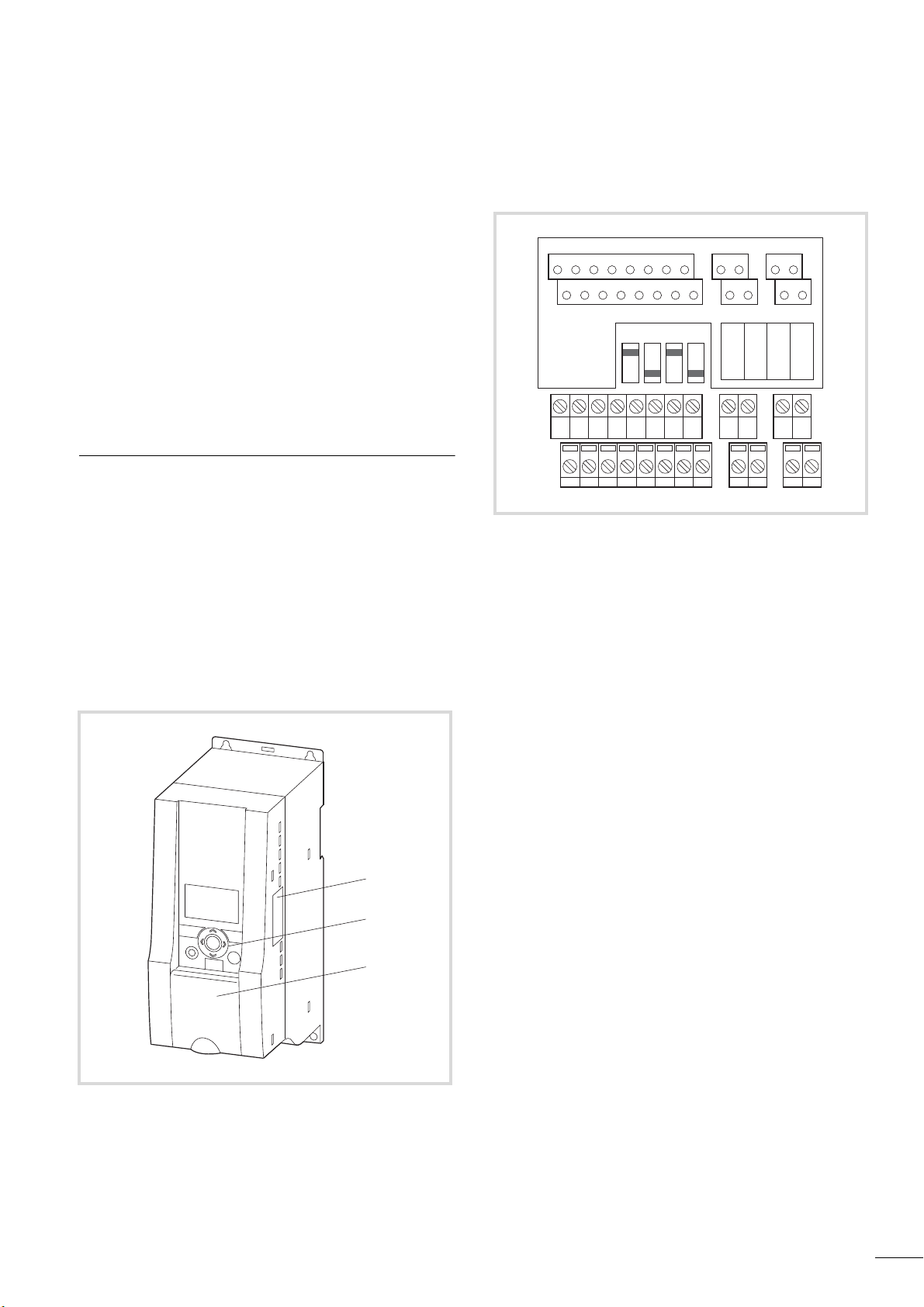

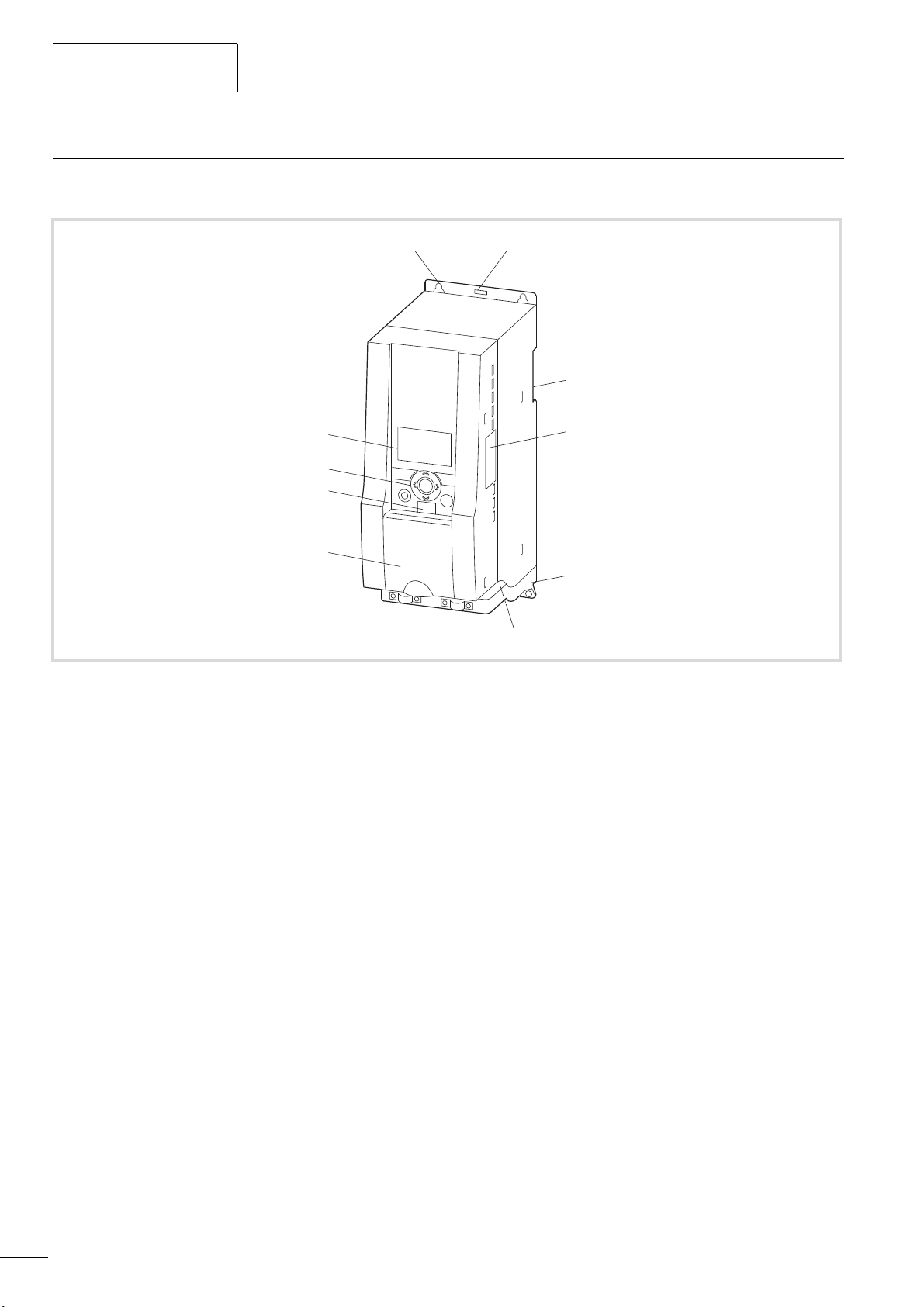

Description of the M-Max

TM

The following drawing shows an M-Max

TM

device.

Figure 6: Description of the M-Max

TM

a Mounting holes (screw fastening)

b Release (removal from mounting rail)

c Recess for mounting on mounting rail (DIN EN 50022-35)

d Interface for fieldbus connection modules (Option, MMX-NET-XA)

e EMC installation accessories

f Power section terminals

g Cover flap of control signal terminals and microswitches

h Interface for PC connection module MMX-COM-PC (Option)

i Keypad with 9 control buttons

j Display unit (LCD)

Features

The M-Max

TM

frequency inverter convert the voltage and

frequency of an existing AC network into a DC voltage. This DC

voltage is used to generate a three-phase AC voltage with

adjustable frequency and assigned amplitude values for the

variable speed control of three-phase asynchronous motors.

18

04/10 MN04020001Z-EN

ba

c

f

g

h

de

+

R+

EMC

L1

L2/N

L3

PE

R-

M

3

h

i

U/T1

V/T2

W/T3

PE

Features

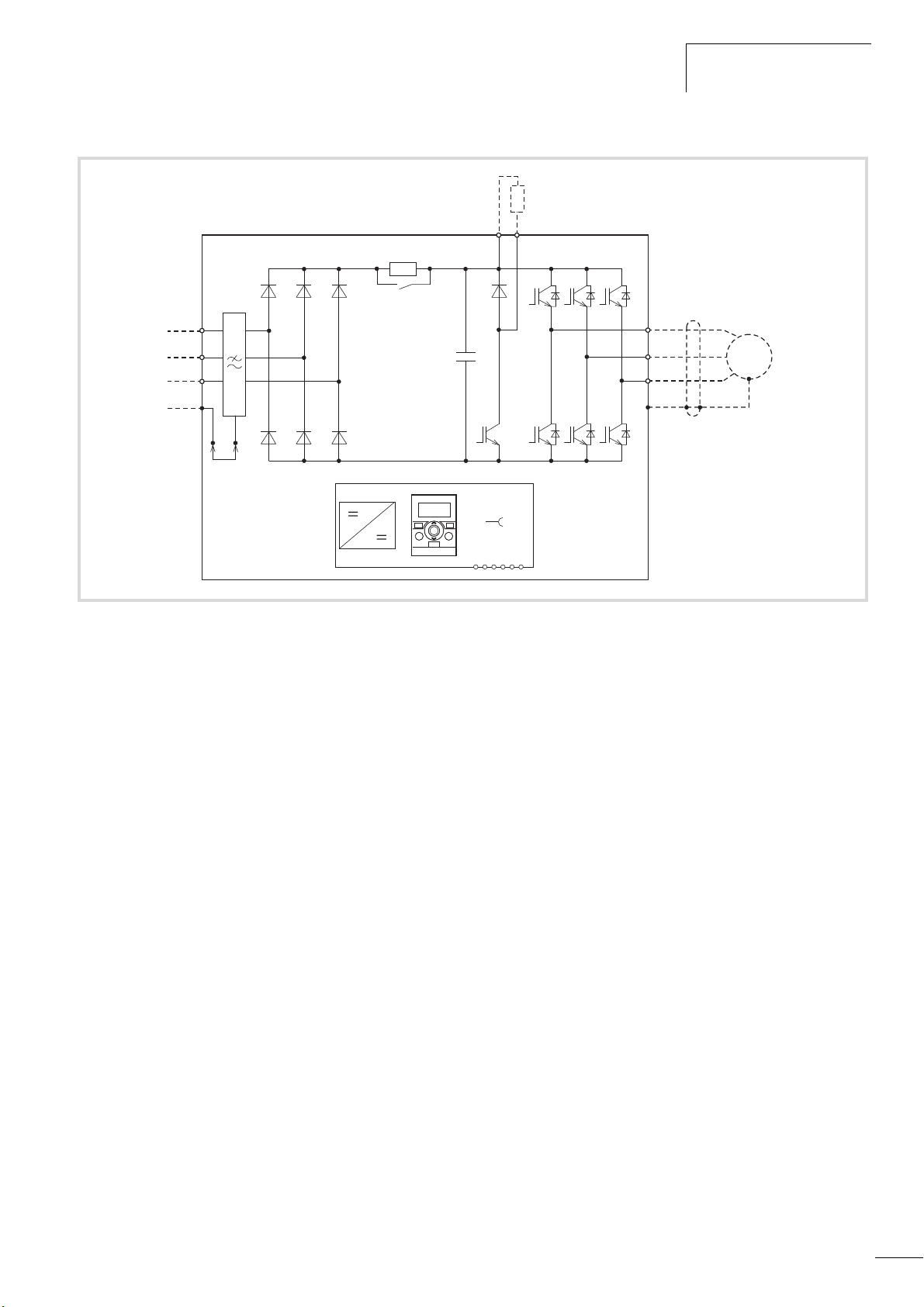

Figure 7: Block diagram, elements of the M-MaxTM frequency inverters

a Supply L1, L2/N, L3, PE, mains supply voltage U

LN=Ue

at 50/60 Hz:

MMX11: 100 V class, single-phase mains connection (1 AC 120 V),

MMX12: 200 V class, single-phase mains connection (1 AC 230 V/240 V),

MMX32: 200 V class, three-phase mains connection (3 AC 230 V/240 V),

MMX34: 400 V class, three-phase mains connection (3 AC 400 V/480 V).

b Internal interference suppression filter (MMX... F...), category C2 and C3, to IEC/EN 61800-3. EMC-connection of internal interference suppression

filter to PE.

c Rectifier bridge, single phase (MMX1…) or three-phase (MMX3…), converts the AC voltage of the electrical network into DC voltage.

d DC link with charging resistor, capacitor and switching mode power supply unit (SMPS = Switching Mode Power Supply):

DC link voltage U

with single-phase mains connection (1 AC): UDC= 1.41 x U

DC

LN

DC link voltage UDCwith three-phase mains connection (3 AC): UDC= 1.35 x ULN.

e Inverter. The IGBT based inverter converts the DC voltage of the DC link (U

frequency (f

f Motor connection U/T1, V/T2, W/T3 with output voltage U

output current (I

). Sinusoidal pulse width modulation (PWM) with V/f control can be switched to speed control with slip compensation.

2

(0 to 100 % Ue) and output frequency f2 (0 to 320 Hz)

):

2

2

) into a three-phase AC voltage (U2) with variable amplitude and

DC

MMX11: 1.7 A - 4.8 A,

MMX12: 1.7 A - 9.6 A,

MMX32: 1.7 A - 11 A,

MMX34: 1.3 A - 14 A.

100 % at an ambient temperature of +50 °C with an overload capacity of 150 % for 60 s every 600 s and a starting current of 200 % for 2 s every

20 s.

g Keypad with control buttons, LCD display, control voltage, control signal terminals, microswitches and interface for the PC interface module (Option).

h Braking transistor: connections R+ and R- for external braking resistance (only with MMX34 / at 3.3 A).

i Three-phase asynchronous motor, variable speed control of three-phase asynchronous motor for assigned motor shaft power values (P

MMX11: 0.25 - 1.1 kW (230 V, 50 Hz) or 0.33 - 1 HP (230 V, 60 Hz),

MMX12: 0.25 - 2.2 kW (230 V, 50 Hz) or 0.25 - 3 HP (230 V, 60 Hz),

MMX32: 0.25 - 2.2 kW (230 V, 50 Hz) or 0.25 - 3 HP (230 V, 60 Hz),

MMX34: 0.37 - 7.5 kW (400 V, 50 Hz) or 0.5 - 10 HP (460 V, 60 Hz).

):

2

19

M-MaxTM Series

230 / 400 V d / Y

4.0 / 2.3

0,75

0.67

j

cos

kW

min

-1

1410 50 Hz

A

b

c

a

U, I, f

I

OK

BACK

RESET

LOC

REM

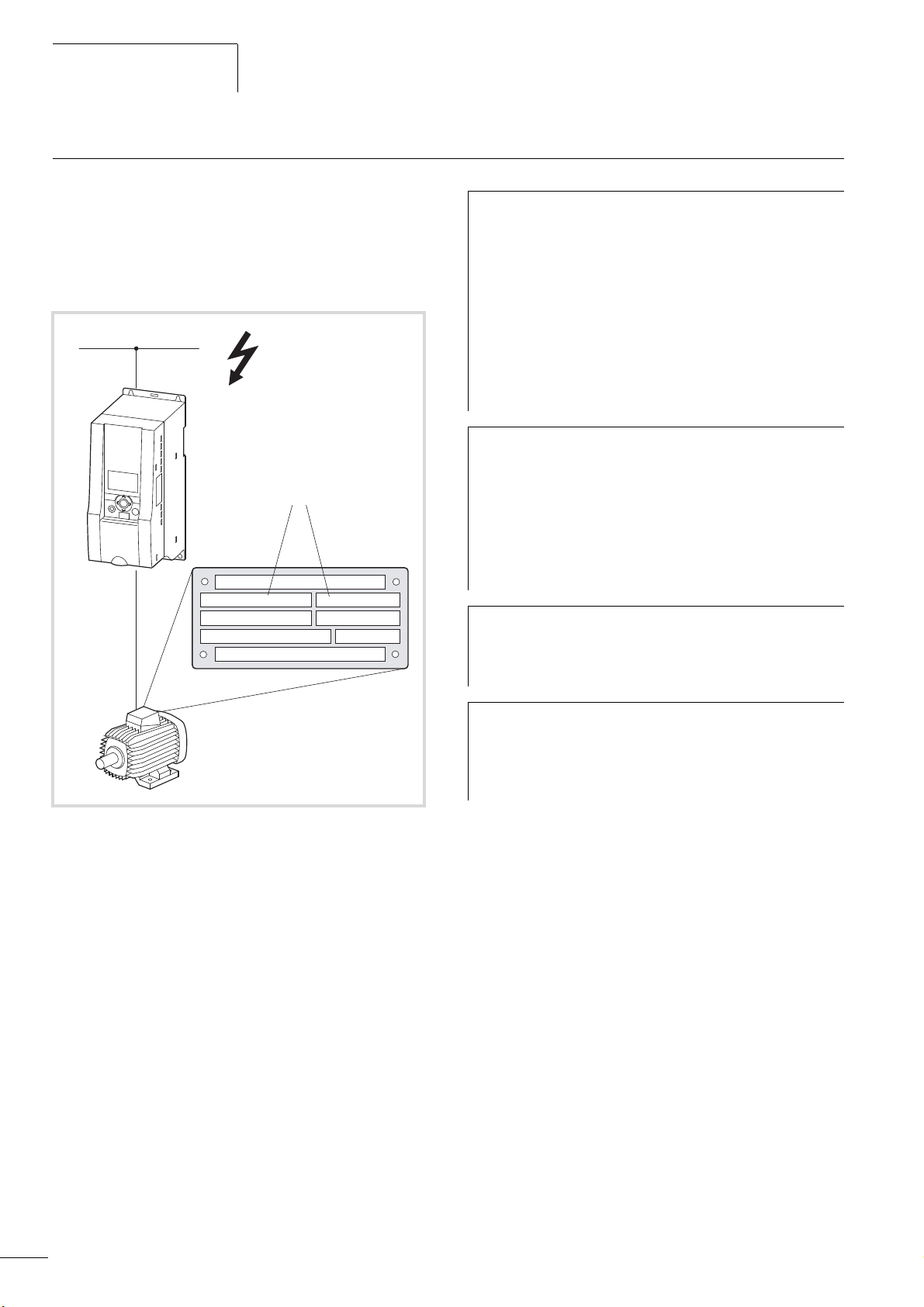

Selection criteria

04/10 MN04020001Z-EN

The frequency inverter c is selected according to the supply

voltage U

assigned motor b. The circuit type (

of the mains supply a and the rated current of the

LN

D / Y) of the motor must be

selected according to the supply voltage a. The rated output

current I

of the frequency inverter must be greater than/equal to

e

the rated motor current.

When connecting multiple motors in parallel to the output

h

of a frequency inverter, the motor currents are added

geometrically – separated by effective and idle current

components. When you select a frequency inverter, make

sure that it can supply the total resulting current. If necessary, for dampening and compensating the deviating

current values, motor reactors or sinusoidal filters must be

connected between the frequency inverter and the motor.

The parallel connection of multiple motors in the output

of the frequency inverter is only permitted with U/f-characteristic curve control.

If you connect a motor to an operational frequency

h

inverter, the motor draws a multiple of its rated

operational current. When you select a frequency inverter,

make sure that the starting current plus the sum of the

currents of the running motors will not exceed the rated

output current of the frequency inverter.

Switching in the output of the frequency inverter is only

permitted with U/f-characteristic curve control.

The speed control with slip compensation (P11.8)

h

increases the drive dynamics and optimizes the output.

For this the frequency inverter processes all motor data in

an electrical image.

Figure 8: Selection criteria

When selecting the drive, the following criteria must be known:

• Type of motor (three-phase asynchronous motor)

• Mains voltage = rated operating voltage of the motor

(e.g. 3 AC ~ 400 V),

• Rated motor current (guide value, dependent on the circuit type

and the supply voltage)

• Load torque (quadratic, constant),

• Starting torque,

• Ambient temperature (rated value +40 °C).

The speed control operating mode (P11.8) must only be

h

used with single drives (one motor at the output of the

frequency inverter). The rated current of the motor must

be assigned to the rated operational current of the

frequency inverter (same rating).

20

04/10 MN04020001Z-EN

Proper use

The M-MAX

TM

frequency inverters are not domestic appliances.

They are designed only for industrial use as system components.

The M-Max

TM

frequency inverters are electrical apparatus for

controlling variable speed drives with three-phase motors. They

are designed for installation in machines or for use in combination

with other components within a machine or system.

After installation in a machine, the frequency inverters must not be

taken into operation until the associated machine has been

confirmed to comply with the safety requirements of Machinery

Safety Directive (MSD) 89/392/EEC (meets the requirements of

EN 60204). The user of the equipment is responsible for ensuring

that the machine use complies with the relevant EU Directives.

TM

The CE markings on the M-MAX

frequency inverter confirm

that, when used in a typical drive configuration, the apparatus

complies with the European Low Voltage Directive (LVD) and the

EMC Directives (Directive 73/23/EEC, as amended by 93/68/EEC

and Directive 89/336/EEC, as amended by 93/68/EEC).

TM

In the described system configurations, M-MAX

frequency

inverters are suitable for use in public and non-public networks.

Proper use

A connection to IT networks (networks without reference to earth

potential) is permissible only to a limited extent, since the device’s

built-in filter capacitors connect the network with the earth potential (enclosure). On earth free networks, this can lead to

dangerous situations or damage to the device (isolation monitoring required).

To the output of the frequency inverter (terminals U, V, W)

h

you must not:

• connect a voltage or capacitive loads (e.g. phase

compensation capacitors),

• connect multiple frequency inverters in parallel,

• make a direct connection to the input (bypass).

Observe the technical data and connection requirements. For

additional information, refer to the equipment nameplate or label

at the frequency inverter and the documentation.

Any other usage constitutes improper use.

21

M-MaxTM Series

04/10 MN04020001Z-EN

Maintenance and inspection

Provided that the general rating data (see Section “Rating data on

the nameplate”, page 14) and the special technical data

( a section “Special technical data” in the Appendix) of the

TM

ratings concerned are observed, the M-Max

frequency inverters

function and the lifespan of the M-Max

therefore recommend that the devices are checked regularly and

the following maintenance measures are carried out at the

specified intervals.

TM

frequency inverter. We

are maintenance free. However, external influences may affect the

Maintenance measures Maintenance interval

Clean cooling vents (cooling slits) If required

Check the fan function 6 - 24 months (depending on the environment)

Filter in the switching cabinet doors (see manufacturer specifications) 6 - 24 months (depending on the environment)

Check the tightening torques of the terminals (control signal terminals, power

terminals)

Check connection terminals and all metallic surfaces for corrosion 6 - 24 months (depending on the environment)

Charge capacitors 12 months, see Section “Charging DC link capacitors”

Regularly

There are no plans for replacing or repairing individual

TM

components of M-Max

If the M-Max

TM

frequency inverter is damaged by external

frequency inverters.

influences, repair is not possible. Dispose of the device in

accordance with the respectively applicable environmental laws

and provisions for the disposal of electrical or electronic devices.

Storage

If the frequency inverter is stored before use, suitable ambient

conditions must be ensured at the site of storage:

• Storage temperature: -40 - +70 °C,

• Relative average air humidity: < 95 %, non condensing

(EN 50178),

• To prevent damage to the DC link capacitors, storage times

longer than 12 months are not recommended (see Section

“Charging DC link capacitors”).

Charging DC link capacitors

After long storage times or long down times without a power

supply (> 12 months), the capacitors in the DC link must undergo

controlled recharging, in order to avoid damage.

For this the M-Max

TM

frequency inverters must be fed with a

regulated DC power supply unit via two mains connection

terminals (e.g. L1, L2/N). To avoid any possible excessive leakage

currents from the capacitors, the inrush current should be limited

to around 300 to 800 mA (depending on the rating). In this case,

the frequency inverter must not be enabled (no start signal). The

DC voltage must then be set to the values of the corresponding DC

link voltage (U

) and fed for around two hours (regeneration

DC

time).

MMX11: Due to the internal voltage doubler circuit, the

h

capacitors cannot be recharged via the connection

terminals. Contact your local sales partner.

Service and warranty

In the unlikely event that you have a problem with your Moeller M-

TM

Max

frequency inverter, please contact your local sales office.

When you call, have the following information ready:

• the exact frequency inverter part no.

(see nameplate),

• the date of purchase,

• a detailed description of the problem which has occurred with

the frequency inverter.

If some of the information printed on the nameplate is not legible,

please state only the information which is clearly legible.

Information concerning the guarantee can be found in the Moeller

General Terms and Conditions of Sale.

24-hour hotline: +49 (0)1805 223 822

E-Mail: FieldserviceEGBonn@Eaton.com

• MMX12, MMX32 about 324 V DC (= 1.41 x U

phase line-to-line voltage (230 V)

• MMX34 about 540 V DC (= 1.35 x U

to-line voltage (400 V).

22

) with single-

LN

) with three-phase line-

LN

04/10 MN04020001Z-EN

2 Engineering

Introduction

This chapter describes the most important features in the energy

circuit of a drive system (PDS = Power Drive System), which you

should take into consideration in your project planning.

L1

L2

a

L3

PE

b

c

I > I > I >

RCD

k

d

e

R+ R-

L1 L2/N

PE

U

L3 PE

VW

M

3

˜

j

g

f

#

h

PES

i

PES

i

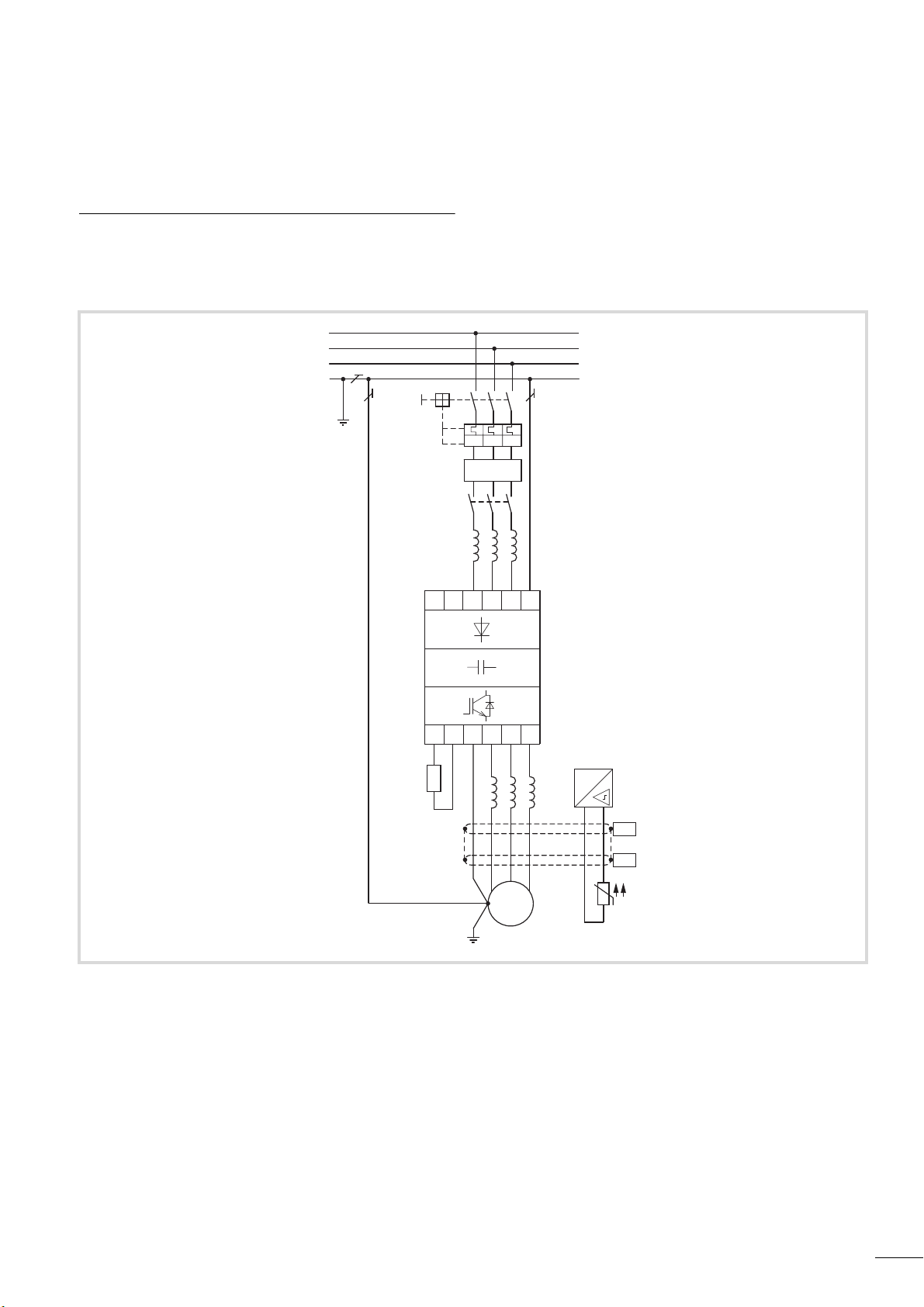

Figure 9: Drive system (PDS)

a Network configuration, mains voltage, mains frequency, interaction with p.f. correction systems

b Fuses and cable cross-sections, line protection

c Protection of persons and domestic animals with residual-current protective devices

d Mains contactor

e Mains reactor, radio interference suppression filter, mains filters

f Frequency inverter: mounting, installation; power connection; EMC measures; circuit examples

g Motor reactor, du/dt filter, sine-wave filter

h Motor protection; thermistor

i Cable lengths, motor cables, shielding (EMC)

j Motor and application, parallel operation of multiple motors on a frequency inverter, bypass circuit; DC braking

k Braking resistance; dynamic braking

23

Engineering

L2

N

L1

L3

PE

04/10 MN04020001Z-EN

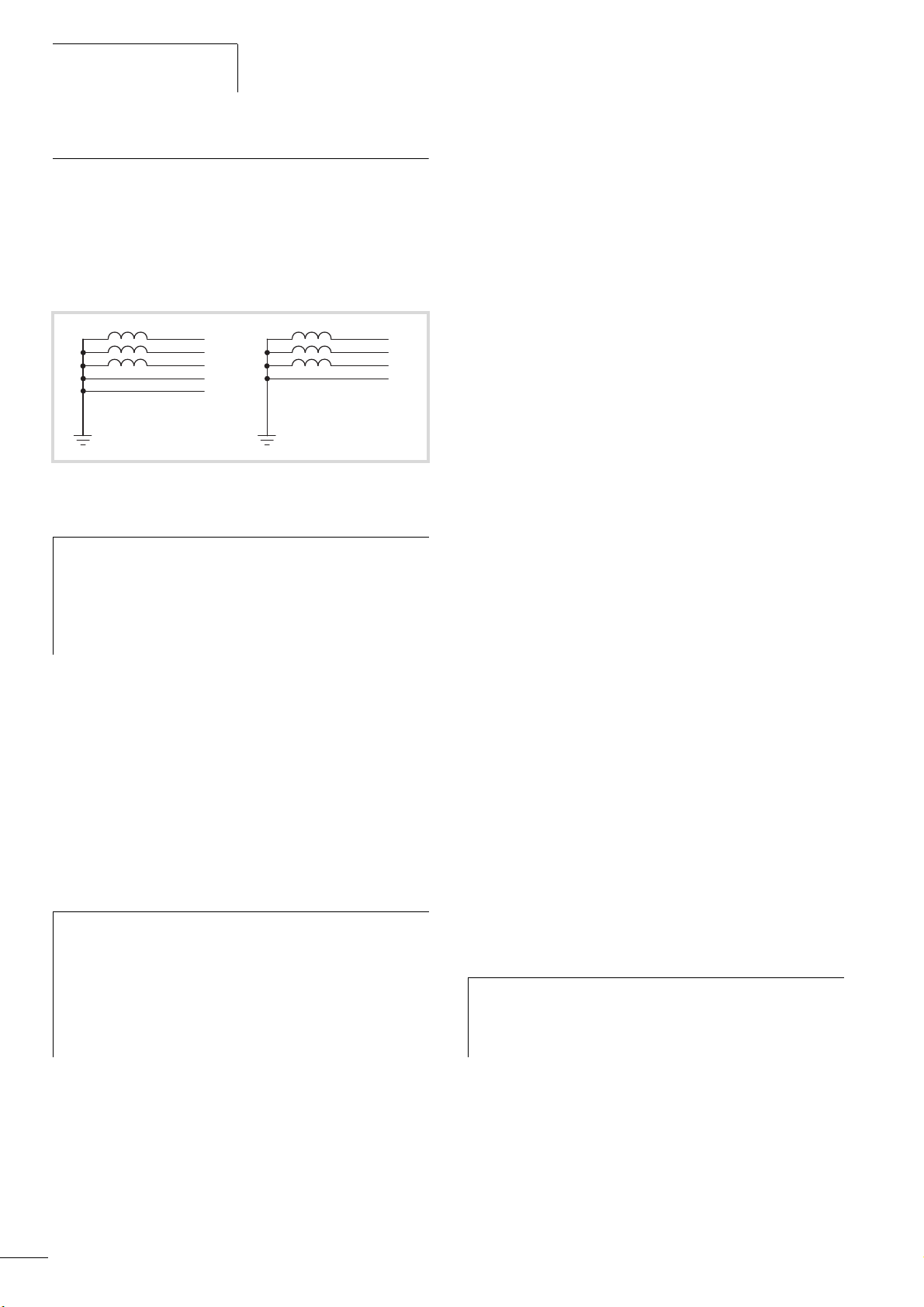

Electrical power network

Mains connection and configuration

TM

The frequency inverters of the M-Max

series can be connected

and operated with all control-point grounded AC power networks

(see IEC 60364 for more information in this regard).

L1

L2

L3

PEN

Figure 10: AC power networks with grounded center point (TN-/TT

networks)

While planning the project, consider a symmetrical

h

distribution to the three external conductors, if multiple

frequency inverters with single phase supplies are to be

connected. The total current of all single phase consumers

is not to cause an overload of the neutral conductor

(N-conductor).

The connection and operation of frequency inverters to

asymmetrically grounded TN networks (phase-grounded Delta

network "Grounded Delta", USA) or non-grounded or highresistance grounded (over 30 O) IT networks is only conditionally

permissible.

TM

If the M-Max

frequency inverters are connected to an

asymmetrically grounded network or to an IT network (non

grounded, insulated), the internal interference suppression filter

must be disconnected (unscrew the screw marked EMC,

a section “Electrical Installation”, page 37).

The required filtering for electromagnetic compatibility (EMC) is

then no longer present.

Measures for electromagnetic compatibility are

h

mandatory in a drive system, to meet the legal

requirements for EMC- and low-voltage regulations.

Mains voltage and frequency

The standardized mains voltages (IEC 60038, VDE017-1) for

energy suppliers (EVU) guarantee the following conditions at the

transition points:

• Deviation from the rated value of voltage:

maximum ±10 %

• Deviation in voltage phase balance: maximum ±3 %

• Deviation from rated value of the frequency:

maximum ±4 %

TM

The broad tolerance band of the M-Max

frequency inverter

considers the rated value for

European as (EU: U

American as (USA: U

= 230 V/400 V, 50 Hz) and

LN

= 240 V/480 V, 60 Hz) standard voltages:

LN

• 120 V, 50/60 Hz at MMX11

• 230 V, 50 Hz (EU) and 240 V, 60 Hz (USA) at MMX12 und

MMX32,

• 400 V, 50 Hz (EU) and 480 V, 60 Hz (USA) at MMX34…

For the bottom voltage value, the permitted voltage drop of 4 %

in the consumer circuits is also taken into account, therefore a

total of U

- 14 %.

LN

• 100 V device class (MMX11):

110 V -15 % - 120 V +10 % (94 V -0 % - 132 V +0 %)

• 200-V device class (MMX12, MMX32):

208 V - -15 % – 240 V + +10 % (177 V - 0 % – 264 V + 0 %)

• 400-V device class (MMX34):

380 V - -15 % – 480 V + +10 % (323 V - 0 % – 528 V + 0 %)

The permitted frequency range is 50/60 Hz here (45 Hz - 0 % – 66

Hz + 0 %).

Voltage balance

Because of the uneven loading on the conductor and with the

direct connection of greater power ratings, deviations from the

ideal voltage form and unsymmetrical voltages can be caused in

three-phase AC power networks. These asymmetric divergences in

the mains voltage can lead to different loading of the diodes in

mains rectifiers with three-phase supplied frequency inverters and

as a result, to an advance failure of this diode.

24

Good grounding measures are a prerequisite for the

effective insert of further measures such as shielding or

filters here. Without respective grounding measures,

further steps are superfluous.

In the project planning for the connection of three-phase

h

supplied frequency inverters (MMX32, MMX34), consider

only AC power networks that handle permitted

asymmetric divergences in the mains voltage F +3 %.

If this condition is not fulfilled, or symmetry at the connection

location is not known, the use of an assigned main choke is

recommended (see “Appendix“, Section “Mains chokes”,

page 169).

04/10 MN04020001Z-EN

K

U

2

2

U+

3

2

U

4

2

U

n

++

2

+

U

1

2

U+

2

2

U

3

2

U

4

2

U

n

++

2

++

-------------------------------------------------------------------------------------------

100%=

THD

U

2

2

U+

3

2

U

4

2

U

n

++

2

+

U

1

------------------------------------------------------------------------------=

Electrical power network

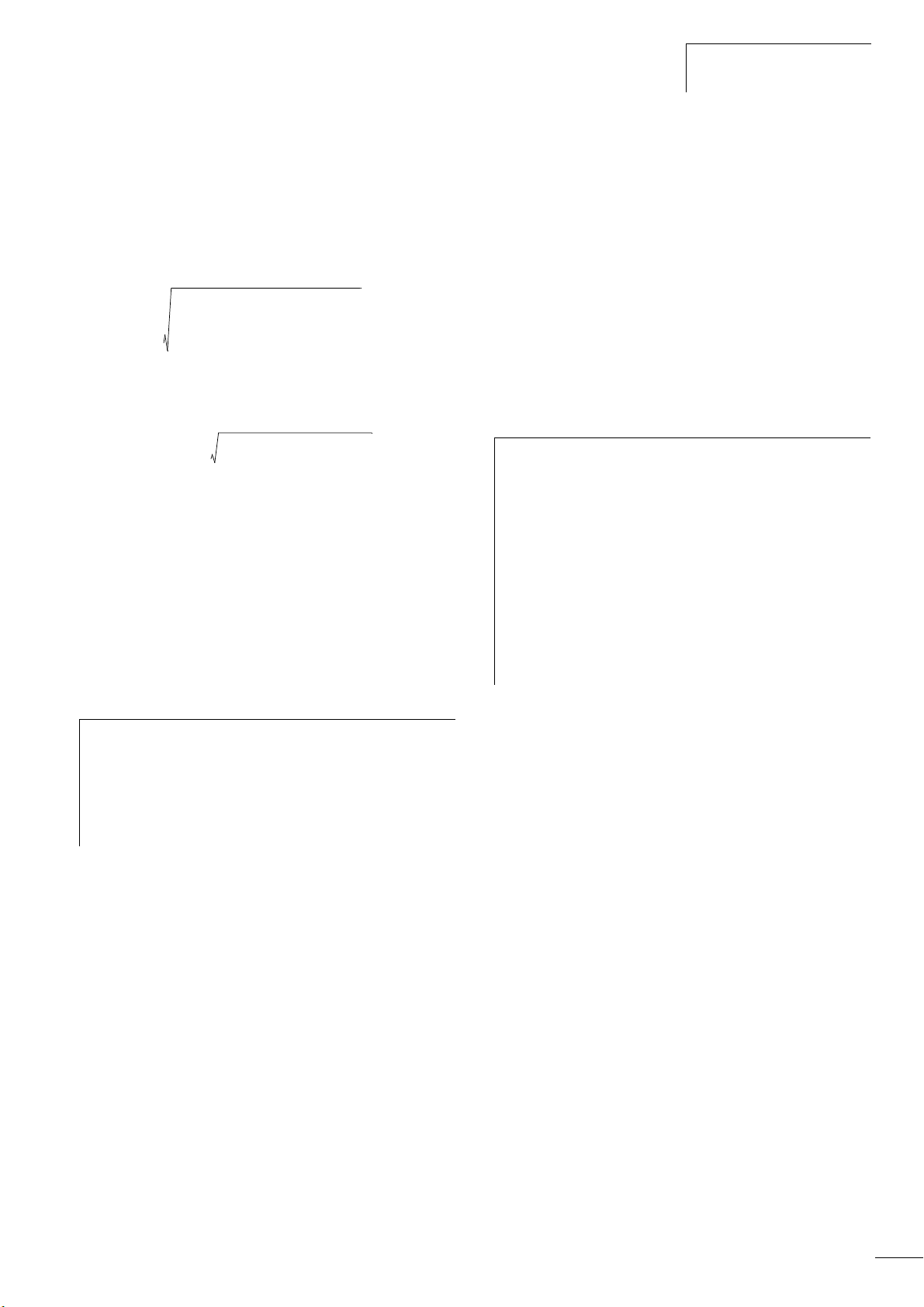

Total harmonic distortion (THD)

The THD (Total Harmonic Distortion) is a measurement for the

occurring harmonic distortion of the sinusoidal oscillation (mains

power side) input variables with the frequency inverter. It is given

in percent of the total value.

U1 = fundamental component

THD k = 0.1 l K = 10 % ~ -20 dB (THD suppression)

THD (Total Harmonic Distortion)

TM

With the frequency inverters of the M-Max

series, the permitted

value for the total harmonic distortion THD >120 %.

Idle power compensation devices

Compensation on the power supply side is not required for the

TM

frequency inverters of the M-MAX

series. From the AC power

supply network they only take on very little reactive power of the

fundamental harmonics (cos

In the AC power networks with non-choked idle current

h

v ~ 0.98).

compensation devices, current deviations can enable

parallel resonance and undefinable circumstances.

Mains reactors

A mains reactor (also called commutation inductors) increases the

inductance of the power supply line. This extends the current flow

period and dampens mains deviations.

On frequency inverters, a mains reactor limits the mains feedback

to permissible values. The harmonic current emissions that are fed

back into the mains network ("mains feedback") are reduced. This

reduces the mains-side apparent current to about 30 %.

Towards the frequency inverter, the mains reactors dampen the

interference from the supply network. This increases the withstand

voltage of the frequency inverter and lengthens the lifespan

(diodes of the mains power rectifier, intermediate circuit

capacitors).

For the operation of the M-MAXTM frequency inverter, the

h

application of main chokes is not necessary.

We do recommend however that an upstream main choke

is used since the network quality is not known in most

cases.

While planning the project, consider that a mains reactor

is only assigned to a single frequency inverter for

isolation. Using a large mains reactor for multiple small

frequency inverters should therefore be avoided if at all

possible.

When using an adapting transformer (assigned to a single

frequency inverter), a main choke is not necessary.

Mains reactors are designed based on the mains-side input current

) of the frequency inverter. Mains chokes and the assignment

(I

LN

to M-MAX

TM

frequency inverters are explained in the appendix.

In the project planning for the connection of frequency

inverters to AC power networks with undefined

circumstances, consider using main chokes.

25

Engineering

04/10 MN04020001Z-EN

Safety and switching

Fuses and cable cross-sections

The fuses and wire cross-sections allocated for power-side

connections depend on the rated mains current I

frequency inverter (without mains reactor).

Caution!

h

When selecting the cable cross-section, take the voltage

drop under load conditions into account.

The consideration of other standards (e.g. VDE 0113 or

VDE 0289) is the responsibility of the user.

The recommended fuses and their assignment to the frequency

inverters are listed in page 157 the appendix.

The national and regional standards (for example VDE 0113, EN

60204) must be observed and the necessary approvals (for

example UL) at the site of installation must be fulfilled.

When the device is operated in a UL-approved system, use only

UL-approved fuses, fuse bases and cables.

The leakage currents to ground (to EN 50178) are greater than

3.5 mA. The connection terminals marked PE and the housing

must be connected with the ground circuit.

The leakage currents for the individual performance variables are

listed in the appendix on page 147 ff.

of the

LN

Residual current circuit breakers protect persons and animals from

the existence (not the origination) of impermissibly high contact

voltages. The prevent dangerous, in cases deadly injuries caused

by electrical accidents and also serve as fire prevention.

Warning!

j

With frequency inverters, only AC/DC sensitive residual

current circuit breakers (RCD type B) are to be used

(EN 50178, IEC 755).

Identification on the residual-current circuit-breakers

AC/DC sensitive

(RCD, type B)

Frequency inverters work internally with rectified AC currents. If an

error occurs, the DC currents can block an RCD circuit breaker of

type A from triggering and therefore disable the protective

functionality.

Caution!

h

Debounced inputs may not be used in the safety

circuit diagram.

Residual current circuit breakers (RCD) are only to be

installed between the AC power supply network and the

frequency inverter.

Safety-relevant leakage currents can occur while handling and

when operating the frequency inverter, if the frequency inverter is

not grounded (because of a fault).

Caution!

h

The specified minimum PE conductor cross-sections (EN

50178, VDE 0160) must be maintained.

Choose the cross-section of the PE conductor in the motor

h

lines at least as large as the cross-section of the phase

lines (U, V, W).

Cables and fuses

The cross-sections of the cables and line protection fuses used

must correspond with local standards.

For an installation in accordance with UL guidelines, the fuses and

copper cable that are UL-approved and have a heat-resistance of

+60/75 °C are to be used.

Use power cables with insulation according to the specified mains

voltages for the permanent installation. A shielded cable is not

required on the mains side.

A completely (360°) shielded low impedance cable on the motor

side is required. The length of the motor cable depends on the

RFI class and must not exceed 30 m for the M-Max

Residual-current device (RCD)

TM

.

Leakage currents to ground are mainly caused by foreign

capacities with frequency inverters; between the motor phases

and the shielding of the motor cable and via the Y-capacitors of

the noise filter. The size of the leakage current is mainly dependent

upon the:

• length of the motor cable,

• shielding of the motor cable,

• height of the pulse frequency (switching frequency of the

inverter),

• design of the noise filter,

• Grounding measures at the site of the motor.

The leakage current to ground is greater than 3.5 mA with

h

a frequency inverter. Based on the requirements of

EN 50178, an increased ground (PE) has to be connected.

The cable cross-section must be at least 10 mm

consist of two separately connected ground cables.

As long as you use residual current circuit breakers, they

h

must be suitable for:

• the protection of installations with DC current

component in case of fault scenario (RCD type B),

• high leakage currents (300 mA),

• brief discharges of pulse current spikes.

2

or

RCD (Residual Current Device): Residual current device, residual

current circuit breaker (FI circuit breaker)

26

Loading...

Loading...