EATON GVX9000 User Guide

GVX9000 AF Drives

User Manual

New Information

June 2006

MN04000001E For more information visit: www.EatonElectrical.com

Important Notice – Please Read

The product discussed in this literature is subject to terms and conditions

outlined in Eaton Electrical Inc. selling policies. The sole source

governing the rights and remedies of any purchaser of this equipment is

the relevant Eaton Electrical Inc. selling policy.

NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WARRANTIES OF

FITNESS FOR A PARTICULAR PURPOSE OR MERCHANTABILITY, OR

WARRANTIES ARISING FROM COURSE OF DEALING OR USAGE OF

TRADE, ARE MADE REGARDING THE INFORMATION,

RECOMMENDATIONS AND DESCRIPTIONS CONTAINED HEREIN. In no

event will Eaton Electrical Inc. be responsible to the purchaser or user in

contract, in tort (including negligence), strict liability or otherwise for any

special, indirect, incidental or consequential damage or loss whatsoever,

including but not limited to damage or loss of use of equipment, plant or

power system, cost of capital, loss of power, additional expenses in the

use of existing power facilities, or claims against the purchaser or user by

its customers resulting from the use of the information,

recommendations and descriptions contained herein.

The information contained in this manual is subject to change without

notice.

Cover Photo: Eaton GVX9000 Drives

GVX9000 User Manual i

This page intentionally left blank.

ii GVX9000 User Manual

Table of Contents

LIST OF FIGURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

LIST OF TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

SAFETY MESSAGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Definitions and Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Hazardous High Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

High Voltage, Warnings and Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

CHAPTER 1 — INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

How to Use This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Conventions Used in This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Warranty and Liability Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Related Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

CHAPTER 2 — OVERVIEW OF THE GVX9000 DRIVE . . . . . . . . . . . . . . . . . . . . 2-1

Receiving and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Nameplate Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Catalog Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Style Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

External Parts and Label Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Digital Keypad Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

CHAPTER 3 — STORAGE AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Transportation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Pollution Degree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Mounting Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Applicable Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Basic Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

External Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Control Terminal Wiring (Factory Settings) . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Main Circuit Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Wiring Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Motor Operation Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

GVX9000 User Manual iii

Table of Contents

CHAPTER 4 — START-UP PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Step-by-Step Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Mounting Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Inverter Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Wiring Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Wire Sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Fuses and Circuit Breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Fusing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Manual Motor Starters/UL489 Circuit Breakers . . . . . . . . . . . . . . . . . . . 4-6

Wiring the Inverter to Incoming Power . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Wiring the Motor to the Inverter Output . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Power-Up Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Powering the Inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

CHAPTER 5 — DESCRIPTIONS OF PARAMETER SETTINGS . . . . . . . . . . . . . . 5-1

Viewing and Changing Parameter Settings . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Parameter Groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Group 20 — Easy Mode Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Group 30 — Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Explanations: Digital Input Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Group 40 — Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

Function Explanations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

Group 50 — AC Drive Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-30

Group 60 — Motor Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-49

Group 70 — Protective Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-55

Group 80 — Keypad / Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-62

Group 90 — Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-67

CHAPTER 6 — MAINTENANCE AND INSPECTION . . . . . . . . . . . . . . . . . . . . . . 6-1

Periodic Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

CHAPTER 7 — TROUBLESHOOTING AND FAULT INFORMATION . . . . . . . . . 7-1

Common Problems and Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Warning Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

APPENDIX A — TECHNICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

APPENDIX B — PARAMETER TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

GVX9000 Parameter Listings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

iv GVX9000 User Manual

Table of Contents

APPENDIX C — ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Fuse Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Braking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

All Braking Resistors and Braking Units Used in AC Motor Drives . . . . C-4

External Brake Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-6

Dimensions for Braking Resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-8

EMI Filter Cross-Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-9

Keypad Remote Mounting Kit (P/N GVXRM) . . . . . . . . . . . . . . . . . . . . . . . . C-19

APPENDIX D — DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Digital Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-3

APPENDIX E — EASY MODE SETTINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

Choosing Easy Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-2

Changed Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-2

APPENDIX F — DECLARATION OF CONFORMITY . . . . . . . . . . . . . . . . . . . . . . F-1

Low Voltage Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-2

EC Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-2

Electromagnetic Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-3

EC Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-3

GVX9000 User Manual v

Table of Contents

List of Figures

Figure 2-1: Example of 5 hp 230V AC drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Figure 2-2: Parts and Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Figure 2-3: Description of Digital Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

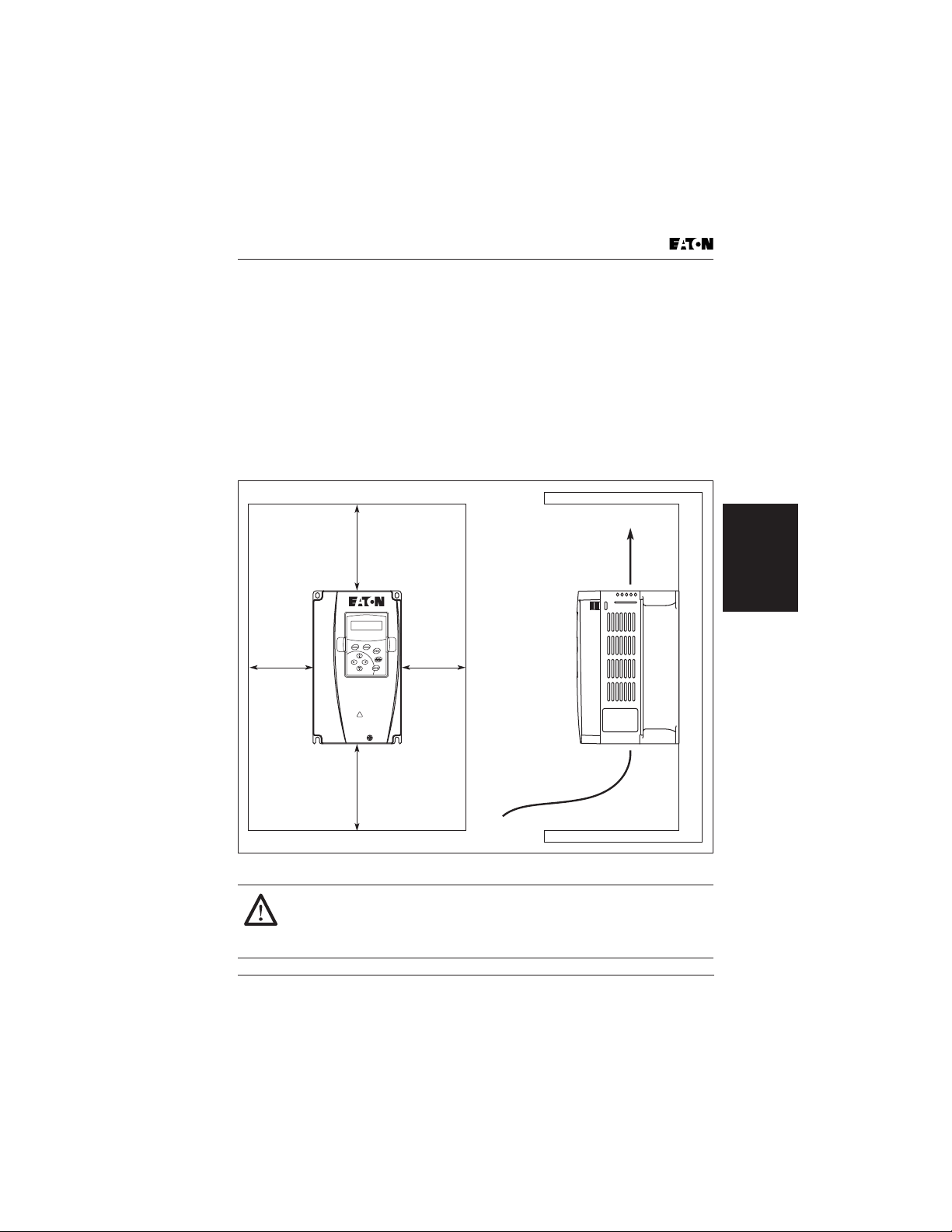

Figure 3-1: Mounting in an Enclosure in Inches (mm) . . . . . . . . . . . . . . . . . . . 3-3

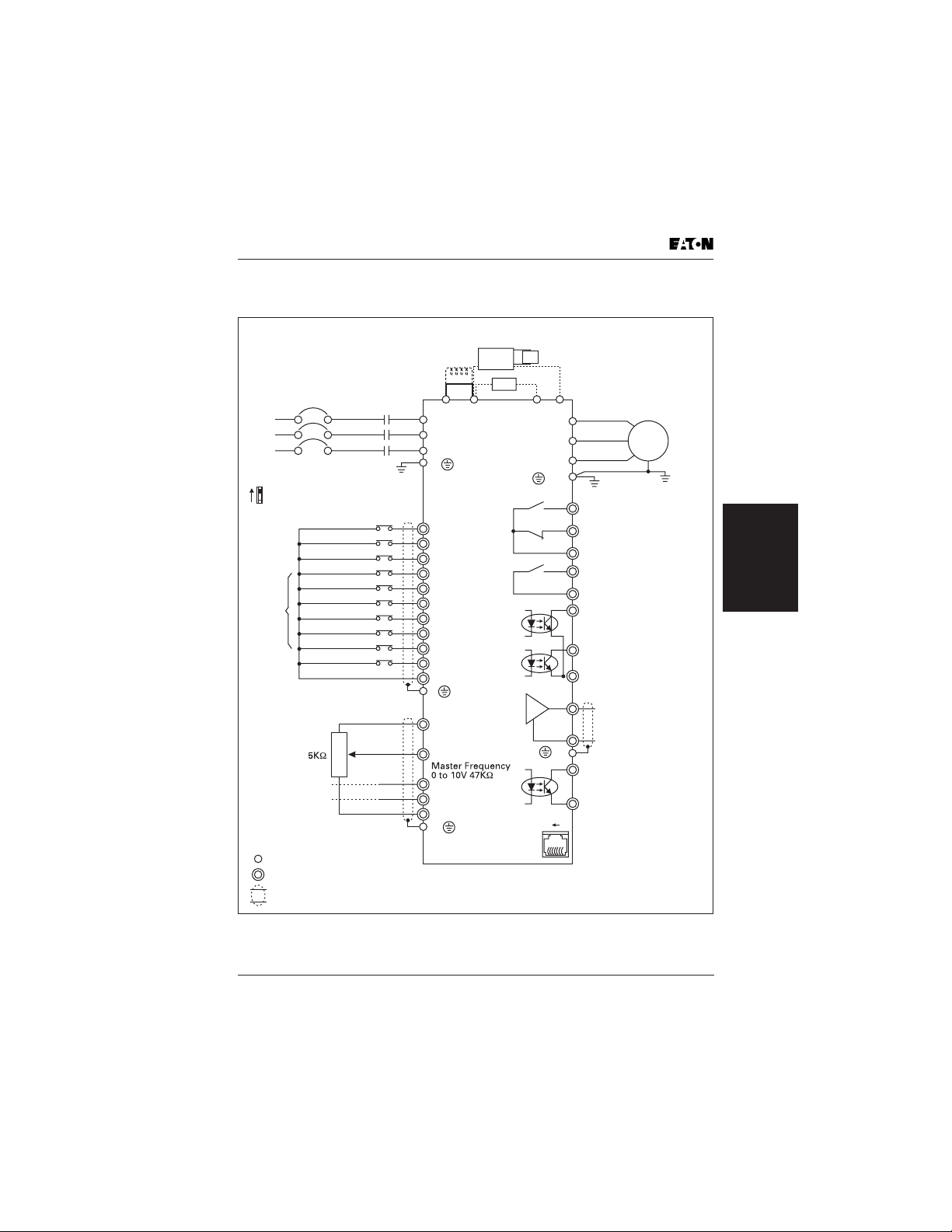

Figure 3-2: Wiring Diagram — 1 – 5 hp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

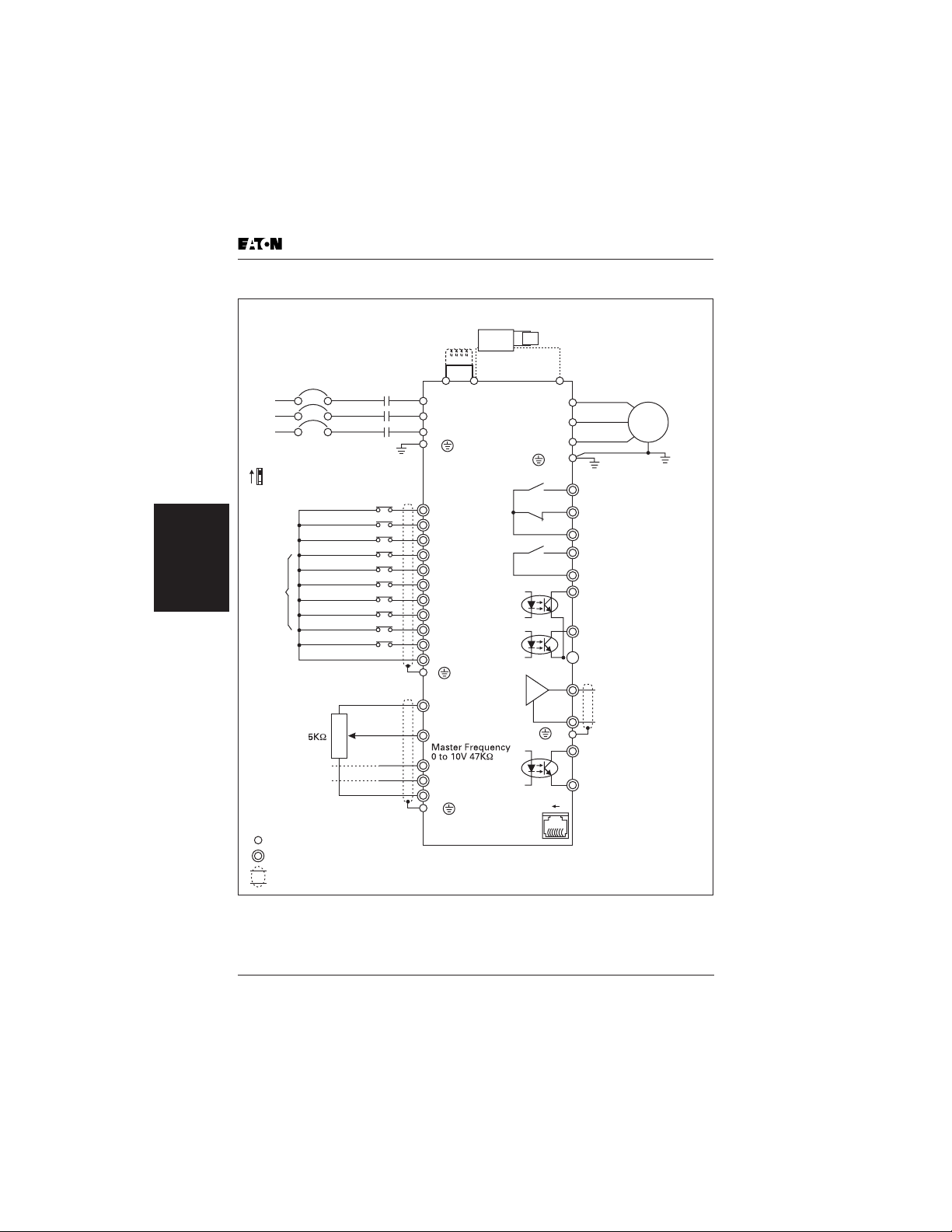

Figure 3-3: Wiring Diagram — 7-1/2 – 100 hp . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Figure 3-4: Wiring Diagram — Sink and Source Modes . . . . . . . . . . . . . . . . . . 3-7

Figure 3-5: External Wiring — 1 – 15 hp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Figure 3-6: External Wiring — 20 – 100 hp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Figure 3-7: Control Terminal Wiring (Sink Mode) . . . . . . . . . . . . . . . . . . . . . . .3-10

Figure 3-8: Control Terminal Wiring (Source Mode) . . . . . . . . . . . . . . . . . . . . . 3-10

Figure 3-9: Main Circuit — 1 to 5 hp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Figure 3-10: Main Circuit — 7-1/2 to 15 hp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Figure 3-11: Main Circuit — 20 to 30 hp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Figure 3-12: Main Circuit — 40 to 50 hp, 460V . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Figure 3-13: Main Circuit — 40 to 50 hp, 230V; 60 to 100 hp, 460V . . . . . . . . . 3-15

Figure 3-14: Parallel Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Figure 4-1: Clearances and Air Flow in Inches (mm) . . . . . . . . . . . . . . . . . . . . . 4-3

Figure 5-1: Page Groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Figure 5-2: Parameter Groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Figure 5-3: Parameter Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Figure 5-4: Scrolling Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Figure 5-5: Programming Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Figure 5-6: Parameter Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Figure 5-7: D1 and D2 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Figure 5-8: Digital Input Terminal Settings 01, 02 . . . . . . . . . . . . . . . . . . . . . . . 5-11

Figure 5-9: Digital Input Terminal Settings 03, 04 . . . . . . . . . . . . . . . . . . . . . . . 5-12

Figure 5-10: Digital Input Terminal Settings 05, 06, 07, 08 . . . . . . . . . . . . . . . . 5-13

Figure 5-11: Digital Input Terminal Setting 09 . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Figure 5-12: Digital Input Terminal Settings 10, 11 . . . . . . . . . . . . . . . . . . . . . . 5-14

Figure 5-13: Digital Input Terminal Settings 12, 13, 14 . . . . . . . . . . . . . . . . . . . 5-14

Figure 5-14: Digital Input Terminal Settings 15, 16 . . . . . . . . . . . . . . . . . . . . . . 5-15

Figure 5-15: Digital Input Terminal Setting 17 . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Figure 5-16: Digital Input Terminal Setting 18 . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Figure 5-17: Digital Input Terminal Setting 19 . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Figure 5-18: Digital Input Terminal Setting 20 . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Figure 5-19: Digital Input Terminal Settings 21, 22 . . . . . . . . . . . . . . . . . . . . . . 5-17

Figure 5-20: Digital Input Terminal Setting 23 . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

Figure 5-21: Digital Input Terminal Setting 24 . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Figure 5-22: Digital Input Terminal Setting 25 . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

vi GVX9000 User Manual

Table of Contents

Figure 5-23: Digital Input Terminal Settings 26, 27, 28 . . . . . . . . . . . . . . . . . . . 5-19

Figure 5-24: Digital Input Terminal Settings 29, 30 . . . . . . . . . . . . . . . . . . . . . . 5-19

Figure 5-25: Digital Input Terminal Setting 31 . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Figure 5-26: Digital Input Terminal Setting 32 . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Figure 5-27: Digital Input Terminal Settings 33, 34 . . . . . . . . . . . . . . . . . . . . . . 5-20

Figure 5-28: Desired Freq. Attained & Preset Freq. Attained . . . . . . . . . . . . . . 5-28

Figure 5-29: GVX Digital Output Option 33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-29

Figure 5-30: Stop Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-32

Figure 5-31: V/F Curve Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-35

Figure 5-32: Acceleration and Deceleration Times . . . . . . . . . . . . . . . . . . . . . . 5-38

Figure 5-33: S-Curve Effects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-40

Figure 5-34: Jog Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-41

Figure 5-35: Power Loss Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-42

Figure 5-36: Skip Frequency Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-44

Figure 5-37: Sleep Time Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-47

Figure 5-38: Auxiliary Motor Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-48

Figure 5-39: DC Braking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-51

Figure 5-40: Over-Voltage Stall Prevention . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-55

Figure 5-41: Over-Current Stall Prevention . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-56

Figure 5-42: I

2

t Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-58

Figure 5-43: Output Voltage Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-59

Figure C-1: GBM2022, GBM4045, GBM5055 Braking Unit . . . . . . . . . . . . . . . . C-6

Figure C-2: Approximate Dimensions in Inches (mm) — RF022B21BA /

RF037B43BA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-10

Figure C-3: Approximate Dimensions in Inches (mm) — RF110B43CA . . . . . . C-11

Figure C-4: Approximate Dimensions in Inches (mm) — 26TDT1W4C . . . . . . C-12

Figure C-5: Approximate Dimensions in Inches (mm) — 50TDS4W4C . . . . . . C-13

Figure C-6: Approximate Dimensions in Inches (mm) — 100TDS84C . . . . . . . C-14

Figure C-7: Approximate Dimensions in Inches (mm) — 150TDS84C . . . . . . . C-15

Figure C-8: Approximate Dimensions in Inches (mm) — 180TDS84C . . . . . . . C-16

Figure C-9: Approximate Dimensions in Inches (mm) — 20TDT1W4C . . . . . . C-17

Figure C-10: Approximate Dimensions in Inches (mm) — 200TDDS84C . . . . C-18

Figure C-11: Approximate Kit Dimensions in Inches (mm) . . . . . . . . . . . . . . . . C-19

Figure D-1: Digital Keypad — Approximate Dimensions in Inches (mm) . . . . D-2

Figure D-2: 1 – 5 hp — Approximate Dimensions in Inches (mm) . . . . . . . . . . D-3

Figure D-3: 7-1/2 – 15 hp — Approximate Dimensions in Inches (mm) . . . . . . D-4

Figure D-4: 20 – 30 hp — Approximate Dimensions in Inches (mm) . . . . . . . . D-5

Figure D-5: 40 – 100 hp — Approximate Dimensions in Inches (mm) . . . . . . . D-6

GVX9000 User Manual vii

Table of Contents

List of Tables

Table 2-1: GVX9000 Catalog Numbering System . . . . . . . . . . . . . . . . . . . . . . . 2-3

Table 2-2: Keypad Operators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Table 3-1: Wiring Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Table 3-2: Terminal Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

Table 3-3: Wire Gauge and Torque Tightening . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

Table 4-1: Wire Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Table 4-2: Fuse Specification Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Table 4-3: Heat Loss Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Table 5-1: Carrier Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-52

Table 7-1: Common Problems and Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Table 7-2: Warning Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-5

Table A-1: GVX9000 230V Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Table A-2: GVX9000 460V Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Table A-3: GVX9000 575V Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Table A-4: General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Table B-1: 20 — Easy Mode Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Table B-2: 30 — Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Table B-3: 40 — Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Table B-4: 50 — AC Drive Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

Table B-5: 60 — Motor Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-13

Table B-6: 70 — Protective Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-14

Table B-7: 80 — Keypad / Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-16

Table B-8: 90 — Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-20

Table C-1: Fuse Specifications — 230V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-2

Table C-2: Fuse Specifications — 460V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-2

Table C-3: Wiring Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-3

Table C-4: Braking Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-4

Table C-5: Braking Unit Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-7

Table C-6: Approximate Dimensions for Braking Resistors . . . . . . . . . . . . . . . C-8

Table C-7: EMI Filter Cross-Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-9

Table E-1: 00 — Factory Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-2

Table E-2: 01 — Basic V/F Curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-2

Table E-3: 02 — PID Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-3

Table E-4: 03 — Preset Speeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-4

Table E-5: 04 — Local/Remote . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-6

Table E-6: 05 — Hand Off Auto (HOA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-7

Table E-7: 06 — Variable Torque (Pump/Fan) . . . . . . . . . . . . . . . . . . . . . . . . . . .E-8

Table E-8: 07 — Spindle Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-9

Table E-9: 08 — Analog Speed Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-10

Table E-10: 09 — Closed Loop Vector Control . . . . . . . . . . . . . . . . . . . . . . . . . . E-11

viii GVX9000 User Manual

Safety Messages

Safety Messages

Definitions and Symbols

A safety instruction (message) includes a hazard alert symbol and a signal word,

WARNING or CAUTION. Each signal word has the following meaning:

HIGH VOLTAGE: This symbol indicates high voltage. It calls your

attention to items or operations that could be dangerous to you and

other persons operating this equipment. Read the message and follow

the instructions carefully.

This symbol is the “Safety Alert Symbol.” It occurs with either of two

signal words: CAUTION or WARNING, as described below.

WARNING: Indicates a potentially hazardous situation which, if not

avoided, can result in serious injury or death.

CAUTION: Indicates a potentially hazardous situation which, if not

avoided, can result in minor to moderate injury, or serious damage to

the product. The situation described in the CAUTION may, if not

avoided, lead to serious results. Important safety measures are

described in CAUTION (as well as WARNING).

Hazardous High Voltage

HIGH VOLTAGE!

Motor control equipment and electronic controllers are connected to

hazardous line voltages. When servicing drives and electronic

controllers, there may be exposed components with housings or

protrusions at or above line potential. Extreme care should be taken to

protect against shock.

Stand on an insulating pad and make it a habit to use only one hand

when checking components. Always work with another person in case

an emergency occurs. Disconnect power before checking controllers or

performing maintenance. Be sure equipment is properly grounded.

Wear safety glasses whenever working on electronic controllers or

rotating machinery.

GVX9000 User Manual ix

High Voltage, Warnings and Cautions

High Voltage

HIGH VOLTAGE!

Before opening the AC drive covers:

•

Disconnect all power to the AC drive.

Wait five minutes for DC bus capacitors discharge.

HIGH VOLTAGE!

Be sure to ground the unit. Otherwise, there is danger of electric shock

and/or fire.

Safety Messages

Warnings

HIGH VOLTAGE!

Wiring work shall be carried out only by qualified personnel.

Otherwise, there is a danger of electric shock or fire.

WARNING!

Make sure that all screws are tightened to the proper torque rating

shown in Table 3-3.

WARNING!

This equipment should be installed, adjusted, and serviced by qualified

electrical maintenance personnel familiar with the construction and

operation of the equipment and the hazards involved. Failure to

observe this precaution could result in bodily injury.

WARNING!

Use 75ºC Cu wire only or equivalent.

WARNING!

The rated voltage for AC motor drive must be equal or less than

240V (equal or less than 480V for 460V models, equal or less than

600V for 575V models) and the mains supply current capacity must

be equal or less than 5000A RMS (equal or less than 10000A RMS

for the 40 hp [30 kW] models).

WARNING!

Disconnect AC power before proceeding!

x GVX9000 User Manual

Safety Messages

Cautions

CAUTION!

When mounting in an enclosure, allow for the recommended free

space. Failure to allow adequate air flow may result in drive over

temperature.

CAUTION!

Do not connect the AC power to the T1, T2, T3 terminals, it will

damage the AC drive.

CAUTION!

Be sure to install the unit on flame-resistant material such as a steel

plate. Otherwise, there is the danger of fire.

CAUTION!

Be sure to install the unit on a perpendicular wall which is not subject

to vibration. Otherwise, it may fall and cause injury to personnel.

CAUTION!

Be sure not to let the foreign matter enter vent openings in the

inverter housing, such as wire clippings, spatter from welding, metal

shavings, dust, etc. Otherwise, there is the danger of fire.

CAUTION!

Be sure not to install or operate an inverter which is damaged or has

missing parts. Otherwise, it may cause injury to personnel.

CAUTION!

Be sure to install the inverter in a well-ventilated room which does not

have direct exposure to sunlight, a tendency for high temperature,

high humidity or dew condensation, high levels of dust, corrosive gas,

explosive gas, inflammable gas, grinding-fluid mist, salt damage, etc.

Otherwise, there is the danger of fire.

CAUTION!

Be sure that the input voltage matches the inverter specifications:

•

Single-/Three-phase 200 to 240V 50/60 Hz (up to 2.2 kW)

•

Three-phase 200 to 230V 50/60 Hz (above 2.2 kW)

•

Three-phase 380 to 460V 50/60 Hz

•

Three-phase 500 to 600V 50/60 Hz

GVX9000 User Manual xi

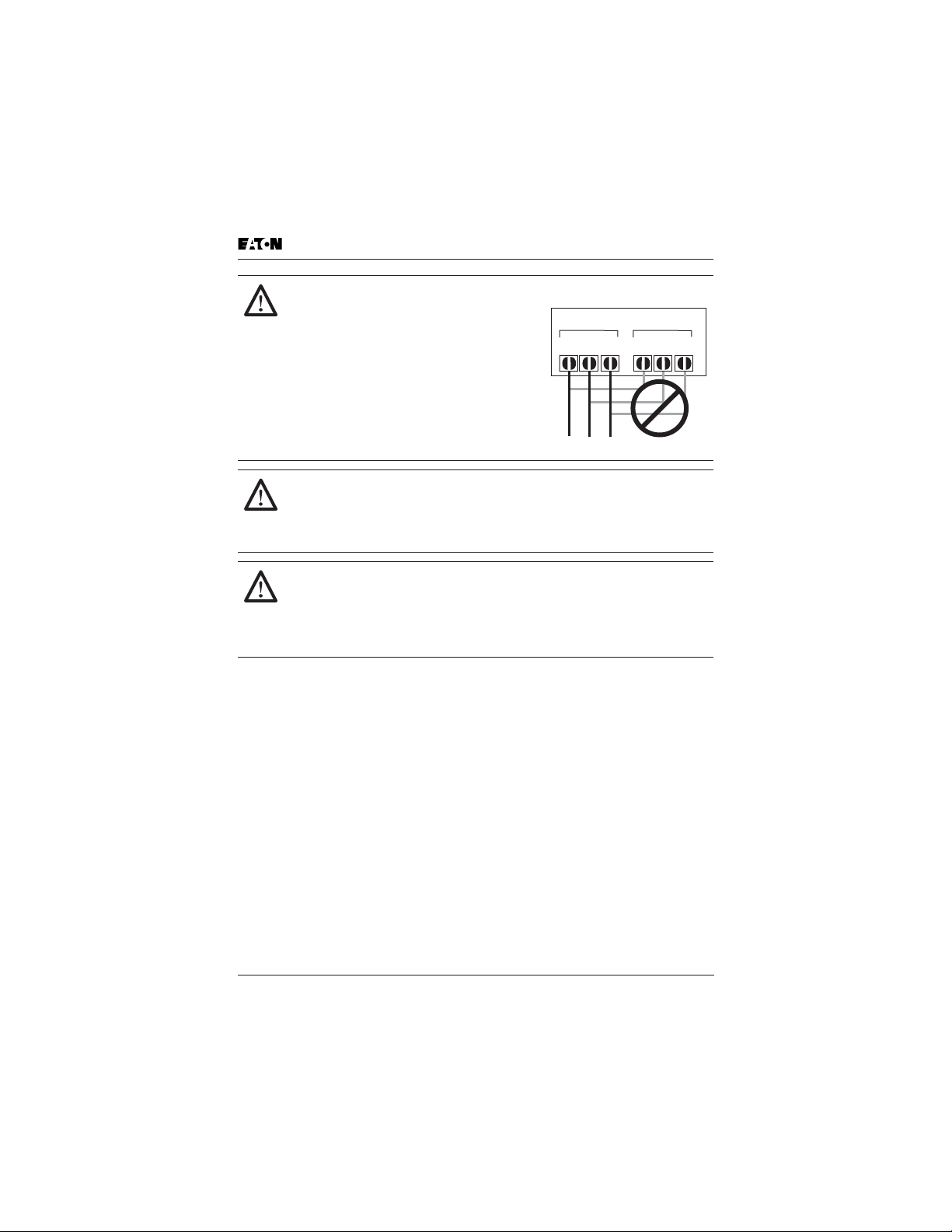

CAUTION!

Be sure not to connect an AC power supply

to the output terminals. Otherwise, there is

the danger of injury and/or fire.

Note:

L1, L2, L3: Three-phase 200 to 230V 50/60 Hz

Three-phase 380 to 460V 50/60 Hz

Three-phase 500 to 600V 50/60 Hz

Any two inputs:

Single-phase 200 to 240V 50/60 Hz

Power Input

L3L2L1

Safety Messages

Power Output

T3

T2T1

CAUTION!

The operation of the inverter can be easily changed from low speed to

high speed. Be sure to check the capability and limitations of the

motor and machine before operating the inverter. Otherwise, there is

the danger of injury.

CAUTION!

If you operate a motor at a frequency higher than the inverter standard

default setting (50 Hz/60 Hz), be sure to check the motor and machine

specifications with the respective manufacturer. Only operate the

motor at elevated frequencies after getting their approval. Otherwise,

there is the danger of equipment damage.

xii GVX9000 User Manual

Chapter 1

Introduction

Inside this chapter …

How to Use This Manual . . . . . . . . . . . . . . . . . . . . . . 1-2

Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Conventions Used in This Manual . . . . . . . . . . . . . . . 1-3

Warranty and Liability Information . . . . . . . . . . . . . . 1-4

Related Publications . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Introduction

GVX9000 User Manual 1-1

How to Use This Manual

This chapter describes the purpose and contents of this manual and the intended

audience. This chapter also explains conventions used in this manual and lists

related publications.

How to Use This Manual

Introduction

The purpose of this manual is to provide you with information necessary to

install, set parameters, troubleshoot and maintain the Eaton GVX9000 Adjustable

Frequency Drives from Eaton’s electrical business. To guarantee safe operation of

the equipment, read the safety guidelines at the beginning of this manual before

connecting power to the AC motor drives. Keep this operating manual handy and

distribute to all users for reference.

Chapter 1 — Introduction is the chapter you are reading now.

Chapter 2 — Overview of the GVX9000 Drive describes receiving and inspection

procedures and provides an introduction to digital keypad operation.

Chapter 3 — Storage and Installation describes planning for drive installation

and drive mounting. This chapter also includes requirements and connections for

wiring.

Chapter 4 — Start-Up Procedures provides a detailed explanation of digital

keypad operation.

Chapter 5 — Descriptions of Parameter Settings provides detailed explanations

for all parameter settings.

Chapter 6 — Maintenance and Inspection describes maintenance procedures.

Chapter 7 — Troubleshooting and Fault Information lists the fault displays,

descriptions, and corrective actions.

Appendix A — Technical Data lists standard specifications.

Appendix B — Parameter Tables provides listing of all parameters with

descriptions, ranges and defaults.

Appendix C — Accessories provides information about circuit breakers, fuses,

braking resistors, and other accessories for the Eaton GVX9000 Drives.

Appendix D — Dimensions displays keypad and drive dimensions.

Appendix E

— is a Declaration of Conformity.

1-2 GVX9000 User Manual

Intended Audience

Intended Audience

The audience for this manual has:

•

Knowledge of standard electrical wiring practices, electronic components,

and electrical schematic symbols.

The audience for this manual will install, start-up, and service the Eaton GVX9000

Drives.

Conventions Used in This Manual

Listed below are terms and language conventions used in this manual. These

terms and conventions are defined here to help you understand their meanings

and applications throughout this manual.

Digital Keypad Display

The Digital Keypad display is an LCD readout of drive parameter selections and

drive operation status. Letters or numbers appear in the display according to

which keys you press.

Digital Keypad Keys

Digital Keypad keys are flat, labeled, pushbutton-type devices that allow you to

select drive parameters, and monitor drive operation.

Parameter

A parameter is selected through the Digital Keypad. Parameters in this manual

are expressed as Parameter Group Number, a decimal (.), and a Parameter

number.

Press

Press a key on the Digital Keypad Control Panel to select a parameter. Refer to

Chapter 2 — Overview of the GVX9000 Drive, Digital Keypad Operation.

Introduction

GVX9000 User Manual 1-3

Warranty and Liability Information

Warranty and Liability Information

Eaton Electrical Inc. warrants the product delivered in the Cutler-Hammer

shipping package to be free from defects in material and workmanship, under

normal use and service, for twenty four (24) months from date of manufacturing.

Products that fail during this period will be repaired or replaced at Eaton’s

Introduction

discretion, with the same or a functionally equivalent product, provided the

original purchaser (A) returns the failed product, and (B) provides proof of

original date of purchase. This warranty does not apply, in the judgment of

Eaton, to damage caused during shipment, handling, storage, or accidental

misuse. The original purchaser of the product must obtain a Cutler-Hammer

Return Material Authorization (RMA) number prior to returning any defective

product. (When purchased through an Authorized Distributor, the Distributor

should supply an RMA number to their customer.)

The maximum liability of this warranty is limited to the purchase price of the

product. In no event, regardless of cause, shall Eaton Electrical Inc. be liable (a)

for penalties or penalty clauses of any description, or (b) for certification not

otherwise specifically provided herein and/or indemnification of purchaser or

others for costs, damages or expenses, each arising out of or related to the

product or services of any order or (c) for any damages resulting from loss of

profits, use of products or for any incidental indirect or consequential damages,

even if advised of the possibility of such damages.

Related Publications

Brochure (Publication Numbers: BR04002001E)

Technical Document (Publication Numbers: TD04002001E)

Manual (Publication Number: TD04002003E)

Contact Name, Number:

Eaton Electrical Inc.

1000 Cherrington Parkway

Moon Township, PA 15108-4312

Tel: 1-800-525-2000

www.EatonElectrical.com

1-4 GVX9000 User Manual

Chapter 2

Overview of the GVX9000 Drive

Inside this chapter …

Receiving and Inspection . . . . . . . . . . . . . . . . . . . . . . 2-2

Nameplate Information . . . . . . . . . . . . . . . . . . . . . 2-2

Catalog Number . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Style Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

External Parts and Label Locations . . . . . . . . . . . . . . 2-4

Digital Keypad Operation . . . . . . . . . . . . . . . . . . . . . . 2-5

Overview of the

GVX9000 Drive

GVX9000 User Manual 2-1

Receiving and Inspection

Receiving and Inspection

This GVX9000 AC drive has gone through quality control tests at the factory before

shipment. After receiving the AC motor drive, please check for the following:

•

Check to make sure that the package includes an AC drive and User Manual.

•

Inspect the unit to insure it was not damaged during shipment.

•

Make sure that the part number indicated on the nameplate corresponds with

the part number of your order.

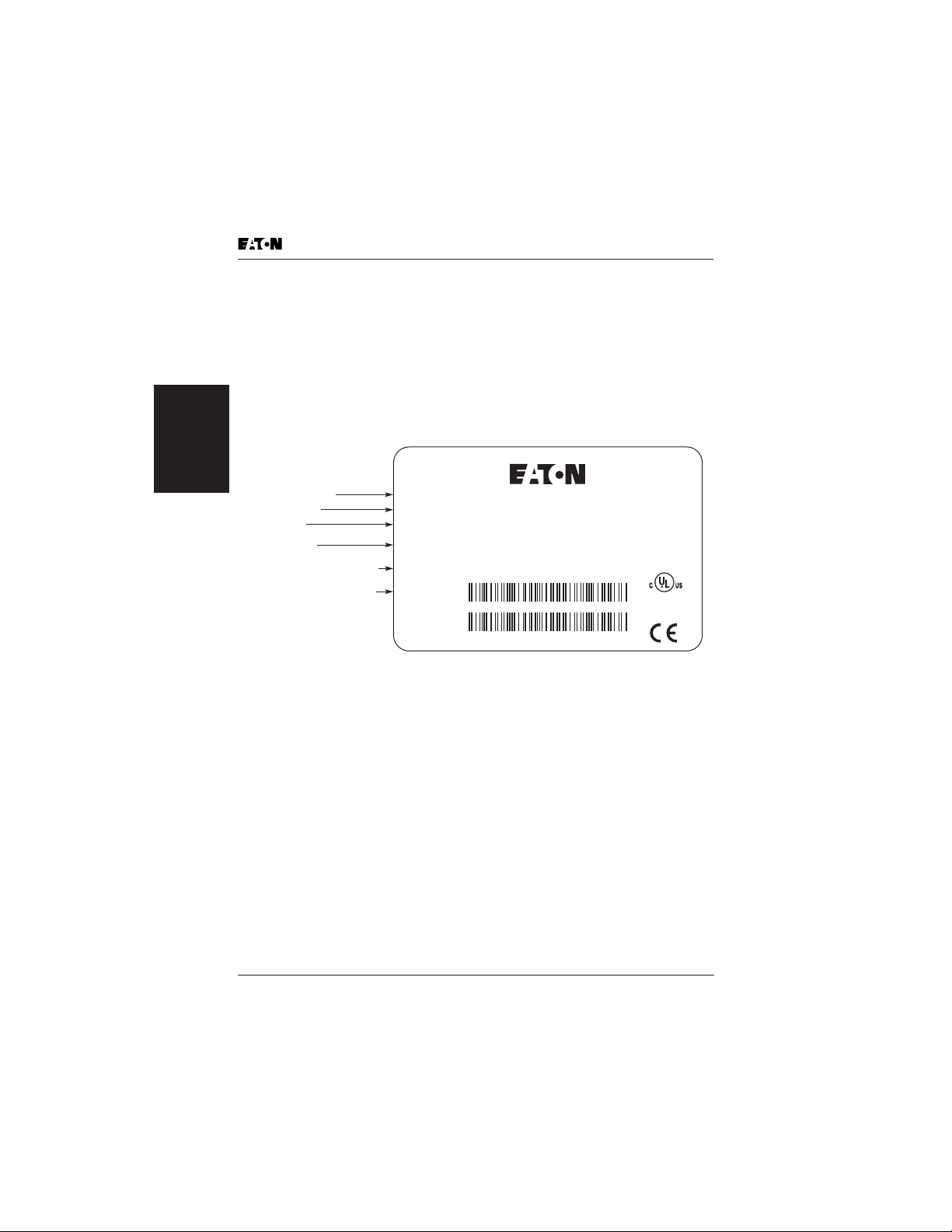

Nameplate Information

GVX9000 Drive

Overview of the

Catalog Number

Style Number

Input Spec.

Output Spec.

Output Frequency Range

Serial Number Bar Code

Cat. No. :

Style No. :

Input :

Output :

GVX005A1-2

200-240Vac, 50-60Hz, 3ph, 20.6A

CT: 0-240Vac, 3PH, 17A, 5HP

VT: 0-240Vac, 3PH, 17A, 5HP

Frequency Range : 0.1-400Hz Output

7 82116 97861 8

MADE IN XXXXXX

G005A120T6160001

Figure 2-1: Example of 5 hp 230V AC drive

LISTED

Ind. Cont. Eq.

19XK

2-2 GVX9000 User Manual

Receiving and Inspection

Catalog Number

Table 2-1: GVX9000 Catalog Numbering System

G V X 0 0 1 A1 -2

Model Number

Motor Horsepower

001 = 1 hp (0.7 kW)

002 = 2 hp (1.5 kW)

003 = 3 hp (2.2 kW)

005 = 5 hp (3.7 kW)

007 = 7-1/2 hp (5.5 kW)

010 = 10 hp (7.5 kW)

015 = 15 hp (11 kW)

020 = 20 hp (15 kW)

025 = 25 hp (18.5 kW)

030 = 30 hp (22 kW)

040 = 40 hp (30 kW)

050 = 50 hp (37 kW)

060 = 60 hp (45 kW)

075 = 75 hp (55 kW)

100 = 100 hp (75 kW)

2 = 230V AC

4 = 460V AC

5 = 575V AC

Enclosure

Version Type

Voltage

Overview of the

GVX9000 Drive

GVX9000 User Manual 2-3

External Parts and Label Locations

Style Number

The style number contains the same information as the Catalog Number, and is

used internally for ordering purposes.

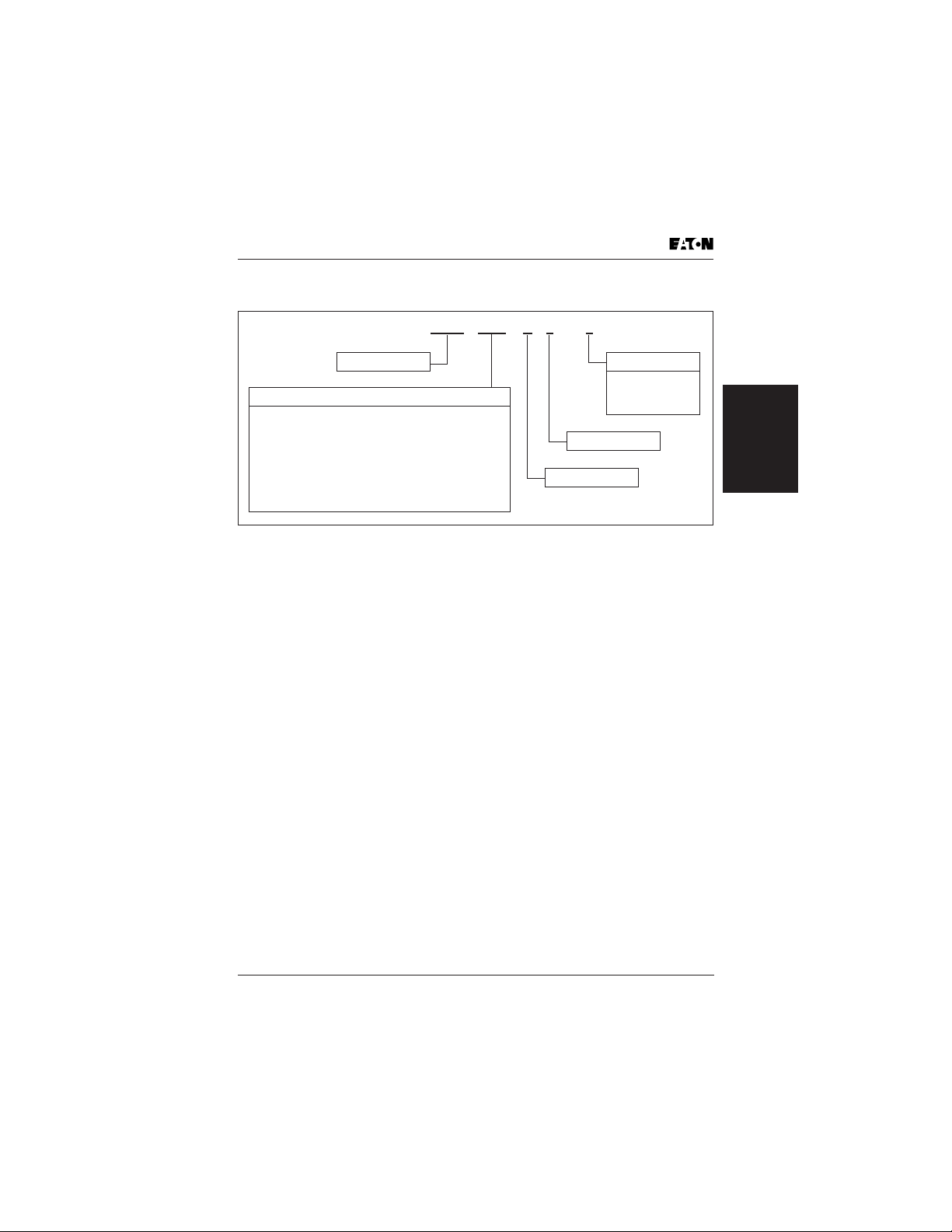

External Parts and Label Locations

GVX9000 Drive

Overview of the

RUN

STOP

FWD

REV

LO

FWD

C

REV

LOC

REM

+2

R/L1+1S/L2 T/L3

U/T1 V/T2 W/T3

-

2

B

B

1

Screw Torque :

18Kgf-cm

Wire Gauge :

18~10AWG

Figure 2-2: Parts and Label

2-4 GVX9000 User Manual

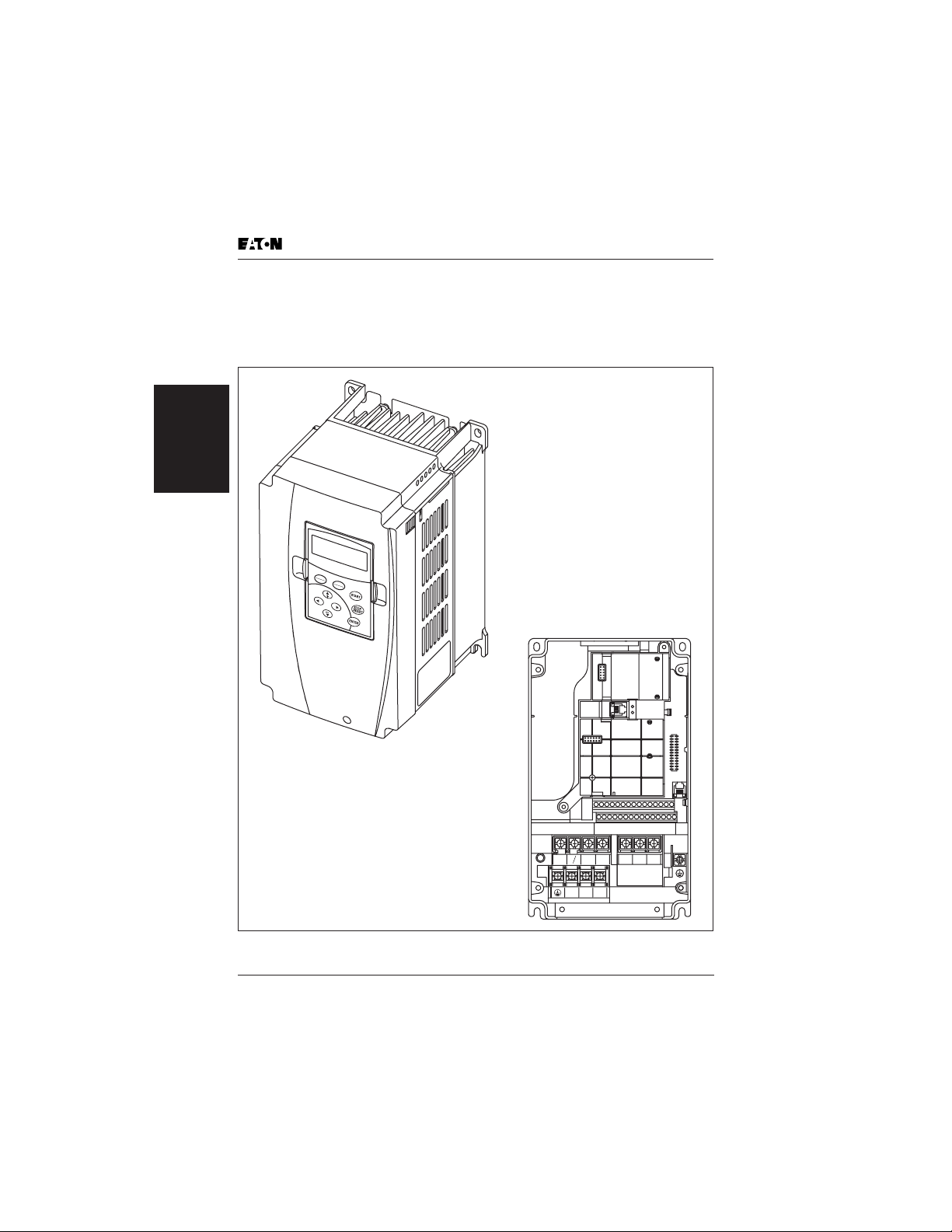

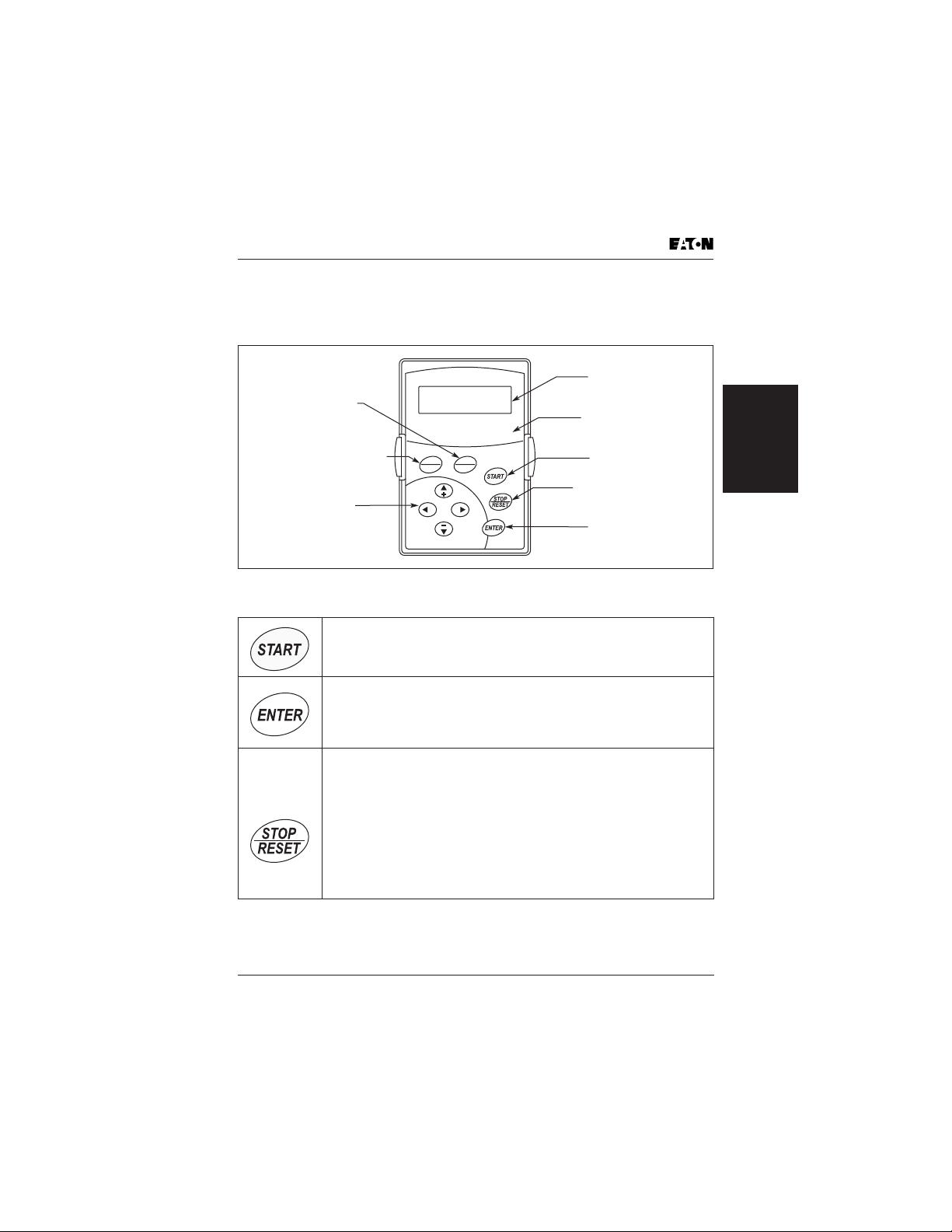

Digital Keypad Operation

Digital Keypad Operation

The digital keypad includes the display panel and the keypad. The display panel

provides the parameter display and shows the operation status of the AC drive.

The keypad provides programming and control interface.

LCD Display

Indicates Motor and

LOC REM Key

Switches the Control

from Local Control Source

to Remote Control Source

FORWARD REVERSE Key

Up, Down and

Right/Left Keys

Scrolls Display,

Enter/Exit Parameter Mode,

Change Parameter Settings

Figure 2-3: Description of Digital Keypad

Table 2-2: Keypad Operators

START

This button operates as Start button for normal operation

• Motor START from the panel; active control place has to be

selected at “Panel”

ENTER

This button in the parameter edit mode is used to enter the

programming mode and enter the parameter selection.

• used for parameter edit confirmation, acceptance (confirmation)

of the edited parameter value with exit from parameter edit mode

STOP / RESET

This button has two integrated operations. The button operates as

Stop button for normal operation. In the parameter edit mode it is

used to cancel previous action and back-up one step, and in fault

mode it is used to reset the fault.

STOP

• motor STOP from the panel; active control place has to be

selected at “Panel”

RESET

• used to reset an Active Fault on the drive and shown in the

display

RUN STOP FWD REV LOC

LOC

FWD

REM

REV

Drive Parameter

LED Indicators

Lamp Lights During Run,

Stop, Fwd, Rev, Loc Operations

START Key

Start Command

STOP/RESET Key

Stop Command and Reset

the Drive After a Fault Occurs

ENTER Key

Used in Parameter Mode

to Enter and Change Values

Overview of the

GVX9000 Drive

GVX9000 User Manual 2-5

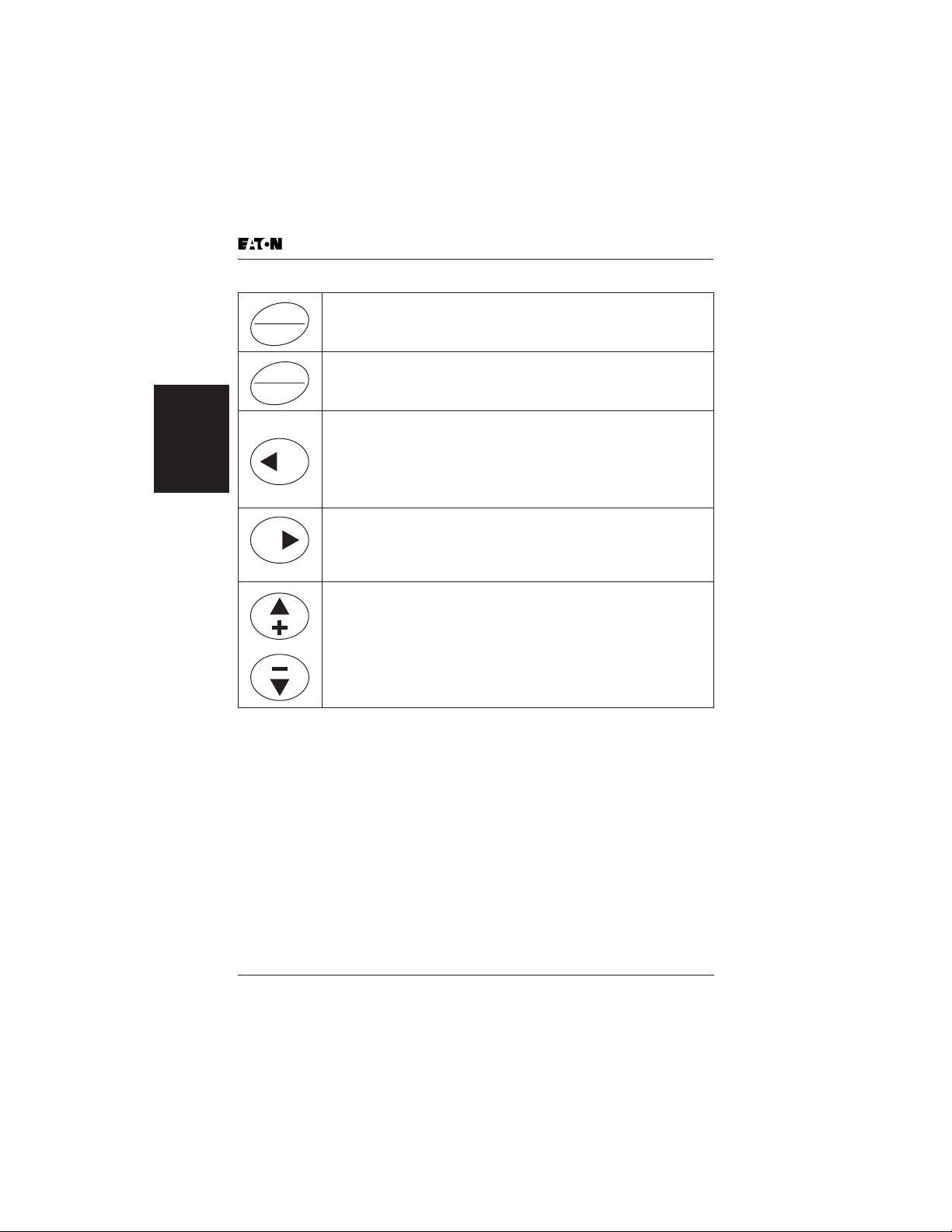

Table 2-2. Keypad Operators (Continued)

This button switches the Control Location from the Local Source to

LOC

the Remote Source.

REM

This button changes the direction of the motor connected to the

FWD

GVX9000 drive.

REV

LEFT Arrow

• navigation button, movement to left

• in display mode, enter parameter group mode

GVX9000 Drive

Overview of the

• in parameter edit mode, exits mode, backs up one step

• cancels edited parameter (exit from a parameter edit mode)

RIGHT Arrow

• navigation button, movement to right

• enter parameter group mode

• enter parameter mode from group mode

• Changes the cursor location when entering data into a parameter

UP and DOWN Arrows

• move either up or down the group list in order to select the

desired group menu.

• move either up or down the parameter list in order to select the

desired parameter in the group.

• increasing/decreasing of reference value on the keyboard (when

selected).

Digital Keypad Operation

2-6 GVX9000 User Manual

Chapter 3

Storage and Installation

Inside this chapter …

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Transportation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Pollution Degree . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Mounting Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Applicable Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Basic Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

External Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Control Terminal Wiring (Factory Settings) . . . . . . . . 3-10

Main Circuit Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Wiring Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Motor Operation Precautions . . . . . . . . . . . . . . . . . . 3-18

Storage and

Installation

GVX9000 User Manual 3-1

Storage

The AC drive should be stored in the shipping carton before installation. In order

to retain the warranty coverage, the AC drive should be stored properly when it is

not to be used for an extended period of time. Some storage suggestions are:

• Store in a clean and dry location free from direct sunlight or corrosive fumes.

• Store within an ambient temperature range of -20 to +60°C.

• Store within a relative humidity range of 0 to 90% and non-condensing

environment.

• Store within an air pressure range of 86 to 106 kPA.

Environment

Operation

Air Temperature: 1 hp – 100 hp -10 to +50°C (14 to 122°F)

Relative Humidity: 0% to 90%, no condensation allowed

Atmosphere Pressure: 86 to 106 kPa

Installation Site Altitude: below 1000m

Vibration: Maximum 9.80 m/s2 (1G) at less than 20 Hz

Installation

Storage and

Storage

Temperature: -20 to +60°C (-4 to 140°F)

Relative Humidity: Less than 90%, no condensation allowed

Atmosphere Pressure: 86 to 106 kPa

Maximum 5.88 m/s2 (0.6G) at 20 to 50 Hz

Storage

Transportation

Temperature: -20 to +60°C (-4 to 140°F)

Relative Humidity: Less than 90%, no condensation allowed

Atmosphere Pressure: 86 to 106 kPa

Vibration: Maximum 9.80 m/s2 (1G) at less than 20 Hz,

Maximum 5.88 m/s2 (0.6G) at 20 to 50 Hz

Pollution Degree

UL Type 0, Pollution Degree 2: good for a factory type environment

Relative Humidity: Less than 90%, no condensation allowed

Atmosphere Pressure: 86 to 106 kPa

3-2 GVX9000 User Manual

Mounting Area

Mounting Area

Improper installation of the AC drive will greatly reduce its life. Be sure to

observe the following precautions when selecting a mounting location. Failure to

observe these precautions may void the warranty!

Do not mount the AC drive near heat-radiating elements or in direct sunlight.

Do not install the AC drive in a place subjected to high temperature, high

humidity, excessive vibration, corrosive gases or liquids, or airborne dust or

metallic particles.

Mount the AC drive vertically and do not restrict the air flow to the heatsink fins.

The AC drive generates heat. Allow sufficient space around the unit for heat

dissipation as shown in Figure 3-1.

2.0 (50)

or More

5.9 (150)

or More

RUN STOP FWD REV LOC

LOC

FWD

REM

REV

GVX9000

Sensorless Vector

!

WARNING

HIGH VOLTAGE!

WAIT AT LEASTS 10 MINUTES BEFORE OPENING.

SEE USER’S MANUAL FOR OPERATION.

2.0 (50)

or More

Air Flow

Storage and

Installation

5.9 (150)

or More

Figure 3-1: Mounting in an Enclosure in Inches (mm)

CAUTION!

When mounting in an enclosure, allow for the recommended free

space. Failure to allow adequate air flow may result in drive over

temperature.

GVX9000 User Manual 3-3

Wiring

HIGH VOLTAGE!

Before opening the AC drive covers:

• Disconnect all power to the AC drive.

Wait five minutes for DC bus capacitors discharge.

Any electrical or mechanical modification to this equipment without prior

written consent of Eaton will void all warranties and may result in a safety

hazard in addition to voiding the UL listing.

Short Circuit Withstand: The rated voltage for AC motor drive must be equal or

less than 240V (equal or less than 480V for 460V models, equal or less than 600V

for 575V models) and the mains supply current capacity must be equal or less

than 5000A RMS (equal or less than 10000A RMS for the 40 hp [30 kW] models).

Applicable Codes

All Eaton GVX9000 AC drives are Underwriters Laboratories, Inc. (UL) and Canadian

Underwriters Laboratories (cUL) listed, and therefore comply with the requirements

of the National Electrical Code (NEC) and the Canadian Electrical Code (CEC).

Installation intended to meet the UL and cUL requirements must follow the

instructions provided in “Wiring Notes” as a minimum standard. Follow all local

Installation

Storage and

codes that exceed UL and cUL requirements. Refer to the technical data label

affixed to the AC drive and the motor nameplate for electrical data.

The “Line Fuse Specification” in Appendix C lists the recommended fuse part

number for each GVX9000 part number. These fuses (or equivalent) must be

used on all installations where compliance with UL standards is required.

According to the Low Voltage Directive 73/23/EEC and the Amendment Directive

93/68/EEC Digital Keypad, the following AC Motor Drives, GVX001A1-2, GVX002A1-2,

GVX003A1-2, GVX005A1-2, GVX007A1-2, GVX010A1-2, GVX015A1-2, GVX020A1-2,

GVX025A1-2, GVX030A1-2, GVX040A1-2, GVX050A1-2, GVX001A1-4, GVX002A1-4,

GVX003A1-4, GVX005A1-4, GVX007A1-4, GVX010A1-4, GVX015A1-4, GVX020A1-4,

GVX025A1-4, GVX030A1-4, GVX040A1-4, GVX050A1-4, GVX060A1-4, GVX075A1-4,

GVX100A1-4, are herewith confirmed to comply with the requirements set out in the

Council Directive 73/23/EEC for electrical equipment used within certain voltage limits

and the Amendment Directive 93/68/EEC. For the evaluation of the compliance with

this Directive, the following standard was applied: EN 50178.

According to the Electromagnetic Compatibility 89/336/EEC and the Amendment

Directive 93/68/EEC, the following equipment, AC Motor Drive, GVX001A1-2,

GVX002A1-2, GVX003A1-2, GVX005A1-2, GVX007A1-2, GVX010A1-2, GVX015A1-2,

GVX020A1-2, GVX025A1-2, GVX030A1-2, GVX040A1-2, GVX050A1-2, GVX001A1-4,

GVX002A1-4, GVX003A1-4, GVX005A1-4, GVX007A1-4, GVX010A1-4, GVX015A1-4,

GVX020A1-4, GVX025A1-4, GVX030A1-4, GVX040A1-4, GVX050A1-4, GVX060A1-4,

GVX075A1-4, GVX100A1-4, is herewith confirmed to comply with the requirements set

out in the Council Directive 89/336/EEC for electromagnetic compatibility and the

Amendment Directive 93/68/EEC. For the evaluation of the compliance with this

Directive, the following standards were applied: EN61800-3, EN55011, EN50081-2,

EN50082-2, EN61000-4-2, EN61000-4-3, EN61000-4-4, EN61000-4-5, EN61000-4-6,

EN61000-4-8.

Wiring

3-4 GVX9000 User Manual

Basic Wiring Diagram

Basic Wiring Diagram

For Models of GVX9000 Series —

1 to 5 horsepower

Refer to Appendix for the use of Special Braking Resistor/Unit

Fuse/NFB

(None Fuse Breaker)

R(L1)

S(L2)

T(L3)

Factory Setting: SINK Mode

Sink

Refer to Figure 3-4 for

wiring of SINK Mode

Sw1

and SOURCE Mode.

Source

Factory

Setting

* Donít apply the mai ns voltage

directly to above terminals.

RUN/STOP

REV/FWD

Multi-Step 1

Multi-Step 2

Multi-Step 3

Multi-Step 4

Reset

E.F.

Digital Signal Common

3

2

1

4~20mA

-10~+10V

Analog Signal Common

Main Circuit (Power) Terminals

Control Circuit Terminals

Shielded Leads & Cable

Figure 3-2: Wiring Diagram — 1 – 5 hp

Braking Resistor/Unit (Optional)

BR

DC Chock

(Optional)

Jumper

R(L1)

S(L2)

T(L3)

E

+24V

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

COM

E

+10V

Power Supply

+10V 20mA

AI1

AI2

AI3

AE

* Three-phase input power may apply to single-phase drives.

* For the single-phase drives, the AC input line can be

connected to any two of the three input terminals R, S, T.

GBM

BR

B2

DO1

DO2

(minus sign)

DPO

-

U(T1)

V(T2)

W(T3)

E

RA1

RA3

Factory Setting:

Drive Running

RA2

RB1

Factory Setting:

Fault Indication

RB2

48V50mA

Factory Setting:

Warning

Factory Setting: Freq.

Setting I

48V50mA

Digital Output

Common

DOC

AO+

A-

E

Digital Frequency

Output Terminal

Factory Setting: 1:1

Duty=50%

Digital Signal Common

COM

6 1

RS-485

Serial Interface

3: SG4: SG+

Analog Multi-Function

Output Terminal

Factory Default: Analog

Freq./Current Meter

0~10VDC/2mA

Analog Signal Common

+2/B1

+1

Motor

IM

3~

ndication

Storage and

Installation

GVX9000 User Manual 3-5

Basic Wiring Diagram

For Models of GVX9000 Series —

Refer to Appendix for the use of Special Braking Resistor/Unit

Fuse/NFB

(None Fuse Breaker)

R(L1)

S(L2)

T(L3)

Factory Setting: SINK Mode

Sink

Refer to Figure 3-4 for

wiring of SINK Mode

Sw1

and SOURCE Mode.

Source

Installation

Storage and

Factory

Setting

* Don’t apply the mains voltage

directly to above terminals.

RUN/STOP

REV/FWD

Multi-Step 1

Multi-Step 2

Multi-Step 3

Multi-Step 4

Reset

E.F.

Digital Signal Common

3

2

1

4~20mA

-10~+10V

Analog Signal Common

Main Circuit (Power) Terminals

Control Circuit Terminals

Shielded Leads & Cable

Figure 3-3: Wiring Diagram — 7-1/2 – 100 hp

7-1/2 to 100 horsepower

Braking Resistor/Unit (Optional)

BR

DC Chock

(Optional)

Jumper

R(L1)

S(L2)

T(L3)

E

+24V

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

COM

E

+10V

Power Supply

+10V 20mA

AI1

AI2

AI3

AE

* Three-phase input power may apply to single-phase drives.

* For the single-phase drives, the AC input line can be

connected to any two of the three input terminals R, S, T.

GBM

DO1

DO2

(minus sign)

DPO

-

U(T1)

V(T2)

W(T3)

E

RA1

RA3

Factory Setting:

Drive Running

RA2

RB1

Factory Setting:

Fault Indication

RB2

48V50mA

Factory Setting:

Warning

Factory Setting: Freq.

Setting In

48V50mA

Digital Output

Common

DOC

AO+

A-

E

Digital Frequency

Output Terminal

Factory Setting: 1:1

Duty=50%

Digital Signal Common

COM

6 1

RS-485

Serial Interface

3: SG4: SG+

Analog Multi-Function

Output Terminal

Factory Default: Analog

Freq./Current Meter

0~10VDC/2mA

Analog Signal Common

+2

+1

Motor

IM

3~

dication

3-6 GVX9000 User Manual

Loading...

Loading...