Eaton digtrip 510 with zone Interlock, Digitrip 510 basic, digtrip 610, digtrip 910, digtrip 810 Installation, Operation And Maintenance Manual

SAFETY PRECAUTIONS

www . ElectricalPartManuals . com

WARNING

POWER CIRCUIT BREAKERS ARE EQUIPPED

WITH HIGH SPEED, HIGH ENERGY OPERATING

MECHANISMS. THE BREAKERS AND THEIR

ENCLOSURES ARE DESIGNED WITH SEVERAL

BUILT-IN INTERLOCKS AND SAFETY FEATURES INTENDED TO PROVIDE SAFE AND

PROPER OPERATING SEQUENCES. TO PROVIDE MAXIMUM PROTECTION FOR PERSONNEL ASSOCIATED WITH THE INSTALLATION,

OPERATION, AND MAINTENANCE OF THESE

BREAKERS, THE FOLLOWING PRACTICES

MUST BE FOLLOWED. FAILURE TO FOLLOW

THESE PRACTICES MAY RESULT IN DEATH,

PERSONAL INJURY, OR PROPERTY DAMAGE.

• Only qualified persons, as defined in the National

Electric Code, who are familiar with the installation

and maintenance of power circuit breakers and their

associated switchgear assemblies should perf orm

any work associated with these breakers.

IL 33-K2C-3

Page 1

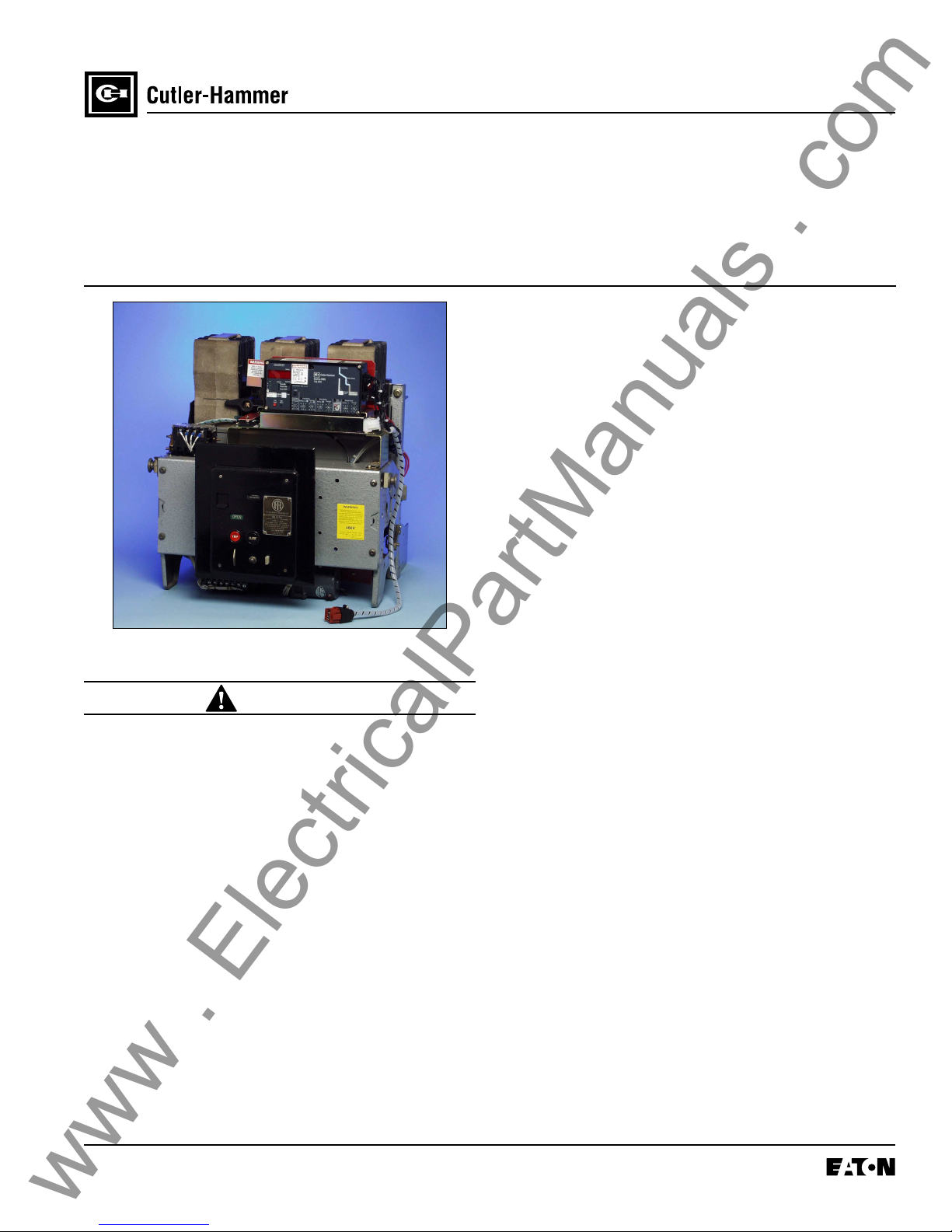

Digitrip Retrofit System for the

ITE K-Line Breakers: K-1600

(Black or Red), KDON-1600

(Black or Red), and K-2000 (Red)

• Completely read and understand all instructions

before attempting any installation, operation,

maintenance, or modification of these breakers.

• Always turn off and lock out the power source

feeding the breaker prior to attempting any

installation, maintenance, or modification of the

breaker. Do not use the circuit breaker as the

sole means for isolating a high voltage circuit.

Follow all lockout and tagging rules of the

National Electric Code and all other applicable

codes, regulations, and work rules.

• Do not work on a closed breaker or a breaker with

the closing springs charged. Trip (open) the breaker

and be sure the stored energy springs are

discharged before perf orming any work. The

breaker may trip open or the charging springs may

discharge, causing crushing or cutting injuries.

• For draw out breakers, trip (open), and then remove

the breaker to a well-lit work area before beginning

work.

• Do not perform any maintenance: including breaker

charging, closing, tripping, or any other function

which could cause significant movement of the

breaker while it is on the extension r ails. Doing so

may cause the breaker to slip from the rails and fall,

potentially causing severe personal injury to those

in the vicinity.

• Do not leave the breaker in an intermediate

position in the switchgear cell. Always leave it

in the connected, disconnected, or (optional)

test position. Failure to do so could lead to

improper positioning of the breaker and

flashover, causing death, serious personal

injury, and / or property damage.

• Do not defeat any safety interlock. Such

interlocks are intended to protect personnel and

equipment from damage due to flashover and

exposed contacts. Defeating an interlock could

lead to death, severe personal injury, and / or

property damage.

Effective 10/00

IL 33-K2C-3

www . ElectricalPartManuals . com

Digitrip Retrofit System for the

ITE K-Line Breakers: K-1600

(Black or Red), KDON-1600

(Black or Red), and K-2000 (Red)

CONTENTS

Page 2

Description

Introduction .......................................................... 4

Before Beginning the Retrofit Process

Identify the Breaker and the Retrofit Kit ................ 5

Following the Icons to a Successful Retrofit ......... 5

Step 1: General Breaker Preparation .............. 6

Step 2: Preparing the Breaker for

Retrofitting ............................................ 7

Step 3: Drilling the Breaker Angles ................. 8

Step 4: Preparing the DTA Assembly for

Installation ............................................ 9

Step 5: Installing the DTA Assembly in

the Breaker ......................................... 11

Step 6: Installing the Breaker Mounted

CPT on the DTA Mounting Angle ...... 13

Step 7: Final DTA and Reset

Installation and Adjustment .............. 17

Step 8: Installing the Copper Connectors .... 20

Step 9: Preparing the Trip Unit Assembly ....21

Step 10: Installing the Trip Unit on the

Breaker .............................................. 23

Step 11: Final Connection of the PT

and / or HV Wires ............................. 24

Step 12: Installing the Sensors ................ 27, 28

Step 13: Connecting the Sensor Harness

and the DTA Harness ....................... 29

Step 14: Connecting the External Harness

and Optional Components .............. 31

Step 15: Testing the Breaker .......................... 33

Step 16: Mounting the Cell Harness.............. 34

Step 17: Installing the Retrofitted Breaker in

the Cell .............................................. 34

Figures

1 Original Electromechanical Trip Units ............ 7

2. Removing the Glastic Moldings ..................... 7

3. Drilling Plan “A” – Front View ......................... 8

4. Optional Drilling Plan”A” ................................ 8

5. Drilling Plan “B” – Front View ......................... 9

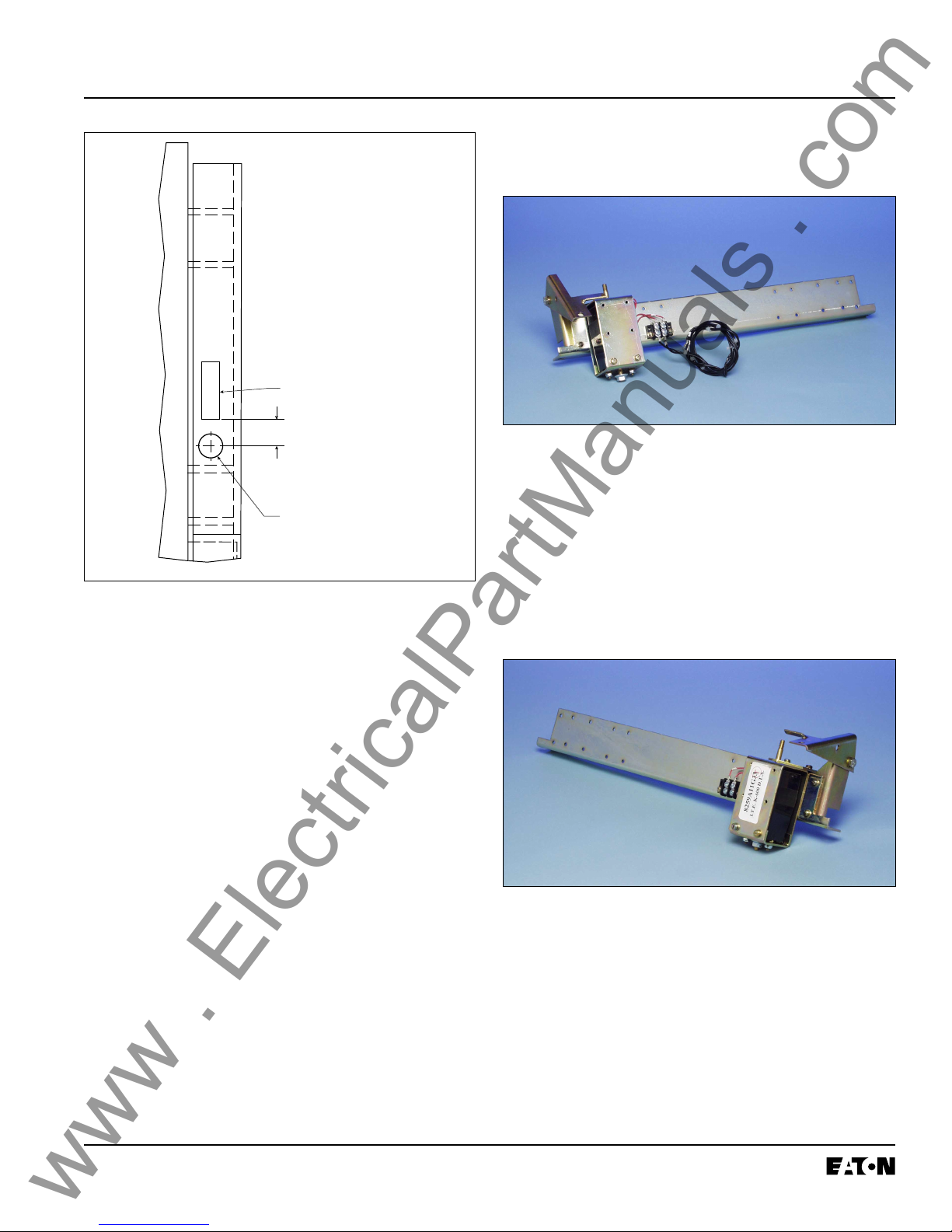

6. Overview – DTA Assembly ............................. 9

7. Optional DTA Mounting Location ................... 9

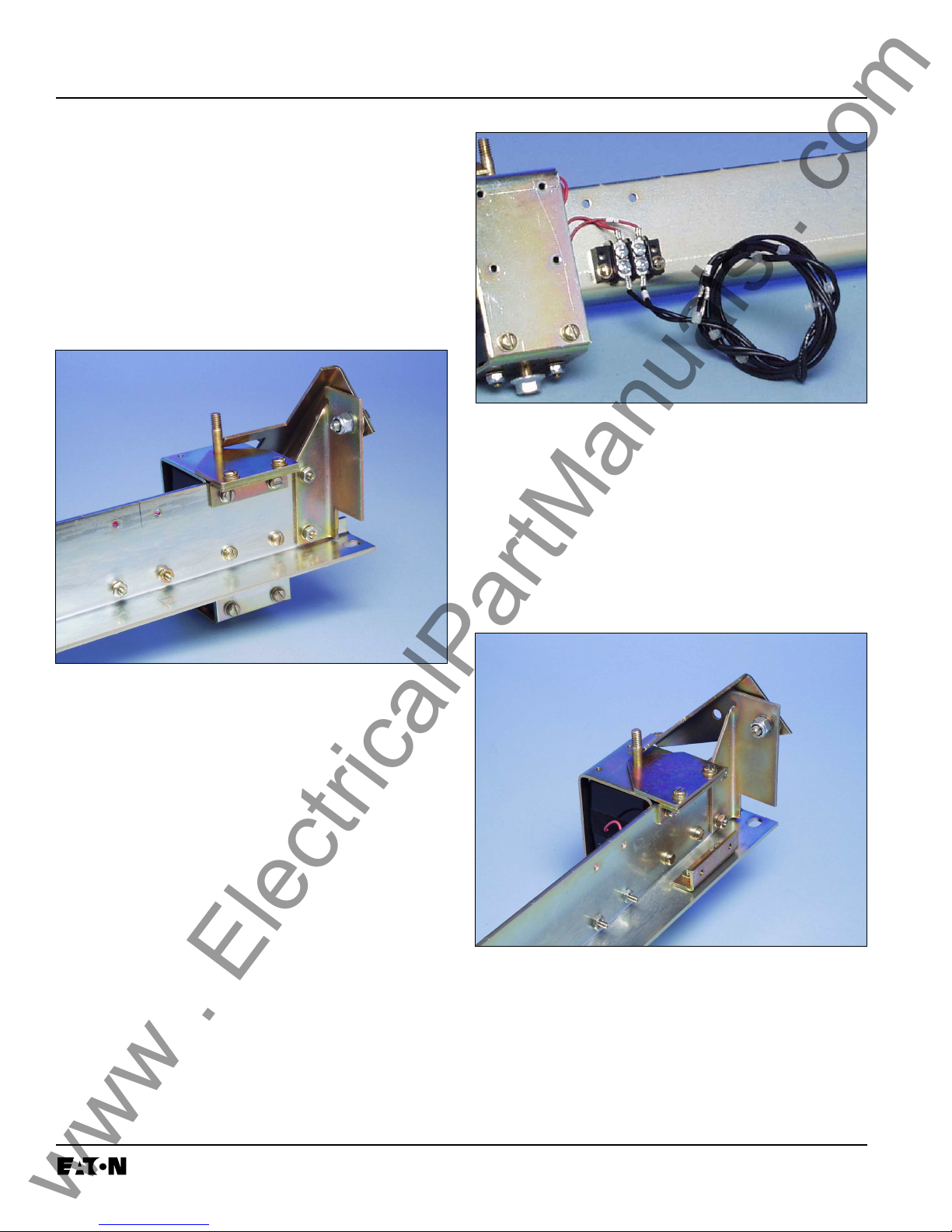

8. DTA Mounted to the DTA Mounting Angle... 10

9. Connections at the 2- Point Terminal

Block ............................................................ 10

10. Location of the DTA Insulation Plate

Mounting Bracket......................................... 10

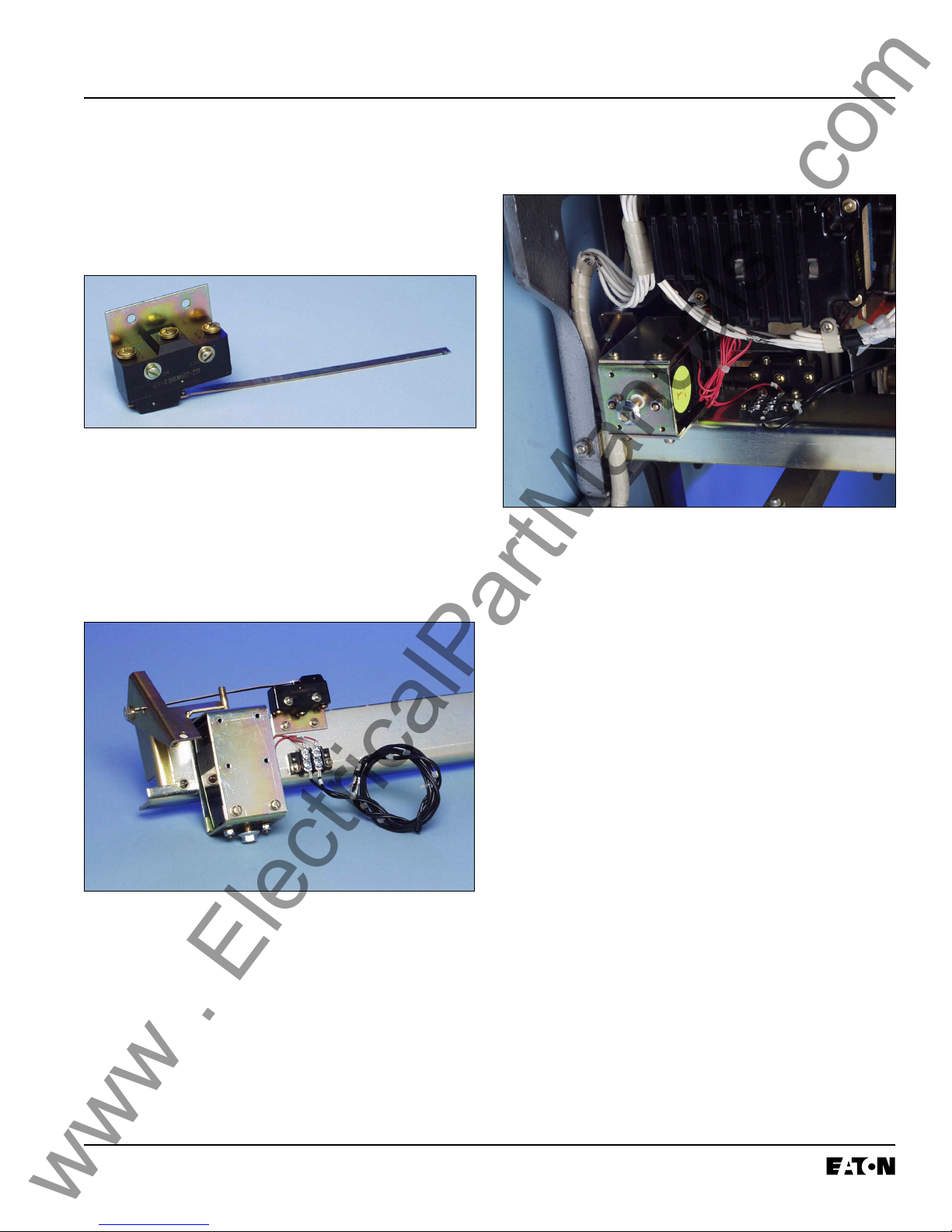

11. Auxiliary Switch Assembly ........................... 10

12. Correct Installation of the Auxiliary Switch

Assembly...................................................... 11

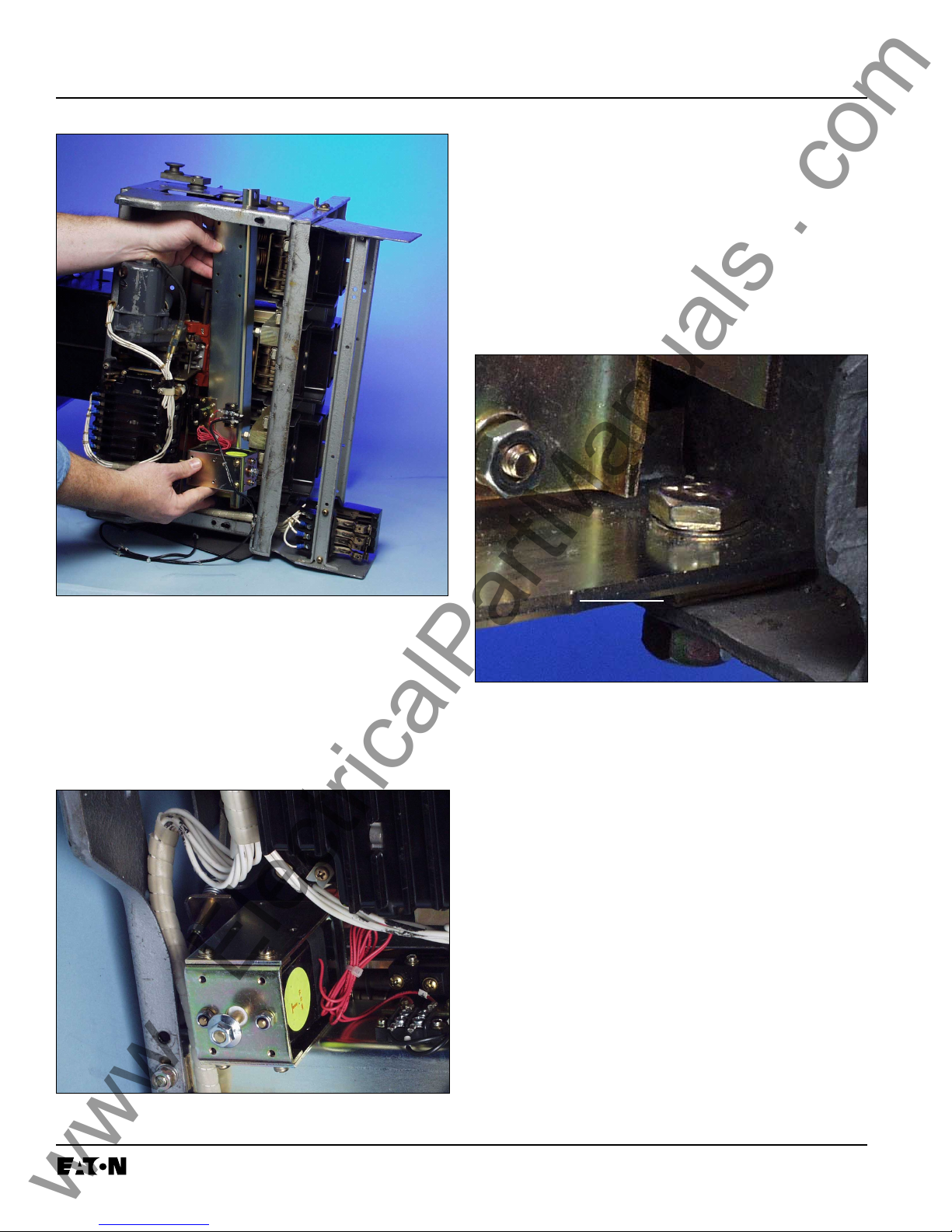

13. Overview – DTA Assembly installed in the

Breaker ......................................................... 11

14. Installing the DTA Assembly ........................ 12

15. Correct Wiring Harness Position .................. 12

16. Spacers Installed with the DTA Assembly ... 12

17. Routing of the DTA Extension Harness ........ 13

18. Overview – CPT Installed in the Breaker ..... 13

19. CPT Orientation and Screw Location .......... 14

20. Bracket Mounted to the CPT Insulation

Barrier........................................................... 14

Effective 10/00

21. Identification of the Line and Load Side

www . ElectricalPartManuals . com

HV Wires ...................................................... 14

22. Routing of the HV Wires ............................... 15

23. CPT Harness and HV Wires connected

to the CPT .................................................... 15

24. CPT Mounted to the DTA Assembly ...........16

25. CPT Mounting Screw Location .................... 16

26. Insulation Plate Mounted to the CPT ........... 16

27. Supplied CPT Voltage Labels ...................... 16

28. Overview – DTA and Reset Adjustment ....... 17

29. DTA Trip Plate Installed on the DTA Shaft.... 17

30. Setting the DTA Gap .................................... 18

31. Mounting the DTA Insulation Plate –

K-2000 Breakers Only .................................. 18

32. Connecting the Auxiliary Switch

Drive Link ..................................................... 18

33. Reset Rod Assembly.................................... 19

34. Correct Connection of the Reset Rod

Assembly and the Auxiliary Switch Drive

Link ............................................................... 19

35. Reset Rod Assembly Mounted in the

Breaker ......................................................... 19

36. Adjusting the Reset Rod Assembly ............. 20

37. Overview – Installation of the New

Copper Connectors ..................................... 20

38. Copper Connectors for the K-1600 / 2000

Breakers .......................................................20

38. Overview – Trip Unit Assembly .................... 21

39. Glass Poly Barrier Mounted to the Aux.

CT Module ................................................... 21

40. PT Module Mounted to the Glass Poly

Barrier........................................................... 22

41. Correct Installation of the Support Clips ..... 22

42. Overview – Trip Unit Assembly Installed

on the Breaker.............................................. 23

43. Installing the Trip Unit Assembly

Mounting Brackets ....................................... 23

44. Connecting the Aux. CT Harness ................ 24

45. Overview – Final Routing of the PT and

HV Wires ...................................................... 24

46. Correct Position of the Insulated Tubing ..... 25

IL 33-K2C-3

Page 3

47. PT Wires Connected to the

Breaker Stags .............................................. 25

48. Correct Position of the Insulated Tubing

and HV Fuses ............................................... 26

49. HV Wires Connected to the Top

Breaker Stabs .............................................. 26

50. Overview – Installed Top Mounted

Sensors ........................................................ 27

51. Securing the Sensor Assembly to the

Breaker ......................................................... 27

52. K-2000 Sensors Installed ............................. 27

53. Overview – Installed Bottom Mounted

Sensor .......................................................... 28

54. Drilling Plan “C” ............................................ 28

55. Securing the Sensor Mounting Platform ...... 29

56. Overview – Installing the Sensor and

DTA Harness ............................................... 29

57. Connecting the DTA Harness ....................... 30

58. Connecting the Sensor Harness ..................30

59. Routing of the Sensor Harness .................... 30

60. Sensor Harness Connected to the Top

Mounted Sensors ......................................... 31

61. Sensor Harness Connected to the

Bottom Mounted Sensors ............................ 31

62. 510 Basic Kit External Harness Plug ........... 31

63. Overview – Connecting the External

Harness ........................................................ 31

64. Securing the External Harness .................... 32

65. Connecting the Auxiliary Switch .................. 32

66. Location of the Wire Tie ............................... 32

67. Retrofit Components .................................... 40

Tables

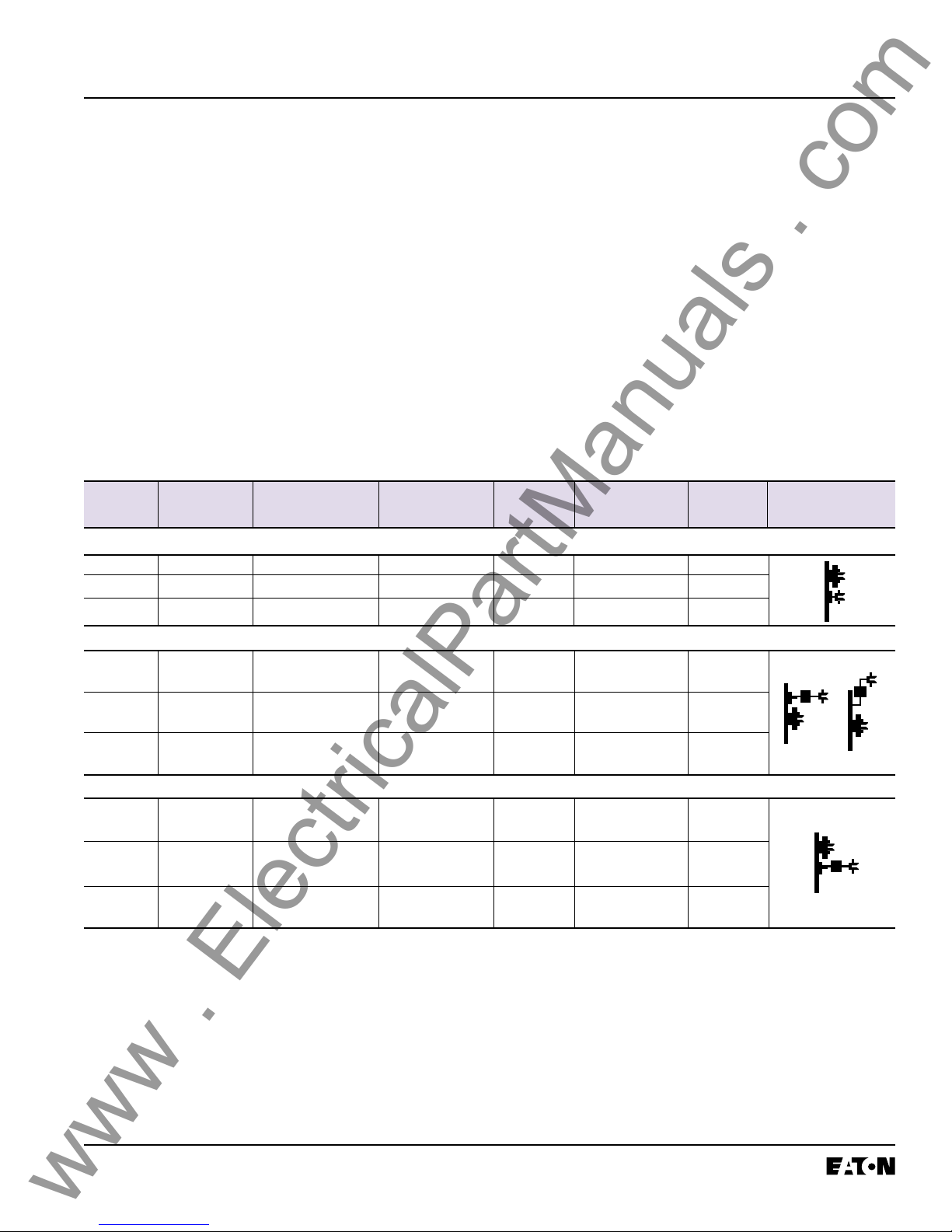

1. Available Retrofit Kits ..................................... 4

2. Identifying the K-Line Breaker ....................... 5

3. CPT Voltage Taps ......................................... 15

4. Sensor Taps Ratings .................................... 30

5. Torque Values for General Mounting and

Screw Size Conversion ................................ 39

6. Torque Values for Copper BUS

Connectors................................................... 39

Effective 10/00

Page 4

www . ElectricalPartManuals . com

IL 33-K2C-3

INTRODUCTION

Cutler-Hammer Digitrip Retrofit Kits are available in

a number of configurations that provide a wide

range of features. The Digitrip System starts with

the 510 Basic Kit which offers true RMS sensing,

overcurrent protection, and self-testing features.

Advanced Digitrip Retrofit Kits feature zone

interlocking, digital alphanumeric displays, remote

alarm signals, PowerNet communications, energy

monitoring capabilities, power factors, and

harmonic content measurements.

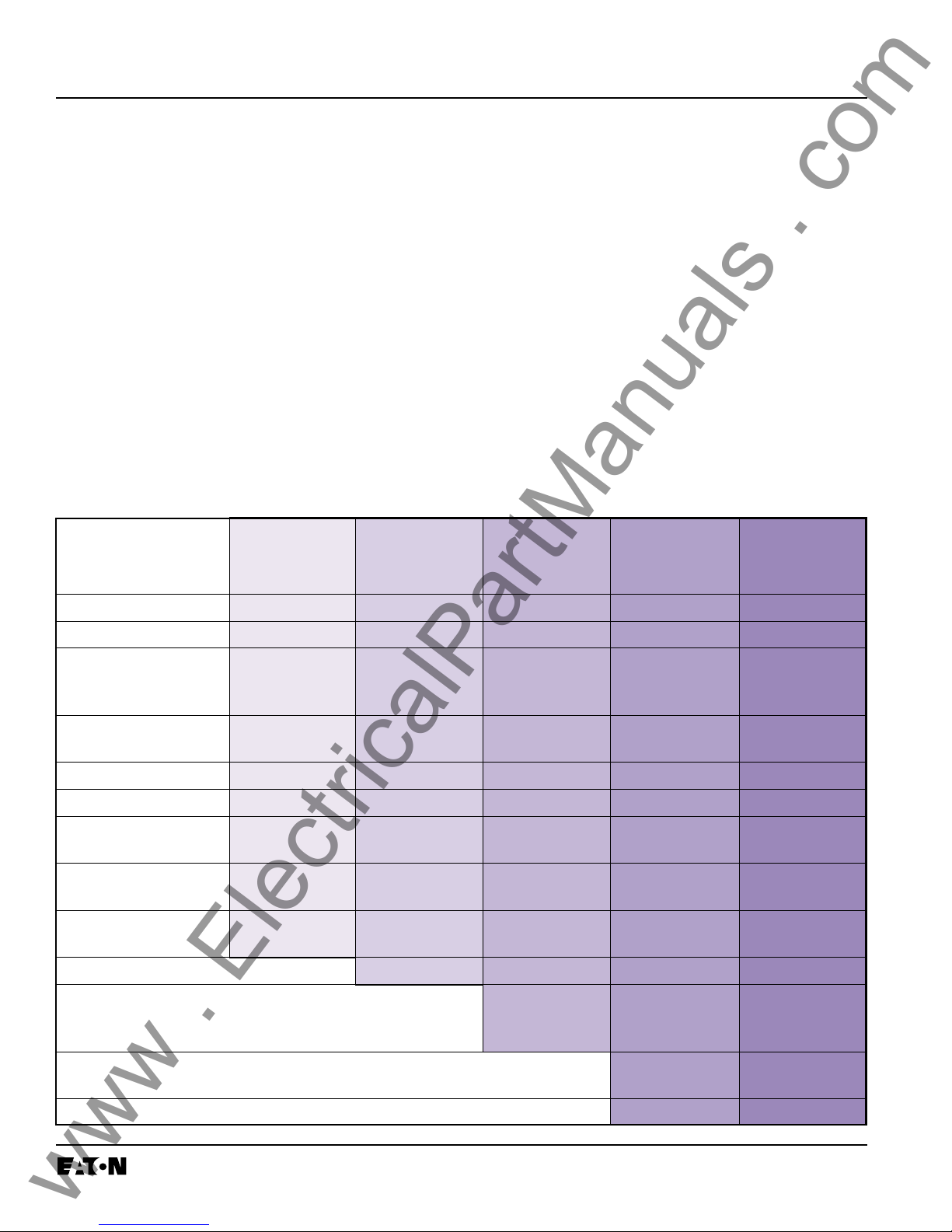

The following table provides a quick reference of

the components supplied with each level of Retrofit

Kit. Before beginning the Retrofit process, take a

minute to review the information contained in the

Table 1 Available Retrofit Kits

Components 510 Basic 510 with 610 810 910

Zone

Interlock

table. It is important that the Retrofitter

understands which level of Retrofit Kit is to be

installed and which components are included with

the Kit. The instructions contained in this manual

cover the installation of all levels of Retrofit Kit. If

the Kit you are installing does not contain a certain

component, skip the instructions for that

component and proceed to the next.

Throughout the Retrofit process, refer to the Torque

Tables at the back of this manual for specific

torque values.

If you have any questions concerning the Retrofit

Kit and / or the Retrofit process, contact

Cutler-Hammer at: 1-800-937-5487.

Trip Unit

Rating Plug

Auxiliary Current

Transformer

(CT) Module

Auxiliary

CT Harness

Sensors

Sensor Harness

Direct Trip

Actuator (DTA)

Mounting Brackets

and Hardware

External Plug 1 Connector 2 Connector 4 Connector 4 Connector

Harness Harness Harness Harness Harness

Cell Harness

Breaker Mounted

Control Power

Transformer (CPT)

Potential Transformer

(PT) Module

Auxiliary Switch

Effective 10/00

IL 33-K2C-3

www . ElectricalPartManuals . com

Page 5

Before Beginning the Retrofit Process

Identify the Breaker and the Retrofit Kit

Please refer to the following table and verify that

the first three (3) characters of the Retrofit Kit

Code Number correspond to the Breaker being

It is important to verify exactly which version of ITE

Retrofitted.

K-Line Breaker(s) is to be Retrofitted and to insure

that the correct Cutler-Hammer Retrofit Kit(s) was

Following the Icons to a Successful Retrofit

ordered. Each Breaker must be identified using all

of the following sources:

During certain parts of the Retrofit Process, procedures may differ depending on the version of the

1. Name Plate Information;

2. Back Plate Color;

3. Type of Finger Clusters

(Rectangular or Round); and

4. Fuse Use and Configuration

Breaker being Retrofitted. To enable the Retrofitter

to quickly identify the correct procedures for the

Breaker, Icon(s) will appear. Simply follow only the

instructions identified by the Icon for the Breaker

being Retrofitted.

(Horizontal or Vertical).

Table 2 Identifying the K-Line Breaker

Breaker Back Plate Desired Sensor Finger Cluster Fuse Fuse Retrofit ICON

Rating Color

Non-Fused

K-1600 Black Top Rectangular None N.A. K1C

K-1600 Red Top Rectangular None N.A. K2C

K-2000 Red Top Round None N.A. K2D

1

Location Type Location Configuration Kit Code

Top Mounted Horizontal and Vertical Fused

KDON- Black

1600 or Vertical

KDON- Red Bottom Rectangular To p Horizontal K4C

1600 or Vertical

KDON- Red Bottom Round Top Horizontal K7C

1600 or Vertical

Bottom Mounted Horizontal Fused

KDON- Black

1600

KDON- Red Top Rectangular Bottom Horizontal K2C

1600

KDON- Red Top Round Bottom Horizontal K5C

1600

NOTES: 1. Black or Red refers to the color of the Breaker Back Plate.

GENERAL NOTE: If the existing Breaker components mandate that the new DTA, supplied with the Retrofit Kit, be mounted inside the

2

2

2. If specified during ordering, special Trip Unit Brackets have been supplied for some older models of the

KDON-1600 Black Breaker equipped with trigger fuses. If the Brackets are needed but were not ordered,

contact Cutler-Hammer at: 1-800-937-5487.

Breaker on the right side instead of the left, as detailed in these instructions, contact Cutler-Hammer at: 1-800-937-5487

to obtain the special parts required. See Step 4 for details.

Bottom Rectangular Top Horizontal K6C

Top Rectangular Bottom Horizontal K1C

Effective 10/00

Page 6

www . ElectricalPartManuals . com

IL 33-K2C-3

STEP 1: GENERAL BREAKER PREPARATION

Before attempting to remove the Breaker from the

Cell or perform any Retrofit operation, be sure to

read and understand the Safety Precautions

section of this manual. In addition, be sure to read

and understand the Instructions for the Application

of Digitrip RMS Retrofit Kits on Power Circuit

Breakers (Retrofit Application Data – Publication

AD-33-855-2), supplied with the Digitrip Retrofit

Kit.

WARNING

DO NOT ATTEMPT TO INSTALL OR PERFORM

MAINTENANCE ON EQUIPMENT WHILE IT IS

ENERGIZED. SEVERE PERSONAL INJURY OR

DEATH CAN RESULT FROM CONTACT WITH

ENERGIZED EQUIPMENT. VERIFY THAT NO

VOLTAGE IS PRESENT BEFORE PROCEEDING.

A. Trip the Breaker and remove it from the Cell.

Move the Breaker to a clean, well-lit work

bench.

To begin the Retrofit Process, refer to the components list at the end of this manual. Lay out the

components and hardware according to the steps

outlined. The parts bags are labeled with the

corresponding step number. The components and

hardware will be used to complete each step in the

Retrofit Process.

NOTE: It is the responsibility of the Retrofitter to

insure that the Breaker and all original

components are in good condition. Visually inspect all Breaker components for

signs of damage or wear. If any signs of

damage or wear are detected for components not included in the Retrofit Kit,

secure the necessary replacement parts

before beginning the Retrofit Process.

The force necessary to trip the Breaker

should not exceed three (3) lbs.

NOTE: It is the responsibility of the Retrofitter to

insure that the proper, manufacturer’s

recommended crimping tools and terminals are used for each type of connector.

It is also the responsibility of the

Retrofitter to insure that all wire

preparations, connections, strippings,

terminations, and wiring techniques are

performed according to the latest IEEE,

NEC, and / or NEMA industry standards,

specifications, codes, and guidelines.

Effective 10/00

IL 33-K2C-3

www . ElectricalPartManuals . com

STEP 2: PREPARING THE BREAKER FOR

RETROFITTING

Page 7

Refer to the ITE K-Line Instruction Manual, originally supplied with the Breaker, to perform the

following procedures.

NOTE: For all photographs contained within this

manual, an ITE K-1600 Black Breaker

(without blown fuse indicators) was used

as the subject. Depending on the version

and age of the Breaker being Retrofitted,

some components / views may differ from

those depicted in the manual.

Note the orientation of the existing fuses.

Follow the ITE K-1600 / 2000 Instruction

Manual, originally supplied with the Breaker,

and remove the fuses, fuse mountings, and

associated hardware from the bottom Breaker

Stabs. Set all parts aside for reinstallation later

in the Retrofit Process.

C. Remove the four (4) screws securing each

bottom Glastic Molding to the Breaker.

D. Remove the four (4) screws securing each of

the three (3) copper pieces to the Breaker Pole

Assemblies.

E. Remove the Glastic Moldings, with the at-

tached Electromechanical Trip Units, from the

Breaker.

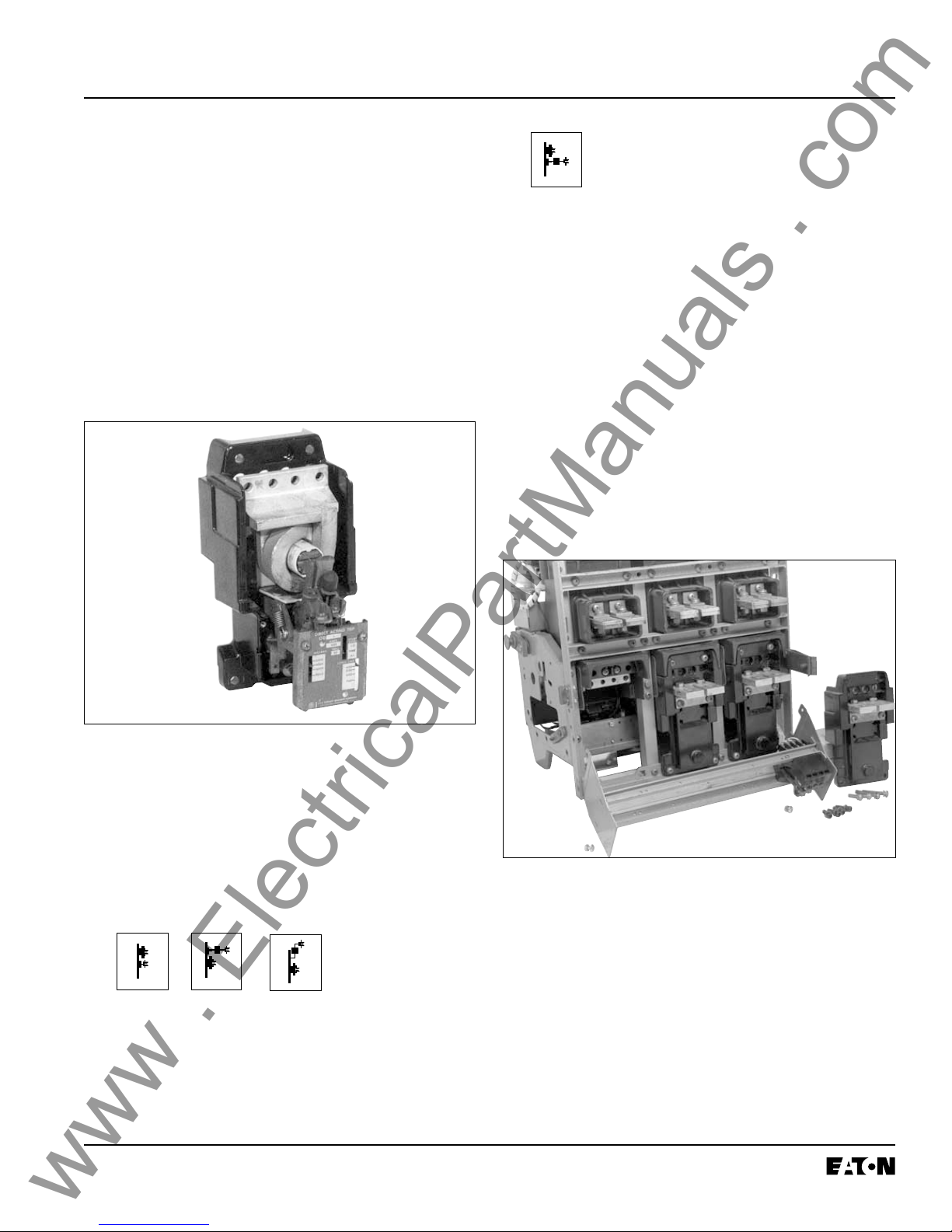

Fig. 1 Original Electromechanical Trip Unit

A. For Breakers equipped with a Secondary

Contact Bracket, move the back of the Breaker

near the edge of the work bench. Remove the

two (2) screws securing the top of the Secondary Contact Bracket. Loosen the two (2)

bottom screws then rotate the bracket down

over edge of work bench

B.

Remove the retaining clips then the pins securing the Finger Clusters to the Bottom Breaker

Stabs. Remove the Finger Clusters. Set all

parts aside for reinstallation later in the Retrofit

Process.

Effective 10/00

Fig. 2 Removing the Glastic Moldings

F. Working from the rear of the assembly, remove

the Electromechanical Trip Units by carefully

drilling out the four (4) .190" screws that secure

each Trip Unit to the Molding.

G. Remove the two (2) screws securing the Cop-

per Extensions then remove the Trip Unit from

each Molding.

Page 8

www . ElectricalPartManuals . com

IL 33-K2C-3

STEP 3: DRILLING THE BREAKER ANGLES

A. Working from the rear of the Breaker and using

a .500" drill bit, drill a hole in the left Breaker

Angle (See Drilling Plan “A”). This hole will be

used later in the Retrofit Process when installing the Sensor Harness.

FRONT

VIEW

EXISTING SLOT

NOTE: The hole should be drilled slightly below

the Breaker Cross Rail and be located so

as not to interfere with the Lifting Rack

when installed.

After Retrofitting, care should be taken

when installing the Lifting Rack so that

any new wires or harnesses that pass

through the rear Breaker Angles are not

damaged.

DRILL

.500"

HOLE

.50"

.500" DIA. (1) FOR

SENSOR HARNESS

(ALL KITS)

Fig. 3 Drilling Plan “A” - Front View

NOTE: On some versions of the K-1600 / 2000

Breakers, the hole for the Sensor Harness

can not be drilled where indicated in

Drilling Plan “A”. If this is the case with

the Breaker Being Retrofitted, follow the

instructions in Step 3-B.

B. For Use on Some Versions: Working from the

rear of the Breaker and using a .500" drill bit,

drill a hole in the left Breaker Angle, directly

below the top Breaker Cross Rail (See Fig. 4).

This hole will be used later in the Retrofit

Process when installing the Sensor Harness.

Fig. 4 Optional Drilling Plan “A”

For Kits Supplied with a PT Module and / or

Breaker Mounted CPT Only.

C. Working from the rear of the Breaker and using

a .500" drill bit, drill a hole in the right Breaker

Angle (See Drilling Plan “B”). This hole will be

used later in the Retrofit Process when installing the PT and / or HV Wires.

Effective 10/00

IL 33-K2C-3

www . ElectricalPartManuals . com

Page 9

STEP 4: PREPARING THE DTA ASSEMBLY

FOR INSTALLATION

FRONT

VIEW

EXISTING SLOT

.50"

.500" DIA. (1) FOR

HV AND / OR

PT WIRES

Fig. 5 Drilling Plan “B” - Front View

NOTE: On some versions of the K-1600 / 2000

Breakers, the hole for the PT and / or HV

Wires can not be drilled where indicated in

Drilling Plan “B”. If this is the case with

the Breaker Being Retrofitted, follow the

instructions in Step 3-D.

D. For Use on Some Versions: Working from the

rear of the Breaker and using a .500" drill bit,

drill a hole in the right Breaker Angle, directly

below the top Breaker Cross Rail (similar to the

hole for the Sensor Harness drilled in Step

3-B). This hole will be used later in the Retrofit

Process when connecting the PT and / or HV

Wires.

Fig. 6 Overview - DTA Assembly

NOTE: If an existing Breaker component does not

allow the DTA to be mounted on the right

side of the Breaker (when viewed from the

rear of the Breaker), a left hand DTA

mounting kit is available. For details and

to acquire the necessary parts, contact

Cutler-Hammer at: 1-800-937-5487.

Fig. 7 Optional DTA Mounting Location

A. Apply Loc-Tite

the DTA Bearing Plate to the DTA Bearing Plate

Mounting Bracket, as shown, using the (2)

.164-32 × .312" pan lock screws and (2) flat

washers supplied.

®

243 to the threads then mount

Effective 10/00

Page 10

www . ElectricalPartManuals . com

B. Apply Loc-Tite® 243 to the threads then mount

the DTA and the DTA Bearing Plate Assembly

to the DTA Mounting Angle, as shown, using

the (2) .164-32 × .312" pan lock screws, (2)

.164-32 × .500" pan screws, (2) lock washers,

and (4) flat washers supplied.

NOTE: Insure that the DTA Shaft moves freely

after mountng. If not, reposition the

mounting hardware.

IL 33-K2C-3

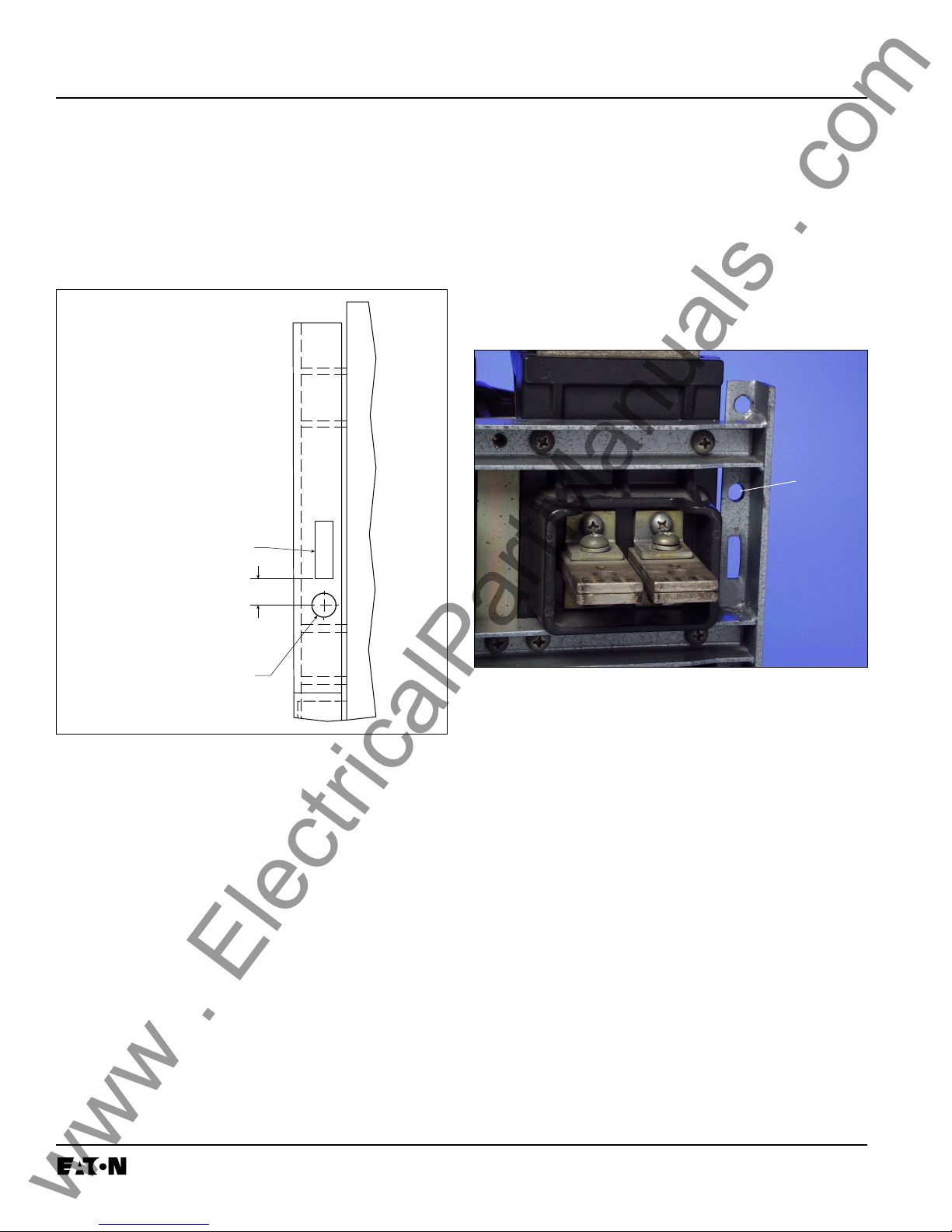

Fig. 9 Connections at the 2-Point Terminal Block

D. For K-2000 Breakers Only: Mount the DTA

Insulation Plate Mounting Bracket to the DTA

Assembly, as shown, using the (2) .164-32 ×

.625" screws, (4) flat washers, (2) lock washers,

and (2) nuts supplied. Note that the nonthreaded holes in the Mounting Bracket are

used to secure the Mounting Bracket to the

DTA Assembly.

Fig. 8 DTA Mounted to the DTA Mounting Angle

C. Connect the DTA Wires to the two (2) top

terminals of the 2-Point Terminal Block. Connect the DTA Extension Harness to the two (2)

bottom terminals of the 2-Point Terminal Block.

Connect the “+” wire to the same terminal as

the “+” wire from the DTA. Connect the

unmarked wire to the same terminal as the

unmarked wire from the DTA.

Fig.10 Location of the DTA Insulation Plate

Mounting Bracket

Effective 10/00

IL 33-K2C-3

www . ElectricalPartManuals . com

Page 11

E. For Kits Supplied with an Auxiliary Switch Only:

Cut .250" from the end of the Microswitch Arm.

Mount the Microswitch the to Auxiliary Switch

Mounting Bracket, as shown, using the (2)

.138-32 × 1.00" screws, (4) flat washers, (2)

lock washers, and (2) nuts supplied.

Fig. 11 Auxiliary Switch Assembly

F. Mount the Auxiliary Switch Assembly to the

DTA Assembly, as shown, using the (2) .138-32

× .375" screws, (4) flat washers, (2) lock washers, and (2) nuts supplied. Note that the

Microswitch Arm must extend through the hole

in the DTA Reset Arm.

STEP 5: INSTALLING THE DTA ASSEMBLY IN

THE BREAKER

Fig.13 Overview – DTA Assembly installed in the

Breaker

A. Carefully lay the Breaker on its left side.

Fig. 12 Correct Installation of the Auxiliary Switch

Assembly

B. Working from the bottom of the Breaker, drill a

.312" diameter hole in each of the bottom

Breaker Flanges 1.75" from the Breaker Back

Plate. Insure that no metal shavings fall into

the Breaker during the drilling process.

C. Insert the DTA Assembly into the Breaker and

align the holes in the DTA Mounting Angle with

the holes just drilled in Step 5-B. Note that it is

necessary for the DTA Assembly to slightly

protrude through the window in the right side

of the Breaker to achieve proper alignment.

Effective 10/00

Page 12

www . ElectricalPartManuals . com

IL 33-K2C-3

E. Return the Breaker to its upright position.

Verify that there is clearance between the

bottom of the DTA Shaft and the work bench.

If not, turn the Breaker back on its side, remove the mounting hardware securing the DTA

Assembly to the Breaker. Use one (1) or two

(2) of the supplied spacers on each side, as

required, to raise the DTA Assembly. Using the

hardware just removed, again temporarily

mount the DTA Assembly to the Breaker.

Fig. 14 Installing the DTA Assembly

D. Temporarily mount the DTA Assembly on the

inside of the bottom Breaker Flanges using the

(2) .250-20 × .750" bolts, (4) flat washers, (2)

lock washers, and (2) nuts supplied. Note that

the existing wiring harness must be below the

DTA Assembly.

SPACERS

Fig. 16 Spacers Installed with the DTA Assembly

Return the Breaker to its upright position and

verify that there is clearance between the

bottom of the DTA Shaft and the work bench.

If clearance exists, tighten the DTA Assembly

mounting hardware.

NOTE: If proper clearance can not be achieved

by using the spacers provided, or if proper

Trip and Reset functioning can not be

achieved with the spacers installed, the

DTA Shaft may be carefully cut to provide

the proper clearance.

For Kits Supplied with a Breaker Mounted CPT

Only: Do not tighten the DTA Assembly mount-

ing hardware at this time. This hardware will be

tightened after the Breaker Mounted CPT is

installed in Step 6.

Fig. 15 Correct Wiring Harness Position

Effective 10/00

IL 33-K2C-3

www . ElectricalPartManuals . com

Page 13

F. Route the DTA Extension Harness up through

the Breaker, then through the existing hole in

the Breaker Platform. Insure that the DTA

Extension Harness is clear of all moving parts

within the Breaker.

For Kits Supplied with a Breaker Mounted CPT

Only.

STEP 6: INSTALLING THE BREAKER

MOUNTED CPT ON THE DTA

MOUNTING ANGLE

Fig. 17 Routing of the DTA Extension Harness

Fig. 18 Overview – CPT Installed in the Breaker

NOTE: If a left-hand mounting kit was used to

install the DTA on the DTA Mounting Angle

in Step 4, the Breaker Mounted CPT can

not be installed on the DTA Assembly as

detailed in the following steps. The CPT

will have to be mounted either in another

location on the Breaker or in the Breaker

Cell. Alternative mounting of the CPT is

the sole responsibility of the Retrofitter.

NOTE: On some versions of the K-1600 / 2000

Breakers originally supplied with a Breaker

Interlock Mechanism, the Breaker

Mounted CPT can not be installed on the

DTA Assembly as detailed in the following

steps. The CPT will have to be mounted

either in another location on the Breaker

or in the Breaker Cell. Alternative mounting of the CPT is the sole responsibility of

the Retrofitter.

Effective 10/00

Page 14

www . ElectricalPartManuals . com

IL 33-K2C-3

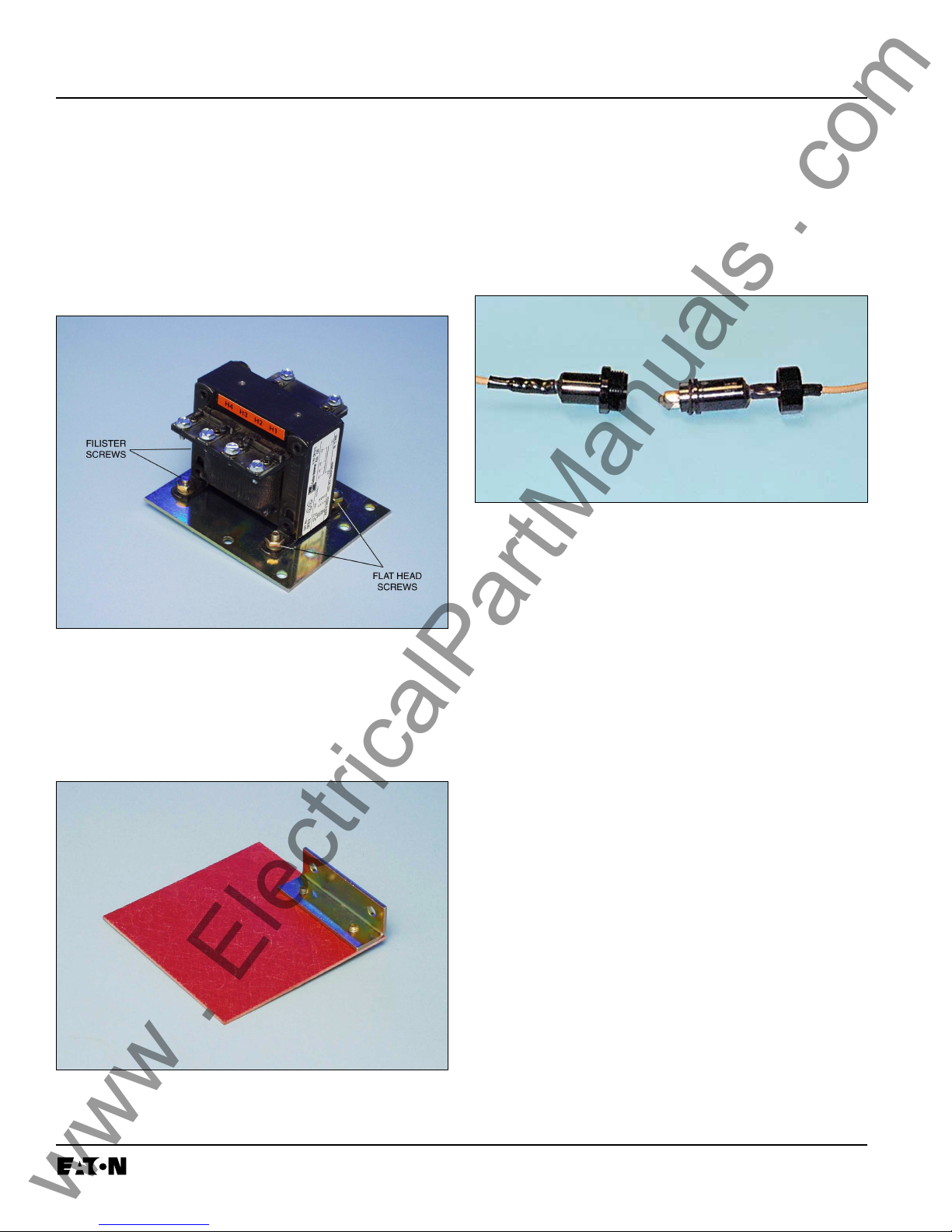

A. Mount the Breaker Mounted CPT to the

CPT Mounting Plate, as shown, using the

(2) .190-32 × .500" flat head screws, (2) .19032 × .500" filister head screws, (6) flat washers,

(4) lock washers, and (4) nuts supplied. Note

the orientation of the CPT to the holes in the

Mounting Plate. The CPT must be mounted in

this position.

Fig. 19 CPT Orientation and Screw Location

B. Attach the CPT Insulation Barrier to the CPT

Insulation Barrier Mounting Bracket, as shown,

using the (2) .164-32 × .312" pan lock screws

and (2) flat washers supplied.

NOTE: The High Voltage (HV) Wires have a LOAD

Side and a LINE Side. The HV Wires must

be installed in the correct orientation

during the following procedure. For the

purpose of identification, the words “Load

Side” are marked on the female fuse

receptacle of each HV Wire.

LINE SIDE

Fig. 21 Identification of the Line and Load Side

HV Wires

NOTE: The Load Side HV Wires are longer than

necessary and are cut during the following

steps. Before cutting the wires, insure

that sufficient length is left so that the

connections can be made to the correct

terminals on the CPT.

C. Route the Load Side HV Wires and the CPT

Harness through the existing hole in the

Breaker Platform, then down to the bottom

right corner of the Breaker. Note that the final

location of the HV Fuses will be along the right

side of the Breaker. Note also that the CPT

Harness will be connected to the new Trip Unit

later in the Retrofit Process. Insure that, when

cutting the HV Wires and CPT Harness in the

following steps, sufficient length is left for these

connections to be made.

LOAD SIDE

Fig. 20 Bracket Mounted to the CPT Insulation

Barrier

Effective 10/00

Loading...

Loading...