Eaton DST-2-7.5-500, DST-2-15-VR+500, DST-2-7.5-VR+500, DST-2-15-VR+500U, DST-2-15-500 Instruction Book

...

Instruction Book IB182942EN

Supersedes March 2018

Effective

July 2018

DST-2-VR

+

VR-Series+ Replacement Circuit Breaker

DST-2-VR+ 250 2000A Shown

DST-2-VR

+

VR-Ser ies+ Replacement Circuit Breaker

DISCLAIMER OF WARRANTIES AND LIMITATION OF LIABILITY

The information, recommendations, descriptions and safety notations in this document are based on Eaton’s experience and judgment and

may not cover all contingencies. If further information is required, an Eaton sales office should be consulted. Sale of the product shown in

this literature is subject to the terms and conditions outlined in appropriate Eaton selling policies or other contractual agreement between

Eaton and the purchaser.

THERE ARE NO UNDERSTANDINGS, AGREEMENTS, WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING WARRANTIES OF FITNESS

FOR A PARTICULAR PURPOSE OR MERCHANTABILITY, OTHER THAN THOSE SPECIFICALLY SET OUT IN ANY EXISTING CONTRACT

BETWEEN THE PARTIES. ANY SUCH CONTRACT STATES THE ENTIRE OBLIGATION OF EATON. THE CONTENTS OF THIS DOCUMENT

SHALL NOT BECOME PART OF OR MODIFY ANY CONTRACT BETWEEN THE PARTIES.

In no event will Eaton be responsible to the purchaser or user in contract, in tort (including negligence), strict liability or other-wise for any

special, indirect, incidental or consequential damage or loss whatsoever, including but not limited to damage or loss of use of equipment,

plant or power system, cost of capital, loss of power, additional expenses in the use of existing power facilities, or claims against the

purchaser or user by its customers resulting from the use of the information, recommendations and descriptions contained herein. The

information contained in this manual is subject to change without notice.

DANGER

IMPROPERLY INSTALLING OR MAINTAINING THESE PRODUCTS MAY

CAUSE THE EQUIPMENT TO FAIL, RESULTING IN DEATH, SEVERE

PERSONAL INJURY, EQUIPMENT DAMAGE AND/OR IMPROPER

OPERATION.

READ AND UNDERSTAND THESE INSTRUCTIONS BEFORE ATTEMPTING

ANY UNPACKING, ASSEMBLY, OPERATION OR MAINTENANCE OF THE

CIRCUIT BREAKERS.

INSTALLATION OR MAINTENANCE SHOULD BE ATTEMPTED ONLY

BY QUALIFIED PERSONNEL. THIS INSTRUCTION BOOKLET SHOULD

NOT BE CONSIDERED ALL INCLUSIVE REGARDING INSTALLATION OR

MAINTENANCE PROCEDURES. IF FURTHER INFORMATION IS REQUIRED,

YOU SHOULD CONSULT EATON’S ELECTRICAL SERVICES & SYSTEMS.

THE CIRCUIT BREAKERS DESCRIBED IN THIS BOOK ARE DESIGNED AND

TESTED TO OPERATE WITHIN THEIR NAMEPLATE RATINGS. OPERATION

OUTSIDE OF THESE RATINGS MAY CAUSE THE EQUIPMENT TO FAIL,

RESULTING IN DEATH, SEVERE PERSONAL INJURY, EQUIPMENT DAMAGE

AND/OR IMPROPER OPERATION.

ALL SAFETY CODES, SAFETY STANDARDS AND/OR REGULATIONS AS

THEY MAY BE APPLIED TO THIS TYPE OF EQUIPMENT MUST BE STRICTLY

ADHERED TO.

THESE VACUUM REPLACEMENT CIRCUIT BREAKERS ARE DESIGNED TO

BE INSTALLED PURSUANT TO THE AMERICAN NATIONAL STANDARDS

INSTITUTE (ANSI). SERIOUS INJURY, INCLUDING DEATH, SEVERE

PERSONAL INJURY, EQUIPMENT DAMAGE AND/OR IMPROPER

OPERATION.

This product was manufactured by Eaton at the Power Breaker

Center (PBC): 310 Maxwell Avenue, Greenwood, SC 29646.

All possible contingencies which may arise during installation,

operation or maintenance, and all details and variations of this

equipment do not purport to be covered by these instructions. If

further information is desired by purchaser regarding his particular

installation, operation or maintenance of particular equipment,

contact an Eaton representative.

ii

Instruction Book IB182942EN July 2018 www.eaton.com

Table of Contents

SECTION 1: INTRODUCTION 4

1.1 VISUAL INSTRUCTION BOOKLET ESSENTIALS 4

1.2 QUICK RESPONSE CODE 4

1.3 AVAILABLE DST-2-VR+ CIRCUIT BREAKERS 4

SECTION 2 : SAFE PRAC TICES 7

SECTION 3 : RECEIVING, HANDLING, AND STORAGE 8

3.1 RECEIVING 8

3.2 HANDLING 9

3.3 STORAGE 9

3.4 APPROXIMATE WEIGHT BY TYPE 9

SECTION 4: DESCRIPTION AND OPERATION 12

4.1 VACUUM INTERRUPTER 12

4.1.1 VACUUM INTERRUPTER ASSEMBLY 12

4.1.2 CONTACT EROSION INDICATOR 12

4.1.3 CONTACT WIPE AND STROKE 13

4.2 LINE AND LOAD CONDUCTOR ASSEMBLIES 13

4.3 STORED ENERGY MECHANISM 13

4.3.1 CLOSING SPRING CHARGING 13

4.3.2 CLOSING OPERATION 13

4.3.3 TRIPPING OPERATION 14

4.3.4 TRIP-FREE OPERATION 14

4.4 CONTROL SCHEMES 14

4.4.1 TIMING 14

4.5 SECONDARY CONNECTION BLOCK 14

4.6 INTERLOCKS 14

4.6.1 ANTI-CLOSE INTERLOCK 14

4.6.2 SHUTTER OPERATING MECHANISM 14

4.6.3 RACKING SYSTEM TRIP AND

SPRING RELEASE INTERLOCKS 16

4.7 RACKING MECHANISM 16

4.7.1 LE VERING SYSTEM TRIP A ND

SPRING RELEASE INTERLOCKS 16

4.8 GROUNDING CONTACT 16

4.9 MISCELLANEOUS ITEMS 16

4.9.1 OPERATIONS COUNTER 16

SECTION 5: INSPECTION & INSTALLATION 20

5.1 EXAMINATION FOR DAMAGE 20

5.1.1 NAMEPL ATE VERIFICATION 20

5.2 SURE CLO SE MECHANISM ADJUSTMENT 20

DST-2-VR

+

VR-Ser ies+ Replacement Circuit Breaker

5.3 MANUAL OPERATION CHECK 21

5.4 VACUUM INTERRUPTER INTEGRIT Y 21

5.5 LOW FREQUENCY WITHSTAND

TEST ( INSULATION CHECK ) 21

5.6 CONTACT EROSION AND WIPE 21

5.7 PRIMARY CIRCUIT RESISTANCE 21

5.8 ELECTRICAL OPERATIONS CHECK 21

5.9 MECHANICAL INTERLOCK (FLOOR

TRIP) OPERATIONAL CHECKS 21

5.10 OPERATION, INSERTION AND

REMOVAL ( LEVERING-IN VERSION) 22

5.10.1 OPERATIONAL POSITIONS ( LEVERING-IN VERSION) 22

5.10.2 INSERTION PROCEDURE ( LEVERING- IN VERSION ) 22

5.10.3 REMOVAL PROCEDURE (LE VERING- IN VERSION ) 23

5.11 OPERATION, INSERTION, AND REMOVAL FOR 5kV AND

15kV MODELS WITH ROTARY RACKING PROVISIONS 24

5.11.1 Operational Positions ( Domestic and

some Canadian Rotary Racking Versions) 24

5.11.2 5kV Insertion Procedure (DST-2-5-VR+ 250, Domestic

and Canadian Rotary Racking Version) 24

5.11.3 5kV Removal Procedure (DST-2- 5-VR+ 250, Domestic

and Canadian Rotary Racking Version) 25

5.11.4 15kV Insertion Procedure ( DST-2-15-VR+ 500/750

Domestic and Canadian Rotary Racking Version) 25

5.11.5 15kV Removal Procedure (DST-2-15-VR+ 500/750

Domestic and Canadian Rotary Racking Version) 26

SECTION 6: INSPECTION & MAINTENANCE 27

6.1 INSPECTION FREQUENCY 27

6.2 INSPECTION AND MAINTENANCE PROCEDURES 27

6.3 VACUUM INTERRUPTER INTEGRIT Y TEST 28

6.4 CONTACT EROSION AND WIPE 28

6.5 INSULATION 29

6.6 INSULATION INTEGRIT Y CHECK 29

6.7 PRIMARY CIRCUIT RESISTANCE CHECK 29

6.8 VR-SERIES+ CIRCUIT BREAKER

ELEMENT MECHA NISM CHECK 29

6.8.1 CLOSURE™ TEST 29

6.9 MAINTENANCE RECOMMENDATION 33

SECTION 7: REPLACEMENT PARTS 35

7.1 GENERAL 35

7.2 ORDERING INSTRUCTIONS 35

Instruction Book IB182942EN July 2018 www.eaton.com

iii

DST-2-VR

+

VR-Ser ies+ Replacement Circuit Breaker

SECTION 1: INTRODUCTION

This instruction booklet provides information on receiving and

handling, storage, installation, operation and maintenance of the

DST-2 VR-Series+ vacuum replacement circuit breaker. The Vacuum

Replacement circuit breakers (also referred to as VR-Series+) are

designed to be used in existing Federal Pacific type DST-2 metal-clad

switchgear. The VR-Series+ circuit breakers provide superior electrical

and mechanical performance as compared to the design ratings

of the original circuit breaker. VR-Series+ circuit breakers provide

reliable control, protection and performance, with ease of handling

and maintenance. Like ratings of the VR-Series+ circuit breakers are

interchangeable with each other.

The VR-Series+ circuit breaker element offers:

• 10-year or 10,000 operation scheduled maintenance intervals.

When applied in “usual service conditions” as defined by IEEE

C37.04-1999, the VR-Series+ circuit breaker element requires

maintenance only once every ten years or ten thousand

operations, which ever comes first.

ote:N See Inspection & Maintenance section in this booklet for details.

• Increased mechanical endurance. Circuit breakers in repetitive

duty applications offer 50% more operations over conventional

vacuum circuit breaker elements before parts replacement may

be needed.

• Increased short circuit capability. The VR-Series+ circuit breaker

short circuit capability can be increased to 41 kA, provided a bus

bracing study is performed and the switchgear is adequately

braced to meet the requirements per IEEE C37.59.

Use this instruction bulletin in conjunction with the technical

information provided with the original equipment order which

includes electrical control schematic and wiring diagrams, outline

diagrams, installations plans, and procedures for installation and

maintenance of accessory items.

Satisfactory performance is dependent on proper application, correct

installation, and adequate maintenance. It is very important that

this installation and maintenance instruction booklet be read and

followed closely to achieve optimum performance and a long useful

circuit breaker life in its application.

1.1 VISUAL INSTRUCTION BOOKLET ESSENTIALS

Eaton provides additional documentation designed to enhance the

technical information provided in this instruction booklet for the

VR-Series+ circuit breakers. The Visual Instruction Booklet Essentials

(VIBE) is a digital supplemental booklet featuring user interactive

content and informative videos intended to assist with the

maintenance of the VR-Series+ circuit breaker. The VIBE document is

available for immediate download at www.eaton.com/VR-Series.

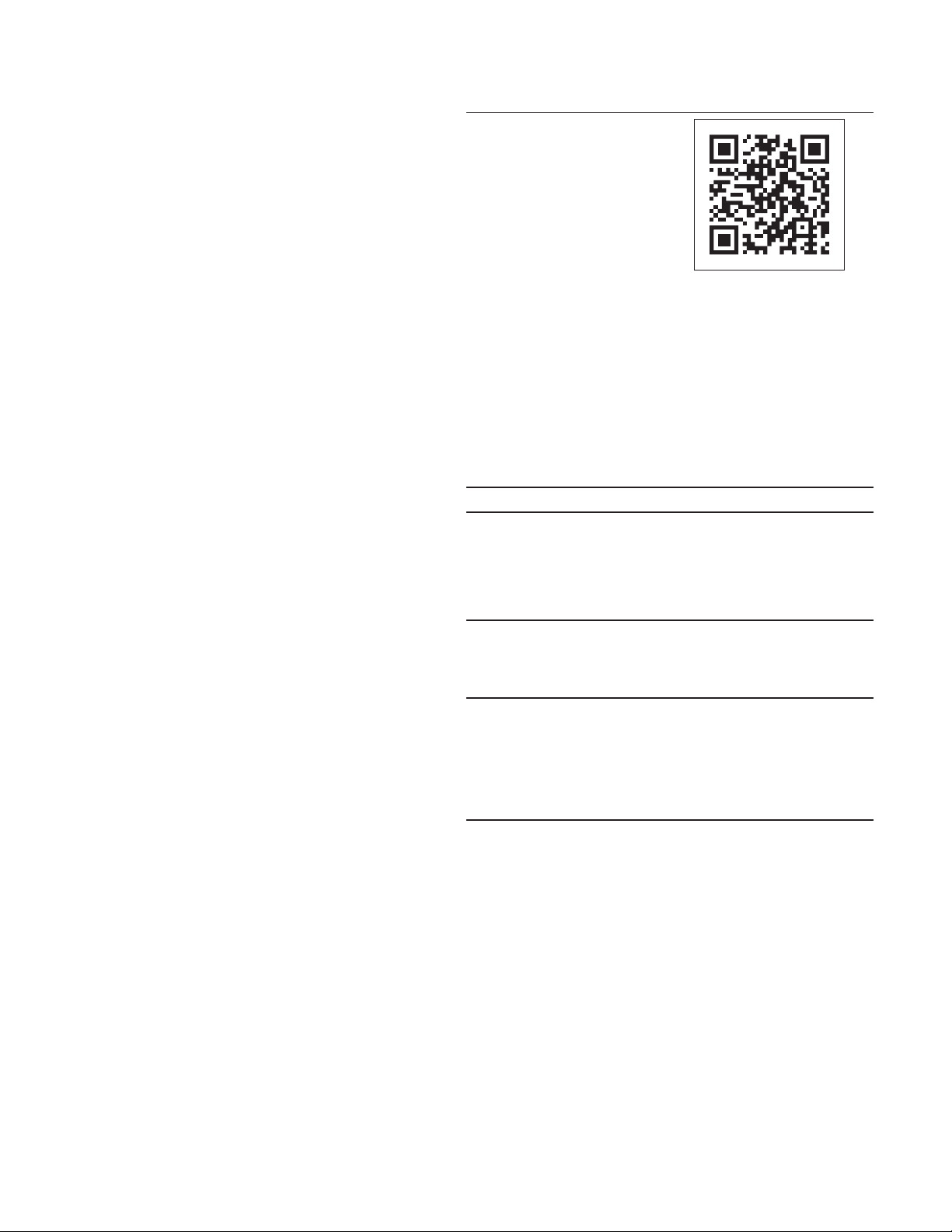

Figure 1.1. Quick Response Code

VR-Series+ QR Code

1.2 QUICK RESPONSE CODE

VR-Series+ circuit breakers have a quick response code (QR Code)

on the escutcheon of the circuit breaker front cover. This QR Code is

a matrix barcode that provides direct access to download VR-Series+

specific documentation, such as product instruction booklets and the

VIBE documentation. See Figure 1.1 for the featured VR-Series+ QR

Code.

ote:N A smart phone with an adequate QR Code Scanner application must be

used. Downloading content may incur data charges from the mobile service

provider.

WARNING

SATISFACTORY PERFORMANCE OF THESE CIRCUIT BREAKERS IS

CONTINGENT UPON PROPER APPLICATION, CORRECT INSTALLATION

AND ADEQUATE MAINTENANCE. THIS INSTRUCTION BOOKLET MUST

BE CAREFULLY READ AND FOLLOWED IN ORDER TO OBTAIN OPTIMUM

PERFORMANCE FOR LONG USEFUL LIFE OF THE CIRCUIT BREAKERS. IT IS

FURTHER RECOMMENDED THAT THE INSTALLATION BE PERFORMED BY

AN EATON TRAINED ENGINEER OR TECHNICIAN.

+

VR-SERIES

THEY ARE MAXIMUM RATED DEVICES. THEREFORE, THEY SHOULD NOT

UNDER ANY CIRCUMSTANCE BE APPLIED OUTSIDE THEIR NAMEPLATE

RATINGS.

ALL POSSIBLE CONTINGENCIES WHICH MIGHT ARISE DURING

INSTALLATION, OPERATION, OR MAINTENANCE, AND ALL DETAILS

AND VARIATIONS OF THIS EQUIPMENT ARE NOT COVERED BY THESE

INSTRUCTIONS. IF FURTHER INFORMATION IS DESIRED BY THE

PURCHASER REGARDING A PARTICULAR INSTALLATION, OPERATION, OR

MAINTENANCE OF THIS EQUIPMENT, THE LOCAL EATON REPRESENTATIVE

SHOULD BE CONTACTED.

1.3 AVAILABLE DST-2-VR+ CIRCUIT BREAKERS

Refer to Table 1.

CIRCUIT BREAKERS ARE PROTECTIVE DEVICES, AS SUCH,

4

Instruction Book IB182942EN July 2018 www.eaton.com

Table 1. DST-2-VR+ Availability and Interchangeability

Nominal

3-Phase

Existing

DST-2

Circuit Breaker

Type

DST-2-7.5-500

DST-2-15-500

DST-2-15-500U

DST-2-15-750

DST-2-15-500/750

a

All circuit breakers have a 3 second short-time and 3-cycle interrupting ratings.

b

Non-standard rating.

c

Requires bus bracing study and additional switchgear bracing.

+

DST-2-VR

Circuit Breaker

a

Type

DST-2-7.5-VR+500

DST-2-15-VR+500

DST-2-15-VR+500U

DST-2-15-VR+750

DST-2-15-VR+41

Maximum

Voltage

kV MVA Amps K

8.25 500 1200 / 2000 1.25 36 95 33 41 66 / 111

15.0 500 1200 / 2000 1.30 36 95 18 23 37 / 62

c

15.0 500 1200 / 2000 1.30 36 95 28 36 58 / 97

15.0 750 1200 / 2000 1.30 36 95 28 36 58 / 97

b c

15.0 N/A 1200 / 2000 1.0 36 95 41 41 77 / 130

MVA

Class

Existing Circuit

Breaker Rated

Continuous

Current at 60 Hz

Rated

Voltage

Factor

Rated Withstand

ANSI Test Voltage

Low Freq.

kV RMS

Impulse

kV PeakIkA RMS

DST-2-VR

VR-Ser ies+ Replacement Circuit Breaker

Closing and

Rated

Short-Circuit

Maximum Sym.

Interrupting

Capability

KI

kA RMS kA RMS / Peak

Latching /

Momentary

Capabilities

+

Instruction Book IB182942EN July 2018 www.eaton.com

5

DST-2-VR

+

VR-Ser ies+ Replacement Circuit Breaker

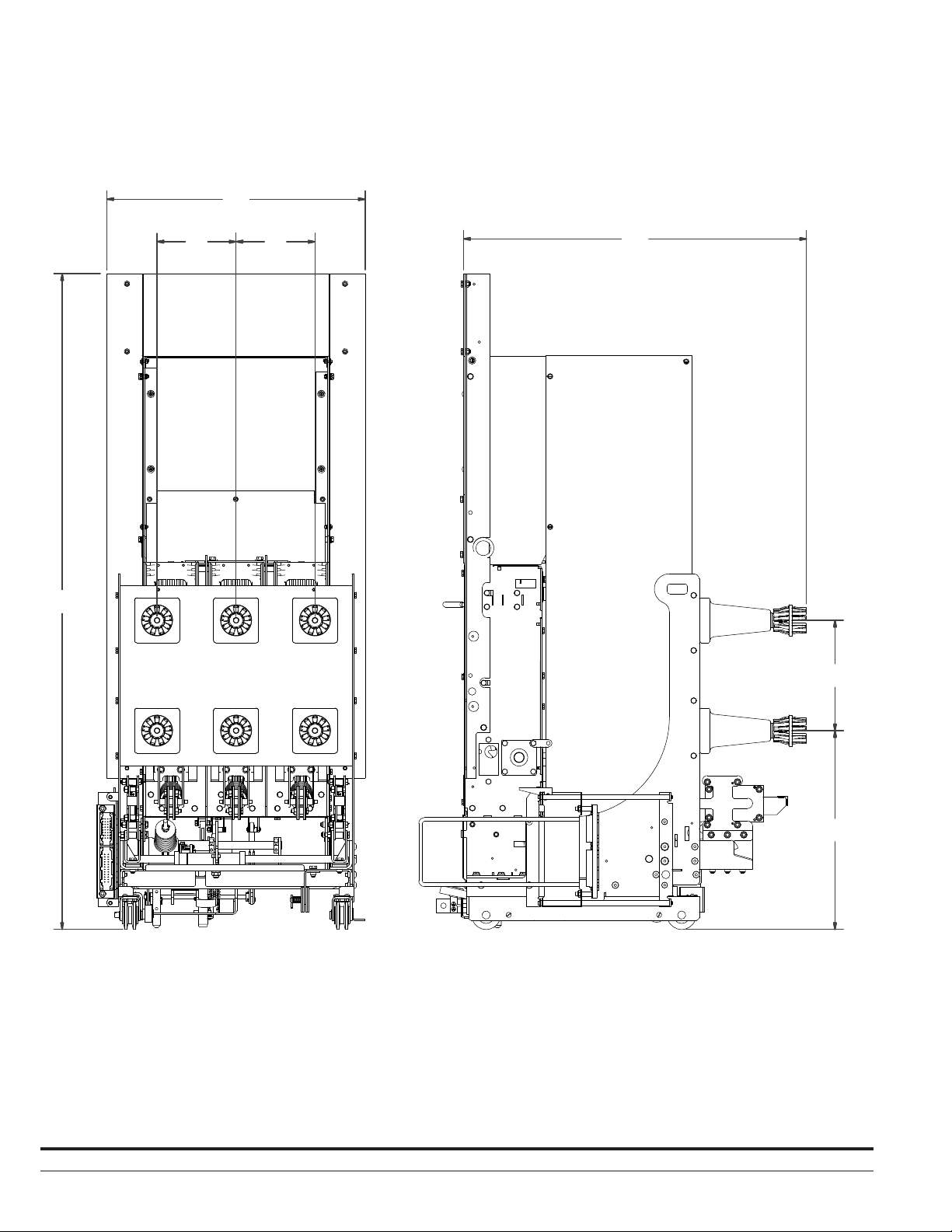

B

C C

A

D

E

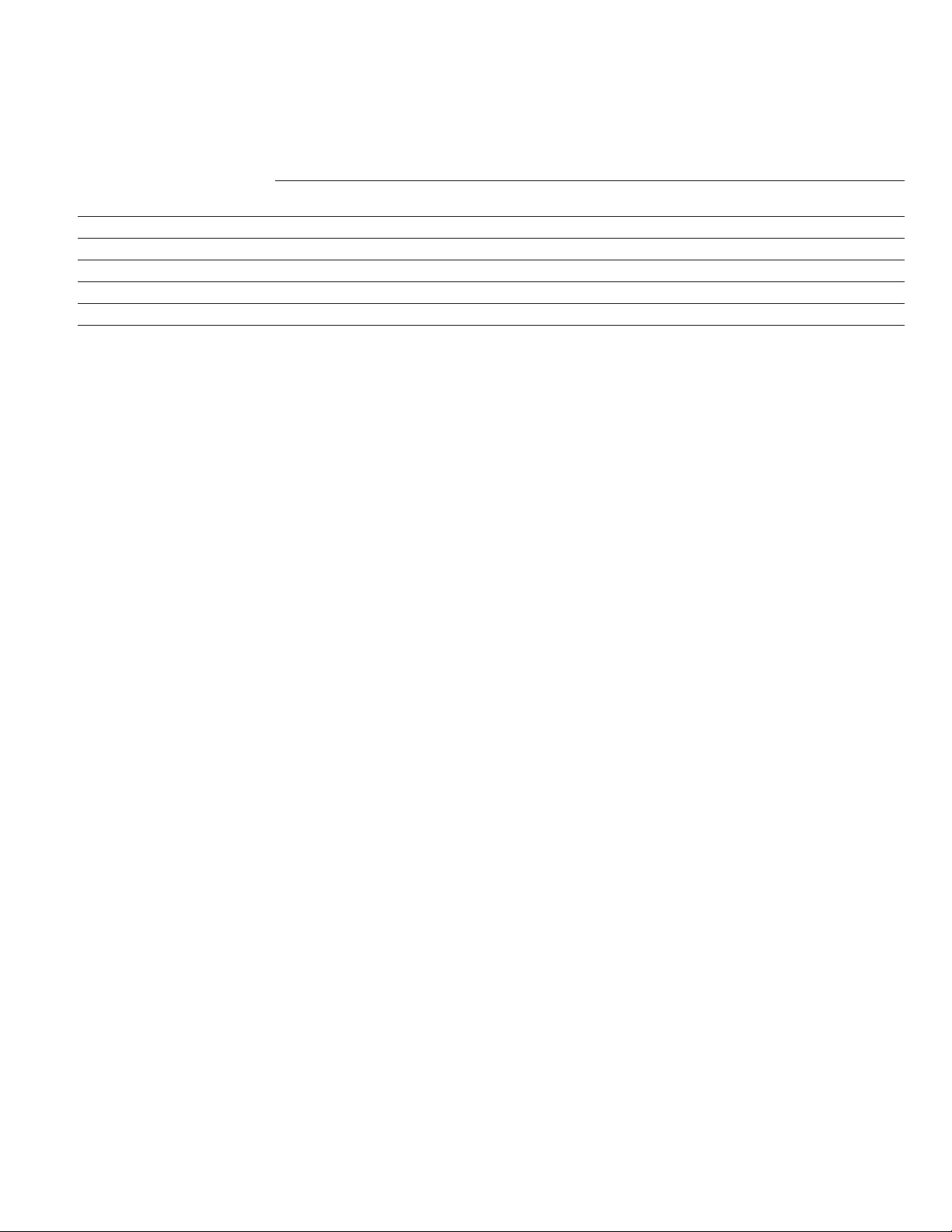

Table 2. DST-2-VR+ Dimensions

Existing Circuit

Breaker Rated

Continuous

Current at 60 Hz

Circuit Breaker Type

DST-2-VR+

6

(Amps) A B C D E F

1200 / 2000 65.38 25.75 7.88 34.18 11.00 19.81

Instruction Book IB182942EN July 2018 www.eaton.com

F

SECTION 2: SAFE PRACTICES

VR-Series+ circuit breakers are equipped with high speed, high

energy operating mechanisms. They are designed with several builtin interlocks and safety features to provide safe and proper operating

sequences.

DANGER

TO PROTECT THE PERSONNEL ASSOCIATED WITH INSTALLATION,

OPERATION, AND MAINTENANCE OF THESE CIRCUIT BREAKERS, THE

FOLLOWING PRACTICES MUST BE FOLLOWED:

•

Only qualified persons, as defined in the National Electrical

Safety Code, who are familiar with the installation and

maintenance of medium voltage circuits and equipment,

should be permitted to work on these circuit breakers.

•

Read these instructions carefully before attempting any

installation, operation or maintenance of these circuit

breakers.

•

Always remove the circuit breaker from the enclosure before

performing any maintenance. Failure to do so could result in

electrical shock leading equipment failure, resulting in death,

severe personal injury, equipment damage and/or improper

operation.

•

Do not work on a circuit breaker with the secondary test

coupler engaged. Failure to disconnect the test coupler could

result in an electrical shock leading to death, severe personal

injury, equipment damage and/or improper operation.

•

Do not work on a closed circuit breaker or a circuit breaker

with closing springs charged. The closing spring should be

discharged and the main contacts open before working on

the circuit breaker. Failure to do so could result in cutting or

crushing injuries.

•

Do not use a circuit breaker by itself as the sole means of

isolating a high voltage circuit. Remove the circuit breaker

to the ‘Disconnect’ position and follow all lockout and

tagging rules of the National Electrical Code and any and all

applicable codes, regulations and work rules.

•

Do not leave the circuit breaker in an intermediate position

in the circuit breaker compartment. Always have the circuit

breaker either in the ‘Test’ or ‘Connect’ position. Failure to do

so could result in a flash over causing the equipment to fail,

resulting in death, severe personal injury, equipment damage

and/or improper operation.

•

Always remove the maintenance tool from the circuit breaker

after charging the closing springs.

•

Circuit breakers are equipped with safety interlocks. Do not

defeat them. This may result in equipment failure, resulting

in death, severe personal injury, equipment damage and/or

improper operation.

DST-2-VR

VR-Ser ies+ Replacement Circuit Breaker

+

Instruction Book IB182942EN July 2018 www.eaton.com

7

DST-2-VR

+

VR-Ser ies+ Replacement Circuit Breaker

SECTION 3: RECEIVING, HANDLING, AND

STORAGE

VR-Series+ circuit breakers are subjected to complete factory

production tests and inspection before being packed. They are

shipped in packages designed to provide maximum protection to the

equipment during shipment and storage and at the same time to

provide convenient handling. Accessories such as the maintenance

tool, code plate, (if applicable) etc. are shipped with the circuit

breaker.

3.1 RECEIVING

Until the circuit breaker is ready to be delivered to the switchgear

site for installation, DO NOT remove it from the shipping crate. If the

circuit breaker is to be placed in storage, maximum protection can

be obtained by keeping it in its crate.

Upon receipt of the equipment, inspect the crates for any signs of

damage or rough handling. Open the crates carefully to avoid any

damage to the contents. Use a nail puller rather than a crow bar

when required.

When opening the crates, be careful that any loose items or

hardware are not discarded with the packing material. Check the

contents of each package against the packing list.

Examine the circuit breaker for any signs of shipping damage

such as broken, missing or loose hardware, damaged or deformed

insulation and other components. If damaged or loss is detected,

file claims immediately with the carrier and notify an Eaton

representative.

Figure 3.1.a. Typical Tools and Accessories

Figure 3.1.b. Rotary Racking Handle

Tools and Accessories

Maintenance Tool (Style# 94C9506G01): This tool is used to

manually charge the closing springs. One maintenance tool is

provided with each vacuum replacement circuit breaker.

Rotary Racking Handle (Style# 94B4102G21): Rotary racking is

possible utilizing a speed-handle, suitable extensions and a standard

3/4” socket. One rotary racking handle is provided per order. If

necessary, additional racking handles may be purchased directly

from Eaton. This handle is used with the rotary racking system for

insertion and removal.

Levering Handle: The original DST-2 levering handle is used to assist

in moving the circuit breaker into and out of the cell. However, it

cannot be used with the rotary racking system. Its use is illustrated

in section 5 of this manual.

Secondary Connection Block Extension Cable: The extension

cable can be used to connect the circuit breaker to a “test cabinet”

or to the switchgear cell’s secondary receptacle block so that

the breaker can be electrically operated while not installed in the

switchgear cell. This extension cable is the same one provided with

the original Federal Pacific breaker and is therefore not included as

part of the vacuum replacement breaker

Lifting Strap (Style# 94B1194G01): Optional item recommended

for lifting the DST-2-VR+ circuit breaker.

.

8

Instruction Book IB182942EN July 2018 www.eaton.com

DST-2-VR

VR-Ser ies+ Replacement Circuit Breaker

+

3.2 HANDLING

WARNING

DO NOT USE ANY LIFTING DEVICE AS A PLATFORM FOR PERFORMING

MAINTENANCE, REPAIR OR ADJUSTMENT OF THE CIRCUIT BREAKER OR

FOR OPENING, CLOSING THE CONTACTS OR CHARGING THE SPRINGS.

THE CIRCUIT BREAKER MAY SLIP OR FALL CAUSING SEVERE PERSONAL

INJURY. ALWAYS PERFORM MAINTENANCE, REPAIR AND ADJUSTMENTS

ON A WORKBENCH CAPABLE OF SUPPORTING THE CIRCUIT BREAKER

TYPE.

VR-Series+ circuit breaker shipping containers are designed to be

handled either by use of an overhead lifting device or by a fork lift

truck. If containers must be skidded for any distance, it is preferable

to use roller conveyors or individual pipe rollers.

Once a circuit breaker has been inspected for shipping damage, it

is best to return it to its original shipping crate until it is ready to be

installed in the metal-clad switchgear.

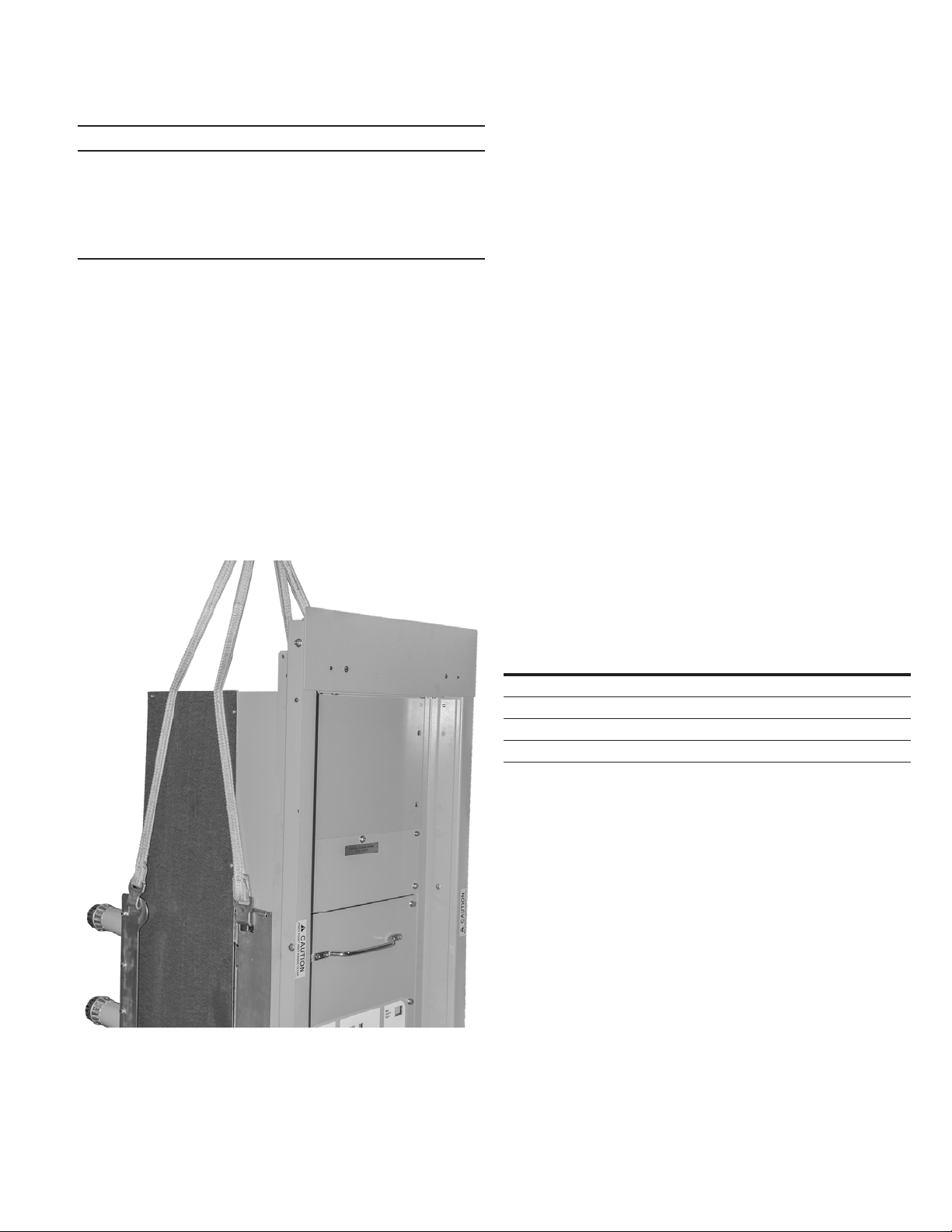

When the circuit breaker is ready for installation, a lifting harness in

conjunction with an overhead lift or portable floor lift can be used to

move the circuit breaker. If the circuit breaker is to be lifted, position

the lifting device over the circuit breaker and insert the lifting harness

hooks into the circuit breaker side lifting points and secure (lifting

straps should have at least a 1000lbs lift capacity). Be sure the hooks

are firmly attached before lifting the circuit breaker. Stand a safe

distance away from the circuit breaker while lifting and moving.

Figure 3.2. Lifting DST-2-VR

+

3.3 STORAGE

If the circuit breaker is to be placed in storage, maximum protection

can be obtained by keeping it in the original shipping crate. Confirm

that the circuit breaker is free from shipping damage and is in

satisfactory operating condition before placing it in to storage.

The circuit breaker is shipped with its contacts open and closing

springs discharged. The indicators on the front cover should confirm

this. Insert the end of the maintenance tool into the manual charge

socket opening and charge the closing springs by moving the

handle up and down the full range of motion. When charging is

complete the ratchet will no longer advance and the spring charged

/ discharged indicator displays ‘Charged’. (Figure Set 3.3). Remove

the maintenance tool. Push the “manual close” operator. The circuit

breaker will close as shown by the circuit breaker contacts ‘Closed’

indicator. Push the “manual trip” operator. The circuit breaker will

trip as shown by the circuit breaker contacts ‘Open’ indicator. After

completing this initial check, leave the closing springs ‘Discharged’

and circuit breaker contacts ‘Open’.

Outdoor storage is NOT recommended. If unavoidable, the outdoor

location must be well drained and a temporary shelter from sun,

rain, snow, corrosive fumes, dust, dirt, falling objects, excessive

moisture, etc. must be provided. Containers should be arranged

to permit free circulation of air on all sides and temporary heaters

should be used to minimize condensation. Moisture can cause

rusting of metal parts and deterioration of high voltage insulation.

A heat level of approximately 400 watts for each 100 cubic feet of

volume is recommended with the heaters distributed uniformly

throughout the structure near the floor.

Indoor storage should be in a building with sufficient heat and

circulation to prevent condensation. If the building is not heated, the

same general rule for heat as for outdoor storage should be applied.

3.4 APPROXIMATE WEIGHT BY TYPE

Table 3. Approximate Weight by Type

Type Amperes LBs

DST-2-VR+ 500

DST-2-VR+ 750

ote:N * = An additional 75# is added with the optional internal Rotary Racking

system.

1200 650*

2000 750*

1200 630*

2000 750*

Instruction Book IB182942EN July 2018 www.eaton.com

9

DST-2-VR

+

VR-Ser ies+ Replacement Circuit Breaker

Figure 3.3.a. Front External View of DST-2-VR

+

3

3

4

5

6

7

8

9

1

2

10

11

12

Front External View

1 Lock Out / Tag Out 5 Manual Charging Socket 9 Push To Close Button

2 Levering In Access 6 Spring Charged / Discharged Indicator 10 Interlock Pedal

3 Handle 7 Operations Counter 11 Manual Motor Cut-Off Switch

4 Breaker Position Indicator 8 Push To Open Button 12 Tow Hitch

10

Instruction Book IB182942EN July 2018 www.eaton.com

Figure 3.3.b. Rear External View of DST-2-VR

DST-2-VR

+

VR-Ser ies+ Replacement Circuit Breaker

+

1

1

3

4

2

5

6

Rear External View

1 Lifting Points 4 Anti Rotation Self Adjuster (Optional)

2 Secondary Disconnects 5 Ground Contact

3 Primary Disconnects 6 Shutter Roller

Instruction Book IB182942EN July 2018 www.eaton.com

11

Loading...

Loading...