Eaton DS7 User Manual

Manual

DS7

Soft starter

09/16 MN03901001Z-EN

All proprietary names and product designations are brand names or trademarks

registered to the relevant title holders.

Break-Down Service

Please call your local representative:

http://eaton.com/moeller/aftersales

or

Hotline After Sales Service:

+49 (0) 180 5 223822 (de, en)

AfterSalesEGBonn@eaton.com

Original operating manual

The German-language edition of this document is the original operating manual.

Translation of the original operating manual

All editions of this document other than those in German language are translations of

the original operating manual.

st

1

published 2010, edition date 07/10

nd

2

edition 2011, edition date 03/11

rd

3

edition 2011, edition date 06/11

th

4

edition 2011, edition date 11/11

th

5

edition 2012, edition date 07/12

th

6

edition 2013, edition date 09/13

th

7

edition 2016, edition date 09/16

See revision protocol in the “About this manual“ chapter

© 2010 by Eaton Industries GmbH, 53105 Bonn

Authors: Rainer Günzel, Jörg Randermann, Philipp Hergarten, Mustafa Akel

Redaction: René Wiegand

All rights reserved, also for the translation.

No part of this manual may be reproduced, stored in a retrieval system, or

transmitted in any form or by any means, electronic, mechanical, photocopying,

micro-filming, recording or otherwise, without the prior written permission of

Eaton Industries GmbH, Bonn.

Subject to alteration.

Danger!

Dangerous electrical voltage!

Before commencing the installation

• Disconnect the power supply of the device.

• Ensure that devices cannot be accidentally retriggered.

• Verify isolation from the supply.

• Ground and short-circuit.

• Cover or enclose neighbouring units that are live.

• Follow the engineering instructions (IL) of the device

concerned.

• Only suitably qualified personnel in accordance with

EN 50110-1/-2 (VDE 0105 Part 100) may work on this device/

system.

• Before installation and before touching the device ensure

that you are free of electrostatic charge.

• The functional earth (FE) must be connected to the

protective earth (PE) or to the potential equalizing.

The system installer is responsible for implementing this

connection.

• Connecting cables and signal lines should be installed so

that inductive or capacitive interference do not impair the

automation functions.

• Install automation devices and related operating elements

in such a way that they are well protected against unintentional operation.

• Suitable safety hardware and software measures should

be implemented for the I/O connection so that a cable or

wire breakage on the signal side does not result in

undefined states in the automation device.

• Ensure a reliable electrical isolation of the low voltage for

the 24 V supply. Only use power supply units complying

with IEC 60364-4-41 or HD 384.4.41 S2 (VDE 0100 part 410).

• Deviations of the mains voltage from the nominal value

must not exceed the tolerance limits given in the technical

data, otherwise this may cause malfunction and

dangerous operation.

• Emergency-Stop devices complying with IEC/EN 60204-1

must be effective in all operating modes of the automation

devices. Unlatching the emergency switching off devices

must not cause restart.

• Built-in devices for enclosures or cabinets must only be

run and operated in an installed state, desk-top devices or

portable devices only when the housing is closed.

• Measures should be taken to ensure the proper restart of

programs interrupted after a voltage dip or failure. This

Eaton Industries GmbH

should not cause dangerous operating states even for a

Safety instructions

short time. If necessary, emergency switching off devices

should be implemented.

• Wherever faults in the automation system may cause

damage to persons or property, external measures must

be implemented to ensure a safe operating state in the

event of a fault or malfunction (for example, by means of

separate limit switches, mechanical interlocks, etc.).

• During operation, and depending on their degree of

protection, variable frequency drives may have live,

uninsulated, moving, and/or rotating parts, as well as hot

surfaces.

• The impermissible removal of the required cover,

improper installation or incorrect operation of the motor or

variable frequency drive can cause the failure of the

device and serious injury and/or material damage.

• Comply with all applicable national accident prevention

regulations (e.g. BGV A3) when working with energized

variable frequency drives.

• The electrical installation must be carried out in

accordance with the relevant regulations (e.g. with regard

to cable cross sections, fuses, PE).

• All transport, installation, commissioning and maintenance work must only be carried out by trained personnel

(observe IEC 60364, HD 384 or DIN VDE 0100 and national

accident prevention regulations).

• If applicable, systems in which variable frequency drives

are installed must be equipped with additional monitoring

and protective devices in accordance with the applicable

safety regulations, e.g., the German Equipment and

Product Safety Act, accident prevention regulations, etc.

Making changes to the variable frequency drives by using

the operating software is allowed.

• Keep all covers and doors closed during operation.

• When designing the machine, the user must incorporate

mechanisms and measures that limit the consequences of

a drive controller malfunction or failure (an increase in

motor speed or the motor’s sudden stop) so as to prevent

hazards to people and property, e.g.:

– Additional stand-alone devices for monitoring parame-

ters that are relevant to safety (speed, travel, end

positions, etc.)

– Electrical and non-electrical safety devices (interlocks

or mechanical locks) for mechanisms that protect the

entire system

– Due to the possibility of there being capacitors that are

still holding a charge, do not touch live device parts or

terminals immediately after disconnecting the variable

frequency drives from the supply voltage. Heed the

corresponding labels on the variable frequency drives

I

II

Contents

Contents

0 About this Manual ..................................................................... 5

0.1 List of revisions ............................................................................ 5

0.2 Further manuals for this device.................................................... 5

0.3 Sources ........................................................................................ 6

0.4 Target group................................................................................. 6

0.5 Writing conventions ..................................................................... 7

0.5.1 Hazard warnings of material damages ......................................... 7

0.5.2 Hazard warnings of personal injury .............................................. 7

0.5.3 Tips............................................................................................... 7

0.6 Abbreviations ............................................................................... 8

0.7 Mains supply voltages.................................................................. 8

0.8 Units of measurement ................................................................. 9

1 Device series DS7....................................................................... 11

1.1 Front View.................................................................................... 11

1.2 Features ...................................................................................... 11

1.3 System overview ......................................................................... 12

1.4 Description ................................................................................... 13

1.4.1 DS7-340…, DS7-342… ................................................................ 13

1.4.2 DS7-34D… ................................................................................... 14

1.5 Key to part numbers..................................................................... 15

1.6 Checking the Delivery .................................................................. 17

1.7 Technical data .............................................................................. 19

1.7.1 Assigned motor outputs............................................................... 19

1.7.2 General data ................................................................................. 21

1.7.3 Device version.............................................................................. 22

1.7.4 Permissible environmental conditions ......................................... 22

1.8 Intended use ................................................................................ 22

1.9 Maintenance and inspection ........................................................ 23

1.10 Storage......................................................................................... 24

1.11 Service and warranty.................................................................... 24

1.12 Disposal........................................................................................ 24

1.13 Selection criteria........................................................................... 25

1.14 Function ....................................................................................... 26

2 Engineering................................................................................. 33

2.1 Selection of devices ..................................................................... 33

2.2 EMC compliance .......................................................................... 34

2.3 Network configurations................................................................ 34

2.4 Power connection ........................................................................ 35

2.5 emergency switching off ............................................................. 36

2.6 Protection..................................................................................... 36

2.6.1 Type 1 coordination...................................................................... 36

2.6.2 Type 2 coordination...................................................................... 36

2.7 Residual current circuit-breaker (RCD) ......................................... 37

2.8 motor protection .......................................................................... 38

2.9 DS7-SWD and PKE motor-protective circuit-breakers.................. 39

2.10 Cables, contactors, line filters ...................................................... 40

DS7 Soft starter 09/16 MN03901001Z-EN www.eaton.com 1

Contents

2.11 Motor connection......................................................................... 41

2.11.1 Connection configurations (star/delta configuration).................... 41

2.11.2 Connection and phase sequence................................................. 42

2.11.3 Delta connection.......................................................................... 43

2.11.4 Actuation of resistive loads.......................................................... 44

2.11.5 Connection of AC motors ............................................................ 45

2.11.6 Long motor supply cables............................................................ 46

2.11.7 Parallel motor connection ............................................................ 46

2.11.8 Connecting motors ...................................................................... 47

2.11.9 Cascade circuit............................................................................. 48

2.11.10 Motors with power factor correction capacitor............................ 48

2.11.11 Bypass circuit............................................................................... 49

2.11.12 Bypass circuit for emergency operation ...................................... 49

2.11.13 Repair and maintenance switch................................................... 51

2.12 Loading conditions ....................................................................... 53

2.12.1 Overload capability (load to AC-53a) ............................................ 53

2.12.2 Conversion of the overload capability to lower overcurrents....... 53

2.12.3 Different overload current............................................................ 54

2.12.4 Configuration options of DS7....................................................... 56

2.13 Design with different load cycles................................................. 57

2.14 Overtemperature (Derating)......................................................... 57

2.15 Example of other load cycles ....................................................... 58

3 Installation.................................................................................. 61

3.1 Introduction.................................................................................. 61

3.2 Mounting positions ...................................................................... 61

3.3 Flush mounting in control panel................................................... 62

3.3.1 Increased cooling......................................................................... 63

3.3.2 Mounting instructions (BG 1 and BG 2) ....................................... 69

3.3.3 Mounting instructions (size 3 and 4)............................................ 74

3.4 Electrical Installation .................................................................... 77

3.4.1 Connection to power section....................................................... 78

3.4.2 Connection in control section ...................................................... 80

3.4.3 Connection to SmartWire-DT....................................................... 82

3.4.4 Functions of control signal terminals ........................................... 85

3.4.5 Control section power supply ...................................................... 86

3.4.6 Internal device voltages ............................................................... 86

3.4.7 Ground control voltage................................................................. 86

3.4.8 Relay contacts.............................................................................. 87

3.4.9 Relay contacts - connection examples......................................... 89

3.5 Block diagrams............................................................................. 90

3.6 Insulation test .............................................................................. 91

4 Operation.................................................................................... 93

4.1 Checklist for commissioning........................................................ 93

4.2 Commissioning ............................................................................ 95

4.3 Extended functionality ................................................................. 96

4.4 Potentiometer settings ................................................................ 98

4.4.1 How the potentiometers work..................................................... 98

4.4.2 Examples ..................................................................................... 102

2 DS7 Soft starter 09/16 MN03901001Z-EN www.eaton.com

Contents

4.5 Commissioning instructions......................................................... 104

4.6 Start the motor............................................................................. 105

4.7 Operation ..................................................................................... 105

4.8 LED indicators .............................................................................. 106

4.8.1 Operating state signals ................................................................ 109

4.8.2 Signals in DS7-34D…-D ............................................................... 110

4.8.3 Messages in the event of faults................................................... 111

4.8.4 Error messages ............................................................................ 112

5 Diagnostics ................................................................................. 115

5.1 Fault retrieval................................................................................ 115

5.1.1 Motor not starting ........................................................................ 115

5.1.2 Motor stops immediately after start completed .......................... 115

5.1.3 Motor running unevenly ............................................................... 115

5.1.4 Motor consuming too much current ............................................ 116

5.1.5 Connected motor overheating ..................................................... 116

5.2 Acknowledgment of error messages........................................... 116

6 Parameterization........................................................................ 117

6.1 Operating principles ..................................................................... 117

6.2 Default settings of the basic device............................................. 117

7 Connection examples ................................................................ 119

7.1 Size 1 (4 – 12 A) ........................................................................... 119

7.1.1 Connection without soft stop ramp ............................................. 119

7.1.2 Connection with soft stop ramp................................................... 120

7.1.3 Standard connection with upstream mains contactor and

soft stop ramp.............................................................................. 121

7.1.4 Simple change of rotation ............................................................ 122

7.1.5 Rotation direction reversal with soft stop ramp ........................... 123

7.1.6 Reversing the direction of rotation with MSC-R .......................... 124

7.1.7 Connection for ac motor .............................................................. 126

7.2 Size 2 (16 – 32 A) ......................................................................... 127

7.2.1 Connection without soft stop ramp ............................................. 127

7.2.2 Connection with soft stop ramp................................................... 128

7.2.3 Standard connection with upstream mains contactor and

soft stop ramp.............................................................................. 129

7.2.4 Rotation direction reversal with soft stop ramp ........................... 130

7.3 Size 3 and 4 (41 – 200 A).............................................................. 132

7.3.1 Connection without soft start ramp ............................................. 132

7.3.2 Connection with soft start ramp .................................................. 133

7.3.3 Standard connection with upstream mains contactor and

soft stop ramp.............................................................................. 134

7.3.4 Rotation direction reversal with soft stop ramp ........................... 135

7.3.5 Compact motor starter with maintenance switch........................ 137

7.3.6 DS7 soft starter and NZM circuit-breaker with emergency-stop

function to IEC/EN 60204 and VDE 0113 Part 1 .......................... 138

7.3.7 Bypass circuit for emergency operation....................................... 139

7.3.8 Starting several motors sequentially with a soft starter............... 141

DS7 Soft starter 09/16 MN03901001Z-EN www.eaton.com 3

Contents

8 SmartWire-DT ............................................................................ 145

8.1 Introduction.................................................................................. 145

8.2 Profiles for DS7-SWD .................................................................. 146

8.3 1-0-A switch................................................................................. 146

8.4 Abbreviations ............................................................................... 147

8.5 SmartWire-DT response time ...................................................... 147

8.6 Interoperability ............................................................................. 148

8.6.1 Gateways..................................................................................... 148

8.6.2 Fieldbus description files ............................................................. 148

8.6.3 SWD-Assist.................................................................................. 148

8.7 Part numbers ............................................................................... 149

8.8 Replacing soft starters................................................................. 149

8.9 Programming ............................................................................... 150

8.9.1 Introduction.................................................................................. 150

8.9.2 State diagrams ............................................................................. 150

8.9.3 Cyclic data.................................................................................... 159

8.9.4 Cyclic data via PROFIBUS-DP ...................................................... 185

8.9.5 acyclic data................................................................................... 185

8.9.6 Acyclic parameter channel for DS7-SWD soft starter.................. 198

8.9.7 Data types.................................................................................... 202

8.9.8 Acyclic data via PROFIBUS-DP: DS7 ........................................... 208

8.9.9 Acyclic data via PROFIBUS-DP: PKE............................................ 210

8.10 SmartWire-DT diagnostics ........................................................... 211

8.10.1 Basic SWD Diagnostics ............................................................... 211

8.10.2 Advanced SmartWire-DT diagnostics .......................................... 212

8.10.3 PROFIdrive diagnostics................................................................ 213

8.10.4 SmartWire-DT diagnostic LEDs ................................................... 214

9 Appendix.................................................................................... 215

9.1 Standards..................................................................................... 215

9.2 Applicable product standards and approvals................................ 215

9.3 Specific technical data ................................................................. 216

9.3.1 Power supply dependent data ..................................................... 216

9.3.2 Terminal capacity, control cables, actuating circuit...................... 217

9.3.3 Heat dissipation PV ...................................................................... 218

9.4 Conversion to other load cycles................................................... 219

9.5 accessories .................................................................................. 221

9.5.1 Protection, short-circuit rating...................................................... 221

9.5.2 Protection, overload relay, optional mains contactor ................... 223

9.5.3 system accessories ..................................................................... 224

9.5.4 Device fans .................................................................................. 227

9.5.5 SmartWire-DT .............................................................................. 227

9.6 Dimensions.................................................................................. 228

Index ........................................................................................... 233

4 DS7 Soft starter 09/16 MN03901001Z-EN www.eaton.com

0 About this Manual

0.1 List of revisions

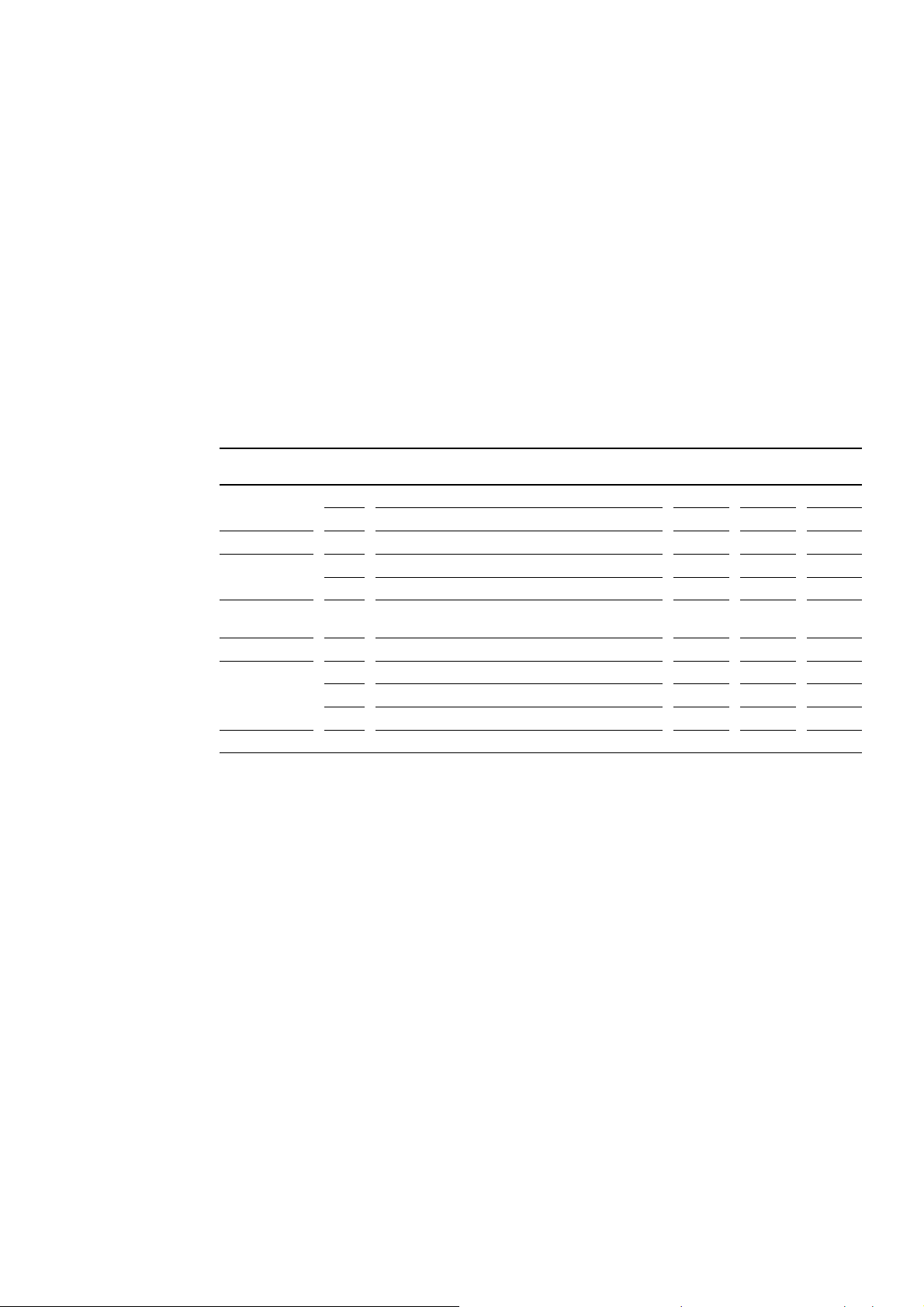

Publication date Page Subject new modified deleted

09/16 96 Extended functionality ✓

09/13 Fully revised; firmware version V46 ✓

07/12 145ff. Chapter “SmartWire-DT” ✓

11/11 89 Size 2 (16 - 32 A) – Isolated relay contacts

06/11 All Complete revision ✓✓

04/11 56 Configuration options of DS7 ✓

07/10 Initial issue

0 About this Manual

0.1 List of revisions

This manual contains special information that you will need to connect a soft

starter correctly and configure it to your requirements using the parameters.

The details apply to the indicated hardware and software versions.

The manual describes all construction sizes of the DS7 series soft starters.

Differences and special characteristics of each rating level and construction

size are listed accordingly.

The following significant amendments have been introduced since previous

issues:

44 Actuation of resistive loads ✓

All Complete revision ✓

✓

Size 3 and 4 (41 - 200 A) – Isolated relay contacts

216 Power supply dependent data (further) ✓

19 Power values ✓

0.2 Further manuals for this device

Further information can be found in the following manuals:

On “Soft starter”

• “Design of soft starters” - MN03902001Z-EN

(previous description AWB8250-1346D)

On “SmartWire-DT”

• “SmartWire-DT The system” – MN05006002Z-EN

(previous designation AWB2723-1617en)

• “SmartWire-DT module” – MN05006001Z-EN

(previous designation AWB2723-1613en)

• “SmartWire-DT Gateways” – MN05013002Z-EN

(previous designation AWB2723-1612en)

• “XIOC signal modules” – MN05002002Z-EN

(previous designation AWB2725-1452en

DS7 Soft starter 09/16 MN03901001Z-EN www.eaton.com 5

0 About this Manual

0.3 Sources

0.3 Sources

0.4 Target group

→

[1] Profile Drive Technology, PROFIdrive Technical Specification for

PROFIBUS and PROFINET, Version 4.1, May 2006; Order No: 3.172

The content of the manual is written for engineers and electricians. A

specialist knowledge of electrical engineering is needed for commissioning.

More information on the devices described here can be found on

the Internet under:

http://www.eaton.eu/Europe/Electrical/ProductsServices/

AutomationControl/SwitchingProtectingDrivingMotors/SoftStarters/DS7/

as well as

http://www.eaton.de/EN/EatonDE/ProdukteundLoesungen/Electrical/

Kundensupport/DownloadCenter/index.htm

→ Customer support → Download Center – Documentation

In the Quick Search box, enter the document name

(MN03901001).

The chapter “SmartWire-DT” is intended for automation technicians and

engineers. Detailed knowledge of the field bus systems used is presumed.

In addition you should be familiar with the handling of the SmartWire-DT

system.

6 DS7 Soft starter 09/16 MN03901001Z-EN www.eaton.com

0.5 Writing conventions

Symbols used in this manual have the following meanings:

▶ Indicates instructions to be followed.

0.5.1 Hazard warnings of material damages

NOTICE

Warns about the possibility of material damage.

0.5.2 Hazard warnings of personal injury

CAUTION

0 About this Manual

0.5 Writing conventions

0.5.3 Tips

→

Warns of the possibility of hazardous situations that may

possibly cause slight injury.

WARNING

Warns of the possibility of hazardous situations that could result

in serious injury or even death.

DANGER

Warns of hazardous situations that result in serious injury or

death.

Indicates useful tips.

DS7 Soft starter 09/16 MN03901001Z-EN www.eaton.com 7

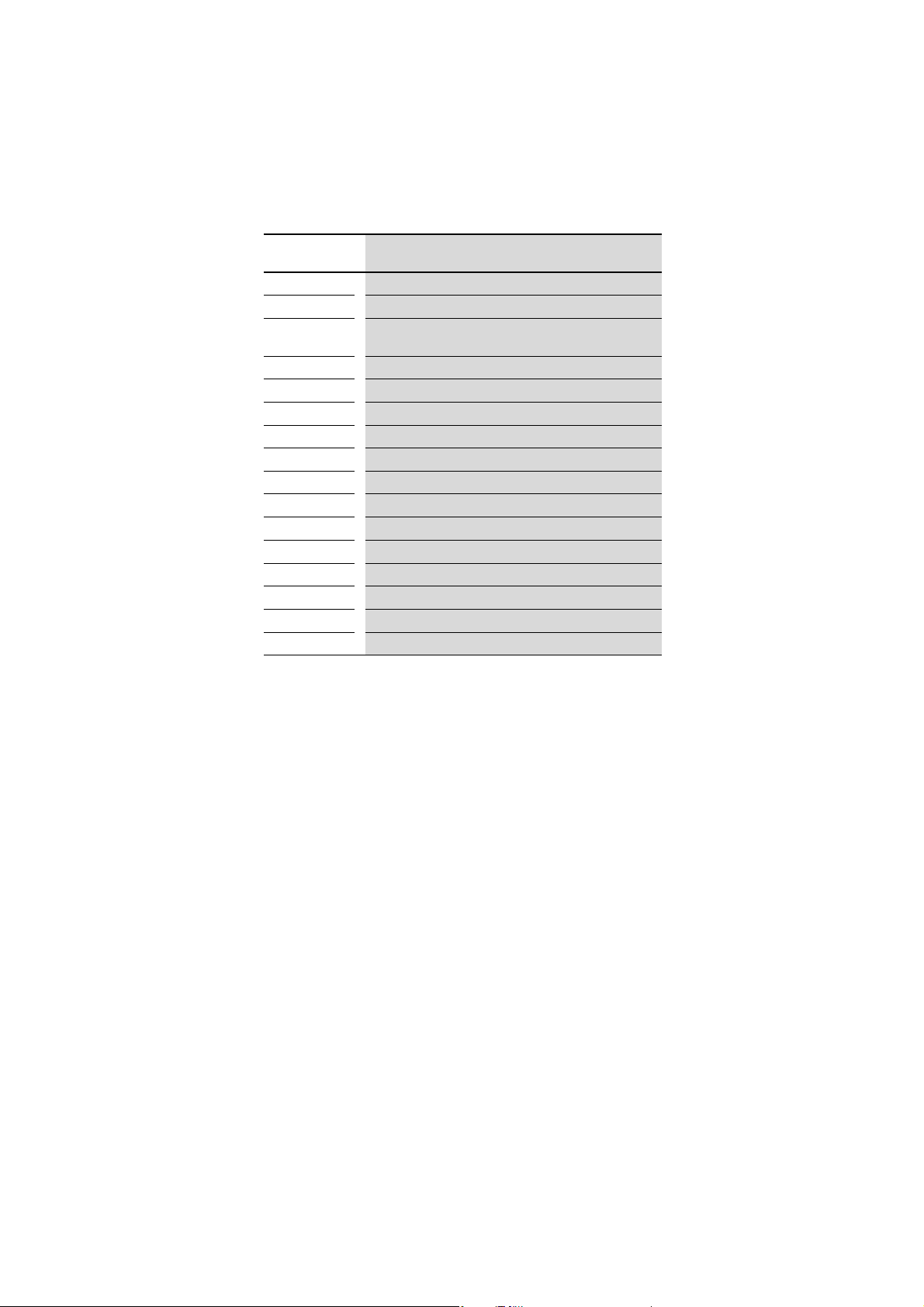

0 About this Manual

0.6 Abbreviations

0.6 Abbreviations

The following abbreviations are used in this manual:

Abbreviation Meaning

BG Construction size

DS

DS7-SWD

EMC

GND

LED

PDS

RCD

SmartWire-DT

TOR

t-Start

t-Stop

U-Start

UL

U

LN

+U

/-U

s

s

Default settings

DS7 soft starter with SmartWire-DT

(abbreviated designation for devices with part no. DS7-34D…)

Electromagnetic compatibility

Ground (0-V-potential)

Light Emitting Diode (LED)

Power Drive System (magnet system)

Residual Current Device (residual current circuit-breaker)

SmartWire-DT

Top of Ramp

Ramp time for start voltage

Ramp time for voltage reduction

Start voltage

Underwriters Laboratories

Mains voltage

Control voltage

0.7 Mains supply voltages

The rated operating voltages stated in the following table are based on the

standard values.

In ring networks (as found in Europe) the rated operating voltage at the

transfer point of the power supply companies is the same as the value in the

consumer networks (e.g. 230 V or 400 V).

In star networks (as found in North America), the rated operating voltage at

the transfer point of the utility companies is higher than in the consumer

network.

Example: 120 V → 115 V, 240 V → 230 V, 480 V → 460 V.

The wide tolerance range of the DS7 soft starters allows for voltage drops of

10% and a voltage drop of additional 4 %, as well as an excess voltage of

10 % that are permissible in consumer supply networks.

The rated mains voltage operational data is always based on mains

frequencies of 50/60 Hz (50 Hz - 5 % – 60 Hz +5 %).

8 DS7 Soft starter 09/16 MN03901001Z-EN www.eaton.com

0.8 Units of measurement

Designation

Length inch 1 in (’’) 25.4 mm 0.0394

Power horsepower 1HP=1.014PS 0.7457 kW 1.341

Moment of torque pound-force inches 1 lbf in 0.113 Nm 8.851

Temperature

Rotational speed Revolutions per minute 1rpm 1min

Weight pound 1lb 0.4536 kg 2.205

Flow rate cubic feed per minute 1cfm 1.698 m3/min 0.5889

0 About this Manual

0.8 Units of measurement

Every physical dimension included in this manual uses international metric

system units, otherwise known as SI (Système International d’Unités) units.

For the purpose of the equipment’s UL certification, some of these

dimensions are accompanied by their equivalents in imperial units.

Table 1: Unit conversion examples

US-American

designation

Fahrenheit 1°F (TF) -17.222 °C (TC) TF=TC×9/5+32

Imperial unit SI value Conversion value

-1

1

DS7 Soft starter 09/16 MN03901001Z-EN www.eaton.com 9

0 About this Manual

0.8 Units of measurement

10 DS7 Soft starter 09/16 MN03901001Z-EN www.eaton.com

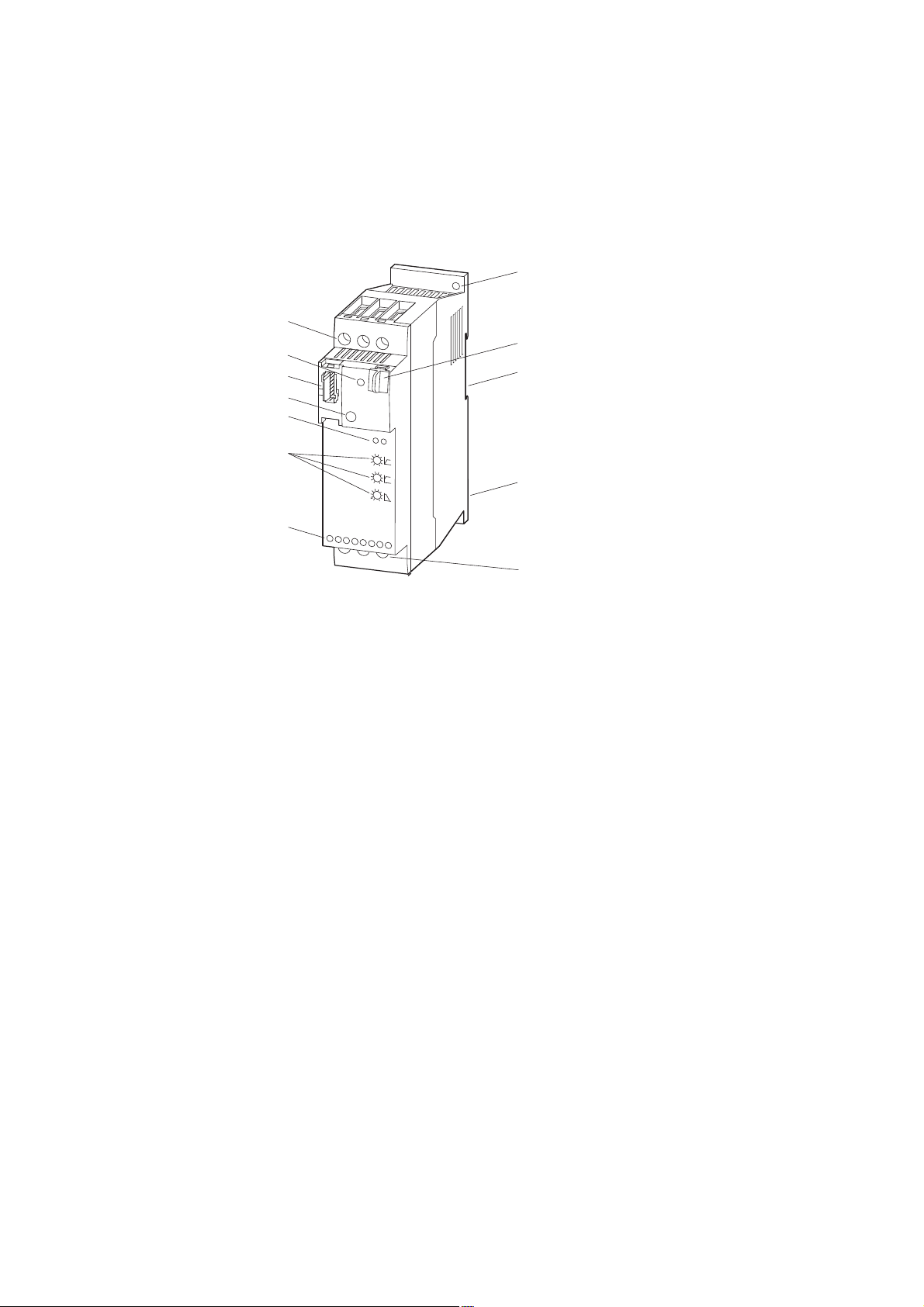

1 Device series DS7

1.1 Front View

1 Device series DS7

1.1 Front View

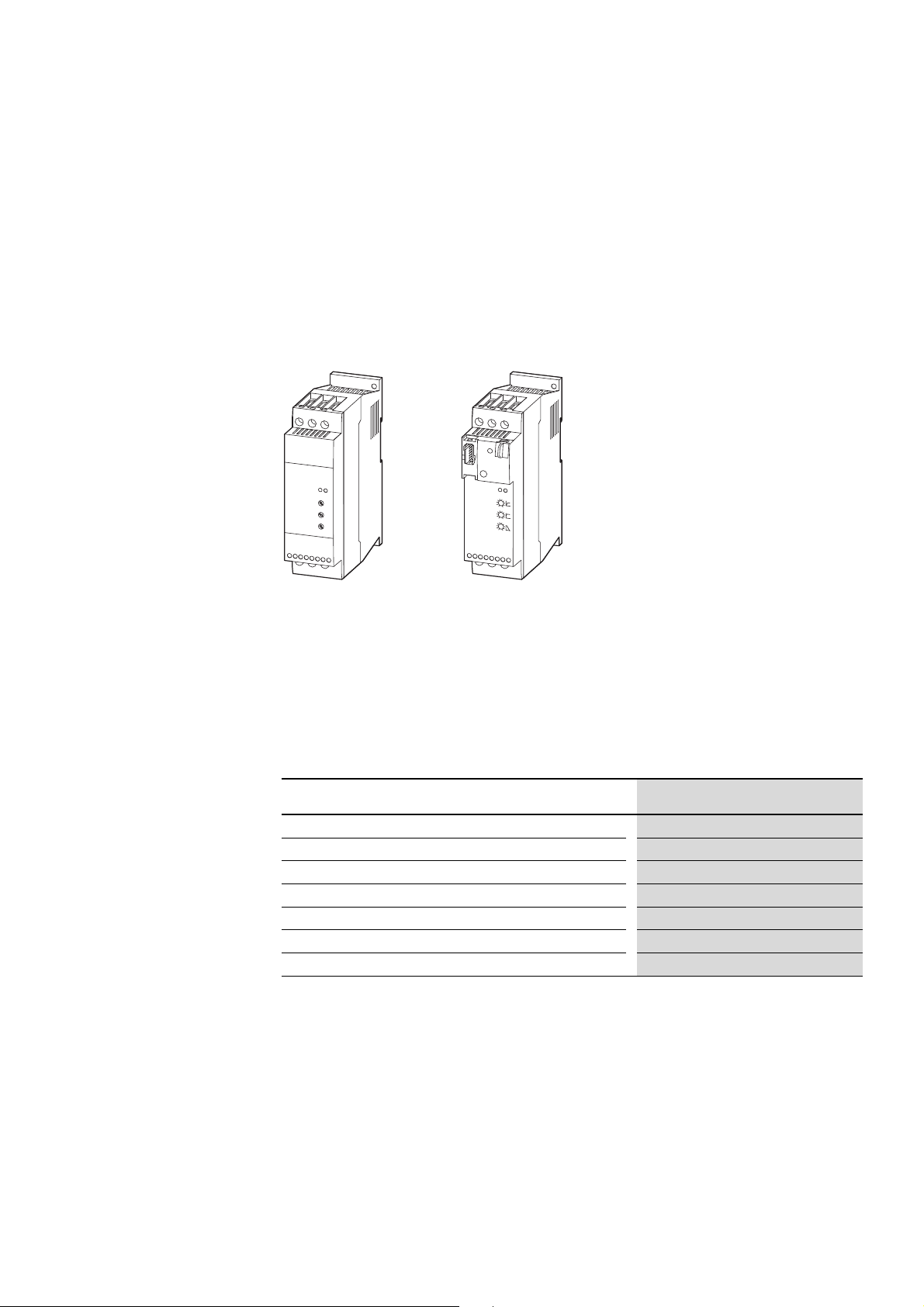

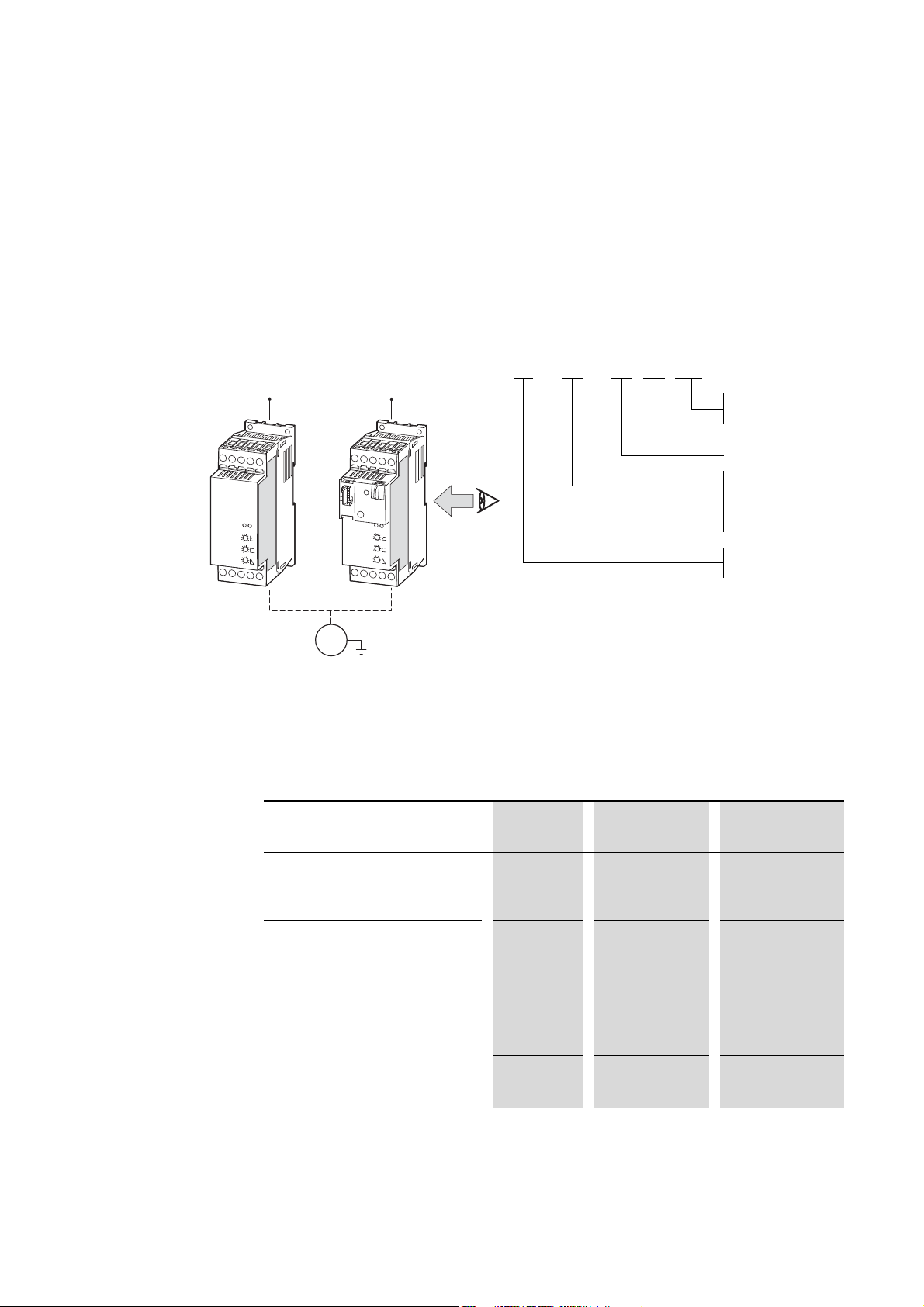

The following two devices are used as examples of the DS7 series:

• DS7-340SX032N0-N (left) – without SmartWire-DT interface

• DS7-34DSX032N0-D (right) with SmartWire-DT interface

1.2 Features

Figure 1: Front view of DS7 soft starter

Left: Without SmartWire-DT interface

Right: With SmartWire-DT interface

DS7 series soft starters comply with the IEC/EN 60947-4-2 product standard

and are provided with the following standard features:

Table 2: Features of the DS7 soft starters

Feature Instance

Compact design ✓

Adjustable start voltage

Separately adjustable ramp times for start and stop

Digital inputs

Relay output

Standard controller card and parameters over the entire performance range

Communication

✓

✓

✓ 1 (size 1), 2 (size 2, size 3, size 4)

✓ 1 (size 1), 2 (size 2, size 3, size 4)

✓

✓ via SmartWire-DT (with types DS7-34D…-D)

DS7 Soft starter 09/16 MN03901001Z-EN www.eaton.com 11

1 Device series DS7

S

W

D

4

-8

S

F

2

SWD

4-

8S

F

2

-

5

+ 1

5V

S

W

D4

-8

S

F

2

①

②

④

⑤

③

1.3 System over view

1.3 System overview

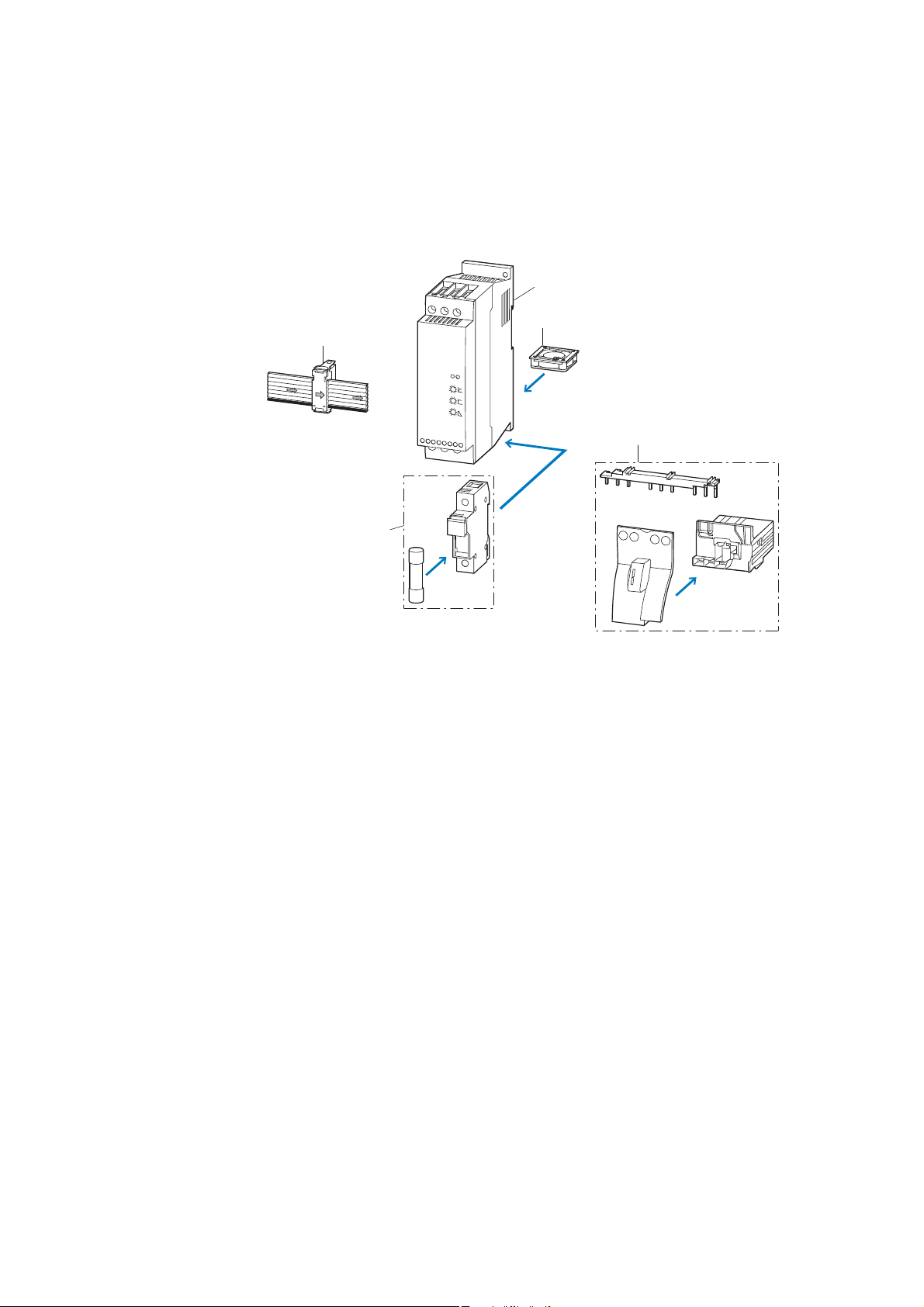

The following figure shows a DS7 soft starter together with (optional)

accessories.

Figure 2: System overview, DS7 soft starters

a DS7 soft starters

b Device fan (DS7-FAN-…)

c Communication System SmartWire-DT

d Mounting accessories

e Superfast semiconductor fuse and fuse base

12 DS7 Soft starter 09/16 MN03901001Z-EN www.eaton.com

1.4 Description

1.4.1 DS7-340…, DS7-342…

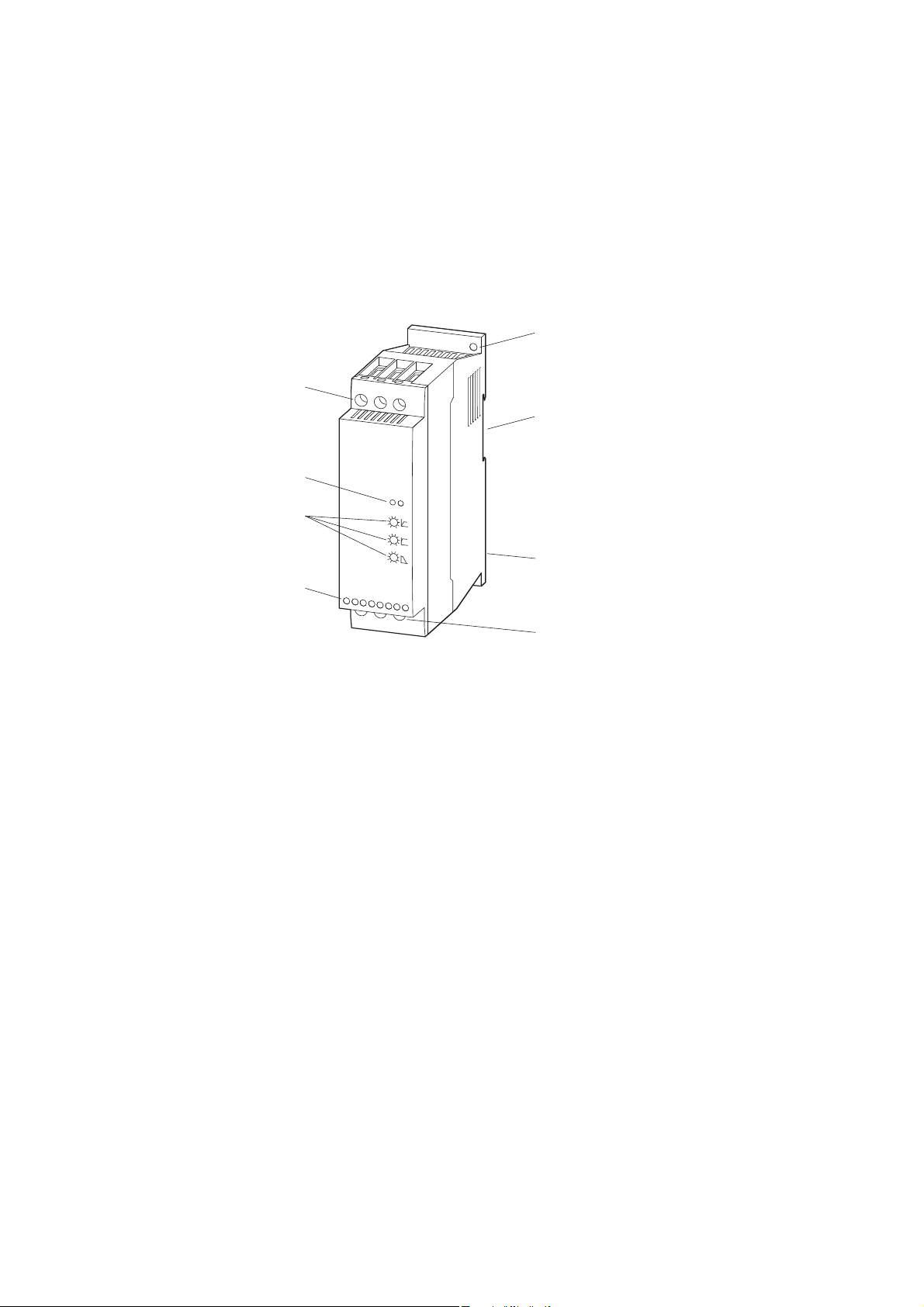

The following drawing shows a DS7 soft starter (without SmartWire-DT)

of size 2.

⑧

⑦

⑥

1 Device series DS7

1.4 Description

①

②

③

⑤

④

Figure 3: Description of the DS7-34…-N soft starter

a Fixing holes (screw fastening)

b Cutout for mounting on mounting rail (DIN EN 50022-35)

c Device fan (mounting space on back)

d Connection terminals of the power section, motor connection (2T1, 4T2, 6T3)

e Control signal terminals

f Potentiometer (U-Start, t-Start, t-Stop)

g LEDs (RUN, error)

h Connection terminals of the power section, mains voltage (1L1, 3L2, 3L3)

DS7 Soft starter 09/16 MN03901001Z-EN www.eaton.com 13

1 Device series DS7

①

②

④

⑤

⑥

⑦

⑧

⑫

③

⑨

⑩

⑪

1.4 Description

1.4.2 DS7-34D…

The following drawing shows a DS7-34D… soft starter with a SmartWire-DT

connection (hereafter referred to with the abbreviation DS7-SWD) of size 2.

Figure 4: Description of the DS7-34D…-D soft starter

a Fixing holes (screw fastening)

b Data interface for PKE32-COM

c Cutout for mounting on mounting rail (DIN EN 50022-35)

d Device fan (mounting space on rear)

e Connection terminals of the power section, motor connection (2T1, 4T2, 6T3)

f Control signal terminals

g Potentiometer (U-Start, t-Start, t-Stop)

h Light-emitting diodes (RUN, Error): DS7 diagnostic LEDs

i 1-0-A switch

j Connection for SmartWire-DT external device plug

k LED: SmartWire-DT diagnostic LED

l Connection terminals of the power section, mains voltage (1L1, 3L2, 3L3)

The SmartWire-DT external device plug with an adapted

→

SmartWire-DT ribbon cable is connected to the DS7-SWD soft

starter via connection ⑩.

For detailed instructions on how to use the SmartWire-DT

external device plug (SWD4-8SF2-5) with the 8-pin SmartWire-DT

cable, refer to the “Setting up SWD4-8SF2-5 external device

plugs” section in manual MN05006002Z-EN,

“SmartWire-DT - The System.”

→

SmartWire-DT diagnostic LED ⑪ shows the communication

status, the status of the DS7-SWD soft starter, and the

switching command via the SmartWire-DT system.

For more information on the SmartWire-DT diagnostic LED,

refer to → section 8.10.4, “SmartWire-DT diagnostic LEDs”,

page 214.

14 DS7 Soft starter 09/16 MN03901001Z-EN www.eaton.com

1.5 Key to part numbers

1 Device series DS7

1.5 Key to part numbers

The soft starters of the DS7 series are assigned part numbers according to

the following key to part numbers:

DS7 - 3 4 x SX yyy N 0 - z Explanation

Instance:

N = no option

D = SmartWire-DT

Degree of protection:

0 = IP00, IP20, NEMA 0

EMC filter

N = no filter

SX = Standard soft starter with internal bypass relay

Control voltage and Control signals:

D = 24 V DC

0 = 24 V AC/DC

2 = 120/230 V AC

Figure 5: DS7 key to part numbers

Rated operational current I

Examples: 004 = 4 A

012 = 12 A

200 = 200 A

Device version:

Mains supply voltage:

4 = 400 V (200 – 480 V)

Supply phases:

3 = three-phase incoming unit

Soft starter series:

Drives motor starter, Generation 7

:

e

DS7 Soft starter 09/16 MN03901001Z-EN www.eaton.com 15

1 Device series DS7

1.5 Key to part numbers

Example of key to part numbers

An example of the key to part numbers is shown below:

DS7 - 3 4 2 SX 024 N 0 - N Explanation

Instance:

N = no option

Degree of protection:

0 = IP00, IP20, NEMA 0

EMC filter

N = no filter

Rated operational current I

024

= 24 A

Device version:

SX = Standard soft starter with internal bypass relay

Control voltage and Control signals:

2 = 120/230 V AC

Mains supply voltage:

4 = 400 V (200 - 480 V)

Supply phases:

3 = three-phase incoming unit

Soft starter series:

Drives motor starter, Generation 7

:

e

16 DS7 Soft starter 09/16 MN03901001Z-EN www.eaton.com

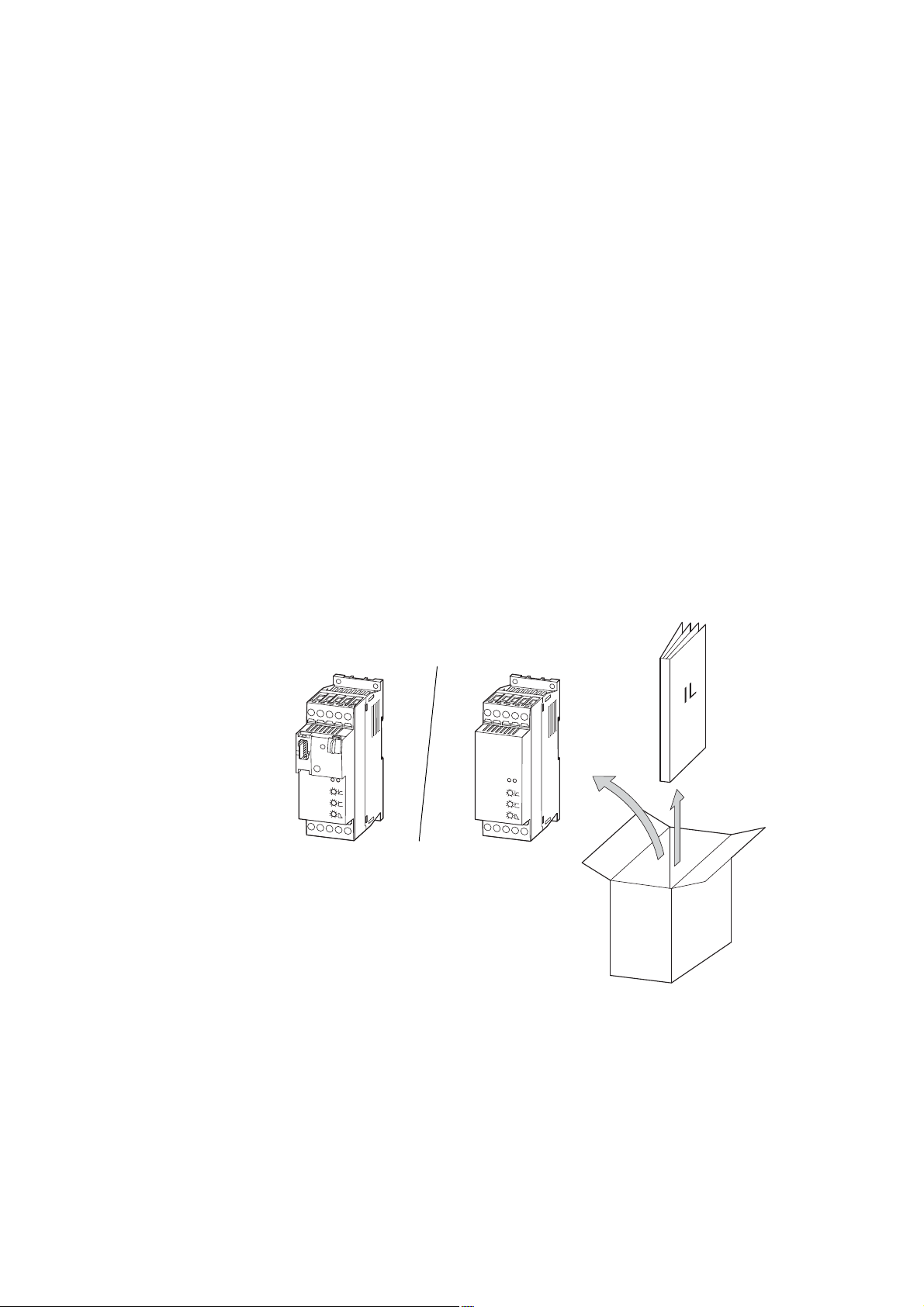

1.6 Checking the Delivery

1 Device series DS7

1.6 Checking the Delivery

→

The DS7 series soft starter are carefully packed and prepared for shipment.

These devices should only be shipped in their original packaging with suitable

transportation materials. Please take note of the labels and instructions on

the packaging, as well as of those meant for the unpacked device.

Open the packaging with adequate tools and inspect the contents

immediately after receipt in order to ensure that they are complete and

undamaged.

The packaging must contain the following parts:

• A soft starter from the DS7-34…-N or DS7-34…-D series

• an instructional leaflet IL (see table below).

If the delivered items are damaged, incomplete, or incorrect, please notify

the responsible sales office immediately.

Before opening the packaging go over the nameplate on the

packaging and check for whether the delivered soft starter is

the same part no. as the one you ordered.

Figure 6: Equipment supplied with DS7 soft starter

DS7 Soft starter 09/16 MN03901001Z-EN www.eaton.com 17

1 Device series DS7

1.6 Checking the Delivery

The part no. on the nameplate indicates the specific DS7 soft starter version

corresponding to the unit.

In the figure below, the following letters are used to provide the following

information:

• x: Control voltage U

• yyy: Rated operational current I

• z: Options / characteristics

Mains

U

LN

M

Motor

Figure 7: Nameplate and part no. position

The following table shows which instructional leaflets are meant for which

DS7 soft starter sizes:

or U

s

c

e

DS7-34 - x SX yyy N0- z

N = No Option

D = SmartWire-DT

I

e

U

s , Uc

0 = 24 V AC/DC

2 = 120/230 V AC

D = 24 V DC

≦ ULN:

U

e

200 - 480 VAC 3ph 50/60Hz

Table 3: Instruction leaflet for soft starter series DS7

Instruction leaflet Construction

IL03902003Z

(previous designation AWA8250-2541)

IL03902004Z

(previous designation AWA8250-2542)

IL03902005Z

(previous designation AWA8250-2543)

18 DS7 Soft starter 09/16 MN03901001Z-EN www.eaton.com

size

For device type Rated operational

BG1 DS7-34…SX004…

DS7-34…SX007…

DS7-34…SX009…

DS7-34…SX012…

BG2 DS7-34…SX016…

DS7-34…SX024…

DS7-34…SX032…

BG3 DS7-34…SX041…

DS7-34…SX055…

DS7-34…SX070…

DS7-34…SX081…

DS7-34…SX100…

BG4 DS7-34…SX135…

DS7-34…SX160…

DS7-34…SX200…

current I

004 = 4 A

007 = 7 A

009 = 9 A

012 = 12 A

016 = 16 A

024 = 24 A

032 = 32 A

041 = 41 A

055 = 55 A

070 = 70 A

081 = 81 A

100 = 100 A

135 = 135 A

160 = 160 A

200 = 200 A

e

1.7 Technical data

1.7.1 Assigned motor outputs

The following motor outputs can be connected if using three-phase

asynchronous motors and a load suitable for soft starters.

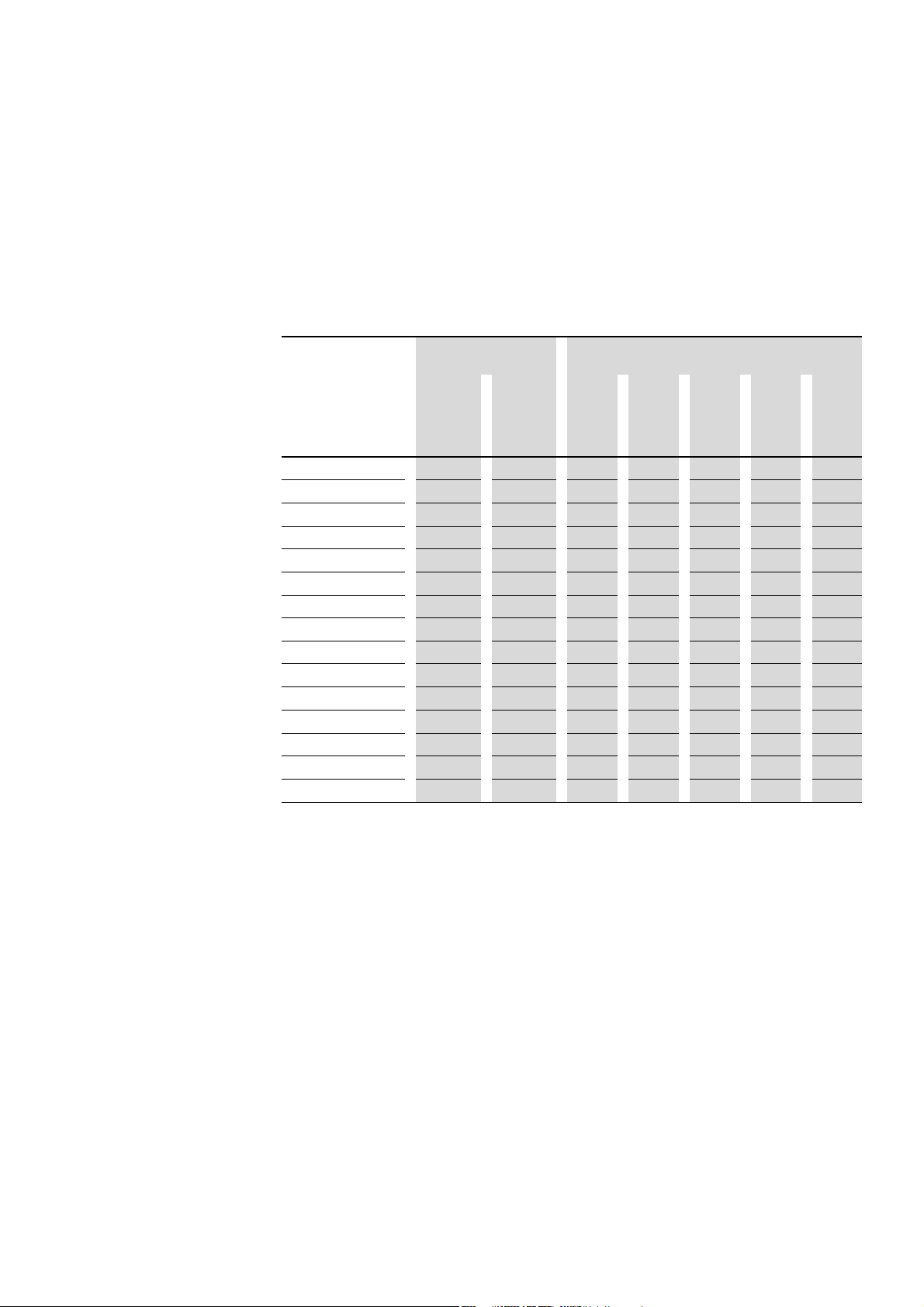

Table 4: Assigned rated motor outputs for three-phase asynchronous motors

Part no. Soft starter’s rated

DS7-34xSX004N0-… 4 4.2 0.75 1.5 ¾ 1 2

DS7-34xSX007N0-…

DS7-34xSX009N0-…

DS7-34xSX012N0-…

DS7-34xSX016N0-…

DS7-34xSX024N0-…

DS7-34xSX032N0-…

DS7-34xSX041N0-…

DS7-34xSX055N0-…

DS7-34xSX070N0-…

DS7-34xSX081N0-…

DS7-34xSX100N0-…

DS7-34xSX135N0-…

DS7-34xSX160N0-…

DS7-34xSX200N0-…

1) Motor shaft output for normal four-pole internally and surface cooled three-phase asynchronous motors

2) IEC: Mains voltage = Motor voltage (at load) 230 V, 400 V

3) Reduced overload current acc. to UL 508C

4) Mains voltage 208 V / 240 V / 480 V ↔ motor voltage 200 V / 230 V / 460 V

operational current

2)

Ie (IEC)

A A kW kW HP HP HP

7 7.6 1.5 3 2 2 5

9 9.6 2.2 4 2 3 5

12 14 3 5.5 3 3 10

16 17.5 4 7.5 5 5 10

24 25.3 5.5 11 7½ 7½ 15

32 34 7.5 15 10 10 25

41 42 11 22 10 15 30

55 54 15 30 15 20 40

70 68 15 37 20 25 50

81 80 22 45 25 30 60

100 96 30 55 30 30 75

135 130 30 75 40 50 100

160 156 45 90 50 60 125

200 192 55 110 60 75 150

(1500 rpm at 50 Hz or 1800 rpm at 60 Hz)

Ie (UL)

1 Device series DS7

1.7 Technical data

Assigned motor output1) at

3), 4)

230 V 400 V 200 V 230 V 460 V

50 Hz 50 Hz 60 Hz 60 Hz 60 Hz

DS7 Soft starter 09/16 MN03901001Z-EN www.eaton.com 19

1 Device series DS7

1.7 Technical data

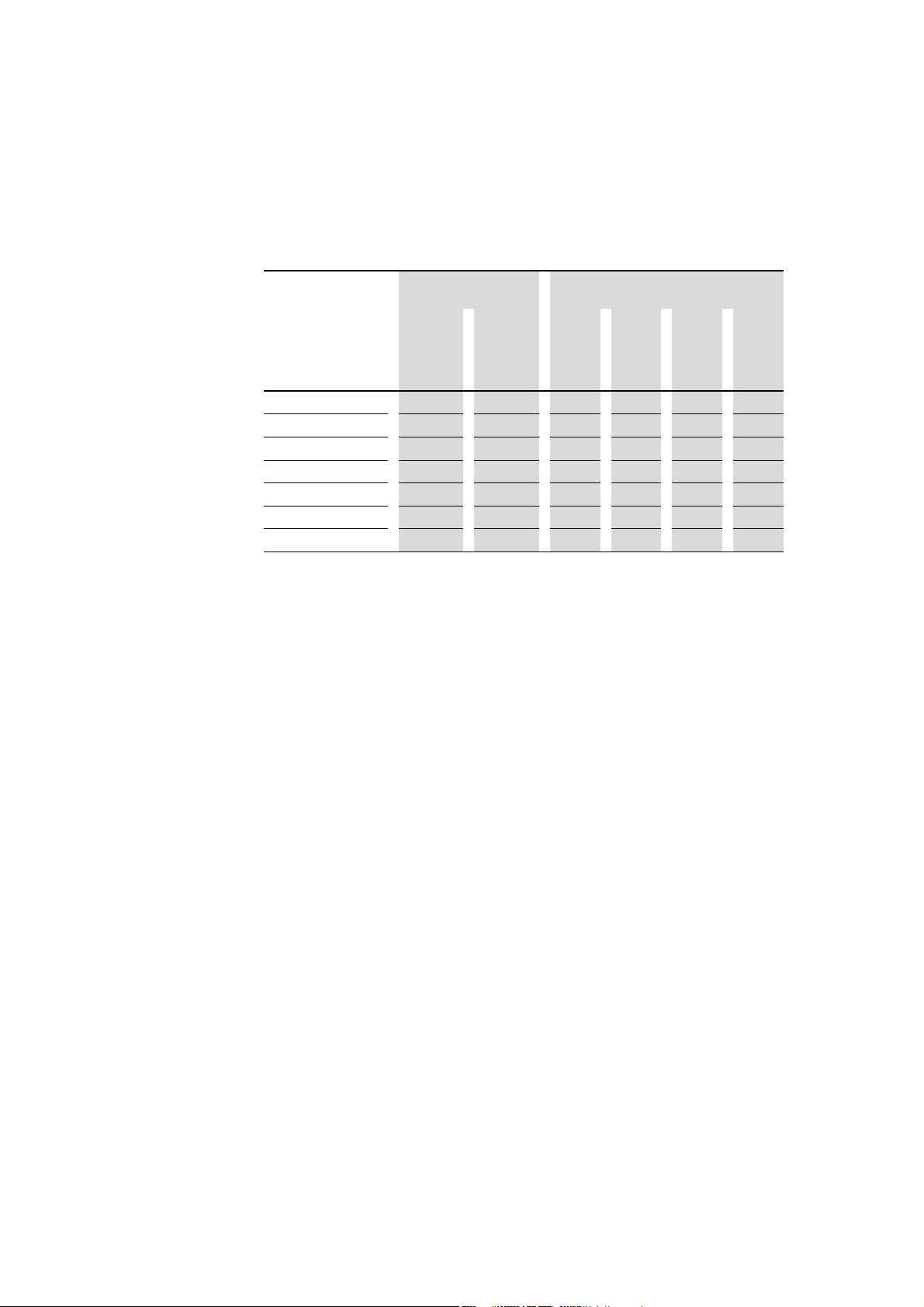

The motor outputs listed below can be connected when using single-phase

AC motors (asynchronous capacitor motors) and a load suitable for soft

starters within an industrial environment:

Table 5: Assigned rated motor outputs for AC motors

Part no. Soft starter’s rated

DS7-34xSX004N0-… 4 4.2 0.37 ¼ ⅓ ⅓

DS7-34xSX007N0-…

DS7-34xSX009N0-…

DS7-34xSX012N0-…

DS7-34xSX016N0-…

DS7-34xSX024N0-…

DS7-34xSX032N0-…

1) Motor shaft output for normal four-pole internal and surface-cooled AC motors

(1500 rpm at 50 Hz or 1800 rpm at 60 Hz)

2) IEC: Mains voltage = Motor voltage (at load) 230 V

3) Reduced overload current acc. to UL 508C

4) Mains voltage 208 V / 240 V ↔ motor voltage 200 V / 230 V

operational current

2)

Ie (IEC)

A A kW HP HP HP

7 7.6 0.75 ½ ½ ¾

9 9.6 1.1 ¾ 1 1

12 14 1.5 1 1½ 1½

16 17.5 2.2 2 2 2

24 25.3 3 3 3 3

32 34 4 5 5 5

Ie (UL)

Assigned motor output1) at

3), 4)

230 V 200 V 208 V 230 V

50 Hz 60 Hz 60 Hz 60 Hz

→

When using single-phase AC motors, the rated operational

current will depend on the system frequency and the capacitor

being used.

Example:

240 V, 50/60 Hz, 1.5/2.1 A

1300/1350 rpm, 5.0 μF CAP

20 DS7 Soft starter 09/16 MN03901001Z-EN www.eaton.com

1.7.2 General data

Table 6: General Technical Data

General

Product standard IEC/EN 60 947-4-2

Approvals, certificates

Mounting position

Degree of protection

Busbar tag shroud

Mechanical shock resistance

Vibration resistance to EN 60721-3-2

Power section

Rated operating voltage 200 - 480 V AC ±10 %

Mains frequency

Overload cycle to EN 60947-4-2

Minimum load current

Rated impulse withstand voltage

U

1.2/50 μs

imp

Rated insulation voltage U

Overvoltage category/pollution degree

Control section (inclusive SmartWire-DT)

Supply-/control voltage depending on variant

Mains frequency (with AC versions)

Rated impulse withstand voltage U

Rated insulation voltage U

Over voltage category

Soft start functions

Ramp times

Acceleration 1 - 30 s

Lag

Start voltage (= switch-off voltage)

Controlling and signalling

Control inputs depending on variant

Relay

LED

i

imp

i

CE, UL, CSA, CCC, Gost

vertical

IP20 for the front and operator control and operating

elements.

IP20 on all sides in size 1

IP00 on all sides in size 2, 3, 4

Finger- and back-of-hand proof

8 g/11 ms

2M2

50/60 Hz ±5 %

AC53a: 3-5: 75-10

0.5 A

4kV

500 V

II/2

24 V AC / 24 V DC (18 - 30 V ± 0 %)

120 - 230 V AC (98 - 264 V ± 0 %)

50/60 Hz ±5 %

2.5 kV

300 V

II

0 (= free run-down), 1 - 30 s

30 - 100 %

2 with size 1

4 with size 2

5 with size 3, size 4

depending on variant

1 with size 1 (non-isolated)

2 with size 2, 3, 4 (potential-free)

2 at DS7 without SWD (DS7-340…, DS7-342…)

3 at DS7 without SWD (DS7-34D…)

1 Device series DS7

1.7 Technical data

DS7 Soft starter 09/16 MN03901001Z-EN www.eaton.com 21

1 Device series DS7

TL

U

e

U

c

1.8 Intended use

1.7.3 Device version

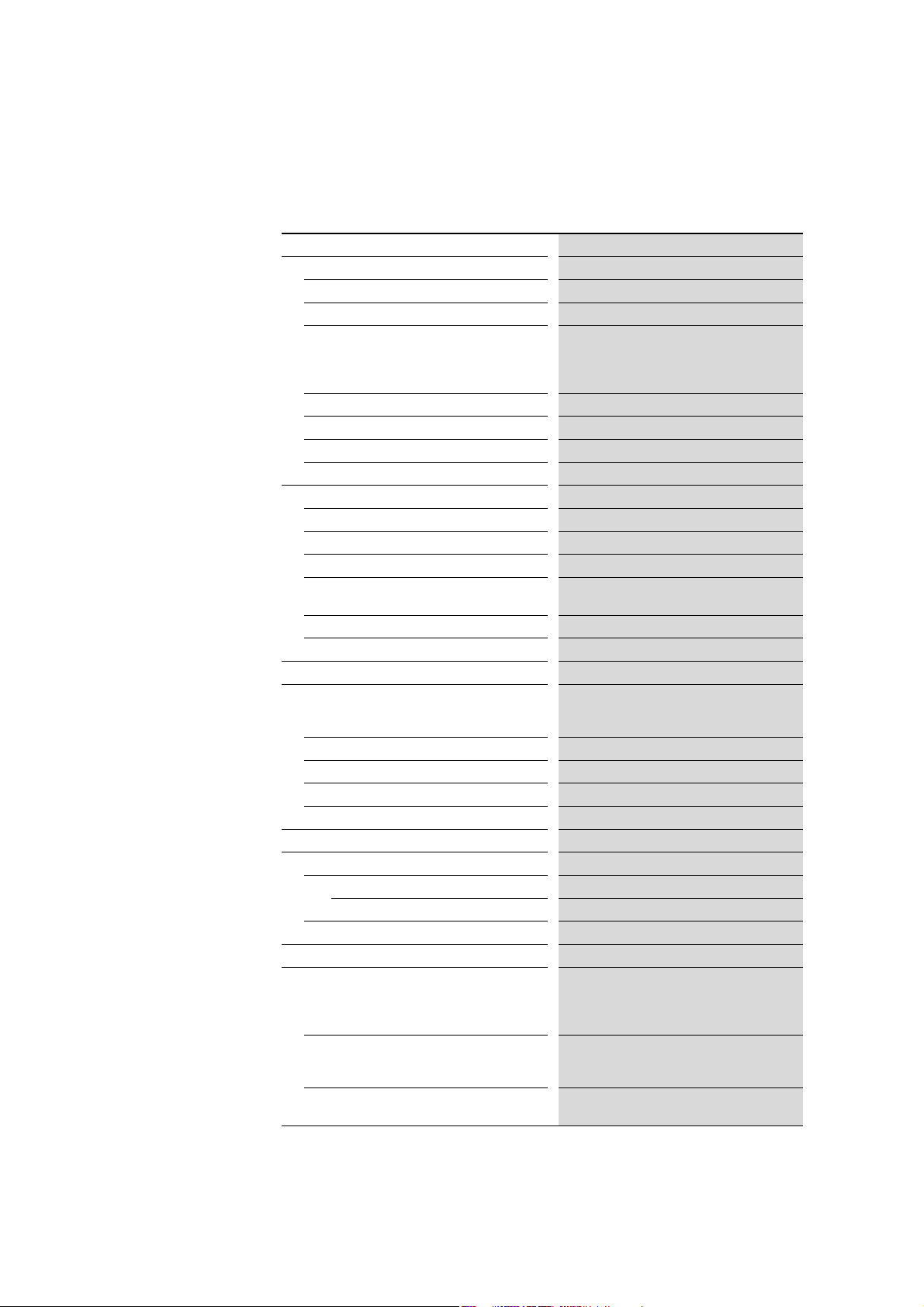

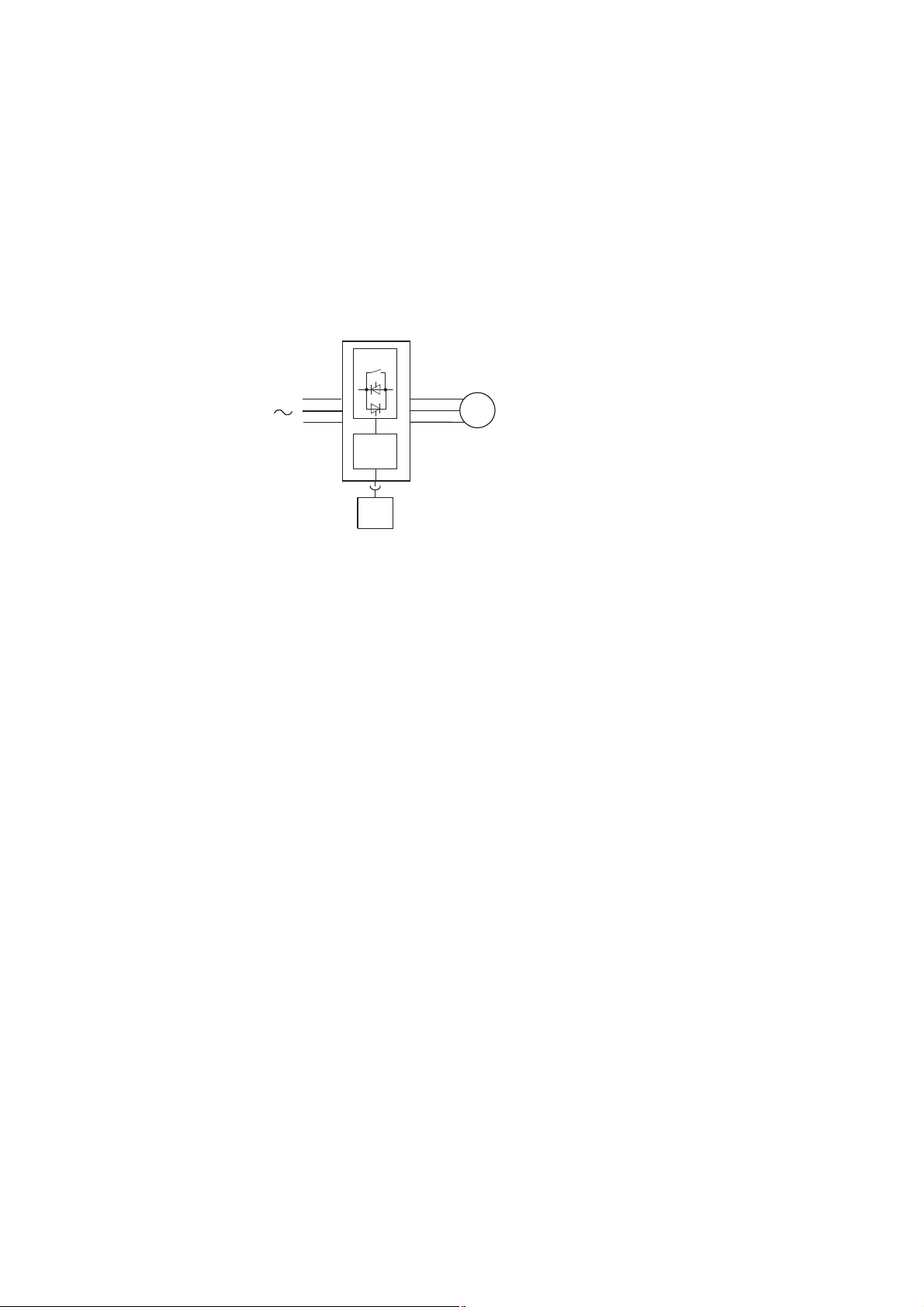

DS7 soft starters are classified in accordance with IEC 60947-4-2:2011,

Table 1

(Functional possibilities of semiconductor motor control devices).

The soft starters belonging to the DS7 series correspond to device version 1.

Figure 8: Semi-conductor – Motor – Controlgear

1.7.4 Permissible environmental conditions

The following shows the permissible values for the ambient influences on

soft starters of the DS7 series.

Table 7: Permissible environmental conditions

Property Value

1.8 Intended use

Installation altitude

Temperature

Operation -5 to +40 °C without current reduction,

Storage

Transport

Climatic proofing

Permissible humidity rating

Permissible pollution

1) Higher installation altitude upon request

1)

Up to 1000 m a.s.l.;

higher than this up to 2000 m with a current reduction of 1 % I

up to +60 °C with a current reduction of 1 % I

device fan is fitted

up to +60 °C with a current reduction of 2 % I

-25 - +60 °C continuous

-25 - +60 °C continuous

damp heat, cyclic, to DIN IEC Part 68 2-10

damp heat constant to DIN IEC 68 Part 2-3

Relative air humidity 85 %, non condensing

Pollution degree 2 to EN 60947-1

per Kelvin, if the DS7-FAN-032

e

per Kelvin without device fan

e

per 100 m

e

The devices of the DS7 series

• are not devices for household use, and are designed exclusively for use

in commercial applications,

• can be used in the described system configurations in the industrial

environment,

• are not machines in the sense of the EC Machinery Safety Directive,

• comply in a typical drive configuration with the requirements of the EU

EMC Directive, the EU Low Voltage Directive, as well as the specified

standards.

The soft starters of the DS7 series are electrical apparatus for installation in

the control panels of electrical systems or machines. They are designed for

the soft starting of single-phase or three-phase AC motors mounted in a

machine or for assembly with other machine or plant components.

22 DS7 Soft starter 09/16 MN03901001Z-EN www.eaton.com

1 Device series DS7

1.9 Maintenance and inspection

If installed in machines, the soft starters must not be commissioned until it

has been determined that the corresponding machines comply with the

safety requirements in Machinery Directive 2006/42/EC. Standard EN 60204

must be complied with within this context. Commissioning is only permitted

if the requirements of the EMC Directive (2014/30/EU) have been observed.

The soft starters of the DS7 series meet the requirements of the Low

Voltage Directive 2014/35/EU and the product standard EN 60947-4-2.

The user is responsible for ensuring that the use of the relevant machines,

as well as the corresponding applications, complies with all applicable EC

Directives. Any other usage constitutes improper use.

→

Observe the technical data and connection requirements. These are shown

on the rating plate of the soft starter as well as in this documentation.

1.9 Maintenance and inspection

DS7 soft starters will be maintenance-free provided that the corresponding

general rated operational data, as well as all specific technical data

(→ section 1.7, “Technical data”) for the relevant versions, is observed.

However, please note that external factors may have an impact on the

operation and lifespan of DS7 soft starters.

We therefore recommend that the devices are checked regularly and the

following maintenance measures are carried out at the specified intervals.

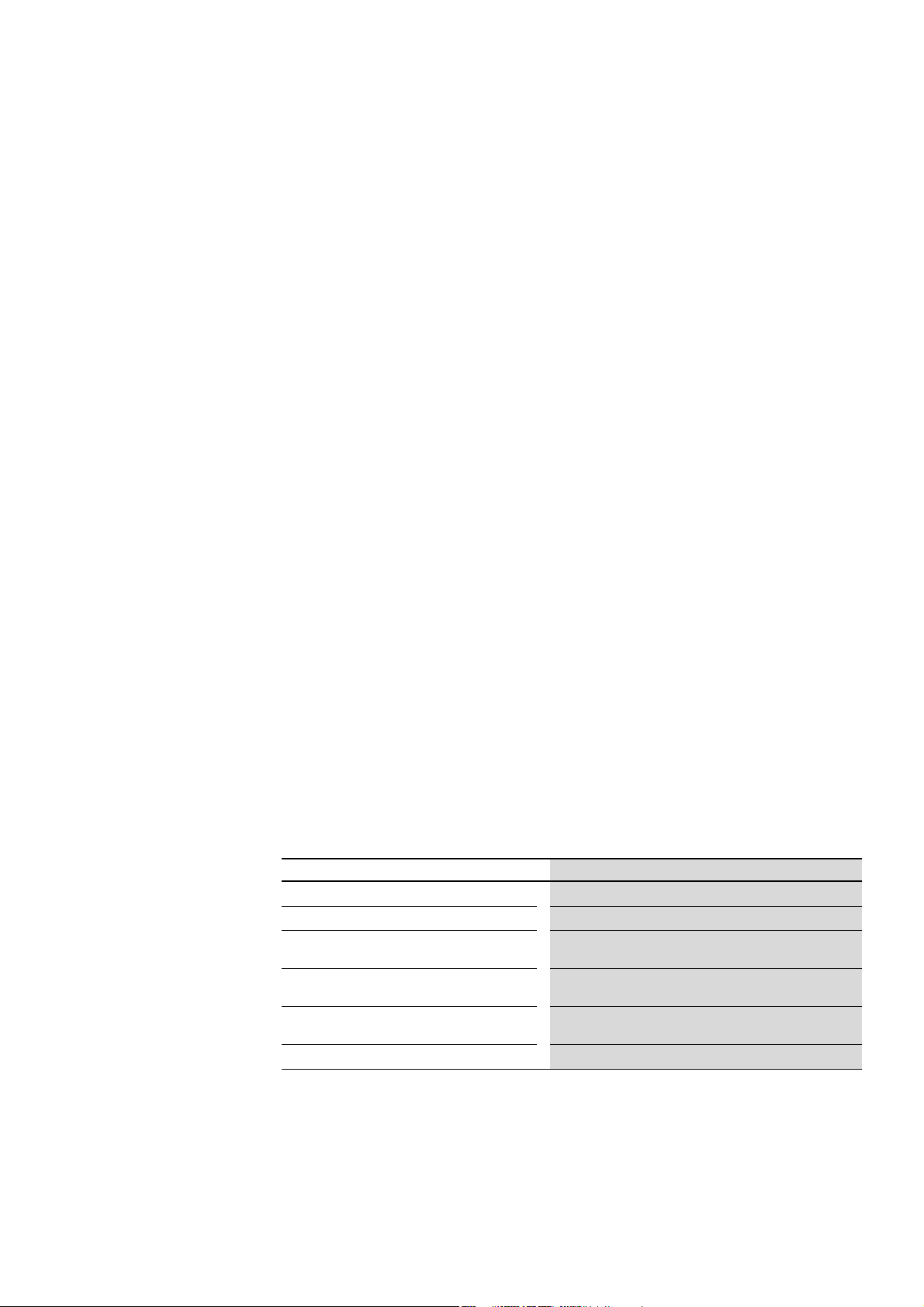

Table 8: Maintenance measures and maintenance intervals

Maintenance measures Maintenance interval

Clean cooling vents (cooling slits)

Check the fan function

Filter in the control panel doors

(see the manufacturer’s specifications)

Check the terminal’s (control signal terminals,

power terminals) tightening torques

Check connection terminals and all metallic surfaces for

corrosion

Motor cable

At the output of a DS7 soft starter (terminals U, V, W) you must

not

• connect any capacitive load (e.g. phase compensation

capacitors),

• do not connect any further soft starters (parallel connection

on output side).

please enquire

6 - 24 months (depending on the environment)

6 - 24 months (depending on the environment)

regularly

6 - 24 months; when stored, no more than 12 months later

(depending on the environment)

According to manufacturer specifications, no later than 5 years

DS7 soft starters are not designed in such a way as to allow for the

replacement or repair of their individual components or sub-assemblies.

DS7 Soft starter 09/16 MN03901001Z-EN www.eaton.com 23

1 Device series DS7

1.10 Storage

1.10 Storage

1.11 Service and warranty

If the DS7 soft starter is stored before use, suitable ambient conditions must

be ensured at the storage site:

• Storage temperature: -25 - +60 °C,

• Average relative humidity: < 85%; no condensation

In the unlikely event that you experience a problem with your DS7 soft

starter, please contact your local sales office.

When you call, have the following data ready:

• The exact part no. (see nameplate)

• the date of purchase,

• A detailed description of the problem related to the DS7 soft starter

If some of the information printed on the rating plate is not legible, please

state only the data which are clearly legible.

1.12 Disposal

Information concerning the guarantee can be found in the Terms and

Conditions Eaton Industries GmbH.

Hotline After Sales Service

+49 (0) 180 5 223822 (de, en)

AfterSalesEGBonn@eaton.com

The soft starters of the DS7 series can be disposed of as electronic scrap in

accordance with national regulations.

24 DS7 Soft starter 09/16 MN03901001Z-EN www.eaton.com

1.13 Selection criteria

1 Device series DS7

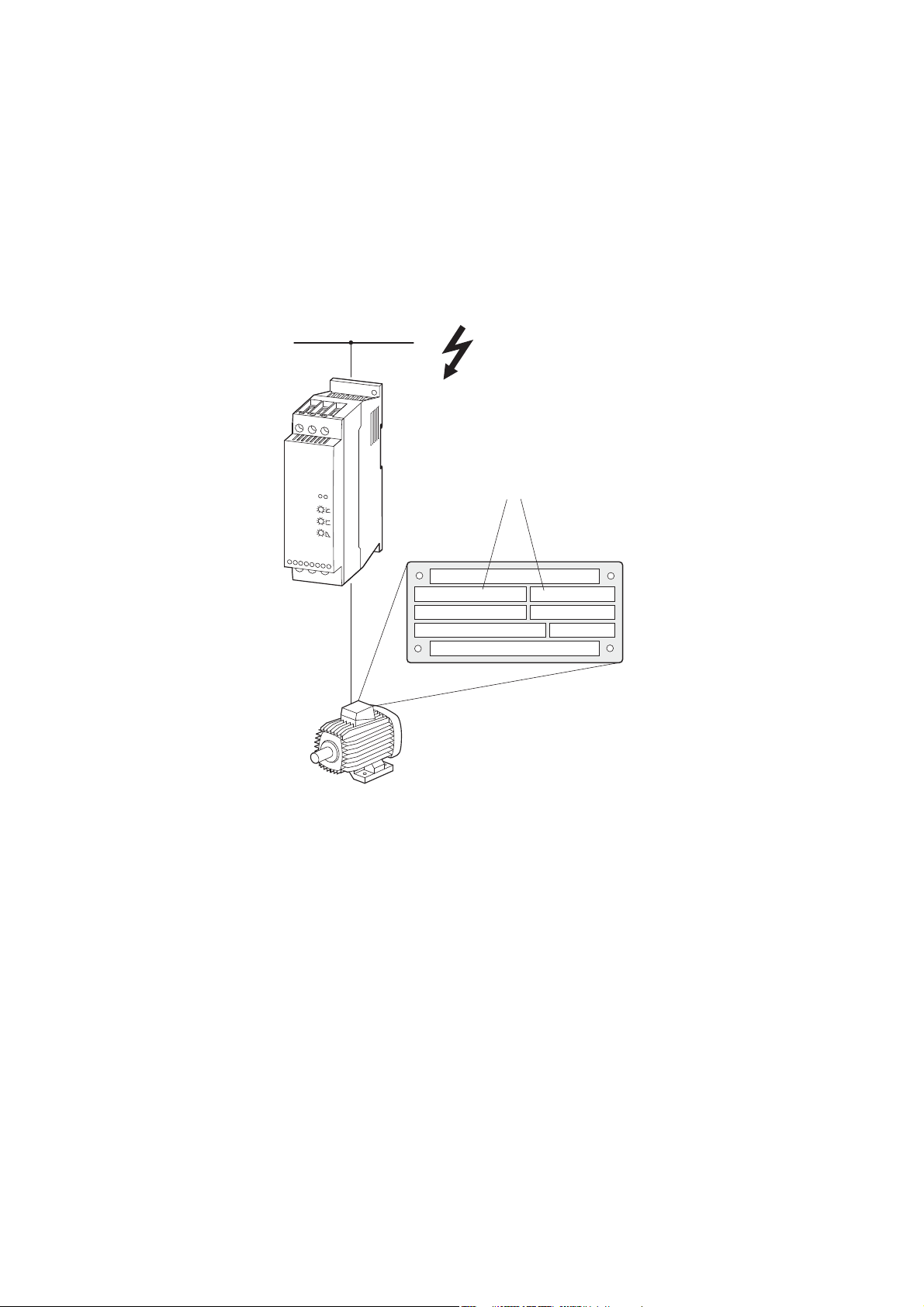

1.13 Selection criteria

The soft starter DS7 ③ is selected on the basis of the supply voltage ULN of

the supply network

motor

②. The circuit type (Δ

the supply voltage ①. The rated output current I

greater than/equal to the rated motor current.

① and the rated operational current of the assigned

/

) of the motor must be selected according to

of the soft starter must be

e

③

U, I, f

①

②

230 / 400 V ∆ /

1.1 kW

min

1430 50 Hz

4.6 / 2.6

A

cos ϕ

0.81

-1

Figure 9: Selection criteria

When selecting the drive, the following criteria must be taken into account:

• Type of motor (e.g.three-phase asynchronous motor)

• Mains voltage = rated operating voltage of the motor (e.g. 3 AC ~ 400 V),

• Rated motor current (recommended value, dependent on the circuit type

and the power supply),

• Load torque (quadratic, linear),

• Starting torque,

• Ambient air temperature (rated value +40 °C).

With heavy starting duty motors, the soft starter must be

→

overdimensioned in terms of its overload capacity.

In the case of single-phase AC motors (→ page 20), the

→

selection must be based on the mains voltage (= the motor’s

rated operating voltage) and the rated motor current for the

specific line frequency.

DS7 Soft starter 09/16 MN03901001Z-EN www.eaton.com 25

1 Device series DS7

①

②

③

④

⑤

M

3 ∼

1.14 Function

1.14 Function

DS7 soft starters use phase control for controlling the voltage of the supply

network smoothly from an adjustable start value up to 100 % of the rated

value U

. This voltage control enables the inrush current of a three-phase

LN

asynchronous motor to be limited and its starting torque to be considerably

reduced. This enables a smooth and jerk-free increase in torque, adjusted to

the load behavior of the machine.

Figure 10: Function chart

a Mains supply voltage U

b Antiparallel thyristors in two phases with bypass contact for controlling the motor voltage

c Output voltage U

ramp function at a constant line frequency

Output current I

Rated motor shaft output P

d Controller card for controlling the power section

This is used to initiate control commands and set the parameters.

e SmartWire-DT interface (optional) for configuring parameters and for control and monitoring

2N

3 × 200 V bis 3 × 480 V

LN

: three-phase, from an adjustable start voltage to 100% mains voltage with the use of a

2

: 4 - 200 A at a maximum ambient air temperature of +40 °C

: 1.5 - 110 kW with 400 or 3 - 150 HP with 480 V

2

The following limitations apply to single-phase AC motors:

→

① U

③ Output current I

Rated motor shaft output P

: 1 x 200 - 240 V

LN

: 4 - 32 A

2N

with 230 V: 0.37 - 4 kW or 1/3 - 5 HP

2

26 DS7 Soft starter 09/16 MN03901001Z-EN www.eaton.com

Loading...

Loading...