Eaton MGR10 Operating Manual

SEFELEC REFERENCE PENT0060

Operating manual MGR10 - English

MGR10 A/B/C - Revision : I (for 7.0 software revision) 2

WARRANTY:

SEFELEC warrants that units are free from defects in material and workmanship.

SEFELEC warrants also that, when properly used, that units will perform in

accordance with specifications of this manual.

If within one year after original delivery it is found not to meet this standard, it will

be repaired at no charge in SEFELEC service facility in Lognes.

Changes in the unit not approved by SEFELEC will cancel this warranty.

SEFELEC will not be liable for any indirect damages resulting of the use of the

unit.

This warranty is in lieu of all other warranties.

MGR10 A/B/C - Revision : I (for 7.0 software revision) 3

Table of Contents

SECTION 1. INTRODUCTION .............................................................................................................................................. 5

1.1 OVERVIEW ................................................................................................................................................................... 6

1.2 Definitions and terminology ............................................................................................................................................ 8

1.3 Principles of measurement ............................................................................................................................................... 8

1.4 MGR10 and MGR10A technical specifications ........... ....................................... ........................................................... 9

1.4.1 Measurement Accuracy ......................................................................................................................................... 9

1.4.2 Programmable current ........................................................................................................................................... 9

1.4.3 Accuracy against current level ........................................................... ............. ....... ............. ...... ............. ............. . 9

1.5 MGR10B technical specifications ................................ .................................................... ............................................ 10

1.5.1 Measurement Accuracy ....................................................................................................................................... 10

1.5.2 Programmable current ......................................................................................................................................... 10

1.5.3 Accuracy against current level ........................................................... ............. ....... ............. ............ ....... ............ 10

1.6 MGR10C technical specifications ................................ .................................................... ............................................ 11

1.6.1 Measurement Accuracy ....................................................................................................................................... 11

1.6.2 Programmable current ......................................................................................................................................... 11

1.7 Common specification to all model numbers ............................................................................................................... 12

1.7.1 Temperature compensation .................................................... ....................................... ...................................... 12

1.7.2 Lead resistance ...................................................................................................................................................... 12

1.7.3 Mains supply ............................................................................ .................................................. ........................... 12

1.7.7 Operating conditions : ............................................................. ............................................................................ 13

1.7.8 Weight and Size : .................................................. .......................................................... ...................................... 13

SECTION 2 : SETTING UP THE MGR10 ............................................................................................................................. 14

2.1 Safety information ........................................................................................................................................................ 14

2.2 Unpacking the instrument ............................................................................................................................................. 14

SECTION 3 : ABOUT THE MGR10 ...................................................................................................................................... 15

3.1 The Front Panel ............................................................................................................................................................. 15

3.2 ON/OFF Switch ........................................................................................................................................................... 15

3.3 The Function Keypad ................................................................................................................................................... 15

3.4 Summary of basic functions ......................................................................................................................................... 16

3.5 About the MGR10 Display screen ................................................................................................................................ 18

3.6 About the function keys ................................................................................................................................................. 19

SECTION 4 : SETTING UP MEASUREMENT PARAMETERS ................................ ......................................................... 21

4.1 Range Selection ............................................................................................................................................................ 21

4.2 Current Selection .......................................................................................................................................................... 22

4.3 Measurement Mode ...................................................................................................................................................... 23

4.4 Temperature Compensation .......................................................................................................................................... 28

4.5 Limits ............................................................................................................................................................................ 31

4.6 Data Logging Function ................................................................................................................................................. 33

4.7 General setup menu ...................................................................................................................................................... 36

4.8 Measure/Hold function ................................................................................................................................................. 40

4.9 Measure Stop Function ........................................................................................ ......................................................... 41

4.10 ZERO Function ........................................................................................................................................................... 41

SECTION 5 : MEASURING WITH THE MGR10 ................................................................................................................. 42

5.1 Connecting to the MGR10 ............................................................................................................................................ 42

5.2 Connecting to the resistance ......................................................................................................................................... 43

5.3 Resistance measurement ............................................................................................................................................... 44

5.4 Resistance measurement with temperature compensation ............................................................................................ 44

5.5 Measurement with Limits ............................................................................................................................................. 45

SECTION 6 :REMOTE CONTROL INTERFACE ................................................ ................................................................ 47

6-1 PLC remote control ( option MGR10-02) ..................................................................................................................... 47

6-1-1 Unit setup : ............................................................................................................................................................ 47

6-1- 2 Contact specifications : ........................................................... ............................................................................ 47

6-1-3 Logical states definition : ..................................................................................................................................... 48

6-1- 4 Connection : ......................................................................................................................................................... 48

MGR10 A/B/C - Revision : I (for 7.0 software revision) 4

6-1- 6 How to trigger a measurement : ............................. .......................... .................... ......................... ................... 51

6-1-7 Analog output : ..................................................................................................................................................... 51

6.2 RS232 and IEEE488 PROGRAMMING INTERFACES : ........................................................................................... 53

6.2.1 RS-232 SERIAL INTERFACE ( option MGR10-01 ) .............................................................. ......................... 53

6.2.1.1 Connection ............................................................................................................................................................... 53

6.2.1.2 Front Panel Set-up ................................................................................................................................................... 54

6.2.2 IEEE-488 PARALLEL INTERFACE (OPTION MGR10-06) ............................................................. ............ 56

6.2.2.1 Connection ............................................................................................................................................................... 56

6.2.2.2 Front Panel Set-up ................................................................................................................................................... 56

6.2.2.3 Interface Functions .................................................................................................................................................. 57

6.2.2.4 Single Wire Interface Messages .............................................................................................................................. 58

6.2.2.5 Multiwire Interface Messages (ATN True) ............................................................................................................. 60

6.2.2.6 Device Dependent Messages (ATN False) ............................................................................................................. 62

6.3 PROGRAMMING THE RS-232 & IEEE INTERFACES ............................................................................................ 63

6.3.1 Introduction ................................................................................................................................................................ 63

6.3.2 Configuration & Measurement Commands ................................................................................................................ 66

6.3.3 Data Operation Commands ......................................................................................................................................... 72

6.3.4 Other function Commands .......................................................................................................................................... 75

6.3.5 System Related Commands ........................................................................................................................................ 77

6.3.6 Status Reporting Commands ...................................................................................................................................... 79

6.3.7 RS-232 Interface Commands ...................................................................................................................................... 87

6.3.8 Front Panel Operations ............................................................................................................................................... 87

APPENDIX I : RS-232/IEEE-488 COMMAND SUMMARY ....................................................................................... 88

APPENDIX II : RS-232 Pin Connections........................................................................................................................ 93

APPENDIX III : IEEE-488 Pin Connections .................................................................................................................. 94

APPENDIX IV : RS232 demo programme ..................................................................................................................... 95

APPENDIX V : IEEE488 for National Instrument demo programme ........................................................................... 99

SECTION 7 : ACCESSORIES .............................................................................................................................................. 105

7.1 LEADS ....................................................................................................................................................................... 105

7.2 OPTIONS ................................................................................................................................................................... 105

SECTION 8: MAINTENANCE AND CALIBRATION ....................................................................................................... 106

8.1 PRELIMINARY ......................................................................................................................................................... 106

8.2 INSTRUMENT RETURN .......................................................................................................................................... 106

8.3 MAINTENANCE ....................................................................................................................................................... 106

8.4 CLEANING ................................................................................................................................................................ 107

8.5 CALIBRATION ....................................................................................................................................................... 1076

MGR10 A/B/C - Revision : I (for 7.0 software revision) 5

SECTION 1. INTRODUCTION

Warning : This unit must be used by qualified pe ople. Every precautions for the

use of units connected to the main must be taken during its use. In pa rticular, this

unit must be connected to earth.

The specifications of this manual, the correct operation of the unit as well as the operator’s

security are guaranteed only when the supplied accessories a re used. The measurement probes

can include limitation or protective elements, therefore it is forbidden to modify without written

agreement from SEFELEC company.

In case of use under other conditions than the one specified in this manual, the security of the

user will be in danger.

MEANING OF THE DIFFERENT SYMBOLS ON THE INSTRUMENT

Warning (See document attache d)

Warning, risk of electric chock.

DC voltage.

AC and DC voltages.

AC voltage.

Earth connection.

MGR10 A/B/C - Revision : I (for 7.0 software revision) 6

1.1 OVERVIEW

The MGR10 Microhmmeter is a high accuracy instrument designed for industrial and laboratory

resistance measurements.

Features include:

Programmable measuring current user selectable in 100 steps

Temperature Compensation

Hi/Lo Limits with red/green front panel warning Pass/Fail lamps

Switched current mode with automatic averaging ensures elimination of thermal emf errors

Large graphic LCD display for resistance measurement values as well as configuration

settings and statistical results

Advanced functions include data logging a nd statistic al repor ti ng wi t h max/m in, avera ge

values peak to peak values an d standard deviation

Analogue output, IEEE-488 and RS232 communication, and PLC interfaces available for

automated monitoring an d controlling applications

Rear panel terminals available as an option

MGR10 A/B/C - Revision : I (for 7.0 software revision) 7

The MGR10 is a true four wire measuring instrument eliminating the need to compensate for lead

resistance. The measured value is displayed in large characters with decimal point and units k, ,

or m. For maximum accuracy the measuring current may be automatically reversed and the

average of measurement displayed. For measurements on unstable samples, a rolling average filter

is available.

Resistance measurement accuracy is typically 0.03% (1 year specification) and the value may be

displayed with or without temperature compensation, the final accuracy depends upon the current

selected.

The front panel measurement connections are made via 4mm sockets located on the front panel

(rear panel connection is an option). The connection to a Pt100 temperature sensor is made with a

standard DIN connector.

Available models :

Model Description

MGR10 Basic unit

MGR10A Basic unit with batteries power

MGR10B Basic unit for NFC93050 contact resistance measuremen t

MGR10C Basic unit for pyrotechnic measurement

MGR10 A/B/C - Revision : I (for 7.0 software revision) 8

1.2 Definitions and terminology

Standard features of the MGR10 Microhmmeter include:

Direct display of resistance

Illuminated display

Up to 10 Amps measuring current (programmable)

Temperature compensation

Display hold function

Display zero function

4000 event data logger

Statistical reporting

Measuring current reversal

Hi/Lo Limits with Red/Green front panel warning LEDs

Digital filter for smoothing display

1.3 Principles of measurement

The MGR10 generates a constant current which is connected using the +I and -I leads across the

unknown resistance to be measured. Th is current also passes through a stable and accurate inte rnal

standard. The volt drop across the unknown resistance is then measured together with th e volt drop

across the internal standard, the ratio of these two mea sur emen ts is then co mputed and displayed on

the front panel.

MGR10 A/B/C - Revision : I (for 7.0 software revision) 9

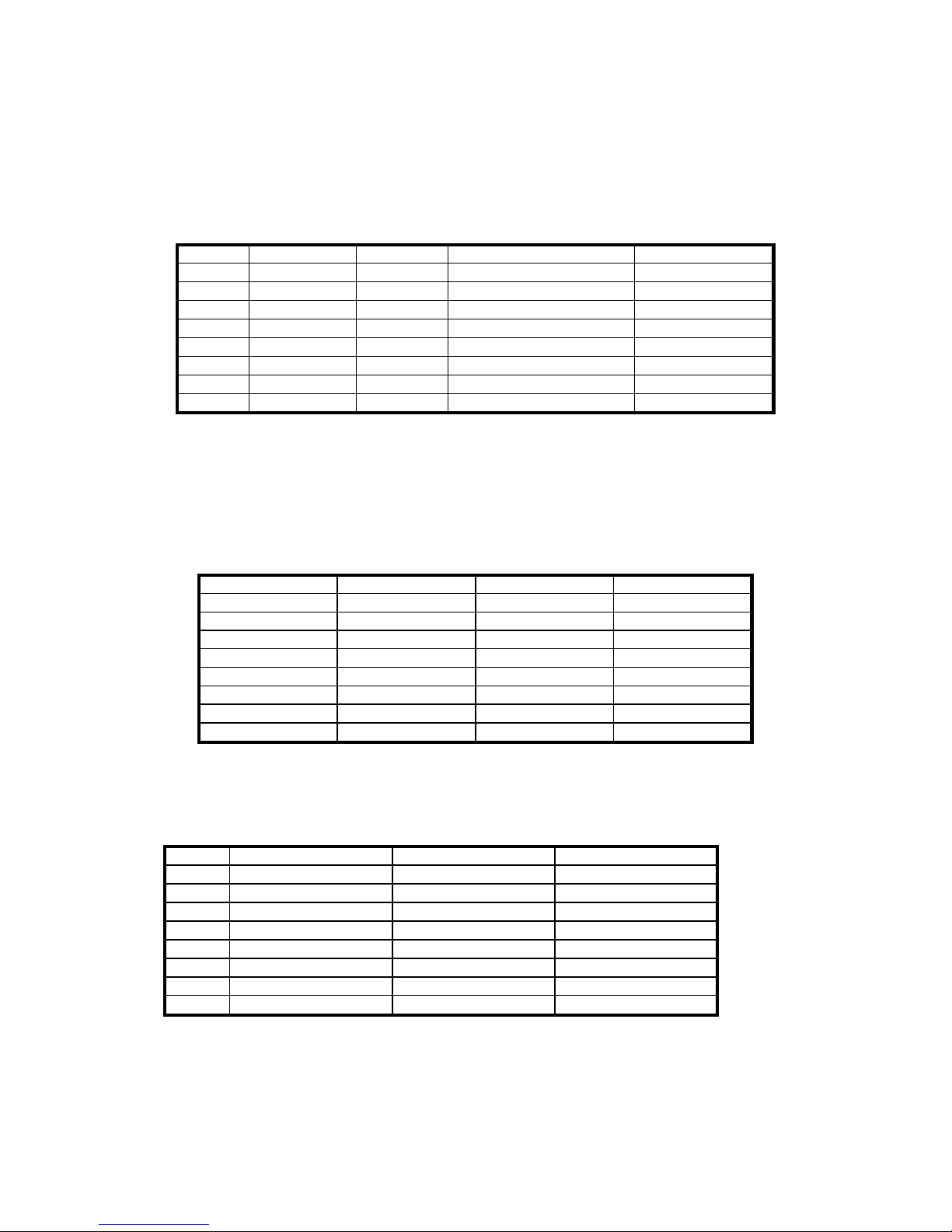

1.4 MGR10 and MGR10A technical specifications

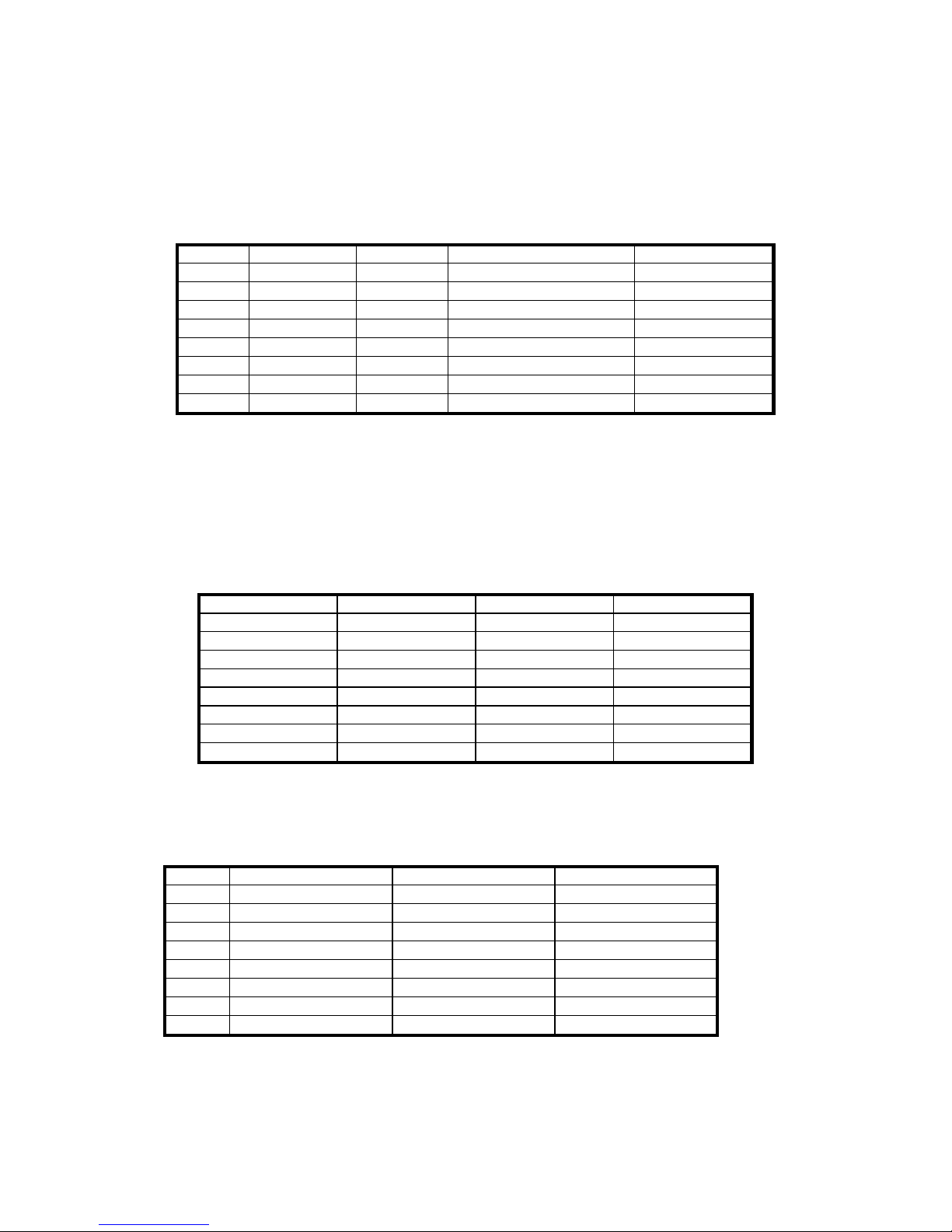

1.4.1 Measurement Accuracy

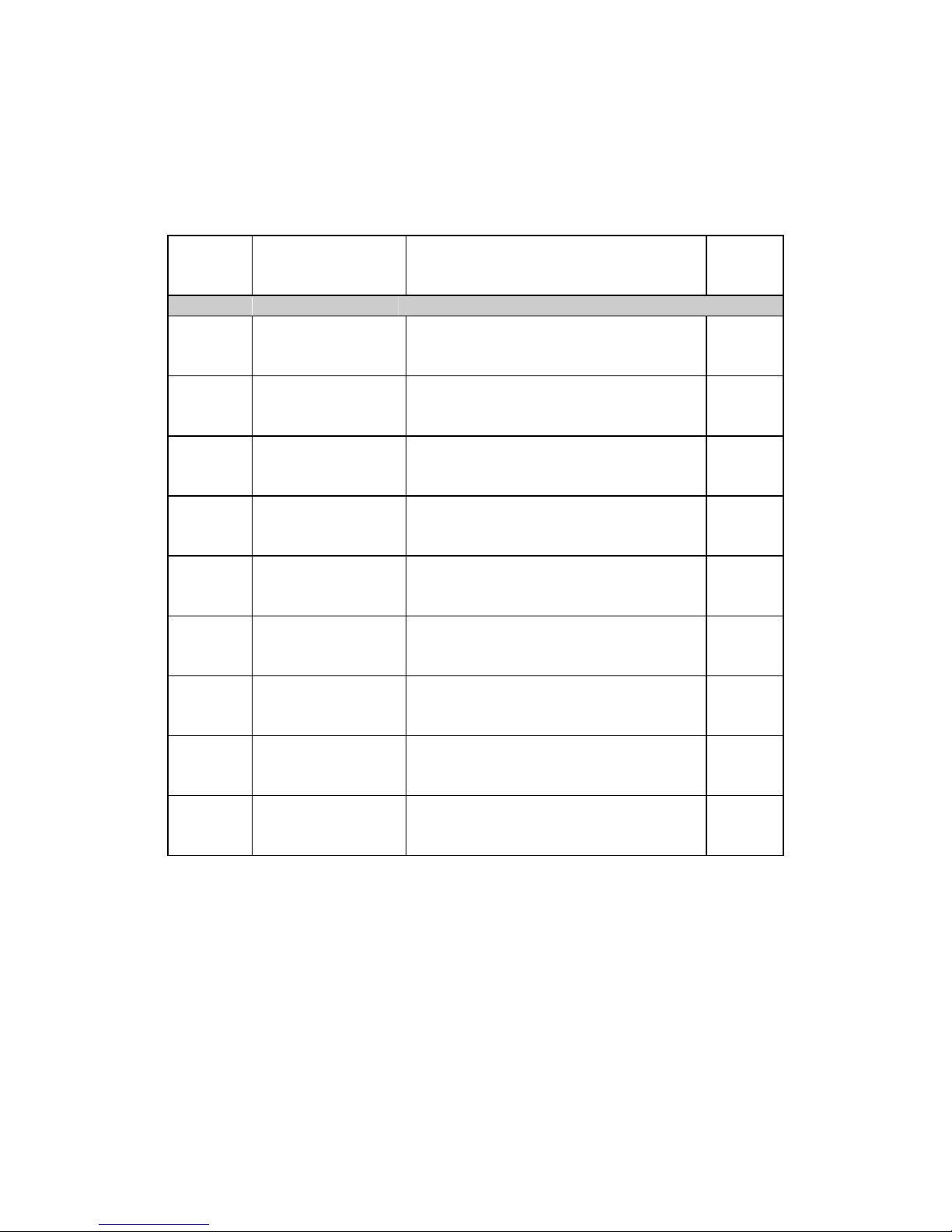

Range Max. Current Resolution Accuracy at full rated current Temp. Coefficient

30 k 100A 1

±(0.03%Rdg+0.02%FS)

50 ppm

3 k

1mA

100m

±(0.03%Rdg+0.01%FS)

50 ppm

300

10mA

10m

±(0.03%Rdg+0.01%FS)

50 ppm

30

100mA

1m

±(0.03%Rdg+0.01%FS)

50 ppm

3

1A

100

±(0.03%Rdg+0.01%FS)

50 ppm

200m

10A

10

±(0.03%Rdg+0.01%FS)

50 ppm

30m

10A

1

±(0.03%Rdg+0.01%FS)

50 ppm

3m

10A

100n

±(0.03%Rdg+0.02%FS)

50 ppm

The accuracy is quoted at full rated current in SLOW measurement speed and the display count

is 30,000 plus sign and unit.

FS = Full Scale

1.4.2 Programmable current

The measurement current is adjustable on each resistance range as follows:

Range Max Current Min Current Steps

30 k 100A 10A 1A

3 k

1mA

100A 10A

300

10mA 1mA

100A

30

100mA 10mA 1mA

3

1A 100mA 10mA

200m

10A 1A 100mA

30m

10A 1A 100mA

3m

10A 1A 100mA

The accuracy of current is ±0.1% .

Open circuit voltage is 5 V +/-5%

1.4.3 Accuracy against current level

Range 100% Current 50% Current 10% Current

30 k

±(0.03%Rdg+0.02%FS) ±(0.04%Rdg+0.02%FS) ±(0.05Rdg+0.02%FS)

3 k

±(0.03%Rdg+0.01%FS) ±(0.04Rdg+0.01%FS) ±(0.05Rdg+0.01%FS)

300

±(0.03%Rdg+0.01%FS) ±(0.04Rdg+0.01%FS) ±(0.05Rdg+0.01%FS)

30

±(0.03%Rdg+0.01%FS) ±(0.04Rdg+0.01%FS) ±(0.05Rdg+0.01%FS)

3

±(0.03%Rdg+0.01%FS) ±(0.04Rdg+0.01%FS) ±(0.05Rdg+0.01%FS)

200m

±(0.03%Rdg+0.01%FS) ±(0.04Rdg+0.01%FS) ±(0.05Rdg+0.01%FS)

30m

±(0.03%Rdg+0.01%FS) ±(0.04Rdg+0.01%FS) ±(0.05Rdg+0.01%FS)

3m

±(0.03%Rdg+0.02%FS) ±(0.04Rdg+0.02%FS) ±(0.05Rdg+0.02%FS)

MGR10 A/B/C - Revision : I (for 7.0 software revision) 10

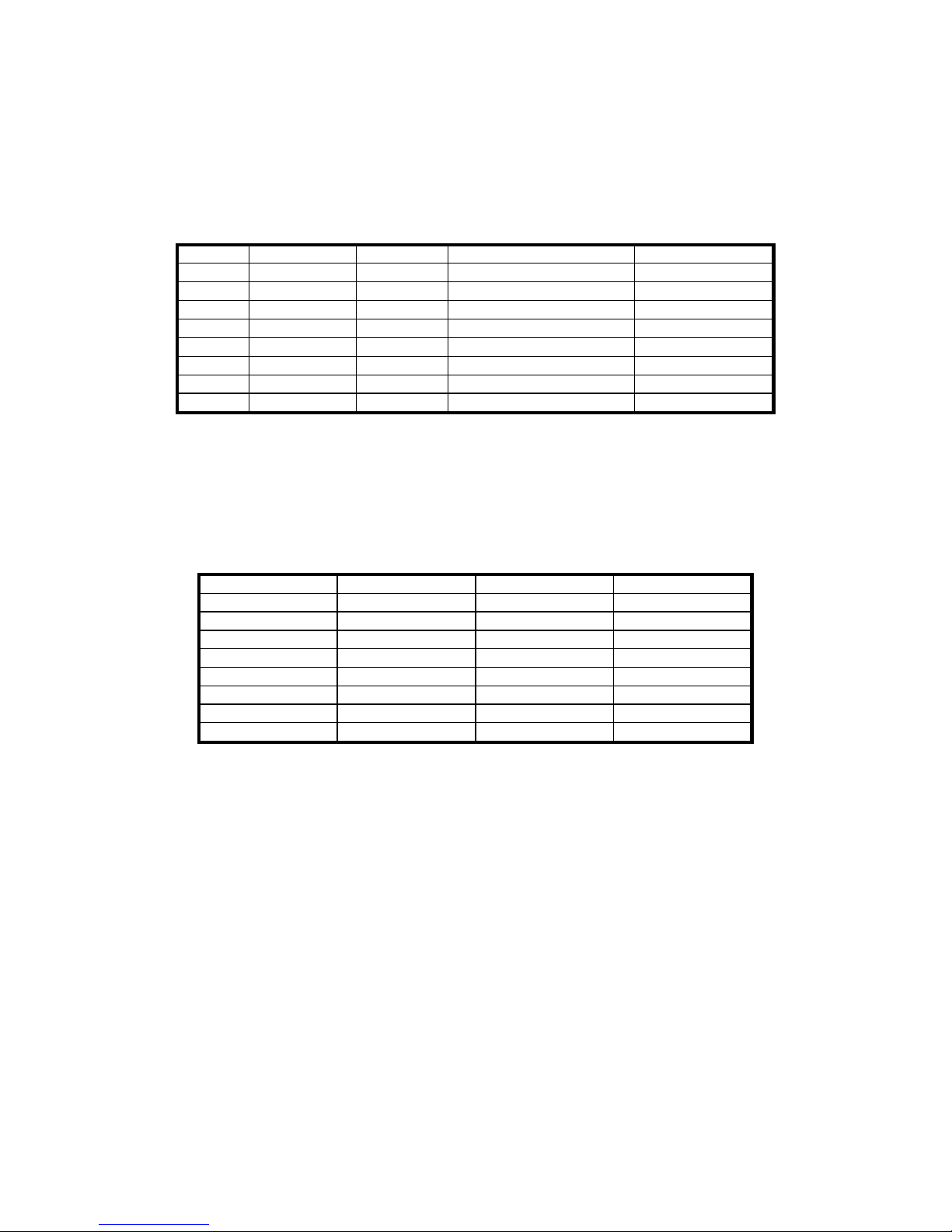

1.5 MGR10B technical specifications

1.5.1 Measurement Accuracy

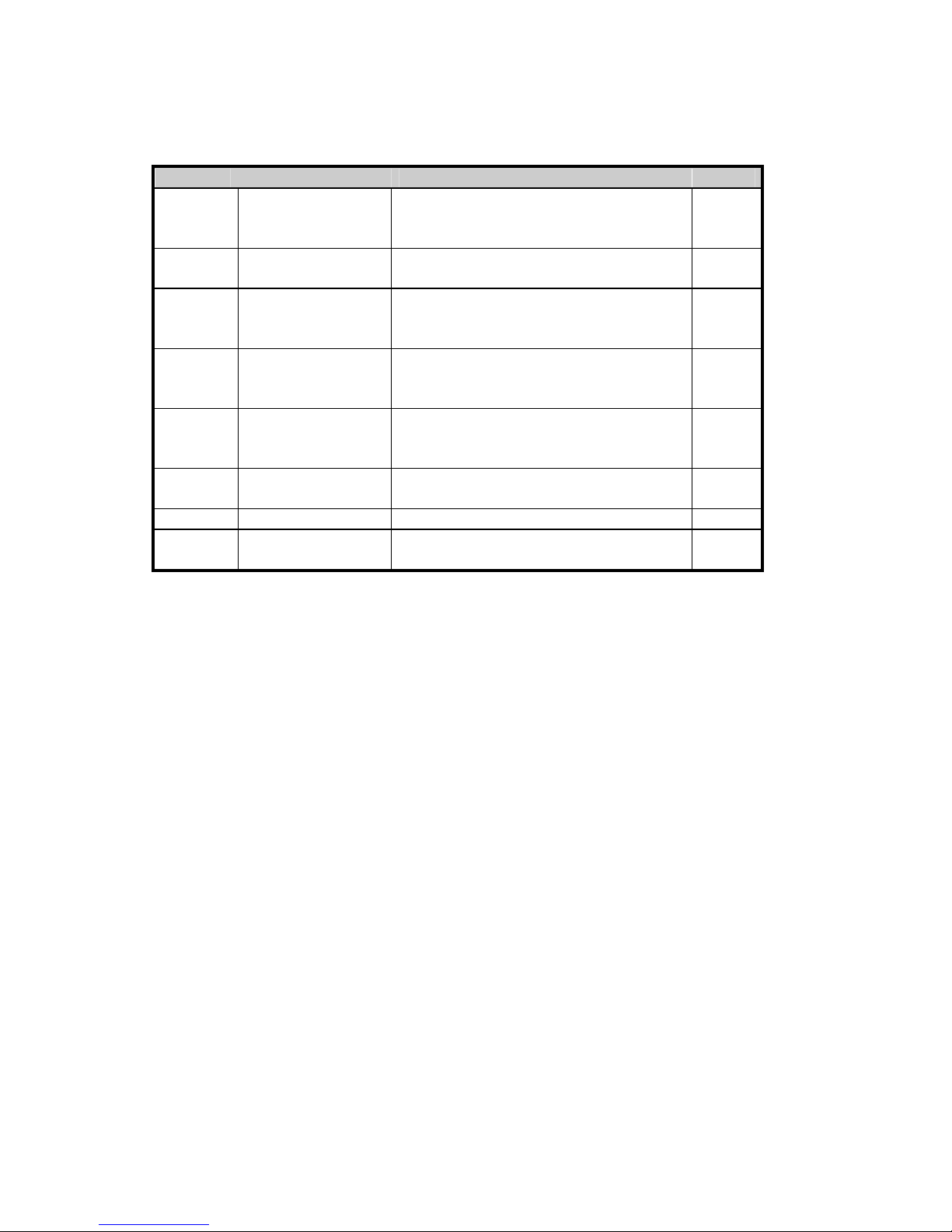

Range Max. Current Resolution Accuracy at full rated current Temp. Coefficient

30 k 100A 1

±(0.03%Rdg+0.02%FS)

50 ppm

3 k

1mA

100m

±(0.03%Rdg+0.01%FS)

50 ppm

300

10mA

10m

±(0.03%Rdg+0.01%FS)

50 ppm

30

100mA

1m

±(0.03%Rdg+0.01%FS)

50 ppm

3

100mA

100

±(0.05%Rdg+0.01%FS)

50 ppm

200m

100mA

10

±(0.05%Rdg+0.01%FS)

50 ppm

30m

Not available

3m

Not available

The accuracy is quoted at full rated current and the display count is 30,000 plus sign and unit.

FS = Full Scale

1.5.2 Programmable current

The measurement current is adjustable on each resistance range as follows:

Range Max Current Min Current Steps

30 k 100A 10A 1A

3 k

1mA

100A 10A

300

10mA 1mA

100A

30

100mA 10mA 1mA

3

100mA 10mA 1mA

200m

100mA 10mA 1mA

30m

Not available

3m

Not available

The accuracy of current is ±0.1% .

Open circuit voltage is 5 V +/-5% . Can be limited to 20 or 50 mV to comply with NFC93050

1.5.3 Accuracy against current level

Range 100% Current 50% Current 10% Current

30 k

±(0.03%Rdg+0.02%FS) ±(0.04%Rdg+0.02%FS) ±(0.05Rdg+0.02%FS)

3 k

±(0.03%Rdg+0.01%FS) ±(0.04Rdg+0.01%FS) ±(0.05Rdg+0.01%FS)

300

±(0.03%Rdg+0.01%FS) ±(0.04Rdg+0.01%FS) ±(0.05Rdg+0.01%FS)

30

±(0.03%Rdg+0.01%FS) ±(0.04Rdg+0.01%FS) ±(0.05Rdg+0.01%FS)

3

±(0.05%Rdg+0.01%FS) ±(0.06Rdg+0.01%FS) ±(0.07Rdg+0.01%FS)

200m

±(0.05%Rdg+0.01%FS) ±(0.06Rdg+0.01%FS) ±(0.07Rdg+0.01%FS)

30m

Not available

3m

Not available

MGR10 A/B/C - Revision : I (for 7.0 software revision) 11

1.6 MGR10C technical specifications

1.6.1 Measurement Accuracy

Range Max. Current Resolution Accuracy at full rated current Temp. Coefficient

30 k 10A 1

±(0.05%Rdg+0.02%FS)

50 ppm

3 k

0,1mA

100m

±(0.05%Rdg+0.01%FS)

50 ppm

300

1mA

10m

±(0.05%Rdg+0.01%FS)

50 ppm

30

10mA

1m

±(0.05%Rdg+0.01%FS)

50 ppm

3

10mA

100

±(0.05%Rdg+0.01%FS)

50 ppm

200m

Not available

30m

Not available

3m

Not available

The accuracy is quoted at full rated current and the display count is 30,000 plus sign and unit.

FS = Full Scale

1.6.2 Programmable current

The measurement current is not adjustable on each resistance range

Range Max Current Min Current Steps

30 k 10A 10A

Not available

3 k 100A 100A

Not available

300

1mA 1mA Not available

30

10mA 10mA Not available

3

10mA 10mA Not available

200m

Not available

30m

Not available

3m

Not available

The accuracy of the current i s ± 1% .

Open circuit voltage is 2 V +/-5% .

MGR10 A/B/C - Revision : I (for 7.0 software revision) 12

1.7 Common specification to all model numbers

1.7.1 Temperature compensation

The accuracy of the temp erature measur emen t is ±0.1% and uses a standard Pt1 00 sensor. This

accuracy does not include errors due to the sen sor itself. The tempe rature measureme nt range is

0…+40C and the resistance measurement is referenced to 20C when this option is used.

Accuracy of the MGR10-04 sensor : +/- ( 0.2% + 1°C)

1.7.2 Lead resistance

A maximum lead resistance of 0.5 / Imes ( = 0.05 for 10A and 500 for 1mA ) is

permissible in each of the four measuring leads.

1.7.3 Mains supply

Universal power inlet

Mains : 115/230V~ 10% single phase 47 to 63 Hz.

Power consumption : 40VA without load, 70 VA maxim um .

Switching from 115 to 230 volts by switch in the line input plug.

Temporized fuse protective in rear panel

- 2AT for 230V 4AT for 110V.

Battery powered with built in charger ( MGR10A version)

The two batteries used are 5Ah, and the following performance can be expected from

fully charged batteries:

o Digital :11 hours continuous use, with backlight on, an d IEEE and PLC cards

fitted.

o Analogue: Over 6000 simple measurements in FAST mode, using 10A

measuring current. (Or approximately 3000 measurements using SLOW

mode).

The battery condition is consta n tly monitored, and if it is low, a warning symbol is displayed .In

this situation operate as follows :

Connect a mains cable on the unit rear m ains soc ket

Connect the mains cable on the mains

Switch the rear panel switch in the ON position

The FAST red Led lamp should light on to indicate the battery charging mode

When the red Led lights off , the charge is over

MGR10 A/B/C - Revision : I (for 7.0 software revision) 13

1.7.7 Operating conditions :

The instrument must be used inside, in horizontal position or on tripode.

Temperature :

In storage : -10°C to +60°C.

In operation : 0°C to +45°C.

Accuracy is rated after half an hour of warm up and for a relative humidity < 50%.

Altitude : up to 2000 meters

Max. humidity rate : 80% for a temperature of 31°C.

1.7.8 Weight and Size :

Size : 131 x 339 x 324 mm (H W D)

Weight : 9.8 kg mains version

: 12 kg mains and battery version

Over voltage category :

CAT II.

Rate of pollution :

Pollution 2 : Occasional conductive pollution only by condensation.

Safety class :

Class I instrument : Earth protection by mains connection.

MGR10 A/B/C - Revision : I (for 7.0 software revision) 14

SECTION 2 : SETTING UP THE MGR10

2.1 Safety information

Please read and follow these important safety instructions:

Read the safety information at the beginning of this manual before operating the MGR10;

Make the necessary electrical safety connection checks. In particular, select the correct line voltage

and make sure that the correct fuse is installed. Incorrect voltage or fuse selection present both an

electrical safety and a fire haza rd. Ensure that the rear panel fan is operating and that the vent is not

blocked.

When connecting to an electrical supply mains supply, the mains cord provided with the equipment

should be used, and connected only to a mains supply with a suitable earth connection. Under no

circumstance should the equipment be operated with earth disconnected.

2.2 Unpacking the instrument

When you unpack the MGR10, check that the following items are present before starting to use the

unit:

1 x MGR10 Microhmmeter

1 x Mains Cord

1 x Operating manual

1 x Calibration Certificate

Please contact the Sefelec Customer Support Team immediately if any of these items are missing or

damaged.

MGR10 A/B/C - Revision : I (for 7.0 software revision) 15

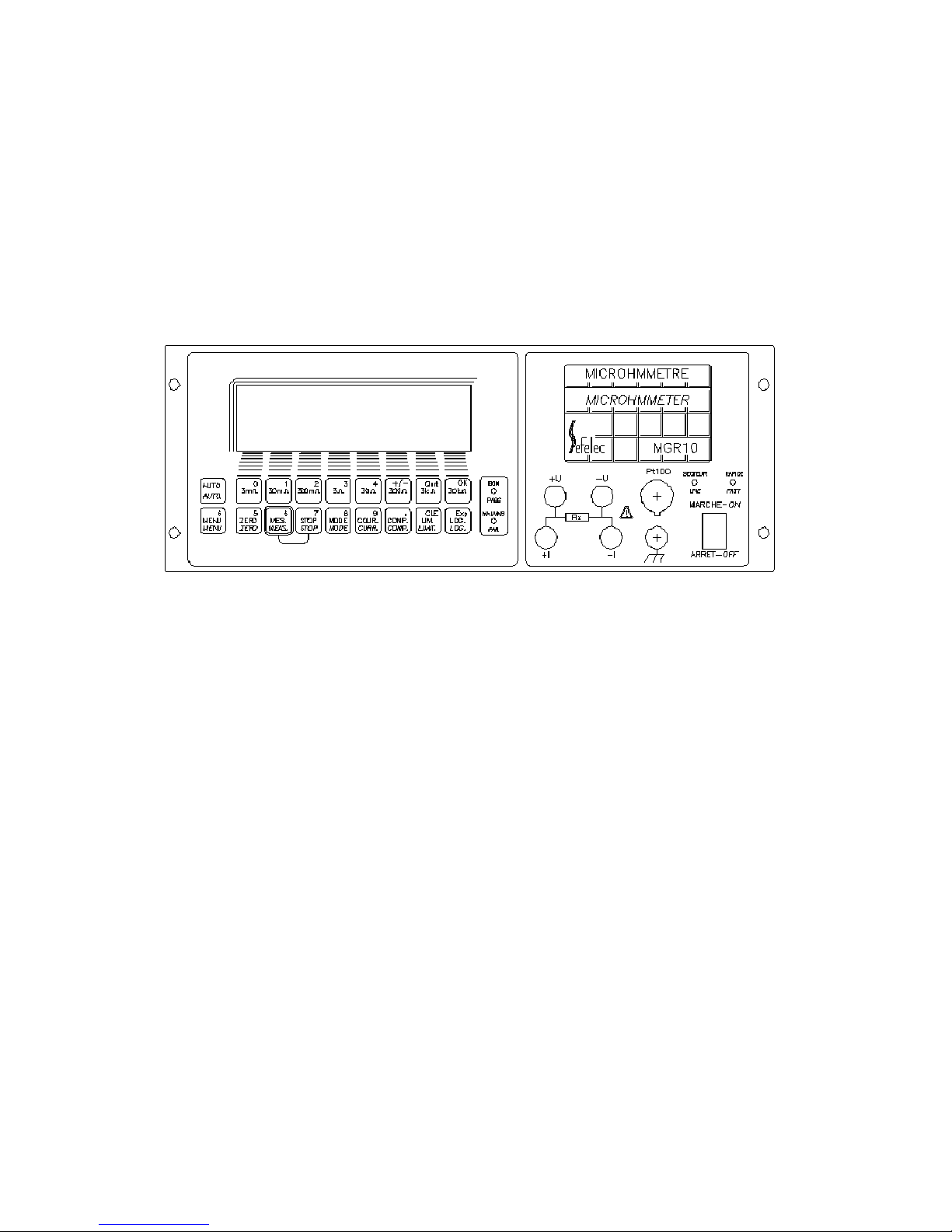

SECTION 3 : ABOUT THE MGR10

This section introduces you to the features and functions of the MGR10 Microhmmeter

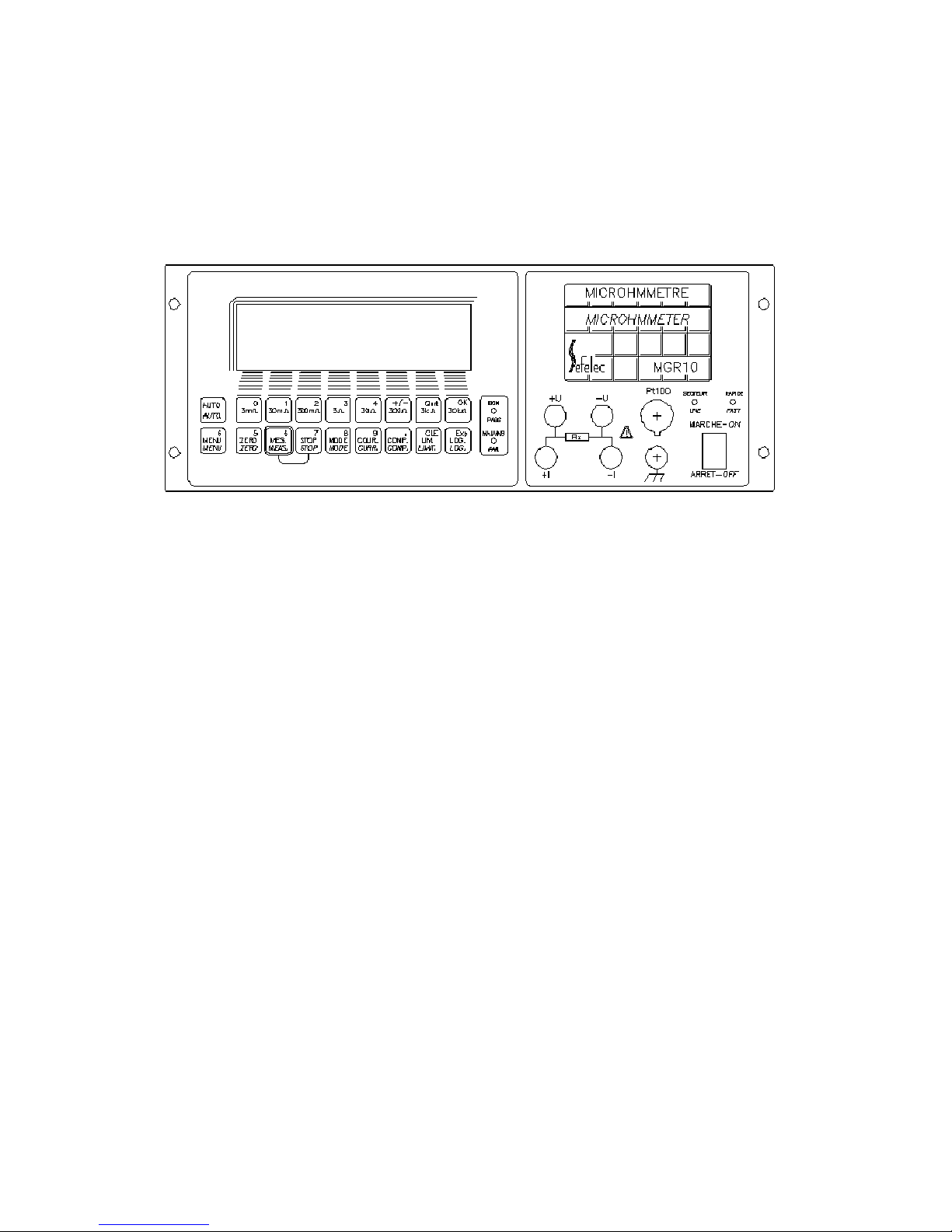

3.1 The Front Panel

3.2 ON/OFF Switch

The On/Off switch switches the MGR10 on and off. During Power On the last measurement

function setup is restored. The rear mounted cooling fan will always run and the cooling vent must

not be blocked.

3.3 The Function Keypad

All MGR10 measurements and programming facilities are accessed through the function keypad.

A brief description of key functions is given in the following table. For a detailed description of

how to use the keys to configure a nd ope r a t e t he MGR10, refer to section 5.

MGR10 A/B/C - Revision : I (for 7.0 software revision) 16

3.4 Summary of basic functions

Key

Symbol

Description

Function

Direct

function

or menu

Selection of Range

3m

Selects 3m range

Selects and displays the m easured value

using the 3m range

Direct

from

keypad

30m

Selects 30m range

Selects and displays the m easured value

using the 30m range

Direct

from

keypad

200m

Selects 200m

range

Selects and displays the m easured value

using the 200m range

Direct

from

keypad

3

Selects 3 range

Selects and displays the m easured value

using the 3 range

Direct

from

keypad

30

Selects 30 range

Selects and displays the m easured value

using the 30 range

Direct

from

keypad

300

Selects 300 range

Selects and displays the m easured value

using the 300 range

Direct

from

keypad

3k

Selects 3k range

Selects and displays the m easured value

using the 3k range

Direct

from

keypad

30k

Selects 30k range

Selects and displays the m easured value

using the 30k range

Direct

from

keypad

Auto

selects autorange The instrument will select the optimum

range required and display the measured

value

Direct

from

keypad

MGR10 A/B/C - Revision : I (for 7.0 software revision) 17

Setting up measurement options

CURR

Current selection Selects the current to be used for

measurement plus single polarity or

switched average

Menu

COMP

Temperature

compensation

Selects temperature compensation Menu

ZERO

Measurement

display zero

function

Nulls the display at the current reading

and displays measured values relative to

the null value

Direct

from

keypad

MES

Measure run/hold Display hold function triggers

measurement and data logger cycles.

Direct

from

keypad

STOP

Measure stop/start Stop s the current measurement and

disconnects the measurement current

Direct

from

keypad

LOG

Data logging

function

Selects the data logging and statistical

analysis menu functions

Menu

LIMIT

Limit functions Selects Hi/Lo limit menu Menu

MENU

Menu functions Selects interface options and calibration

functions

Menu

MGR10 A/B/C - Revision : I (for 7.0 software revision) 18

3.5 About the MGR10 Display screen

The liquid crystal graphic display clearly indicates the measured resistance and measurement status as

well as displaying available menu options and measurement analysis when selected.

Figure 3.5.1 - Example of Resistance Measurement Mode

The keypad below the display screen contr o ls the MGR10. Some keys perform a function directly. For

example, selects 3m range.

Other keys switch the display to configuration mode which allows you to select options through a

series of menus.

The option menus all follow the same format. The conf iguration mode is in dicated on the screen by a

dashed line displayed directly below the main reading. An instruction prompt under the dashed line

indicates the current menu. The available menu options are displayed on the bottom row of the display

as shown in figure 3.5. Press the corresponding function key to select an option.

AUTO1: 30m 10.0A (AVE) Slow

+ 18.000 m

T= +20.0C (EXT) R

20

= 18.006m (Cu)

Meas Cont

0

3m

MGR10 A/B/C - Revision : I (for 7.0 software revision) 19

Figure 3.5.2 Example of current mode menu

The lines printed on the front panel helps you to link the menu option printed on the screen with the

correct key on the keypad.

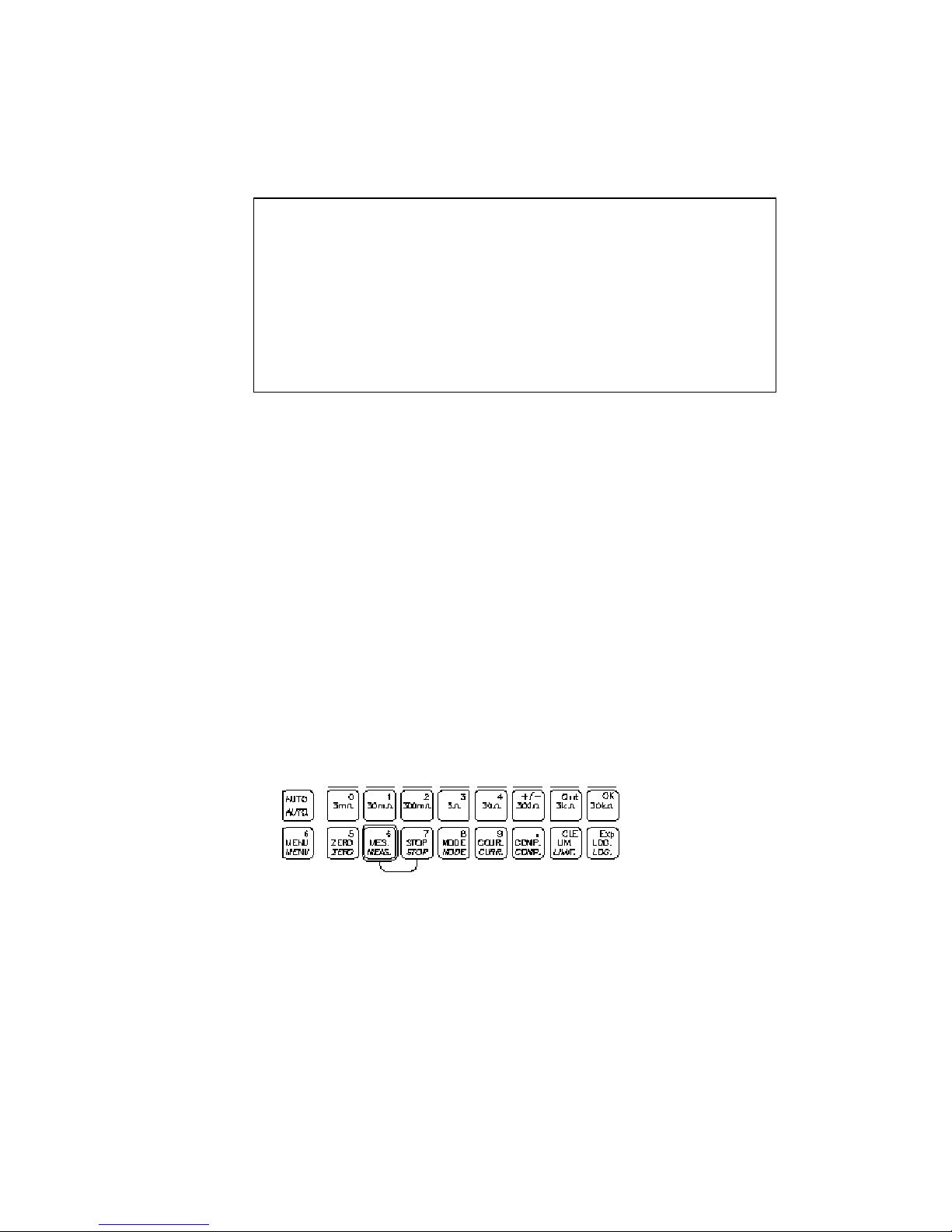

3.6 About the function keys

The top row of function keys are only used to select menu options. The lower row of function keys

is enabled only when entering values; these instances are covered lat er in this section. Both rows of

function keys are shown in figure 3.#

Figure 3.6.1 - Function keys

AUTO1: 30m 10.0A (AVE) Slow

+ 18.000 m

----------------------------------------------------------------------------------------

Powr

+I -I Ave Mode Mag Quit

MGR10 A/B/C - Revision : I (for 7.0 software revision) 20

The [Quit] and [OK] menu options consistently use the following keys.

Use the [Quit] k ey to leave a menu or return to the Resi stance Measurement mo de screen. Use the

[OK] key to confirm a particular choice and continue to the next set of menu options.

Not all function keys are used to access the Configuration Mode. Some just invoke the function

which is printed on the key. For example pressing

immediately sets the measured value displayed to zero.

The rest of this section describes each key in det ail and gives examples of how to configure the

measurement to your requirements.

The last used set up conditions are stored when the instrument is turned off and restored upon

switch on.

Quit

3k

OK

30k

5

ZERO

ZERO

MGR10 A/B/C - Revision : I (for 7.0 software revision) 21

SECTION 4 : SETTING UP MEASUREMENT PARAMETERS

4.1 Range Selection

Two modes of range selection are possible, Manual and Auto range. The 8 ranges may be selected

individually by pressing the appropriate range key. The range selected is indicated on the top left

hand side of the display. Auto range is selected using [AUTO] key.

This key toggles the selected function as follows; AUTO1 auto ranges starting with the highest

range,. AUTO2 auto ranges starting with the current range selected; Range manual range is

selected.

The range mode selected is indicated in the top left corner of the display.

WARNING : The maximum measurement current is 10 A on the 3 lowest ranges , check if the

current level intensity selected cannot damaged the resistor under test .

AUTO.

AUTO.

MGR10 A/B/C - Revision : I (for 7.0 software revision) 22

4.2 Current Selection

Press

Selects the current configuration menu;

+I , -I or Ave :

Select the current direction by pressing [+I] , [ -I ] or [Ave] , this function reverses automatically

the current direction and display the average of the 2 measured values : this cancels the errors

coming from the emf effect . The polarity or the average mode are displayed on the top line of the

LCD screen .

Mag :

Press on [Mag] to change the current intensity , as a percentage between 10 and 100 % of the

maximum value .

Press on [Chg] to modify the current value

Enter the requested percentage with the numeric keypad ( numbers are located in the right

upper corner of the keys )

Press on [OK] to enter the value.

Press on [OK] to go back to the previous page

The current value is displayed on the center top line of the LCD screen . The % value is

applied to all the ranges .

Press on [QUIT ] to escape the menu .

+I -I Ave Mag Quit

9

COUR

CURR.

MGR10 A/B/C - Revision : I (for 7.0 software revision) 23

4.3 Measurement Mode

Press on :

to select the measurement mode options.

For the greatest flexibility and v ersatility of meas urement the MGR10 has man y advanced featu res

which can be selected from this m enu.

The

km function gives the possib ility to display the measured resistan ces on a known leng th of

cables computed to the value for 1 kilometer.

:

Press on [] to select a resistance display in Ohms ( standard display )

/km :

Press on [ /km] to select a resistance display in Ohms per kilometer

Press on [ No. ] to modify the number of cable connected in series or parallel

o Enter a number between 1 and 99 wit h the numeric keypad

o Press on [OK] to enter the value

Press on [ Len ] to modify the cabl e l ength

o Enter the value according to unity with the numeric keypad

o Press on [OK] to enter the value

Press on [ Unit ] to select Meter or Kilometer

o Press on [ meter ] or [ km]

o Press on [OK] to enter the selecti on

Press on [ Conn ] to define if the cables are series or parallel connected .

o Press on [ Ser ] or [ Par ]

o Press on [OK] to enter the selecti on

Press on [OK] to go back to the previous page

-------DISPLAY------- Trig Read

km km Mode Rate Filt Sett Quit

8

MODE

MOD

E

MGR10 A/B/C - Revision : I (for 7.0 software revision) 24

Press on [QUIT ] to escape the menu .

According to the input parameters the unit will display the resistance value for a distance of 1 km.

i.e. :

A measured resistor of 220 ohms on a 100 meters long cable , the value for 1 kilometer will be :

1km/100m x 220 ohms = 2200 ohms

A measured resistor of 220 ohms on a 2000 meters long cable , the value for 1 kilometer will be :

1km/2km x 220 ohms = 110 ohms

A measured resistor of 220 ohms on 2 parallel 100 meters long cables , the value for 1 kilometer

will be : 1km/100m x 220 ohms x 2 = 4400 ohms

A measured resistor of 220 ohms on 2 series 100 meters long cables , the value for 1 kilometer will

be : 1km/100m x 220 ohms / 2 = 1100 ohms

NOTA : the ohm per km value will be displayed in big characters and the true value will be displayed

in small characters ( Rx= 220,00 ohm)

km :

Press on [km] to select the resistance display in kilometers.

Press on [ No. ] to modify the number of cable connected in series or parallel

o Enter a number between 1 and 99 wit h the numeric keypad

o Press on [OK] to enter the value

Press on [ Res ] to modify the resistor per distance unity (km or meter)

o Enter the value according to unity with the numeric keypad

o Press on [OK] to enter the value

Press on [ Unit ] to select Meter or Kilometer

o Press on [ meter ] or [ km]

o Press on [OK] to enter the selecti on

Press on [ Conn ] to define if the cables are series or parallel connected .

o Press on [ Ser ] or [ Par ]

o Press on [OK] to enter the selecti on

Press on [OK] to go back to the previous page

Press on [QUIT ] to escape the menu .

According to the input resistance per meter or kilometer value the unit will display the length of the

cable .i.e. :

A resistor per kilometer of 220 ohm x km on 1 cable with a measured resistance of 220 ohms , the

cable length value will be :

220 ohms / 220 ohmxkm = 1 kilometer

A resistor per kilometer of 220 ohm x km on 2 series cables with a measured resistance of 220

ohms , the cable length value will be :

220 ohms / 220 ohmxkm /2 = 0.5 kilometer

A resistor per kilometer of 220 ohm x km on 2 parallel cables with a measured resistance of 220

ohms , the cable length value will be :

220 ohms / 220 ohmxkm x 2 = 2 kilomete r

NOTA : the km value will be displayed in big characters and the true value will be displayed in small

characters ( Rx= 220,00 ohm)

MGR10 A/B/C - Revision : I (for 7.0 software revision) 25

MGR10 A/B/C - Revision : I (for 7.0 software revision) 26

IMPORTANT NOTICES ON THE /km and km MODES :

1) The

/km and km functions are not operating in RS232 or IEEE488 modes but are op erating

in the PLC mode .

2) The temperature compensation function stays operating .

3) The comparison function with high and low limits , the analog output and the data storage are

not following the

/km and km modes and continue to work on the real Rx valu e in Ohms .

4) The ZERO function is not working in the

/km and km modes

5) Only the SLOW mode allows operating

/km and km functions .

Trig Mode :

Press on [Trig Mode ] to select the measurement trigger modes.

Press on [Cont] to activate the continuous measurement mode

Press on [Sing ] to activate single measurement mode. This mode performs a measurement

and memorizes the value on the display .To trigger a new measurement , press on the

[MES] key .

Press on [OK] to go back to the previous page

Press on [QUIT ] to escape the menu .

Read rate :

Press on [Read rate ] to select the measurement speed

Press on [Slow] to activate a display with large characters and with a rate of 2 measurements

per second which gives the best resolu tio n a n d accuracy .

Press on [Med] to activate a display with large characters and with a rate of 4 measurements per

second which gives the best resolution and accuracy .

Or press on [Fast ] to perform measurement with a rate of 50 per second . This mode is

mainly advised when operating the unit from a remote interface . The measured values are

displayed in small characters and the accuracy is reduced .

Press on [OK] to go back to the previous page

Press on [QUIT ] to escape the menu .

Filt :

Press on [Filt] to select the digital filter, this feature should be used when the sample to be

measured is unstable and the measured value displayed is constantly changing. The filter is a

rolling average of n measurem ents, where n may be set between 1 and 32.

Press on [No. Rdgs] to enter the number of measurements : No of readings : 10 .

Press on [Chg] to change the value and enter the value with the numeric keypad .

Press on [OK] to enter the new value .This value will be displayed in the right upper

corner of the LCD screen if the filter is activated . Filt : n

Or press on [OK] to keep the previous value

Press on [On] to activate the filter mode.

MGR10 A/B/C - Revision : I (for 7.0 software revision) 27

Or press on [Off] to cancel the filter mode

Press on [OK] to go back to the previous page

Press on [QUIT ] to escape the menu .

Sett :

Press on [Sett] to select the Settling Algorithm intended for measuring the resistance of inductive

specimens.

When the ‘MEAS’ button pressed, con tinuous measurements will be made until two consecutive

results are within the selected limit, or until the selected maximum number of measurements has been

reached. In the first case, the final result will be displayed, and in the second case, the message:

“MEASUREMENT ERROR – Current settle faile d” will be displayed. If appropriate, the result (or the

‘error value’) will also be data-logged, sent out on the bus, and sent to the Analogue Output on the PLC

card. Finally, if the Measurement Limits facility is selected, then the PASS/FAIL result will be

displayed.

The Settling facility cannot be used in ‘FAST’ mode, and ‘SLOW’ mode is recommended.

Normally, the Settling facility should be used in ‘SINGLE’ trigger mode, and the above description

assumes this. Howev e r, if ‘CONTINUOUS’ trigger mode is used, then the operation is the same,

except that once the measurement has settled, the settling facility is effectively disabled, and the

MGR10 continues to take measurements without interrupting the current, until ‘STOP’ is pressed.

When ‘MEAS’ is pressed again, the Settling facility will be re-engaged.

Press on [Limit] to enter the number of digits : No of digits : 10 .

Press on [Chg] to change the value and enter the value with the numeric keypad .

Press on [OK] to enter the new value .This value will be displayed in the right upper

corner of the LCD screen if the filter is activated . Sett : n

Or press on [OK] to keep the previous value

Press on [No. Rdgs] to enter the number of measurements : No of readings : 10 .

Press on [Chg] to change the value and enter the value with the numeric keypad .

Press on [OK] to enter the new value .This value will be displayed in the right upper

corner of the LCD screen if the filter is activated . Sett : n

Or press on [OK] to keep the previous value

Press on [On] to activate the settling mode.

Or press on [Off] to cancel the settling mode

Press on [OK] to go back to the previous page

Press on [QUIT ] to escape the menu .

MGR10 A/B/C - Revision : I (for 7.0 software revision) 28

4.4 Temperature Compensation

Press on

to select the setup menu for temperature compensation

The temperature compensation mod e should be used when measuremen ts are required to b e referenced

to 20C. This is particularly useful when measuring materials with a high temperature coefficient such

as copper, as the ambient temperature varies so will the resistance value being measured. Using the

temperature compensation mode references all values back to a temperature of 20C.

The true resistance value measured will be displayed in large digits in the center of the display and the

compensated resistance will be displayed in smaller text below.

The compensation formula is :

))20(1( Ct

Rx

Rc

With : R

t

= resistance value @ t temperature

Rc = resistance @ 20°C

= 3980 ppm/°C or 4100 ppm/°C according to the material

t = measurement temperat ure

Mode :

Press on [Mode] to select the temperature compensation

Press on [Ext] to select an external temperature sensor .This mode require the connection of a

PT100 sensor on the front panel connector named Pt100.

.

COMP

COMP

Compensation : On MANUAL COPPER

Mode Ref On Off Quit

MGR10 A/B/C - Revision : I (for 7.0 software revision) 29

Or press on [Man] to enter manually the compensation temperature .This mode request to the

operator to enter the ambiance temperature .

Press on [Chg] to modify the temperature value

Use the keypad to enter the new value in °C or °F

Press on [OK] to enter the new value

Press again on [OK] to go back to the previous page

Press on [Cu] to select compensati on f or coppe r material with a coefficient : 3980 ppm/C

Or press on [Al] to select compensation for aluminum material with a coefficient : 4100 ppm/C

Or press on [User] to select a coefficient which c an be defined by the operator

Press on [Chg] to modify the coefficient value in ppm/°C

Use the keyboard to enter the new coefficient value

Press on [OK] to enter the new value

Press again on [OK] to go back to the previous page

Press again on [OK] to go back to the previous page

Ref :

Press on [Ref] to select the reference temperature value (standard and initial value set to 20°C)

Press on [UP arrow] or [DOWN arrow] keys to modify the temperature value

Press on [OK] to enter the new value

Press again on [OK] to go back to the previous page

On :

Press on [On] to activate the temperature compensation mode

Off :

Or press on [Off] to cancel the temperature compensation mode

Press on [Quit] to escape the menu

MGR10 A/B/C - Revision : I (for 7.0 software revision) 30

In the compensation mode , the compensated value of the resistance is displayed with big characters

and the true value is displayed with small characters .

Figure 4.4.1 Measurement screen with temperature compensati on

AUTO1: 30m +10.0A (AVE) SLOW

+ 9.619 m

T= + 30.0C (Man) RX = 9.997 m (Cu)

Meas Sing

Loading...

Loading...