Eaton Digitrip RMS, Digitrip OPTIM Instruction Leaflet

Supersedes IL29C713D dated March 2007

Digitrip RMS and Digitrip OPTIM Trip Units Used with

R-Frame Circuit Breakers

TABLE OF CONTENTS PAGE

1.0 Supplementary Information................................... 2

2.0 Digitrip RMS and Digitrip OPTIM Trip Units .......... 2

3.0 Rating Plugs.......................................................... 3

3.0.1 Digitrip RMS Plugs for 510, 610, 810,910............. 3

3.0.2 Digitrip RMS Plug for 310 ..................................... 3

3.0.3 Digitrip RMS Plugs for OPTIM 750, 1050 ............. 3

3.0.4 Rating Plugs – Battery .......................................... 3

3.1 Installation and Removal of Trip Components ..... 4

3.2 Installation of Rating Plug ..................................... 4

3.3 Trip Unit Removal ................................................. 5

3.4 Trip Unit Replacement .......................................... 6

4.0 Digitrip RMS Model Considerations ...................... 6

4.1 Digitrip RMS 310 ................................................... 6

4.2 Digitrip RMS 510 ................................................... 7

4.3 Digitrip RMS 610 ................................................... 7

4.4 Digitrip RMS 810 ................................................... 8

4.5 Digitrip RMS 910 ................................................... 8

4.6 Digitrip OPTIM 750................................................ 8

4.7 Digitrip OPTIM 1050.............................................. 8

4.8 Reset Operation.................................................... 9

5.0 Principle of Operation............................................ 9

5.1 General ................................................................. 9

5.2 Digitrip RMS Trip Assembly ........................... 9

5.3 Flux Shunt Trip.................................................... 11

5.4 Ground Fault Protection ...................................... 12

5.4.1 General ............................................................... 12

5.4.2 Residual Sensing ................................................ 12

5.4.3 Source Ground Sensing...................................... 12

5.4.4 Ground Fault Settings ......................................... 12

5.5 Current Sensors.................................................. 12

5.6 Digitrip RMS Accessories.................................... 13

5.6.1 Power/Relay Module ........................................... 13

5.6.2 Potential Transformer Module............................. 13

5.6.3 Dielectric Testing ................................................ 13

5.7 Connection Diagram ........................................... 13

5.8 Trip Unit Settings Protection ............................... 13

6.0 Testing ................................................................ 14

6.1 Function Field Testing......................................... 14

6.2 Performance Testing for Ground Fault Trip Units 14

6.2.1 Code Requirements ............................................ 14

6.2.2 Standards Requirements .................................... 14

6.2.3 General Test Instructions.................................... 15

7.0 Record Keeping .................................................. 16

8.0 References.......................................................... 16

8.1 R-Frame ....................... ................................ 16

8.2 Digitrip RMS Trip Units........................................

8.3 Time Current Curves........................................... 18

8.4 Miscellaneous .................................................... 18

18

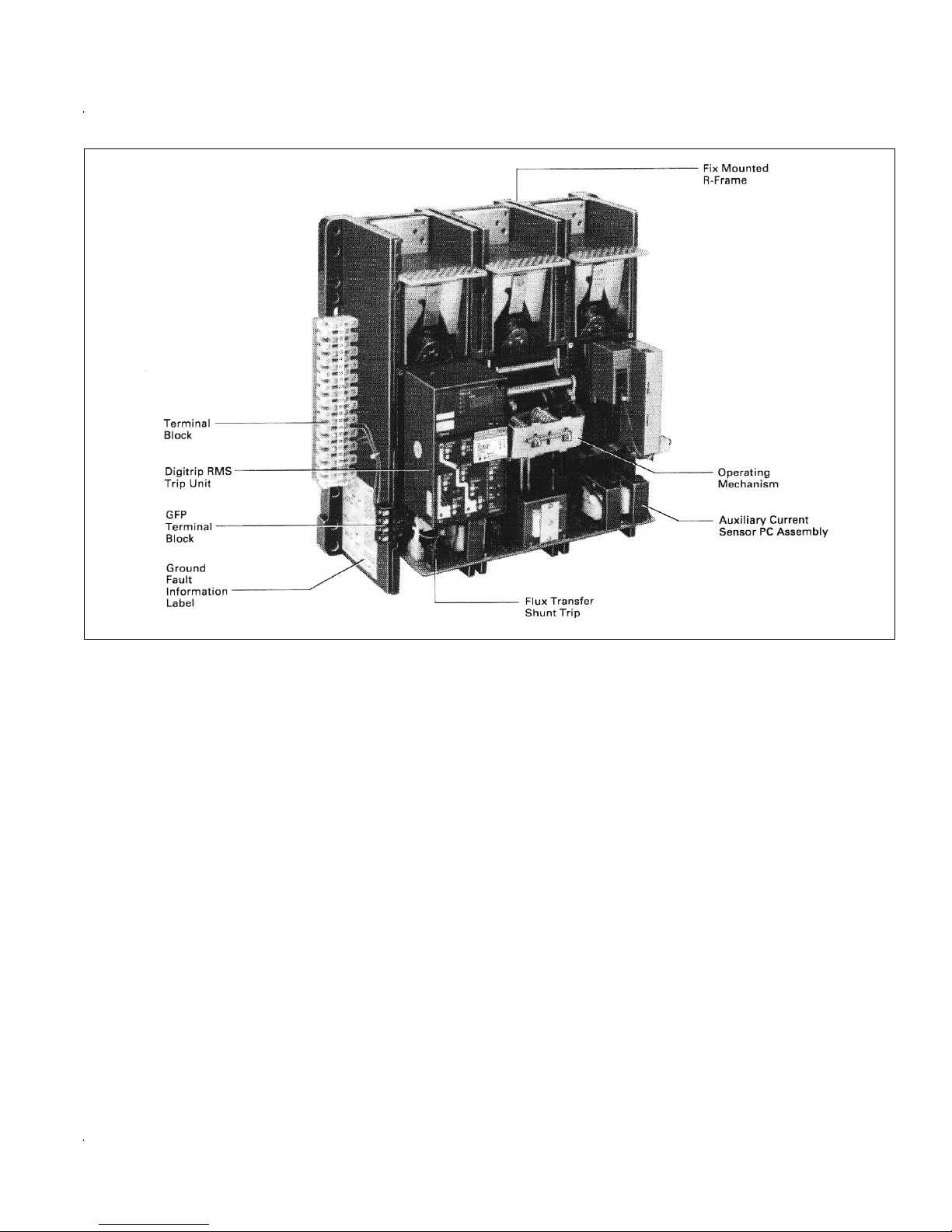

Fig. 1. View of R- Frame Circuit Brea ker

Shown with Digitrip RMS 510 Trip Unit Installed

WARNING

DO NOT ATTEMPT TO INSTALL OR PERFORM MAINTENANCE ON EQUIPMENT WHILE IT IS ENERGIZED.

DEATH, SEVERE PERSONAL INJURY, OR SUBSTANTIAL PROPERTY DAMAGE CAN RESULT FROM CONTACT WITH ENERGIZED EQUIPMENT. ALWAYS

VERIFY THAT NO VOLTAGE IS PRESENT BEFORE

PROCEEDING WITH THE TASK, AND ALWAYS FOLLOW GENERALLY ACCEPTED SAFETY PROCEDURES.

EATON IS NOT LIABLE FOR THE MISAPPLICATION

OR MISINSTALLATION OF ITS PRODUCTS.

The user is cautioned to observe all recommendations,

warnings and cautions relating to the safety of personnel

and equipment, as well as all general and local health

and safety laws, codes , and procedures .

The recommendations and information contained herein

are based on Eaton experience and judgment,

but should not be considered to be all-inclusive or covering every application or circumstance which may arise. If

any questions arise, contact Eaton for further

information or instructions.

Eective Date October 2010 Instruction Leaet 29C713E

Eective October 2010

Fig. 2a View of Five Basic Models of the Digitrip RMS Trip Unit

1.0 SUPPLEMENTARY INFORMATION

The instructions contained in this book supplement the

instructions for R- F rame Circuit Breakers cov

in l.L. 29C107 and Connection Diagram 290714.

2.0 DIGITRIP RMS AND DIGITRIP OPTIM TRIP UNITS

This instruction book specically covers the application of

Digitrip RMS and Digitrip OPTIM Trip Units installed in

R- Frame Circuit Breakers as illustrated in Fig. 1.

Digitrip RMS and Digitrip OPTIM Trip Units are ac

devices that employ microprocessor-based technology

that provides true rms current sensing means for proper

correlation with thermal character

equipment. The

circuit protection. This is achiev

ondary current signals received from the circuit breaker

current sensors and initiating tr

breaker shunt trip when pre-set current levels and time

delay settings are exceeded.

In addition to the basic protection function, Digitrip RMS

Trip Unit models 510, 610, 810, 910 and Digitrip OPTIM

750 and 1050, provide mode of trip information and integral test provisions.

The protection section of the Digitrip Trip Unit can be

equipped with a maximum of ve phase and two ground

(time current) curve shaping adjustments. The exact

primary function of the Digitrip Trip Unit is

istics of conductors and

ed by analyzing the sec-

ip signals to the circuit

ered

Fig. 2b View of the Two Basic Models of the Digitrip

OPTIM Trip Unit

selection of the available protection function adjustments

is optional to satisfy the protection needs of any specic

installation. The short delay and ground fault pick-up

adjustments can be set for either at or I²t response. A

pictorial representation of the applicable time-current

curve for the selected protection functions is provided on

the face of the trip unit for user reference.

On the Digitrip Models 510, 610, 810, 910, 750 and 1050

red LEDs that are imbedded in the Time-Current curves

EATON CORPORATION www.eaton.com Page 2

Eective Date October 2010 Instruction Leaet 29C713E

Eective October 2010

depicted on the face of the trip unit provide mode of trip

indication for ground fault, overload and short circuit trip

operations.

Digitrip RMS Models 510, 610, 810, and 910 that are not

equipped with an adjustable instantaneous trip element

(LS and LSG) are provided with a making current release

which is referred to as a DIScriminator. The DIScriminator is switch selectable to disable this function. In addition, on all models, a high-level instantaneous override

circuit is provided to ensure rapid circuit clearing under

abnormal fault current conditions. The override is set for

16,000A ±15%.

Digitrip RMS Trip Units are available in ve basic models,

as illustrated in Fig. 2a: 310, 510, 610, 810, and 910.

Separate instruction leaets referenced in Section 8.2

cover the basic functions and features of each model.

Digitrip OPTIM Trip Units are available in two models as

illustrated in Fig. 2b: 750 and 1050. A separate related

series of 3 instruction leaets, referenced in Section 8.0,

cover the two trip unit models, the hand held OPTIMizer

and the panel mounted BIM (Breaker Interface Module).

This instruction book is arranged to describe the unique

features of each type as they relate to their application in

R- Frame Circuit Breakers . Table 1 illustrates the

available functions and features of each of the trip unit

models.

3.0 RATING PLUGS

3.0.1 Digitrip RMS Plugs 510, 610, 810, 910

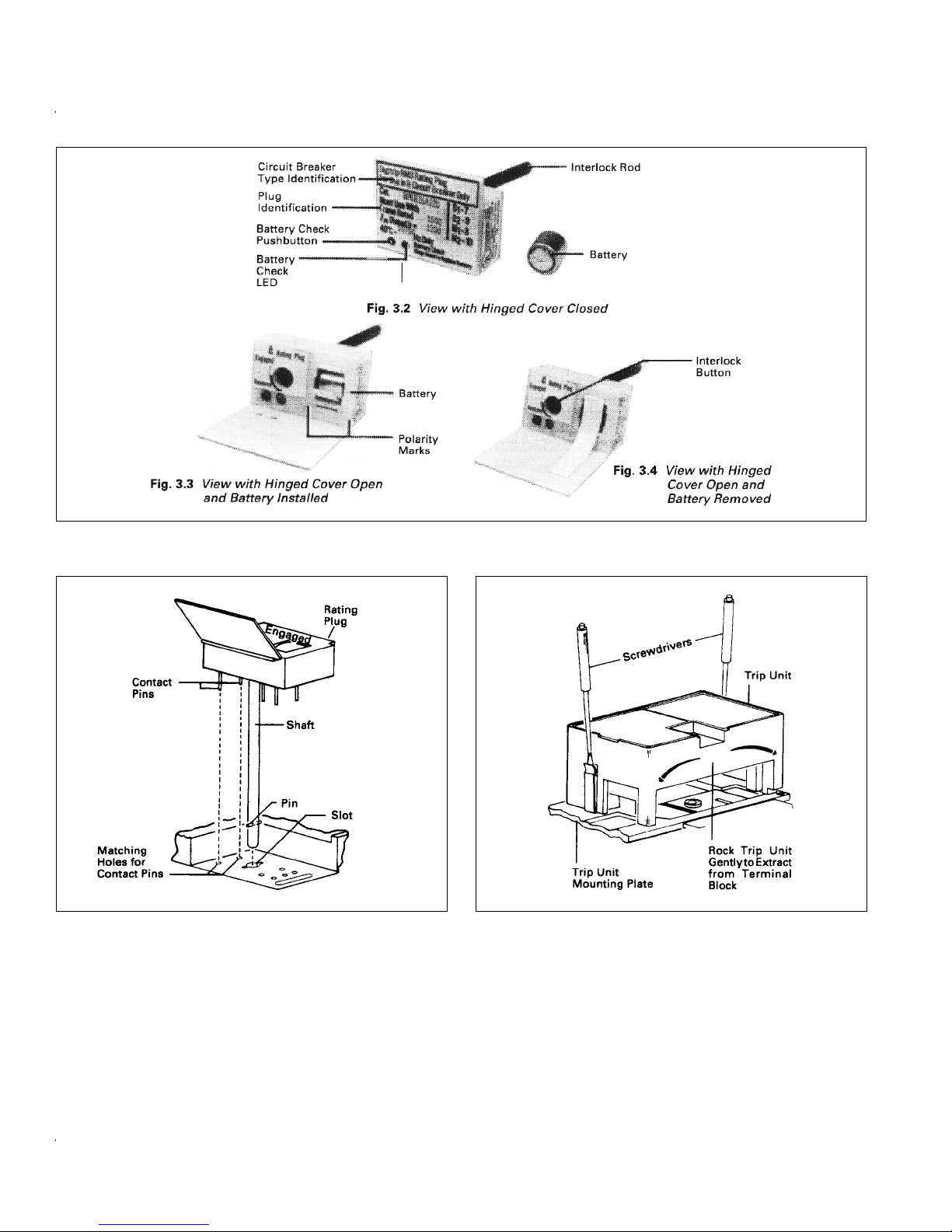

Rating Plugs, as illustrated in Figures 3.2 thru 3.4, determine the maximum continuous current rating of the circuit

breaker. All protection function settings on the face of the

trip unit are expressed in per unit multiples of the plug

ampere rating (I

) . A fractional multiplier of the plug

n

ampere rating is set by the long delay setting switch to

further dene the (l

) continuous current rating for the

r

long time and short time functions. See curve references

in Section 8.3.

Available rating plugs are shown in Table 2b. Plugs must

be selected to match the desired continuous current rating of the circuit breaker as well as the frame rating.

3.0.2 Digitrip RMS 310- Plugs

This family of plugs is illustrated in Fig. 3.1. This plug

design will not mechanically t into the other Digitrip

models. On the model 310 units the continous current

rating (I

) equals the rating plug ampere rating (l ). The

r

n

Fig. 3.1 Typical Rating Plug for Digitrip RMS 310

plug scaled by the short delay pickup or instantaneous

switch settings provides short circuit protection levels.

See curve references in Section 8.3. Available rating

plugs are shown in Table 2a. Plugs must be selected to

match the desired continuous current rating of the circuit

breaker as well as frame rating.

3.0.3 Digitrip RMS Plugs for OPTIM, 750 and 1050

The Digitrip OPTIM rating plugs are similar in construction to the plug family described in Section 3.0.1. The

plugs are marked Digitrip RMS. The plug determines the

maximum continuous current rating of the circuit breaker.

The pickup settings are ultimally loaded via software into

the trip unit in per unit but are displayed for user's ease as

an ampere value. The Long Delay Current Setting (Long

Delay Pickup) loaded in amperes via an external device

is actually a fractional multiplier of the plug ampere rating

(I

) and in turn denes a (l ) continuous current rating for

n

the long time and short time functions. See curve refer-

r

ences in Section 8.3. Available rating plugs are shown in

Table 2c. Plugs must be selected to match the desired

continuous current rating of the circuit breaker as well as

frame rating.

3.0.4 Rating Plugs Battery

For all models except Digitrip 310, rating plugs are

equipped with a back-up battery to maintain the mode of

trip operation following a circuit breaker tripping operation

when external control power is not available. The battery

is a long-life lithium type, that is replaceable from the front

of the trip unit, when required, without removing the rating plug. See Figs. 3.2 thru 3.4. Replacement types and

instructions are provided in the Digitrip RMS Trip Unit

instruction leaet referred to in Section 8.2 of this book.

Following a trip operation and with no supplementary

control power available, the battery will maintain the

mode of trip LED for approximately 60 hours.

EATON CORPORATION www.eaton.com Page 3

Eective Date October 2010 Instruction Leaet 29C713E

Eective October 2010

Fig. 3.2 thru 3.4 Typical Rating Plug for Digitrip RMS 510, 610, 810, 910 and Digitrip OPTIM 750, 1050

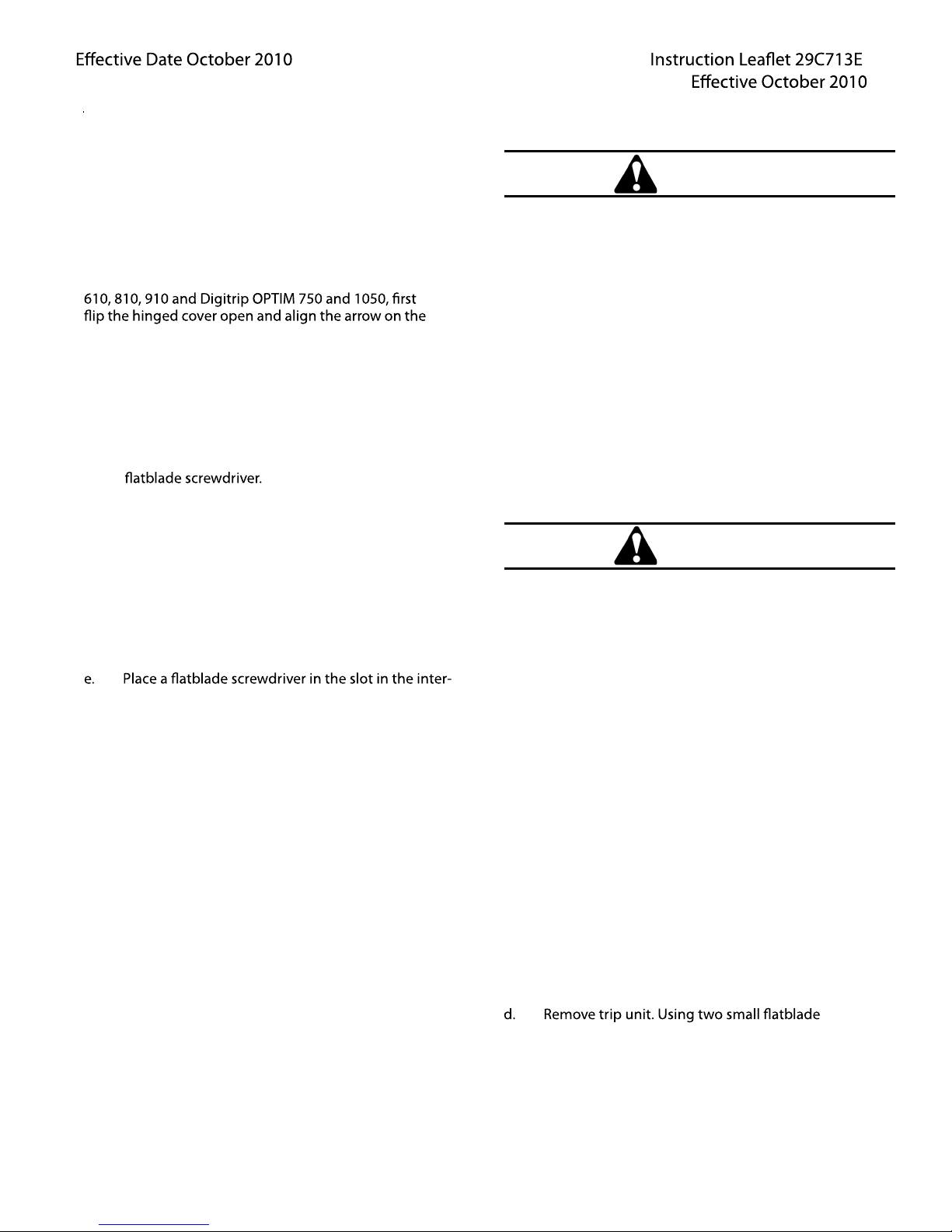

Fig. 3.5. Installation of Rating Plug

Note: The rating plug must be securely tightened in

the trip unit before operating the circuit breaker.

3.1 Installation and Removal of Trip Components

R- F rame circuit breakers are shipped with the

trip unit installed. Make sure that the trip unit and the circuit breaker are suitable for the intended installation by

comparing nameplate data with any existing equipment

Fig. 3.6. Removal of Trip Unit

and system requirements. If both trip unit and circuit

breaker are suitable, the circuit breaker requires only the

installation of a rating plug to make it operational.

3.2 Installation of Rating Plug

Note: The rating plug mechanically interlocks with

the circuit breaker frame. If the rating plug is not cor-

EATON CORPORATION www.eaton.com Page 4

rectly installed, the circuit breaker cannot be reset or

placed in the ON position.

WARNING

Before the rating plug can be installed, the transparent trip unit cover must be removed from the circuit breaker.

To install the rating plug on Digitrip RMS Models 510,

interlock button to point towards the REMOVE position.

a. Remove transparent trip unit cover after loosening

the four thumbscrews.

b. Make sure arrow on rating plug interlock button is

pointing at REMOVE. Adjust, if necessary, using a

c. Position the rating plug over the trip unit as shown

in Fig. 3.5. The pin on the rating plug shaft must

line up with the matching slot in the trip unit.

d. Push the rating plug in as far as it will go. The

electrical contact pins will enter matching holes in

the trip unit. A springiness will be felt when the rating plug bottoms in the trip unit.

lock button. Press in approximately 1/16-inch and

turn button 90° clockwise to the “ENGAGED” position.

BEFORE YOU FIT THE RATING PLUG INTO THE

TRIP UNIT, BE SURE TO CHECK THAT THE

BREAKER TYPE AND FRAME RATING (OR

SENSOR RATING IF APPLICABLE), MATCH

THOSE PRINTED ON THE RATING PLUG COVER.

INSTALLING A RATING PLUG THAT DOES NOT

MATCH THE BRAKER TYPE AND FRAME

RATING (OR SENSORRATING, IF APPLICABLE),

CAN PRODUCE SERIOUS MISCOORDINATION

AND/OR FAILURE OF THE PROTECTION

SYSTEM.

3.3 Trip Unit Removal

Use the following instructions to remove a Digitrip trip unit

from a circuit breaker.

WARNING

THE VOLTAGES IN ENERGIZED EQUIPMENT CAN

CAUSE DEATH OR SEVERE PERSONAL INJURY.

BEFORE REMOVING THE COVER OF AN R-FRAME

CIRCUIT BREAKER MOUNTED IN AN ELECTRICAL

SYSTEM, MAKE SURE THERE IS NO VOLTAGE AT

LINE OR LOAD TERMINALS. SPECIAL ATTENTION

SHOULD BE PAID TO REVERSE FEED APPLICATIONS TO ENSURE NO VOLTAGE IS PRESENT.

Note: If unit is a Digitrip RMS 310, and an adjustable

rating plug is installed, set rating plug switch marked

a. Press the Push-to-Trip button in the circuit breaker

cover to trip the circuit breaker.

A, B, C, D to the current rating desired.

b. Remove eight cover screws and circuit breaker

f. After adjusting trip unit settings to the desired set-

cover.

tings, close the rating plug's hinged cover and re-

install trip unit transparent cover. Secure in position

with four thumbscrews

.

c. Remove the rating plug. Flip the hinged cover

open. Turn the interlock button counter clockwise to

the REMOVE position. Rating plug will raise

g. Circuit break

the ON and OFF positions.

er can now be reset and switched to

slightly. Grasp rating plug and pull out gently. Make

sure pin in shaft lines up with slot in trip unit. Adjust

position of interlock button as required to ensure a

smooth withdrawal of the shaft.

screwdrivers, lift up on the spring clips located at

each end of the trip unit (see Fig. 3.5).

EATON CORPORATION www.eaton.com Page 5

e. With the screwdrivers in position, gently rock the

trip unit from side to side until it works free from the

circuit breaker.

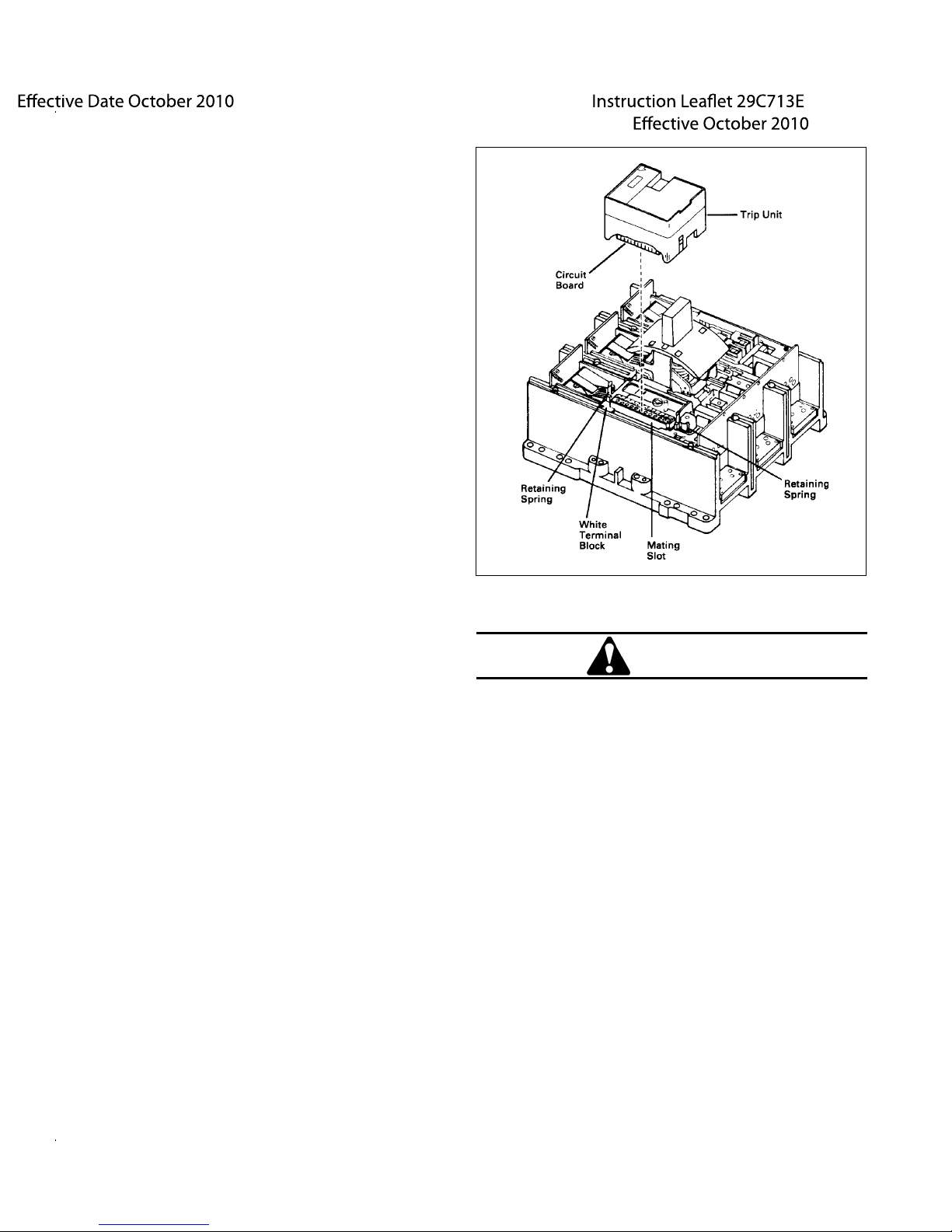

3.4 Trip Unit Replacement

Make sure the trip unit to be installed is suitable for the

intended installation by comparing the trip unit catalog

number with the nameplate on the circuit breaker frame

located to the right of the handle. Rejection pins are used

in the circuit breaker frame to prevent the installation of

an incorrect trip unit.

a. Remove any existing trip unit by following the

procedures in paragraphs 3.3.a through e.

Note: The replacement trip unit should be installed

before the circuit breaker cover is re-installed.

b. Position the replacement trip unit above the white

terminal block to the left of the circuit breaker handle. Align the protruding circuit board with the mating slot in the white terminal block (see Fig. 3.7).

c. Carefully press the trip unit into place. A sharp click

will be heard as the retaining springs click into position.

Fig. 3.7. Installation of Trip Unit

d. Install rating plug (see paragraphs 3.2.b through e).

e. Reinstall the circuit breaker c over. Torque cover

screws to 24 in-lbs.

4.0 DIGITRIP RMS MODEL CONSIDERATIONS

4.1 Digitrip RMS 310

The Digitrip RMS 310 Tr

RMS 310 Trip Unit as described in I.L. 29C883, 3 or 4

auxiliary current transformers and a stab-in trip unit terminal block as shown in Figs. 4 and 5.

The fourth auxiliary current transformer is supplied when

the optional ground fault or neutral protection function is

selected in the trip unit. Also, a side mounted 4-point terminal block is provided to pre-wire the mode of ground

fault sensing used, i.e., residual or source ground. These

connections are shown in Fig. 16.

ip Assembly consists of a Digitrip

CAUTION

IN A DRAWOUT MOUNTED BREAKER TESTING OF A

CIRCUIT BREAKER BY INITIATING A TRIP OPERATION

WHILE IN THE CELL " CONNECTED" POSITION BY

THE EXTERNAL TEST KIT OR THE INTEGRAL TEST

PROVISIONS IN THE DIGITRIP RMS TRIP UNIT IS

NOT RECOMMENDED.

THE TRIPPING OPERATION OF THE CIRCUIT

BREAKER WILL CAUSE DISRUPTION OF SERVICE

AND POSSIBLY PERSONAL INJURY RESULTING

FROM UNNECESSARY SWITCHING OF CONNECTED EQUIPMENT.

TESTING OF A CIRCUIT BREAKER SHOULD BE

DONE ONLY IN THE " TEST", " DISCONNECTED" OR

“ WITHDRAWN" CELL POSITIONS.

WHERE A CIRCUIT BREAKER TRIP OPERATION IS

DESIRED FOR A FIXED MOUNTED CIRCUIT

BREAKER, TESTING SHOULD BE CONDUCTED

ONLY WHEN THE EQUIPMENT IN WHICH THE

BREAKER IS MOUNTED IS COMPLETELY DE-ENERGIZED.

EATON CORPORATION www.eaton.com Page 6

Eective Date October 2010 Instruction Leaet 29C713E

Eective October 2010

Fig. 4. View of 1600A, Type R-Frame Circuit Breaker with Front Cover Removed to Expose Digitrip RMS Trip Unit

4.2 Digitrip RMS 510

The Digitrip RMS 510 Trip Assembly consists of a Digitrip

RMS 510 Trip Unit as described in I.L. 29-885, 3 or 4 auxiliary current transformers and a stab-in trip unit terminal

block as shown in Figs. 4 and 5.

4.3 Digitrip RMS 610

The Digitrip RMS 610 Trip Assembly consists of a Digitrip

RMS 610 Tr

ip Unit

as described in l.L. 29-886, 3 or 4 aux-

iliary current transformers, a stab-in trip unit terminal

lock and a Power/Rela

b

y module mounted as illustrated

in Figs. 4 and 5. The Digitrip RMS 610 Trip Unit is similar

The fourth auxiliary current transformer is supplied when

the optional ground fault protection function is selected in

the trip unit. Also, a side mounted 4-point terminal block

is provided to pre-wire the mode of ground fault sensing

used, i.e., residual or source ground.

to a Digitrip RMS 510 Trip Unit with the addition of a fourdigit display, three-phase (l

rent (I

) or one neutral current ( I ) green pointer LEDs

G

along with a stepping push button as illustrated in

, I

, IC) and one ground cur-

B

A

D

Table 1. Signal contacts are provided for hard wiring

three remote mode of trip indicators (long delay, short cir-

The trip unit contains a receptacle for use with an

cuit, ground fault) and a High-Load remote alarm.

optional Auxiliary Power module (Cat. No. PRTAAPM).

When this module is plugged in the trip unit and connected to a 120V, 50/60 Hz supply, the circuit breaker can

be bench tested using the integral test panel. With the cir-

The ground current pointer LED and ground fault mode of

trip signal contact are supplied only when the ground

fault protection function is provided in the trip unit.

cuit breaker in the closed position, it can be "tripped”

when the test selector switch is in either the "6T ” or “GFT ”

positions.

A 120V, 50/60 Hz 6 VA Power/Relay module is standard

for operating the display and internally mounted signal

relays. The relay contacts are each rated 120V, 1.0A. A

230V 50/60 Hz 6 VA power relay module is also available.

EATON CORPORATION www.eaton.com Page 7

Eective Date October 2010 Instruction Leaet 29C713E

Eective October 2010

The Power/Relay module will maintain the cause of trip

LEDs history and trip history as long as the control power

supply is available. With loss of the control power supply,

only the cause of trip LEDs will be maintained by the

back-up battery located in the rating plug.

The High-Load message and remote alarm switch are

pre-set at 85% of the value of the long delay setting. The

High-Load relay operates and the LED turns "ON” when

the 85% level is exceeded only after an approximate 40

second delay to ride through momentary High-Load conditions.

4.4 Digitrip RMS 810

The Digitrip RMS 810 Trip Assembly is

similar to

the Digitrip RMS 610 Trip Assembly with the addition of a fourdigit display, three-phase (I , I

rent (l

) or one neutral current (l ), green pointer LEDs

G

, IC) and one ground cur-

A

B

D

along with a stepping push button, peak demand, present

demand and energy consumed green pointer LEDs along

with a peak demand reset push button as illustrated in

Table 1. The Digitrip RMS 810 Trip Unit is described in

l.L. 29-888.

The Trip Assembly provides for both local displays on the

face of the trip unit and remote communications via an

IMPACC communication network signal link as illustrated

in Table 1.

4.5 Digitrip RMS 910

The Digitrip RMS 910 Trip Assembly is similar to the Digitrip RMS 810. It is a communicating trip unit that provides all the functions described in Section 4.4 plus the

addition of the following features both locally displayed

and remotely communicated:

1. Phase-to-phase voltages - V ,

AB

, V

V

BC

CA

2. System power factor - PF

, I

3. Total harmonic distortion THD for I

, I

B

C

A

The THD calculation also includes the individual harmonic currents up to the 27 harmonic as a percentage of

the fundamental. Also included with the THD is provisions for waveform capture information via a host computer. Detailed information is provided in l.L. 29-889.

4.6 Digitrip OPTIM 750

The Digitrip OPTIM 750 is a programmable communicating microprocessor-based RMS current sensing trip unit.

For the R-Frame breaker it is physically the same plug-in

trip unit as all the other Digitrip models. There are two

style oerings – Phase Protection with Ground Fault Trip

(Cat. P76LSIG) and Phase Protection with Ground Fault

Alarm (Cat. P77LSIA).

In addition, if desired, an Assemblies Electronic Monitor

(AEM) as described in l.L. 17-216, may also be installed

to show the parameters in Table 1 covered under Note 2.

A communicating panel mounted device, the Breaker

Interface Module (BIM), as described in l.L. 29C893 can

be used to display metering and other transmittable data.

Interconnections for the IMPACC circuit must be connected as shown in l.L. 29-888 and wiring diagram using

twisted pair (shielded) No. 18 AWG conductors.

The three-digit IMPACC address must be set on each trip

unit per instructions given in l.L. 29-888. To insure that

each circuit breaker in an assembly is properly located

after the address is set, the breaker should be identied

with its proper cell location and that reference along with

the breaker IMPACC address marked on the face of the

trip unit in the spaces provided.

In addition to the communication of the breaker data, the

IMPA

CC module allows for remote tripping (via the ux

shunt trip) and closing of the circuit breaker.

The front panel of the unit has 3 or 4 causes of trip LEDs

and a telephone type receptacle for purposes of programming settings, testing and displaying phase currents

via a separate hand-held unit called the OPTIMizer.

There are up to 10 trip functions that can be programmed

which includes both a 1

2

t and 14t curve for the Long-Time

slope. There are also typically ten times the number of

setpoints compared to a front adjustable trip unit. All

transmittable data as well as programming of the trip

curve settings can also be communicated over a twisted

pair cable via the breaker's secondaries (terminals C11,

C12) to either a host computer or a panel mounted

Breaker Interface Module (BIM).

The breaker includes a Power/Relay module per Fig. 5 to

provide power for the communications function and delay

output for alarming.

Detail information on Digitrip OPTIM tr

ip units is in

l.L. 29C891.

4.7 Digitrip OPTIM 1050

The Digitr

ip OPTIM 1050 is a programmable communicating microprocessor-based RMS current sensing trip

unit. For the R-Frame breaker it is physically the same

EATON CORPORATION www.eaton.com Page 8

Loading...

Loading...