Eaton EAFR-101C User Manual

Instruction Booklet IB0191002EN

Effective November 2019

EAFR-101C arc point sensor relay

user manual

Contents

Description Page

1 Introduction ............................2

2 General ................................2

3 Operation and configuration ................4

4 Arc sensors ............................7

5 System self-supervision ...................8

6 Application examples .....................9

7 Connections ............................9

8 Dimensions and installation ...............11

9 Testing ...............................12

10 Troubleshooting guide ...................14

11 Technical data .........................14

12 Ordering codes .......................16

Instruction Booklet IB0191002EN

Effective November 2019

EAFR-101C arc point sensor relay

user manual

CAUTION

ELECTRICAL EQUIPMENT SHOULD BE INSTALLED, OPERATED, SERVICED,

AND MAINTAINED ONLY BY QUALIFIED PERSONNEL. LOCAL SAFETY

REGULATIONS SHOULD BE FOLLOWED.

NO RESPONSIBILITY IS ASSUMED BY EATON FOR ANY CONSEQUENCES

ARISING OUT OF THE USE OF THIS MATERIAL.

1 Introduction

Read these instructions carefully and inspect the equipment to

become familiar with it before trying to install, operate, service, or

maintain it.

Electrical equipment should be installed, operated, serviced, and

maintained only by qualified personnel. Local safety regulations

should be followed. No responsibility is assumed by Eaton for any

consequences arising out of the use of this material.

Eaton reserves right to changes without further notice.

1.1 Abbreviations

CB – Circuit breaker

CBFP – Circuit breaker failure protection

EMC – Electromagnetic compatibility

EPROM – Erasable programmable read only memory

HW – Hardware

LED – Light emitting diode

LV – Low voltage

ms – Millisecond

MV – Medium voltage

NC – Normally closed

NO – Normally open

PMSG – Permanent magnet synchronous generator

Rx – Receiver

SF – System failure

SW – Software

Tx – Transceiver

uP – Microprocessor

2 General

The Eaton arc flash relay 101C (EAFR-101C) is a sophisticated

micro-processor based arc flash protection relay including complete

self-supervision functionality. It is designed to minimize the damage

caused by an arcing fault (arc flash) by sensing light from the point

sensor and acting to trip the circuit breaker sourcing the fault

current. The EAFR-101C complete system self-supervision function

provides the highest level of dependability by continuously monitoring all internal system functions along with external connections.

The EAFR-101C is designed according to the latest protection relay

standards and is therefore suitable for installations in rough environments, such as utility, traditional or renewable power plants, off

shore, marine, oil and gas, mining, steel, or any other heavy industry

applications. It is also well suited for commercial and institutional

electrical systems. The EAFR-101C is suitable for either medium

voltage or low voltage switchgear and motor control center applications in both new and retrofit installations.

2.1 EAFR-101C features

The EAFR-101C is a multipurpose arc flash protection relay that can

receive light from four different channels of light point sensors and

can be applied for variety of applications. The EAFR-101C can be

used as a stand-alone relay or as part of a more complex arc protection system through the binary bus.

Main features of EAFR-101C:

•

(110-220) Vac / (125-250) Vdc auxiliary power supply;

•

(18-72) Vdc optional power supply;

•

Four arc point sensor channels (S1, S2, S3, and S4);

•

Six binary inputs (BI1, BI2, BI3, BI4, BI5, and BI6) nominal voltage

of 24 Vdc;

•

Three normally open trip relay outputs with direct trip circuit rated

contacts (T1, T2, and T3);

•

One normally open electronic lock-out trip relay with direct trip

circuit rated contacts (T2);

•

Two 24 Vdc binary outputs (BO1 and BO2);

•

One system failure relay, form C output (SF);

•

16 indication LEDs; and

•

One push-button (SET).

Figure 1. The EAFR-101C arc protection IO relay.

2

EATON www.eaton.com

EAFR-101C arc point sensor relay

user manual

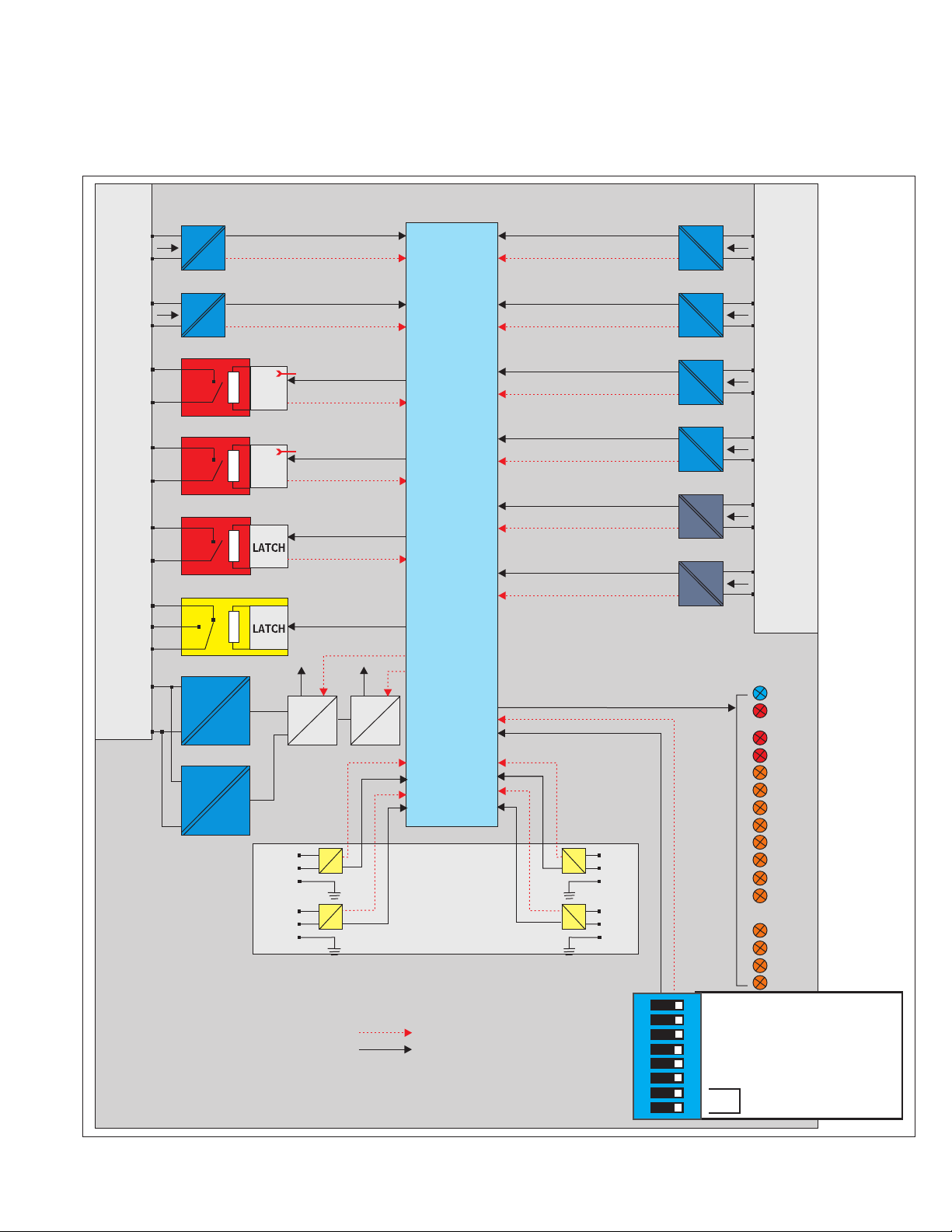

2.2 Simplified block diagram

The EAFR-101C simplified block diagram (see Figure 2) shows the

main components of the EAFR-101C relay.

Instruction Booklet IB0191002EN

Effective November 2019

X2

BI1

BI2

T1

T2

T3

SF

X1

15

14

13

12

EN

11

10

9

8

7

LATCH

LATCH

SW6

EN

SW6

15

14

12

11

10

9

8

7

6

5

BI3

BI4

BI5

BI6

BO1

uP

6

5

4

3

4

3

BO2

Uaux

2

1

125...250

Vdc

24 Vdc

110...220

Vac/dc

24 Vdc

S1

S2

24 Vdc

12 Vdc

12

11

10

9

8

7

12 Vdc

5 Vdc

X3

Self supervision

Control and power supply

6

S3

5

4

3

S4

2

1

ON OFF

Power

Error

T1,T3

T2,T3

BI1

BI2

BI3

BI4

BI5

BI6

BO1

BO2

S1

S2

S3

S4

8

S1/S2 Chan: L/L+C

7

S3/S4 Chan: L/L+C

6

T1/T2: Latch/NL

5

CB1 in use: Yes/no

4

CB2 in use: Yes/no

MT/C

3

2

1

Configuration

select

Figure 2. EAFR-101C simplified block diagram.

EATON www.eaton.com

3

Instruction Booklet IB0191002EN

Effective November 2019

EAFR-101C arc point sensor relay

user manual

3 Operation and conguration

3.1 LED indicator functions

The EAFR-101C contains 16 indication LEDs. A user definable text

pocket can be slid in under the label for identifying each LED function (except POWER and ERROR LEDs). LEDs are located at the

front plate of the relay for clear viewing without a need for opening

doors.

During power up, the relay performs an LED test. All LEDs are

turned on for two seconds and then off. Only the blue POWER LED

will remain on. After powered up, the relay goes into protection

mode in 50 ms even while the LED test is being performed.

During normal operation, the blue power LED is ON, as are any CB

open/close status LED’s for connected CB’s.

The sensor LEDs are off during the inactive condition. If a point arc

sensor is activated, the corresponding sensor channel LED will turn

on if the activation is longer than 1.5 ms. The sensor LED activation

In case of a loose sensor wire and binary input wires or configuration mismatch (new sensor attached without running auto-configuration system setup (see Section 3.3.1) situation, the corresponding

LED for that sensor will start flashing and the ERROR LED will

activate.

The Binary I/O LEDs indicate the I/O-line status. If any of the lines

become active for more than 1.5 ms, the corresponding LED will

turn on (latch).

In a trip situation, the corresponding trip LED will turn on. Trip

outputs are controlled by the dipswitch settings (see Section 3.5).

All activation and trip indication LEDs are latched, even if the

dipswitch setting is in the non-latched mode. They have to be

cleared by pushing the “SET” button.

LED indications are stored in non-volatile EPROM memory for identifying the trip information in case the auxiliary power is lost. When

re-powering the relay after power supply loss, the actual LED status

can be visualized from the front of the relay.

function is latched (steady light). To clear the LED, the “SET” button

should be pressed.

3.2 LED operation quick guide

Table 1. LED operation quick guide.

LED Off Steady On Blinking Action if Abnormal

POWER - Blue Auxiliary supply

disconnected.

ERROR - Red System healthy. System failure. Configuration mismatch.

T1, and T3 - Red Normal status. Trip relays T1 and T3 activated. N/A Check the reason for trip. Clear the fault

T2, and T3 - Red Normal status. Trip relays T2 and T3 activated. N/A Check the reason for trip. Clear the fault

BI1 - Amber CB open. CB closed. Loose connection/dipswitch

BI2 - Amber CB closed. CB open. Loose connection/dipswitch

BI3 - Amber CB open. CB cLosed. Loose connection/dipswitch

BI4 - Amber CB closed. CB open. Loose connection/dipswitch

BI5 - Amber Normal status. Current/MT indication. Binary input 5 has loose

BI6 - Amber Normal status. Blocking signal input.. Binary input 6 has loose

BO1 - Amber Normal status. Light > output. N/A N/A

BO2 - Amber Normal status. Blocking signal high. N/A N/A

S1 - Amber Normal status. Sensor channel 1 activated by

S2 - Amber Normal status. Sensor channel 2 activated by

S3 - Amber Normal status. Sensor channel 3 activated by

S4 - Amber Normal status. Sensor channel 4 activated by

Auxiliary power connected. N/A Check the power source.

Verify system condition. See Sections

11: Troubleshooting guide and 5: System

self-super vision.

and reset indications by pushing SET

button.

and reset indications by pushing SET

button.

Check the binary input wiring/dipswitch

setting.

Check the binary input wiring/dipswitch

setting.

Check the binary input wiring/dipswitch

setting.

Check the binary input wiring/dipswitch

setting.

Check the binary input wiring.

Check the binary input wiring.

Check why the sensor activated, check

the sensor wire connection, or perform

the system set-up (see Section 3.3.1:

Auto-configuration (System setup).

Check why the sensor activated, check

the sensor wire connection, or perform

system set-up (see Section 3.3.1: Autoconfiguration (System setup).

Check why the sensor activated, check

the sensor wire connection, or perform

system set-up (see Section 3.3.1: Autoconfiguration (System setup).

Check why the sensor activated, check

the sensor wire connection, or perform

system set-up (see Section 3.3.1: Autoconfiguration (System setup).

light information

light information.

light information.

light information

Protection partly operational.

mismatch.

mismatch.

mismatch.

mismatch.

connection.

connection.

Sensor channel 1 has loose

connection or the system setup was not performed. Also

activated by pressure information

(if L+P sensors used).

Sensor channel 2 has loose

connection or system set-up

not performed. Also activated

by pressure information (if L+P

sensors used).

Sensor channel 3 has loose

connection or system set-up

not performed. Also activated

by pressure information (if L+P

sensors used).

Sensor channel 4 has loose

connection or system set-up

not performed. Also activated

by pressure information (if L+P

sensors used).

4

EATON www.eaton.com

EAFR-101C arc point sensor relay

user manual

Instruction Booklet IB0191002EN

Effective November 2019

3.3 Push-button description

The EAFR-101C contains one single push-button (SET) that can be

used for all operational functions of the relay. The push-button is

used to initialize the auto-configuration of the system (see Section

3.3.1) and for resetting the indicators and latched output relays.

3.3.1 Auto configuration (System setup)

When all sensors and binary lines have been connected, an

auto-configuration procedure must be executed. The initialization sequence is performed by pressing the “Set” button for two

seconds. The EAFR-101C sensor LEDs and all binary LEDs start

blinking. The relay scans these inputs to see if they are connected

and when an input is detected, the corresponding LEDs are illuminated to mark that a connection was found. The inputs without

connection continue blinking during the remaining three seconds.

After five seconds, all LEDs are turned off. During this system

setup, the dipswitch setting are also stored in non-volatile memory.

All sensor inputs will remain operational even when they are not

auto-configured. The auto-configuration is only used for self-supervision purposes.

ote: N To redo auto-configuration for a relay containing fewer connections

(binary inputs/outputs or sensors) than in a previously memorized set-up,

a dipswitch (any one) must be moved back and forth prior to performing auto-configuration. The timeout allowing a new configuration is one

minute. Reconfiguration with more connections is allowed without moving a

dipswitch.

3.4 Reset

All LED indications and latched trip relays are reset by pressing the

“SET” button for one second. Otherwise, the latched trip relays will

remain activated until auxiliary power is disconnected. All LED indications will remain active until reset is performed by the operator,

even when auxiliary power supply is disconnected (see Section 3.6:

Non-volatile memory).

3.5 Dipswitch settings

EAFR-101C functionality, such as tripping logic, is configured using

dipswitch settings. Different trip configurations can be easily

programmed by selecting the appropriate dipswitch positions. This

gives users the flexibility to change settings dependent on the

application. Tripping may be selected based on arc light only or arc

light and current thresholds. Current threshold or other tripping

criteria may be applied to binary input BI1 for blocking a trip caused

by natural light sources. Dipswitches 1 and 2 are used as configuration selection. Dipswitch 3 is for configuring BI5 to operate as a

Master Trip input or as a current information input. Dipswitch 4 and

5 are for setting binary input pairs 1-2 and 3-4 as active or inactive.

If a circuit breaker is connected to a binary input pair, the respective

dipswitch should be set to ON. Dipswitch 6 sets whether trip relay

outputs T1 and T2 latch or activate momentarily. Dipswitches 7 and

8 set whether sensor channels 1/2 and 3/4, respectively, pick up on

light only or on light and current.

Dipswitches are located at the back of the relay for easy access

(see Figure 3: EAFR-101C Dipswitch SW1 and Table 2: EAFR-101C

dipswitch setting selection for details of settings).

S1/S2 Chan: light

S3/S4 Chan: light

Configuration select:

Figure 3. EAFR-101C dipswitch SW1.

T1/T2: latch

CB1 in use: yes

CB2 in use: yes

Master trip

8

Light and current

7

Light and current

6

Non-latch

No

5

No

4

Current

3

2

1

EATON www.eaton.com

5

Instruction Booklet IB0191002EN

Effective November 2019

EAFR-101C arc point sensor relay

user manual

Table 2. EAFR-101 dipswitch setting selection.

Dipswitch Function selection ON (left position) OFF (right position)

8 Point sensor channels S1,S2 trip criteria. Trip on light only. (L) Trip on light and over-current. (L+C)

7 Point sensor channel S3,S4 trip criteria. Trip on light only. (L) Trip on light and over-current. (L+C)

6 Latch or non-latch for trip relays T1 and

T2.

5 Binary Input 1 & 2 activation. CB in use/

not in use.

4 Binary Input 3&4 activation. CB in use/

not in use.

3 Binary Input 5 function selection. Master trip. Current.

2 Configuration selection.

1 Configuration selection.

T1 and T2 operate as latched. T1 and T2 operate as non-latched.

ote: N Trip relay T3 is always latched. Binary output BO1 (light out) function is

always non-latched.

CB in use. CB not in use.

CB in use. CB not in use.

Both signals are required simultaneously

to trip.

Both signals are required simultaneously

to trip.

6

EATON www.eaton.com

Loading...

Loading...