Eaton DS-206S series, DS series, DSL series, DS-206 series, DS-416S series Instructions Manual

...

Instruction Booklet IB 33-790-1J

Effective November 2010

Supersedes IB 33-790-1I Dated 10/98

Instructions for Low Voltage Power

Circuit Breakers Types DS and DSL

Instruction Booklet IB 33-790-1J

Effective November 2010

This Page Left Intentionally Blank.

Instructions for Low Voltage Power

Circuit Breakers Types DS and DSL

EATON CORPORATION www.eaton.com

Instructions for Low Voltage Power

Circuit Breakers Types DS and DSL

Instruction Booklet IB 33-790-1J

Effective November 2010

Table of Contents

Description Page

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Basic Breaker Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Arc Chutes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Optional Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Special Circuit Breakers: DS-206S and DS-416S. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Recommended Safety Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Section 1 -Receiving, Handling and Storing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.0 Receiving and Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1 Storing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Weights: Circuit Breakers a nd Fuse Tr ucks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Section 2 -First Removal of Breaker from Compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.0 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Setting the Rails in Front of the Compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Removing Shipping Brace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Lifting the Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

. . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Section 3 -Preliminary Examination of Circuit Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.0 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1 Independent Manual and Power-operated Breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.1.1 Closing Facilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.1.2 Tripping Facilities .

3.2 Levering Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Section 4 -Basic Operating Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.0 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.1 Levering Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2 Charge the Closing Springs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.3 Close the Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.4 Open the Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.5 Place the Breaker in the Tes t Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.6 Place the Breaker in the Connect Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.7 Remove the Breaker for Final Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.8 Final Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.9 Amptector Trip Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.10 Place the Breaker in S ervice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Section 5 -Description and Explanation of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.0 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.1 The Operating Mechanism a nd How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.1.1 Power-Operated Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1.2 Explanation of Spring-Charging Mechanism for Power-operated Breakers . . . . . . . . . . . . . . . 17

5.1.2.1 Power Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.1.3 Manual-operated Mechanisms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.4 Explanation of Spring-charging Mechanism for Manually-o perated Breakers . . . . . . . . . . . .

5.1.5 Circuit Breaker Closing Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.6 Circuit Breaker Tr ipping or Opening Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

. 15

24

. 24

26

EATON CORPORATION www.eaton.com

i

Instruction Booklet IB 33-790-1J

Effective November 2010

Instructions for Low Voltage Power

Circuit Breakers Types DS and DSL

Description Page

5.1.6.1 Miscellaneous Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.1.7 Mechanical Interlocking, Description, and Explanation of Operation . . . . . . . . . . . . . . . . . . . . . 30

5.1.7.1 The REMOVE Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.1.7.2 The DISCONNECT Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.1.7.3 The TEST Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.1.7.4 The CONNECT Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.1.8 Detailed Explanation of Mechanical Interlock System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.1.8.1 Spring Discharge Interlock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.1.8.2 Connected Breaker Manual Close Interlock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.1.8.3 Breaker Equipped for Electric Lockout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.1.8.4 Closed Breaker Interlock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.1.8.5 Padlocking Provision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Section 6 -Circuit Breaker Pole Units, Description and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

38

6.0 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.1 Moving Contact Sub-assemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Stationary Contact Sub-assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

38

40

Section 7 -Arc Chute . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.0 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Section 8 -Circuit Breaker Automatic Tr ipping System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

8.0 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

8.1 The Amptector II-A Tr ip Unit . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . 56

8.2 The Amptector I-A Tr ip Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

8.2.1 Ground Fault Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

8.3 Making Current Release (Discriminator) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

8.4 Servicing of Amptector Tr ip Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

8.5 Actuator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

8.6 Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

8.7 Optional Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

8.7.1 Undervoltage Tr ip Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

8.7.2 Overcurrent Trip Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

8.7.3 High Load Switch (Available with Amptector l-A Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

8.7.4 Latch Check Switch . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

8.7.5 Auxiliary Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

8.7.6 Amptector Tr ip Unit Test Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

8.7.6.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

8.7.6.2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

8.7.6.3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Section 9 -DSL Circuit Breakers and Fuse Trucks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

9.0 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

9.1 DSL Current Limiters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

9.2 Blown Limiter Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

9.3 Fuse Tr ucks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

9.3.1 Installing Fuse Tr ucks . . .

9.3.2 Replacing Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

9.3.3 Blown Fuse Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

ii

EATON CORPORATION www.eaton.com

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Instructions for Low Voltage Power

Circuit Breakers Types DS and DSL

Instruction Booklet IB 33-790-1J

Effective November 2010

Description Page

Section 10 -Fixed Breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

10.0 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Section 11 -Drawout Dummy Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

11.0 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Section 12 -Inspection and Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

12.0 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

12.1.1 When to Inspect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

12.1.2 What to Inspect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

12.1.2.1 DS-206, DS-206S, DS-416, DS-416S, and DS-420 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

12.1.2.2 DS-632 and DS-840 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

12.1.3 Replacement of Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. 78

12.1.3.1 DS-206 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

12.1.3.2 DS-416, DS-416S, DS-420, DS-632, and DS-840 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

12.1.4 Arc Chutes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

12.1.5 General Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

12.1.5.1 Power Operated Mechanisms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

12.2 Factory Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

12.2.1 Trip Latch Overlap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

12.2.2 Breaker Open Position Stop (DS-632 Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

12.2.3 Moving Contact Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

12.2.4 Levering Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

12.3 Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

12.3.1 Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

12.3.2 Location and Lubricant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Section 13 -Renewal Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

13.0 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

13.1 Identifying Parts for DS-416S and DS-206S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

13.1.1 DS-416S Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

13.1.2 DS-206S Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

List of Tables

1. Type DS Breaker Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2. DSL Breakers - Current Limiting Ty pe Breakers and Combinations. . . . . . . . . . . . . . . . . . . . . . . . . 2

3. Approximate Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4. Frame Size and Sensor Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5. Sensor and Limiter Ratings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . 69

EATON CORPORATION www.eaton.com

iii

Instruction Booklet IB 33-790-1J

Effective November 2010

Instructions for Low Voltage Power

Circuit Breakers Types DS and DSL

List of Illustrations

Figure Title Page

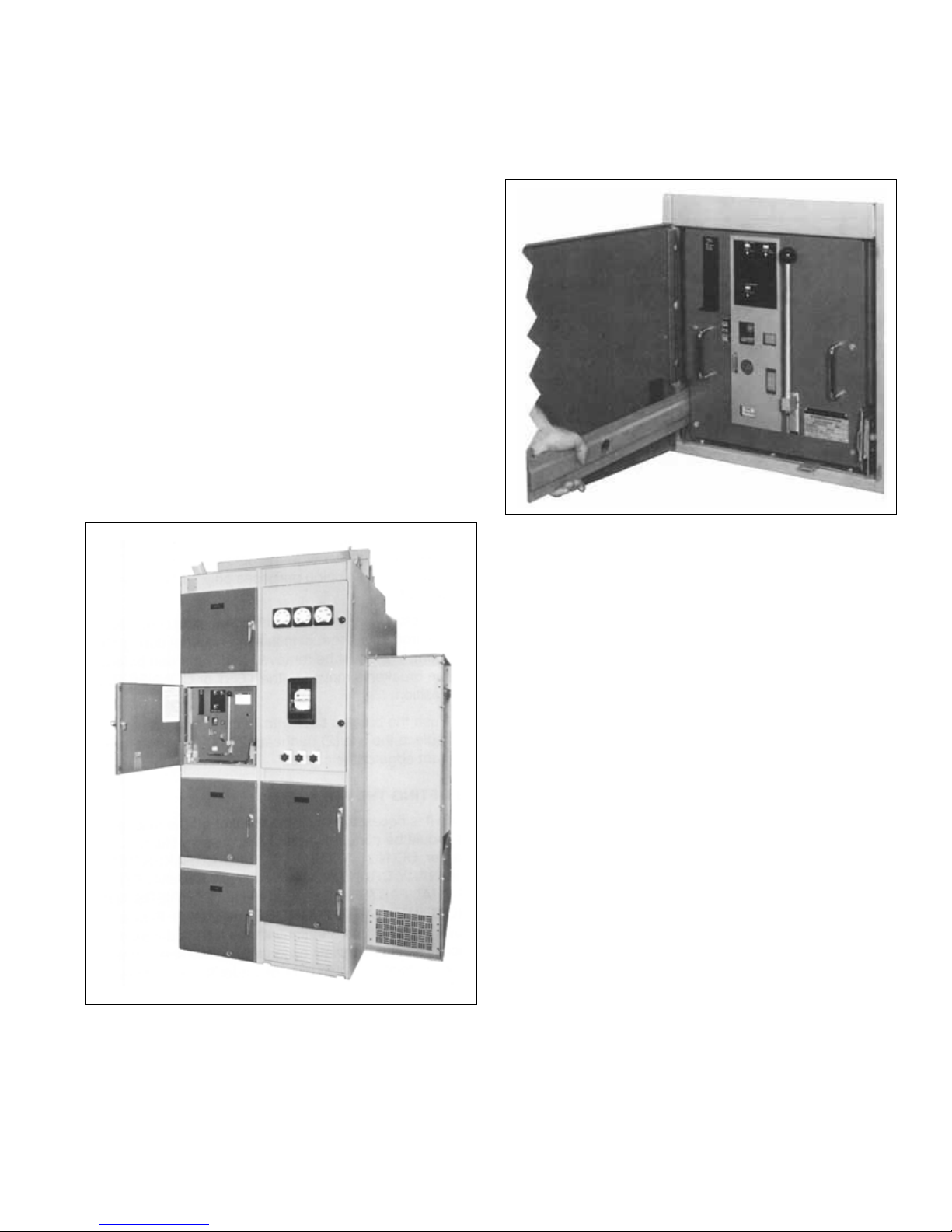

1 The Type DS Low Voltage Power Circuit Breaker Is Shipped Inside Its Own Compartment 7

2 Rails Are Stowed Away in the Compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

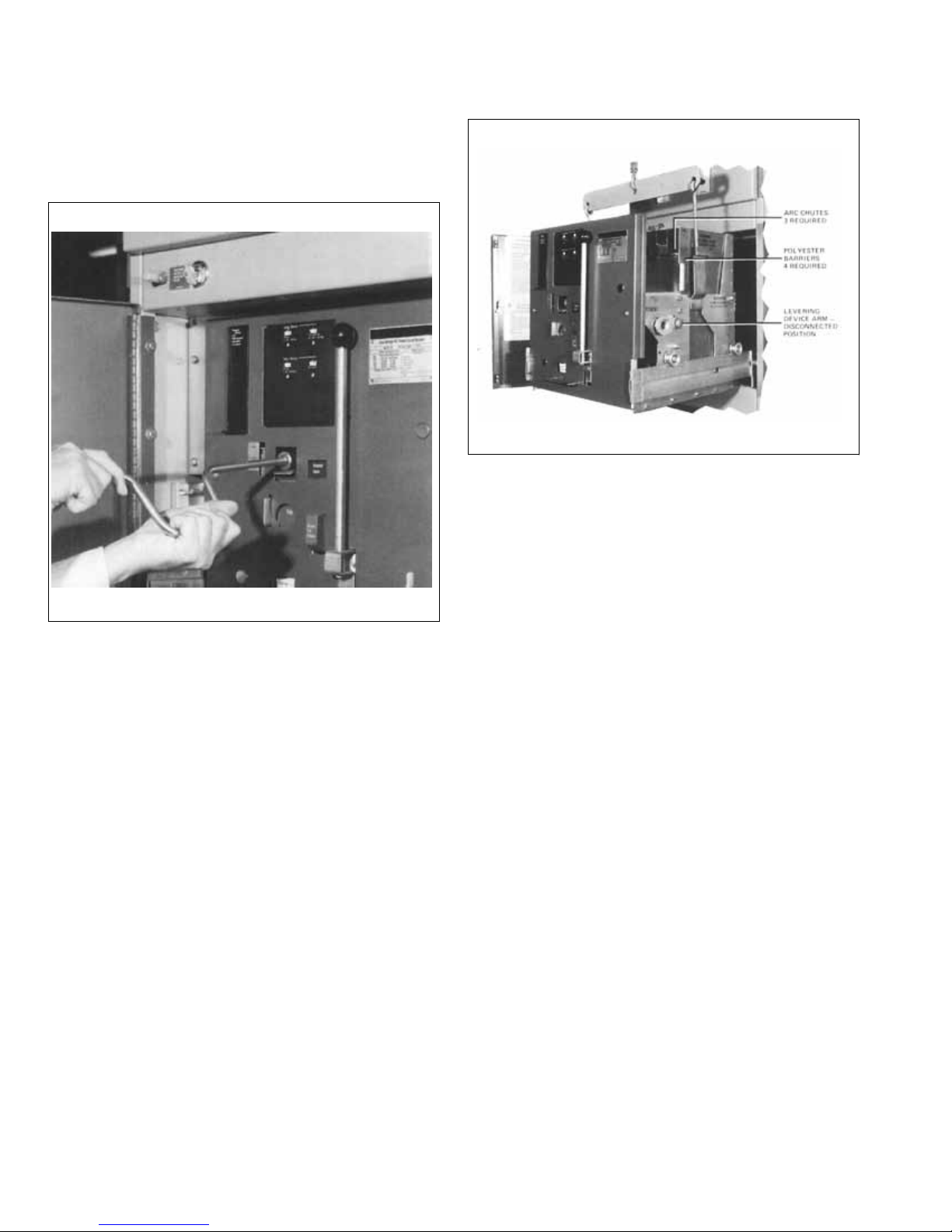

3 Levering Device Crank Handle Installed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Use of Breaker Lifting Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

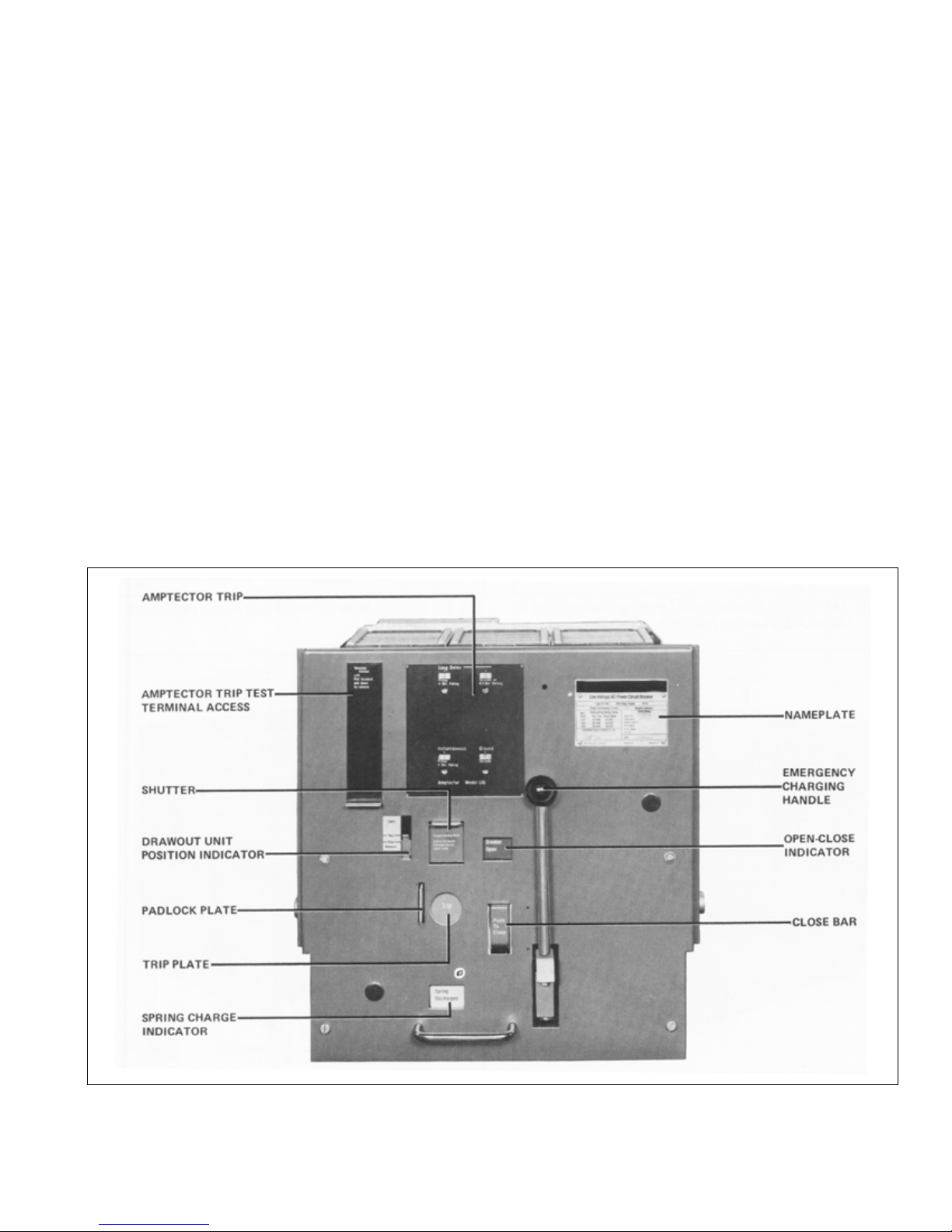

5a View Showing Controls on the Panel (Pre 1988) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

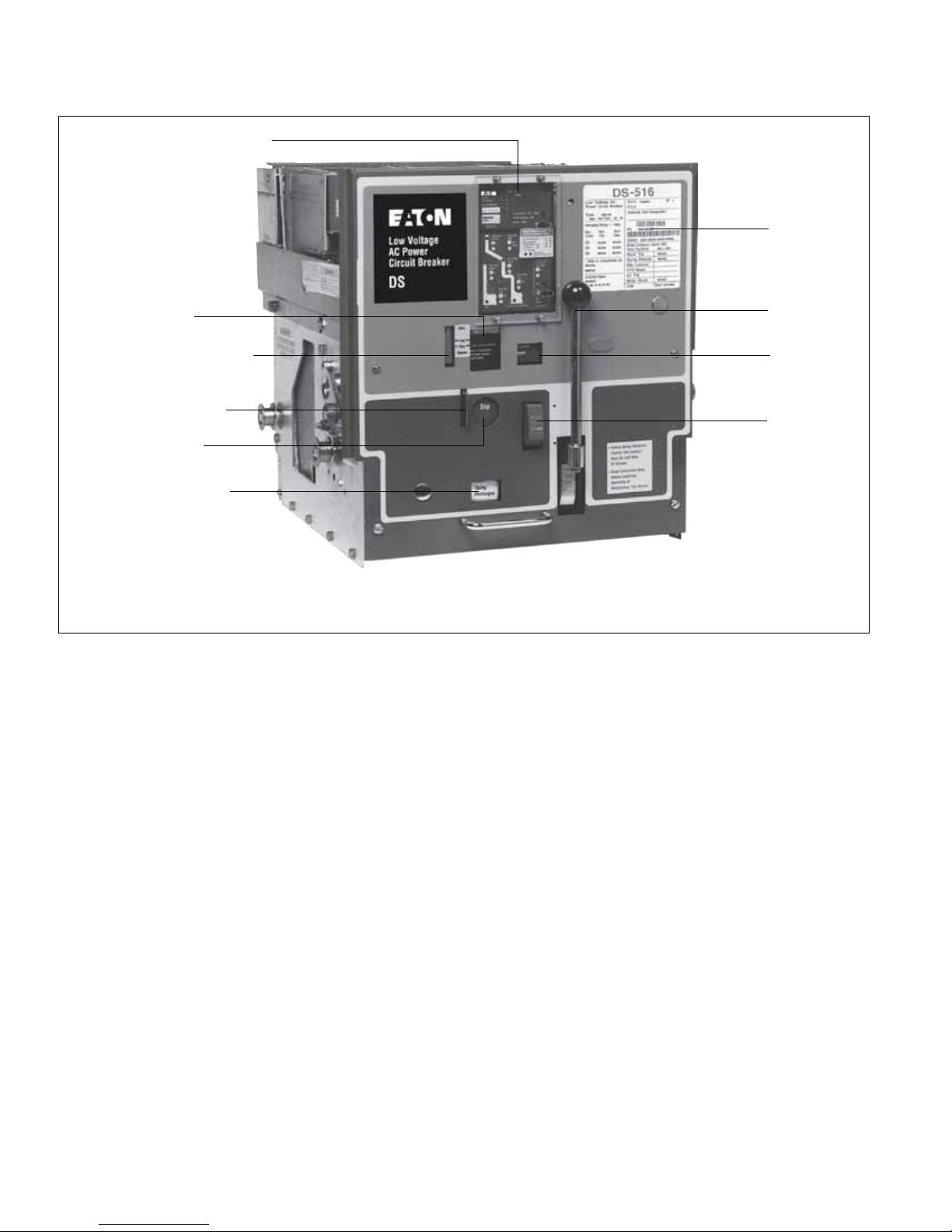

5b View Showing Controls on the Panel (Post 1988) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6a Left Side of Breaker with Levering Device Arm in REMOVE Position . . . . . . . . . . . . . . . . . . 11

6b DS 416 Breaker with Front Panel Removed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7 Right Side Showing Levering Device Arm in TEST Position . . . . . . . . . . . . . . . . . . . . . . . . . 11

8 Rear View Showing Levering Device Arm in CONNECT Position . . . . . . . . . . . . . . . . . . . . . 11

9 Method Used to Press Trip Plate and Lower Shutter with One Hand,

Preparatory to Inserting Crank . . . . . . . . . . . . . . . . . . . . . . . . . . .

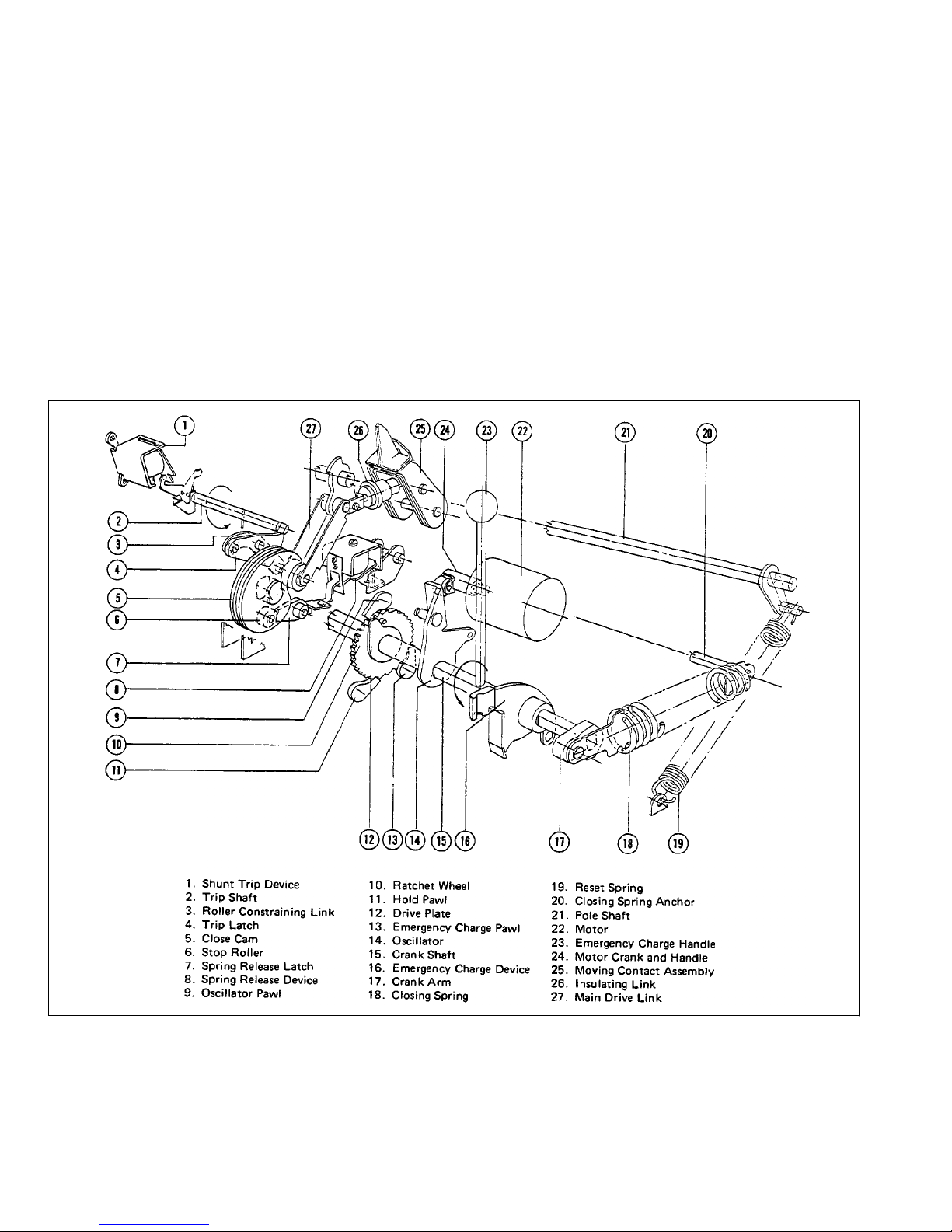

10 Front View of Mechanism (Manual Spring Charge Except for DS-632/840) . . . . . . . . . . . . . 16

11 Front View of Mechanism (Power-Operated Spring Charge) . . . . . . . . . . . . . . . . . . . . . . . . . 16

12 Rear of Power-operated Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

13 Rear View of Mechanism (Left Close Spring Removed) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

14 Arrangement of the Principal Parts of a Power Operated Mechanism

The Close Spring is Shown in the Charged Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

15 Front View Showing Major Parts of the Crank Shaft Assembly

Some Parts are Omitted for Clarity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

16 Power-operated Spring-charge Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

17 Crank Shaft Assembly of Power-operated Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

18 Emergency Spring-charge on

19 Standard Schematic and Connection Diagrams for Power-Operated Breakers . . . . . . . . . . . 22

20 Principal Parts in a Manually Charged Spring Operated Mechanism . . . . . . . . . . . . . . . . . . 23

21 Spring-charging Mechanism on Manual Operated Breakers . . . . . . . . . . . . . . . . . . . . . . . . . 24

22 These Sketches Show the Four Basic Positions of Breaker and Linkage

with Enlarged View of Tr ip Shaft and Latch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

23 Shunt Trip Details Showing Tr ip Shaft Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

24 Actuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

25 DS-632 Breaker with Front Panel Removed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

26a Bottom View of Breaker Unit Showing Interference Interlock,

Motor Cut-off Switch and Other Details not Visible from Above . . . . . . . . . . . . . . . . . . . 29

26 Front View S

26 Rear View Showing the Seismic Positioner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

27 Drawout Unit Position Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28 Relation of Shutter, Tr ip Plate, and Tr ip Shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

29 Relation of Shutter, Interlock Cam, and Levering Device Arms . . . . . . . . . . . . . . . . . . . . . . . 34

30 Close-Release Interlock to Discharge Springs on Levering Out of Compartment and

Conn. Position No Manual Close Interlock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

31 Close Interlock to Prevent Efforts to Close a Breaker that Is Already Closed . . . . . . . . . . . . 36

32 Padlock Device - Locked Tr ip Free and Shutter Raised . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

33 Three-Pole Assembly of DS-206 Pole Units on Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

34 Three-Pole Assembly of DS-416 and DS-420 Pole Units on Frame . . . . . . . . .

35 Three-Pole Assembly of DS-632 Pole Units on Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

36 Three Pole Assembly of DS-840 Pole Units on Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

37 Type DS-206 Pole Unit Assembly - Front View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

38 Type DS-206 Pole Unit Assembly - Rear View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

howing Close Bar Guard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Power-operated Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . 21

. . . . . . . . . . . . . . . . . 13

. . . . . . . . . . 39

30

iv

EATON CORPORATION www.eaton.com

Instructions for Low Voltage Power

Circuit Breakers Types DS and DSL

Instruction Booklet IB 33-790-1J

Effective November 2010

Figure Title Page

39 Type DS-416 Pole Unit Assembly - Front View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

40 Type DS-416 Pole Unit Assembly - Rear View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

41 Type DS-420 Pole Unit Assembly - Front View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

42 Type DS-420 Pole Unit Assembly - Rear View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

43 Type DS-632 Pole Unit Assembly - Front View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

44 Type DS-632 Pole Unit Assembly - Rear View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

45 Type DS-840 Pole Unit Assembly - Front View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

46 Type DS-840 Pole Unit Assembly - Rear View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

47 Moving and Stationary Contact Details DS-206 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

48 Moving and Stationary Contact Details DS-416 . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . 47

49 Moving and Stationary Contact Details DS-420 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

50 Moving Contact Details DS-632 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

51 Stationary Contact Details DS-632 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

52 Moving Contact Details DS-840 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

53 Stationary Contact Details DS-840 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

54 Breaker with Barrier Removed to Show Mounting of Arc Chutes . . . . . . . . . . . . . . . . . . . . . 53

55 DS-206 Arc Chute with Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

56 DS-416/420 Arc Chute with Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

57 DS-632 Arc Chute with Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

58 DS-840 Arc Chute with Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

59 Schematic Illustration of Tr ipping System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

60 Standard Amptector II-A Sol

id-State Tr ip Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

61 Amptector II-A Tr ip Unit with Front Cover Removed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

62 Optional Amptector I-A Solid-State Trip Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

63 Amptector I-A Tr ip Unit with Front Cover Removed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

64 Trip Actuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

65 DS-840 Breaker with Front Panel Removed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

66 DS-840 Breaker Rear View Showing Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

67 Undervoltage Tr ip Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

68 Undervoltage Tr ip Device Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

69 Overcurrent Tr ip Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

70 Overcurrent Tr ip Switch Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

71 High Load Switch . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

72 Latch Check Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

73 Latch Check Switch Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

74 Auxiliary Switch Construction Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

75 Amptector Trip Unit Test Kit (For Amptector I-A and II-A) . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

76 Test Kit in Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

77 DSL-206 Breaker Side View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

78 DSL-206 Breaker Front View (DSL-416 Similar) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

79 DSL-416 Breaker Side View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

80 Blown Limiter Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

81 DS-3200 Fuse Truck Front View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

82 DS-3200 Fuse Truck with Front Cover Re

moved . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

83 DS-4000 Fuse Truck Side View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

84 Contacts and their Adjustment, DS-206 Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

85 Contacts and their Adjustment, DS-416/420 Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

EATON CORPORATION www.eaton.com

v

Instruction Booklet IB 33-790-1J

Effective November 2010

Instructions for Low Voltage Power

Circuit Breakers Types DS and DSL

Figure Title Page

86 Contacts and Their Adjustment, DS-632 Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

87 Contacts and Their Adjustment, DS-840 Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

88 Open Position Stop and Anti-rebound Latch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

89 Levering Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

90 Lubrication Points on Left Side of Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

91 Lubrication Points on Right Side of Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

vi

EATON CORPORATION www.eaton.com

Instructions for Low Voltage Power

Circuit Breakers Types DS and DSL

This instruction book is expressly intended to cover the installation, operation and maintenance

of Low Voltage Power Circuit Breakers, Types DS and DSL.

For application information, consult your nearest Eaton sales office, see Eaton

Descriptive Bulletin 32-850, or appropriate ANSI Standards.

Instruction Booklet IB 33-790-1J

Effective November 2010

PURPOSE

NOTE: This manual covers both Pre and Post 1988 versions of DS and DSL Low Voltage Power

Circuit Breakers. The two main differences are the front cover and the trip unit (Amptector

vs. Digitrip RMS) - see IL8700C39 supplied with the breaker for the Digitrip RMS trip unit details.

Except for the front cover and trip unit, all other sections in this manual apply to current production.

SAFETY

All Safety Codes, Safety Standards and/or Regulations as they may be applied to this type of

equipment must be strictly adhered to.

All possible contingencies which may arise during installation, operation, or maintenance, and all details and variations of this equipment do not

purport to be covered by these instructions. If further information is desired by purchaser regarding his particular installation, operation or

maintenance of his equipment, the local Eaton representative should be contacted.

EATON CORPORATION www.eaton.com

vii

Instruction Booklet IB 33-790-1J

Effective November 2010

Instructions for Low Voltage Power

Circuit Breakers Types DS and DSL

CAUTION

The circuit breakers described in this book were

designed and tested to operate within their nameplate

ratings. Operation outside of these ratings may cause

the equipment to fail, resulting in bodily injury and

property damage.

viii

EATON CORPORATION www.eaton.com

Instructions for Low Voltage Power

Circuit Breakers Types DS and DSL

Instruction Booklet IB 33-790-1J

Effective November 2010

Introduction

These instructions cover the description, operation and

maintenance of Eaton Type DS and Type DSL

Low Voltage AC Power Circuit Breakers and Type DS

Drawout Fuse Trucks. These breakers are usually supplied as part of low voltage metal enclosed switchgear of

the four-position drawout type. These instructions apply

only to the circuit breaker and its auxiliary drawout details

which have been designed as a completely integrated

drawout unit. Type DS Breakers (not DSL) may also be

supplied in a fixed mounted version. In this case the sections of this book referring to the levering device, position

interlocks, and spring discharge interlock will not apply.

The DS and DSL Circuit Breakers operate on the magnetic De-ion principle of interruption. In these br

eakers

the arc rises into a series of insulated steel plates. The

plates break the rising arc into a series of smaller arcs to

cool and extinguish them and funnel the heat to ambient

air.

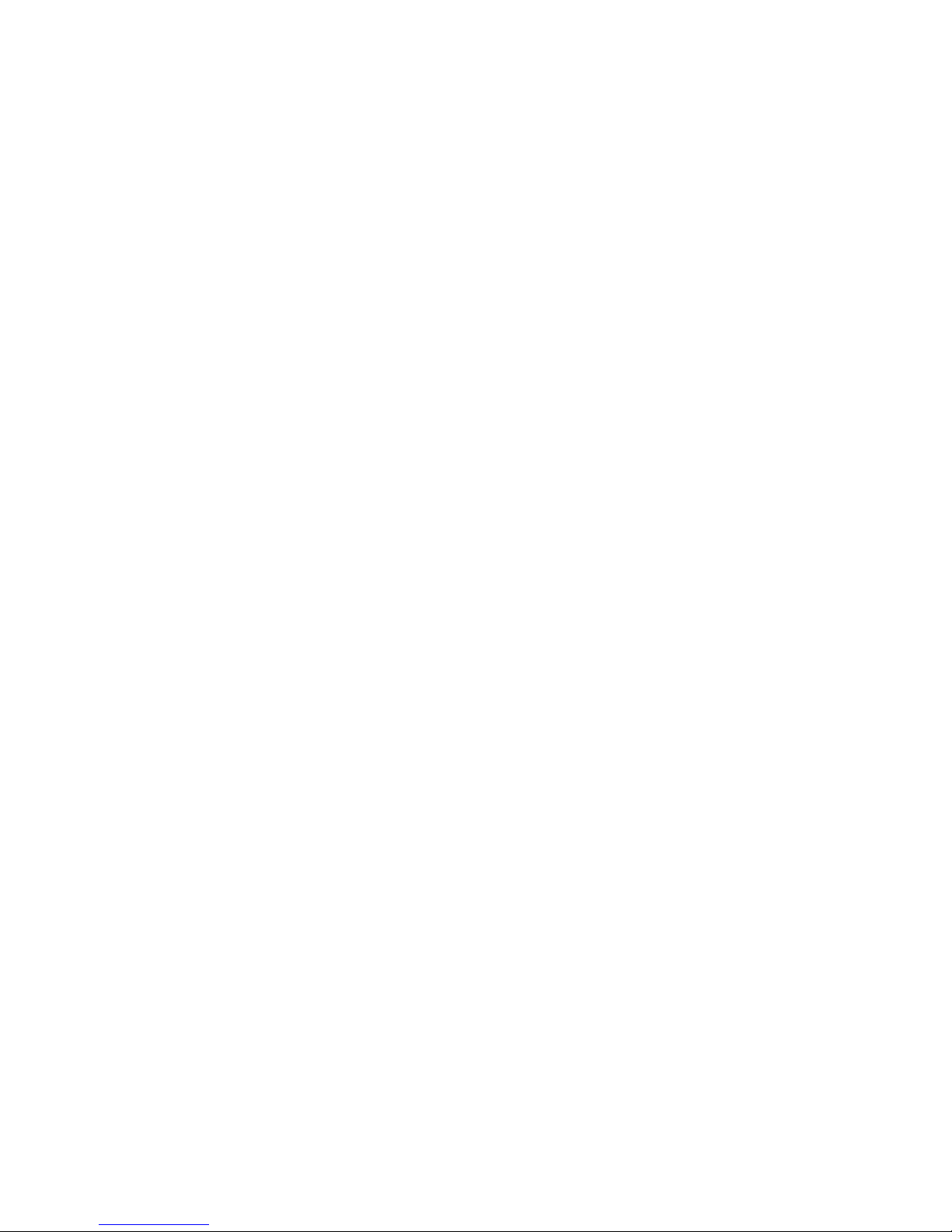

Table 1 - Type DS Breaker Ratings

Interrupting Ratings, RMS Symmetrical Amperes

Breaker

Type

Frame Size,

Amp.

208-240V 480V 600V 208-240V 480V 600V

With Instantaneous Trip With Short Delay Trip

DS and DSL Breakers are available for application at voltages from 208 to 600 Vac; with continuous currents of 50

to 4000 amps; and with interrupting capabilities up to

200,000 amps. Refer to the breaker nameplate for the

complete rating information for any given breaker. Breakers conform to NEMA, ANSI, and IEEE standards.

TYPE DS AND DSL BREAKERS ARE PROTECTIVE

DEVICES. AS SUCH, THE Y ARE MAXIMUM CURRENT RATED DEVICES. THEREFORE, THE Y

SHOULD NOT UNDER ANY CIRCUMSTANCES BE

APPLIED OUTSIDE THE IR NAMEPLATE RATINGS.

OPERATION OUTSIDE OF THESE RATINGS MAY

CAUSE THE EQUIPMENT TO FAIL, RESULTING IN

BODIL

Y INJURY AND P

ROPERTY DAMAGE.

The available DS and DSL Breakers and their rated performance capabilities are given in Tables 1 and 2.

DS-206 800 42,000 30,000 30,000 30,000 30,000 30,000

DS-206S 800 50,000 42,000 42,000 42,000 42,000 42,000

DS-416 1600 65,000 50,000 42,000 50,000 50,000 42,000

DS-416S 1600 65,000 65,000 50,000 65,000 65,000 5

0,000

DS-420 2000 65,000 65,000 50,000 65,000 65,000 50,000

DS-632 3200 85,000 65,000 65,000 65,000 65,000 65,000

DS-840 4000 130,000 85,000 85,000 85,000 85,000 85,000

Also short-time ratings.

Short circuit ratings of non-automatic breakers except the DS-840 which is 65,000.

Maximum voltages at which the interrupting ratings apply are:

System Voltage

208 or 240 254

480 508

600 635

Interrupting ratings are based on the standard duty cycle consisting of an opening operation, a 15 second interval and a

close-open operation, in succession, with delayed tripping in

case of short-delay devices.

The standard duty cycle for short-time ratings consists of maintaining the rated current for two periods of 1/2 second each,

with a 15-second interval of zero current between the two periods.

Maximum Voltage

EATON CORPORATION www.eaton.com

1

Instruction Booklet IB 33-790-1J

Effective November 2010

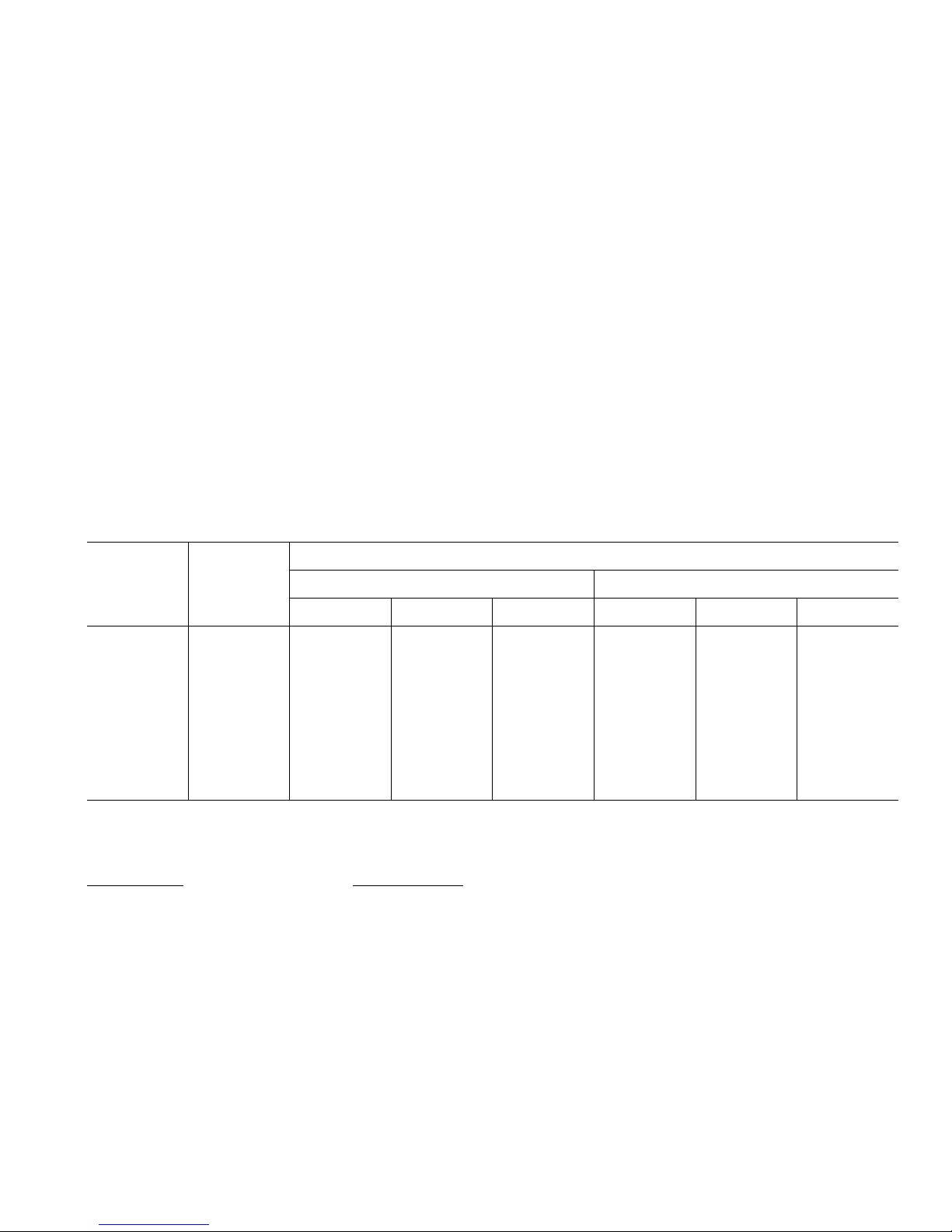

Table 2 - DSL Breakers - Current Limiting Type Breakers and Combinations

Instructions for Low Voltage Power

Circuit Breakers Types DS and DSL

048-LSD236-LSD614-LSD602-LSDepyT

Frame Size, Amperes

800 1600 3200 4000

Max. Interrupting Rating,

RMS Symm. Amp., System

Voltage 600 or Below 200,000 200,000 200,000 200,000

Notes: DSL-206 and DSL-416 include limiters integral

with drawout breaker elements. DSL-632 includes

DS-632 breaker and DS-3200 drawout fuse truck, in

separate interlocked compartments. Maximum continuous rating limited to 3000A when fuse compartment is above breaker compartment in same unit.

DSL-840 includes DS-840 breaker and DS-4000 draw-

On the front of the breaker are the control items needed

for proper operation of the circuit breaker. They are:

breaker position indicator, breaker open/closed indicator

levering device shutter and shaft, breaker trip plate, closing spring charged/discharged indicator, Amptector trip

test terminal access, Amptector trip controls, closing

spring charge handle, close bar, and padlock plate.

out fuse truck, in separate interlocked compartments. Maximum interrupting rating limited to

150,000 amperes when 6000A f

uses are used.

Arc Chutes

Each arc chute contains vertical steel splitter plates, insulating spacers and plates. These are all assembled in an

GENERAL DESCRIPTION

Eaton DS and DSL Circuit Breakers are horizontal

insulating arc chute jacket. The arc chutes mount on top

of the pole units and are vented to atmosphere.

drawout magnetic air circuit breakers. They are

designed for use in Metal-Clad Switchgear assemblies

having maximum voltages of 635 volts AC for DS Circuit

Breakers and 600 volts for DSL. They are equipped with

spring-stored, energy-closing mechanisms. All primary

Optional Components

Optional components provided upon order are: under-

voltage trip attachment, overcurrent trip switch, high-load

trip switch, latch check switch, auxiliary switches.

insulation to ground is glass polyester. These breakers

have many common features, but they will vary in size

and detail

depending on the specific breaker type number

and ratings. Figure 1 shows Type DS Low Voltage Power

Circuit Breaker shipped inside its own compartment. Figures 78 and 79 show Types DSL-206 and DSL-416 Circuit Breakers.

Each DS and DSL Circuit Breaker consists of a basic

breaker assembly, three interrupter assemblies (arc

chutes), barriers, and an Amptector solid-state trip unit.

DSL breakers have added current limiters to extend their

interrupting

range to 200,000 amps. Various accessories

are also provided.

Basic Breaker Assembly

The basic breaker assembly includes a chassis, a control

panel, an operating mechanism, a levering-in device, various interlocks, and three insulated pole unit assemblies

Accessories

Levering crank and Amptector Test Kit are supplied as

required.

Since the major components and the accessories

depend on the particular type and rating of circuit

breaker, packing lists provided with each shipment and

more detailed sections of this instruction book should be

red to for special information. Any questions about

refer

the circuit breakers may be referred to the nearest Eaton

Sales Office. When making inquiries about type DS

(DSL) circuit breakers always provide the specific

type number, continuous current rating, mechanism type,

applicable order numbers, breaker shop orders or style

numbers, date of manufacture and other pertinent information as shown on the circuit breaker nameplate. Inquiries can be handled fast

er when complete information is

provided with the initial inquiry.

mounted on a base.

,

2

EATON CORPORATION www.eaton.com

Instructions for Low Voltage Power

Circuit Breakers Types DS and DSL

Instruction Booklet IB 33-790-1J

Effective November 2010

Special Circuit Breakers: DS-206S and DS-416S

Table 1 gives the interrupting rating of DS-206S as

42,000 amperes at 600 volts AC. It is an improved model

of DS-206, which has an interrupting capacity of 30,000

amperes at 600 volts AC. Yet, the maximum continuous

current rating of 800 amperes is the same for both types.

Also, their parts are similar except for these differences:

1. DS-206S uses the three piece base of the DS-416

type, instead of the one piece molded base of t

he

DS-206.

2. DS-206S uses the DS-416 arc chute.

3. DS-206S main disconnects have 50% more fingers

than the DS-206.

4. DS-206S has twice as many main contacts and arms

as the DS-206.

5. The pole unit hinge joint of DS-206S is a forked construction or a miniature version of the DS-416 hinge.

6. Fifty ampere sensors cannot be installed on

DS-206S; but they can be put on DS-206.

Similarly, the parts of DS-416S are almost identical to

those of DS-420. Their interrupting

ratings are the same:

65,000 amperes at 480 volts AC and 50,000 amperes at

600 volts AC. But, the maximum continuous current rating of DS-420 is 2,000 amperes and for DS-416S it is

1600 amperes.

Compared to Type DS-416, DS-416S has higher interrupting ratings, giving it improved operating flexibility (see

Table 1).

EATON CORPORATION www.eaton.com

3

Instruction Booklet IB 33-790-1J

Effective November 2010

Instructions for Low Voltage Power

Circuit Breakers Types DS and DSL

Safety Features

Type DS (DSL) Breakers are manufactured with several

built-in interlocks and safety features to reduce hazards

and provide proper operating sequences. UNDER NO

CIRCUMSTANCES SHOULD THEY BE MADE INOPERATIVE AS THIS MAY RESULT IN BODILY INJURY

OR PROPERTY DAMAGE.

1. Positive mechanical indicators on front panel show

whether the breaker is open or closed, and whether

the closing spring is charged or discharged.

2. Closing Spring Automatic Discharge - Mechani

interlocking automatically discharges the closing

springs when the breaker is removed from its compartment.

3. Mechanical interlocking prevents levering of breaker

unless its contacts are open. Contacts cannot be

closed until the breaker is levered into TEST or CONNECT positions.

4. Mechanical interlocking prevents closing of breaker

contacts while it is being levered into or out of its cell,

or while it is standing in any intermediate location

ween the TEST and the CONNECT positions or

bet

the DISCONNECT position.

cal

5. Provisions for Padlocking-Breakers can be padlocked

open to prevent electrical or manual closing. This

padlocking can also secure the breaker in the connected, test, or disconnected position by preventing

levering.

6. In the CONNECT position automatic mechanical

interlocking prevents the disconnecting or withdrawal

of a closed breaker. This avoids drawing dangerous,

destructive arcs on the d

the circuit is energized.

7. In the REMOVE position mechanical interlock system

prevents the closing springs from being charged or

remaining charged.

8. The integral fuses on Types DSL-206 and DSL-416

breakers are inaccessible until the breaker is completely withdrawn from its compartment, thereby

assuring complete isolation.

Likewise, the Type DSL-632 and DSL-840 fuses are inaccessible until the separate fuse truck is

drawn and the fuses isolated. The fuse truck is key

interlocked with the breaker to prevent withdrawing or

insertion unless the breaker is open.

isconnecting contacts when

completely with-

4

EATON CORPORATION www.eaton.com

Instructions for Low Voltage Power

Circuit Breakers Types DS and DSL

Recommended Safety Practices

Instruction Booklet IB 33-790-1J

Effective November 2010

Type DS circuit breakers are complex electrical devices

containing high speed, high energy, operating mechanisms. They are designed to operate within the current

and voltage limitations on the breaker nameplate. Do not

apply these breakers to systems with currents and/or

voltages exceeding these limits.

1. To perform work on Type DS Circuit Breakers

requires personnel with training and experience in

high voltage circuits. Only

ers, familiar with the construction and operation of

such equipment and the hazards involved, should be

permitted to work on these circuit breakers.

2. Only Qualified Persons as defined in the National

Electric Safety Code should be permitted to assemble, operate or maintain these breakers.

3. The breakers are equipped with various interlocks.

DO NOT MAKE ANY OF THE INTERLOCKS INOPERATIVE AS THIS MAY RESULT IN BODILY

INJURY O

4. Never put a breaker into a cell without barriers and

arc chutes.

5. Always be sure that all switch hardware is in place

and bolted tightly before inserting breaker into cell.

R PROPERTY DAMAGE.

qualified electrical work-

7. Use handle on front panel of circuit breaker to move it

into or out of cell. Keep fingers and hands off top, bot

tom or sides of breaker when moving it into or out of

cell to prevent bodily injury.

8. When operating breaker without arc chutes and barriers, keep hands, arms, head and tools out of area

where contacts travel. Severe bodily injury could

result from being struck by the moving contacts

either as they open or close.

9. Be sure circuit breaker contacts are open and closing

springs are discharged before doing maintenance

work.

10. Be sure circuit breaker

springs are discharged after completing maintenance

work.

11. Never leave breaker in an intermediate position in a

cell. Always have the breaker either in the disconnect, test or connected position because control circuits may be either improperly connected (or

disconnected) and may cause electrical failures.

12. Avoid trip-free type operation because it causes

more shock on some parts of breaker than normal

closing ope

rations. Refer to last paragraph in Item 4.1.

contacts are open and closing

-

6. Do not lift breaker with ordinary crane hooks, ropes,

chains, etc., to avoid possible damage to parts or

dropping the unit. Use breaker lifting adapter.

13. Before operating breaker in test position, be sure that

closing the breaker will not cause another electrically

interlocked breaker to inadvertently trip.

EATON CORPORATION www.eaton.com

5

Instruction Booklet IB 33-790-1J

Effective November 2010

Section 1 - Receiving, Handling and Storing

Instructions for Low Voltage Power

Circuit Breakers Types DS and DSL

1.0 RECEIVING AND HANDLING

The circuit breakers may be shipped completely assembled and inside their respective compartments.

Receiving and handling of this equipment is covered in

Eaton Instruction Book 32-690 for Low-Voltage

Metal-Enclosed Switchgear, Types DS and DSO.

If the circuit breakers are not shipped in the switchgear

assembly, they will be packed separately in individual cartons or crates. These packages must be handled with

care to avoid hidden d

If the circuit breakers have been shipped in the switchgear assembly, proceed as described in Section 2. If the

breakers have been shipped in separate packages, remove them from the crate or carton carefully so as not to

cause damage. Place the breakers on the switchgear

extension rails. (See Section 2.3 before attempting to lift

breakers.) Remove the insulating barriers and arc chutes.

Inspect the contact structures to be sure no damage has

occurred during shipment. Repla

insulating barriers and proceed as described in Section 3.

1.1 STORING

If it is necessary to store the equipment before installation, keep it in a clean dry place, protected from dirt and

water and with ample air circulation and heat, if necessary, to prevent condensation. Like all electrical apparatus, these units contain insulation. Although it is of

highest quality, it, like all other insulation, must be protected against dirt and moisture. Refer to Instruct

Book 32-690-C for details.

amage to the circuit breakers.

ce the arc chutes and

ion

Note: Breakers that have been stored or have infrequent operations shall be operated a minimum of five

times before being placed in service.

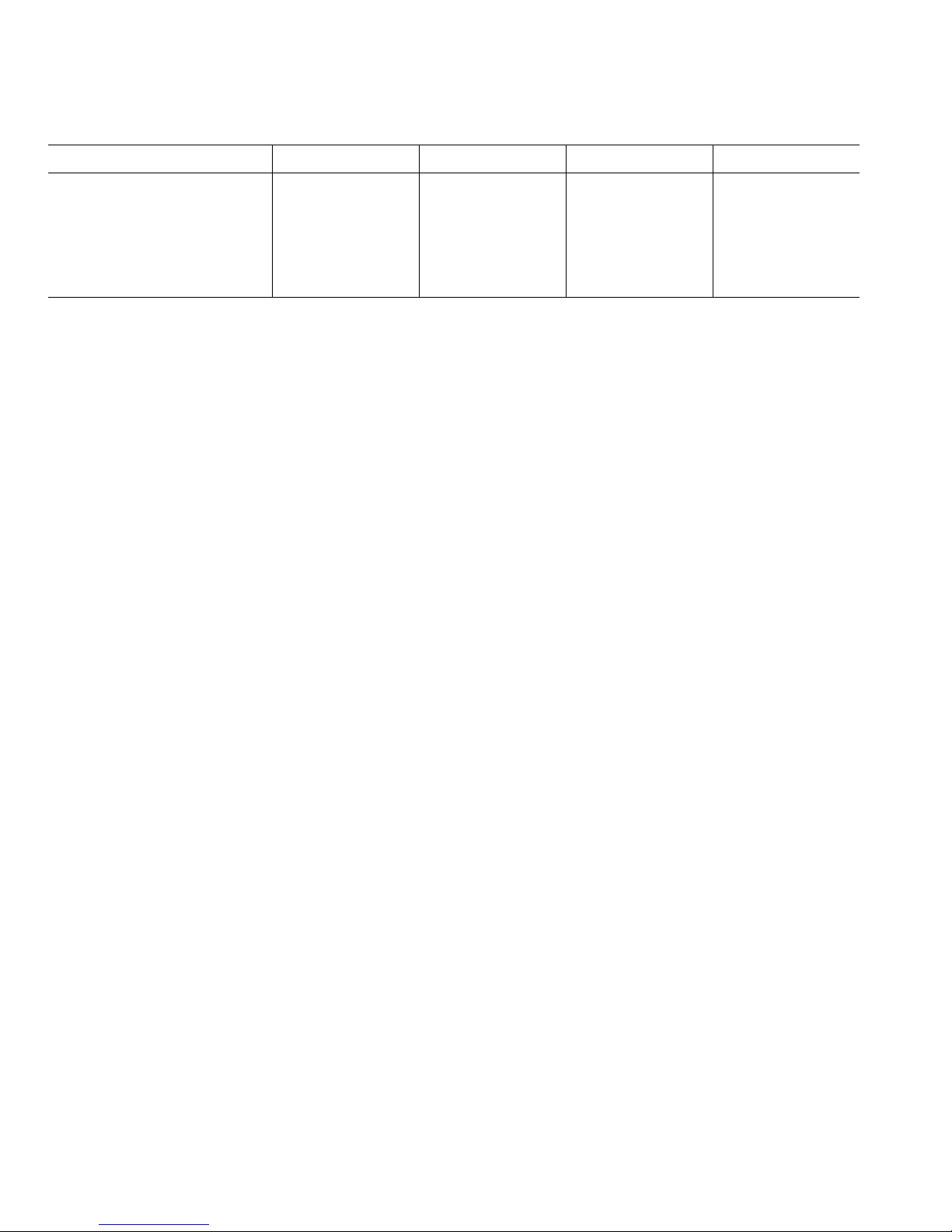

1.2 WEIGHTS: CIRCUIT BREAKERS AND FUSE

TRUCKS

Table 3 gives the approximate weights of DS and DSL circuit breakers. They will vary slightly due to the differences in functional components of the individual DS

Breaker, and the size of the current limiters supplied on

DSL Breakers. Fuse tru

ences of fuse sizes.

Table 3 - Approximate Weights

DS-206 Circuit Breaker . . . . . . . . . . . . . . 150

DS-206S Circuit Breaker . . . . . . . . . . . . . 160

DS-416 Circuit Breaker . . . . . . . . . . . . . . 195

DS-416S Circuit Breaker. . . . . . . . . . . . . 200

DS-420 Circuit Breaker . . . . . . . . . . . . . . 200

DS-632 Circuit Breaker . . . . . . . . . . . . . . 300

DS-840 Circuit B

DSL-206 Circuit Breaker . . . . . . . . . . . . . 200

DSL-416 Circuit Breaker . . . . . . . . . . . . . 260

DS-3200 Fuse Truck . . . . . . . . . . . . . . . . 325

DS-4000 Fuse Truck . . . . . . . . . . . . . . . . 430

ck weights will vary due to differ-

sdnuoPstnemelE tuowarD

reaker . . . . . . . . . . . . . . 400

6

EATON CORPORATION www.eaton.com

Instructions for Low Voltage Power

Circuit Breakers Types DS and DSL

Section 2 - First Removal of Breaker from Compartment

2.0 GENERAL

To examine and become familiar with the construction

and operation of the breaker, it first must be withdrawn

from the compartment. There are rails provided which

permit the breaker to be rolled out of the compartment so

that it can be examined on all sides and operated. First

unlatch and open the compartment door.

2.1 SETTING THE RAILS IN FRONT OF THE COMPARTMENT

Refer to Figures 1 and 2. There are two rails for each

breaker compartment whic

on the inside of the compartment in a back-sloping position. Withdraw each rail completely and let it down into a

horizontal position, as shown in Figure 2.

The first movement of the breaker toward the front of the

compartment must be done with the levering device.

h, when not in use, are stored

Instruction Booklet IB 33-790-1J

Effective November 2010

Fig. 1 The Type DS Low Voltage Power Circuit Breaker is

Shipped Inside Its Own Compartment.

Fig. 2 Rails are Stowed away in the Compartment.

Withdraw as Shown.

2.2 REMOVING SHIPPING BRACE

Before th

its compartment for the first time, two shipping braces

must be removed from the lower part of the breaker front

panel. These braces are small steel angles bolted to the

front of the circuit breaker and to the bottom cradle of the

circuit breaker compartment.

During shipment, the front wheels of the breaker are lifted

approximately 1/16 inch above the compartment rails,

and the uni

TEST positions by means of its levering device and the

shipping angle.

1. With a screwdriver, remove the two (2) outside .25-20

2. The levering device is now used to release the

e circuit breaker element can be withdrawn from

t is held part way between

panhead screws with captive washers from the bottom leg of the two angles. Do not discard, as later

they will be returned to their tapped holes. Do not

remove the center screw from the bottom cradle.

breaker from the shipping position. When the bre

is part way between DISCONNE

tions as described above the breaker levering device

interlock will hold the shutter down and the trip plate

depressed. The hex shaft of the levering device will

be exposed and ready to receive the levering crank

handle (see Figure 3). Insert the crank and turn in a

counter-clockwise direction and observe the action of

DISCONNECT and

aker

CT and TEST posi-

EATON CORPORATION www.eaton.com

7

Instruction Booklet IB 33-790-1J

Effective November 2010

the drawout position indicator. The indicator will move

down to the REMOVE position at which time the load

on the crank handle increases because a stop has

been reached.

Fig. 3 Levering Device Crank Handle Installed. Read

Section 2.2 on this Operation.

Note: Do not apply force on the crank handle after

the stop has been reached as the breaker is now free.

3. When the position indicator shows the levering

device to be in the REMOVE position, remove the

hand crank. Pull the breaker out onto the extended

rails. This will require more effort than normal as the

rear wheels are jammed into the cradle hold-down

hooks by two lengths of plastic tubing. Refer to illustrations in the stationary structure Instruction Book

32-690 covering shipping braces.

4. Remove the two (2) .25-20 panhead screws holding

the two shipping angles to the front panel of the

breaker. Care must be exercised to prevent marring

front panel. Two or more flat washers are used

the

between the angle and front panel for shipping. Discard the angles.

5. Immediately replace the two panhead screws discarding all washers.

Instructions for Low Voltage Power

Circuit Breakers Types DS and DSL

Fig. 4 Use of Breaker Lifting Adapter.

6. With the breaker pulled completely to the end of the

rails, remove the two (2) six inch long pieces of split

plastic tubing that are on the rear of the stationary

rails immediately below the hold-down hooks. This

tubing is for shipping p

carded.

7. The stationary secondary disconnecting contacts are

covered by a sheet of insulating material during shipment. This must be removed and discarded before

the breaker is moved to the TEST or CONNECTED

position.

8. Push the breaker back into its compartment, and

replace the two (2) panhead .25-20 screws at the

front edge of the cradle.

2.3 LIFTING THE BREAKER

When it is necessary to lift the breaker off the rails, all lifting should be done only with the

adapter. DO NOT ATTEMPT TO LIFT BREAKER WITH

ORDINARY CRANE HOOKS, ROPES, CHAINS ETC.,

AS VITAL PARTS SUCH AS WIRING, BARRIERS AND

ARC CHUTE PARTS MIGHT BE DAMAGED. Figure 4

shows a view of the breaker with the lifting adapter in

place. The lifter consists essentially of two sheet steel

hooks specially shaped to hook under the top edges of

the large openings on each circuit breaker side sheet, or

in the specially provided lifting lugs on some break

and a spreader. Actual lifting may be with a crane, chain

block or with the optional lifting mechanism which can be

supplied for the switchgear. The breaker must be pulled

completely to the end of the rails.

urposes only and is to be dis-

accessory lifting

ers,

8

EATON CORPORATION www.eaton.com

Instructions for Low Voltage Power

Circuit Breakers Types DS and DSL

Section 3 - Preliminary Examination of Circuit Breaker

Instruction Booklet IB 33-790-1J

Effective November 2010

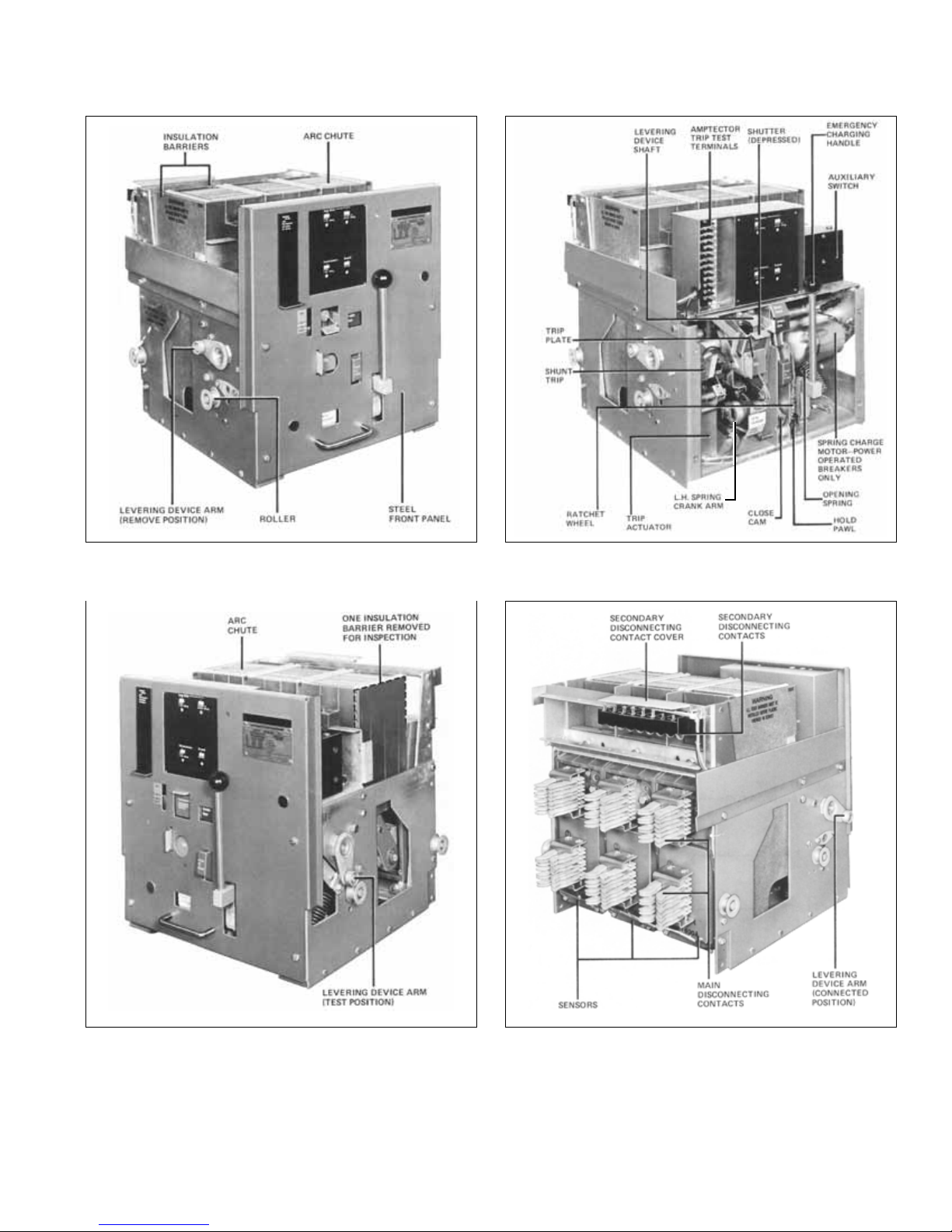

3.0 GENERAL

Read these instructions carefully and look at the breaker

as it stands out of the compartment before trying to operate it. Refer to Figures 5a, 5b, 6, 7 and 8.

The complete drawout element includes the circuit

breaker itself and its auxiliaries. The circuit breaker consists of four major components:

1. The operating mechanism.

2. The contacts, operated by the mechanism.

3. The arc chutes, which interrupt the arc which always

from opening the breaker under load or short

results

circuit conditions.

4a.

The Amptector

tem.

4b.

Digitrip

Fig. 5b).

®

®

solid-state overcurrent tripping sys-

RMS overcurrent tripping system (see

The remainder of the drawout element includes the following auxiliary components:

1. Interphase insulating barriers which isolate the arc

chutes from each other and from ground.

2. Drawout element frame and rollers.

3. The levering device, for placing the element into its

various positions inside the compartment.

4. The main disconnecting

breaker to power source and load.

5. The secondary contacts, for connecting the control

circuits to the electrical operating parts of the element.

6. The interlocks, which increase the safety of operation.

7. Drawout element position indicator.

contacts, for connecting the

Fig. 5a View Showing Controls on the Panel (Pre 1988).

EATON CORPORATION www.eaton.com

9

Instruction Booklet IB 33-790-1J

Effective November 2010

DIGITRIP RMS TRIP UNIT

SHUTTER

DRAWOUT UNIT

POSITION INDICATOR

Instructions for Low Voltage Power

Circuit Breakers Types DS and DSL

NAMEPLATE

EMERGENCY

CHARGING

HANDLE

OPEN-CLOSE

INDICATOR

PADLOCK PLATE

TRIP PLATE

SPRING CHARGE

INDICATOR

Fig. 5b View Showing Controls on the Panel (Post 1988).

CLOSE BAR

10

EATON CORPORATION www.eaton.com

Instructions for Low Voltage Power

Circuit Breakers Types DS and DSL

Instruction Booklet IB 33-790-1J

Effective November 2010

Fig. 6a Left Side of Breaker with Levering Device Arm in

REMOVE Position.

Fig. 6b DS 416 Breaker with Front Panel Removed.

Fig. 7 Right Side Showing Levering Device Arm in TEST

Position.

Fig. 8 Rear View Showing Levering Device Arm in

CONNECT Position.

EATON CORPORATION www.eaton.com

11

Instruction Booklet IB 33-790-1J

Effective November 2010

Instructions for Low Voltage Power

Circuit Breakers Types DS and DSL

8. Open-Close indicator.

9. Spring charge indicator.

10. The close bar and trip plate.

11. Steel front cover.

12. Nameplate with complete rating information.

The Type DSL-206 and DSL-416 drawout elements also

include the following components:

1. Current limiters.

2. Isolating transformers, connected in parallel with the

limiters.

3. Combination “Blown Limiter Indicator” and anti-single

phase device, connected to the isolating transformers, actuated by blowing of one or more of the current

ters. This device has individual phase indicators

limi

and a common “RESET” button extending through

the front cover.

Each breaker is equipped with a spring-type stored

energy closing mechanism. This mechanism closes the

circuit breaker contacts with the necessary speed and

force, independently of the operator. Basically, the closing springs must first be charged or cocked before the

breaker can be closed. The springs are then released by

releasing the

spring release latch. The breaker is opened

by releasing the tripping latch.

3.1 INDEPENDENT MANUAL AND POWER-

OPERATED BREAKERS

3.1.1 Closing Facilities

On manually operated breakers, the closing springs can

be charged only by hand, by means of the spring-charge

handle. The actual closing of the breaker is done only by

hand-push on the close bar. As optional equipment, the

electrical spring release attachment normally supplied

only on power-operated breakers can be supplied on

manually operated

breakers.

On power-operated breakers, the springs are normally

charged by an electric motor. Closing may be done electrically by an electro-magnet which lifts the closing spring

release latch. Both of these operations can be done by

hand if the control power source fails.

3.1.2 Tripping Facilities

The breaker can be tripped open by hand by pushing with

the finger on the trip plate on the breaker panel or the trip

plate on the breaker compartment door (the latter is oper

ative only when the breaker is in the connected position).

The breaker can also be tripped electrically by the following devices:

1. Shunt trip device, optional equipment on manually

operated breakers.

2. Trip Actuator, energized from the Amptector trip unit.

3. Undervoltage Trip Device (Optional on all breakers).

4. Blown Limiter Indicator (for DSL breakers).

3.2 LEVERING DEVICE

The drawout element has four normal positions in its

compartment, determined by the leve

ring device:

1. The REMOVE position, Figure 6.

2. The DISCONNECT position.

3. The TEST position, Figure 7.

4. The CONNECT position, Figure 8.

The REMOVE position is the first position in the compartment as the element is pushed directly by hand as far as

it will go. The DISCONNECT, TEST, and the CONNECT

positions are reached only by means of the levering

device. This is hand operated with a removable crank

handle. This handle is placed on the levering device

worm shaft, wh

ich is exposed by depressing the shutter.

-

12

EATON CORPORATION www.eaton.com

Instructions for Low Voltage Power

Circuit Breakers Types DS and DSL

Section 4 - Basic Operating Instructions

Instruction Booklet IB 33-790-1J

Effective November 2010

4.0 GENERAL

The breaker is now ready for trial mechanical operation.

Keep the breaker standing on the compartment rails, out

in front of the compartment. Examine it externally for any

signs of obvious damage or foreign material. When

everything appears to be in order, perform the following

operations as “dry run” practice. If any malfunctioning is

found during these operations, see that it is corrected

before further operations or before pl

service.

acing the breaker in

TION. Watch the movement of the levering device arms.

At the start of cranking the arms are horizontal, with rollers toward the rear, Figure 6. As the crank is turned

kwise the levering device arms rotate downward.

cloc

When they have moved approximately 40° from the horizontal, the shutter will rise until it touches the crank

socket. The position indicator will be opposite “DISC”

which is the DISCONNECT position wherein the breaker

is held in its compartment with both main and secondary

contacts disengaged. If the crank is withdrawn, the shutter will close completely, and the breaker may be locked

in this position as later described

instruction book. There is very little movement of the

breaker into its compartment between the REMOVE and

DISCONNECT positions.

Continued rotation of the crank in the clockwise direction

moves the arms downward to the vertical position, and

the indicator will show “TEST” as in Figure 7. The shutter

will rise.

Further clockwise rotation of the crank handle rotates the

arms to the CONNECT position. This is about 65

degrees from the test

When this position is reached, the crank suddenly

becomes hard to turn. At this point, stop turning the

crank, as the worm shaft bottoms in the tapped hole of

the stop nut.

position, as shown in Figure 8.

in Section 5.1.8.5 of this

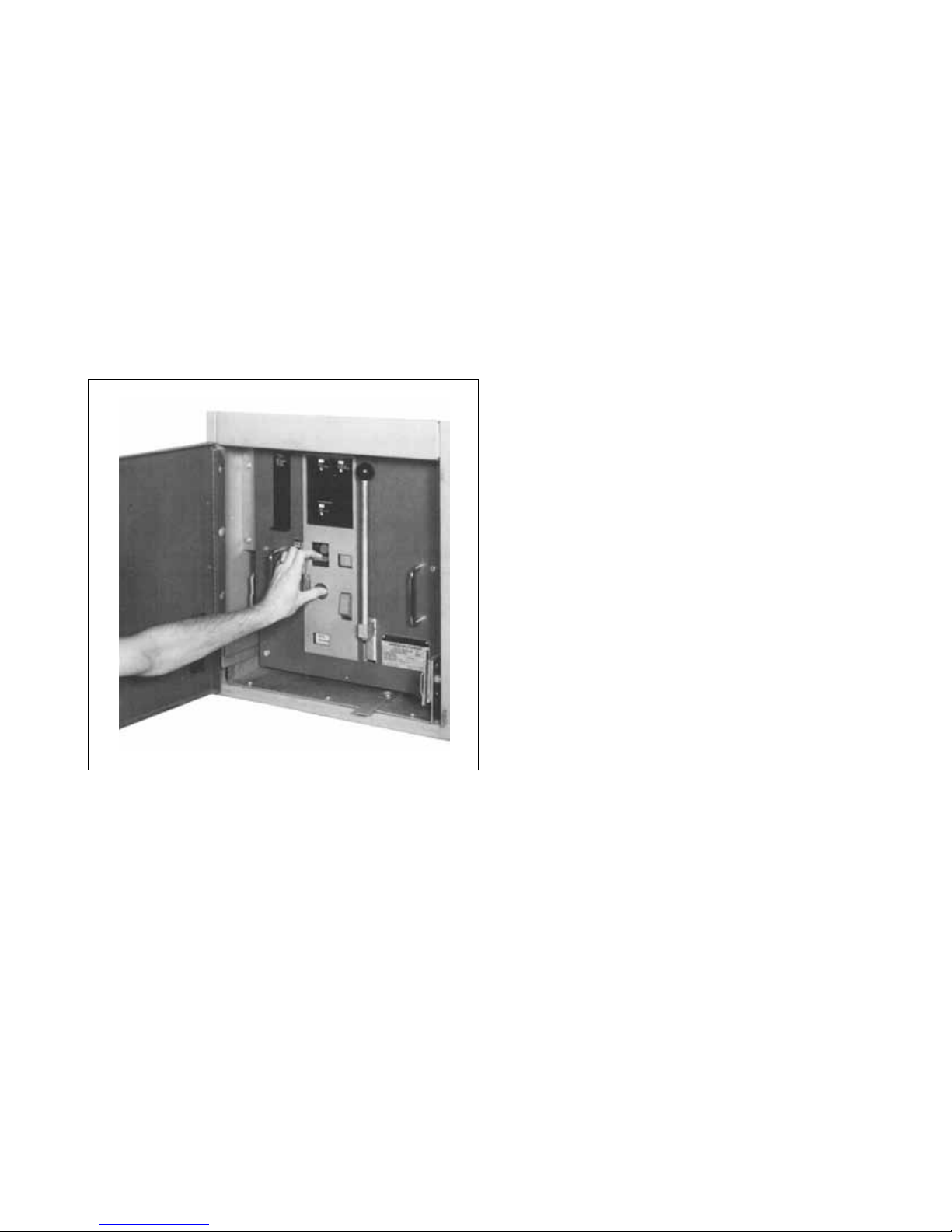

Fig. 9 Method Used to Press Trip Plate and Lower

Shutter with One Hand, Preparatory to

Inserting Crank.

4.1 LEVERING DEVICE

If the circuit breaker was shipped in a separate package,

the levering device was probably left in the REMOVE

position. If not it will be necessary to return it to this position. Push in the TRIP plate and depress the shutter over

the levering shaft, using one hand, as shown in Figure 9,

and insert the levering crank as sh

the crank counterclockwise until the position indicator is

in the REMOVE position, at which time the load on the

crank handle increases because a stop has been

reached. Now rotate the crank clockwise to simulate

levering the breaker inward toward the CONNECT POSI-

own in Figure 3. Turn

Note: Further turning effort is useless. The breaker

will be secure, even if the stop is only lightly

touched. Remember this when actually levering the

breaker into the connect position.

Rotation of the crank counterclockwise will turn the levering device arms to withdraw the unit from the

position to the TEST position and then to the DISCONNECT and REMOVE positions. Then, when the crank is

removed from the worm shaft, the shutter will remain

down and the trip plate will remain trapped by the shutter.

Note: If the breaker is levered out from the TEST

position to the REMOVE position with the closing

springs charged, a trip-free “closing” operation automatically will be performed but the breaker contacts

will not close. When a power-operated breaker is

emoved from cell, it must go through a trip-free

r

operation.

4.2 CHARGE THE CLOSING SPRINGS

The closing springs must be charged before the breaker

can be closed. To manually charge the closing springs,

CONNECT

EATON CORPORATION www.eaton.com

13

Instruction Booklet IB 33-790-1J

Effective November 2010

Instructions for Low Voltage Power

Circuit Breakers Types DS and DSL

the levering device arms must be rotated away from the

REMOVE position to the TEST position. If charging is

attempted in the REMOVE position, the closing cam will

rotate past the charged position and go through a

trip-free “closing” operation, i.e., the springs will discharge without moving the breaker contacts. Do not

attempt to charge the springs in the DISCONNECT position as the same action may occur. After turning the

levering device to TEST position, manually charge th

springs. On manually operated breakers, the springs are

charged by a single stroke downward on the

spring-charge handle, rotating it about 90° toward you

until it suddenly becomes very easy to move and then

tends to run away from your hand. At the same time, you

will hear a metallic “click!” as the over center closing

spring stop is reached. Note that the spring charge indicator now shows “Spring Charged.”

e

CAUTION

DO NOT RELEASE THE HANDLE BEFORE THE

HARGING OPERATION IS COMPLETED. TO

C

RELEASE HANDLE BEFORE CHARGING COMPLETION WILL RETURN HANDLE UPWARDS WITH SUCH

VELOCITY THAT IT MAY BREAK THE HANDLE KNOB

OR CAUSE BODILY INJURY.

CAUTION

HOLD BREAKER TO PREVENT TILTING FORWARD

WHEN HAND CHARGING CLOSING SPRINGS WITH

THE BREAKER ON THE EXTENDED RAILS. OTHERWISE, IT MAY TOPPLE TO THE FLOOR AND CAUSE

BODILY INJURY OR EQUIPMENT DAMAGE.

On power operated breakers, a short spring-charge handle is included for emergency operation. This works on a

ratchet

tions to completely charge the springs. At this point, the

same metallic “click” will be heard; and the spring charge

indicator will show “Spring Charged.” The handle must

not be forced beyond this point.

Note: Power-operated breakers, when being levered

into the compartment, will have the spring-charge

motor run and charge the spring automatically as the

TEST position is reached.

4.3 CLOSE THE BREAKER

The breaker can be closed only w

tions are met:

principle, and requires 10 to 12 pumping opera-

hen the following condi-

1. The closing springs are charged.

2. The levering arms are in either the TEST position, as

in Figure 7 or in the CONNECT position, Figure 8.

3. The levering device crank handle has been removed

and the shutter is closed.

4. Undervoltage trip device (if included) has been energized.

5. Blown limiter indicator (for DSL breakers only) is

reset.

Having met these conditions, close the breaker by pushing on the close ba

cator shows “Breaker Closed”, against a red background.

Also that the spring-charge indicator now shows “Spring

Discharged.”

Some power-operated breakers are interlocked to prevent manual closing from the close bar on the front panel

when in the CONNECT position. In this case crank the

levering device to the TEST position to operate. This

interlock is covered by Section 5.1.8.2.

It is possible to recharge the springs immed

closing the breaker. This results in increased strain on

the mechanism, and it is recommended that this be done

only if the operating procedure requires this condition.

Note: If closing is attempted with the levering arms in

other than the TEST or CONNECT positions, with or

without the levering crank in place, a trip-free “closing” operation is performed but the breaker contacts

do not close. This trip free type of operation results

in more shock on some

normal closing operations. Therefore, this type of

operation should be avoided if possible.

4.4 OPEN THE BREAKER

The breaker can be opened in the following ways:

1. By hand operation of the trip plate (on the breaker or

on the compartment door.)

2. Automatically by overload, short circuit or undervoltage condition.

3. Breakers equipped for power operation can be

tripped electrically by a shunt trip device energized

by hand switch

For the present purpose of getting acquainted with the

breaker, open it by pushing on the trip plate. Note that the

breaker position indicator now shows “Breaker-open”,

against a green background.

r. Note that the breaker position indi-

iately after

parts of the mechanism than

or relay.

14

EATON CORPORATION www.eaton.com

Instructions for Low Voltage Power

Circuit Breakers Types DS and DSL

Instruction Booklet IB 33-790-1J

Effective November 2010

Note: On breakers equipped for power operation,

when they are in the compartment and in either the

TEST or CONNECT position, the spring-charge motor

normally runs automatically and charges the closing

springs as soon as the breaker opens. The closing

springs normally remain discharged while the

breaker stands in the closed position. Also see Section 5.1.2.1.

Now to become better acquainted with the breaker,

charge the closing springs, close and open the breaker

several times. Also, place

the levering crank handle on

the levering device work shaft and rotate the levering

arms to their various positions by turning the levering

crank handle. Leave the levering arms horizontal, with

rollers toward rear of breaker, i.e. in the remove position.

The breaker is now ready to be put into its various operating positions in the compartment.

4.5 PLACE THE BREAKER IN THE TEST POSITION

Push the breaker into the REMOVE position.

YOU WILL NOTE THAT, WITH THE COMPA

RTMENT

DOOR OPEN, THE FRONT PANEL ASSEMBLY OF

THE BREAKER FORMS A STEEL PROTECTIVE

SHIELD.

Place crank on the levering device worm shaft. Turn

crank clockwise until drawout unit position indicator

shows “TEST.” Remove the levering device crank. The

shutter will close over the hex shaft. All manual operations can now be performed. On power operated breakers the spring is charged automatically as the breaker

arrives in the TEST position. The break

er can also be

opened with the shunt trip device, and it can be electrically closed with the spring release device.

4.6 PLACE THE BREAKER IN THE CONNECT

POSITION

Press the trip plate and lower the shutter. Place the crank

handle on the levering device worm shaft and turn the

crank clockwise until the CONNECT position stop is

reached, as indicated by sudden increase in load on the

crank, as previously described in paragraph 4.1.

Note however, that before the stop is

reached, an

increase in load on the crank will be felt after the breaker

has moved about an inch. This is caused by the making

up on the main disconnecting contacts. The load on the

crank will decrease after reaching a peak. The next

increase in load is when the stop is reached.

Note: Do not try to crank after the stop is reached.

Further tightening of the crank does not help keep

the breaker in position. When the crank handle is

removed, the shutter and

the trip plate should snap

into normal position.

4.7 REMOVE THE BREAKER FOR FINAL

INSPECTION

Withdraw the breaker from the CONNECT position in the

compartment to the end of the extended rails following

the reverse procedure described above. Inspect it thoroughly to see that no foreign objects have lodged within

it. If any defects were found during these preliminary

operations, complete their corrections at once.

4.8 FINAL INSPECTION

MAKE SURE THE THREE (3) ARC CHUTES ARE

OPERLY INSTALLED. MAKE SURE ALL FOUR (4)

PR

INSULATING BARRIERS ARE PROPERLY INSTALLED.

1. With the breaker withdrawn, rotate levering device to

connected position before attempting to charge the

spring.

2. Close and trip the breaker several times as previ-

ously described.

3. Return the levering device to the remove position;

i.e., with the roller arms pointing toward the rear as

shown in Figure 6.

4. This completes the “dry run.”

4.9 AMPTECTOR TRIP SETTINGS

When the break

er is shipped, the calibrating dials of the

Amptector trip unit are at the nominal settings. For specific overload tripping characteristics to coordinate with

the load or the system, refer to Section 8 and Curves

found later in this instruction book.

4.10 PLACE THE BREAKER IN SERVICE

Lever the breaker into the connected position as previously described, and latch the compartment door.

EATON CORPORATION www.eaton.com

15

Instruction Booklet IB 33-790-1J

Effective November 2010

Section 5 - Description and Explanation of Operation

5.0 GENERAL

The following paragraphs give a general description and

explanation of the operation of the breaker.

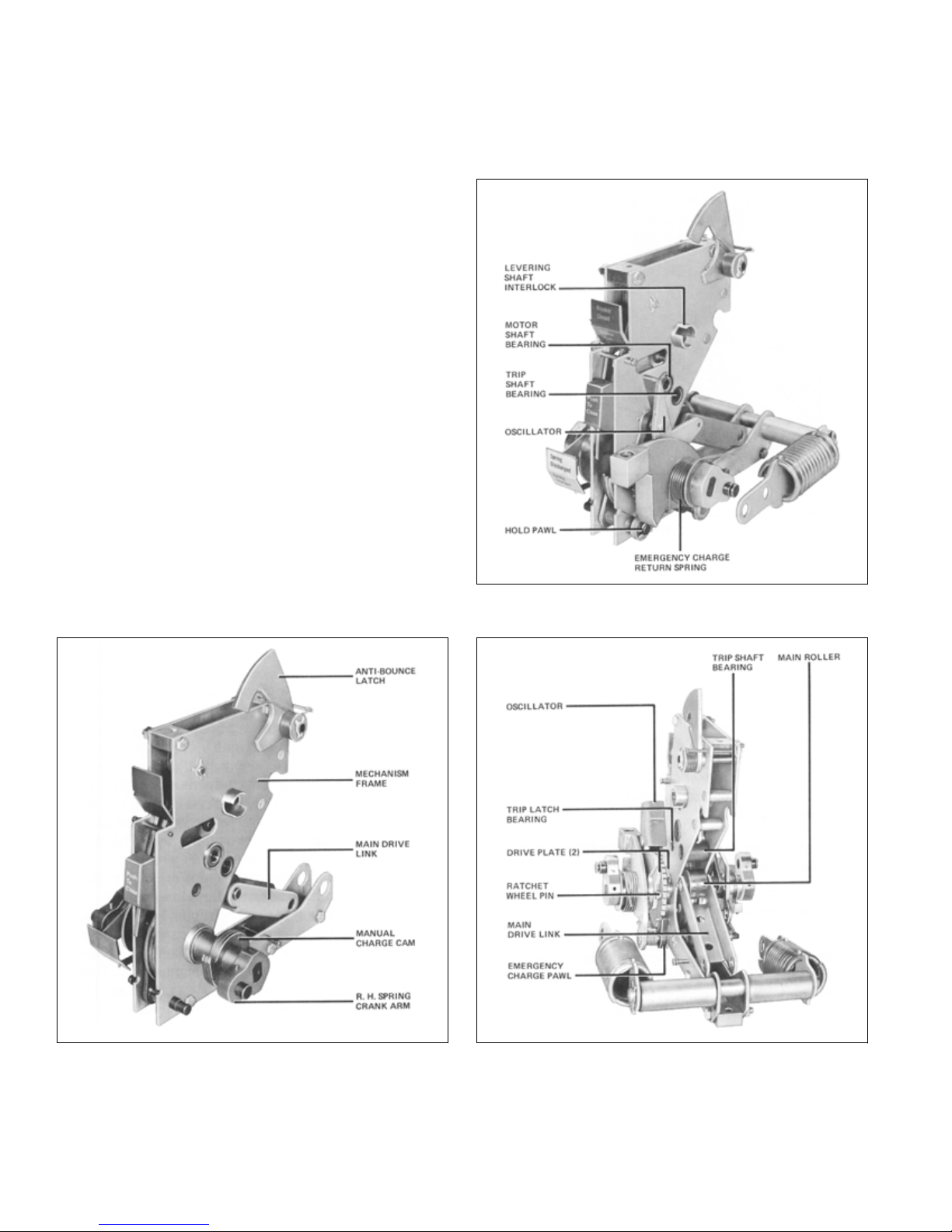

5.1 THE OPERATING MECHANISM AND HOW IT

WORKS

The operating mechanism is of the spring charged stored

energy type. This means that it consists of two major

parts:

(1) The stored energy or spring-charging mechanism.

(2) The mechanism for closing and opening the breaker.

The basic parts of these are combined into one

sub-assembly illus

There are two varieties of mechanisms for the complete

line of DS and DSL breakers:

trated in Figures 10, 11, 12, and 13.

Instructions for Low Voltage Power

Circuit Breakers Types DS and DSL

Power-Operated; and

Manually Operated.

Fig. 11 Front View of Mechanism (Power-Operated

Spring Charge).

Fig. 10 Front View of Mechanism (Manual Spring Charge

Except for DS-632/840).

16

EATON CORPORATION www.eaton.com

Fig. 12 Rear of Power-Operated Mechanism.

Instructions for Low Voltage Power

Circuit Breakers Types DS and DSL

Fig. 13 Rear View of Mechanism (Left Close Spring

Removed).

Instruction Booklet IB 33-790-1J

Effective November 2010

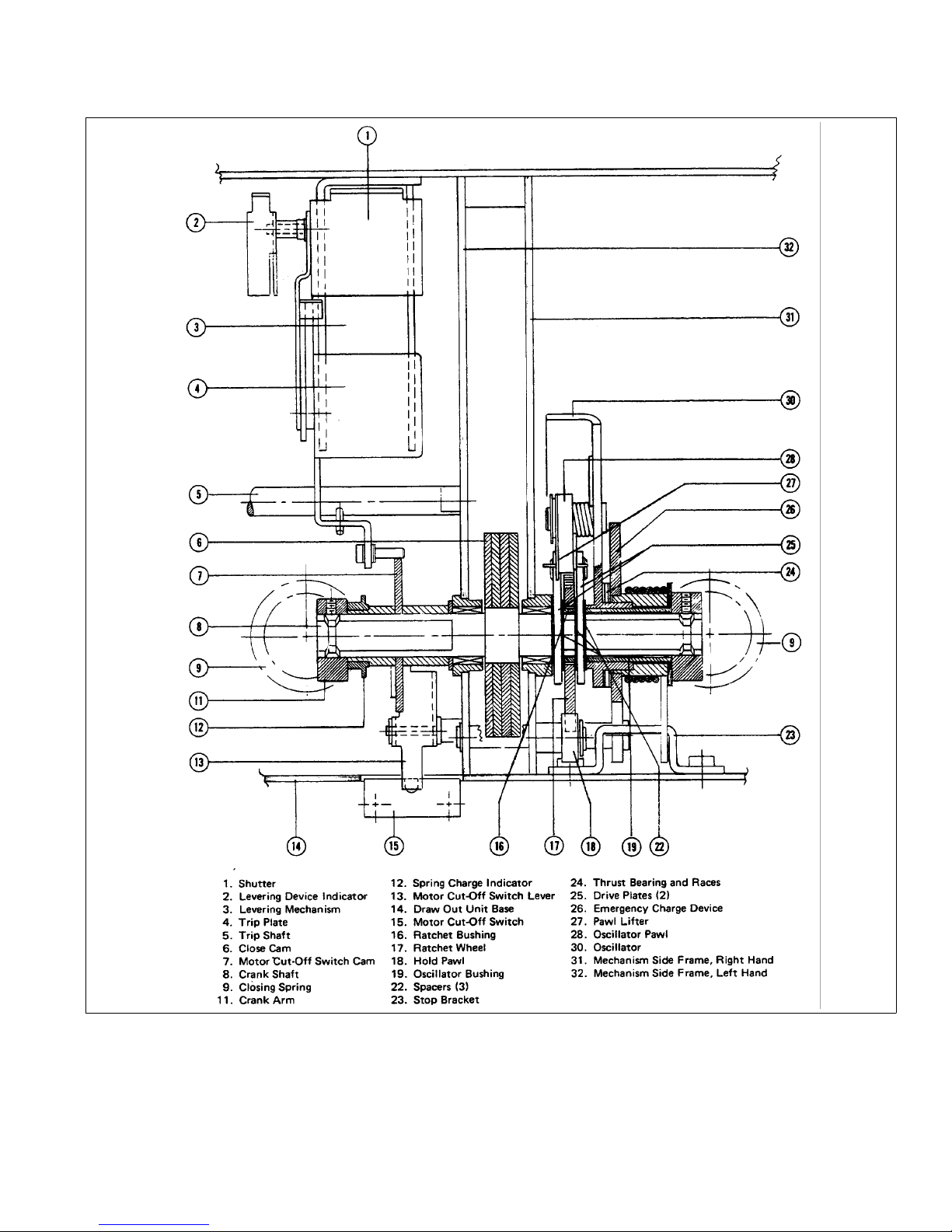

Referring to Figure 15, the basic elements are mounted

on the crank shaft (8). This is a straight shaft with four

flats machined on it, and a crank arm (11) attached