Eaton MDS-408, MDN-508, MDS-508, MDS-808, MDS-608 Instructions For Installation, Operation And Maintenance

...

Double-wide Fixed

Standard Frame Fixed

Narrow Frame Fixed

Instructions for Installation, Operation and Maintenance of

Magnum DS, DSX and DSL Low Voltage Power Circuit Breakers

I.B. 2C12060H08 Supersedes I.B. 2C12060H07 dated April 2005

Effective May 2006

IB2C12060H08

For more information visit: www.EatonElectrical.com

www . ElectricalPartManuals . com

www . ElectricalPartManuals . com

Instruction Book

Page iii

Effective: May 2006

I.B. 2C12060H08

For more information visit: www.EatonElectrical.com

For application information, consult Cutler-Hammer or

see applicable Product Guides, Technical Documents,

Application Publications and/or Industry Standards.

SAFETY

All safety codes, safety standards and/or regulations

must be strictly observed in the installation, operation

and maintenance of this equipment.

THE WARNINGS AND CAUTIONS INCLUDED AS

PART OF THE PROCEDURAL STEPS IN THIS MANUAL ARE FOR PERSONNEL SAFETY AND PROTECTION OF EQUIPMENT FROM DAMAGE. AN EXAMPLE OF A TYPICAL WARNING LABEL HEADING IS

SHOWN ABOVE TO FAMILIARIZE PERSONNEL

WITH THE STYLE OF PRESENTATION. THIS WILL

HELP TO INSURE THAT PERSONNEL ARE ALERT

TO WARNINGS. IN ADDITION, CAUTIONS ARE ALL

UPPER CASE AND BOLDFACE.

PURPOSE

This instruction manual is expressly intended to cover

the installation, operation and maintenance of Magnum

DS (MDS), DSX (MDSX) and Magnum DSL (MDSL)

Power Circuit Breakers. These circuit breakers may be

supplied as part of complete switchboard assemblies or

as separate components. This manual applies only to

the circuit breaker and (if drawout) it’s mating cassette.

The Magnum DSL circuit breaker can only be supplied

as a drawout device. In the case of fixed versions of

Magnum DS circuit breakers, certain sections of this

manual, referring to such items as position interlocks

and the drawout mechanism, will not apply.

Trip units associated with Magnum DS, DSX and DSL

Power Circuit Breakers will be addressed in a general

manner in this manual. Specific trip unit details and

time-current characteristic curves are covered in separate documents specific to the trip units.

Magnum DS, DSX and DSL circuit breaker accessory

items are discussed briefly in this manual. Field installation instructions for such items, however, are covered in

individual instruction leaflets specific to the accessory.

This information is also available from the CutlerHammer website at www.EatonElectrical.com

All possible contingencies which may arise during installation operation or maintenance, and all details and variations

of this equipment do not purport to be covered by these instructions. If further information is desired by purchaser

regarding his particular installation, operation or maintenance of particular equipment, contact the local CutlerHammer Inc. representative.

!

WARNING

www . ElectricalPartManuals . com

Instruction Book

Page iv

Effective: May 2006

I.B. 2C12060H08

For more information visit: www.EatonElectrical.com

TABLE OF CONTENTS

SECTION 1: INTRODUCTION PAGE

1-1 General Information.............................................................................................................................................1

1-2 Safety Features ...................................................................................................................................................2

1-3 Safety Practices ..................................................................................................................................................2

1-4 Qualified Personnel .............................................................................................................................................3

1-5 Other Publications and Documentation...............................................................................................................3

SECTION 2: RECEIVING, HANDLING AND INSTALLATION

2-1 General Information.............................................................................................................................................4

2-2 Suggested Tools .................................................................................................................................................4

2-3 Unpacking Circuit Breaker...................................................................................................................................4

2-3.1 Storing Circuit Breaker ...........................................................................................................................4

2-4 Lifting Circuit Breaker ..........................................................................................................................................5

2-5 Circuit Breaker Inspection ...................................................................................................................................6

2-6 Installing Drawout Circuit Breaker .......................................................................................................................6

2-6.1 Rejection Interlocks ................................................................................................................................6

2-6.2 Circuit Breaker Positioning .....................................................................................................................7

2-6.3 Levering Circuit Breaker .........................................................................................................................9

2-7 Fixed Circuit Breaker.........................................................................................................................................10

2-8 Circuit Breaker Operation..................................................................................................................................10

SECTION 3: CIRCUIT BREAKER DESCRIPTION AND OPERATION

3-1 Introduction........................................................................................................................................................11

3-1.1 MDSL Application/Operation ................................................................................................................15

3-2 Basic Circuit Breaker Assembly ........................................................................................................................15

3-3 Pole Units ..........................................................................................................................................................15

3-3.1 Primary Moving Contacts .....................................................................................................................16

3-3.2 Primary Stationary Contacts.................................................................................................................16

3-4 Operating Mechanism .......................................................................................................................................17

3-4.1 Manual Operation .................................................................................................................................17

3-4.2 Electrical Operation ..............................................................................................................................18

3-4.3 Anti-Pump Feature ...............................................................................................................................18

3-5 Arc Chambers ...................................................................................................................................................18

3-5.1 Arc Chute .............................................................................................................................................18

3-6 Electronic Tripping System................................................................................................................................19

3-6.1 Microprocessor-based Trip Unit ...........................................................................................................19

3-6.2 Rating Plug ...........................................................................................................................................21

3-6.3 Current Sensors ...................................................................................................................................21

3-6.4 Trip Actuator .........................................................................................................................................22

3-6.5 Mechanical Trip Flag ............................................................................................................................22

3-6.6 Making Current Release.......................................................................................................................22

3-6.7 High Instantaneous Trip Option (Magnum DS Only) ............................................................................22

3-6.8 Voltage Taps ........................................................................................................................................23

3-7 Secondary Contacts and Connection Diagrams ...............................................................................................23

3-7.1 Connection Diagrams ...........................................................................................................................24

www . ElectricalPartManuals . com

Instruction Book

Page v

Effective: May 2006

I.B. 2C12060H08

For more information visit: www.EatonElectrical.com

PAGE

3-8 Accessory Devices ............................................................................................................................................46

3-8.1 Plug-In Electrical Accessories ..............................................................................................................46

3-8.2 Internal Electrical Accessories .............................................................................................................48

3-8.3 Mechanical Accessories .......................................................................................................................50

3-9 MDSL Limiters/Blown Limiter Indication............................................................................................................53

3-9.1 MDSL Current Limiters .........................................................................................................................53

3-9.2 Blown Limiter Sensing ..........................................................................................................................53

SECTION 4: DRAWOUT CIRCUIT BREAKER AND CASSETTE

4-1 General .............................................................................................................................................................55

4-1.1 Drawout Cassette .................................................................................................................................55

4-2 Drawout Circuit Breaker Dimensions ................................................................................................................57

4-3 Drawout Cassette Dimensions ..........................................................................................................................57

SECTION 5: FIXED CIRCUIT BREAKER

5-1 General .............................................................................................................................................................59

5-2 Fixed Circuit Breaker Dimensions .....................................................................................................................59

SECTION 6: INSPECTION AND MAINTENANCE

6-1 General .............................................................................................................................................................60

6-2 General Cleaning Recommendations ...............................................................................................................60

6-3 When to Inspect ................................................................................................................................................60

6-4 What to Inspect .................................................................................................................................................61

6-4.1 Functional Field Testing .......................................................................................................................61

6-4.2 Arc Chute Inspection ............................................................................................................................62

6-4.3 Primary Contact Inspection ..................................................................................................................63

6-5 Circuit Breaker Modifications and Changes ......................................................................................................64

6-5.1 Rating Plug Replacement.....................................................................................................................64

6-5.2 Current Sensor Replacement ...............................................................................................................65

6-5.3 Current Limiter Replacement (MDSL) ..................................................................................................66

6-5.3.1 Replacing Type MA and MB Current Limiters ......................................................................................55

6-5.3.2 Replacing Type MD Current Limiters ...................................................................................................66

6-5.3.3 Replacing Type MD Current Limiters on MDSL20 Breakers................................................................66

SECTION 7: TROUBLESHOOTING

7-1 Introduction........................................................................................................................................................67

SECTION 8: RENEWAL PARTS

8-1 General .............................................................................................................................................................70

www . ElectricalPartManuals . com

Instruction Book

Page vi

Effective: May 2006

I.B. 2C12060H08

For more information visit: www.EatonElectrical.com

FIGURES

Figure Title Page

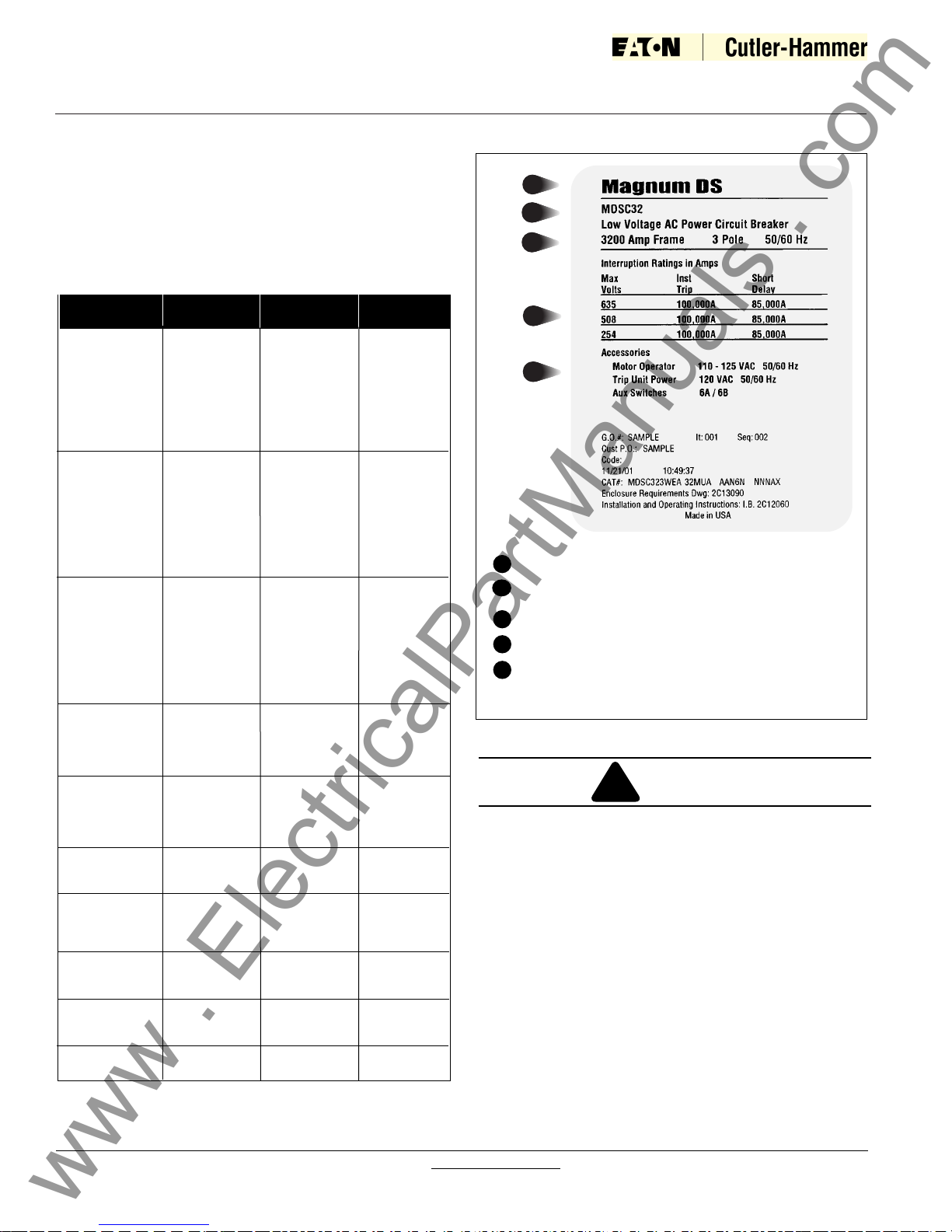

1-1 Magnum DS Family of Low Voltage Power Fixed and Drawout Circuit Breakers (800-5000 Amperes) ..1

1-2 Typical Magnum Nameplate ....................................................................................................................2

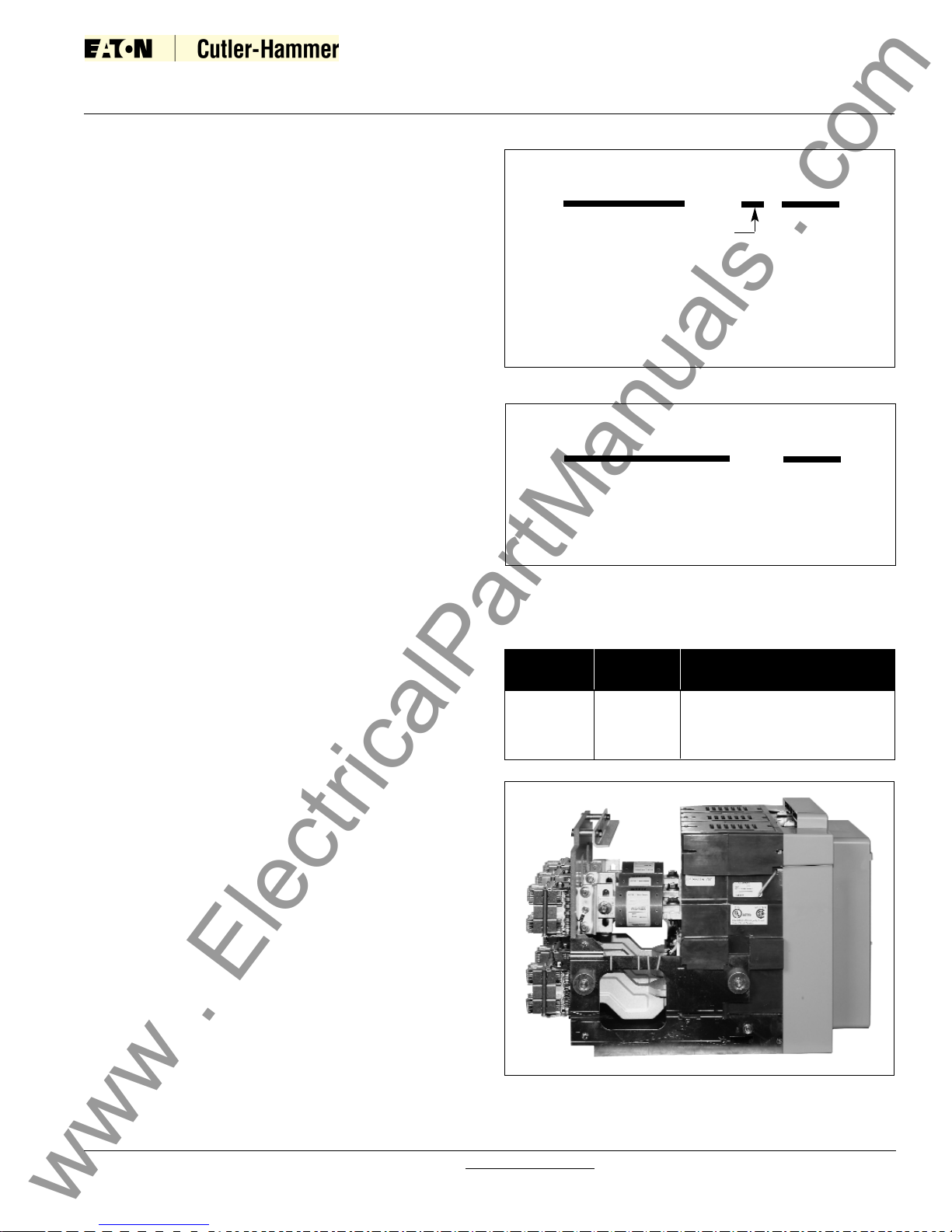

1-3 & 1-4 Sample Designation Examples ................................................................................................................3

1-5 Typical Magnum DSL (MDSL) Drawout Breaker with Integral Current Limiters ......................................3

2-1 Shipping Clamps for Drawout Circuit Breaker ..........................................................................................4

2-2 Magnum DS Circuit Breaker with Lifting Yoke Attached ..........................................................................5

2-3 Rear View Showing Current Sensor Rating Through Viewing Window ....................................................6

2-4 One Side of Drawout MDS Circuit Breaker Properly Seated on Extension Rail ......................................6

2-5 Cassette Rejection Interlock Pin Positioning/Installation ..........................................................................7

2-6 Remove Position ......................................................................................................................................8

2-7 Disconnect Position ..................................................................................................................................8

2-8 Test Position ............................................................................................................................................8

2-9 Connect Position ......................................................................................................................................9

2-10 Cassette Label Showing Disconnected, Test and Connected Position of Recessed Cover ....................9

2-11 Levering Position Indication ....................................................................................................................10

2-12 Typical Fixed Magnum DS Circuit Breaker ............................................................................................10

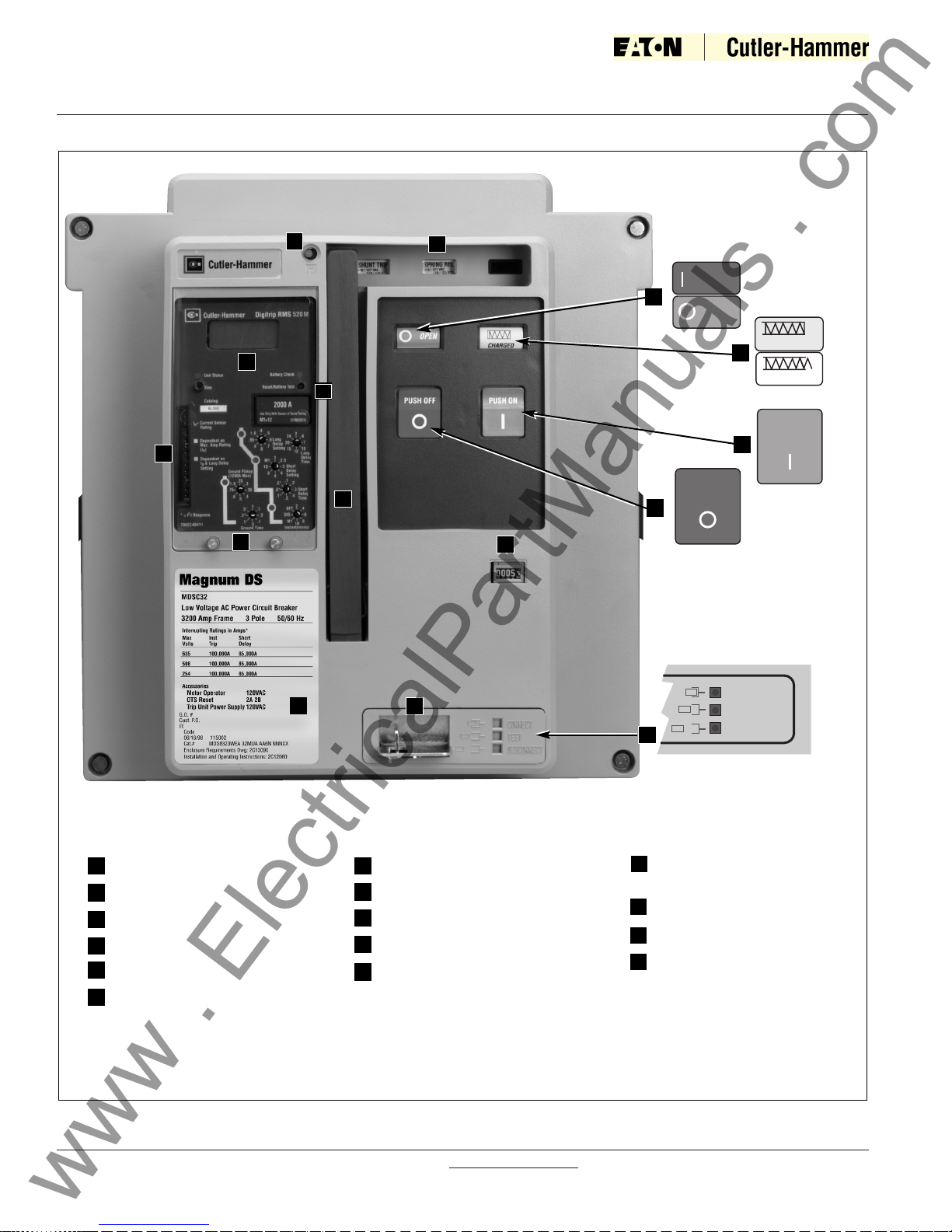

3-1 Typical MDS Drawout Circuit Breaker Features (Front and Rear Views) ..............................................11

3-2 Typical MDS Fixed Circuit Breaker Features (Front and Rear Views)....................................................12

3-3 Typical MDSL Drawout Circuit Breaker Features (Front and Rear Views) ............................................12

3-4 Typical Double-wide MDS Standard Frame Circuit Breaker Features (Front and Rear Views)..............13

3-5 Typical Magnum DS Drawout Circuit Breaker Front Cover ....................................................................14

3-6 Typical Magnum Construction (Right Side View)....................................................................................15

3-7 Features of Magnum Moving Conductor Assembly ................................................................................15

3-8 Narrow Frame (8-finger) Moving Conductor Assembly ..........................................................................16

3-9 Standard Frame (12-finger) Moving Conductor Assembly......................................................................16

3-10 Parital Cross-Sectional View (Shown in Closed Position) ......................................................................16

3-11 Electrically Operated Drawout MDS Circuit Breaker with Front Cover Removed ..................................17

3-12 Circuit Breaker Closing Springs Being Manually Charged......................................................................18

3-13 Electrical Motor Operator to Charge Closing Spring ..............................................................................18

3-14 Cross Section of Conductor and Arc Control System ............................................................................19

3-15 Integral Arc Runner as Viewed From Top of Arc Chamber

(Arc Chute Removed and Circuit Breaker Closed) ................................................................................19

3-16 Magnum Arc Plate Assembly ..................................................................................................................19

3-17 Pictorial Diagram of Typical Current Sensing, Processing and Tripping System....................................20

3-18 Digitrip RMS 1150 Programmable Trip Unit Installed in Magnum DS Circuit Breaker............................21

3-19 Hand Held Tester ....................................................................................................................................21

3-20 Replaceable Current Sensors Shown with Bottom Adapters and Cover Plate Removed ......................22

3-21 Line Side Voltage Tap for 1150 Trip Unit ................................................................................................23

3-22 Top View Secondary Connectors............................................................................................................23

3-23 Secondary Connector Protective Hood ..................................................................................................23

3-24 Cassette Mounted Secondary Wiring ......................................................................................................24

3-25 AMP Secondary Wiring Removal Tool.....................................................................................................24

3-26 Digitrip Connection Diagrams .................................................................................................................25

thru

3-46 Digitrip Connection Diagrams .................................................................................................................45

3-34 Through-the-Window Electrical Accessories ...........................................................................................46

3-35 Shunt Trip with Cutoff Switch...................................................................................................................46

3-36 Shunt Trip Switch Installed ......................................................................................................................46

3-37 Spring Release with Optional Latch Check Switch ..................................................................................47

3-38 Undervoltage Release Device .................................................................................................................47

www . ElectricalPartManuals . com

Instruction Book

Page vii

Effective: May 2006

I.B. 2C12060H08

For more information visit: www.EatonElectrical.com

Figure Title Page

3-39 Shunt Trip, Spring Release and Undervoltage Release Installed............................................................47

3-40 Auxiliary Switch (2A/2B)...........................................................................................................................48

3-41 Mechanical Trip Indicator with Associated Overcurrent Trip Switch ........................................................48

3-42 Motor Operator Kit ...................................................................................................................................49

3-43 Motor Operator Installed in Narrow Frame Circuit Breaker......................................................................49

3-44 Cover Mounted Key Lock and Operations Counter................................................................................. 50

3-45 Cassette Mounted Key Lock ....................................................................................................................50

3-46 ON-OFF Pushbutton Lockable Cover Plate.............................................................................................50

3-47 Safety Shutters in Closed Position...........................................................................................................51

3-48 Safety Shutters in Open Position .............................................................................................................51

3-49 Cell Switch (Drawout Position Indicator) Unmounted ..............................................................................51

3-50 Cell Switches Mounted on Cassette ........................................................................................................51

3-51 Door Escutcheon and Gasket ..................................................................................................................51

3-52 IP54 Waterproof Cover ............................................................................................................................52

3-53 Cassette-Mounted 2-Way Cable Interlock ...............................................................................................52

3-54 Magnum DSL Circuit Breaker (Side View)...............................................................................................53

3-55 Blow Fuse Indicator .................................................................................................................................53

4-1 Drawout Circuit Breaker in Cassette .......................................................................................................55

4-2 Drawout Circuit Breaker with Automatic Primary Disconnects ................................................................55

4-3 Drawout Cassette Features .....................................................................................................................56

4-4 Narrow Frame Cassette (Horizontal Terminals) ......................................................................................57

4-5 Standard Cassette (Vertical Terminals) ..................................................................................................57

4-6 Basic Cassette (Without Stabs) ...............................................................................................................57

4-7 Universal Cassette, 4-Pole (Flat Terminal Pads).....................................................................................57

4-8 Typical MDSL Standard Cassette (Front View) .......................................................................................58

4-9 Typical MDSL Standard Cassette (Rear View)........................................................................................58

5-1 Fixed Circuit Breaker with Available Vertical Adaptor..............................................................................59

6-1 Top Rear View of Circuit Breaker with One Arc Chute Removed............................................................62

6-2 Bottom View of Arc Chute........................................................................................................................62

6-3 Primary Contacts with Circuit Breaker Open (Not Used for Contact Wear Inspection) ...........................63

6-4 Contact Inspection Area with Circuit Breaker Open.................................................................................63

6-5 Use of Contact Wear Indicator with Circuit Breaker Closed ....................................................................64

6-6 Trip Unit Rating Plug Location .................................................................................................................64

6-7 Current Sensor Cover in Place Over Sensors .........................................................................................65

6-8 One Current Sensor Shown Removed and Disconnected.......................................................................65

6-9 MD Limiters Shown Mounted in Extension ..............................................................................................66

www . ElectricalPartManuals . com

Instruction Book

Page viii

Effective: May 2006

I.B. 2C12060H08

For more information visit: www.EatonElectrical.com

TABLES

Table Title Page

1.1 Magnum DS Ratings at 240, 480, 600 volts ..............................................................................................2

1.2 Magnum DSL Ratings at 600 volts ............................................................................................................3

2.1 Circuit Breaker Weights .............................................................................................................................5

2.2 Rejection Interlock Pin Locations ...............................................................................................................7

3.1 Magnum Digitrip Trip Units ......................................................................................................................20

3.2 Magnum DS Current Sensors and Matching Rating Plugs ......................................................................22

3.3 Shunt Trip Ratings ...................................................................................................................................46

3.4 Spring Release Ratings ...........................................................................................................................47

3.5 Undervoltage Release .............................................................................................................................48

3.6 Auxiliary Switch, Overcurrent Trip Switch and Cell Switch Contact Ratings............................................48

3.7 Motor Operator.........................................................................................................................................49

3.8 MDSL Integral Current Limiter Selection .................................................................................................54

6.1 Inspection Frequency...............................................................................................................................60

7.1 Circuit Breaker Troubleshooting Guide ....................................................................................................67

www . ElectricalPartManuals . com

SECTION 1: INTRODUCTION

1-1 GENERAL INFORMATION

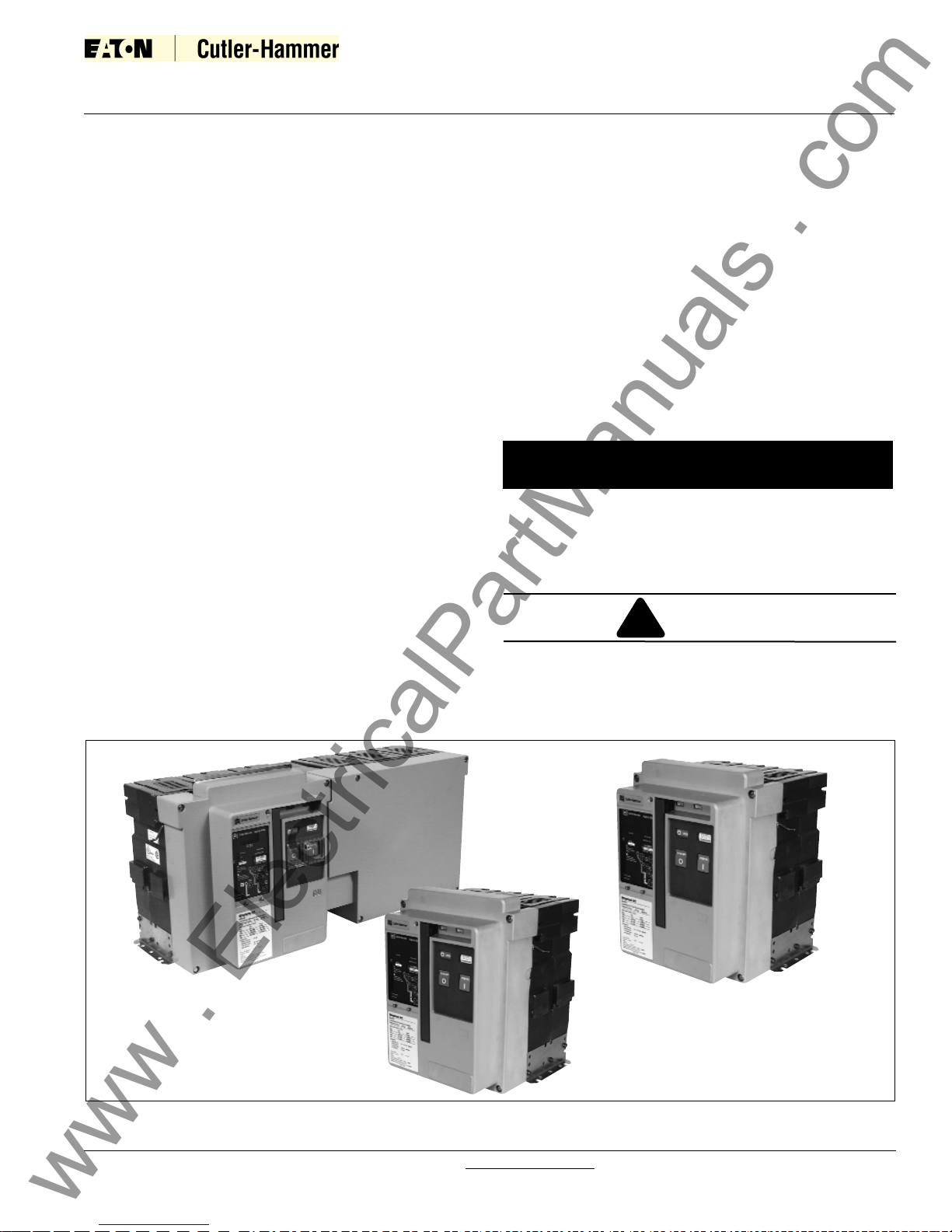

The Magnum DS and DSX Power Circuit Breakers can

be fixed or drawout air circuit breakers utilizing an electronic tripping system. The Magnum DSL circuit breaker

utilizes the same tripping system, but is available only in

the drawout configuration. MDSL and MDSX versions

have current-limiting characteristics as indicated by the

“Current Limiting” badge on the front covers. All breakers are designed for use in both switchboard and metalenclosed switchgear assemblies having maximum voltages of 635 volts ac MDS type breakers, 600 volts ac for

MDSL type breakers, and 480 volts ac for MDSX type

breakers. Magnum DS circuit breakers are available in

three physical frame sizes with continuous current ratings from 800 through 6000A. and interrupting capacities

from 42 kA to 200 kA. The three MDS physical frame

sizes have common height and depth dimensions, differing only in width (Figure 1-1). Magnum DSL circuit break-

ers are available in one frame size with continuous current ratings from 800 through 2000A and an interrupting

capacity up to 200,000A (Figure 1-5). Circuit breaker

nameplates provide complete rating information. All

Magnum DS, Magnum DSX, and Magnum DSL circuit

breakers are 100 percent rated, UL listed, and are built

and tested in an ISO 9002 certified facility to applicable

NEMA, ANSI, IEEE and UL standards (Tables 1.1 and

1.2, Figures 1-2, 1-3 and 1-4).

Magnum circuit breakers use a rigid frame housing of

engineered thermoset composite resins which has high

strength structural properties, excellent dielectric char-

acteristics and arc tracking resistance.

MDS, MDSX and MDSL drawout circuit breakers are a

through-the-door design having three breaker positions

with the compartment door closed (CONNECT, TEST,

DISCONNECT) and one position out of its compartment

on extension rails (REMOVE). The operating mechanism is a two-step stored energy mechanism, either

manually or electrically operated.

When withdrawn on captive compartment cassette

extension rails, MDS, MDSX and MDSL circuit breakers

can be inspected, accessory items added, and minor

maintenance performed. The inside of the compartment

can also be inspected with the circuit breaker on its

extension rails.

Please read and understand these instructions

before attempting to unpack, install, operate or

maintain this equipment. Study the breaker and its

mechanism carefully before attempting to operate it

on an energized circuit.

MAGNUM CIRCUIT BREAKERS SHOULD NOT

UNDER ANY CIRCUMSTANCES BE APPLIED OUTSIDE THEIR NAMEPLATE RATINGS. OPERATION

OUTSIDE OF THESE RATINGS COULD RESULT IN

DEATH, BODILY INJURY OR PROPERTY DAMAGE.

Instruction Book

Page 1

Effective: May 2006

I.B. 2C12060H08

For more information visit: www.EatonElectrical.com

Figure 1-1 Family of Magnum DS (MDS) Low Voltage Power Fixed and Drawout Circuit Breakers (800-5000 Amperes)

NOTICE

Double-wide Fixed MDS

Narrow Frame Fixed MDS

Standard Frame Drawout MDS

!

WARNING

www . ElectricalPartManuals . com

Instruction Book

Page 2

Effective: May 2006

I.B. 2C12060H08

For more information visit: www.EatonElectrical.com

1-2 SAFETY FEATURES

Magnum DS, DSX and DSL circuit breakers and associated drawout equipment are manufactured with built-in

interlocks and safety related features. They are provided

to reduce hazards to operating personnel and provide

proper operating sequences.

MAGNUM DS, DSX AND DSL CIRCUIT BREAKERS

ARE ROBUST AND ARE PROVIDED WITH SAFETY

FEATURES. NEVERTHELESS, THE VOLTAGES,

CURRENTS AND POWER LEVELS AVAILABLE IN

AND AROUND THIS EQUIPMENT WHEN IT IS IN

OPERATION ARE EXTREMELY DANGEROUS AND

COULD BE FATAL. UNDER NO CIRCUMSTANCES

SHOULD INTERLOCKS AND OTHER SAFETY FEATURES BE MADE INOPERATIVE, AS THIS MAY

RESULT IN DEATH, BODILY INJURY OR PROPERTY

DAMAGE.

1-3 SAFETY PRACTICES

To protect personnel associated with the installation,

operation and maintenance of this equipment, the following practices must be followed:

Table 1.1 Magnum DS/DSX Ratings at 240, 480, 600 volts

!

WARNING

A

B

C

D

E

A

Figure 1-2 Typical Magnum DS (MDS) Nameplate

Low voltage power circuit breaker family name

Breaker family designation number

C

Breaker frame size in amperes

D

Interrupting capacity rating

E

Factory Equipped Accessories

Maximum Breaker Interrupting Short Time

Amperes Designation Rating Rating

800 MDN-408 42 kA 42 kA

MDN-508 50 kA 50 kA

MDN-608 65 kA 65 kA

MDS-X08 200 kA (240v, 480v.) 30 kA

MDS-408 42 kA 42 kA

MDS-508 50 kA 50 kA

MDS-608 65 kA 65 kA

MDS-808 85 kA 85 kA

MDS-C08 100 kA 85 kA

1200 MDN-412 42 kA 42 kA

MDN-512 50 kA 50 kA

MDN-612 65 kA 65 kA

MDS-X12 200 kA (240v, 480v.) 30 kA

MDS-412 42 kA 42 kA

MDS-512 50 kA 50 kA

MDS-612 65 kA 65 kA

MDS-812 85 kA 85 kA

MDS-C12 100 kA 85 kA

1600 MDN-416 42 kA 42 kA

MDN-516 50 kA 50 kA

MDN-616 65 kA 65 kA

MDS-X16 200 kA (240v, 480v.) 30 kA

MDS-416 42 kA 42 kA

MDS-516 50 kA 50 kA

MDS-616 65 kA 65 kA

MDS-816 85 kA 85 kA

MDS-C16 100 kA 85 kA

2000 MDS-520 50 kA 50 kA

MDS-X20 200 kA (240v, 480v.) 30 kA

MDS-620 65 kA 65 kA

MDS-820 85 kA 85 kA

MDS-C20 100 kA 85 kA

2500 MDS-525 50 kA 50 kA

MDS-X25 200 kA (240v, 480v.) 50 kA

MDS-625 65 kA 65 kA

MDS-825 85 kA 85 kA

MDS-C25 100 kA 85 kA

3000 MDS-630 65 kA 65 kA

MDS-830 85 kA 85 kA

MDS-C30 100 kA 85 kA

3200 MDS-X32, 3N 200 kA (240v, 480v.) 50 kA

MDS-632 65 kA 65 kA

MDS-832 85 kA 85 kA

MDS-C32 100 kA 85 kA

4000 MDS-X40 200 kA (240v, 480v.) 50 kA

MDS-840, 84N 85 kA 85 kA

MDS-C40, C4N 100 kA 100 kA

5000 MDS-X50 200 kA (240v, 480v.) 50 kA

MDS-850, 85N 85 kA 85 kA

MDS-C50, C5N 100 kA 100 kA

6000 MDS-860, 86N 85 kA 85 kA

MDS-C60, C6N 100 kA 100 kA

B

www . ElectricalPartManuals . com

M D S C 3 2

Instruction Book

Page 3

Effective: May 2006

I.B. 2C12060H08

For more information visit: www.EatonElectrical.com

1. Only qualified electrical personnel familiar with the

equipment, its operation and the associated hazards

should be permitted to work on the equipment.

Additionally, only qualified personnel should be permitted to install or operate the equipment.

2. Always be certain that the primary and secondary circuits are de-energized or the circuit breaker is

removed to a safe work location before attempting

any maintenance.

3. For maximum safety, only insert a completely assembled breaker into an energized cell.

4. Always ensure that drawout circuit breakers are in

one of their designed cell positions, such as Connect,

Test, Disconnect or Remove. A circuit breaker permitted to remain in an intermediate position could

result in control circuits being improperly connected

resulting in electrical failures.

1-4 QUALIFIED PERSONNEL

For the purpose of operating and maintaining low voltage power circuit breakers, a person should not be considered qualified if the individual is not thoroughly

trained in the operation of the circuit breaker and how it

interfaces with the assembly in which it is used. In addition, the individual should have knowledge of the connected loads.

For the purpose of installing and inspecting circuit

breakers and their associated assembly, a qualified person should also be trained with respect to the hazards

inherent to working with electricity and the proper way to

perform such work. The individual should be able to deenergize, clear and tag circuits in accordance with

established safety practices.

1-5 OTHER PUBLICATIONS AND

DOCUMENTATION

In addition to this instruction manual, other printed information and documentation is available and supplied as

appropriate. This additional information can include, but

not necessarily be limited to, an instruction manual for a

specific electronic trip unit, instruction leaflets for accessory items, renewal parts information, necessary dimensional drawings and a Product (application) Guide.

Specific reference documents associated with Magnum

DS, DSX and DSL circuit breakers are listed in a sepa-

rate document entitled Engineering Data TD01301004E

Figure 1-3 Typical Magnum DS Designation Example

Circuit Breaker

Type

MDS - Standard and

Double Wide Frames

MDN - Narrow Frame

Interrupting

Capacity

4 - 42,000

5 - 50,000

6 - 65,000

8 - 85,000

C - 100,000

E - 150,000

X - 200,000

Frame

Size

08 - 800 Amps

12 - 1200 Amps

16 - 1600 Amps

20 - 2000 Amps

25 - 2500 Amps

30 - 3000 Amps

32 - 3200 Amps

40 - 4000 Amps

50 - 5000 Amps

M D S L 0 8

Figure 1-4 Typical Magnum DSL Designation Example

Circuit Breaker

Type

MDSL- Standard Frame

with Integral Current

Limiters

Interrupting

Capacity

L - 200,000

Frame

Size

08 - 800 Amps

12 - 1200 Amps

16 - 1600 Amps

20 - 2000 Amps

Table 1.2 Magnum DSL Ratings at 600 Volts and Below

Breaker

Designation

Frame Size

Amperes

Max. Interrupting Rating, RMS Sym.

Amp., System Voltage 600 or Below

MDSL08

MDSL12

MDSL16

MDSL20

800

1200

1600

2000

200,000

200,000

200,000

200,000

Figure 1-5 Typical Magnum DSL(MDSL) Drawout

Circuit Breaker with Integral Current Limiters

www . ElectricalPartManuals . com

I.B. 2C12060H08

For more information visit: www.EatonElectrical.com

Instruction Book

Page 4

Effective: May 2006

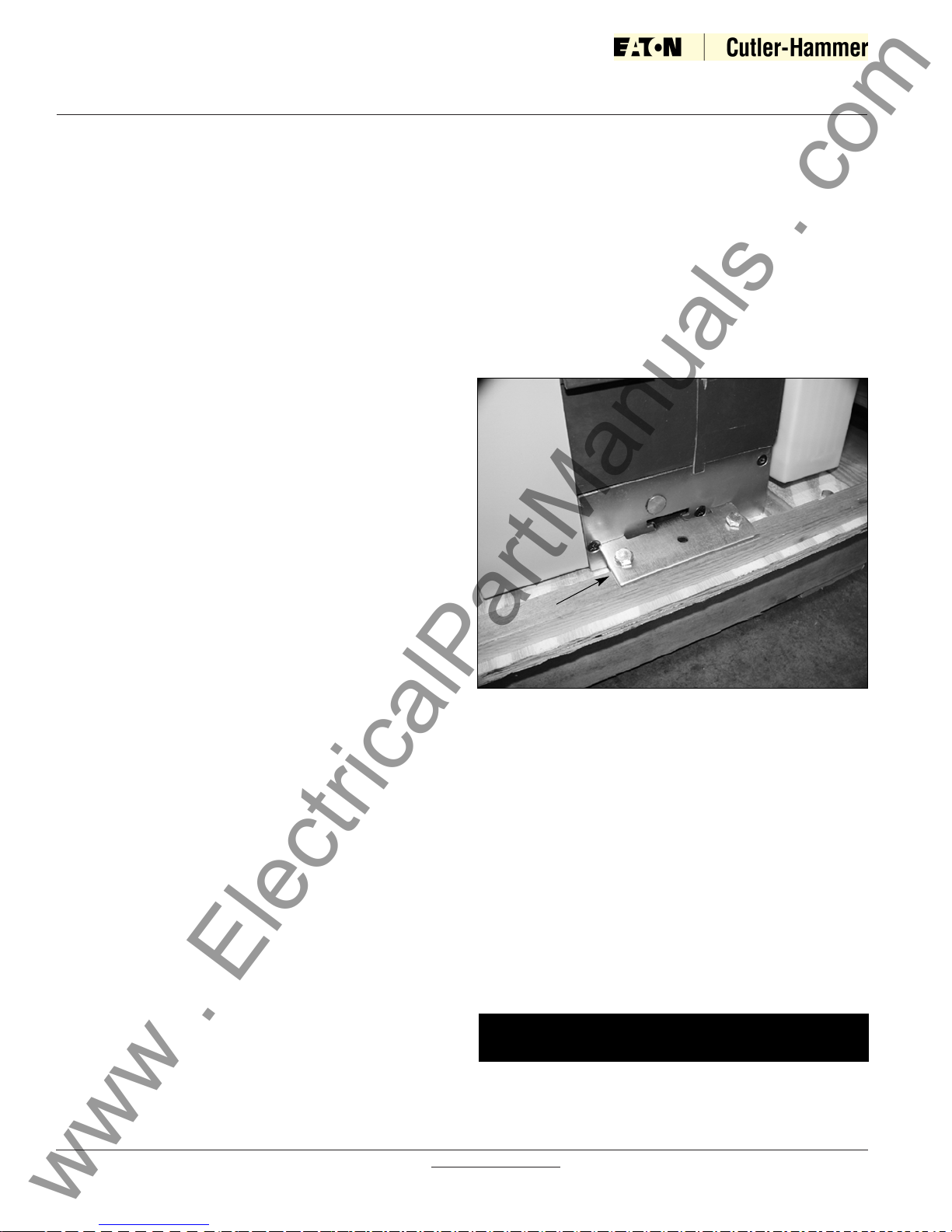

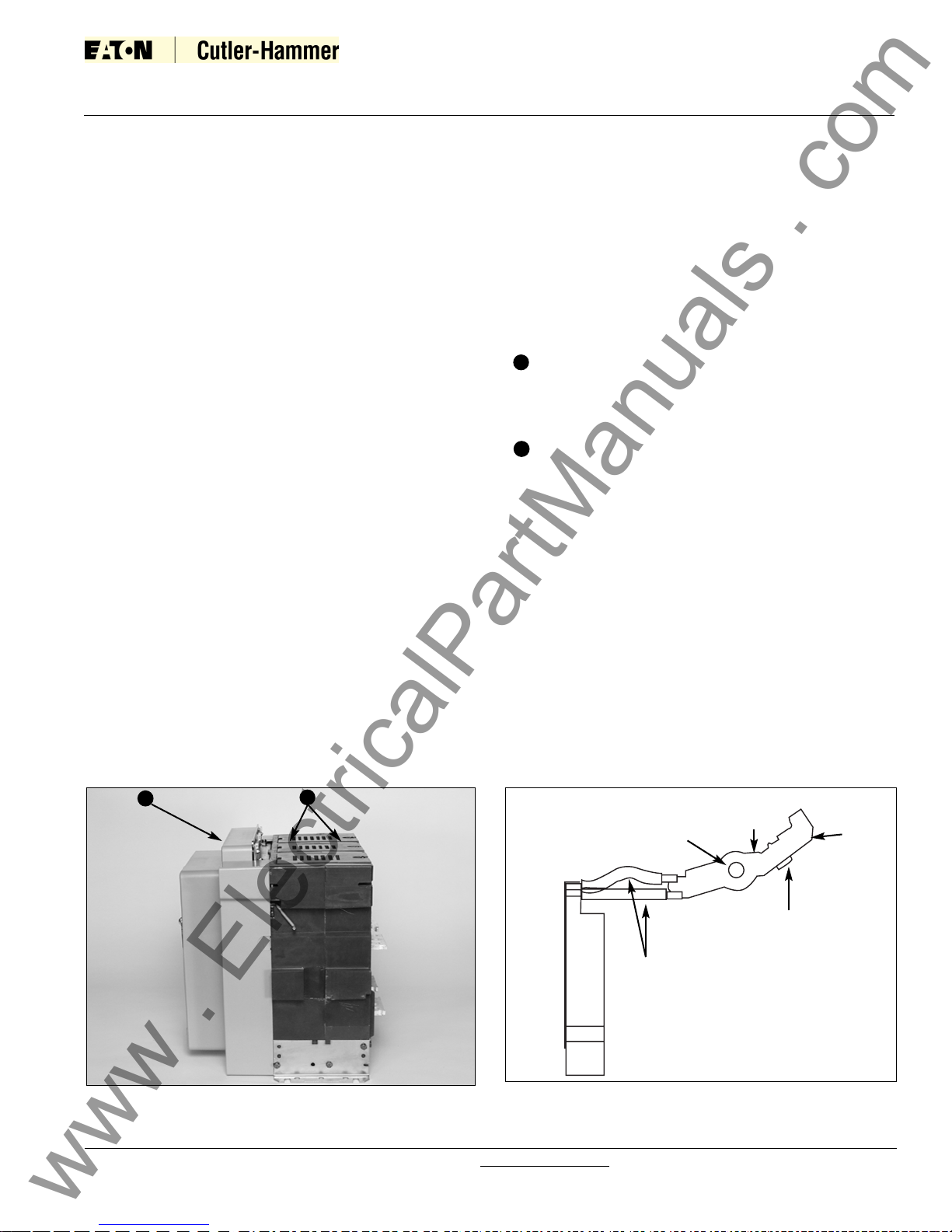

Figure 2-1 Shipping Clamps for Drawout Circuit Breaker

SECTION 2: RECEIVING, HANDLING AND

INSTALLATION

2-1 GENERAL INFORMATION

Magnum DS, DSX and DSL Power Circuit Breakers,

when supplied as part of an assembly, may be shipped

already installed in their respective breaker compartments. Receiving and handling of this equipment is

addressed in an assembly instruction manual supplied

with the assembled equipment. This instruction manual

applies to only the circuit breakers.

2-2 SUGGESTED TOOLS

A large number of different tools are not required to

properly install and maintain Magnum DS, DSX and

DSL circuit breakers. The following tools are, however,

suggested:

• Flat blade screwdriver

• Phillips head screwdriver

• 3/8” socket (rachet) wrench

• 10 mm socket

• 17 mm socket

• Secondary wiring removal tool

2-3 UNPACKING CIRCUIT BREAKER

Before beginning to unpack new Magnum circuit breakers, read and understand these directions. Following the

directions will ensure that no damage is caused.

Shipping containers should be inspected for obvious

signs of rough handling and/or external damage

incurred during the transportation phase. Record any

observed damage for reporting to the transportation carrier and Cutler-Hammer, once the inspection is completed. All reports and claims should be as specific as possible and include the order number and other applicable

nameplate information.

Every effort is made to ensure that Magnum circuit

breakers arrive at their destination undamaged and

ready for installation. Care should be exercised, however, to protect the breakers from impact at all times. Do

not remove protective packaging until the breakers are

ready for inspection, testing and/or installation.

When ready to inspect and install a Magnum circuit

breaker, carefully remove the banding straps and lift off

the cardboard box. Remove any additional packing

material and internally packed documentation. The circuit breaker and/or cassette are mounted to a wooden

shipping pallet.

On drawout circuit breakers shipped without a cassette,

two shipping clamps hook into the breaker side plates

and are held to the pallet with 4 lag screws (Figure 2-1).

Remove the lag screws and clamps. Save the screws

and clamps for future shipment of the breaker. On

empty cassettes, remove the 4 or 5 lag screws and/or

machine screws which pass through the floorpan of the

cassette holding it to the wooden pallet. On drawout

breakers shipped in a cassette, first remove the breaker

from the cassette using the levering mechanism and

drawout rails. After the breaker is removed the machine

screws passing through the floorpan can be removed.

Shipping Clamp

On fixed breakers, remove the lag screws passing

through the mounting feet which hold the breaker to the

pallet.

Circuit breakers are designed to be easily lifted from

the wooden pallet using an appropriate lifting yoke and

overhead or portable lifting device (Figure 2-2).

2-3.1 STORING CIRCUIT BREAKER

If it is necessary to store a circuit breaker before installation, do so in its original shipping container. Keep the

circuit breaker in a clean dry place. Ensure there is

ample air circulation and heat, if necessary, to prevent

condensation. It is very important that the circuit breaker not be exposed to dirt or moisture.

A circuit breaker that has been stored for any

length of time should be operated a minimum of

five times before it is placed in service.

NOTICE

www . ElectricalPartManuals . com

I.B. 2C12060H08

For more information visit: www.EatonElectrical.com

Instruction Book

Page 5

Effective: May 2006

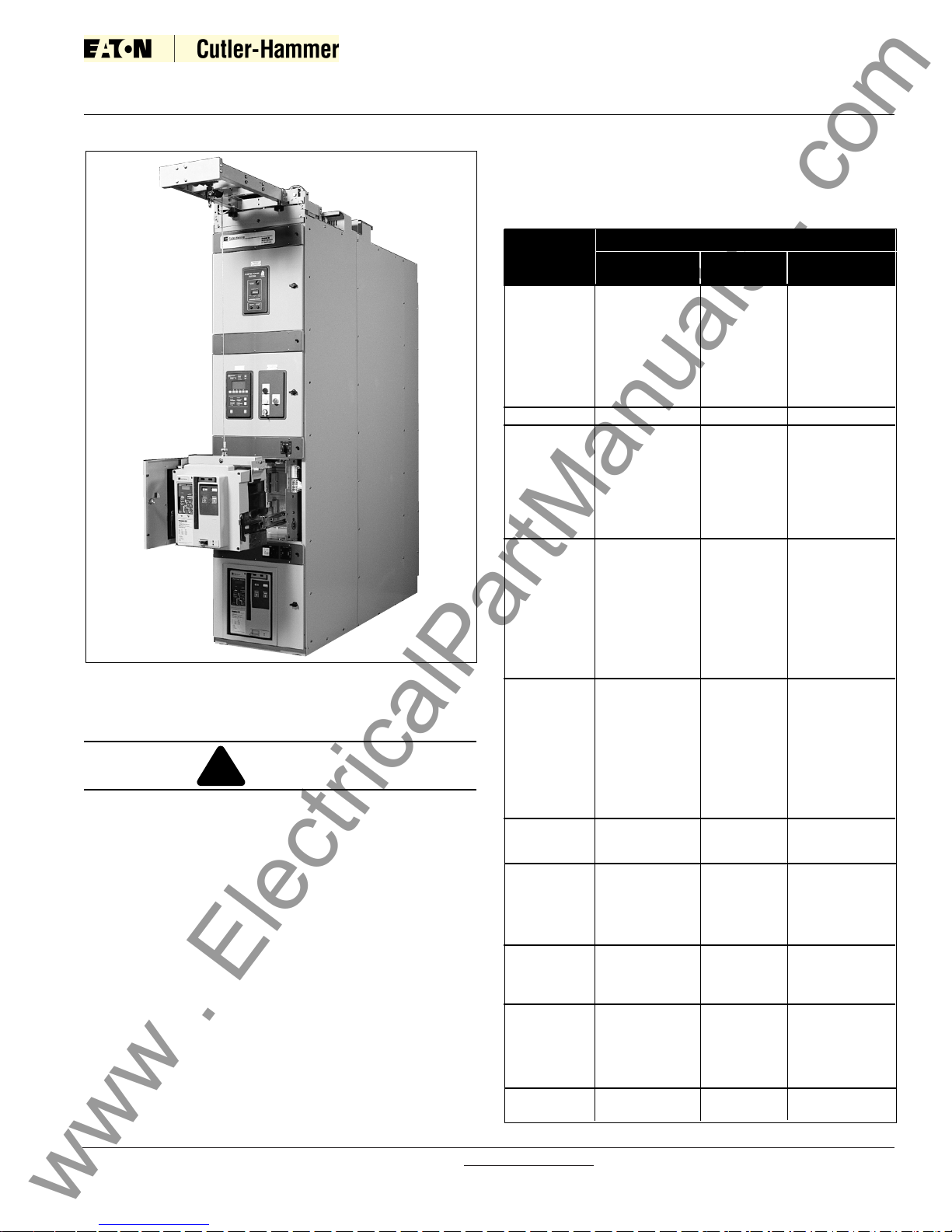

Breaker Weights (lbs)

Model Fixed Drawout Universal Cassette

3P 4P 3P 4P 3P 4P

MDN-408 95 120 107 136 61 70

MDN-508

MDN-608

MDN-412

MDN-512

MDN-612

MDN-416

MDN-516

MDN-616

MDS-408 114 141 130 161 117 123

MDS-508 118 146 138 172 117 123

MDS-608

MDS-412

MDS-512

MDS-612

MDS-416

MDS-516

MDS-616

MDS-520 128 160 155 194 117 123

MDS-620

MDS-808

MDS-812

MDS-816

MDS-820

MDS-C08

MDS-C12

MDS-C16

MDS-C20

MDS-525 150 190 189 240 123 150

MDS-625

MDS-630

MDS-632

MDS-825

MDS-830

MDS-832

MDS-C25

MDS-C30

MDS-C32

MDS-840, 84N 237 319 303 366 199 250

MDS-C40, C4N

MDS-E40, E4N

MDS-850, 85N 276 360 343 441 212 266

MDS-860, 86N

MDS-C50, C5N

MDS-C60, C6N

MDS-E50, E5N

MDS-E60, E6N

MDSL08 NA NA 180 NA 124 NA

MDSL12 200 124

MDSL16 200 124

MDSL20 215 131

MDS-X08 169 NA 210 NA 140 NA

MDS-X12

MDS-X16

MDS-X20

MDS-X25

MDS-X32

MDS-X40 279 NA 345 NA 210 NA

MDS-X50

Table 2.1 Basic Circuit Breaker Weights

2-4 LIFTING CIRCUIT BREAKER

DO NOT ATTEMPT TO LIFT CIRCUIT BREAKERS

WITH ORDINARY CRANE HOOKS, ROPES, CHAINS

OR OTHER SUCH DEVICES. FAILURE TO FOLLOW

THIS CAUTION COULD RESULT IN DAMAGE TO

VITAL PARTS SUCH AS ARC CHUTES, BARRIERS

AND WIRING OR THE ENTIRE CIRCUIT BREAKER.

To closely examine, install or just become more familiar

with the circuit breaker, carefully lift and place the circuit

breaker on a solid work surface capable of handling the

circuit breaker’s weight (Table 2.1) or on the captive

drawout extension rails of the breaker compartment

(Figure 2-2). This is accomplished by using the appropriate lifting yoke and lifter. The lifting yoke consists of

two steel hooks specially shaped to hook under the integral molded lifting handles on both sides of the circuit

breaker (Figure 3-1). Every effort should be made during lifting to minimize circuit breaker swing and tilt.

If the circuit breaker is to be lifted onto compartment

extension rails, follow the instructions in paragraph 2-6

entitled “Installing Drawout Circuit Breaker.”

!

CAUTION

Figure 2-2 Magnum DS Circuit Breaker with Lifting

Yoke Attached

www . ElectricalPartManuals . com

I.B. 2C12060H08

For more information visit: www.EatonElectrical.com

Instruction Book

Page 6

Effective: May 2006

2-5 CIRCUIT BREAKER INSPECTION

All circuit breakers, once removed from their shipping

containers, should be visually inspected for any obvious

damage.

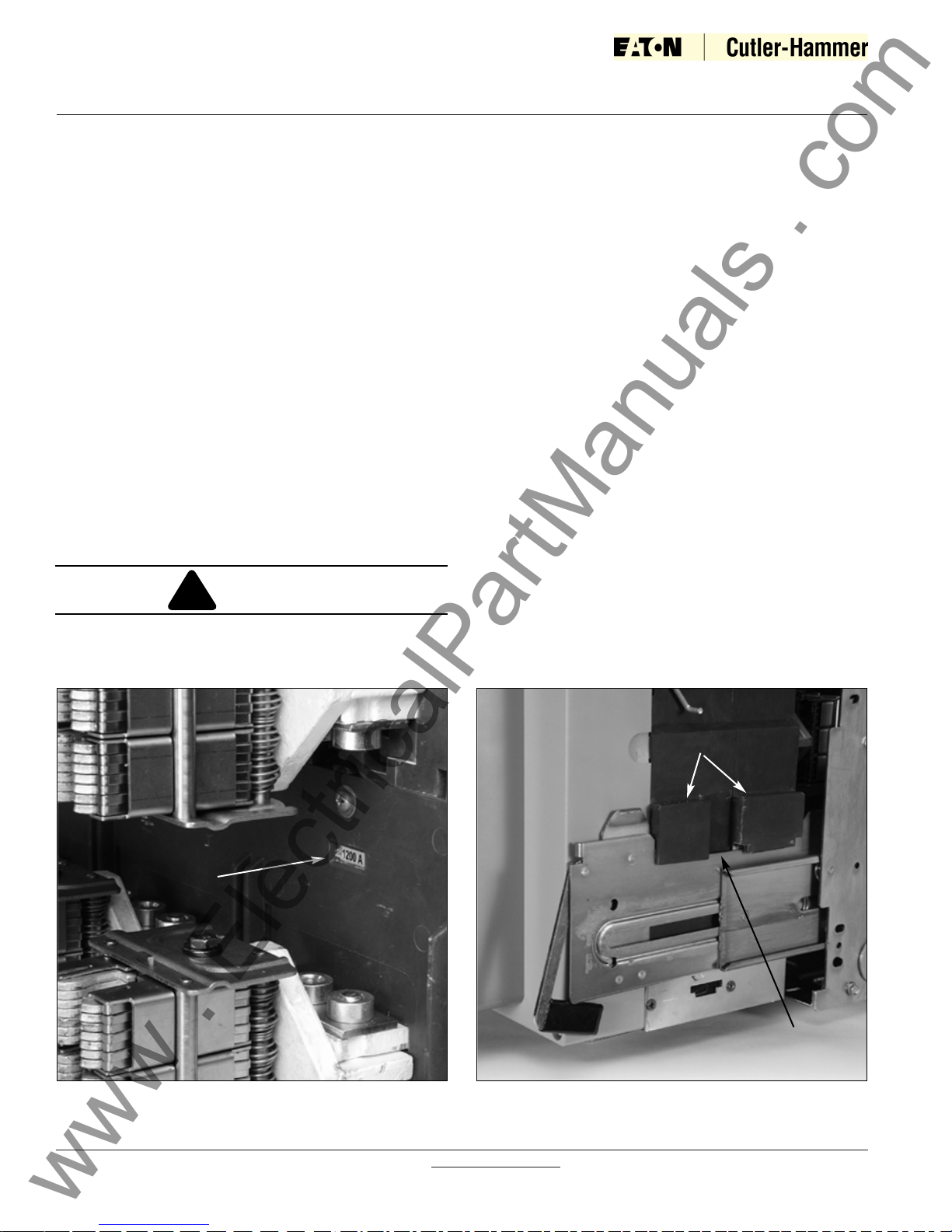

The current rating of the rating plug installed in the trip

unit should match the current rating of the sensors

mounted on the lower primary stabs of the circuit break

er. Check to make sure that this match exists. The rating plug rating can be viewed from the front of the circuit

breaker (Figure 3-4). The sensor rating can be viewed

through the viewing windows at the rear of the circuit

breaker (Figure 2-3). Sensors and rating plugs can be

easily changed as described in Section 6.

2-6 INSTALLING DRAWOUT CIRCUIT BREAKER

In structures equipped for drawout circuit breakers, a

bolted-in cassette with movable extension rails supports

the circuit breaker (Figures 2-2 and 2-4). The extension

rails must first be pulled all the way out. Once the rails

are fully extended, the circuit breaker can be carefully

placed on the extension rails.

IT IS IMPORTANT TO TAKE GREAT CARE WHEN

PLACING A DRAWOUT CIRCUIT BREAKER ON ITS

EXTENSION RAILS. IF THE CIRCUIT BREAKER IS

Figure 2-3 Rear View Showing Current Sensor Rating

Through Viewing Window

NOT PROPERLY SEATED ON THE EXTENSION

RAILS, IT COULD FALL FROM THE RAILS CAUSING

EQUIPMENT DAMAGE AND/OR BODILY INJURY.

Carefully lower the circuit breaker down onto the extension rails. Be certain that the circuit breaker’s four molded drawout rail supports are fully seated in the extension rail cutouts on both sides (Figure 2-4). Do not

remove the lifting yoke from the circuit breaker until

it is properly seated on the rails.

Once the circuit breaker is on the extension rails and the

lifting yoke is removed, proceed with the rest of the circuit breaker installation.

2-6.1 REJECTION INTERLOCKS

Within any one physical frame size Magnum type drawout circuit breakers come in a variety of continuous

current and interruption ratings, some of which are

incompatible with others. Double wide circuit breakers

also come with several phase sequence options which

are also incompatible. To prevent the insertion of circuit breakers with (1) inadequate interrupting capability,

(2) with physically incompatible primary disconnects or

(3) with an incompatible phase sequence, rejection

interlock key plates are provided on both the circuit

breaker and cassette. The key plate on the circuit

breaker is pre-assembled at the factory; but the cassette-side rejection plate and key pattern must be

assembled and installed by the switchboard builder.

!

CAUTION

Figure 2-4 One Side of Drawout MDS/MDSX Circuit

Breaker Properly Seated on Extension Rail

Molded Rail

Supports

Extension Rail

Cutout

www . ElectricalPartManuals . com

I.B. 2C12060H08

For more information visit: www.EatonElectrical.com

Instruction Book

Page 7

Effective: May 2006

DO NOT DISABLE REJECTION INTERLOCKS.

DOING SO AND USING A LOWER CAPACITY CIRCUIT BREAKER IN AN INCOMPATIBLE CASSETTE

COULD RESULT IN AN ELECTRICAL FAULT WHICH

COULD RESULT IN DEATH, BODILY INJURY

AND/OR EQUIPMENT DAMAGE.

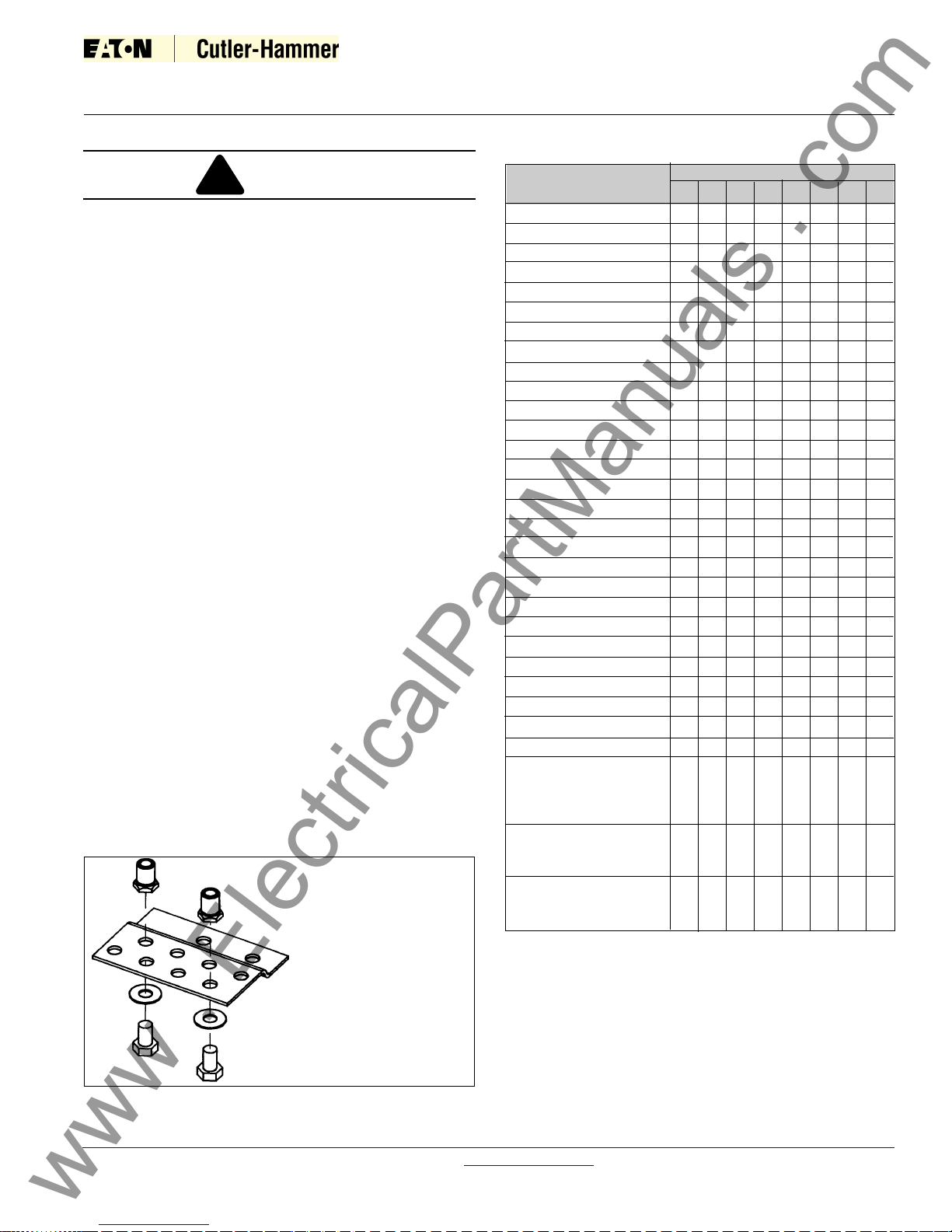

The rejection interlocks are steel pins in the floor of the

circuit breaker cassette. As the circuit breaker is

pushed into the structure, the mating pins on the bottom

of the circuit breaker move past a set of corresponding

pins in the cassette, if the circuit breaker and cassette

are compatible. If the circuit breaker and the cassette

are mismatched, the rejection pins will block the insertion of the circuit breaker into the cassette before the

levering-in mechanism is engaged.

Before attempting to push the circuit breaker into the

DISCONNECT position, compare the positioning of

rejection interlock pins in the cassette in keeping with

Table 2.2 and Figure 2-5 and the information supplied

on the circuit breaker’s nameplate. Proceed if the circuit

breaker and cassette are compatible.

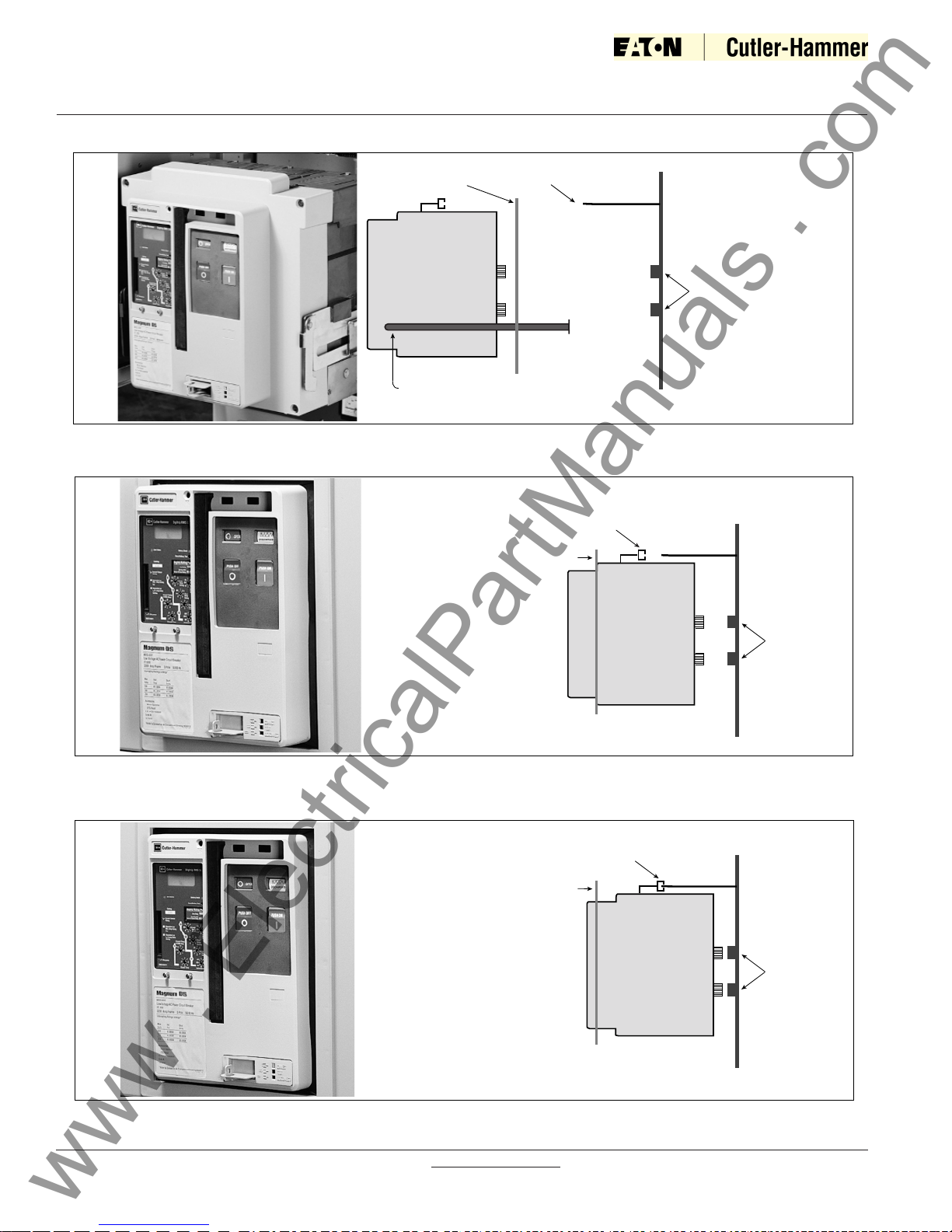

2-6.2 CIRCUIT BREAKER POSITIONING

Magnum DS, DSX and DSL drawout circuit breakers

have four normal positions:

• REMOVE (Withdrawn) (Figure 2-6)

• DISCONNECT (Figure 2-7)

• TEST (Figure 2-8)

• CONNECT (Figure 2-9)

The REMOVE position is a position outside the compartment on the cassette’s drawout rails where the circuit breaker is not engaged with the levering mecha

!

CAUTION

nism. The DISCONNECT, TEST, and CONNECT, positions are reached by means of the levering mechanism.

With the breaker solidly positioned on the cassette’s

extension rails and the levering-in mechanism in the

DISCONNECT position, carefully and firmly push the

circuit breaker into the compartment as far as it will go.

The outer (recessed) portion of the circuit breaker face

plate should align with the GREEN target line (labelled

DISC) on the inside top left wall of the cassette (Figure

2-10).

Figure 2-5 Cassette Rejection Interlock Pin

Positioning/Installation

From Table 2.2, make a

pin location comparison.

Stop nuts should be

torqued to 8-10 Ft.-Lb.

Table 2.2 Rejection Interlock Pin Locations

1

2

3

4

5

6

7

8

Pin Locations

Cell For: 1 2 3 4 5 6 7 8

MDN-408, 412, 416

MDN-508, 512, 516

MDN-608, 612, 616

MDS-408, 412, 416

MDS-508, 512, 516, 520

MDS-608, 612, 616, 620

MDS-808, 812, 816, 820

MDS-C08, C12, C16, C20

MDS-525

MDS-625, 630, 632

MDS-825, 830, 832

MDS-C25, C30, C32

MDS-840

MDS-84N

MDS-C40

MDS-C4N

MDS-E40

MDS-E4N

MDS-850, 860

MDS-85N, 86N

MDS-C50, C60

MDS-C5N, C6N

MDS-E50, E60

MDS-E5N, E6N

MDSL08

MDSL12

MDSL16

MDSL20

MDS-X08

MSD-X12

MDS-X16

MDS-X20

MDS-X3N

MDS-X4N

MDS-X5N

MDS-X32

MDS-X40

MDS-X50

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X-LG

X-LG

X-LG

X-LG

X-LG

X-LG

X-LG

X-LG

X-LG

X-LG

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

NOTE: X-LG IN TABLE 2.2 DENOTES LONG LENGTH STOP NUT 0.760 INCHES LONG

www . ElectricalPartManuals . com

I.B. 2C12060H08

For more information visit: www.EatonElectrical.com

Instruction Book

Effective: May 2006

Page 8

■ No Electrical Connections Made

■ Breaker On Extension Rails

■ Remove or Inspection Position

Circuit

Breaker

Side View

Secondary

Connection Not Made

Rear of

Compartment

Primary

Connections

Not Made

Compartment

Front Door

Circuit Breaker

Out of Compartment

On Extension Rails

Secondary

Connection

Not Made

Circuit

Breaker

Side View

Rear of

Compartment

Primary

Connections

Not Made

Compartment

Front Door

■ Only Ground Connection Made

■ Breaker Still Behind Door

■ Typical Storage Position

Circuit

Breaker

Side View

Secondary

Connection Made

Rear of

Compartment

Primary

Connections

Not Made

Compartment

Front Door

■ Breaker and Trip Unit Testing

■ Primary Connection Not Made

■ Secondary and Ground Connections Made

Figure 2-6 Remove Position

Figure 2-7 Disconnect Position

Figure 2-8 Test Position

www . ElectricalPartManuals . com

I.B. 2C12060H08

For more information visit: www.EatonElectrical.com

Instruction Book

Effective: May 2006

Page 9

Circuit

Breaker

Side View

Rear of

Compartment

Primary

Connections

Made

Secondary

Connection Made

Compartment

Front Door

■ Full Breaker Operation

■ Primary, Secondary and Ground Connections Made

■ Fully Racked into Cassette (Compartment)

Figure 2-9 Connect Position

2-6.3 LEVERING CIRCUIT BREAKER

MAKE CERTAIN THAT THE CIRCUIT BREAKER IS

FULLY INSERTED INTO ITS COMPARTMENT

BEFORE ANY ATTEMPT IS MADE TO LEVER THE

CIRCUIT BREAKER. ATTEMPTING TO LEVER THE

CIRCUIT BREAKER IN BEFORE IT IS FULLY POSITIONED INSIDE ITS COMPARTMENT CAN RESULT

IN DAMAGE TO BOTH THE CIRCUIT BREAKER AND

THE COMPARTMENT.

The circuit breaker is now ready to be levered. With the

circuit breaker OPEN, the levering device access door

can be raised. The levering device is hand operated

using a standard 3/8” square drive and ratchet, which is

not provided (Figure 2-11). As long as the access door

is raised, the circuit breaker is held trip free. Begin by

rotating the levering-in screw to the full counterclockwise (DISCONNECT) position.

Close the compartment door and begin levering the

breaker into its different positions using a clockwise

ratcheting motion. When the circuit breaker is levered

fully to the DISCONNECT or CONNECT position the

levering shaft hits a hard stop; do not exceed 25 ft.lb. of

torque or the levering mechanism may be damaged.

The circuit breaker can be levered with the compartment door open or closed, but it is advisable to

close the door prior to levering. The position of the

circuit breaker within its compartment is indicated by

color coded position indicators (Red = Connect, Yellow

= Test, Green = Disconnect) (Figures 2-11 and 3-5). To

remove the circuit breaker from its compartment, follow

the procedure just described using a counterclockwise

ratcheting motion.

Figure 2-10 Cassette Label Showing Disconnected,

Test and Connected Position of Recessed Cover

!

CAUTION

www . ElectricalPartManuals . com

I.B. 2C12060H08

For more information visit:

www.EatonElectrical.com

Instruction Book

Effective: May 2006

Page 10

Figure 2-12 Typical Fixed Magnum DS Circuit Breaker

The circuit breaker mechanism is interlocked such

that charged closing springs are automatically discharged if the circuit breaker is levered into or out

of the cell. Discharge takes place between the DISCONNECT and TEST position.

2-7 FIXED CIRCUIT BREAKER

Magnum DS fixed type circuit breakers differ from the

drawout version in that it has no levering device, primary

disconnects and secondary disconnects (Figure 2-12).

In addition, a fixed circuit breaker does not have a standard feature to hold the breaker in a trip-free position.

To ensure the proper sequence of operation between

two or more circuit breakers, an optional key interlock is

mounted through the front panel (Figure 3-44).

FAILURE TO COMPLY WITH INSTALLATION OF

THE FIXED MOUNTED MDSX ARC HOOD ASSEMBLY COULD RESULT IN EQUIPMENT DAMAGE,

BODILY INJURY OR EVEN DEATH.

The MDSX fixed mounted breaker is shipped with an

included arc hood assembly. This assembly is required

to be installed on the top of the breaker prior to the unit

being placed in service.

Circuit breaker terminals have holes for making bolted

horizontal primary bus connections. Adapters are avail

Mounting

Foot

Figure 2-11 Levering Position Indication

NOTICE

able for making vertical primary bus connections.

Secondary connections can be made through standard

terminal blocks or a special connector compatible with

the drawout circuit breaker’s type secondary connector.

Both secondary connection devices are mounted at the

top front of the circuit breaker.

The fixed circuit breaker frame has two mounting feet,

one on each side, to permit the fixed circuit breaker to

be securely mounted. Each mounting foot has two slotted mounting holes which are used to bolt the circuit

breaker securely in place. Use either M10 or 3/8” bolts

for this purpose. Refer to the dimensional drawings

referred to in Section 5 (Fixed Circuit Breakers) for circuit breaker and bus stab dimensions.

Refer to the circuit breaker weights in Table 2.1 to

ensure that the panel on which a fixed circuit breaker is to be mounted is capable of supporting the

weight.

2-8 CIRCUIT BREAKER OPERATION

Circuit breakers should be operated manually and/or

electrically before they are put into service. This can be

done during the installation process or some later date

prior to start-up. To check circuit breaker operation, follow the operational procedures outlined in Section 3 for

both manually operated and electrically operated circuit

breakers.

NOTICE

!

WARNING

www . ElectricalPartManuals . com

CONNECT

CONNECT

TEST

TEST

DISCONNECT

DISCONNECT

I.B. 2C12060H08

For more information visit: www.EatonElectrical.com

Instruction Book

Page 11

Effective: May 2006

SECTION 3: CIRCUIT BREAKER

DESCRIPTION AND OPERATION

3-1 INTRODUCTION

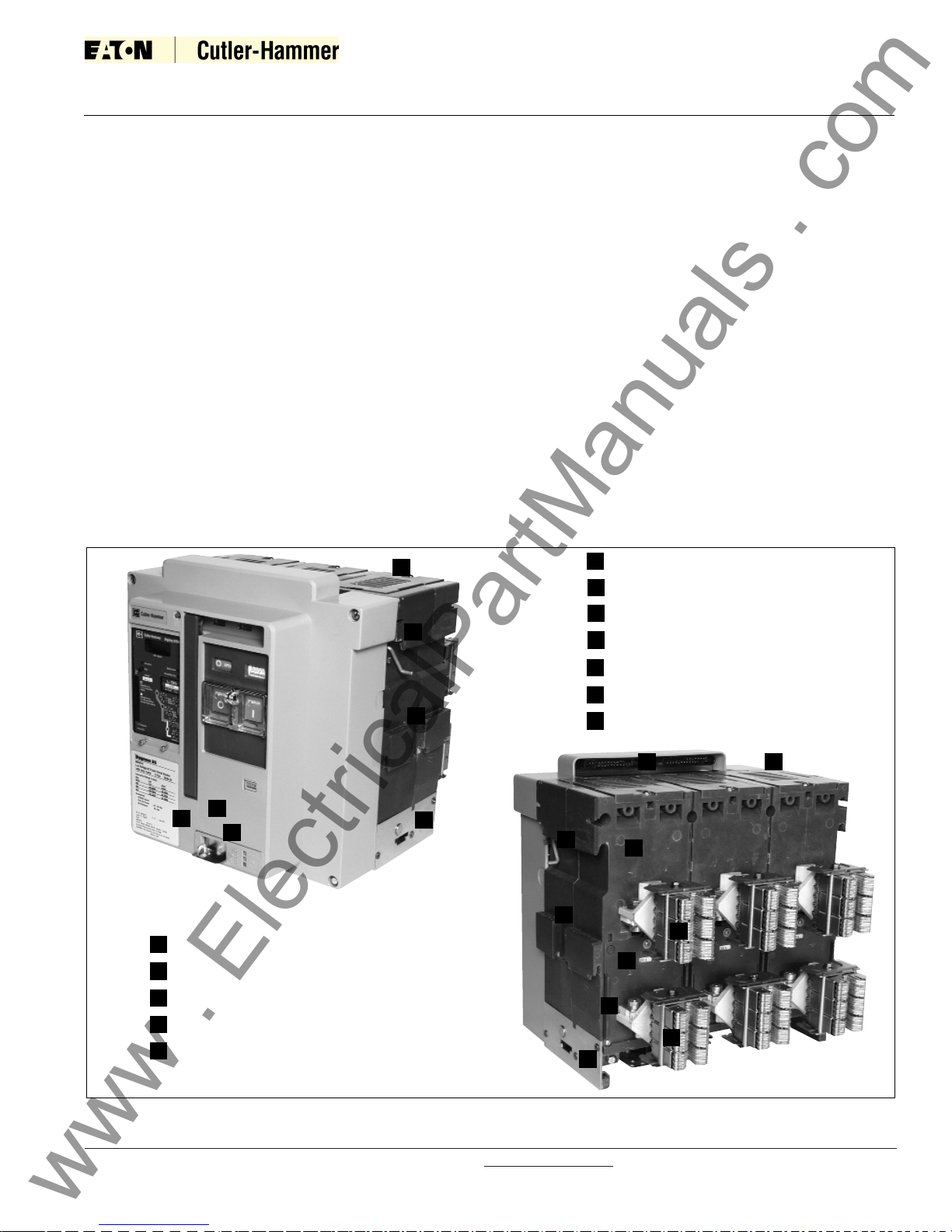

Magnum DS (MDS), DSX (MDSX) circuit breakers are

available in both drawout and fixed mounting configurations (Figures 3-1 and 3-2). Magnum DSL (MDSL) circuit breakers with integral current limiters are available

only in a drawout configuration (Figure 3-3). A majority

of features are common to all configurations, and will be

discussed in this section. The mounting features unique

to the drawout and fixed configurations will be covered

individually in Sections 4 and 5 respectively.

Controls and indicators for both drawout and fixed circuit

breakers are functionally grouped on the front of the circuit breaker. The front escutcheon (faceplate) is common for all Magnum frame sizes up through 5000

amperes.

Double Wide DS and DSX frame circuit breakers utilize

six (or eight) sets of rear primary connections; these circuit breakers are available from the factory with several

different phase sequences, distinguishable by the sixth

character in the model number. The phase sequence is

also labeled on the rear of the circuit breaker (Figure

3-4). For these DS and DSX drawout breakers, phase

sequence labels are also supplied with the cassette and

must be applied by the switchgear builder. Circuit brakers with different phase sequences are not interchangeable. DS and DSX drawout breakers with differing

phase sequence are prevented from insertion into the

cassette by properly assembled rejection key plates

(see section 2-6.2).

The Magnum DSL (MDSL) drawout circuit breaker is

available only in a 3-pole single wide standard configuration. The MDSL is a coordinated combination of a

standard Magnum DS circuit breaker and series connected current limiters. The primary purpose of the current limiters is to extend the interrupting rating of the

MDS circuit breaker up to 200,000 amperes.

Figure 3-1 Typical MDS /MDSX Drawout Circuit Breaker Features (Front and Rear Views)

Baffled Arc Chute Cover

Secondary Disconnects (Contacts)

Faceplate (Front Cover)

Drawout Rail Supports

Integral Lifting Handle

5

2

1

6

7

9

4

3

8

10

Primary Disconnect Finger Cluster

Arc Chamber

Primary Vertical Adapter

Sensor Rating Viewing Window

Levering Device Bearing Plate

Padlockable Levering Device Access Door

Circuit Breaker Nameplate

11

12

1

12

3

4

4

5

5

6

6

7

8

9

10

10

11

12

www . ElectricalPartManuals . com

I.B. 2C12060H08

For more information visit: www.EatonElectrical.com

Instruction Book

Page 12

Effective: May 2006

Figure 3-2 Typical MDS/MDSX Fixed Circuit Breaker Features (Front and Rear Views) (MDSX shown without

required arc hood)

Baffled Arc Chute Cover

Secondary Disconnect

Faceplate (Front Cover)

Integral Lifting Handle

5

2

4

3

Fixed Horizontal Primary Terminal

Fixed Primary Terminal (with optional Vertical Adapter)

Arc Chamber

Sensor Rating Viewing Window

Mounting Foot

6

7

8

9

10

1

1

2

3

4

4

5

6

7

8

9

9

10

Figure 3-3 Typical MDSL Drawout Circuit Breaker Features (Front and Rear Views)

7

8

10

9

11

Arc Chamber

Integral Current Limiter

Levering Device Bearing Plate

Padlockable Levering Device Access Door

Circuit Breaker Nameplate

Baffled Arc Chute Cover

Secondary Disconnects (Contacts)

Faceplate (Front Cover)

Breaker Rollers

Integral Lifting Handle

Primary Disconnect Finger Cluster

5

2

1

4

3

6

1

2

3

4

5

6

7

8

9

9

10

11

4

4

4

1

www . ElectricalPartManuals . com

I.B. 2C12060H08

For more information visit: www.EatonElectrical.com

Instruction Book

Page 13

Effective: May 2006

7

2

1

4

3

5

6

Baffled Arc Chute Cover

Secondary Contact Connector

Faceplate (Front Cover)

Integral Lifting Handle

Fixed Vertical Primary Terminals

with Optional Vertical Adaptor

Arc Chamber

Mounting Foot

Circuit Breaker Nameplate

Phase Identification Labels

Figure 3-4 Typical Double-wide MDS/MDSX Standard Frame Fixed Circuit Breaker Features (Front and Rear

Views) (MDSX shown without required arc hood)

8

9

1

1

2

3

4

4

5

6

7

7

8

9

9

9

www . ElectricalPartManuals . com

I.B. 2C12060H08

For more information visit: www.EatonElectrical.com

Instruction Book

Page 14

Effective: May 2006

Figure 3-5 Typical Magnum DS/DSX Drawout Circuit Breaker Front Cover

Trip Flag (Pop Out Indicator)

Three Accessory Windows

Trip Unit

Rating Plug

Contact Status (Open-Close)

Spring Status (Charged-Discharged)

2

1

4

3

6

2

1

8

7

10

3

9

11

12

Manual “OFF” Button (Push)

Manual “ON” Button (Push)

Manual Charge Handle

Optional Operation Counter

Padlockable Levering Device Access

Door for Drawout Breaker

5

8

7

Color Coded-Breaker

Position Indicator

Nameplate

Trip Unit Test Port

Trip Unit Cover with Two

Mounting Screws (Mounting

Screws will Accept Customer

Supplied Lead Security Meter

Seals

10

9

11

(Red)

(Green)

(Yellow)

(White)

(Green)

(Red)

5

13

14

12

13

4

14

15

6

15

Red = Connect

Yellow = Test

Green = Disconnect

www . ElectricalPartManuals . com

CLOSED

OPEN

CHARGED

DISCHARGED

PUSH ON

PUSH OFF

CONNECT

CONNECT

TEST

TEST

DISCONNECT

DISCONNECT

3-2 BASIC CIRCUIT BREAKER ASSEMBLY

All Magnum circuit breakers use a rigid frame housing

construction of engineered thermoset composite resins.

This construction provides high strength structural properties, excellent dielectric characteristics and resistance

to arc tracking.

The 3-piece construction approach provides support

while isolating and insulating power conductors (Figure

3-6):

(1) A 2-piece engineered thermoset composite resin

case encloses current paths and arc chambers. The

chambers act to channel arc gases up and out of the circuit breaker during interruption.

(2) The operating mechanism sits on the front of the

case and is electrically isolated and insulated from current contact structures. It is covered by an insulating

front cover.

3-3 POLE UNITS

A current carrying pole unit is individually enclosed and

rigidly supported by the case. The individual chambers

provide for pole unit isolation and insulation from one

another. Each pole unit has one primary contact

assembly, which consists of a moving portion and a

fixed portion. The exact design configuration depends

upon the breaker’s frame size. Circuit breakers with

frame sizes of 4000 amperes and higher use two pole

units and arc chute assemblies connected mechanically

and electrically in parallel to form one phase.

I.B. 2C12060H08

For more information visit: www.EatonElectrical.com

Instruction Book

Page 15

Effective: May 2006

Figure 3-6 Typical Magnum Construction (Right Side

View)

2

1

3-1.1 MDSL APPLICATION/OPERATION

MDSL circuit breakers are intended for applications

requiring the overload protection and switching functions

of air circuit breakers on systems whose available fault

currents (1) exceed the interrupting ratings of the circuit

breakers alone and/or (2) exceed the withstand and

interrupting ratings of downstream circuit components.

The 800 through 2000 amp frame MDSL circuit breakers have integrally mounted limiters on the drawout

breaker element. On overloads and faults within the circuit breaker interrupting rating, the circuit breaker protects the limiters. On higher fault currents exceeding

the circuit breaker rating, the limiters protect the circuit

breaker.

Interlock arrangements trip the circuit breaker whenever

any limiter blows. The circuit breaker cannot be

reclosed on a live source unless there are three

unblown limiters on the circuit. The blown fuse indicator, located on the front of the circuit breaker, provides a

visual indication when a current limiter in any phase has

interrupted a short circuit. In addition, a blown limiter

sensing circuit insures that a circuit breaker will be

tripped when any current limiter has blown, preventing

single phasing.

The MDSL circuit breaker must be completely withdrawn from its compartment onto the compartment’s

extension rails, thus assuring complete isolation, before

the integral current limiters are accessible.

Additional information concerning current limiter ratings,

limiter replacement and blown fuse operation is provided later in this chapter.

2

1

Figure 3-7 Features of Magnum Moving Conductor

Assembly

Pivot

Point

Single Contact

Finger

Moving

Arcing

Contact

Area

(Toe)

Moving Main Contact

Conductive Pad

(Heel)

Dual

Flexible

Connections

(Case)(Front Cover)

www . ElectricalPartManuals . com

I.B. 2C12060H08

For more information visit: www.EatonElectrical.com

Instruction Book

Page 16

Effective: May 2006

Figure 3-9 Standard Frame DS (12-finger) Moving

Conductor Assembly

Figure 3-10 General Partial Cross-Sectional View (Shown

in Closed Position) (not specific to any family/frame)

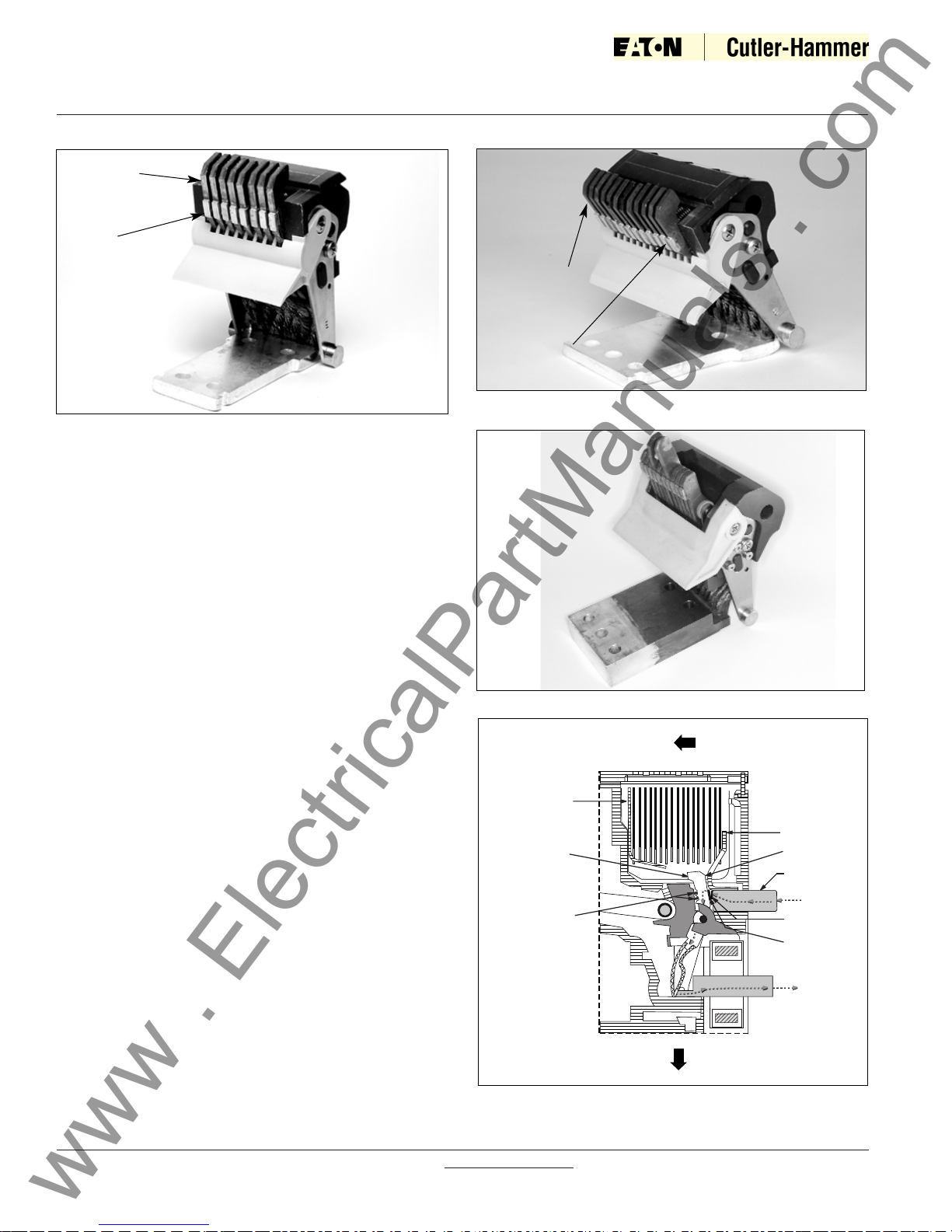

3-3.1 PRIMARY MOVING CONTACTS

Depending upon the frame size, each primary moving

contact assembly is comprised of multiple individual

copper contact fingers connected to the load conductor

through flexible braided connectors (Figure 3-8). Two

flexible connectors are used to connect each finger to

the load conductor. The number of fingers used

depends upon the circuit breaker’s continuous and

short-circuit current ratings (Figures 3-8 and 3-9). On

some ratings fingers are removed and replaced with

spacers.

The single contact finger performs both the main and

arcing contact functions on different parts of the same

finger (Figure 3-7). A highly conductive alloy pad is part

of the contact finger and functions as the moving main

contact, and is called the “Heel.” The tip of the same

contact finger functions as the moving arcing contact,

and is called the “Toe.”

In addition to the contact finger information given above,

DSX (MDSX) utililize an inner and outer carriage design

to facilitate a fast opening blow open contact structure

(Figure 3-9a). The contact fingers mounted in the inner

contact carrier can move independently from both the

outer carrier and the opening mechanism in the breaker.

This independence is the core design feature of its fast

opening blow open contact structure.

Figure 3-8 Narrow Frame (8-finger) Moving Conductor

Assembly

“Heel”

(Main Contact)

“Toe”

(Arcing Contact)

“Toe”

(Arcing Contact)

“Heel”

(Main Contact)

Figure 3-9a MDSX Moving Contact Assembly

www . ElectricalPartManuals . com

Breaker

Front

Arc Chute

Integral

Moving Contact

Fingers

Moving Contact

Springs

Breaker

Bottom

xxxxxxxx

x

x

xxxxxxxx

xxxxxxxx

x

x

xxxxxxxx

x

x

x

x

Arc Runner

Arcing

Contact (Toe)

Line

Conductor

Current

Flow

Stationary

Main Contact

Moving Main

Contact (Heel)

Current

Flow

I.B. 2C12060H08

For more information visit: www.EatonElectrical.com

Instruction Book

Page 17

Effective: May 2006

complete the manual charging process. It is possible to

manually recharge the spring immediately after closing

the circuit breaker and before it has been tripped open.

Standard manually operated circuit breakers are closed

and opened by hand using the Manual “ON” and Manual

“OFF” buttons respectively located on the front of the circuit breaker (Figure 3-5). Performing either operation is

accomplished by pressing and releasing the appropriate

button. Access to these pushbuttons can be limited by

the use of an optional, padlockable cover. In addition,

complete access to the “ON” button can be prevented

with an optional prevent close cover. The status of the

springs and the primary contacts are always indicated in

an indicator window just above the pushbuttons.

Electrically operated optional devices are available to

automatically close or trip a manually operated circuit

breaker. An electrical spring release is available to close

a manually operated circuit breaker. Two optional

devices, a shunt trip and an undervoltage release, are

available to automatically trip (open) a manually operated

circuit breaker. All of these UL listed optional devices can

be installed easily in the field. For more details on these

devices, refer to paragraph 3-8 in this manual.

An electrical operator which is used to charge the closing

spring automatically can be added to a manually operated circuit breaker in the field (Figure 3-13). Manually

operated circuit breakers are pre-wired to accept this

addition.

3-3.2 PRIMARY STATIONARY CONTACTS

The primary stationary contact is a combination of two

items (Figure 3-10). One is a conductive pad mounted

on the line conductor which functions as the stationary

main contact. The other is an arc runner, also connected to the line conductor. The integral arc runner serves

a dual purpose:

• Fixed arcing contact

• Part of the arc chute

3-4 OPERATING MECHANISM

The Magnum DS/DSX/DSL operating mechanism is

based on the proven cam and spring design of the DSII

power circuit breaker. It is easily accessed by removing

four cover screws and the front cover (Figure 3-11).

The mechanism is a two-step stored energy mechanism. Potential energy is stored to close the circuit

breaker. Sufficient energy to open the circuit breaker

remains available after a closing operation.

3-4.1 MANUAL OPERATION

On manually operated circuit breakers, the closing spring

can only be charged manually. To manually charge the

spring, insert one finger in the recess behind the charging

handle and pull out. This permits a gloved hand to grasp

the handle and begin charging (Figure 3-12). It takes

from 5 to 7 downward strokes on the charging handle to

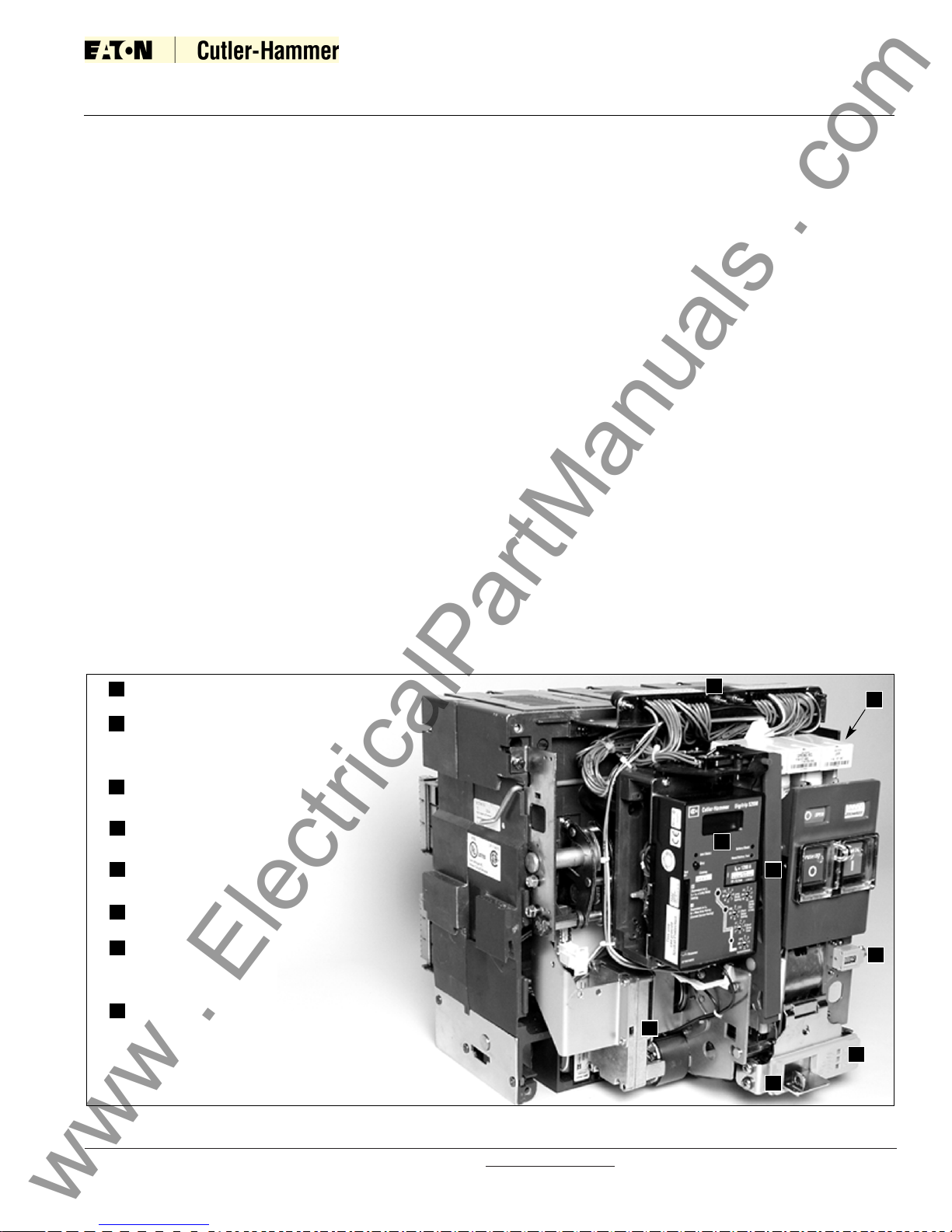

Figure 3-11 Typical Electrically Operated Drawout MDS/MDSX Circuit Breaker with Front Cover Removed

Secondary Wiring Points

Field Installable Accessories

(3 maximum)

Trip Unit

Electric Charging Motor

Manual Charge Handle

Operations Counter (optional)

Padlockable Levering Device

Access Door

Breaker Position Indicator

7

2

1

4

3

5

6

8

2

1

3

5

6

7

8

4

www . ElectricalPartManuals . com

Loading...

Loading...