Eaton EC4P-221-MTXD1, EC4P-221-MTXX1, EC4P-221-MRXD1, EC4P-221-MRXX1, EC4P-221-MTAD1 User guide

...

User Manual

Programmable Logic Controller

easyControl EC4-200

10/10 MN05003003Z-EN

replaces 01/08 AWB2724-1584GB

All brand and product names are trademarks or registered

trademarks of the owner concerned.

Emergency On Call Service

Please call your local representative:

http://www.eaton.com/moeller/aftersales

or

Hotline After Sales Service:

+49 (0) 180 5 223822 (de, en)

AfterSalesEGBonn@eaton.com

Original Operating Instructions

The German-language edition of this document is the original

operating manual.

Translation of the original operating manual

All editions of this document other than those in German language

are translations of the original German manual.

1

st

edition 2006, edition date 09/06

2

nd

edition 12/06

3

rd

edition 03/07

4

th

edition 01/08

5

th

edition 10/10

See revision protocol in the “About this manual“ chapter

© Eaton Industries GmbH, 53105 Bonn

Author: Peter Roersch

Production: Thomas Kracht, Barbara Petrick

Translation: OneWord

All rights reserved, including those of the translation.

No part of this manual may be reproduced in any form

(printed, photocopy, microfilm or any other process) or processed,

duplicated or distributed by means of electronic systems without

written permission of Eaton Industries GmbH, Bonn.

Subject to alteration without notice.

Danger!

Dangerous electrical voltage!

Before commencing the installation

• Disconnect the power supply of the device.

• Ensure that devices cannot be accidentally restarted.

• Verify isolation from the supply.

• Earth and short circuit.

• Cover or enclose neighbouring units that are live.

• Follow the engineering instructions (AWA) of the

device concerned.

• Only suitably qualified personnel in accordance with

EN 50110-1/-2 (VDE 0105 Part 100) may work on

this device/system.

• Before installation and before touching the device ensure

that you are free of electrostatic charge.

• The functional earth (FE) must be connected to the protective

earth (PE) or to the potential equalisation. The system installer

is responsible for implementing this connection.

• Connecting cables and signal lines should be installed so

that inductive or capacitive interference does not impair the

automation functions.

• Install automation devices and related operating elements in

such a way that they are well protected against unintentional

operation.

• Suitable safety hardware and software measures should be

implemented for the I/O interface so that a line or wire

breakage on the signal side does not result in undefined

states in the automation devices.

• Ensure a reliable electrical isolation of the low voltage for the

24 volt supply. Only use power supply units complying with

IEC 60364-4-41 (VDE 0100 Part 410) or HD 384.4.41 S2.

• Deviations of the mains voltage from the rated value must

not exceed the tolerance limits given in the specifications,

otherwise this may cause malfunction and dangerous

operation.

• Emergency stop devices complying with IEC/EN 60204-1 must

be effective in all operating modes of the automation devices.

Unlatching the emergency-stop devices must not cause restart.

• Devices that are designed for mounting in housings or control

cabinets must only be operated and controlled after they have

been installed with the housing closed. Desktop or portable

units must only be operated and controlled in enclosed

housings.

• Measures should be taken to ensure the proper restart of

programs interrupted after a voltage dip or failure. This should

not cause dangerous operating states even for a short time.

If necessary, emergency-stop devices should be implemented.

• Wherever faults in the automation system may cause

damage to persons or property, external measures must be

implemented to ensure a safe operating state in the event of

a fault or malfunction (for example, by means of separate limit

switches, mechanical interlocks etc.).

Eaton Industries GmbH

Safety instructions

I

II

10/10 MN05003003Z-EN

Contents

About this manual 7

List of revisions 7

Additional documentation 7

Reading conventions 8

1 Device application 9

EC4-200 part number overview 9

2 Setup 11

Inputs 11

– Function and cursor buttons as inputs 12

– Diagnostics inputs 12

– Inputs for high-speed counters 12

Outputs 13

Memory card (MCC) 13

– Memory card data 13

– Data access on the memory card 13

RUN/STOP/SF and CAN/NET LEDs 13

Real-time clock 14

Interfaces 14

– Programming interface for connection to a PC 14

– Multi-function interface (MFI) 14

– Cable connections 15

CAN/easyNet interfaces 16

3 Expansion units 17

Inputs 17

– Diagnostics inputs 17

Outputs 17

4 Mounting 19

Mounting on top-hat rail 19

Mounting on mounting plate 19

5 Installation 21

Connecting the power supply 21

Connecting digital inputs 21

Connecting analog inputs 21

– Setpoint potentiometers connection 22

– Temperature sensor connection 22

– Connecting the 20 mA sensor 22

Connecting a pulse transmitter/incremental encoder 23

– Connecting pulse transmitter 23

– Connecting the incremental encoder 23

Connecting outputs 24

– Connect relay outputs 24

– Connecting transistor outputs 25

– Connecting the analog output 26

Memory card, CAN/easyNet, PC connection 27

– Fitting or removing the memory card 27

– CAN/easyNet, PC connection 27

Connecting expansion devices/network modules 28

– Local expansion 28

– Remote expansion 28

1

Contents

10/10 MN05003003Z-EN

6Operation 29

Keypad 29

Selecting menus and entering values 29

Selecting or toggling between menu items 29

– Cursor display 29

– Setting values 29

Choosing the main and system menu 30

– Status display 30

– Status display with time 30

Menu structure 31

– Main menu without password protection 31

– Main menu with password protection 32

– System menu 32

– System menu 33

7 Description of settings 35

Password protection 35

– Password setup 35

– Selecting the scope of the password 35

– Activating the password 35

– Access with password protection 35

– Changing or deleting the password range 36

Changing the menu language 37

Setting date and time 37

Startup behaviour 37

– Setting the startup behaviour 37

Setting LCD contrast and backlight 38

8 Configuration of the inputs/outputs (I/O) 39

Representation of the inputs/outputs in the configuration 39

Displaying the local inputs/outputs 39

Changing the folder function 39

Displaying the inputs/outputs of the expansion devices 40

9Operation 41

General 41

– Overview of memory sizes 41

– Memory definition 41

Startup behaviour 41

– Startup behaviour with boot project on the memory

card 41

Setting the startup behaviour in the programming

software 43

Program START/STOP 43

– Program start (STOP l RUN) 43

– Behaviour after shutdown/interruption of the power

supply 43

–Program stop (RUN l STOP) 43

– Starting/stopping the program via external switch 44

Program processing and system time 44

Cycle time monitoring 44

Reset 44

– Warm reset 44

– Cold reset 44

–Hard Reset 44

– Restoring factory settings (factory set) 44

– Behaviour of variables after Reset 45

2

10/10 MN05003003Z-EN

Contents

Test and commissioning 45

– Breakpoint/single-step mode 45

– Single-cycle mode 45

– Forcing variables and inputs/outputs (Forcing) 45

– Status display in the programming software 45

High-speed counters (Counter) 45

– Counter functions (inputs/outputs) 46

Incremental input 47

– Explanation of the input/output signals (I/Q) 47

– Overview of input/output signals (I/Q) 48

– Functions of the input/output signals 48

– Referencing 48

System events 49

– START, COLD START, WARM START, STOP 49

– Interrupt inputs I1 … I4 50

– Counter interrupt 50

– Timer interrupt 50

Interrupt processing 52

– Steps for interrupt processing 52

– Example of interrupt processing 52

Direct I/O access 53

– Description of functions 53

Error code for “direct I/O access” 54

Generating and transferring a boot project 55

– Storing a boot project on a memory card 55

– Boot project and operating system (OS) on memory

card 55

– Erase boot project 55

Download/update operating system 56

– Transferring the operating system from the PC to the

PLC 56

– Transferring the OS from PC to the memory card 57

– Transferring the OS from the memory card to the

controller 57

10 Browser commands 59

– Setting Ethernet parameters 59

Description of important Browser commands 60

– canload 60

– setrtc 60

11 Libraries, function blocks and functions 61

Using libraries 61

Installing additional system libraries 61

EC4-200 specific functions 62

– EC_Util.lib library 62

– EC_Visu.lib/EC_Visu2.lib library 62

12 Connection setup PC – EC4-200 63

Connection setup via RS232 63

Defining/changing the PC’s communication settings 63

Changing the communication parameters (baud rate) of

the CPU 64

Connection setup via Ethernet 64

Scan/Modify the IP address 66

3

Contents

10/10 MN05003003Z-EN

13 Defining system parameters via the STARTUP.INI file 67

Overview 67

Structure of the INI file 67

Creating the Startup.INI file 67

Switching on the PLC with the fitted memory card

containing the Startup.INI file 67

Changing settings 68

Deleting the Startup.INI file 68

14 Programming:via a CANopen network (Routing) 69

Prerequisites 69

Routing features of the controller 69

Routing through XC200 69

Notes on routing 70

Setting the node ID/routing ID 70

Setting the master station 71

Setting the device station 71

PLC combinations for routing 72

15 RS232 interface in Transparent mode 73

16 Interactive display 75

Display form 75

– Switching between Status display and Entry/output

mode 75

– Function/function block overview 76

Description of important functions / function blocks 77

– FUNCTION Disp_EnableDisplay: BOOL (*Changing

Status display <-> Entry/output mode*) 77

– General programming procedure 80

– Example of text and values output 81

– Example of a screen output with texts and value

entries 83

Multifunction display MFD-CP4 on the EC4-200 86

–MFD setup 86

17 EC4-200 network modules 87

EASY205-ASI 87

– Cyclic data exchange 87

– Configuration 88

– Setting the station address 88

EASY221-CO, EASY204-DP, EASY222-DN 88

– Cyclic data exchange 88

– Configuration 89

– Setting the station address 89

– Acyclic data exchange 89

4

10/10 MN05003003Z-EN

Contents

Appendix 93

Network CAN/easyNet 93

– Accessories 93

Example program for PLC START/STOP using external

switch 94

easy800-PC-CAB connection cable 95

Dimensions and weight 95

Technical data 96

– Transistor outputs 101

– Analog output 103

Character sets 104

Index 107

The previous Chapter 17: "The easyNet network" and

h

Chapter 18: "Programming via easyNet (routing)“ are

omitted.

You will find this information in far greater detail in the

manual MN05006004Z-EN (previously 08/07 AWB2786-

1593) "Data transfer between easy and IEC PLCs

(easyNet)".

5

10/10 MN05003003Z-EN

6

10/10 MN05003003Z-EN

About this manual

List of revisions

The following significant amendments have been introduced since previous issues:

Edition date Page Keyword new Modification

12/06 87 EC4-200 network modules

03/07 9 Addition of types EC4P-222-… j

14 Ethernet interface j

15 Cable connections j

59 Browser commands for Ethernet j

67 Startup.INI mit with Ethernet entries j

104 Character sets j

01/08 29 Selecting or toggling between menu items j

33 System menu j

49 START, COLD START, WARM START, STOP j

50 Interrupt inputs I1 … I4 j

51 Timer interrupt j

87 Chapter 17: "The easyNet network" and

Chapter 18: "Programming via easyNet (routing)“

are omitted.

You will find this information in far greater detail in the manual

MN05006004Z-EN (previously 08/07 AWB2786-1593en)

" Data transfer between easy and IEC PLCs (easyNet)".

10/10 all Change to Eaton notation j

j

Additional documentation

At different points in this manual, references are made to more

detailed descriptions in other manuals. This documentation is

stored as a PDF file when the product CD is installed on your PC.

To find documentation choose the following in the Windows Start

menu:

Programs

l Moeller Software l easy Soft CoDeSys l

Documentation…

It is also possible to download the PDF files from the FTP server.

This always provides the latest data.

ftp://ftp.moeller.net/DOCUMENTATION/AWB_MANUALS/

Concrete information regarding communication with CAN stations

and their configuration can be found in the following listed

documentation:

• AN27K19GB: Communication between two PLCs using

network variables via CAN (AN2700K19GB.PDF)

• AN27K20GB: Coupling multiple stand-alone PLCs

(CAN-Device) via CANopen (AN2700K20GB.PDF)

• Engineering of CAN stations (AN2700K27GB.PDF)

(To be found in Windows start menu under Programs

l

Moeller Software l easy Soft CoDeSys l Application

examples…)

• MN05010001Z-EN (previously AWB2786-1554GB):

Library description CANUser.lib, CANUser_Master.lib.

The functions of the CANUser.lib and CANUser_Master.lib

libraries enable you to access CAN objects directly.

(To be found in Windows start menu under Programs

l

Moeller Software l easy Soft CoDeSys l Documentation…)

7

About this manual

Reading conventions

10/10 MN05003003Z-EN

Select ‹File

“File” menu.

h

h

i

j

For clarity of layout, we adhere to the following conventions in this

manual: at the top of left-hand pages you will find the Chapter

heading, at the top of right-hand pages the current Section

heading; exceptions are the first pages of Chapters and empty

pages at the end of Chapters.

r New› means: activate the instruction “New” in the

Draws your attention to interesting tips and

supplementary information.

Caution!

Warns of the risk of material damage.

Caution!

Warns of the possibility of serious damage and slight

injury.

Warning!

Indicates the risk of major damage to property, or serious

or fatal injury.

8

10/10 MN05003003Z-EN

1 Device application

The controllers of the EC4-200 series are programmable switching

and control devices. They can be used in domestic applications,

machine building and plant construction. An EC4-200 controller

can be used as a stand-alone controller or connected to remote

input/output devices via the CANopen interface. This interface also

allows you to communicate with other PLCs (with a CANopen

interface).

The EC4P-222-... controller types have an additional Ethernet

interface.

From version 2.0 of the operating system the controllers have the

following features:

• Connection of expansion devices/controllers via easyLink

• Connection of the MFD-CP4 multi-function display via the

multi-function interface

• Transparent mode via the multi-function interface

• Direct access to local I/O and the high-speed counters

• Integration in the easyNet network via the easyNet/

CAN interface

Controllers from version 2.10 can be connected to the ASI,

PROFIBUS-DP, CAN or DeviceNet networks with suitable network

interfaces.

The controller is programmed with the easySoft CoDeSys

programming software. This software should be installed on a

standard PC with the Windows NT, 2000 or XP operating system.

Further information on the software is provided in the manual for

the programming software (MN05010003Z-EN; previously

AWB2700-1437GB).

This software provides you with a simple entry in the IEC

programming languages such as:

• Instruction List (IL)

• Function Block Diagram (FBD)

• Ladder Diagram (LD)

• Structured Text (ST)

• Sequential Function Chart (SFC).

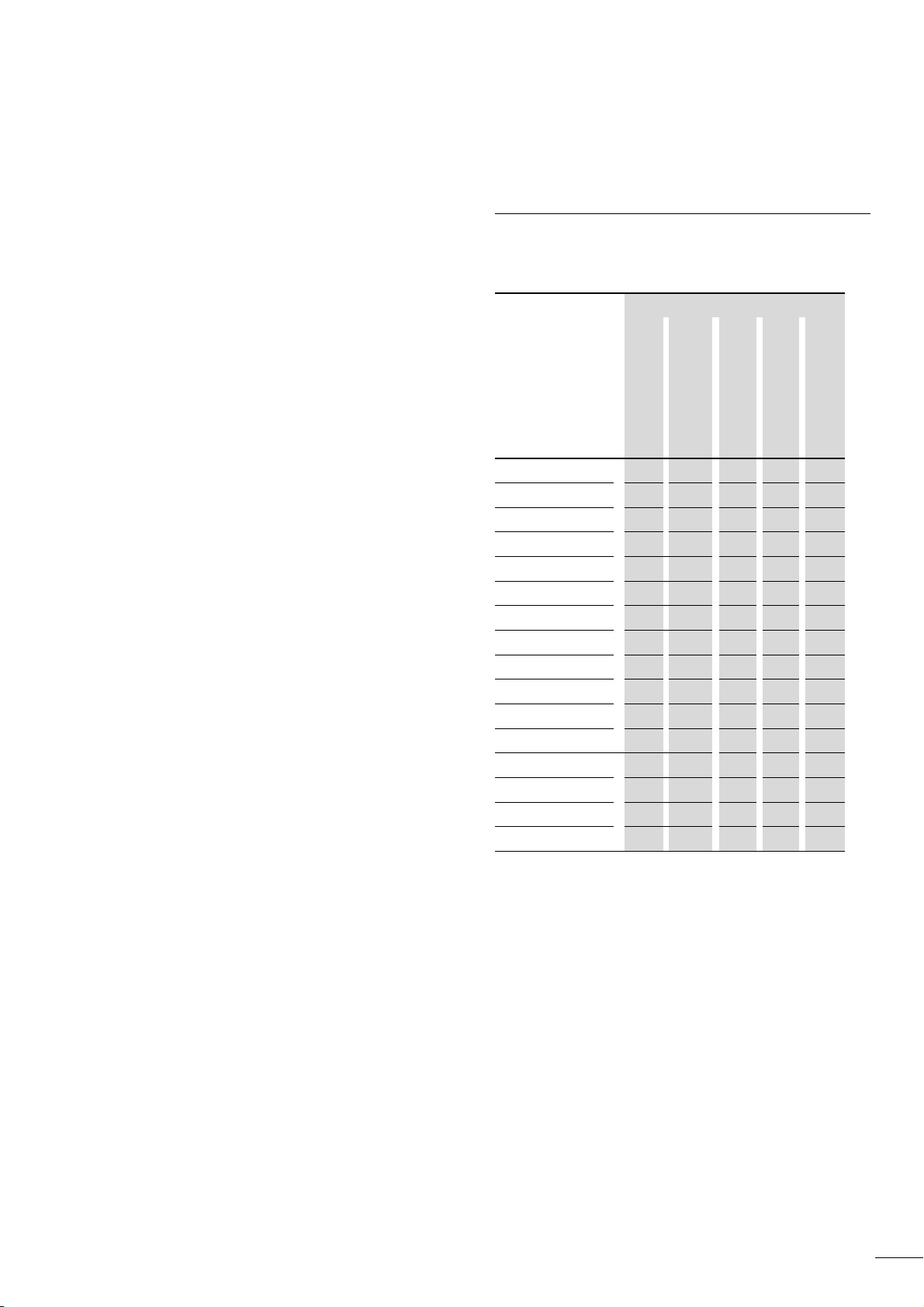

EC4-200 part number overview

The EC4-200 series contains controllers with different displays and

the type and number of inputs/outputs.

Part no. Features

Keys/display

Transistor outputs

EC4P-221-MTXD1 x 8 – – –

EC4P-221-MTXX1 – 8 – – –

EC4P-221-MRXD1 x – 6 – –

EC4P-221-MRXX1 – – 6 – –

EC4P-221-MTAD1 x 8 – x –

EC1P1-MTAX1 – 8 – x –

EC4P-221-MRAD x – 6 x –

EC4P-221-MRAX1 – – 6 x –

EC4P-222-MTXD1 x 8 – – x

EC4P-222-MTXX1 – 8 – – x

EC4P-222-MRXD1

EC4P-222-MRXX1 – – 6 – x

EC4P-222-MTAD1 x 8 – x x

EC1P1-MTAX1 – 8 – x x

EC4P-222-MRAD

EC4P-222-MRAX1 – – 6 x x

x – 6 – x

x – 6 x x

Relay outputs

Analog output

Ethernet connection

This provides a large number of operators such as:

• Logic operators such as AND, OR, …

• Arithmetic operators such as ADD, MUL, …

• Comparison operators such as <,=, >

You use the programming software to create, test and document

a project. Functions for analog processing, closed-loop control and

function blocks such as timers, counters simplify programming.

9

10/10 MN05003003Z-EN

10

10/10 MN05003003Z-EN

Q1 Q2 Q3 Q4 Q5 Q6

RUN

STOP

SF

CAN/

NET

e

abd

c

f

g

h

i

j

k

l

p

r

o

m

q

Q7 Q8Q5 Q6Q3 Q4Q1 Q2+24V 0V

RUN

STOP

SF

CAN/

NET

e

abd

f

g

h

i

j

k

l

p

r

o

n

q

c

2Setup

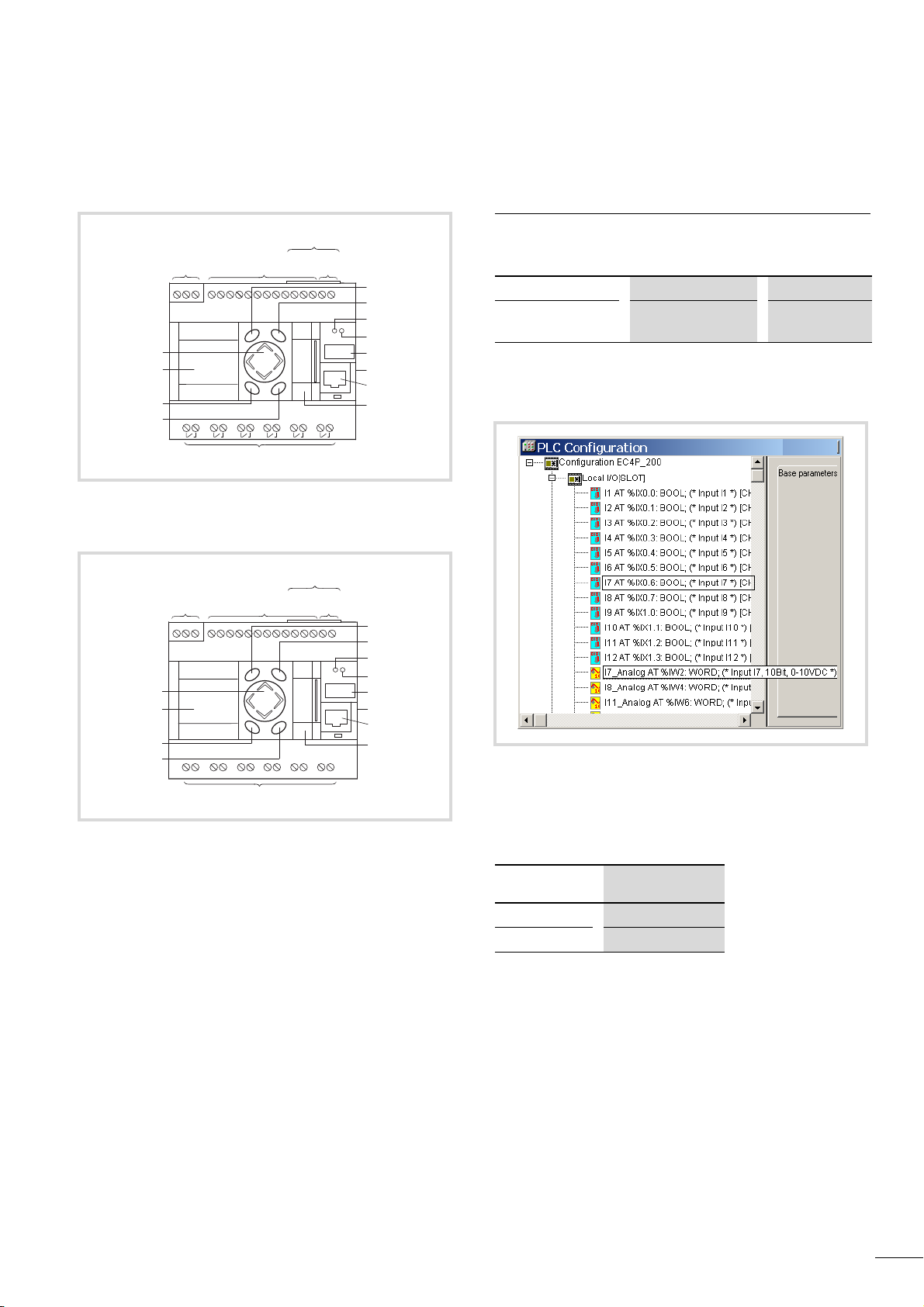

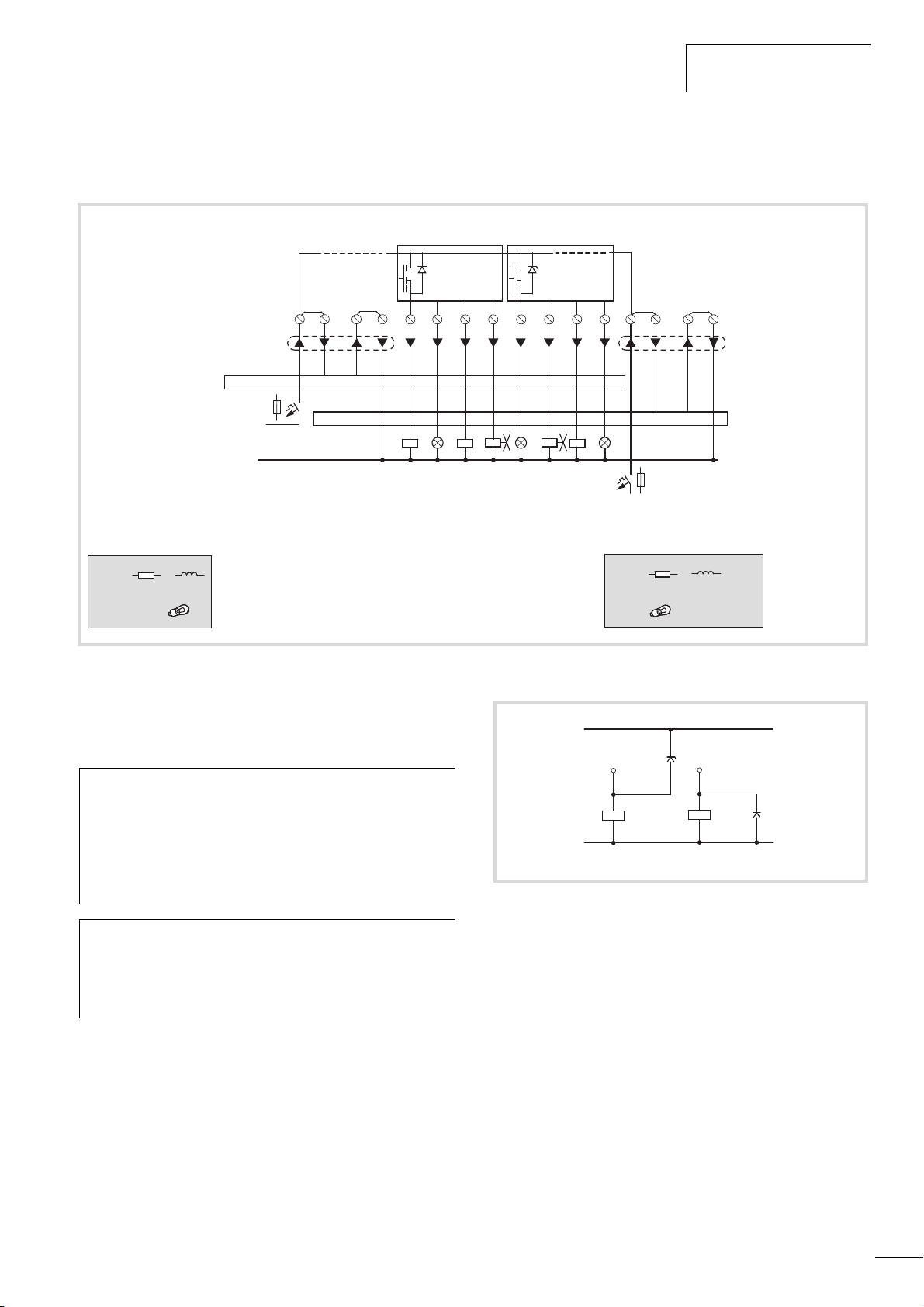

Figure 1: Front of the EC4P-221-MRAD1,

Legend a figure 2

Inputs

Table 1: Type and number of inputs

Digital 12 (I1…I12) 24 V DC

of which can be used

4 (I7, I8, I11, I12) 24 V DC/0…10 V

as analog

Inputs I7, I8, I11, I12 can also be used as analog inputs. They are

selected in the user program by means of the appropriate syntax

used in the PLC configurator.

Figure 2: Front of the EC4P-221-MTAD1

a 24 V DC power supply

b Inputs

c Interface for connecting the CAN network

d Analog output, 0 – 10 V (not active)

e DEL button

f ALT button

g RUN/STOP/SF LED

h CAN/NET LED

i Field for device labelling

j easyLink interface to expansion device

k Programming interface for connection to a PC

l Multi-function interface

m Relay outputs

n Transistor outputs

o OK button

p ESC button

q LCD display (EC4P-22x-M…D1)

r Cursor buttons P1…P4 (rocker button)

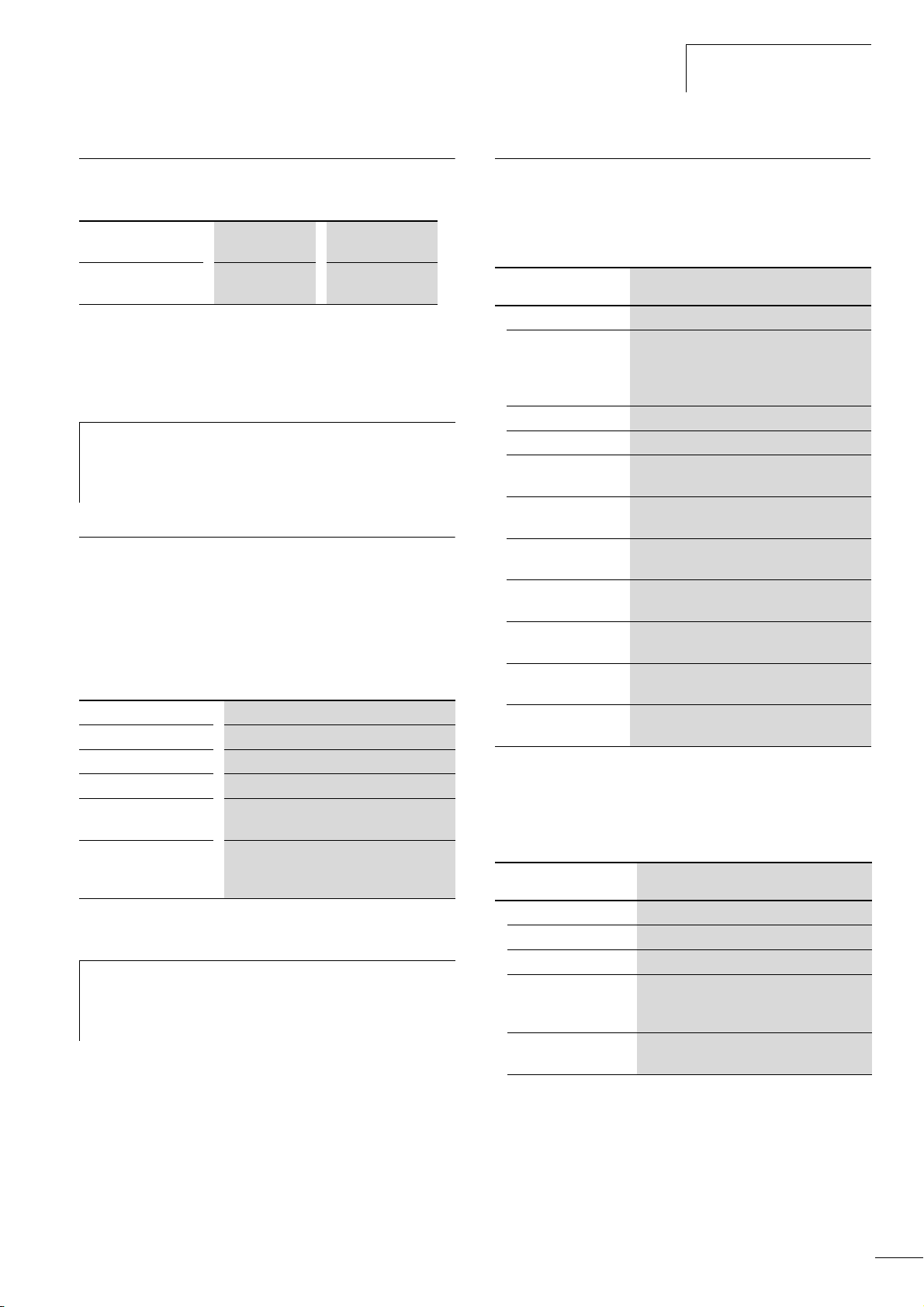

Figure 3: Selection between digital and analog input, e.g. I7

When programming the inputs as digital inputs in the user

program, the input voltage of 8 V forms the limit value for the

TRUE/FALSE signals.

Voltage [V] State

F 8 FALSE

>8

Technical data:

TRUE

a page 96

Inputs I1, I2, I3, I4 can be used for:

• generating interrupts (inputs I1, I2, I3, I4)

• controlling high-speed counters such as:

– 16 or 32-bit counters, for counting pulses (I1, I2),

up/down counting

– Incremental counters, 32-bit, for processing the signals of an

incremental encoder (I1, I2, I3, I4).

The function is selected in the PLC configuration. However, several

functions cannot be used at the same time.

11

Setup

P2

OK

P3

ALT

P4

ESC

P1

DEL

10/10 MN05003003Z-EN

Example: If you are using input I1 for a high-speed counter (16bit), I2 can be used for another high-speed counter (16-bit) but not

for generating an interrupt. Inputs I3 and I4 likewise cannot be

used for generating an interrupt.

Connection description

a figure 22 on page 23.

Function and cursor buttons as inputs

The front plate of the device is provided with the function buttons

DEL, ALT, ESC, OK which are arranged around the rocker switch.

The rocker switch is divided into 4 sections with the cursor button

designations P1 to P4. The function and cursor buttons are

represented in the PLC configuration as inputs. These inputs are

scanned in the program according to general syntax rules. Only

one button can be actuated at a time, otherwise uncontrolled

states may occur when these buttons are scanned.

Figure 4: Function buttons and rocker switch with cursor buttons

P1, P2, P3, P4

Diagnostics inputs

The inputs I13, I14, I15, I16 provide you with additional

information:

Input Function

I13 No function

I14 Expansion device via easyLink (not yet active in the

operating system version 1.x):

0: ok, 1: not ok

I15 Outputs Q1, Q2, Q3, Q4:

0: No short-circuit, 1: Short-circuit

I16 Outputs Q5, Q6, Q7, Q8:

0: No short-circuit, toggle: Short-circuit

The inputs can be scanned in the program with symbolic operands.

Inputs for high-speed counters

You can choose between several different functions:

•1 x 32-bit counter, for counting pulses (up/down)

•2 x 16-bit counters, for counting pulses (up/down); the count

direction (up/down) can be set via the DIRECTION operand in

the program.

•1 x incremental value counter, 32-bit, for processing the

signals of an incremental encoder; the count direction is set by

the edge sequence of the encoder.

Figure 5: Inputs of the rocker and function buttons

The GetDisplayInfo function block from the EC_Visu2.lib library

enables you to control the scanning of the buttons according to

the active menu on the controller,

a section

“EC_Visu.lib/EC_Visu2.lib library”, page 62.

You can select the counter type in the PLC configuration.

The function of the high-speed counter requires the setting of

inputs and the scanning of outputs in a POU, e.g. PLC_PRG.

This POU must not be called by an interrupt generated by a

counter.

For further information see section “High-speed counters

(Counter)”, page 45.

12

10/10 MN05003003Z-EN

Outputs

Outputs

Table 2: Type and number of outputs

EC4P-221/222-MT…

transistor outputs

EC4P-221/222-MR…

relay outputs

8 (Q1…Q8) 24 V DC/0.5 A

6 (Q1…Q6) 250 V AC/8 A

The transistor outputs are provided with a short-circuit monitoring

function. In the event that a short-circuit occurs at one of the

outputs, this is indicated via the diagnostics inputs I15/I16. I15 is

set to 1 if a short-circuit occurs at the outputs Q1 to Q4. Input I16

is toggled if a short-circuit occurs on Q5 to Q6.

Caution!

i

Scan I15/I16 in the program. In the event of a short-circuit

set the outputs to 0 in order to prevent the thermal

overload of the output circuit.

Memory card (MCC)

The memory card is used for data storage and supports the FAT16

file system.

Memory card data

On the memory card you can save the following data:

Data Transfer method

Boot project Browser command: copyprojtommc

Startup.INI file Browser command: createstartupini

Operating system (OS) Updating the OS, a page 56

Source code of the

project

General data Online mode/Online menu:

Online mode/Online menu: load source

code

Write file to PLC

Load file from PLC

A brief description of the browser commands is provided from

page 59.

Caution!

h

In order to avoid any loss of data, ensure that you have

closed all files of the program before removing / inserting

the memory card or switchingoff the power supply.

Data access on the memory card

RUN/STOP/SF and CAN/NET LEDs

After power up, the CPU can switch to the following states, as

indicated by the LEDs:

Table 3: LED status indicator

LED Meaning/CPU status

RUN/STP/SF CAN/NET

red red

orange orange

red off

red

flashing

orange off No user program present

green

flashing

green –

red – Cycle time exceeded

orange

flashing

red

flashing

1) LED is only relevant during startup/system test

1)

1)

red

flashing

– Load user program

–

red

flashing

System test being run (up to 6 seconds after

start; after 6 seconds if no user program is

present).

CPU in NOT READY!

1)

System update in progress

System test finished without error

System test found a fault

1)

CPU in NOT READY

CPU in STOP

Load user program

CPU in RUN

CPU in STOP

Continuous loop detected in program

CPU in STOP

Fatal error

If the CPU is in RUN status, the CAN/NET LED indicates the

following states:

Table 4: LED status signals for CAN/easyNet

LED Meaning

RUN/STP/SF CAN/NET

green off Communication not active

green red Bus status STOP

green orange

green green

Bus status PREOPERATIONAL

Station can be initialised, no transfer of

process data

Bus status OPERATIONAL

Process data transferred

Functions such as FileOpen or FileRead allow you to access the

files of the memory card from the user program. These functions

are provided in the library EC_File.lib and are described in the

Function Blocks manual (MN05010002Z-EN; previously

AWB2786-1456GB).

13

Setup

12345678

10/10 MN05003003Z-EN

Real-time clock

The PLC is provided with a real-time clock that can be accessed in

the user program via functions from the SysLibRTC library.

The functions are described in the PDF file „SysLibRTC“.

After the software is installed, this file can be opened via

<Programs

Documentation

l Moeller Software l easySoft CoDeSys l

l Automation Manuals>.

You can read and set with the browser commands “getrtc” and

“setrtc” respectively. More information is provided in section

“setrtc” on page 60.

During a voltage loss the clock is backed up for at least 72 hours.

Interfaces

Programming interface for connection to a PC

Communication between PLC and the programming device is

implemented via the programming interface, consisting of an RJ45

connector.

The connector is provided with an RS232 interface and an

additional Ethernet interface on the EC4P- 222-... PLC types for

programming.

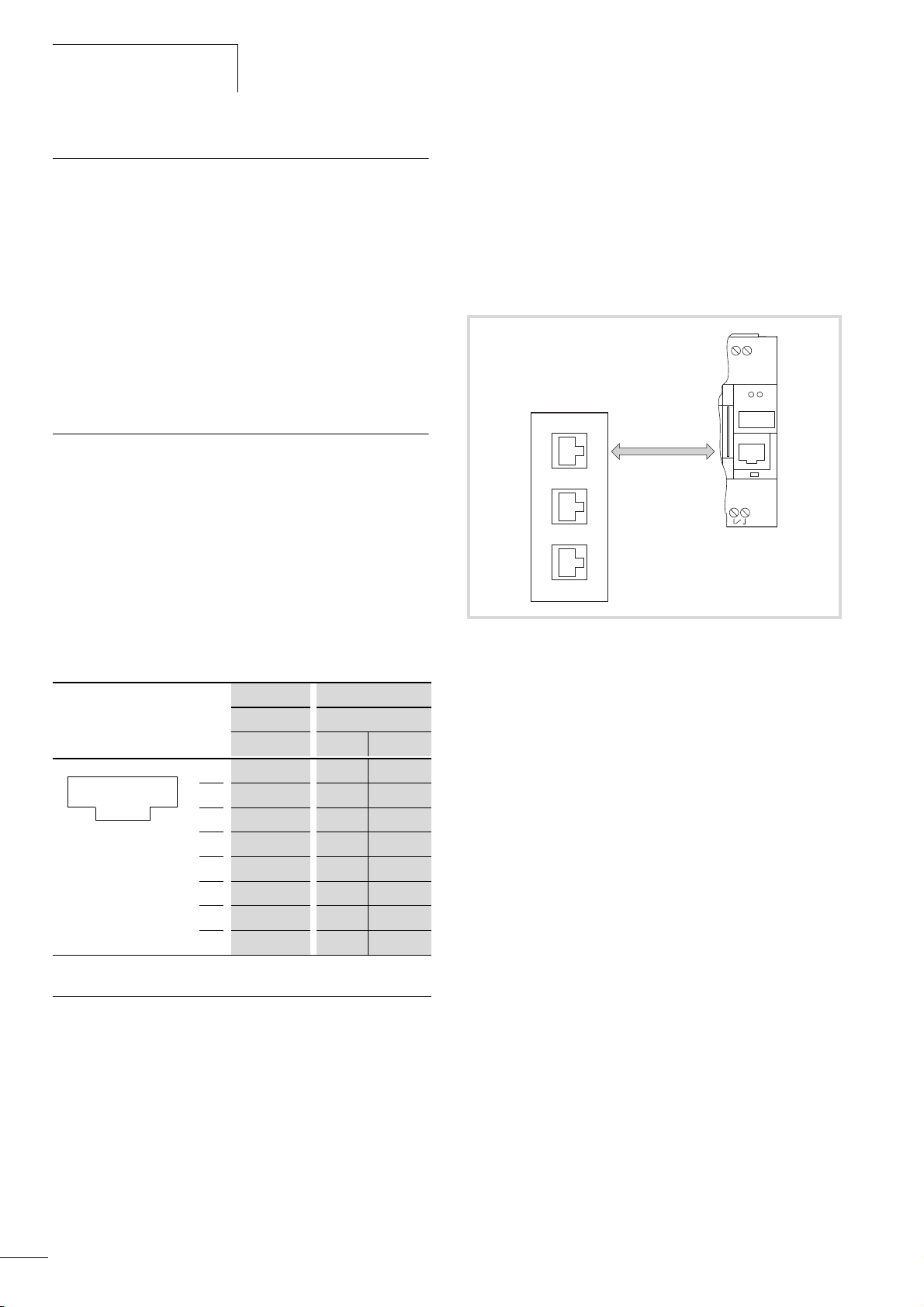

Splitting the RS232/Ethernet interface

Using a cable splitter XT-RJ45-ETH-RS232 you can communicate

simultaneously via the RS232 and the Ethernet interface.

The connection between the PLC and the cable splitter is

established using the EASY-NT-30/80/130 cable. The pin

assignment of the RS232 and Ethernet connector socket of the

cable splitter corresponds with the pin assignment of the

programming interface as shown in table 5.

RUN

CAN/

STOP

NET

SF

XT-RJ45-ETH-RS232

I

N

E

T

H

E

R

N

E

T

R

S

2

3

2

Figure 6: Connecting the PLC with XT-RJ45-ETH-RS232

EASY-NT-30/80/150

RJ45

RJ45

RJ45

Table 5: Signal assignment of the programming interface

EC4P-221… EC4P-222-…

Signal Signal

RJ45 RS232 RS232 Ethernet

1 – – Tx+

2 – – Tx-

3

– – Rx+

4 GND GND

1)

5 TxD TxD –

6

– – Rx-

7 GND GND

1)

8 RxD RxD –

1) The GND signal is not required for an Ethernet connection. Therefore

use a cable with unassigned terminal pins 4 and 7!

Transparent mode

In order to establish a point-to-point connection (without

handshake cables) to another device, switch the RS232 interface

to Transparent mode using the functions from the library

EC_SysLibCom.lib. In Transparent mode, the interface is

addressed as COM1.

a chapter “RS232 interface in Transparent mode”, page 73.

See also:

a section “CAN/easyNet, PC connection”, page 27

a chapter 12 „Connection setup PC – EC4-200“, page 63

Multi-function interface (MFI)

The controller can alternatively communicate with the following

devices via this interface:

•Memory card

The memory card should be fitted in an adapter which is then fitted

on this slot.

• MFD-CP4 multi-function display

The MFD is a display with HMI features that is mounted away from

the PLC. It displays the content of the PLC display. Integrated

buttons enable you to send signals to the controller and control

the processing of the program. The MFD can be mounted in a

control cabinet door up to 5 m away from the controller.

The devices are connected with the cable MFD-CP4-800-CAB5.

• Terminal/printer

A terminal enables you to display and enter alphanumeric

characters. A printer can also be used to output data. The terminal

is connected to the PLC via an RS232 interface using the EASY800PC-CAB cable. The cable with the components for adapting the

PLC signals must be provided with a separate power supply from

the terminal. The signals and pin assignment of the interface must

be implemented in compliance with the RS232 specification.

14

10/10 MN05003003Z-EN

RUN

STOP

SF

CAN/

NET

a

b

PC

(RS232)

c

d

RJ45

Interfaces

In order to supply the components in the cable, the RTS signal

device must be set in the (terminal) device,

a section “easy800-

PC-CAB connection cable” on page 95.

The RS232 interface that is addressed with COM2 must be set to

Transparent mode in order to send or receive data to or from the

terminal.

a chapter “RS232 interface in Transparent mode” on page 73.

The functions for opening and closing the interface and for

sending and receiving data are described in the library

EC_SysLibCom.lib.

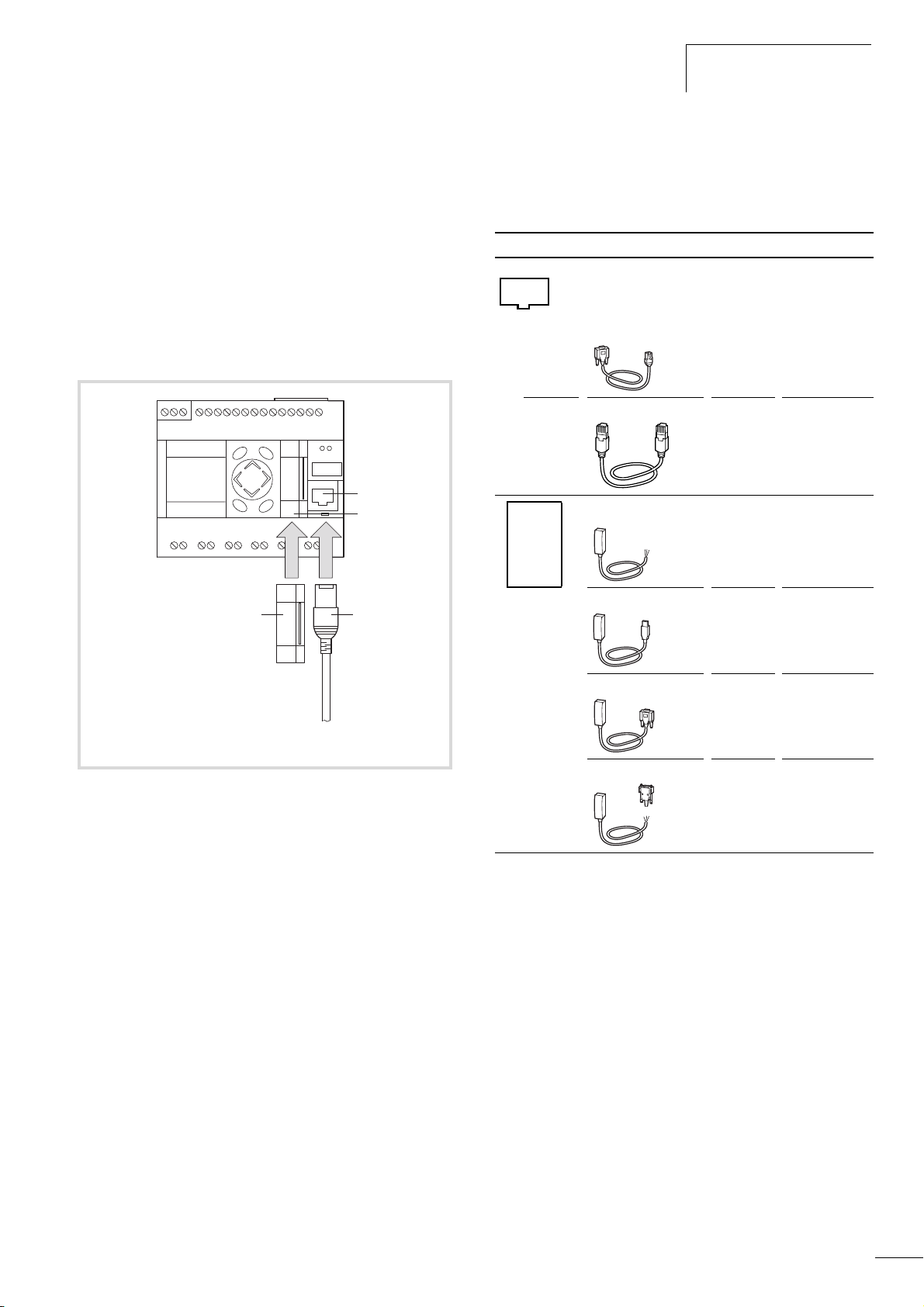

Cable connections

The following overview shows the cable types that can be

connected to the PLC and their functions.

Interface Cable type Device Function

RS232 EU4A-RJ45-CAB1 PC,

terminal/

printer

Ethernet XT-CAT5-X-2 PC Program

MFI MFD-CP4-800-CAB5 MFD-CP4 Display

easy800-USB-CAB PC Program

Program,

transparent

mode (COM1)

extension

Figure 7: Interfaces

a Programming interface for connection to a PC

b Multi-function interface

c Programming cable, e.g. EU4A-RJ45-CAB1

d Adapter with memory card or cable connection

easy800-PC-CAB Terminal/

printer

easy800-MO-CAB PC,

terminal/

printer

Transparent

mode (COM2)

Program,

transparent

mode (COM1)

15

Setup

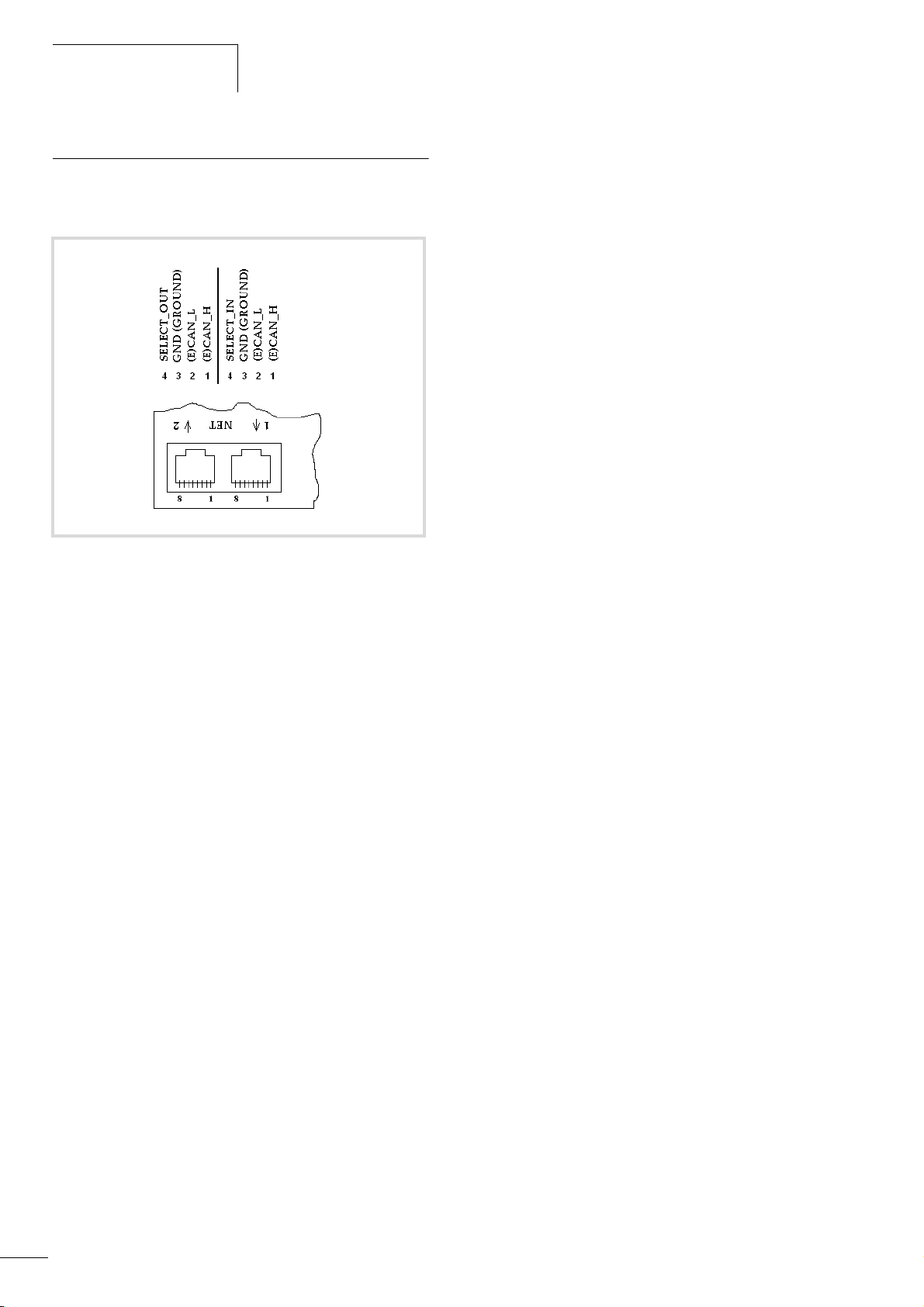

CAN/easyNet interfaces

The PLC is provided with a CAN/easyNET interface with two slots

that are internally connected via terminals.

10/10 MN05003003Z-EN

Figure 8: CAN/easyNet interfaces

CANopen

The CAN interface is designed as a CANopen interface in

compliance with the CIA specification DS301V4.0. The PLC can be

operated both as an NMT master as well as a CAN device on CAN

networks. When used as a CAN device the PLC requires an address

(= Node ID) for identification on the bus. Permissible node IDs are

1, … ,127. The configuration of the master and the device is

carried out in the PLC configuration.

a section “Network CAN/easyNet”, page 93.

16

10/10 MN05003003Z-EN

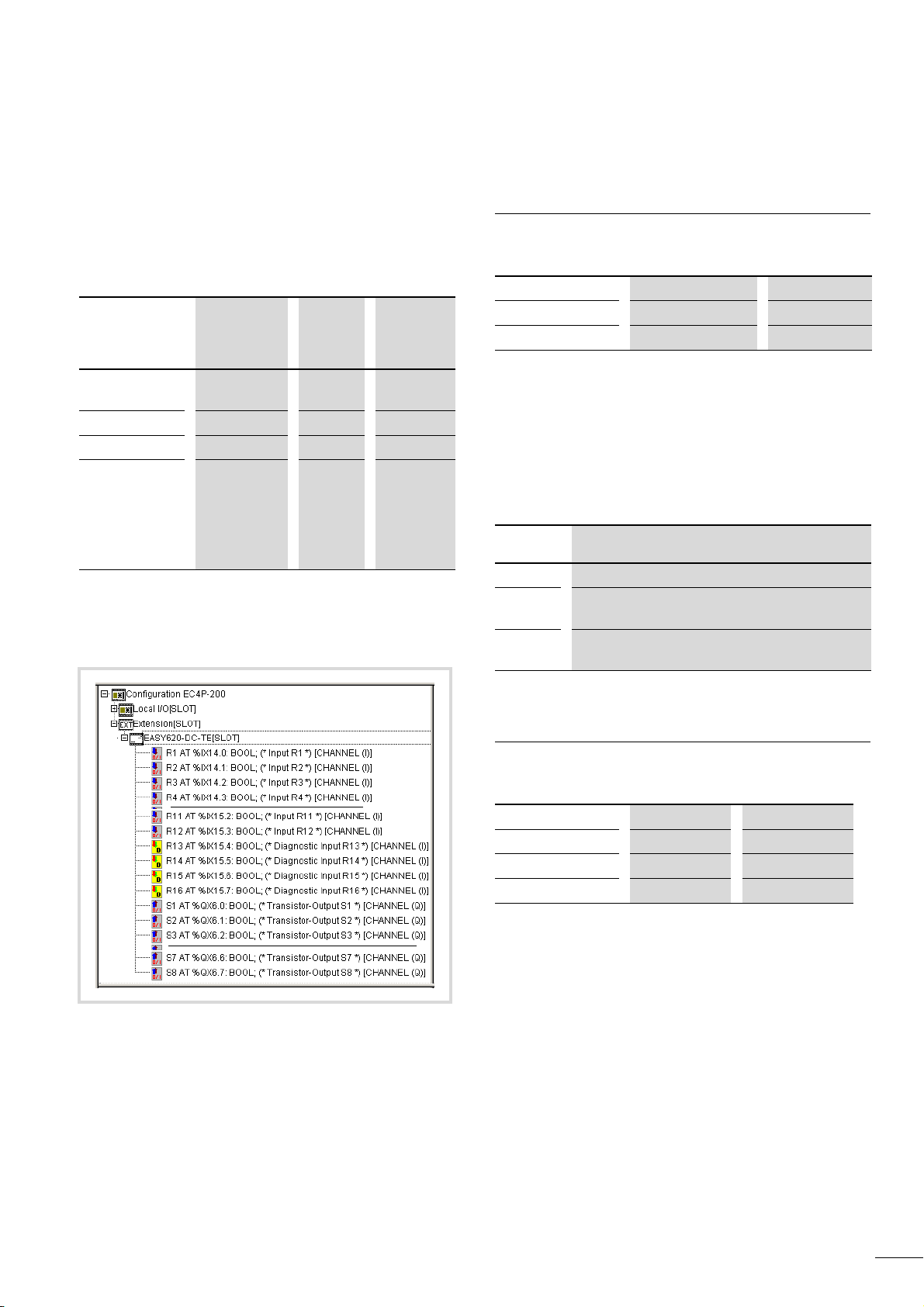

3 Expansion units

You connect the expansion devices directly to the PLC via the

easyLink interface. The following expansion devices can be used to

increase the number of PLC inputs and outputs.

Type overview of expansion devices

Part no. Supply

voltage

connection

EASY618-AC-RE 100 … 230 V AC12 AC 6 relays

EASY618-DC-RE 24 V DC 12 DC 6 relays

EASY620-DC-TE 24 V DC 12 DC 8 transistor

EASY202-RE – – 2 relay

Inputs Outputs

outputs with

common

power supply

for several

outputs

The EASY200-EASY coupling device enables you to connect a

remote expansion device to the controller via a 30 m 2-wire or

multi-core cable.

Overview of inputs/outputs

Inputs

Table 6: Number of inputs and symbolic operands

Part no. Number Operand

EASY6…-…-…

EASY620-DC-TE 4 (diagnostic) R13, … ,R16

12 R1, … ,R12

They are selected in the user program by means of the appropriate

syntax used in the PLC configurator.

Diagnostics inputs

The inputs R15, R16 provide you with additional information:

Table 7: Functions of the diagnostics inputs

Input Function

R13,R14 No function

R15 Outputs S1, S2, S3, S4:

0: No short-circuit, toggle: Short-circuit

R16

Outputs S5, S6, S7, S8:

0: No short-circuit, toggle: Short-circuit

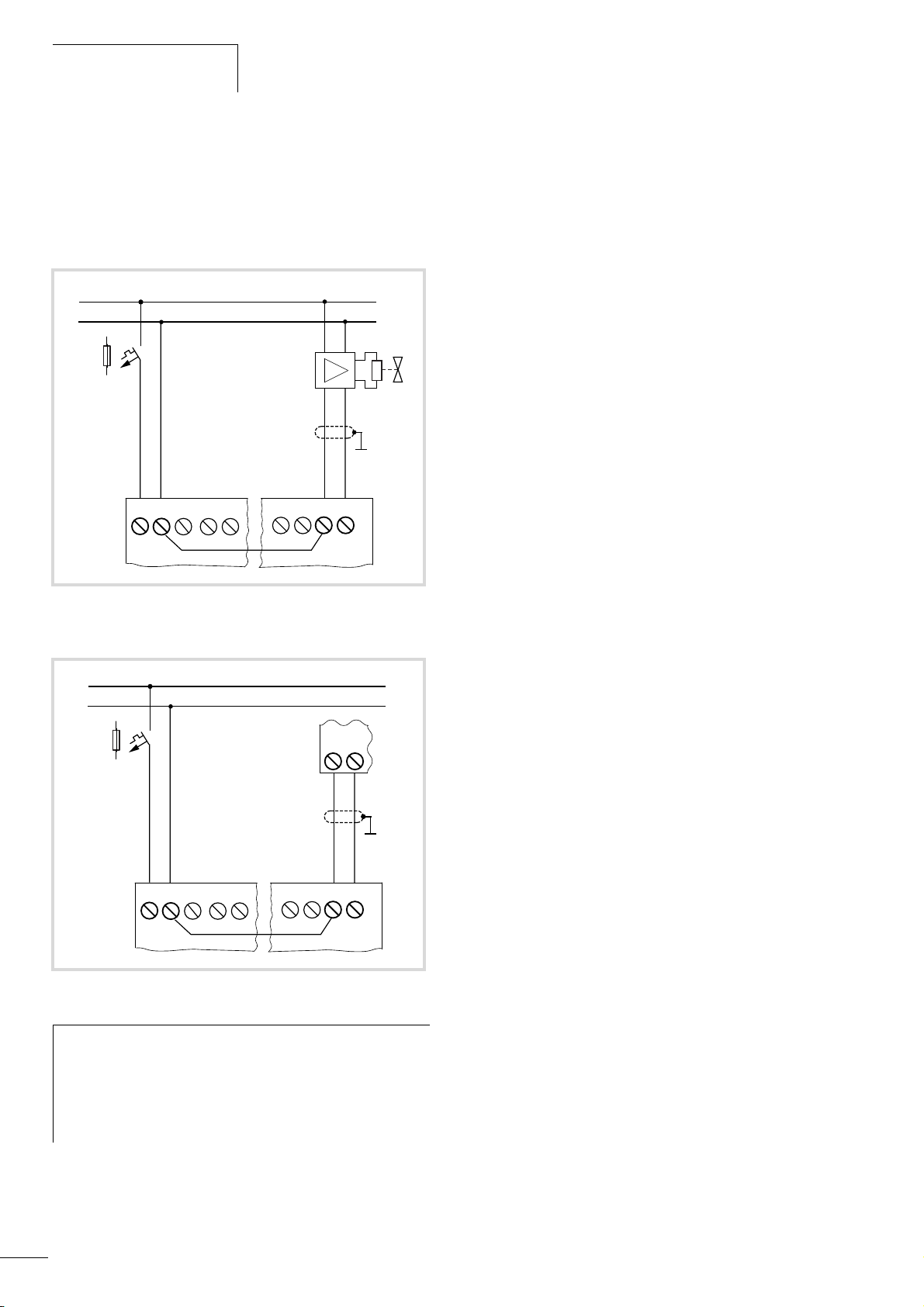

Figure 9: I/Os of the EASY620-DC-TE

The inputs can be scanned in the program with symbolic operands.

Outputs

Table 8: Number of outputs and symbolic operands

Part no. Number Operand

EASY618 6 S1,…, S6

EASY620 8 S1,…, S8

EASY202-RE 2 S1,S2

The transistor outputs are provided with a short-circuit monitoring

function. In the event that a short-circuit occurs at one of the

outputs, this is indicated via the diagnostics inputs R15/R16.

R15 is set to 1 if a short-circuit occurs at the outputs S1 to S4.

Input R16 is toggled if a short-circuit occurs on S5 to S6.

17

10/10 MN05003003Z-EN

18

10/10 MN05003003Z-EN

30 mm

(1.18“)

30 mm

(1.18“)

30 mm

(1.18“)

30 mm

(1.18“)

1

2

CLICK !

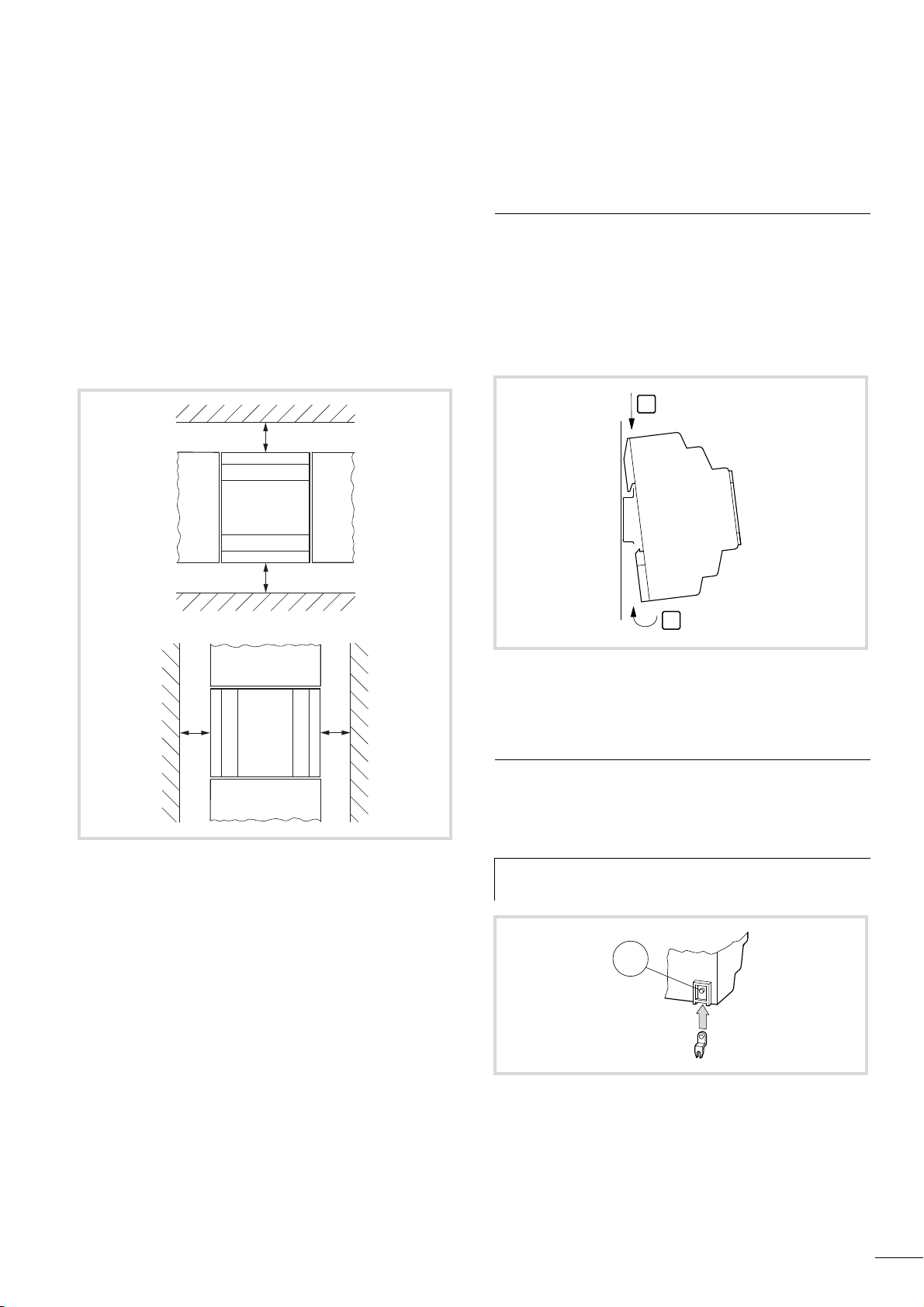

4 Mounting

Install the PLC in a control cabinet, a service distribution board or

in an enclosure so that the power supply terminals and other

terminals are protected against direct contact during operation.

The PLC can be installed vertically or horizontally on a top-hat rail

in compliance with IEC/EN 60715 or on a mounting plate using

fixing brackets.

Ensure that the terminal side has a clearance of at least 3 cm from

the wall and from neighbouring devices in order to simplify wiring.

Mounting on top-hat rail

X Place the device diagonally on the upper lip of the top-hat rail.

Press down lightly on both the device and the top-hat rail until

the unit snaps over the lower edge of the top-hat rail. The

spring mechanism should ensure that the device snaps into

position automatically.

X Check that the device is seated firmly.

Figure 11: Mounting on top-hat rail

.

The device is mounted vertically on a top-hat rail in the same way.

Mounting on mounting plate

Fixing brackets that can be inserted on the rear of the device are

required for screw mounting. The fixing brackets are available as

an accessory.

Figure 10: Observing the clearances for wiring

Three fixing brackets are sufficient for a device with four

h

fixing points.

Figure 12: Inserting a fixing bracket

19

Mounting

aa

aa

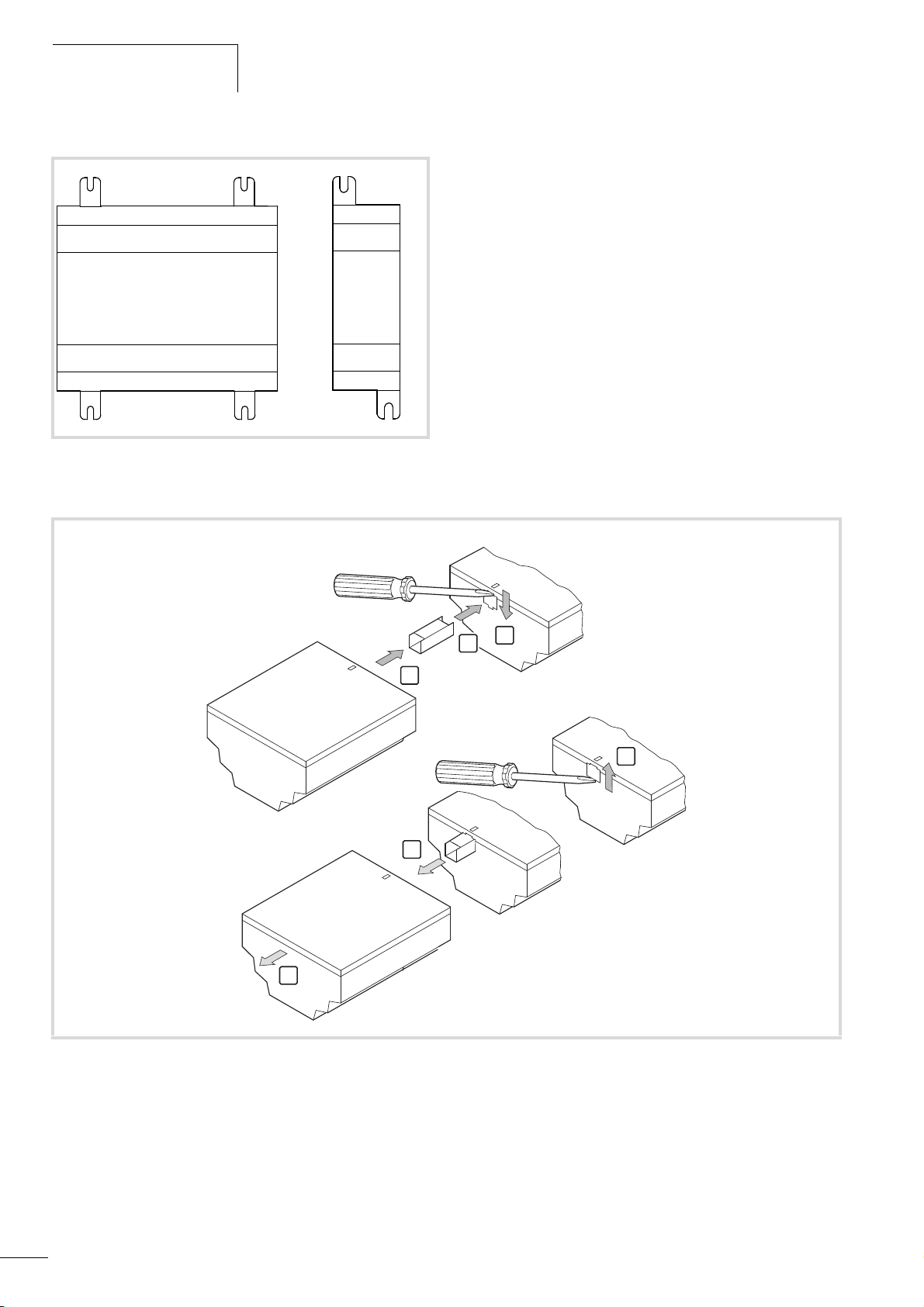

4

5

3

2

1

6

EC4-200

EASY-LINK-DS

EASY200-EASY

EASY202-RE

EASY6…-RE/-TE

Figure 13: Screw fixing the devices

a Fixing brackets

10/10 MN05003003Z-EN

Figure 14: Connecting the expansion unit/network module to the EC4-200

20

10/10 MN05003003Z-EN

...V

0 V0 V

L01 –

F1

L01

+

DC : +24 V

I1

I3I2

I4

I6I5

I7

...

L01+

L01-

0 V l1 I2 I7

...V

F1

0 V

l3 I4

l5 I6

...

5 Installation

Connecting the power supply

Figure 15: Connecting the power supply

The two 0 V terminals are connected internally!

Die EC4-200 is protected against polarity reversal.

h

The necessary connection data is provided chapter

h

“Technical data”, page 96.

Cable protection

Protect the supply cables with a miniature circuit-breaker or at

least a 1A (slow blow) fuse (F1).

Connecting digital inputs

Use input terminals I3 to I4 to connect pushbutton actuators,

switches or 1 or 12-wire proximity switches. Given the high

residual current, do not use 2-wire proximity switches.

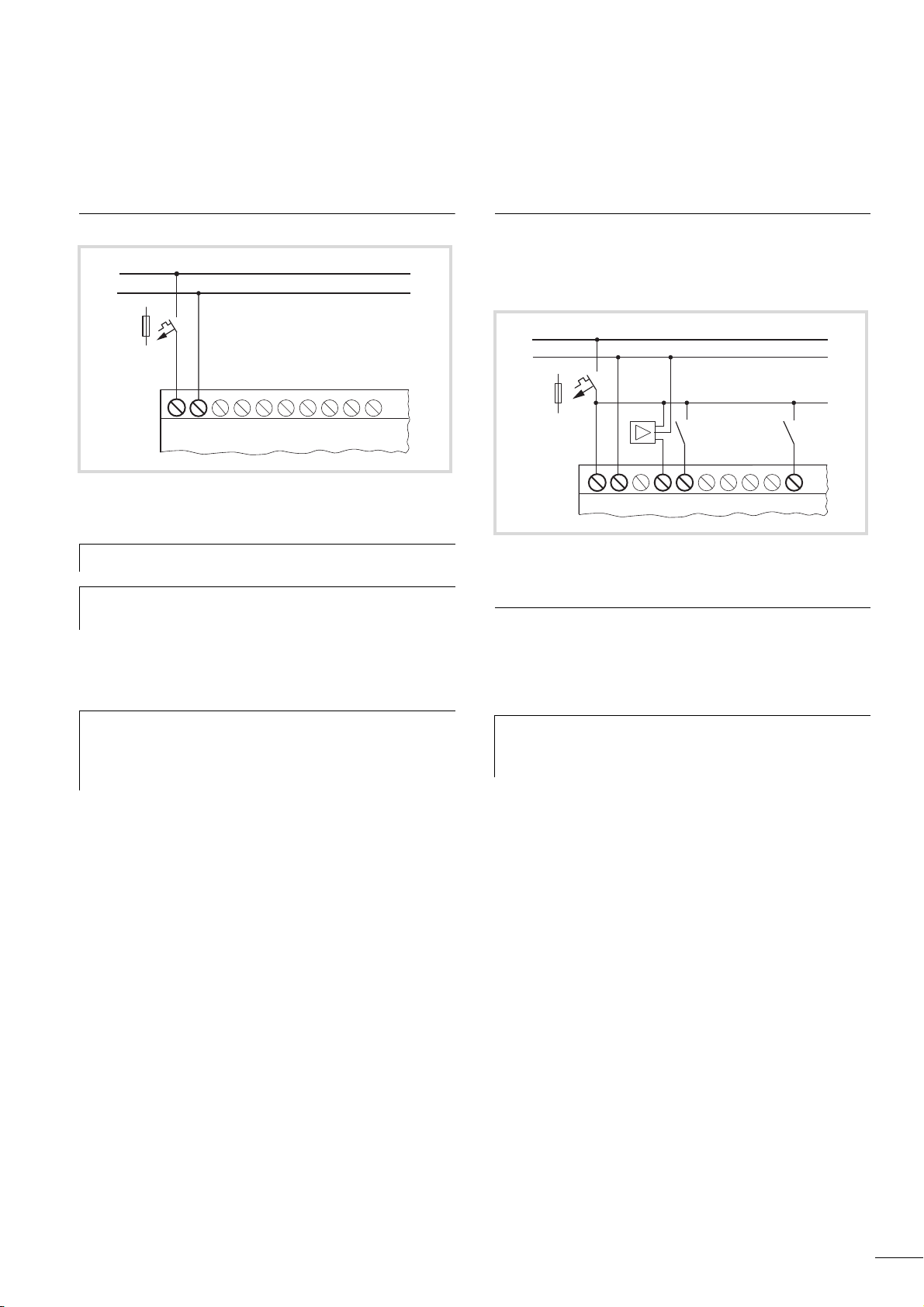

Figure 16: Connecting digital inputs

Connecting analog inputs

Inputs I7, I8, I11 and I12 can also be used to connect analog

voltages ranging from 0 V to 10 V.

The resolution is 10-bit = 0 to 1023.

The controller behaves like a capacitor the first time it is

h

powered up. The switching device and the supply device

for switching on the power supply must be designed for

Caution!

i

Observe the following when laying and connecting analog

cables:

this, i.e. no Reed relay contacts, no proximity switches.

X Use screened, twisted pair conductors, to stop interference of

the analogue signals.

X With short cable lengths, ground the shield at both ends using

a large contact area. If the cable length is more than around

30 m, grounding at both ends can result in equalisation

currents between the two grounding points and thus in the

interference of analog signals. In this case only earth the

conductor on one side.

X Don‘t lay the signal conductor parallel to the power conductor.

X Connect inductive loads that you are switching via the outputs

to a separate power supply or use a suppressor circuit for

motors and valves. If the controller is run with motors, solenoid

valves or contactors via the same power supply, the switching

may cause interference on the analog input signals.

The following circuits show examples of analog measuring

applications.

21

Installation

L01⫹

L01⫺

0 V

+12 V

I724 V

0 V0 V

F1

I2I1

I4I3

I6I5

...

H

h

L01⫺

L01⫹

1.3 kO/0.25 W

1 kO/0.25 W

0 V 0 V I7

24 V

F1

...

I6

I2

I1

I4

I3 I5

0 V

0...10 V

12 V

L01

⫹

L01⫺

0 V

+12 V

I724 V

0 V0 V

...

F1

I2I1

I4I3

I6I5

h

H

+24 V H

0 V

Out

0...10 V

–35...55 °C

+24 V H

0 V

Out

0...10 V

–35...55 °C

L01⫹

L01⫺

I724 V 0 V

F1

I60 V I2I1 I4I3 I5 I8 I10I9 I12I11 0 V –

L01⫹

F1

L01⫺

a

500 O

4…20 mA

I724 V 0 V0 V I2I1 I4I3 I6I5

...

10/10 MN05003003Z-EN

Ensure that the reference potential is galvanically

h

connected. Connect the 0 V of the power supply unit for

the setpoint potentiometer and various sensors shown in

the examples with the 0 V of the power supply.

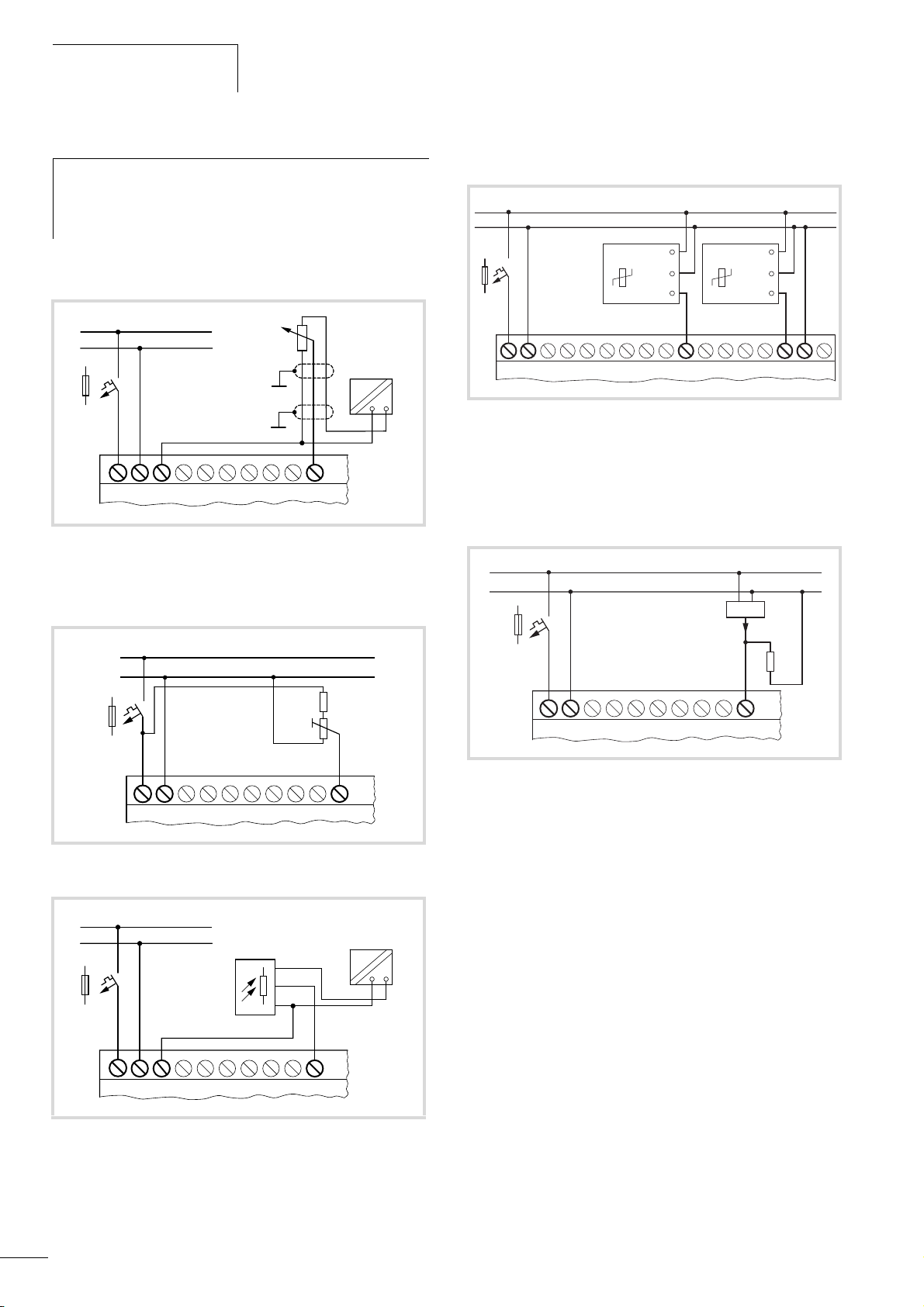

Setpoint potentiometers connection

Figure 17: Setpoint potentiometer

Use a potentiometer with the resistance F 1 kO, e.g. 1 kO,

0.25 W.

Temperature sensor connection

Figure 20: Temperature sensor

Connecting the 20 mA sensor

A 4…20 mA (0…20 mA) sensor can be connected easily with an

external 500 O resistor.

Figure 18: Setpoint potentiometer with upstream resistor

Figure 19: Brightness sensor

Figure 21: 20 mA sensor

a Analog sensor

The following values apply:

• 4 mA = 1.9 V

• 10 mA = 4.8 V

• 20 mA = 9.5 V

(according to U = R x I = 478 O x 10 mA ~ 4.8 V)

22

10/10 MN05003003Z-EN

0 V

0 V

...V

L01 –

F1

L01 +

I1

I2 I3

I4 I5

I6

L02 +

24 V H

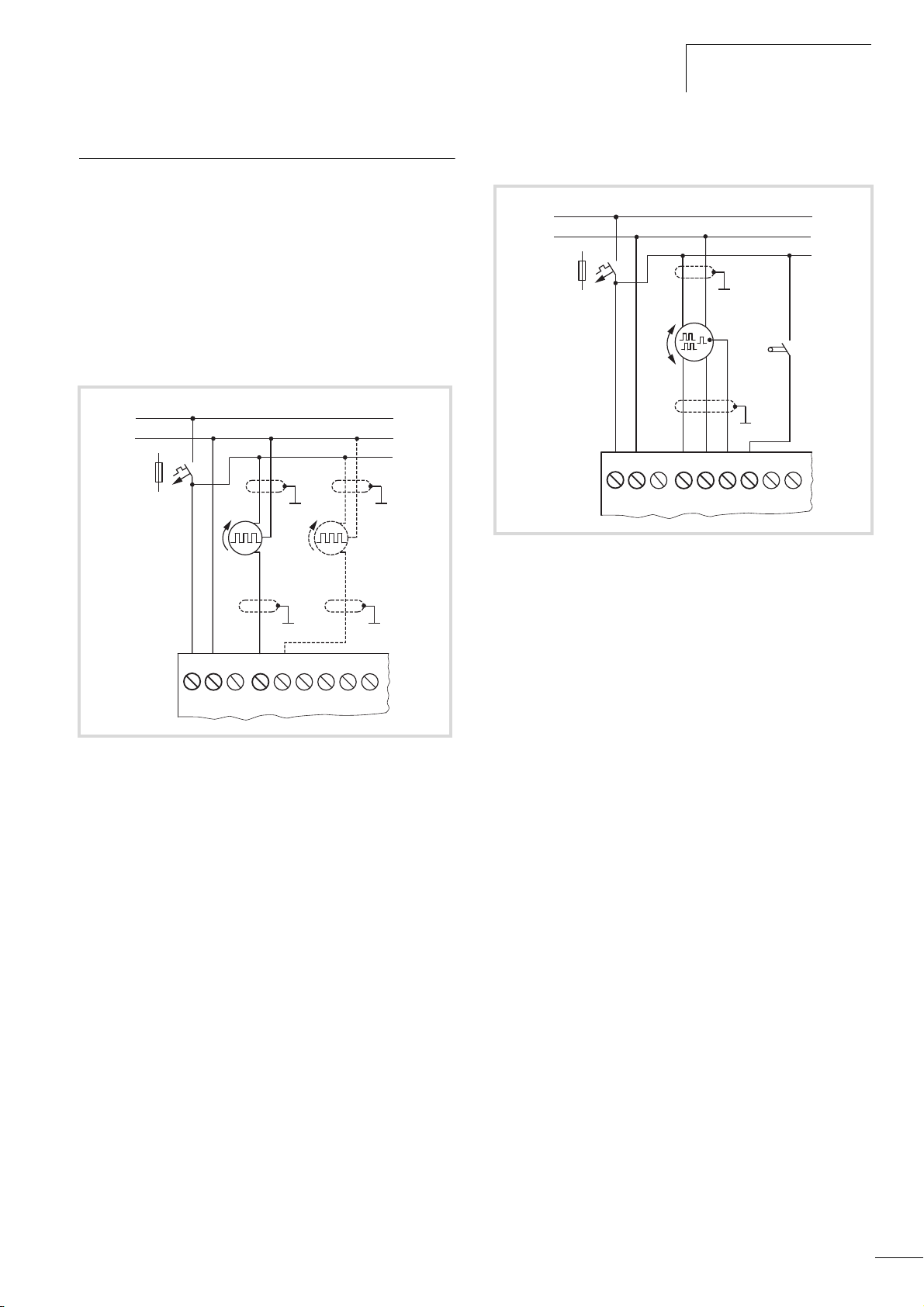

Connecting a pulse transmitter/incremental encoder

Connecting a pulse transmitter/incremental encoder

Inputs I1 to I4 are designed so that high-speed signals from pulse

transmitters/incremental encoders can be counted.

The following connection options are possible:

•1 x pulse transmitters (32-bit)

•2 x pulse transmitters (16-bit)

•1 x incremental encoder (32-bit).

Connecting pulse transmitter

Connecting the incremental encoder

L01 +

L01 –

L02 +

F1

K1

AB

...V

0 V

0 V

24 V H

Figure 23: Connecting the incremental value encoder

A, B: square-wave incremental signals that have a 90 degree phase shift

C: Reference signal

K1: Reference window switch

C

I1

I2 I3

I4 I5

I6

Figure 22: Connecting pulse transmitter

The figure shows the connection of a pulse transmitter which

sends pulses to input I1. An internal counter processes the pulses.

You can choose between a 16-bit counter (max. 65535) and 32-bit

counter (max. 4294967295). The pulse transmitter for the 32-bit

counter must only be connected to I1. Only if a 16-bit counter was

used at I1, can another pulse transmitter (32-bit) be connected to

I2.

23

Installation

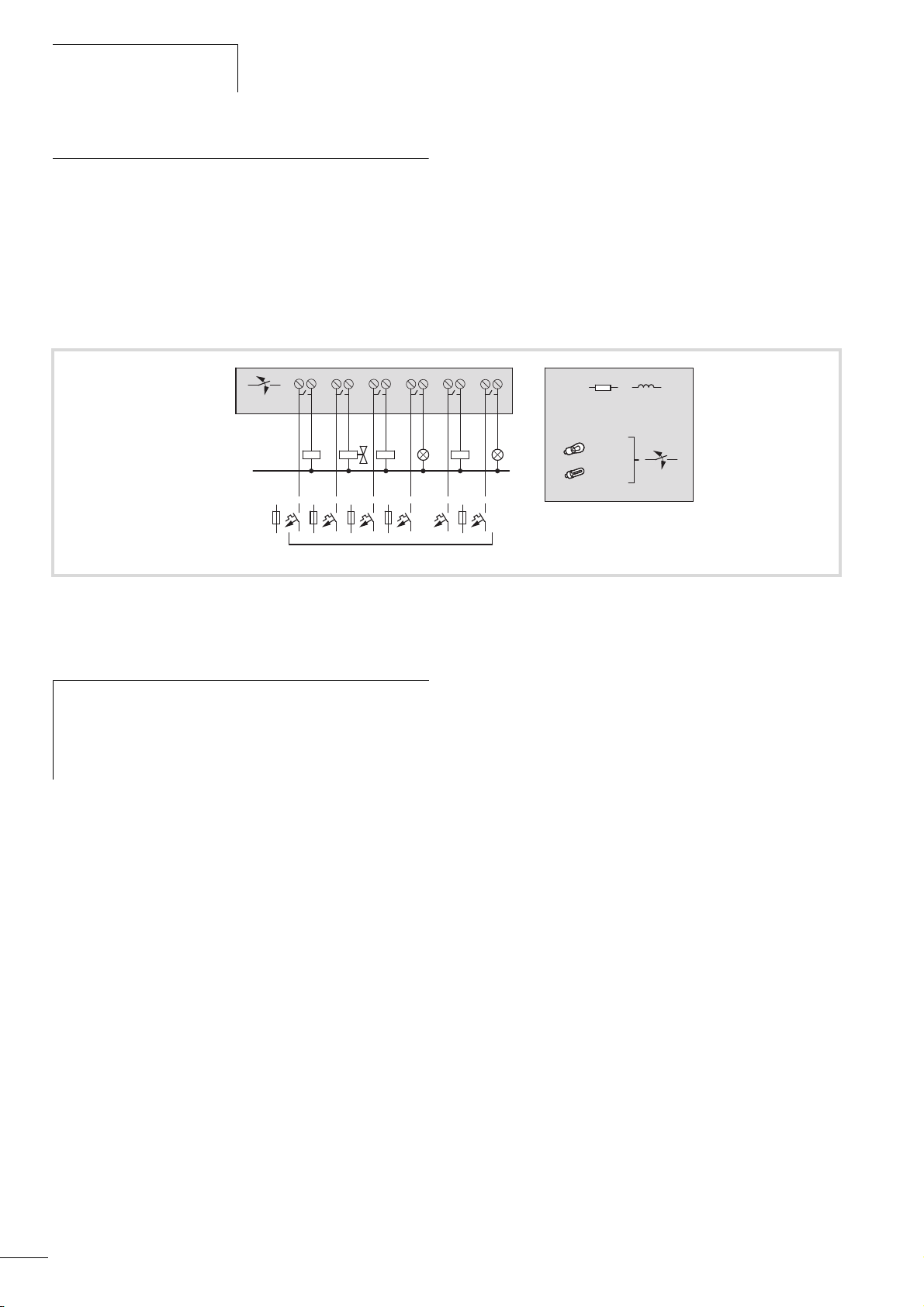

Connecting outputs

The relay or transistor outputs are used to switch loads such as

fluorescent tubes, filament bulbs, contactors, relays or motors.

Check the technical thresholds and output data before installing

such devices (

a page 100, 101).

Connect relay outputs

EC4P-221/222-MR…, EASY6..-DC-RE

10/10 MN05003003Z-EN

10 000 000

0 V H, N

F

8 A/B 16

L1, L2, L3 (115/230 V h)

+ 24 V H

12 2 2 2 2 2

Q1

Q2

1

1

Figure 24: Relay outputs EC4P-221/222-MR…

Unlike the inputs, you can connect the EC4P-221/222-MR…,

EASY6..-..RE relay outputs to different phase conductors.

Caution!

i

Do not exceed the maximum voltage of 250 V AC on a

relay contact. If the voltage exceeds this threshold,

flashover may occur at the contact, resulting in damage to

the device or a connected load.

1

1

1

Q6Q5Q4Q3

RL

24 V H 8 A

115 V h 8A

230 V h 8A

1000 W

10 x 58 W

2A

2A

2A

25 000

24

10/10 MN05003003Z-EN

0 V

Q1

S1 S2 S3 S4 S5 S6 S7 S8

Q2 Q3 Q4 Q5 Q6 Q7 Q8

F 10 A

Q

24 V

Q

0 V

Q

24 V

Q

F 10 A

f 2.5 A

f 2.5 A

0 V H

24 V H

EC4P-221/222-MT…

EASY6…-DC-TE

(20.4 – 28.8 V H)

+ 24 V H

RL

5 W/24 V

0.5 A

24 V H

0.5 A

+ 24 V H

Q., S.

U

emax

< UZ < 33 V

0 V H

Q., S.

Connecting transistor outputs

EC4P-221/222-MT…, EASY6…-DC-TE

Connecting outputs

EC4P-221/222-MT… EASY6…-DC-…

RL

24 V H

Q1 – Q4

Q5 – Q8

0.5 A

3 W

5 W

0.5 A

24 V

Figure 25: Transistor outpus EC4P-221/222-MT…, EASY6-DC-TE

Parallel connection:

Up to four outputs can be connected in parallel in order to increase

the power. This enables a maximum output current of 2 A.

Caution!

i

Please note the following when switching off inductive

loads:

Suppressed inductive loads cause less interference in the

entire electrical system. It is generally recommended to

connect the suppressor as close as possible to the

inductance.

Caution!

i

Only outputs of the same group (Q1 to Q4 or Q5 to Q8)

can be connected in parallel; e.g. Q1 and Q3 or Q5, Q7

and Q8. Outputs connected in parallel must be switched

at the same time.

If inductive loads are not suppressed, the following must be

observed: Several inductive loads should not be switched off

Figure 26: Inductive load with suppressor circuit

Behaviour with short-circuit/overload

A transistor output will switch off in the event of a short-circuit or

overload. The output will switch back on up to the maximum

temperature after a cooling time that depends on the ambient

temperature and the current level. If the fault continues, the

output will switch off and on until the fault is rectified or the power

supply is switched off.

simultaneously to avoid overheating the driver blocks in the worst

possible case. If in the event of an Emergency-Stop the +24 V DC

power supply is to be switched off by means of a contact, and if

this would mean switching off more than one controlled output

with an inductive load, then you must provide suppressor circuits

for these loads (

a following diagrams).

25

Installation

0 V

0 V

24 V H

...V

L01 –

F1

L01 +

I1

I2

I11

I12

0 V

QA1

0 V

0 V

24 V H

24 V

L01 –

F1

L01 +

I1

I2

I11

I12

0 V

QA1

0 V IA

Connecting the analog output

The EC4-200 is provided with one analog output QA 01, 0 V up to

10 V DC, 10-bit resolution (0 to 1023). The analog output can be

used for controlling servo valves and other actuators.

Connecting servo valve

10/10 MN05003003Z-EN

Figure 27: Connecting servo valves

Setpoint entry for a drive

Figure 28: Setpoint entry for a drive

Caution!

i

Analog signals are more sensitive to interference than

digital signals so that more care must be taken when

laying and connecting the signal cables. Incorrect

switching states may occur if they are not connected

correctly.

26

Loading...

Loading...