Eaton Matrix 2000 Installation And Operation Manual

Matrix 2000 Inverter

Installation and Operation Guide

Issue:

IPN 997-00012-72C

Issue Date:

July 2017

Eaton Corporation

Telecommunications Power Solutions

www.eaton.com/telecompower

DCinfo@eaton.com

The product discussed in this literature is subject to terms and conditions outlined in Eaton selling policies. The

sole source governing the rights and remedies of any purchaser of this equipment is the relevant Eaton selling

policy.

No warranties, express or implied, including warranties of fitness for a particular purpose or merchantability, or

warranties arising from course of dealing or usage of trade, are made regarding the information,

recommendations and descriptions contained herein.

In no event will Eaton be responsible to the purchaser or user in contract, in tort (including negligence), strict

liability or otherwise for any special, indirect, incidental or consequential damage or loss whatsoever, including but

not limited to damage or loss of use of equipment, plant or power system, cost of capital, loss of power, additional

expenses in the use of existing power facilities, or claims against the purchaser or user by its customers resulting

from the use of the information, recommendations and descriptions contained herein.

The information contained in this literature is subject to change without notice.

Subject to the right to use its equipment, Eaton Corporation does not convey any right, title or interest in its

intellectual property, including, without limitation, its patents, copyrights and know-how.

No part of this document may be reproduced or transmitted in any form, by any means or for any purpose other

than the Purchaser’s personal use, without the express written permission of Eaton Corporation.

Eaton®, Matrix, Powerware®, IntergyTM, CellSureTM, SiteSureTM, PowerManagerIITM and DCToolsTM are trade

names, trademarks, and/or service marks of Eaton Corporation or its subsidiaries and affiliates. Unless otherwise

noted, brands, product names, trademarks or registered trademarks are the property of their respective holders.

Copyright © 2009-2010 Eaton Corporation. All Rights Reserved.

About This Guide

Copyright © 2017 Eaton Corporation. All Rights Reserved.

IPN 997-00012-72C July 2017

i

About This Guide

Purpose

The purpose of this manual is to provide explanations and procedures for installing, operating,

maintaining, and troubleshooting a Matrix 2000 Inverter.

This manual should be read through carefully before installation and operation.

Please retain this manual for future reference.

Audience

This guide is intended for use by:

Installers competent in:

installing and commissioning dc power systems and inverter systems

safe working practices for ac and dc powered equipment

the relevant local electrical safety regulations and wiring standards

Operators and maintenance staff competent in:

operation of dc power systems and inverter systems

safe working practices for ac and dc powered equipment

Reporting Problems with this Guide

Please use this email address to report any problems you find in this guide:

Eaton DC Product Marketing Communications

EMAIL: DCInfo@eaton.com

For Further Information and Technical Assistance

For further information and technical assistance see Worldwide Support on page 29.

Matrix Standalone Inverter

ii

Copyright © 2017 Eaton Corporation. All Rights Reserved.

IPN 997-00012-72C July 2017

Table of Contents

Copyright © 2017 Eaton Corporation. All Rights Reserved.

IPN 997-00012-72C July 2017

iii

Table of Contents

About This Guide

Purpose .............................................................................................................................................. i

Audience ........................................................................................................................................... i

Reporting Problems with this Guide .......................................................................................... i

For Further Information and Technical Assistance ................................................................. i

General Description

Overview .......................................................................................................................................... 1

Part Numbers .................................................................................................................................. 1

Front View ....................................................................................................................................... 2

Rear Views ....................................................................................................................................... 2

Preparation

Overview .......................................................................................................................................... 3

General ............................................................................................................................................. 3

Battery Precautions ........................................................................................................................ 4

Inspecting the Equipment and Reporting Damage ................................................................ 4

Installation

Overview .......................................................................................................................................... 5

Location ............................................................................................................................................ 5

Unpacking and Inspection ........................................................................................................... 5

Mounting ......................................................................................................................................... 6

AC Connections .............................................................................................................................. 6

DC Connections .............................................................................................................................. 6

Remote Control and Alarm Connections (Optional) ............................................................. 7

Remote Control ................................................................................................................................ 7

Alarm Connections ......................................................................................................................... 8

Operation

Overview .......................................................................................................................................... 9

Pre-Operation Check ..................................................................................................................... 9

Inverter Standalone check list ........................................................................................................ 9

Apply Power ................................................................................................................................. 10

Remote Control Operation (Optional) ........................................................................................ 10

Main Menu .................................................................................................................................... 10

Status Menu ................................................................................................................................... 11

Settings Menu ............................................................................................................................... 12

Inverter Parameter Settings ......................................................................................................... 12

System Parameter Settings ........................................................................................................... 13

Maintenance

Overview ........................................................................................................................................ 15

Troubleshooting ........................................................................................................................... 16

LED display status (Low to High Priority)............................................................................. 17

Alarm Codes ................................................................................................................................. 18

Matrix Standalone Inverter

iv

Copyright © 2017 Eaton Corporation. All Rights Reserved.

IPN 997-00012-72C July 2017

Appendix A Specifications

Appendix B Default Values

Appendix C Menu

Equipment Incident Report

Worldwide Support

Index

Chapter 1

General Description

Copyright © 2017 Eaton Corporation. All Rights Reserved.

IPN 997-00012-72C July 2017

1

C h a p t e r 1

General Description

Overview

Topic Page

Part Numbers 1

Front View 2

Rear Views 2

The Matrix Standalone Inverter is a 1U, 19-inch rack mount module with output up to

2000VA/2000W (at 110/115/120 or 208/220/230/240V ac, 50 or 60Hz) from -48V dc input.

The module has a built-in automatic transfer switch (ATS), high efficiency and a wide operating

temperature range.

Alarm and monitoring is provided by an LCD screen, alarm LEDs and an alarm relay output.

Part Numbers

Part Number

Description

INV-4820ESA

Matrix 2000, 2000VA/2000W standalone inverter module with

automatic transfer switch, 230V ac nominal output. 2 x IEC 320-C13

output sockets.

INV-4820SA

Matrix 2000, 2000VA/2000W standalone inverter module with

automatic transfer switch, 120V ac nominal output. 2 x NEMA 5-20R

output sockets. Includes AC input cord.

For full details refer to the Specifications on page 19.

Matrix Standalone Inverter

2

Copyright © 2017 Eaton Corporation. All Rights Reserved.

IPN 997-00012-72C July 2017

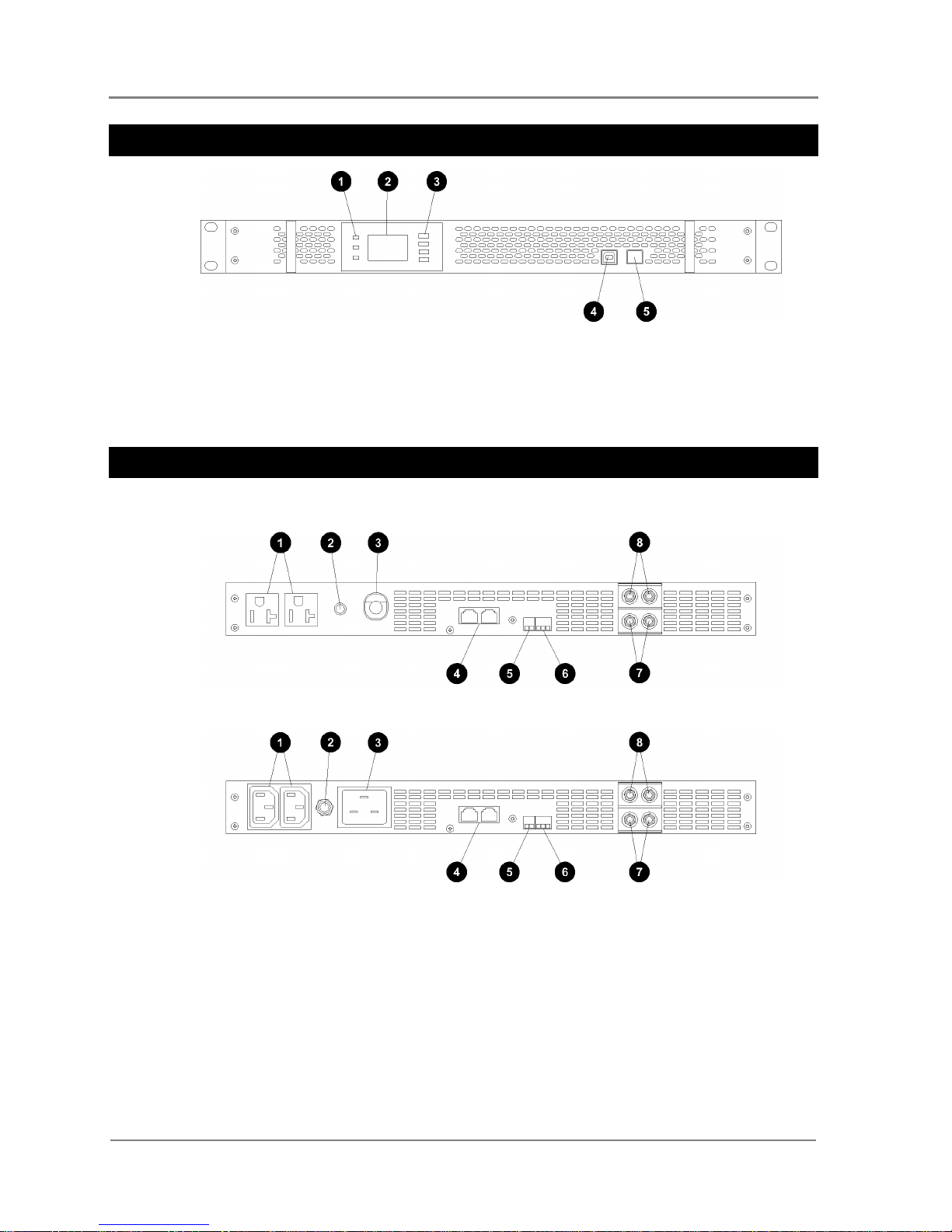

Front View

LEDs: Power (green), minor alarm (yellow), major

alarm (red). See Troubleshooting on page 16.

LCD screen. See Menu details on page 10.

Keypad

USB 1.1 connector (reserved for future use)

ON/OFF power switch

Rear Views

120V Model

230V Model

AC output connectors (see Specifications on page

20).

AC input circuit breaker. Push in to reset.

120V models: AC input cord, 230V models: AC

input connector (see Specifications on page 19).

Parallel signal port (reserved for future use).

Remote on/off connector/screw terminals (wire

size: 0.5 - 2.0mm2, 20 - 14 AWG). See details on

page 7.

Alarm relay output connector/screw terminals (wire

size: 0.5 - 2.0mm2, 20 - 14 AWG). See details on

page 7.

48V dc negative (-) input terminals. 1/4" studs, 5/8"

separation.

48V dc positive (+) input terminals. 1/4" studs, 5/8"

separation.

Chapter 2

Preparation

Copyright © 2017 Eaton Corporation. All Rights Reserved.

IPN 997-00012-72C July 2017

3

C h a p t e r 2

Preparation

Overview

Topic Page

General 3

Battery Precautions 4

Inspecting the Equipment and Reporting Damage 4

General

1 Only mount the Matrix 2000 Inverter in either an open-frame relay rack or an enclosed

cabinet. The Matrix 2000 Inverter is not designed for "bench top" or any other mounting

arrangement.

2 Before installing and using the Matrix 2000 Inverter, read all instructions and cautionary

markings on the equipment and all appropriate sections of this guide. Be sure to read all

instructions and cautionary markings for any equipment attached to this unit.

3 This unit is designed for indoor use only. Do not expose the equipment to rain, snow, or

spray.

4 To reduce the risk of fire hazard, do not cover or obstruct the ventilation openings. Do not

install the equipment in a zero-clearance compartment.

5 Use only attachments recommended or sold by the manufacturer. Doing otherwise may

result in a risk of fire, electric shock, or other injury.

6 To avoid a risk of fire and electric shock, make sure that existing wiring is in good

condition and is not undersized. Do not operate the equipment with damaged or

substandard wiring.

7 Do not operate the equipment if it has been damaged in any way.

8 The Earthing System of the AC output from the inverter will change depending on

whether it is in Mains Priority or Battery Priority (DC supply) mode. When in Mains

Priority the AC output earthing system is the same as the AC supply network. When in

Battery Priority the AC output earthing system is floating and the Neutral system

arrangement at the Inverter output becomes “insulated” (IT), meaning both L1 and L2

being isolated from earth. This is the consequence of a requirement to isolate the input

AC terminals when operating in Battery priority as the AC input is made via a pluggable

connector. Due to EMC capacitors between L1 and L2 and earth, it is possible to measure

half the nominal output voltage between L1 or L2 and earth. This is expected and only

presents a low energy source.

9 Due to the earthing system outlined above, local electricity regulations of certain

countries may mandate the fitment of an Insulation Monitoring Device (IMD) on the

output, and/or the fitment of equipotential bonding conductors between all

simultaneously accessible exposed conductive parts of fixed equipment and extraneous

conductive parts Check with your local regulations.

10 It is not permitted to bond L1 or L2 to earth on the output.

Matrix Standalone Inverter

4

Copyright © 2017 Eaton Corporation. All Rights Reserved.

IPN 997-00012-72C July 2017

Battery Precautions

To avoid personal injury and property damage, read these battery precautions on handling,

charging and disposing of batteries.

1 Never reverse the INPUT+ and INPUT- polarity to the battery.

2 Keep the battery away from heat sources including direct sunlight, open fires, microwave

ovens, and high-voltages. Temperatures over 60ºC may cause damage. Make sure the area

around the battery is well ventilated.

3 Never smoke or allow a spark or flame near the battery.

4 Use caution to reduce the risk of dropping a metal tool on the battery. A spark or short

circuit to the battery or other electrical parts could cause an explosion.

5 Remove all metal items, such as rings, bracelets, and watches when working on the

batteries.

6 Have plenty of fresh water and soap nearby in case battery acid contacts skin, clothing, or

eyes.

7 If battery acid contacts skin or clothing, wash immediately with soap and water. If acid

enters your eye, immediately flood it with running cold water for at least twenty minutes

and get medical attention immediately.

8 If you need to remove a battery, always remove the grounded terminal from the battery

first. Make sure all accessories are off so you do not cause a spark.

Inspecting the Equipment and Reporting Damage

Unpack the equipment and inspect it carefully for possible damage that may have occurred

while in transit. Do not use any damaged equipment.

Report any damage immediately, using a completed Equipment Incident Report on page 27.

Keep the original packaging to use if any item needs to be returned for replacement or repair.

Chapter 3

Installation

Copyright © 2017 Eaton Corporation. All Rights Reserved.

IPN 997-00012-72C July 2017

5

C h a p t e r 3

Installation

Overview

Topic Page

Location 5

Unpacking and Inspection 5

Mounting 6

AC Connections 6

DC Connections 6

Remote Control and Alarm Connections (Optional) 7

Location

Install the Matrix 2000 in a location that meets the following requirements:

Dry: Do not allow water to drip or splash on the inverter.

Cool: Ambient air temperature between -20°C and 50°C.

If the Matrix 2000 is installed in a closed or multi-unit rack assembly, the operating ambient

temperature of the rack environment may be greater than room ambient.

Safe: Do not install in a battery compartment or other areas where flammable fumes may

exist, such as fuel storage areas or engine compartments.

Ventilated: Allow at least 75mm (3") clearance all around for air flow. Ensure the

ventilation openings on the front, rear and top of the unit are not obstructed.

If the Matrix 2000 is installed in a closed rack, ensure there is adequate air flow.

Corrosion and Dust Free: Do not install in a corrosive or dusty environment where

contaminants (such as salt), dust, wood particles or other filings/shavings are present that

may be pulled into the unit when the cooling fan is operating.

Close to Batteries: Avoid excessive cable lengths but do not install in the same

compartment as batteries. Use the recommended wire lengths and sizes (see details on

page 6).

Avoid mounting the inverter where it may be exposed to the gases produced by the battery.

Prolonged exposure to these corrosive gases will damage the inverter.

Unpacking and Inspection

Remove the unit from its packaging and inspect it for scratches, cracks, broken connectors and

missing accessories. Refer to Inspecting the Equipment and Reporting Damage on page 4.

Matrix Standalone Inverter

6

Copyright © 2017 Eaton Corporation. All Rights Reserved.

IPN 997-00012-72C July 2017

The Matrix 2000 includes the following accessories:

4 x M4 screws to connect the brackets to the rack

2 x 19-inch rack mount brackets (factory-fitted)

2 x 23-inch rack mount brackets

Mounting

1 If the Matrix 2000 is to be mounted in a 23-inch rack:

Remove the factory-fitted 19-inch rack mount brackets.

Attach the 23-inch rack mount brackets.

2 Mount the Matrix 2000 in the rack:

Fit cage nuts in the rack.

Position the Matrix 2000.

Align the holes of mounting brackets and rack.

Secure with four cross screws provided.

AC Connections

The ground wire of the ac input must be connected to the ground from your ac utility

source.

The ground wire of the ac output must be connected to the grounding point for your loads.

Do not operate the unit without connecting it to ground. Electrical shock hazard may

result.

1 Refer to the Specifications on page 19 for the correct ac input and output plugs/sockets.

120V models are supplied with an ac input cord and plug.

2 Either:

For 230V models, connect an ac cord from the ac input plug to a nearby (easily

accessible) ac outlet.

or:

For 120V models, connect the ac cord to a nearby (easily accessible) ac outlet.

3 Connect ac cords from the ac output plugs to the load equipment.

DC Connections

The maximum dc input current is 46.3A. The cables from the dc supply to the Matrix 2000 must

be in accordance with local electrical codes or regulations.

Recommended input circuit protection: 60A.

Recommended cable size: 6AWG/10mm

2

(copper).

Increase the cable size if the dc supply is more than 10 feet/3m from the Matrix 2000.

Maximum cable size is 2AWG/25mm2.

Cables that are too small or too long will cause decreased inverter performance such as poor surge

capability and frequent low input voltage warnings and shutdowns. These low input voltage

warnings are due to dc voltage drop across the cables from the inverter to the dc supply. The

longer and/or smaller these cables, the greater the voltage drop.

Loading...

Loading...