Page 1

Instructional Leaet IL66A7508H09

Effective October 2016

Supersedes July 2009

mMINT—Modbus translator module—

installation and use

Contents

Description Page

List of figures ............................2

List of tables .............................2

Section 1: General description ...............2

Section 2: Features ........................3

Section 3: Installation ......................3

Module mounting ........................3

Simplified wiring rules ....................3

Section 4: mMINT module connections ........3

Power connections .......................3

INCOM connections .....................4

Modbus connections .....................4

Section 5: Switches and indicator LEDs ........4

Modbus RS-485 network Rx LED (green) .....4

Modbus RS-485 network Tx LED (green) .....4

INCOM network Rx LED (green) ............4

INCOM network Tx LED (green) ............4

Status LED (green) .......................4

INCOM 100 ohms termination DIP

switch (SW1) ...........................4

Modbus RS-485 baud rate DIP switch (SW2) ..4

Unique mMINT address (SW2) .............5

Modbus 121 ohm termination DIP

switch (SW3) ...........................5

Section 6: Network communication protocols ...5

Overview ..............................5

Function codes ..........................5

Block of registers ........................5

Register access configurations .............5

INCOM routing address configurations .......6

Command/data pass-through ...............6

Control of INCOM product .................6

Energy format ..........................7

Supported diagnostic sub-functions ..........8

Exception codes .........................8

Section 7: Troubleshooting ..................9

Appendix A ..............................9

Page 2

Instructional Leaet IL66A7508H09

Effective October 2016

mMINT—Modbus translator module—

installation and use

List of gures

Description Page

Figure 1. The mMINT module ..............................2

Figure 2. mMINT in a communications network ................2

Figure 3. Connections ....................................3

Figure 4. Indicators ......................................4

Figure 5. Switches .......................................4

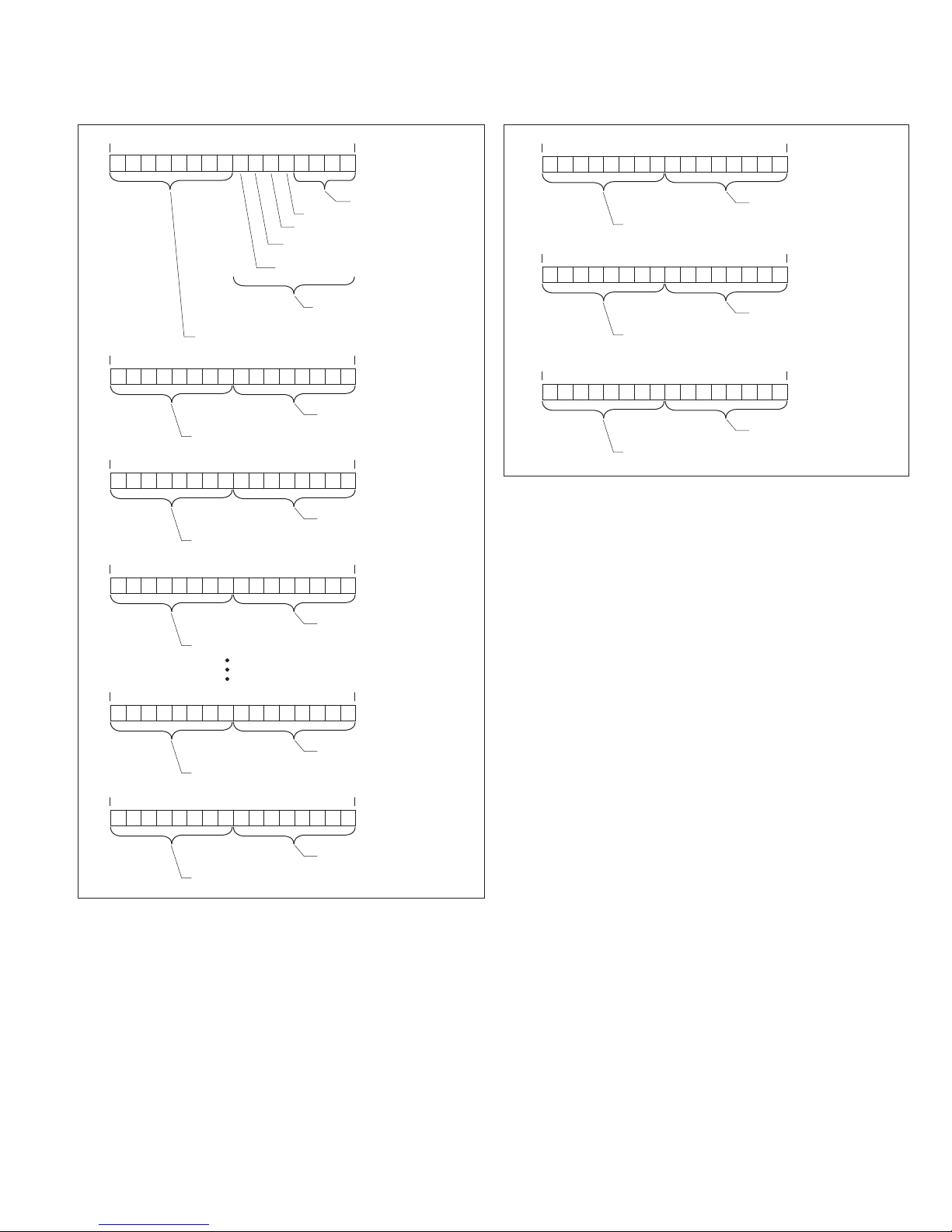

Figure 6. Pass-through to INCOM product query data format .....6

Figure 7. Pass-through to INCOM product response data format ...7

Figure 8. Control to INCOM product data format ...............7

Figure 9. 4-register energy data format ......................8

List of tables

Description Page

Table 1. Power connector pin outs ..........................3

Table 2. INCOM connector pin outs .........................4

Table 3. Modbus RS-485 connector pin outs ..................4

Table 4. RS-485 baud rate switches (normal) ..................5

Table 5. RS-485 baud rate switches (diagnostics) ..............5

Table 6. Diagnostic sub-function numbers ....................8

Table 7. Troubleshooting guide .............................9

Table 8. Modbus register map (in register number order) .......10

Table 9. Modbus register map (in functional order) ............14

Table 10. Primary status code definitions ....................17

Table 11. Secondar y status code definitions .................. 17

Table 12. Cause-of-status code definitions ...................17

Table 13. Control ‘Slave Action Number’ definitions ...........18

Table 14. mMINT configuration registers ....................19

Section 1: General description

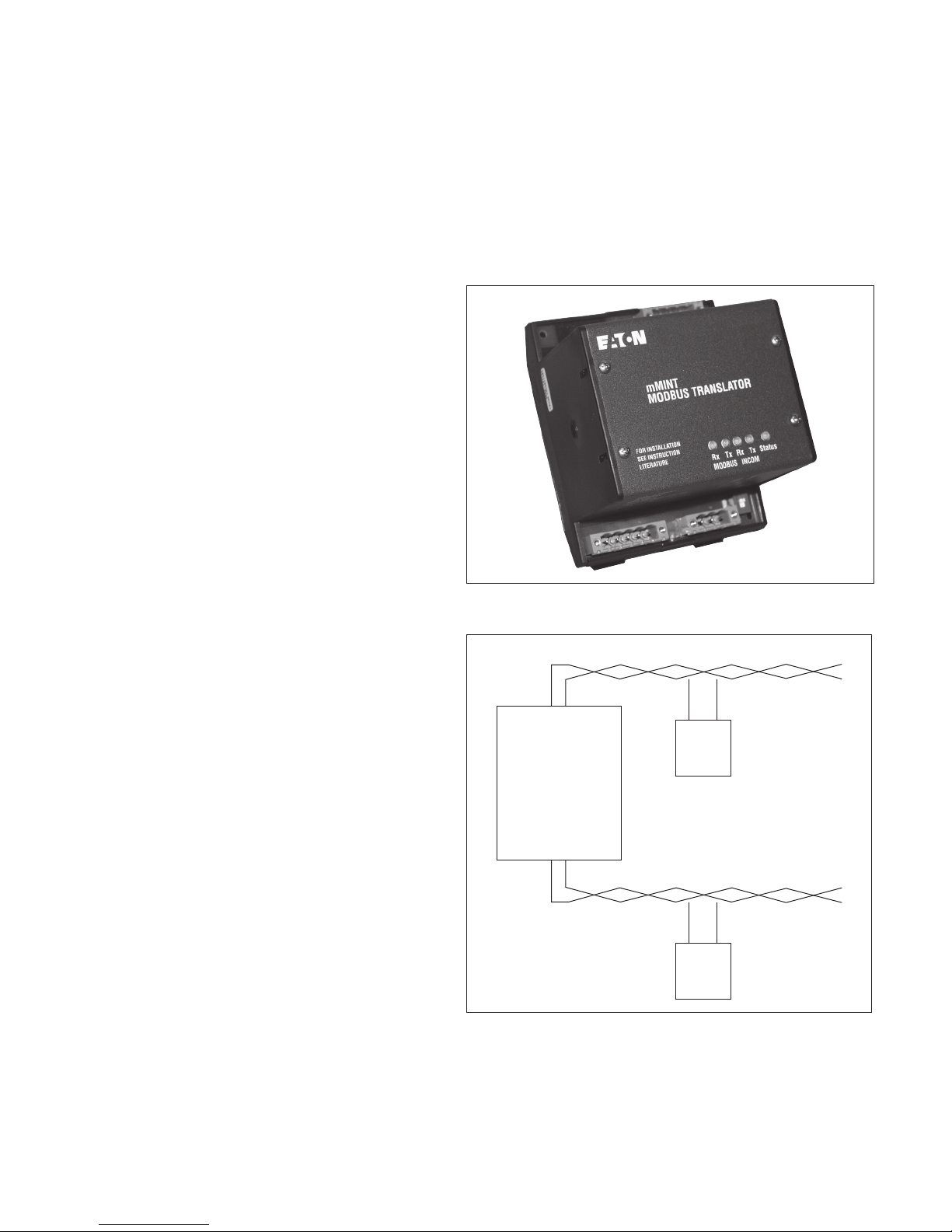

The mMINT (ModbusT Master INCOM network translator) module,

as seen in Figure 1, is an Eaton accessory product that will provide

communication between a Modbus RTU network and an INCOME

(INdustrial COMmunications) network (see Figure 2). This module is

transparent to the Modbus network. It communicates to a master on

the Modbus network using the Modbus RTU (remote terminal unit)

protocol. It communicates to slave devices on the INCOM network

using the PowerNet protocol. The catalog number of this product

is MMINT.

Figure 1. The mMINT module

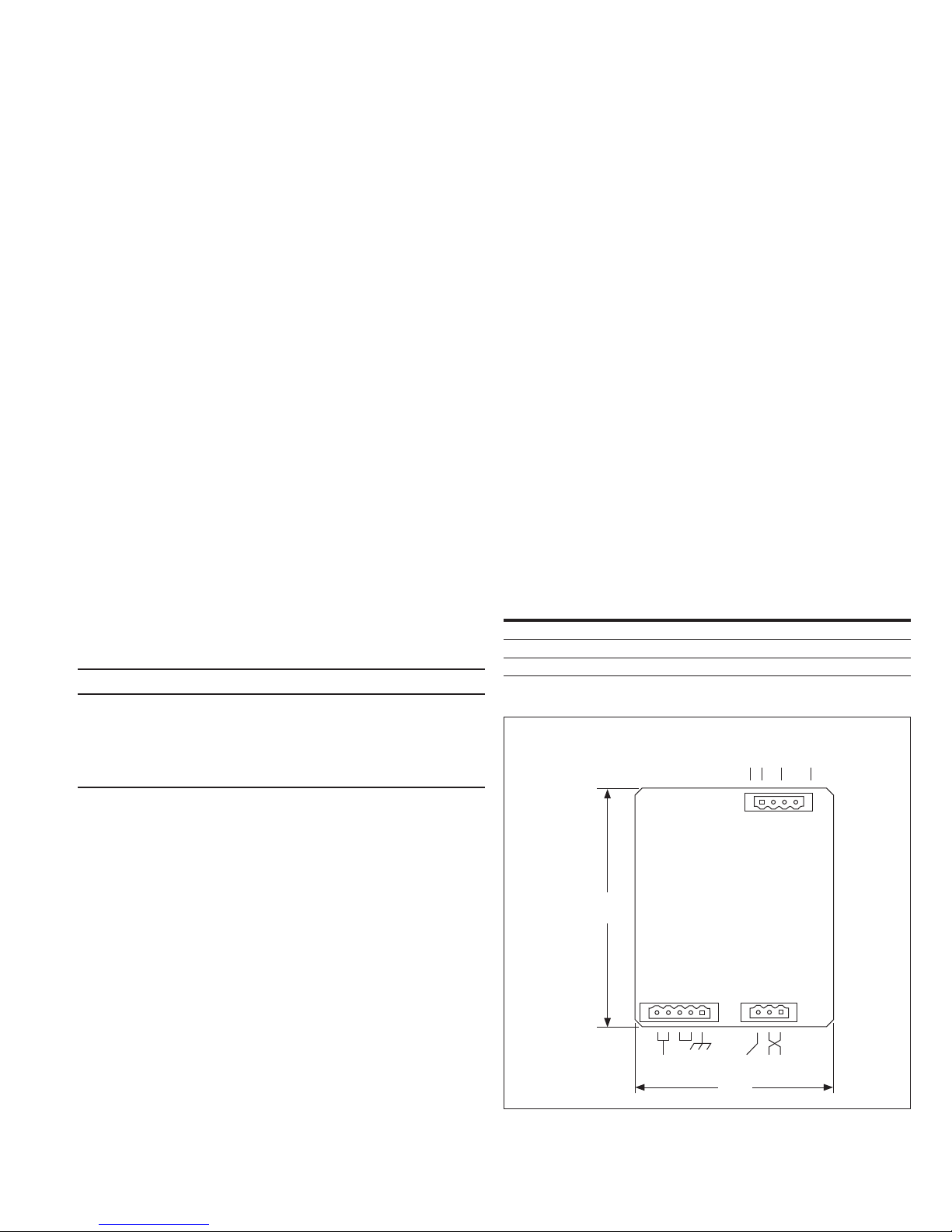

Modbus RTU serial network

(Slave)

Modbus

mMINT

(Master)

INCOM network

Figure 2. mMINT in a communications network

Modbus master

INCOM slaves

2

EATON www.eaton.com

Page 3

mMINT—Modbus translator module—

installation and use

Section 2: Features

The mMINT module is a slave device on the Modbus network and

as such requires a master that will exchange register objects with

the mMINT module.

•

Handles generic pass-through commands

(Modbus/INCOM/Modbus)

•

Capable of passing Modbus register objects from Eaton’s

existing products and newer Plug-n-Play products to a Modbus

RTU master

•

Data in IEEET Floating Point format and fixed point.

•

Modbus RTU communications data transfer rates of 1200, 9600,

or 19200 baud with one start bit, eight data bits, no parity, and

either one or two stop bits

•

Up to 32 products connected to INCOM network port

(246 unique addresses maximum)

•

Flashing Status LED to indicate an active module

•

LED indicators for INCOM transmit and receive

communications exchanges

•

LED indicators for Modbus RS-485 transmit and receive

communications exchanges

•

Input power for the module from either 120 Vac or 24 to 125 Vdc

•

DIN rail mount package

•

0 °C to 60 °C ambient operation

Section 3: Installation

The mMINT module is designed to be installed, operated, and

maintained by adequately trained personnel. These instructions

do not cover all of the details or variations of the equipment

for its storage, delivery, installation, checkout, safe operation,

or maintenance.

m WARNING

DO NOT ATTEMPT TO INSTALL OR PERFORM MAINTENANCE ON

EQUIPMENT WHILE IT IS ENERGIZED. DEATH OR SEVERE PERSONAL

INJURY CAN RESULT FROM CONTACT WITH ENERGIZED EQUIPMENT.

ALWAYS VERIFY THAT NO VOLTAGE IS PRESENT BEFORE PROCEEDING.

ALWAYS FOLLOW SAFETY PROCEDURES. EATON IS NOT LIABLE FOR THE

MISAPPLICATION OR MISINSTALLATION OF ITS PRODUCTS.

Instructional Leaet IL66A7508H09

Effective October 2016

•

Make sure that there is twisted-pair wire that is recommended for

PowerNet network use. Use shielded twisted-pair wire to connect

each slave to the INCOM network, daisy-chain style. The polarity

of the twisted pair is not important.

Modbus RS-485 network

The following simplified rules apply to a given system consisting of

a cable link between master and slave devices (see Figure 2). For

more complex configurations, please refer to standard Modbus RTU

wiring specification rules for the RS-485 network.

•

The recommended Modbus cable has twisted-pair wires

(24 AWG stranded 7x32 conductors with PVC insulation)

having an aluminum/mylar foil shield with drain wire

•

The maximum system capacity is 4000 feet of communications

cable and 247 devices on the Modbus RTU network

•

Make sure that there is twisted-pair wire that is recommended

for Modbus RTU network use. Use shielded twisted-pair wire

to connect each slave to the Modbus RTU network, daisy-chain

style. The polarity of the twisted pair is critically important.

Section 4: mMINT module connections

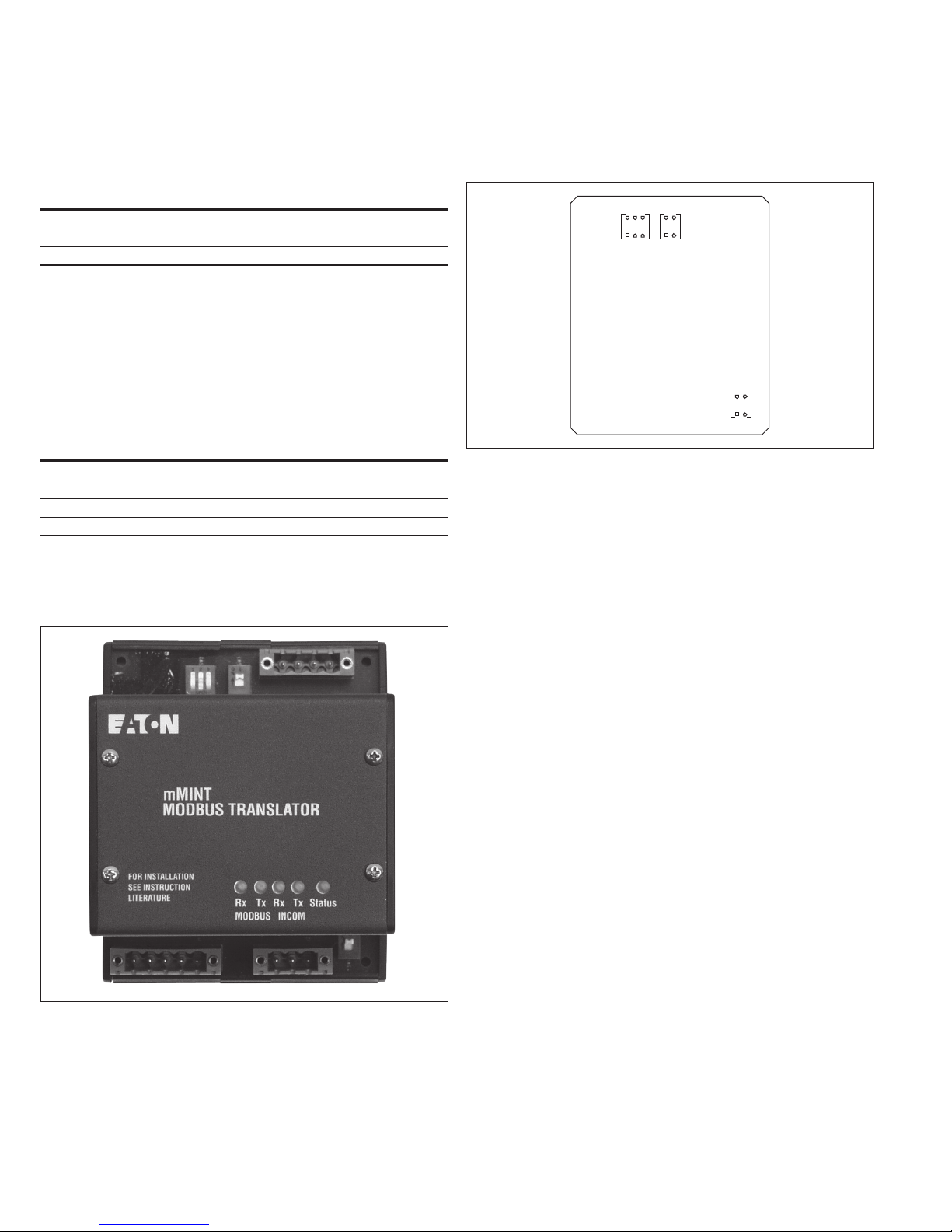

Refer to Figure 3 and the following three pin out tables for

installation specifics.

Power connections

Power connector: Module power uses a 5-pin input connector

(see Figure 3). Power requirements are 120 Vac, 60 Hz or

24–125 Vdc. Refer to Table 1.

Table 1. Power connector pin outs

Pin number Input power

1 Chassis ground

2 and 3 Vac neutral/Vdc common

4 and 5 Vac line/24 –125 Vdc+

RS-485

Modbus

A B

COM SHD

If you have any questions or need further information or instructions,

please contact your local Eaton representative or the Customer

Support Center at 877-ETN-CARE (877-386-2273).

Module mounting

When mounting the mMINT, verify that an 11H x 28W mm DIN rail

is used and that it is within an enclosed space.

Simplified wiring rules

INCOM network

The following simplified rules apply to a given system consisting of

a single daisy-chained main cable link between master and slave

devices (see Figure 2). For more complex considerations, including

star configurations, please refer to the wiring specification T.D. 17513.

•

Recommended INCOM cable styles are Belden 9463 or

C-H style 2A957805G01

•

The maximum system capacity is 10,000 feet of communications

cable and 32 slave devices on the INCOM network under

the mMINT

•

Non-terminated taps, up to 200 feet in length, off the main link

are permitted, but add to the total cable length

4.25

(108.0)

Figure 3. Connections

J1

24–125 Vdc

120 Vac

EATON www.eaton.com

J3

J2

Shield INCOM

3.54

(89.9)

3

Page 4

Instructional Leaet IL66A7508H09

Effective October 2016

mMINT—Modbus translator module—

installation and use

INCOM connections

INCOM connector: This 3-pin connector provides the interface to

the INCOM network. Refer to Table 2.

Table 2. INCOM connector pin outs

Pin number Input/output signal

1 INCOM carrier network

2 INCOM carrier network

3 Shield

Connect shield wire to ground at master device end only.

Interconnect shielding where devices are daisy chained.

Modbus connections

Modbus RS-485 Connector: This 4-pin connector provides the

interface to the Modbus RTU network. The polarity is “critically”

important. Refer to Table 3.

Table 3. Modbus RS-485 connector pin outs

Pin number Input/output signal

1 RS-485 Network-A (non-inverting)

2 RS-4 85 Net work-B (inverting)

3 Common

4 Shield

RS-485 Network-A is the non-inverting differential connection for the

Modbus RTU network. RS-485 Network-B is the inverting differential

connection for the Modbus RTU network.

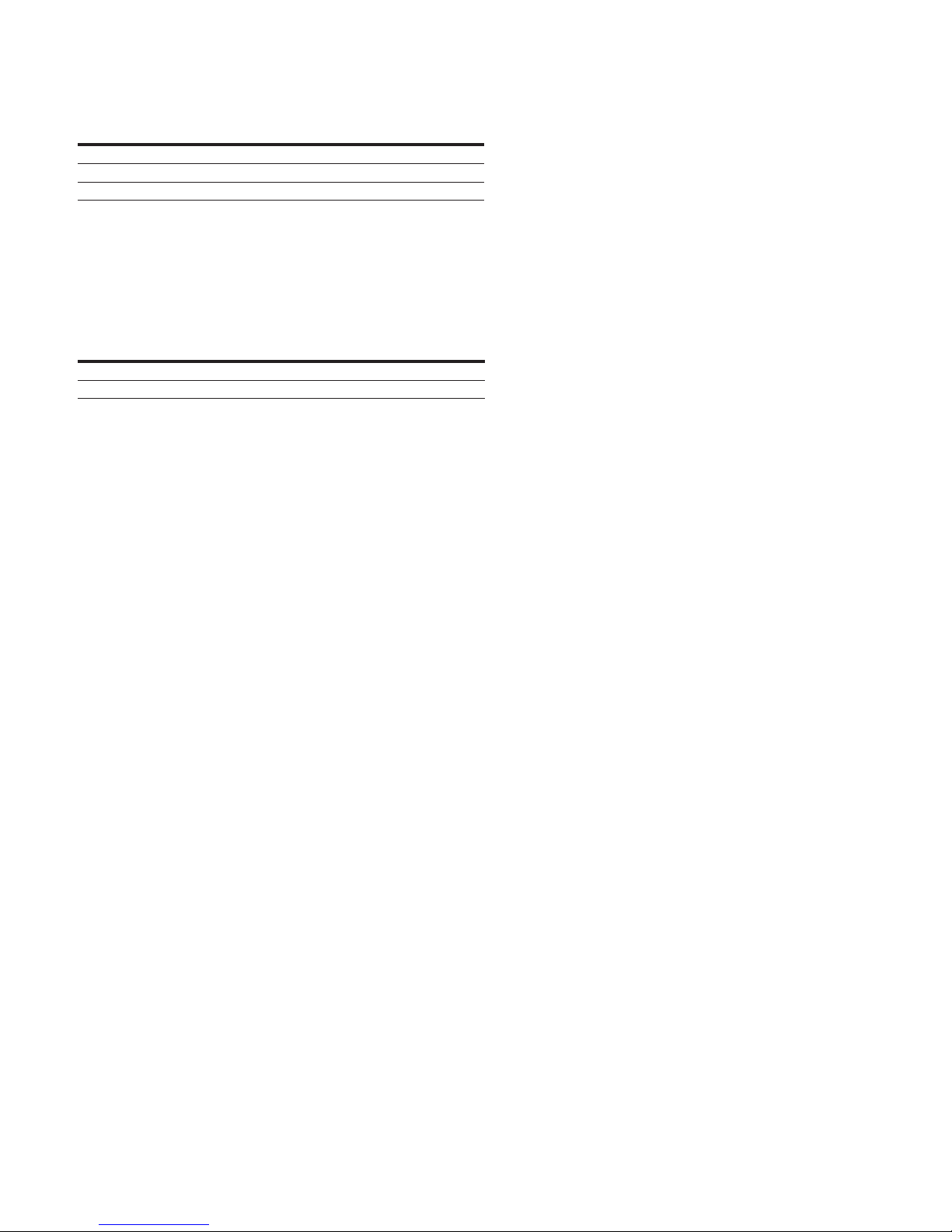

Section 5: Switches and indicator LEDs

Refer to Figure 4 to locate the Status LED for the mMINT module.

Figure 5 shows the location of the configuration switches.

SW2 SW3

Closed

Open

SW1

Figure 5. Switches

Modbus RS-485 network Rx LED (green)

The LED will be lighted whenever the module is receiving from the

Modbus RTU network.

Modbus RS-485 network Tx LED (green)

The LED will be lighted whenever the module is transmitting on the

Modbus RTU network.

INCOM network Rx LED (green)

The LED will be lighted whenever the module is receiving from the

INCOM network.

Figure 4. Indicators

INCOM network Tx LED (green)

The LED will be lighted whenever the module is transmitting on the

INCOM network.

Status LED (green)

This indicator will be flashing whenever the module is powered up

and the microcontroller is executing instructions. The flashing rate is

approximately 1 second ON / 1 second OFF. However, detection of

a communications error on either the Modbus or INCOM network

will result in an increased flashing rate approximately 1/2 second ON

/ 1/2 second OFF. The rate will return to normal when the network’s

diagnostic reset subfunction (clear UART or slave counters,

respectively) is processed by the mMINT. See Section 6 and Table 6.

INCOM 100 ohms termination DIP switch (SW1)

This switch should be moved to the ON position only when it is the

last unit in a chain of units or if it is a single unit.

Modbus RS-485 baud rate DIP switch (SW2)

To configure the data transfer rate for the Modbus RTU network,

three switches in DIP switch SW2 should be moved to either the

CLOSE or the OPEN position based on the rate required. Refer to

Table 4. SW2-1 is for mMINT diagnostics.

4

EATON www.eaton.com

Page 5

mMINT—Modbus translator module—

installation and use

Instructional Leaet IL66A7508H09

Effective October 2016

Table 4. RS-485 baud rate switches (normal)

Baud SW 2-1 SW2-2 SW2-3

1200 X CLOSE CLOSE

9600 X OPEN CLOSE

19200 X CLOSE OPEN

Unique mMINT address (SW2)

The mMINT can be assigned address 247 and 248. For the mMINT

to respond to a diagnostic query related to address 247 or 248 on

the Modbus network, move DIP switch SW2-1 to the OPEN position.

Refer to Table 5. Normally, this switch is in the CLOSE position.

Table 5. RS-485 baud rate switches (diagnostics)

Baud SW 2-1 SW2-2 SW2-3

Addr. 247 or 248 OPEN X X

Normal CLOSE X X

Modbus 121 ohm termination DIP switch (SW3)

This switch should be moved to the ON position only when it is the

last unit in a chain of units or if it is a single unit.

Section 6: Network communication protocols

The lower INCOM communication network for the mMINT is

based on a master-slave protocol. The mMINT is a master on the

INCOM network.

In order to satisfy the mMINT communications needs, please see

Reference Materials:

IL17384—Part A: INCOM Communications Standard, Eaton.

Specific product profiles are located in the other Part sections.

http://www.eaton.com, then search on 17384.

“Modicon Modbus Protocol”

http://www.modicon.com/techpubs/toc7.html

Overview

The contents of Modbus registers are INCOM product objects

—phase A current). The mMINT ensures that unique objects

(e.g., I

A

reside in identical registers independent of INCOM product.

Consequently, for all INCOM products there is a single register

map of objects. See Table 8 or Table 9.

INCOM objects occupy two registers except for certain energy—

real and reactive—objects. These energy objects occupy four

registers. The mMINT can support a maximum of 122 registers

within a single Modbus transaction.

The mMINT is transparent to the Modbus master and responds

to every address of INCOM products attached to it. In its default

configured state, INCOM product addresses are Modbus network

addresses. The mMINT can be configured to route the Modbus

address to a different INCOM product address or an INCOM

sub-network product address. See Section 6.

An upgrade has been incorporated to allow the mMINT to

communicate with Modbus masters that can only access to

register 9999. Registers previously assigned above 9999 have

been assigned dual access, both at the original register (to provide

compatibility) and at a new register assignment below 9999.

The format is given as low/high register numbers followed by

/high16 Modbus register addresses), for example:

(low

16

4xxxx/4yyyyy (XXXX+1

Only the RTU communications mode is recognized by the mMINT.

/YYYY+116). See Table 14.

16

Function codes

The mMINT responds to a limited number of Modbus function

codes. These are function codes 03, 04, 08, and 16 (10

).

16

Block of registers

A block of registers (from the register column of Table 8 or Table 9)

can be established for each INCOM product attached to a mMINT.

Function code 16 (10

the block of registers. The block assignments are stored beginning at

register 41001/420481 (03E8

address is assigned within the block of registers. For example,

although object I

), only register address (120216) is loaded into the block

(1203

16

of assignment registers. Verification of this block of assignment

) is used to load the object assignments for

16

/500016).Only the first object register

16

occupies registers 404611 (120216) and 404612

A

registers can be read from the mMINT by a read function code 03

or 04 from these 41001/420481 (03E8

/500016) registers.

16

Data pertaining to the objects configured in the block of assignment

registers is mapped into registers starting at 41201/420737

/510016) and continuing in successive order for each object

(04B0

16

assigned. The number of objects and their placement order in this

data block of registers is dependent on the configuration of the block

of assignment registers. The total number of data block of registers

is limited to 100.

ote:N An object can occupy one, two, or four registers.

The data can be obtained from the data block of registers by a read

function code 03 or 04. The address of the starting object must be

aligned with a starting address of an object within the data block

of registers. The number of registers to obtain must align with an

ending address of an object within the data block of registers.

Register access configurations

Non-volatile register 42001/425345 (07D016/630016) is used to

configure the mMINT to respond to a group of data objects, of

which some objects are invalid within that group. When non-zero

(factory default value), any attempt to access a group of data objects

that contain an invalid object will result in an illegal data object

exception code 02. See Section 6.

When register 42001/425345 (07D0

the mMINT will respond to a group of objects with data contained in

/630016) is set to zero, however,

16

the valid objects of the group along with an illegal

value, if available else 0000

Non-volatile register 42002/425346 (07D1

configure 32-bit IEEE floating point word order. When non-zero

, data contained in the invalid objects.

16

/630116) is used to

16

(factory default), the floating point low order word is first in the

Modbus register space.

When register 42002/425346 (07D1

the floating point high order word is first in the Modbus register

/630116) is set to zero, however,

16

space.

Non-volatile register 42002/425347 (07D1

configure 32-bit fixed point and 64-bit energy word order. When

/630216) is used to

16

non-zero (factory default), the fixed point and energy low order

word is first in the Modbus register space.

When register 42003/425347 (07D2

the fixed point and energy high order word is first in the Modbus

/630216) is set to zero, however,

16

register space.

Registers not containing a 32-bit or 64-bit format, such as Status and

Product ID objects, pass through registers, INCOM control registers,

and INCOM routing address configuration registers, are not effected

by the word order configuration registers.

Configuring any or all registers 42001/425345 through 42003/425347

/630016 through 07D216/630216) is accomplished using a write

(07D0

16

function code 16 (10

ote:N mMINT SW2-1 must be properly set. See Section 5 and Table 5.

) to mMINT diagnostic address 247 or 248.

16

EATON www.eaton.com

5

Page 6

Instructional Leaet IL66A7508H09

Effective October 2016

INCOM routing address configurations

Non-volatile registers 42101 (083416) through 42592 (0A1F16) are

used to configure the 246 Modbus-to-INCOM Routing Address

registers. Two consecutive INCOM routing registers correspond

to each Modbus address. The first register provides routing to an

INCOM main network address while the second (first+1) register

provides routing to an INCOM sub-network address. Registers 42101

and 42102 correspond to Modbus address 1, registers 42103 and

42104 correspond to Modbus address 2, etc.

Valid INCOM addresses range from 0001

INCOM addresses are 0000

invalid (default) setting in the INCOM main network address register

or Yxxx16, where Y is non-zero. Any

16

will cause the mMINT to access the INCOM product with the

Modbus network address. A valid INCOM main network address

register with an invalid INCOM sub-network address register will

route the Modbus network address to the INCOM product at

the configured main network address. Both a valid INCOM main

network address register and INCOM sub-network address register

will route the Modbus network address to an INCOM product at the

configured sub-network address accessed through a sub-network

master addressed at the INCOM main network address.

All INCOM Routing Address Configuration registers can be reset

to their default state using the Diagnostics function code 08,

sub-function 30 (1E

). See Section 6 and Table 6.

16

Command/data pass-through

A feature of the mMINT is its capability to pass INCOM commands/

data directly through to any of 32 attached INCOM products. Thus,

with access to IL 17384, Parts A through F, every INCOM product

object and capability is available to the Modbus master.

When passing a command or data through to an INCOM product,

the mMINT acts as a dumb slave. Without modification, it passes

the command or data through to the INCOM product.

In the event the product responds, the mMINT saves the response

until the Modbus master queries for that response. The response

data remains in the mMINT until another pass-through command is

issued to an attached product or a mMINT power cycle occurs. The

mMINT makes no modification to or interpretation of the product

response data.

The Modbus master writes the INCOM product command/data

using function code 16 (10

/600016).

(0A28

16

) beginning at register 42601/424577

16

The data format for passing information through the mMINT to an

INCOM product is given in Figure 8.

The Modbus master reads the INCOM product response to a

pass-through query using either function code 03 or 04 beginning

at register 42701/424833 (0A8C

/610016).

16

The number of points (registers) of the read query is 2*nn—

where nn is the number of INCOM messages in the response.

The format of the data acquired by the mMINT from the passthrough INCOM product query’s response is given in Figure 7.

ote:N Each INCOM response message contains a status byte that indicates

its validity.

through 0FFF16. Invalid

16

mMINT—Modbus translator module—

installation and use

Register 42601/424577 (0A2816/600016)

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

nn = Number of Response

Msgs from INCOM Product

0 = Reserved

0 = Data Msg/1 = Control Msg

INCOM Msg Control Byte

INCOM Msg Byte 0

Register 42602/424578 (0A29

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

INCOM Msg Byte 2

Figure 6. Pass-through to INCOM product query data format

Control of INCOM product

Since a control error could result in unwanted actions initiated by

an INCOM device, the mMINT requires a specific protocol by the

Modbus master in order to perform control related functions within

the INCOM product.

A set of registers is reserved for the control protocol. They begin

at register 42901/425089 (0B54

42903/425091 (0B56

with a ‘slave action number’ and its 1’s complement using function

code 16 (10

product dependent, are listed in Table 13. The format of the data

). The current ‘slave action numbers’, their support being

16

/620216). These three registers are written

16

is shown in Figure 8. These three registers, and only these three

registers, must be written in one Modbus transaction.

If the ‘slave action number’ and its 1’s complement are valid, the

mMINT issues the ‘slave action’ control command onto the INCOM

network. If the slave action request is successfully acknowledged

by the INCOM product, the mMINT returns a normal function code

) response to the Modbus master. The Modbus master may

16 (10

16

further determine if the INCOM product completed the slave action

function successfully by interrogating the product, for example, by

reading its status.

If the INCOM product does not acknowledge the slave action

request, the mMINT returns an exception code 04. If the ‘slave

action number’ and its 1’s complement are invalid, the mMINT

responds to the Modbus master with a data value illegal exception

code 03. See Section 6.

/600116)

16

INCOM Msg Byte 1

/620016) and extend through

16

6

EATON www.eaton.com

Page 7

mMINT—Modbus translator module—

installation and use

Instructional Leaet IL66A7508H09

Effective October 2016

Register 42701/424833 (0A8C16/610016)

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

1 = Timeout on INCOM

1 = Overrun Error

1 = BCH Error

0 = Data Msg/1 = Control Msg

Status Byte of INCOM

Response Msg 0

Byte 0 of INCOM Response Msg 0

Register 42702/424834 (0A8D

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Byte 2 of INCOM

Response Msg 0

Register 42703/424835 (0A8E

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Byte 0 of INCOM

Response Msg 1

Register 42704/424836 (0A8F

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Byte 2 of INCOM

Response Msg 1

Register 42701/424833 + (2 * nn))

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Byte 0 of INCOM

Response Msg nn

Register 42702/424834 + (2 * nn))

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Byte 2 of INCOM

Response Msg nn

/6 10116)

16

Byte 1 of INCOM

Response Msg 0

/610216)

16

Status Byte of INCOM

Response Msg 1

/610316)

16

Byte 1 of INCOM

Response Msg 1

Status Byte of INCOM

Response Msg nn

Byte 1 of INCOM

Response Msg nn

0 = Reserved

Register 42901/425089 (0B5416/620016)

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Slave Action Byte 0

Slave Action Byte 1

Register 42902/425090 (0B55

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

1’s Complement of Slave Action Byte 0

Register 42903/425091 (0B56

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

1’s Complement of Slave Action Byte 2

/620116)

16

Slave Action Byte 2

/620216)

16

1’s Complement of

Slave Action Byte 1

Figure 8. Control to INCOM product data format

Energy format

Energy objects in the mMINT are supported in 2-register fixed point

object format and a 4-register power/mantissa format. These objects

do not support IEEE floating point format.

The 2-register format is presented in units of Kwatthours and

is valid for INCOM products reporting energy in watthours or

Kwatthours only. Products reporting in units greater than Kwatthours

(e.g., Mwatthours) could not guarantee consistent Kwatthour

resolution up to and through their rollover values.

All products reporting energy (independent of energy units) support

the energy objects occupying four registers—register 3 through

register 0. Register 3 is the high order register and register 0 is the

low order register.

Register 3 high byte contains a value corresponding to Engineering

Units (power of 10 signed exponent). Register 3 low byte contains a

Mantissa Multiplier value (power of 2 signed exponent).

Register 2 through register 0 contains a 48-bit energy mantissa in

units of watthours. Net and total energy objects are signed values.

All other energy objects are unsigned values.

The data format of these four registers is given in Figure 9.

Energy = 2

Mantissa Multiplier

x (48-bit energy value) x 10

Engineering Units

.

Figure 7. Pass-through to INCOM product response

data format

EATON www.eaton.com

7

Page 8

Instructional Leaet IL66A7508H09

Effective October 2016

Energy Register 0

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Byte 1 of Mantissa

Energy Register 1

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Byte 3 of Mantissa

Energy Register 2

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Byte 5 of Mantissa

Energy Register 3

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Engineering Units

Energy = 2

Mantissa Multiplier

x Mantissa x 10

Engineering Units

Byte 0 of Mantissa

Byte 2 of Mantissa

Byte 4 of Mantissa

Mantissa Multiplier

mMINT—Modbus translator module—

installation and use

Table 6. Diagnostic sub-function numbers

Sub-function

Number (decimal) Name In the query use

0 echo query mMINT or INCOM addr

1 restart communications mMINT or INCOM addr

4 force listen mMINT or INCOM addr

10 clear slave counters mMINT or INCOM addr

11 UART bus message count mMINT or INCOM addr

12 UART communication error count mMINT or INCOM addr

13 slave exception error count mMINT or INCOM addr

14 slave message count mMINT or INCOM addr

15 slave no response count mMINT or INCOM addr

16 slave NAK count mMINT or INCOM addr

17 slave busy count mMINT or INCOM addr

18 UART over run error count mMINT or INCOM addr

20 clear UART counters mMINT or INCOM addr

21 slave INCOM BCH error count INCOM device addr

22 slave INCOM over run count INCOM device addr

23 UART framing error count mMINT or INCOM addr

24 UART noise error count mMINT or INCOM addr

25 UART parit y error count mMINT or INCOM addr

26 mMINT firmware version & rev mMINT addr

27 mMINT firmware month & day mMINT addr

28 mMINT firmware year mMINT addr

29 remove INCOM device(s) mMINT or INCOM addr

30 reset INCOM routing addresses mMINT addr

Figure 9. 4-register energy data format

Supported diagnostic sub-functions

It is possible to obtain diagnostics from the mMINT or an attached

INCOM product using function code 08. See Table 6. A single

register is used for each UART counter within the mMINT. Each

INCOM device and the mMINT contain a unique slave counter.

To use mMINT address 247 or 248 in the diagnostic query, SW2-1

must be properly set. See Section 5 and Table 5.

Exception codes

Under certain circumstances, the mMINT will return an

exception code.

If the function in the query is not supported by the mMINT,

exception code 01 is returned in the response.

If the data (object) register is illegal, exception code 02 is returned in

the response.

If the data value in the query is illegal, exception code 03 is returned.

If the slave INCOM product fails (usually a timeout), exception code

04 is returned.

In certain circumstances, an exception code 05 (ACK) is returned.

If the mMINT cannot perform the requested function, exception

code 07 (NAK) is returned.

If only a partial register is used in the query, exception code 84

is returned.

8

EATON www.eaton.com

Page 9

mMINT—Modbus translator module—

installation and use

Instructional Leaet IL66A7508H09

Effective October 2016

Section 7: Troubleshooting

The most common issues experienced with the installation of an

mMINT module are addressed below.

If you have any questions or need further information or instructions,

please contact your local Eaton representative or the Customer

Support Center at 877-ETN-CARE (877-386-2273).

Table 7. Troubleshooting guide

Symptom Possible solution(s)

Status LED not flashing Verify proper input power to module connector

Modbus Tx LED is flashing, but the

module does not respond to master

command requests

INCOM Tx LED is flashing, but the

module does not respond to master

command requests

Removing an INCOM product and

assigning its INCOM (Modbus)

address to another (different) INCOM

product, and exception codes are

received from the INCOM product

Verify communication cable is connected

correctly from the master to the module

(A, B, +, –)

Verify the data transfer rate is correctly set

using baud rate switch (SW2)

Verify communication cable is connected

correctly from the slave to the module

Verify the product is set up for 9600 baud

Verify that the termination switch (SW1)

is set to ON at the last module

Disconnect the reassigned product from the

INCOM network

Verify that the Modbus Master has sent at

least two requests to the address of the

product that was just disconnected

Connect the reassigned INCOM product

Appendix A

otes:N

1. Modbus is a registered trademark of Schneider Electric.

2. mMINT modules use DIN rail mounting.

3. Control voltage is 120 Vac +/–20% or 24–125 Vdc.

4. Connectors are plug-in types from Phoenix contact.

5. Terminal Types (supplied with module) are 3-point, 4-point, and

5-point Phoenix contact.

• MVSTBR2,5/3-STF-5,08 (Order No. 1835106)

• MVSTBR2,5/4-STF-5,08 (Order No. 1835119)

• MVSTBR2,5/5-STF-5,08 (Order No. 1835122)

6. INCOM communications cable is Eaton C-H style 2A957805G01

or Belden style 9463.

7. Set up switch SW1 to insert 100 ohm terminating resistor on

last module in the INCOM network.

8. Set up switch SW2 to select data transfer rate on the

Modbus network.

9. Set up switch SW3 to insert 121 ohm terminating resistor on

last module in the Modbus network.

10. Power wiring is any approved 300 V, 10 A, 30–12 AWG

(stranded or solid).

11. The register map for INCOM products is shown in register

number order in Table 8 and functional order in Table 9.

Numeric entries indicated with an asterisk (*) have specific

definitions dependent upon the particular INCOM product.

These tables include only a partial list of applicable INCOM

products; however, it contains a complete list of the INCOM

objects directly supported by the mMINT. Due to the mMINT

pass-through feature, all INCOM product objects are accessible

by a Modbus master.

12. The primary and secondary codes are mapped to the high

and low bytes, respectively, of registers 404609 (1200

and 406145 (1800

Table 10. The secondary status codes are shown in Table 11.

). The primary status codes are shown in

16

The cause-of-status codes are mapped to registers 404610

) and 406146 (180116). The cause-of-status codes are

(1201

16

shown in Table 12.

13. Catalog number is MMINT.

)

16

EATON www.eaton.com

9

Page 10

Instructional Leaet IL66A7508H09

Effective October 2016

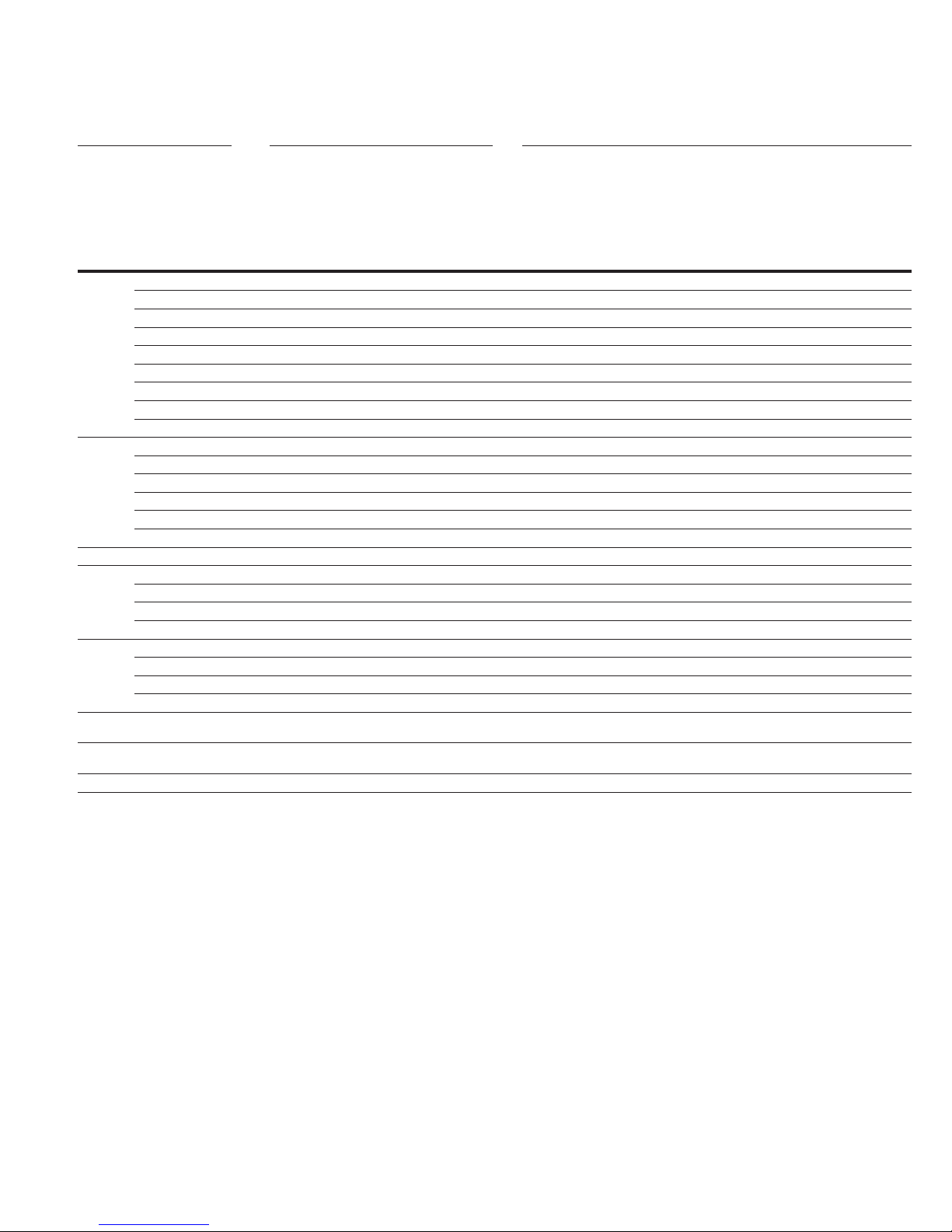

Table 8. Modbus register map (in register number order)

Objects (complete list)

Register number Modbus address

mMINT—Modbus translator module—

installation and use

INCOM products (partial list)

Fixed

point

(FP)

(Hex)

Name Numeric

Status

cause

primary 404609 or 406145 hi byte 1200 or 1800 hi byte

secondary 404609 or 4 06145 lo byte 1200 or 1800 lo byte

Units

IEEE

float

Fixed

point

(FP)

IEEE

float

(Hex)

cause 404610 or 406146 1201 or 1801

Current I

L-L

voltage

L-N v olt a ge V

N-G

voltage

Peak

current

A

I

B

I

C

I

G

I

N

I

Avg

V

AB

V

BC

V

CA

V

LLavg

AN

V

BN

V

CN

V

LN

V

NG

peak IA demand A 404641 406177 122 0 182 0 10

peak IB demand A 404643 406179 1222 1822 10

A 404611 406147 1202 1802 10

A 404613 406149 120 4 180 4 10

A 404615 40 6151 1206 1806 10

A 404617 406153 1208 1808 10

A 404619 40 615 5 120A 180 A 10

A avg 404621 4 06157 120C 180C 10

V 404623 406159 120E 180E 10

V 404625 406161 1210 1810 10

V 404627 406163 1212 1812 10

V avg 404629 40616 5 1214 1814 10

V 404631 40616 7 1216 1816 10

V 404633 40616 9 1218 1818 10

V 404635 406171 121A 181A 10

V avg 404637 406173 121C 181C 10

V 404639 40617 5 121E 181E 10

peak IC demand A 404645 406181 12 24 18 24 10

peak IG demand A 404647 40 618 3 1226 1826 10

peak IN demand A 404649 406185 122 8 182 8 10

Power real three-phase

W 404651 406187 122 A 18 2A 1

(power)

reactive

var 404653 4 06189 122C 182C 1

three-phase

apparent

VA 404655 40 6191 122E 182E 1

three-phase

Power

factor

displacement

three-phase

pf 404657 4 06193 1230 18 30 100

apparent pf 404659 406195 1232 1832 100

Frequency freq Hz 404661 40 619 7 1234 18 34 10

K-factor K-factor 404663 40 619 9 1236 1836 1

THD factor THD factor 404665 406201 123 8 1838 1

ote:N All objects are two registers in length unless specified otherwise.

FP scale factor

IQ 200

DP-4000

IQ Analyzer

IQ Data

IQ Data Plus II

DigitripE OPTIM 55 0

Digit rip OPTIM 750

Digit rip OPTIM 1050

Digitrip 810

Digitrip 910

Digitrip 520MC

Digitrip 1150

IQ Transfer II

n n n n n n n n n n n n n n n n

n n n n n n n n n n n n n n n n

n n n n n n n n n n n n n n n n

n n n n n n n n n n n n n n n

n n n n n n n n n n n n n n n

n n n n n n n n n n n n n n n

n n n n n n n n n n n

n n n n n n n n n

n n n

n n n n n n n n

n n n n n n n n

n n n n n n n n

n n

n n n n n n n

n n n n n n n

n n n n n n n

n n

n

n n n n n n n n n

n n n n n n n n n

n n n n n n n n n

n n n n

n n n

n n n n n n n n n

n n n n n n

n n n n n

n n n n

n n n n n n n n n

n n n n n n n

n

n

MP-3000

Digitrip 3000T

FP-5000

10

EATON www.eaton.com

Page 11

mMINT—Modbus translator module—

installation and use

Table 8. Modbus register map (in register number order) (continued)

Objects (complete list)

Register number Modbus address

Instructional Leaet IL66A7508H09

Effective October 2016

INCOM products (partial list)

Fixed

point

(FP)

(Hex)

Name Numeric

Units

IEEE

float

Fixed

point

(FP)

IEEE

float

(Hex)

Power A ph W 404667 406203 123 A 18 3A 1

B ph W 404669 406205 123C 183C 1

C ph W 404671 406207 123E 183E 1

reactive A ph var 404673 406209 124 0 1840 1

reactive B ph var 404675 4 06211 1242 1842 1

reactive C ph var 404677 406213 1244 184 4 1

apparent A ph VA 404679 4 06215 1246 1846 1

apparent B ph VA 404681 406 217 124 8 184 8 1

apparent C ph VA 404683 406 219 124 A 184 A 1

Power

factor

displacement A ph pf 404685 406221 124C 184C 100

displacement B ph pf 404687 406223 124 E 184 E 10 0

displacement C ph pf 404689 406225 1250 18 50 100

apparent A ph pf 404691 406227 12 52 1852 100

apparent B ph pf 404693 406229 1254 185 4 10 0

apparent C ph pf 404695 406231 1256 1856 100

Power peak demand W 404697 406233 125 8 1858 1

Source 1 V

AB

V

BC

V

CA

V 404699 406235 125 A 18 5A 10

V 404701 406237 125 C 185C 10

V 404703 406239 125 E 18 5E 10

freq Hz 404705 406241 12 60 186 0 10

Source 2 V

AB

V

BC

V

CA

V 404707 406243 1262 1862 10

V 404709 406245 1264 186 4 10

V 4 047 11 406247 1266 1866 10

freq Hz 404713 406249 1268 18 68 10

Power power (real

W 404715 406251 126A 186A 1

three-phase)

Power

pf (*) pf 4 04717 406253 126C 186C 100

factor

Product ID prod ID 404719 or 406255 126E or 186E

FP scale Factor

IQ 200

DP-4000

IQ Analyzer

IQ Data

IQ Data Plus II

Digit rip OPTIM 550

Digit rip OPTIM 750

Digit rip OPTIM 1050

Digitrip 810

Digitrip 910

Digitrip 520MC

Digitrip 1150

IQ Transfer II

n n

n n

n n

n n

n n

n n

n n

n n

n n

n n

n n

n n

n n

n n

n n

n n n n n n n n n

n

n

n

n

n

n

n

n

n n n n n n n n n

n n n n n n n n n

n n n n n n n n n n n n n n n n

MP-3000

Digitrip 3000

FP-5000

ote:N All objects are two registers in length unless specified otherwise.

EATON www.eaton.com

11

Page 12

Instructional Leaet IL66A7508H09

Effective October 2016

Table 8. Modbus register map (in register number order) (continued)

Objects (complete list)

Register number Modbus address

mMINT—Modbus translator module—

installation and use

INCOM products (partial list)

Fixed

point

(FP)

(Hex)

Name Numeric

Units

IEEE

float

Fixed

point

(FP)

IEEE

float

(Hex)

Frequency freq Hz 404721 406257 1270 18 70 100

(K) Energy forward kWh N/A 406259 N/A 187 2 1

reverse kWh N/A 406261 N /A 1874 1

total (*) kWh N/A 406263 N/A 1876 1

Reactive (K)

energy

lead kvarhW N /A 406265 N/A 1878 1

lag kvarhW N/A 406267 N /A 187A 1

net kvarhW N/A 406269 N/A 187C 1

(K) Energy apparent kVAh N/A 406271 N/A 187E 1

Motor phase

% 404737 406273 128 0 18 80 10 0

unbalance

thermal

% 404739 406275 128 2 1882 100

capacity

Temperature motor

°C 404741 406277 1284 188 4 1

winding 1

motor

°C 404743 406279 128 6 1886 1

winding 2

motor

°C 404745 406281 1288 1888 1

winding 3

motor

°C 404747 406283 128A 188A 1

winding 4

motor

°C 404749 406285 128C 188C 1

winding 5

motor

°C 404751 406287 128E 188E 1

winding 6

motor

°C 404753 406289 129 0 1890 1

bearing 1

motor

°C 404755 406291 1292 1892 1

bearing 2

load

°C 404757 406293 129 4 18 94 1

bearing 1

load

°C 404759 406295 1296 189 6 1

bearing 2

auxiliary °C 404761 406297 1298 1898 1

device

temperature

°C 404763 406299 129 A 18 9A 1

404765 406301 129 C 189C

404767 406303 129 E 189E

Energy

(4 reg objects)

forward Wh N/A 406305 N /A 18A0 1

reverse Wh N/A 406309 N/A 18 A4 1

total (*) Wh N/A 406313 N/A 18A8 1

Reactive

energy

(4 reg objects)

lead varh N/A 406317 N/A 18AC 1

lag varh N/A 406321 N/A 18 B0 1

net varh N/A 406325 N/A 18B4 1

Energy (4 reg) apparent VAh N/A 406329 N/A 18B8 1

(4 reg) N/A 406333 N/A 18BC

ote:N All objects are two registers in length unless specified otherwise.

FP scale factor

IQ 200

DP-4000

IQ Analyzer

IQ Data

IQ Data Plus II

Digit rip OPTIM 550

Digit rip OPTIM 750

Digit rip OPTIM 1050

Digitrip 810

Digitrip 910

Digitrip 520MC

Digitrip 1150

IQ Transfer II

n n n n n n n

n n n n n n n n

n n n n n n n n

n n n n n n n n n

n n n n

n n n n

n n n n

n n n n n

n n n n n n n n

n n n n n n n n

n n n n n n n n n

n n n n

n n n n

n n n n

n n n n n

n

n

n

n

n

n

n

n

n

n

n

n

n

MP-3000

Digitrip 3000

FP-5000

12

EATON www.eaton.com

Page 13

mMINT—Modbus translator module—

installation and use

Table 8. Modbus register map (in register number order) (continued)

Objects (complete list)

Register number Modbus address

Instructional Leaet IL66A7508H09

Effective October 2016

INCOM products (partial list)

Name Numeric

Network

voltage

A ph V 404801 406337 12C0 18C 0 10

B ph V 404803 406339 12C2 18 C2 10

Units

IEEE

float

Fixed

point

(FP)

IEEE

float

(Hex)

C ph V 404805 406341 12C4 18C4 10

Transformer

voltage

A ph V 404807 406343 12C 6 18C6 10

B ph V 404809 406345 12 C8 18C8 10

C ph V 4 04811 406347 12C A 18CA 10

Phasing

voltage

A ph V 40 4813 406349 12C C 18CC 10

B ph V 4 048 15 406351 12C E 18CE 10

C ph V 4 04817 406353 12D0 18D0 10

A ph direct V 40 4819 406355 12D 2 18D2 10

A ph

V 404821 406357 12D4 18D4 10

quadrature

B ph direct V 404823 406359 12D6 18D 6 10

B ph

V 404825 406361 12D8 18 D8 10

quadrature

C ph direct V 404827 406363 12DA 18DA 10

C ph

V 404829 406365 12DC 18 DC 10

quadrature

Pos seq direct V 404831 406367 12DE 18DE 10

Pos seq

V 404833 406369 12E0 18 E0 10

quadrature

ote:N All objects are two registers in length unless specified otherwise.

Fixed

point

(FP)

(Hex)

FP scale factor

IQ 200

DP-4000

IQ Analyzer

IQ Data

IQ Data Plus II

Digit rip OPTIM 550

Digit rip OPTIM 750

Digit rip OPTIM 1050

Digitrip 810

Digitrip 910

Digitrip 520MC

Digitrip 1150

IQ Transfer II

MP-3000

Digitrip 3000

FP-5000

EATON www.eaton.com

13

Page 14

Instructional Leaet IL66A7508H09

Effective October 2016

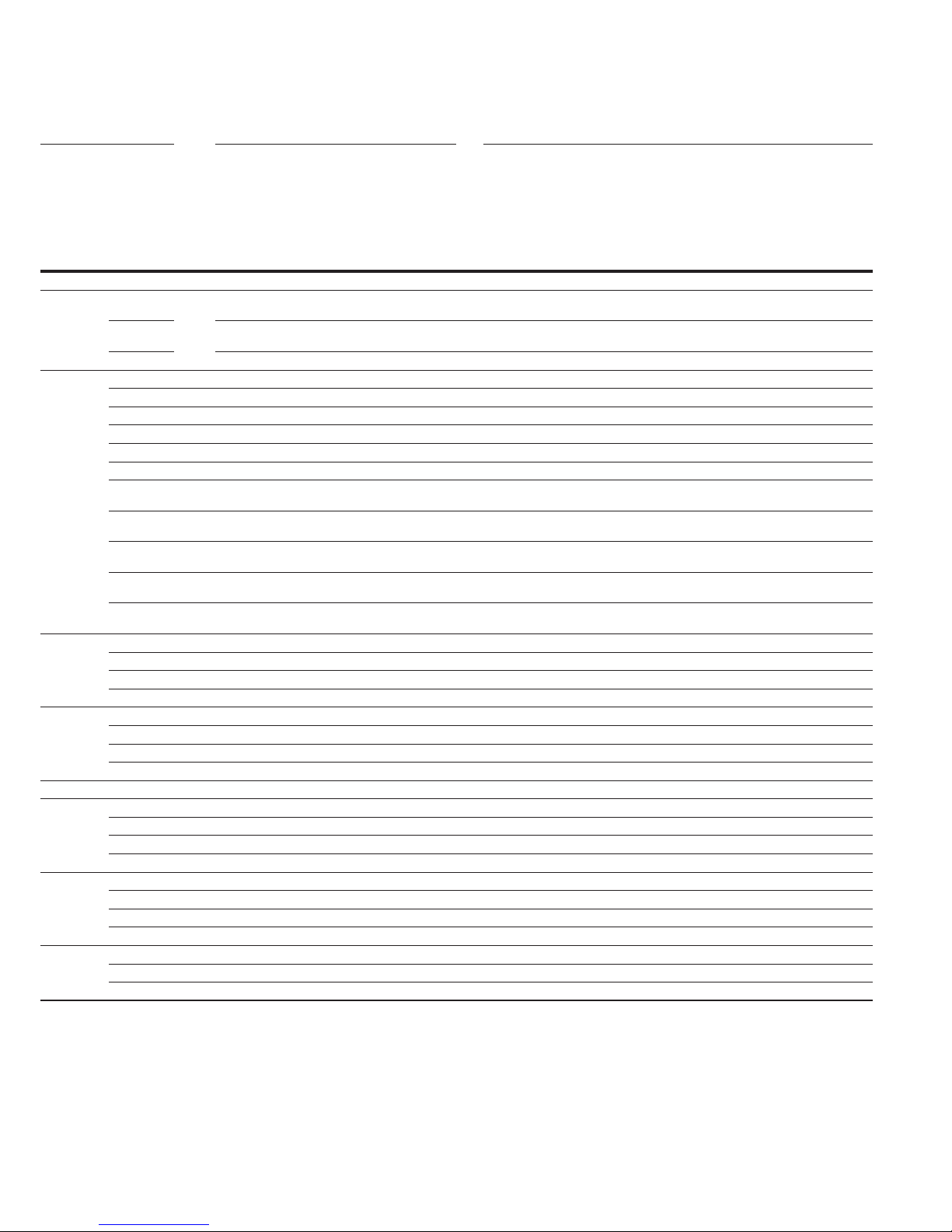

Table 9. Modbus register map (in functional order)

Objects (complete list)

Register number Modbus address

mMINT—Modbus translator module—

installation and use

INCOM products (partial list)

Name Numeric

Units

IEEE

float

Fixed

point

(FP)

IEEE

float

(Hex)

Product ID prod ID 404719 or 406255 126E or 186E

Status cause primary 404609 or 406145 hi

1200 or 1800 hi byte

byte

secondary 404609 or 4 06145 lo

1200 or 1800 lo byte

byte

cause 404610 or 406146 1201 or 1801

Current I

A

I

B

I

C

I

G

I

N

I

Avg

peak IA

A 404611 406147 1202 1802 10

A 404613 406149 120 4 180 4 10

A 404615 406 151 1206 1806 10

A 404617 406153 1208 1808 10

A 404619 406 155 120A 18 0A 10

A avg 404621 4 06157 120C 180C 10

A 404641 406177 122 0 182 0 10

demand

peak IB

A 404643 406179 1222 1822 10

demand

peak IC

A 404645 406181 1224 1824 10

demand

peak I

demand

peak IN

A 404647 406183 122 6 182 6 10

G

A 404649 406185 122 8 182 8 10

demand

L-L voltage V

L-N v olt a ge V

N-G voltage V

Source 1 V

AB

V

BC

V

CA

V

LLavg

AN

V

BN

V

CN

V

LN

NG

AB

V

BC

V

CA

V 404623 40 6159 120E 180E 10

V 404625 406161 1210 1810 10

V 404627 406163 1212 1812 10

V avg 404629 406165 1214 1814 10

V 404631 40 6167 1216 1816 10

V 404633 40 6169 1218 1818 10

V 404635 40 6171 121A 181A 10

V avg 404637 406173 121C 181C 10

V 404639 40 6175 121E 181E 10

V 404699 406235 125A 185 A 10

V 404701 406237 125C 185C 10

V 404703 406239 12 5E 18 5E 10

freq Hz 404705 406241 12 60 1860 10

Source 2 V

AB

V

BC

V

CA

V 404707 406243 1262 1862 10

V 404709 406245 1264 1864 10

V 404711 406247 1266 1866 10

freq Hz 4 047134 406249 1268 1868 10

Network

voltage

A ph V 404801 406337 12C 0 18C0 10

B ph V 404803 406339 12C 2 18C2 10

C ph V 404805 406341 12C4 18C4 10

ote:N All objects are two registers in length unless specified otherwise.

Fixed

point

(FP)

(Hex)

FP scale factor

IQ 200

DP-4000

IQ Analyzer

IQ Data

IQ Data Plus II

Digit rip OPTIM 550

Digit rip OPTIM 750

Digit rip OPTIM 1050

Digitrip 810

Digitrip 910

Digitrip 520MC

Digitrip 1150

IQ Transfer II

n n n n n n n n n n n n n n n n

n n n n n n n n n n n n n n n n

n n n n n n n n n n n n n n n n

n n n n n n n n n n n n n n n n

n n n n n n n n n n n n n n n

n n n n n n n n n n n n n n n

n n n n n n n n n n n n n n n

n n n n n n n n n n n

n n n n n n n n n

n n n

n n n n n n n n n

n n n n n n n n n

n n n n n n n n n

n n n n

n n n

n n n n n n n n

n n n n n n n n

n n n n n n n n

n n

n n n n n n n

n n n n n n n

n n n n n n n

n n

n

n

n

n

n

n

n

n

n

MP-3000

Digitrip 3000

FP-5000

14

EATON www.eaton.com

Page 15

mMINT—Modbus translator module—

installation and use

Table 9. Modbus register map (in functional order) (continued)

Objects (complete list)

Register number Modbus address

Instructional Leaet IL66A7508H09

Effective October 2016

INCOM products (partial list)

Fixed

point

(FP)

(Hex)

Name Numeric

Transformer

voltage

A ph V 404807 406343 12C6 18C6 10

B ph V 404809 406345 12C8 18C8 10

Units

IEEE

float

Fixed

point

(FP)

IEEE

float

(Hex)

C ph V 404811 406347 12C A 18CA 10

Phasing

voltage

A ph V 4 04813 406349 12CC 18 CC 10

B ph V 404 815 406351 12CE 18CE 10

C ph V 404817 406353 12D 0 18D0 10

A ph direct V 4 04819 406355 12D2 18D2 10

A ph quadrature V 404821 406357 12D4 18D4 10

B ph direct V 404823 406359 12D 6 18D 6 10

B ph quadrature V 404825 406361 12D8 18D8 10

C ph direct V 404827 406363 12DA 18DA 10

C ph quadrature V 404829 406365 12DC 18DC 10

pos seq direct V 404831 406367 12DE 18 DE 10

pos seq

V 404833 406369 12E0 18E0 10

quadrature

Frequency freq Hz 404661 406197 123 4 183 4 10

freq Hz 404721 406257 127 0 1870 100

Power power (real

W 404715 40 6251 126A 186A 1

three-phase)

peak demand W 404697 406233 1258 185 8 1

real three-phase

W 404651 406187 122A 182 A 1

(power)

reactive

var 404653 406189 122C 18 2C 1

three-phase

apparent

VA 404655 40 6191 122E 18 2E 1

three-phase

A ph W 404667 406203 123A 183A 1

B ph W 404669 406205 123C 183 C 1

C ph W 404671 406207 12 3E 18 3E 1

reactive A ph var 404673 406209 124 0 1840 1

reactive B ph var 404675 40 6211 1242 1842 1

reactive C ph var 404677 406213 124 4 1844 1

apparent A ph VA 404679 406215 124 6 1846 1

apparent B ph VA 404681 406217 1248 18 48 1

apparent C ph VA 404683 406 219 124A 184 A 1

ote:N All objects are two registers in length unless specified otherwise.

FP scale factor

IQ 200

DP-4000

IQ Analyzer

IQ Data

IQ Data Plus II

Digit rip OPTIM 550

Digit rip OPTIM 750

Digit rip OPTIM 1050

Digitrip 810

Digitrip 910

Digitrip 520MC

Digitrip 1150

IQ Transfer II

n n n n n n n

n n n n n n n

n n n n n n n n n

n n n n n n n n n

n n n n n n n n n

n n n n n n

n n n n n

n n

n n

n n

n n

n n

n n

n n

n n

n n

MP-3000

Digitrip 3000

FP-5000

EATON www.eaton.com

15

Page 16

Instructional Leaet IL66A7508H09

Effective October 2016

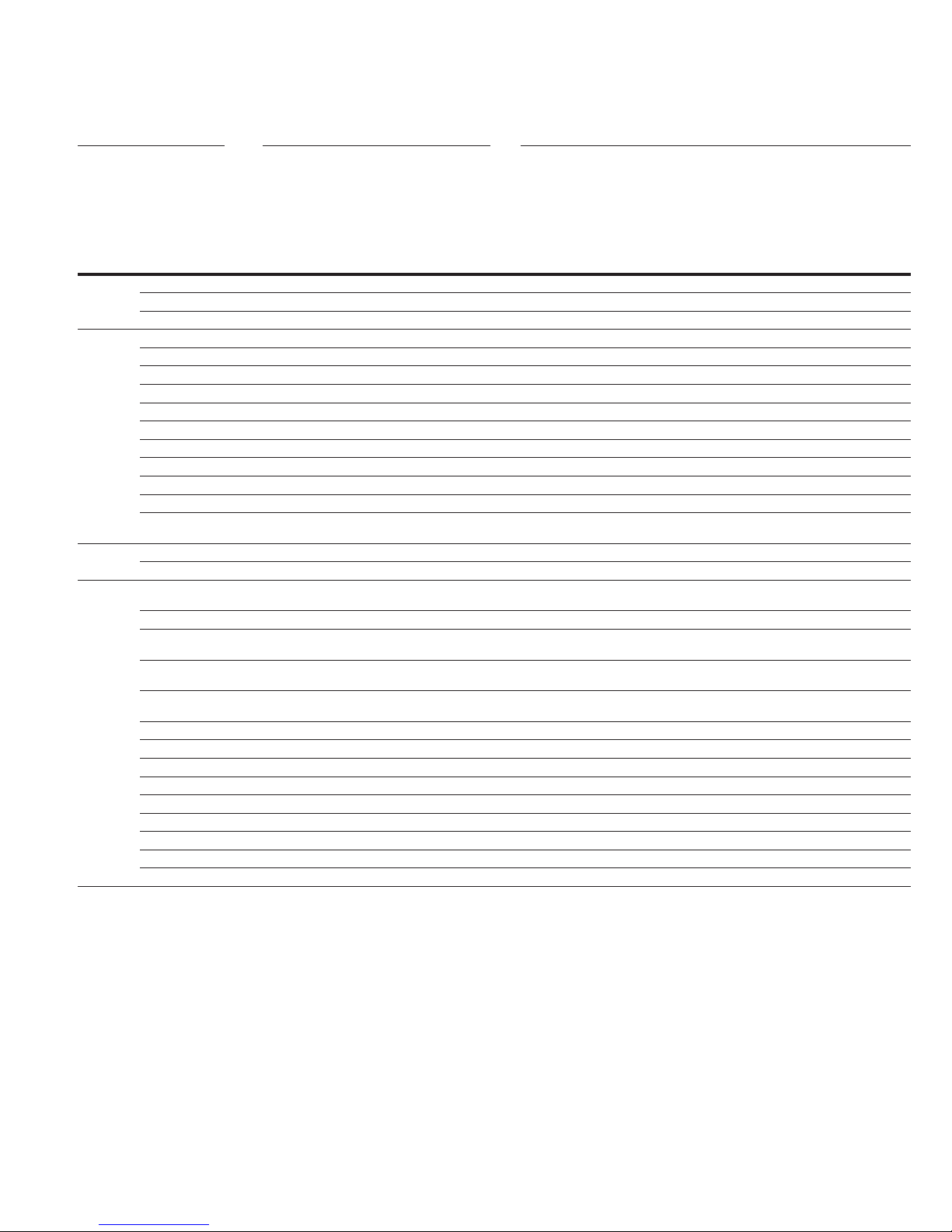

Table 9. Modbus register map (in functional order) (continued)

Objects (complete list)

Register number Modbus address

mMINT—Modbus translator module—

installation and use

INCOM products (partial list)

Fixed

point

(FP)

(Hex)

Name Numeric

Power

factor

pf (*) pf 40 4717 406253 12 6C 186 C 100

displacement 3 ph pf 404657 406193 1230 18 30 10 0

Units

IEEE

float

Fixed

point

(FP)

IEEE

float

(Hex)

displacement A ph pf 404685 406221 124C 184C 10 0

displacement B ph pf 404687 406223 124E 18 4E 100

displacement C ph pf 404689 406225 1250 185 0 100

apparent A ph pf 404691 406227 1252 185 2 100

apparent B ph pf 404693 406229 1254 18 54 10 0

apparent C ph pf 404695 406231 1256 185 6 100

apparent pf 404659 406195 12 32 18 32 100

K-factor K-factor 404663 406199 1236 1836 1

THD factor THD factor 404665 406201 123 8 1838 1

(K) Energy forward kWh N/A 406259 N/A 1872 1

reverse kWh N /A 406261 N/A 18 74 1

total (*) kWh N/A 406263 N/A 18 76 1

apparent kVAh N/A 406271 N/A 187E 1

Energy

(4 reg objects)

forward Wh N/A 406305 N/A 18 A0 1

reverse Wh N/A 406309 N/A 18 A4 1

total (*) Wh N /A 406313 N/A 18A8 1

apparent VAh N/A 406329 N/A 18B8 1

Reactive

(K) energy

lead kvarh N /A 406267 N/A 18 78 1

lag kvarh N/A 406269 N /A 18 7A 1

net kvarh N /A 406271 N/A 187C 1

Reactive

energy

(4 reg objects)

lead varh N/A 406317 N/A 18 AC 1

lag varh N/A 406321 N/A 18 B0 1

net varh N/A 406325 N/A 18 B4 1

Motor phase unbalance % 404737 406273 1280 18 80 100

thermal capacity % 404739 406275 1282 18 82 10 0

Temperature motor winding 1 °C 404741 406277 1284 188 4 1

motor winding 2 °C 4 04743 406279 12 86 18 86 1

motor winding 3 °C 4 04745 406281 128 8 1888 1

motor winding 4 °C 404747 406283 128 A 188 A 1

motor winding 5 °C 4 04749 406285 128C 188C 1

motor winding 6 °C 4 04751 406287 128E 188E 1

motor bearing 1 °C 404753 406289 129 0 189 0 1

motor bearing 2 °C 404755 406291 1292 18 92 1

load bearing 1 °C 404757 406293 1294 18 94 1

load bearing 2 °C 404759 406295 1296 189 6 1

auxiliary °C 404761 406297 1298 189 8 1

device temperature °C 404763 406299 129A 189A 1

ote:N All objects are two registers in length unless specified otherwise.

FP scale factor

IQ 200

DP-4000

IQ Analyzer

IQ Data

IQ Data Plus II

Digit rip OPTIM 550

Digit rip OPTIM 750

Digit rip OPTIM 1050

Digitrip 810

Digitrip 910

Digitrip 520MC

Digitrip 1150

IQ Transfer II

n n n n n n n n n

n n n n

n n

n n

n n

n n

n n

n n

n n n n n n n n n

n

n

n n n n n n n n

n n n n n n n n

n n n n n n n n n

n n n n n

n n n n n n n n

n n n n n n n n

n n n n n n n n n

n n n n n

n n n n

n n n n

n n n n

n n n n

n n n n

n n n n

n

n

n

n

n

n

n

n

n

n

n

n

n

MP-3000

Digitrip 3000

FP-5000

16

EATON www.eaton.com

Page 17

mMINT—Modbus translator module—

installation and use

Instructional Leaet IL66A7508H09

Effective October 2016

Table 10. Primary status code definitions

Code Definition Code Definition

0 Unknown 19 Phase A alarm

1 Open 20 Phase B alarm

2 Closed 21 Phase C alarm

3 Trippe d 22 Neutral alarm

4 Alarmed 23 Ground/earth alarm

5 On 24 Phase AB alarm

6 Off 25 Phase BC alarm

7 Ready 26 Phase CA alarm

8 Starting 27 On good source

9 Operational 28 Running

10 Stopped Reserved 29…2 51

11 Locked-out

12 Tra ns ferre d

13 Picked-up

14 Phase A trip

15 Phase B trip 252 Product-Specific Code 252

16 Phase C trip 253 Product-Specific Code 253

17 Neutral trip 254 Product-Specific Code 254

18 Ground/earth trip 255 Product-Specific Code 255

Table 11. Secondary status code definitions

Code Definition Code Definition

0 Unknown Reserved 9…27

1 Not applicable

2 Program mode

3 Test mode

4 Disabled

5 Disarmed 28 Product-Specific Code 28

6 Controlled device failed to operate 29 Product-Specific Code 29

7 Powered up 30 Product-Specific Code 30

8 Alarm 31 Product-Specific Code 31

Table 12. Cause-of-status code definitions

Code Definition Code Definition

0 Unknown 39 Diagnostic warning #1

1 Normal operating mode 40 Diagnostic failure #1

2 External condition #1 41 Low battery

3 Instantaneous phase overcurrent 42 Multiple causes

4 Instantaneous ground overcurrent 43 Diagnostic warning #2

5 Instantaneous neutral overcurrent 44 Diagnostic warning #3

6 Instantaneous residual overcurrent 45 Diagnostic warning #4

7 Phase inverse-time overcurrent 46 Diagnostic warning # 5

8 Ground inverse-time overcurrent 47 Diagnostic warning # 6

9 Neutral inverse-time overcurrent 48 Diagnostic warning #7

10 Residual inverse-time overcurrent 49 Diagnostic warning #8

11 Overvoltage 50 Diagnostic warning # 9

12 Undervoltage 51 Diagnostic warning #10

13 Auxiliary overvoltage 52 Diagnostic failure #2

14 Auxiliary under voltage 53 Diagnostic failure #3

15 Underfrequency 54 Diagnostic failure #4

16 Overfrequency 55 Diagnostic failure #5

17 Current unbalance 56 Diagnostic failure #6

18 Voltage unbalance 57 Diagnostic failure #7

19 Apparent power factor 58 Diagnostic failure # 8

20 Displacement power factor 59 Diagnostic failure # 9

21 Zone interlock phase 60 Diagnostic failure #10

22 Zone interlock ground 61 Long delay phase overcurrent

23 Watt 62 Short delay phase overcurrent

24 VA 63 Fixed instantaneous phase

overcurrent #1

25 Var 64 Bad / missing rating plug

26 Power demand 65 Reverse power

27 VA demand 66 Fixed instantaneous phase

overcurrent #2

28 Var demand 67 Reverse phase

29 Current demand 68 Reverse sequence

30 Total harmonic distortion 69 Phase current loss

31 Operations count 70 Phase voltage loss

32 Contact maintenance 71 Alarm active

33 Control via communications 72 Bad frame

34 Contact disagreement 73 Phase currents near pickup

35 Breaker failure 74 Lockout

36 Operation time exceeded 75 Making current release

37 Coil supervision 76 Fixed instantaneous phase

overcurrent #3

38 Programmable logic 77 Set points error

EATON www.eaton.com

17

Page 18

Instructional Leaet IL66A7508H09

Effective October 2016

mMINT—Modbus translator module—

installation and use

Table 12. Cause-of-status code definitions (continued)

Code Definition Code Definition

78 Over-temperature 120 Fail to sync on phase

79 Accessory bus 121 Fail to sync on frequency

80 Long delay neutral overcurrent 122 Fail to sync on voltage

81 External condition #2 12 3 Anti-backspin

82 Historical data 124 Zero speed

83 External condition #3 125 Time bet ween starts

84 Ground fault (instantaneous or delay) 126 Source 1

85 Earth fault (instantaneous or delay) 127 Source 2

86 External condition #4 128 Star t

87 External condition #5 129 Manual

88 External condition #6 130 Synchronizing

89 External condition #7 131 Starts per hour

90 External condition #8 132 Preferred source

91 External condition #9 13 3 Plant exerciser

92 Multiple external conditions 134 Neutral ground overvoltage

93 Motor bearing temperature 135 Safety interlock

94 Load bearing temperature 136 Real-time clock

95 Auxiliary temperature 137 High floating voltage

96 Winding temperature 13 8 Tr ip bl ocked

97 Local temperature 139 Incomplete sequence

98 External temperature 140 Cause N/A (none)

99 Rolled phase 141 Trip position

100 Per unit voltage 142 Voltage transient

101 Sensitive 14 3 Tamper

102 Deenergized 144 RTD

103 Non-sensitive 145 Differential

104 Time delayed sensitive 146 Frequency out of range

105 Breaker pumping 147 Sensor mismatch

106 Sub-network malfunction 14 8 Check auxiliar y switch

107 Learning 149 Overcurrent

108 Offline 150 Time delayed watt-VAR

109 Test 151 Overcurrent watt-VAR

110 Jam 152 Power

111 Under load Reserved 153…2 043

112 Delay ground overcurrent

113 Calibration

114 Emergency

115 Torque limit

116 Deceleration 2044 Product-Specific Code 2044

117 Voltage sag 2045 Product-Specific Code 2045

118 Voltage swell 2046 Product-Specific Code 2046

119 Programming error 2047 Product-Specific Code 2047

Table 13. Control ‘Slave Action Number’ definitions

Control

group Definition Byte 2 Byte 1 By te 0

Reset Reset alarm 0 0 1

Reset trip 0 0 2

Reset (peak) demand-watts 0 0 4

Reset energy (kilowatt hours) 0 0 8

Reset device software 0 0 16 (10

Reset time stamped event data buffers 0 0 32 (2016)

Circuit

Breaker

OpenClose

Reset (synchronize) demand

watts window

Snapshot command 0 0 12 8 (8 016)

Reset (peak) demand-currents 0 1 1

Reset operations count

(or trigger counters)

Reset run time 0 1 3

Reset all min./max. values 0 1 4

Unlock waveform buffer

(clear upload-in-progress)

Reset discrete input counters 0 1 6

Reset min./max. currents 0 1 13

Reset min./max. L-L voltages 0 1 14

Reset min./max. L-N voltages 0 1 15

Reset min./max. PF-apparent 0 1 16

Reset min./max. PF-displacement 0 1 17

Reset min./max. power 0 1 18

Reset min./max. current THD 0 1 19

Reset min./max. voltage THD 0 1 20

Reset min./max. per-phase power 0 1 22

Reset op count, run time and

override count

Reset motor data maximum values 0 1 37

Reset motor trip and alarm counters 0 1 38

Reset locked-trigger # X

(X = trigger number)

Reset source 1 available time 0 3 1

Reset source 1 connect time 0 3 2

Reset source 1 run time 0 3 3

Reset source 2 available time 0 3 4

Reset source 2 connect time 0 3 5

Reset source 2 run time 0 3 6

Reset load energized time 0 3 7

Reset transfer status 0 3 8

Reset tamper flag for sensor #X 0 4 X

Open request 1 0 0

Close request 1 0 1

Trip request 1 0 2

0 0 64 (4 016)

0 1 2

0 1 5

0 1 36

0 2 X

)

16

18

EATON www.eaton.com

Page 19

mMINT—Modbus translator module—

installation and use

Instructional Leaet IL66A7508H09

Effective October 2016

Table 13. Control ‘Slave Action Number’ definitions (continued)

Control

group Definition Byte2 By te1 Byte0

Motor

Start-Stop

No action 2 0 0

Start fast forward 2 0 1

Start fast reverse 2 0 2

Stop 2 0 3

Start 2 0 4

Start slow for ward 2 0 5

Start slow reverse 2 0 6

Set direction to forward 2 0 7

Set direction to reverse 2 0 8

Emergency override 2 0 10

System

Control

Release time-stamped event buffer 3 0 0

Capture waveform 3 0 1

Reset INCOM slave-interface

3 0 2

statistics

Reset product-specific statistics 3 0 3

Acknowledge triggered event(s) 3 0 4

Reset sun-network master

3 0 5

INCOM statistics

Acknowledge energy-reset 3 0 6

Acknowledge set points change

3 0 7

buffer

Release time-stamped minor

3 0 8

event buffer

Release time-stamped motor

3 0 9

start profile buffer

Relay

Control

Activate relay output #X

(X = relay number 0–255)

De-activate relay output # X

4 1 X

4 2 X

(X = relay number 0–255)

Automatic

Tra ns fer

Switch

Control

Initiate ATS test 5 0 1

Bypass TDNE/TDEN 5 0 2

Initiate manual transfer 5 0 4

Cancel ATS test 5 0 5

Go to emergency 5 0 6

Cancel Go to emergency 5 0 7

Table 14. mMINT configuration registers

Modbus

address

16

No. of

regs

Register definition R/W

mMIN T (247 or 248 addressed)

Invalid Object Access

R/W 42001 425345 07D0 6300 1

Register

10

Low High Low High

Configuration

Floating Pt Data Word

R/W 42002 425346 07D1 6301 1

Order Configuration

Fixed P t Data Word

R/W 42003 425347 07D2 6302 1

Order Configuration

INCOM Routing

R/W 42101 0834 2 * 246

Address Configuration

INCOM (device addressed)

Mapped Block of

R/W 41001 420481 03E8 5000 100

Registers Configuration

Mapped Block of

R 41201 420737 04B0 5100 4 * 100

Registers Data

Modbus-to-INCOM Query W 42601 424 577 0A28 6000 2

Modbus-to-INCOM Response R 42701 424833 0A8C 6100 2 * 63

Supervisory Control Query R/W 42901 425089 0B54 6200 3

10

EATON www.eaton.com

19

Page 20

Instructional Leaet IL66A7508H09

Effective October 2016

Disclaimer of warranties and

limitation of liability

The information, recommendations, descriptions, and safety

notations in this document are based on Eaton’s experience and

judgment, and may not cover all contingencies. If further information

is required, an Eaton sales office should be consulted.

Sale of the product shown in this literature is subject to the terms

and conditions outlined in appropriate Eaton selling policies or

other contractual agreement between Eaton and the purchaser.

THERE ARE NO UNDERSTANDINGS, AGREEMENTS, WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING WARRANTIES OF

FITNESS FOR A PARTICULAR PURPOSE OR MERCHANTABILITY,

OTHER THAN THOSE SPECIFICALLY SET OUT IN ANY EXISTING

CONTRACT BETWEEN THE PARTIES. ANY SUCH CONTRACT

STATES THE ENTIRE OBLIGATION OF EATON. THE CONTENTS OF

THIS DOCUMENT SHALL NOT BECOME PART OF OR MODIFY

ANY CONTRACT BETWEEN THE PARTIES.

In no event will Eaton be responsible to the purchaser or user in

contract, in tort (including negligence), strict liability, or otherwise

for any special, indirect, incidental, or consequential damage or loss

whatsoever, including but not limited to damage or loss of use of

equipment, plant or power system, cost of capital, loss of power,

additional expenses in the use of existing power facilities, or claims

against the purchaser or user by its customers resulting from the

use of the information, recommendations, and descriptions

contained herein.

The information contained in this manual is subject to change

without notice.

mMINT—Modbus translator module—

installation and use

Eaton

1000 Eaton Boulevard

Cleveland, OH 44122

United States

Eaton.com

© 2016 Eaton

All Rights Reserved

Printed in USA

Publication No. IL66A7508H09 / Z18808

October 2016

Eaton is a registered trademark.

All other trademarks are property

of their respective owners.

Loading...

Loading...