Eaton Magnum MRR1000 Instruction Booklet

Instruction Booklet IB01900004E

Effective July 2016

Supersedes March 2011

Magnum breaker remote

racking device (MRR1000)

Contents

Description Page

Section 1: Introduction .....................3

Section 2: Safe practices for power

circuit breakers ...........................5

Section 3: Receiving, handling, and storage .....5

Section 4: Procedures ......................6

Section 5: Warranty .......................12

Section 6: Troubleshooting .................12

Section 7: Additional publications ............12

Instruction Booklet IB01900004E

Effective July 2016

Magnum breaker remote

racking device (MRR1000)

NOTICE

ALL USERS OF THIS PRODUCT SHOULD READ AND FOLLOW THE

INSTRUCTIONS PROVIDED HEREIN; HOWEVER, THIS INSTRUCTION BOOK

SHOULD NOT BE CONSIDERED ALL INCLUSIVE REGARDING INSTALLATION

OR MAINTENANCE PROCEDURES. IF FURTHER INFORMATION IS REQUIRED,

YOU SHOULD CONSULT EATON’S ELECTRICAL SERVICES & SYSTEMS.

READ AND UNDERSTAND THIS AND OTHER SUPPLIED INSTRUCTIONS

AND DRAWINGS IN THEIR ENTIRETY BEFORE INSTALLING OR OPERATING

THIS DEVICE. ADJUSTMENT, REPAIR OR MAINTENANCE, OTHER THAN

THOSE DESCRIBED HEREIN, MUST BE PERFORMED BY QUALIFIED

PERSONNEL. A QUALIFIED PERSON IS ONE WHO IS FAMILIAR WITH

THE CONSTRUCTION AND OPERATION OF THIS EQUIPMENT AND THE

HAZARDS INVOLVED.

m WARNING

IMPROPER USE OR MAINTENANCE OF THIS PRODUCT, OR OPERATING

IT IN A MANNER FOR WHICH IT WAS NOT INTENDED, MAY RESULT IN

DEATH, SERIOUS PERSONAL INJURY, OR PROPERTY DAMAGE.

READ AND UNDERSTAND THESE INSTRUCTIONS BEFORE ATTEMPTING

ANY OPERATION OR MAINTENANCE OF THE CIRCUIT BREAKERS TO BE

OPERATED BY THIS DEVICE

THE CIRCUIT BREAKERS DESCRIBED IN THIS MANUAL ARE DESIGNED

AND TESTED TO OPERATE WITHIN THEIR NAMEPLATE RATINGS.

OPERATION OUTSIDE OF THESE RATINGS MAY CAUSE THE EQUIPMENT TO

FAIL, RESULTING IN DEATH, BODILY INJURY, OR PROPERTY DAMAGE.

ALL SAFETY CODES, SAFETY STANDARDS, AND/OR REGULATIONS AS

THEY MAY BE APPLIED TO THIS TYPE OF EQUIPMENT MUST BE STRICTLY

ADHERED TO.

This product is manufactured by Eaton at the Asheville Assemblies

Plant: 221 Heywood Road, Arden, NC 28704.

All possible contingencies that may arise during installation,

operation or maintenance, and all details and variations of this

equipment do not purport to be covered by these instructions. If

further information is desired by purchaser regarding his particular

installation, operation, or maintenance of particular equipment,

contact an Eaton sales or service representative.

NOTICE

THE DANGER, WARNING, AND CAUTION MESSAGES INCLUDED AS A

PART OF THE PROCEDURAL STEPS IN THIS MANUAL ARE FOR PERSONNEL

SAFETY AND PROTECTION OF EQUIPMENT FROM DAMAGE. AN

EXAMPLE OF A TYPICAL WARNING LABEL HEADING IS SHOWN ABOVE

THIS PARAGRAPH TO FAMILIARIZE PERSONNEL WITH THIS TYPE OF

PRESENTATION. THIS WILL HELP ASSURE THAT PERSONNEL ARE ALERT

TO THESE TYPE MESSAGES. IN ADDITION, THESE MESSAGES ARE ALL

UPPER CASE AND BOLDFACE.

2

EATON www.eaton.com

Magnum breaker remote

racking device (MRR1000)

Instruction Booklet IB01900004E

Effective July 2016

Section 1: Introduction

Eaton’s MRR1000 provides a means of remotely inserting or

removing any drawout circuit breaker in the Magnum DST family

of power circuit breakers. In addition, the MRR1000 enables the

operator to remotely open and close any Magnum DS circuit breaker

using the pushbuttons on the face of the breaker. Increased safety

precautions and the need to protect personnel from the dangers

of potential arc flash occurrences suggest the need to increase

the distance between an operator and the front of a switchgear

or switchboard during racking operations. With the MRR1000, an

operator can be up to 25 feet away from the breaker compartment

door during the rack-in or rack-out process.

Electric arcs result from thermal ionization that occurs when

current flow is interrupted by the separation of conductors.

Thermal ionization can generate temperatures as high as 35,000 °F.

Conductor materials melt into metal vapor and the surrounding air is

ionized. If the arc is external of the interrupting chamber of a power

circuit breaker, then a violent explosion occurs resulting in an inferno

of ionized gases, molten debris, metal shrapnel, and a flash of light

(arc flash). When arc flash initiates within a switchgear/switchboard

cabinet, the rapidly escalating pressure can dislodge compartment

doors and side sheets of the switchgear and turn hardware into

high-speed projectiles.

Arc flash levels are a function of circuit voltage, maximum

available short circuit current at the point of flashover, conditions

of confinement, and the distance between the point of flashover

and the point of measurement.

Operating personnel are typically within two feet of the front of the

power circuit breaker during the racking process. In the event of an

arc flash event, this close proximity could cause serious injury or

death. NFPA 70E provides guidance for the requirements of personal

protective equipment (PPE) to protect personnel from the dangers

of arc flash exposure. PPE for high levels of arc flash can be bulky,

hot, and uncomfortable. This may dissuade personnel from wearing

proper protection. The best way to limit exposure to arc flash during

the process of racking power circuit breakers is to put more distance

between the person and the possible point of exposure.

Eaton’s remote racking device fulfills the objective of increased

worker safety by permitting routine operations from an increased

distance from the power circuit breaker.

1.1 Compatibility

The remote racking device is compatible with any drawout breaker

in the Magnum DS family of power circuit breakers. This includes

the Magnum DS standard frame, narrow frame and doublewide

frame rated for switchgear (ANSI), Magnum SB switchboard class

and IEC 60947-2 applications, as well as CM52 network protector

breakers. The application may be used while enclosed in Magnum

DS low-voltage switchgear and switchboards with the breaker

compartment door closed. The MRR1000 is also compatible with

Magnum DS arc-resistant switchgear and also compatible with

Magnum DS family of drawout power circuit breakers in other

OEM installations.

m CAUTION

THE CASE DIMENSIONS, RETENTION METHOD, AND OPERATING MECHANISM OF THE MRR1000 ARE DESIGNED TO WORK EXCLUSIVELY WITH THE

MAGNUM DS FAMILY OF POWER CIRCUIT BREAKERS. ANY ATTEMPT TO

USE THE DEVICE WITH ANOTHER MANUFACTURER’S BREAKER WILL PUT

THE OPERATOR AT RISK OF INJURY AND WILL VOID THE WARRANTY.

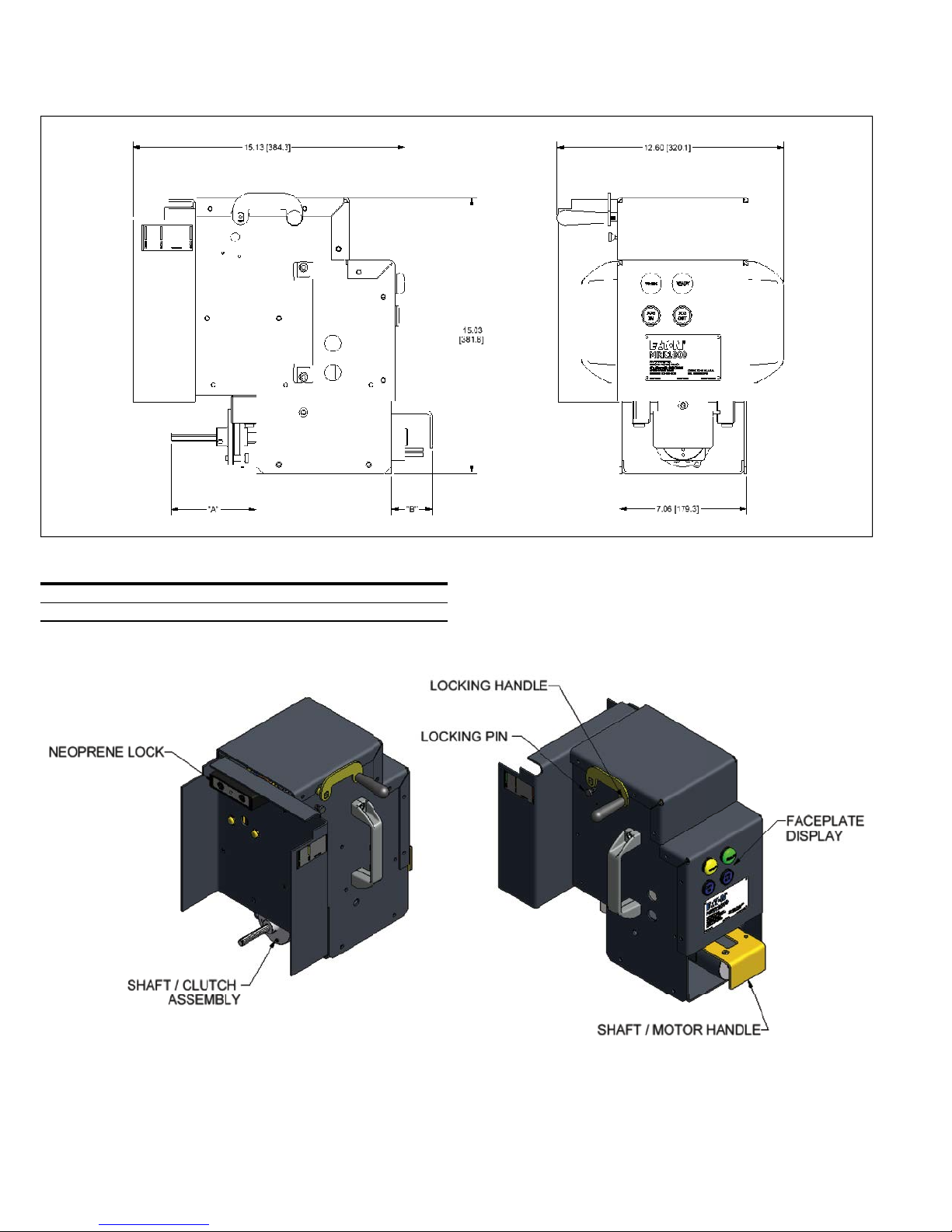

Unlike some remote operating devices, the MRR1000 requires no

additional mounting kit on the body of the circuit breaker or on the

surface of the switchgear/switchboard. In fact, no modification or

additional tools are required. The MRR1000 utilizes features found

on every breaker of the Magnum DS family, making it convenient to

install and use.

m DANGER

WHEN SWITCHGEAR IS CERTIFIED TO BE ARC RESISTANT PER

ANSI C37.20.7, THE ARC-RESISTANT RATING IS ONLY VALID WHEN ALL

DOORS ARE CLOSED AND PROPERLY LATCHED OR BOLTED, AND ALL

COMPONENTS ARE INSTALLED AND WORKING PROPERLY. IN ADDITION,

REMOVAL OF ANY BREAKER FROM ITS CELL WITHOUT REINSTALLING

A BREAKER OR ARC-RESISTANT PROVISION COVER WILL VOID THE

ARC-RESISTANT RATING. FOR COMPLETE INSTRUCTIONS REGARDING

ARC-RESISTANT SWITCHGEAR, SEE IB01900001E, LISTED IN SECTION 7.

EATON www.eaton.com

3

Instruction Booklet IB01900004E

Effective July 2016

Magnum breaker remote

racking device (MRR1000)

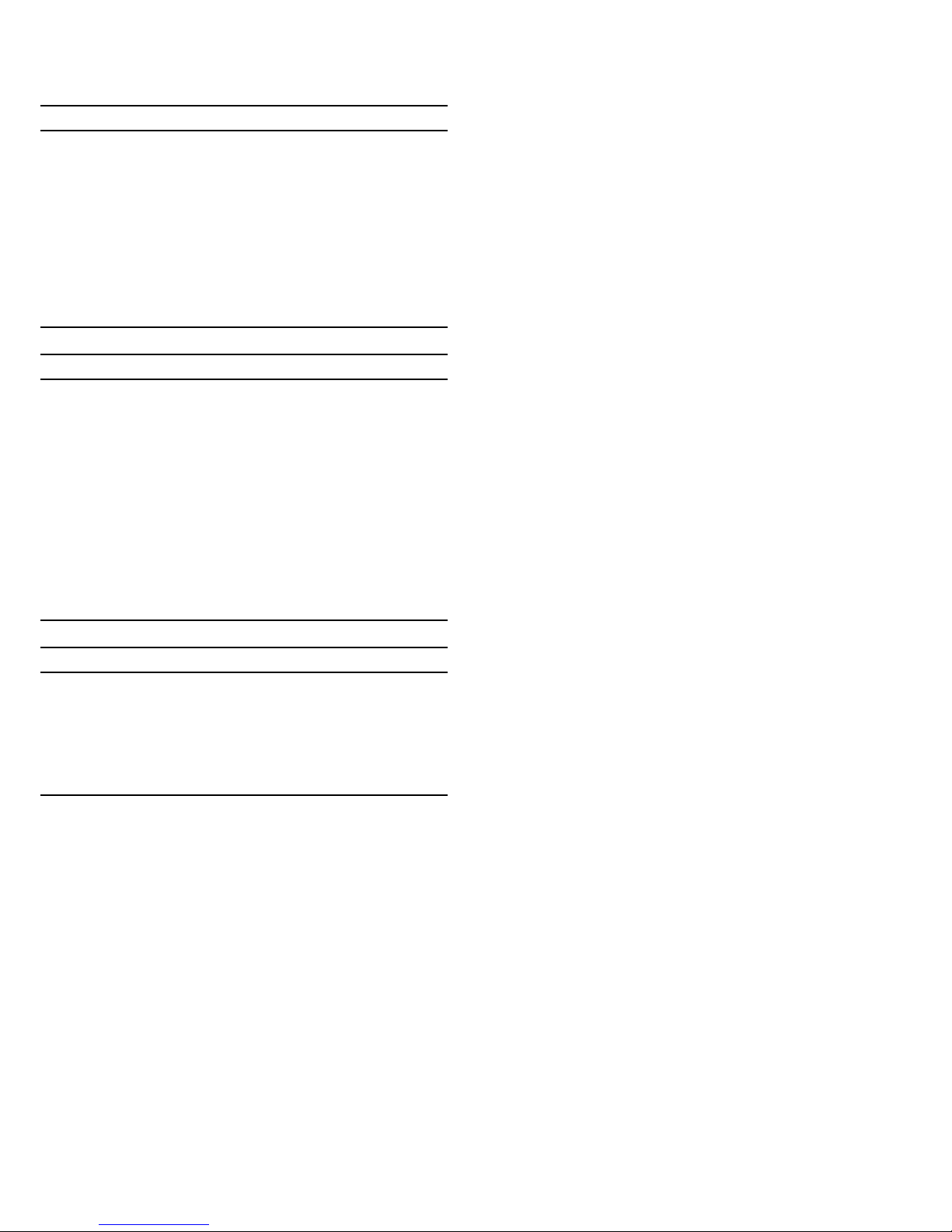

“A” shaft

inch (mm)

Retracted position 2.75 (69.85) 4. 28 (108.71)

Extended position 4.75 (120.65) 2. 28 (5 7.91)

“B” hand le

inch (mm)

4

EATON www.eaton.com

Loading...

Loading...