Eaton Digitrip 520V, Digitrip 520MCV Instructions Manual

I.L. 66A7534H04

Instructions for Digitrip Models 520V and 520MCV

for use only in Cutler-Hammer T ype VCP-T, VCP-TR

and T -V AC, T-VACR Circuit Breakers

Table of Contents

I.L. 66A7534H04

Page 1

1.0 General Description of Digitrip Trip Units ................. 2

1.1 Protection ............................................................... 3

1.2 Mode of Trip and S tatus Information ........................ 3

1.3 Installation and Removal.......................................... 3

1.3.1 Installation of the Trip Unit............................ 3

1.3.2 Installation of the Rating Plug....................... 3

1.3.3 Trip Unit/Rating Plug Removal...................... 4

1.4 Installing the CH T ype-V Curent Sensors................. 5

1.4.1 Installation of the Rating Plug...................... 5

1.4.2 CH T ype-V Current Sensor Functiionality .... 5

1.5 Plexiglass Cover ..................................................... 5

1.6 Ground Alarm/Power Supply Module (520MCV)....... 5

1.6.1 Auxilary Power............................................ 7

1.6.2 Ground Alarm .............................................. 7

1.6.3 Ground Fault Trip ........................................ 7

1.6.4 Ground Fault Alarm..................................... 7

1.7 Display Feature (520MCV) ...................................... 7

1.8 UL, CSA and CE Recognition.................................. 8

2.0 General Description of VCP-T , VCP-TR

and T-V AC, T -VACR Circuit Breakers.......................8

2.1 General ...................................................................8

2.2 Low Energy Trip Actuator ........................................ 9

2.3 Ground Fault Protection .......................................... 9

2.3.1 General ........................................................ 9

2.3.2 Zero Sequence Sensing ............................... 9

2.3.3 Residual Sensing......................................... 9

2.3.4 Ground Fault Settings................................ 10

3.0 Principles of Operation .......................................... 12

3.1 General ................................................................. 12

3.2 Trip and Operation Indicators................................. 12

3.3 Zone Interlocking ............................................. 12, 28

4.0 Protection Settings ............................................... 14

4.1 General ................................................................. 14

4.2 Long Delay Current Setting ................................... 14

4.3 Long Delay Time Setting ....................................... 14

4.4 Short Delay Current Setting................................... 15

4.5 Short Delay Time Setting ...................................... 15

4.6 Instantaneous Current Setting ............................... 15

4.7 Ground Fault Current Setting................................. 16

4.8 Ground Fault Time Delay Setting .......................... 16

4.9 INCOM (520MCV).................................................. 16

4.9.1 Breaker Interface Module (BIM) .................. 16

4.9.2 Remote Master Computer .......................... 16

4.9.3 INCOM Network Interconnections .............. 17

5.0 Test Procedures.................................................... 18

5.1 Test Precautions ................................................... 18

5.2 When to Test ........................................................ 18

5.3 Functional Field Testing ........................................ 18

5.3.1 Field Test Kit............................................... 18

5.3.2 Handheld Functional Test Kit...................... 19

5.3.2.1 Description of Handheld Test Kit...... 19

5.3.2.2 Test Procedure................................ 19

5.3.2.3 Currents .......................................... 19

5.3.2.4 Batteries ......................................... 19

5.4 Performance T esting of Digitrip Trip Units .............. 19

5.4.1 General ...................................................... 19

5.4.2 Testing using MS-2 MultiAMP® Tester....... 19

5.4.2.1 Description of MS-2 T ester .............. 19

5.4.2.2 Primary Injection Testing ................. 20

5.4.2.3 Secondary Injection Testing............. 21

6.0 Battery................................................................. 23

6.1 General ................................................................. 23

6.2 Battery Check....................................................... 23

6.3 Battery Installation and Removal ........................... 23

7.0 Frame Ratings

(Sensor Ratings and Rating Plugs)....................... 24

8.0 Record Keeping .................................................... 24

9.0 References ............................................................ 24

9.1 Medium V oltage T ype VCP Circuit Breakers.......... 2 4

9.2 Time-Current Curves .............................................. 24

Appendix A Zone Interlocking Examples..................... 28

Appendix B Troubleshooting Guide ............................ 30

Appendix C T ypical Breaker Master

Connection Diagram................................ 32

Appendix D MODBUS Translator Wiring .................... 33

Manufacturer’s Statement ............................................. 34

Effective 8/2006

Page 2

WARNING

DO NOT A TTEMPT TO INST ALL OR PERFORM

MAINTENANCE ON EQUIPMENT WHILE IT IS

ENERGIZED. DEA TH OR SEVERE PERSONAL INJURY

CAN RESUL T FROM CONTACT WITH ENERGIZED

EQUIPMENT . AL W A YS VERIFY THA T NO VOL T AGE IS

PRESENT BEFORE PROCEEDING . AL W A YS FOLLOW

SAFETY PROCEDURES. CUTLER-HAMMER IS NOT

LIABLE FOR THE MISAPPLICA TION OR

MISINST ALLA TION OF ITS PRODUCTS.

WARNING

OBSERVE ALL RECOMMENDA TIONS, NOTES, CAUTIONS, AND W ARNINGS RELA TING TO THE SAFETY

OF PERSONNEL AND EQUIPMENT. OBSERVE AND

COMPL Y WITH ALL GENERAL AND LOCAL HEAL TH

AND SAFETY LAWS, CODES, AND PROCEDURES.

I.L. 66A7534H04

NOTE: The recommendations and information contained

herein are based on experience and judgement, but should

not be considered to be all inclusive or to cover every

application or circumstance which may arise.

NOTE: If you have any questions or need additional

information or instructions concerning the operation or

installation of this device, please contact your local

representative or the Cutler Hammer Customer Support

Center.

1.0 GENERAL DESCRIPTION OF DIGITRIP TRIP UNITS

The Digitrip Trip Unit is a breaker subsystem that provides

the protective functions for a circuit breaker. The trip unit s

are in removable housings, installed in the circuit breaker,

and can be replaced or upgraded in the field by the

customer.

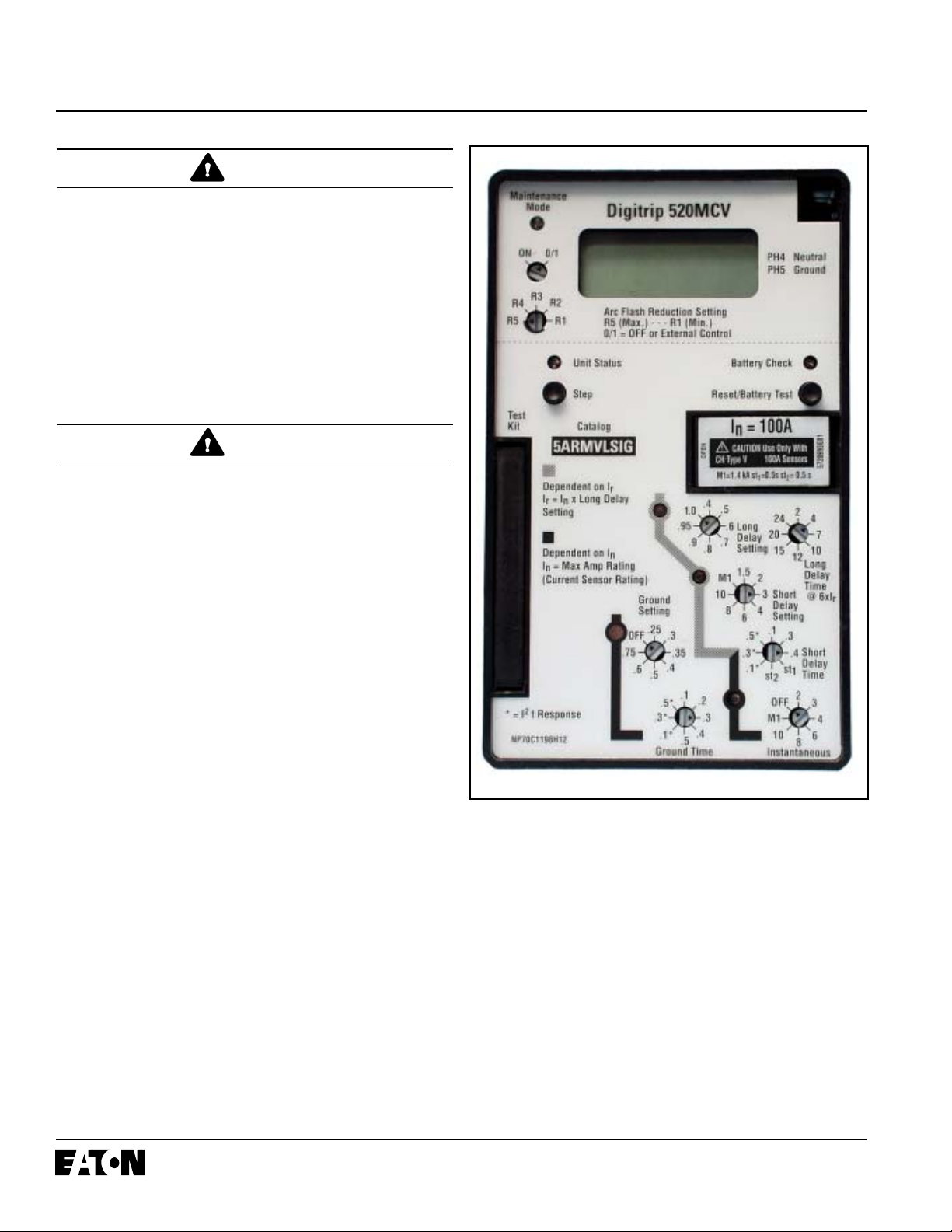

This instruction book specifically covers the application of

the Digitrip Trip Unit s (See Figure 1.1) installed in T ype

VCP-T , VCP-TR, T -V AC or T -V ACR Medium V oltage

Circuit Breakers.

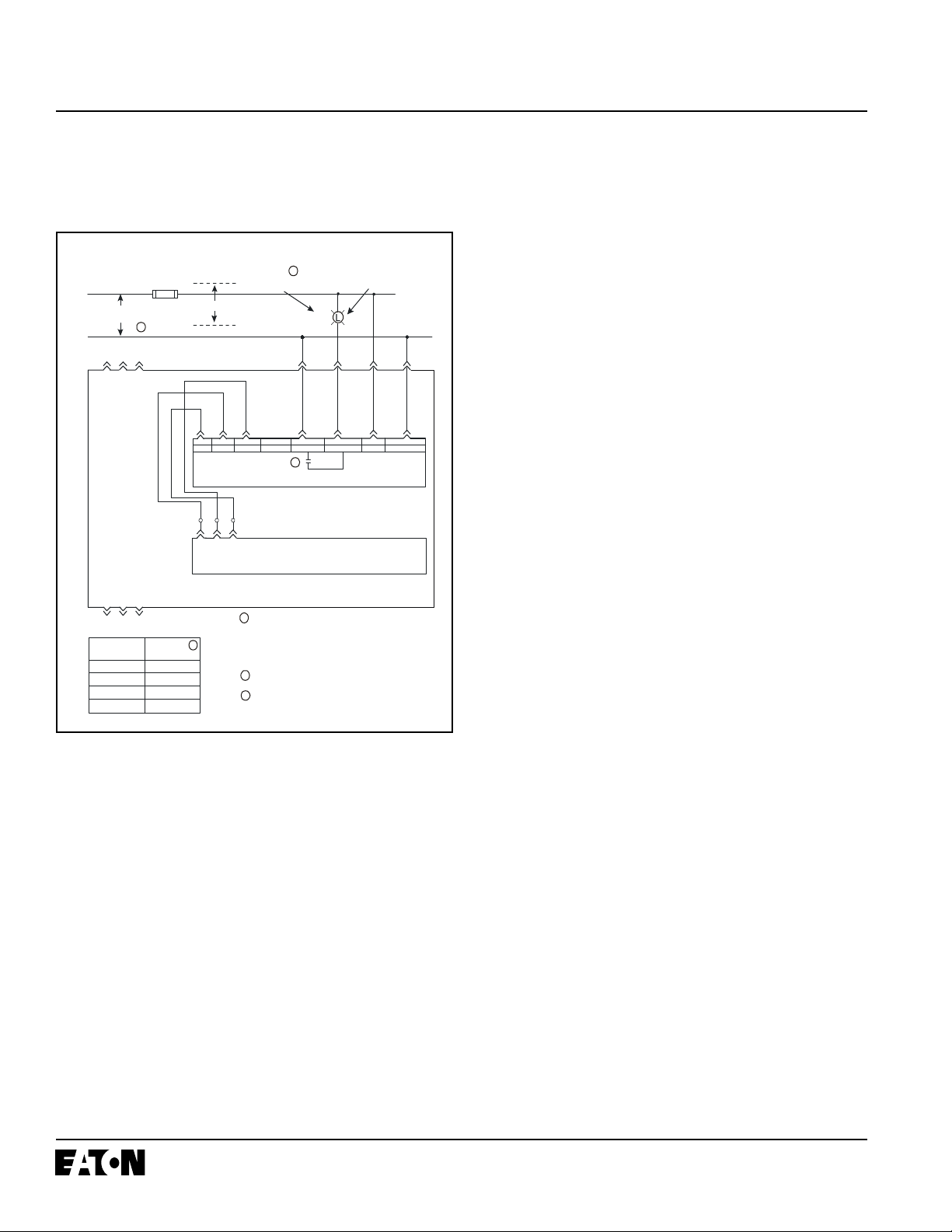

Figure 1.1 Digitrip T rip Unit with Rating Plug

The Digitrip 520V and 520MCV trip units may be applied

on both 50 and 60 Hertz systems. It detects the power and

frequency and adjusts itself automatically .

The Digitrip 520V and 520MCV are self powered and self

protecting trip units designed to function only with the

associated CH T ype-V current sensors.

Effective 8/2006

I.L. 66A7534H04

Page 3

CAUTION

CONNECTING THIS TRIP UNIT TO CURRENT SENSORS OTHER THAN CH TYPE-V MIGHT DAMAGE OR

DESTROY IT .

All trip unit models are microprocessor-based AC protection devices that provide true RMS current sensing for the

proper coordination with the thermal characteristics of

conductors and equipment. The primary function of this

Digitrip trip unit is circuit protection. The Digitrip analyzes

the secondary current signals from the CH T ype-V current

sensors and, when preset current levels and time delay

settings are exceeded, will send an initiating trip signal to

the Trip Actuator of the circuit breaker, causing it to “open.”

In addition to the basic protection function, the Digitrip

520V and 520MCV provide modes of trip indication such

as:

• Long Time trip (overload)

• Short Time trip

• Instantaneous trip

• Ground (Earth) Fault trip

The CH T ype-V current sensors provide the power to the

trip unit. As current begins to flow through the breaker , the

sensors generate a secondary current which powers the

trip unit. No auxilary power is needed to trip the circuit

breaker.

The Digitrip 520V and 520MCV trip units have five phase

and two ground (time-current) curve shaping adjustments.

T o satisfy the protection needs of any specific inst allation,

the exact selection of the available protection function

adjustments is necessary . The short delay and ground

fault pick-up adjustments can be set for either FLA T or I2t

response. A pictorial representation of the applicable timecurrent curves for the selected protection functions is

provided, for user reference, on the face of the trip unit as

shown in Figure 1.1. The user chooses the settings

according to the needs of his application. (See Sections

4.0 & 9.2)

Status LED will also blink at a faster rate if the Digitrip is

in a “Long Pick-up” (overload) mode.

Four red LEDs on the face of the trip units flash to indicate

the cause of trip for an automatic trip operation... i.e.:

Long Delay (overload), Short Delay, Inst antaneous or

Ground (Earth) Fault. A battery , inside the rating plug

compartment of the Digitrip unit, maintains the trip indication until the Reset/Battery T est button is pushed. The

battery is satisfactory if its Battery Check LED lights

green when the Battery Check button is pushed (See

Section 6).

NOTE: The Digitrip unit provides all protection functions

independant of the status of the battery . The battery is

used only to maintain the automatic trip indication.

1.3 Installation and Removal

1.3.1 Installation of the Trip Unit

Align the Digitrip unit with the guide pins and spring clip of

the circuit breaker. Press the unit into the breaker until the

pins on the trip unit seat firmly into the connector housing

and the unit clicks into place (see Figure 1.2).

1.3.2 Installation of the Rating Plug

Insert the rating plug into the cavity on the right-hand side

of the trip unit. Carefully align the three pins on the plug

with the sockets in the cavity . The plug should fit with a

slight insertion force.

WARNING

DO NOT CLOSE THE CIRCUIT BREAKER WHEN THE

DIGITRIP IS REMOVED OR DISCONNECTED. DAMAGE

TO ASSOCIA TED CURRENT TRANSFORMERS MA Y

OCCUR DUE TO AN OPEN CIRCUIT CONDITION.

THERE IS NO PROTECTION FOR THE LOAD CIRCUIT .

1.1 Protection

The Digitrip trip system; including associated CH T ype-V

current sensors, require no external control power to

operate their protection systems. They operate from

current signal levels derived through the CH Type-V current

sensors.

1.2 Mode of Trip and S tatus Information

A green light emitting diode (LED), labeled Unit Status in

Figure 1.1, blinks approximately once each second to

indicate that the trip unit is operating normally . This Unit

Effective 8/2006

CAUTION

IF A RATING PLUG IS NOT INST ALLED IN THE TRIP

UNIT, THE UNIT WILL INITIATE A TRIP WHEN IT IS

ENERGIZED. IN ADDITION THE INST ANT ANEOUS LED

OF THE DIGITRIP TRIP UNIT WILL LIGHT DUE TO A

MISSING OR BAD RA TING PLUG .

Page 4

J3 (3 point)

J4 (4 point)

Connectors

Ground Alarm/Power

Supply Module

(520MCV option only)

Trip

Actuator

Mounting Boss

Steel Mounting Plate

Guide / Rejection Pin

Digitrip 520V / 520MCV

Dimple

Pin 1

Connector K2

M-4 x 80mm

Mounting Screw

Rating Plug

(3 Pins)

Pin 1 - Connector K1

0.045 Dia. Pin s Exiting

0.045 Dia. Pin s Exiting

Digitrip Housing

Digitrip Housing

I.L. 66A7534H04

Wires with

Connectors

Connector I1

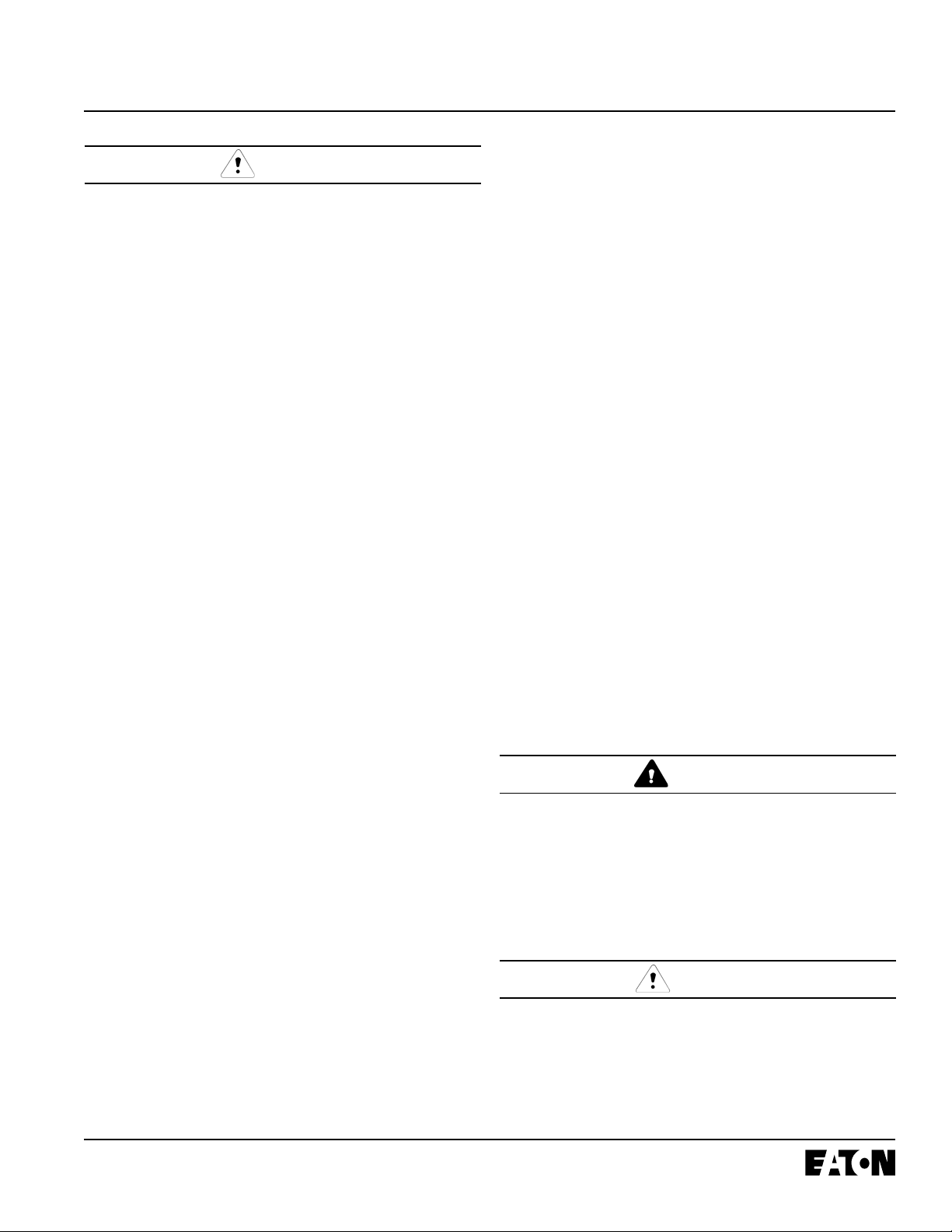

Figure 1.2 Installation of the Digitrip Unit into Breaker (Side View)

CAUTION

THE M4 SCREW SHOULD BE TIGHTENED ONL Y UNTIL

IT IS SNUG BECAUSE THERE IS NO STOP. DO NOT

USE A LARGE SCREWDRIVER. A 1/8" (3mm) WIDE

SCREWDRIVER BLADE IS ADEQUA TE.

1.3.3 Trip Unit/Rating Plug Removal

T o remove the rating plug from the trip unit, make sure the

circuit breaker is open. Now open the left side of the rating

plug door. Use a 1/8" (3mm) wide screwdriver to loosen and

remove the M4x80mm mounting screw. Pull the rating plug

from the trip unit.

T o remove the trip unit from the circuit breaker , remove the

breaker cover screws using a 10mm driver. Deflect the

spring clip under the trip unit to release the unit from the

steel mounting plate. Pull the unit straight forward to

disengage the two 9-pin connectors from the circuit breaker

control circuit. (See Figure 1.2).

Spring Clip

CAUTION

DO NOT FORCE THE RATING PLUG INT O THE CA VITY .

USE A 1/8" (3MM) WIDE SCREWDRIVER TO TIGHTEN

THE M4 SCREW AND SECURE THE PLUG AND THE

TRIP UNIT TO THE CIRCUIT BREAKER (See Figure 1.3).

CLOSE THE RA TING PLUG DOOR.

Figure 1.3 Installating the Rating Plug & Mounting Screw

Effective 8/2006

I.L. 66A7534H04

Page 5

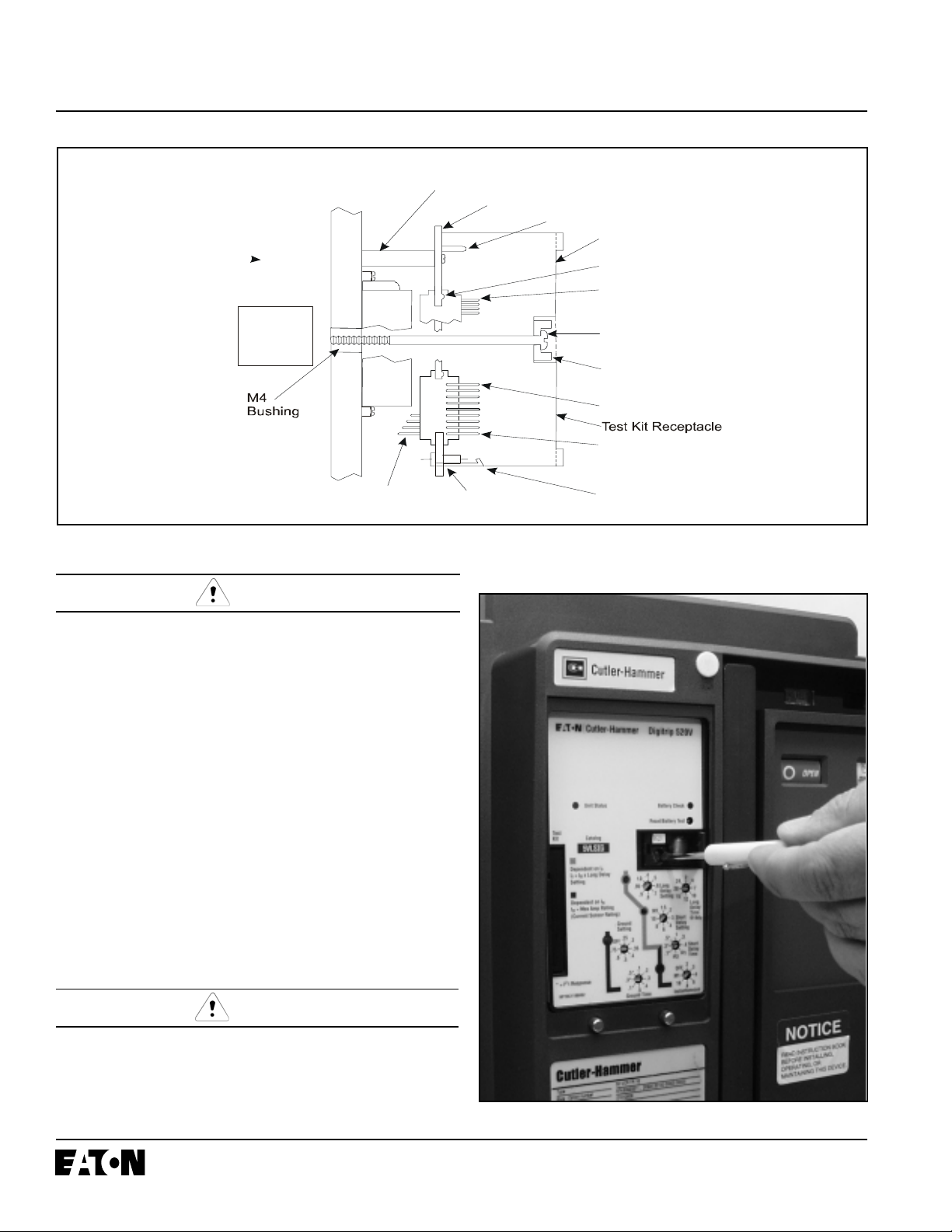

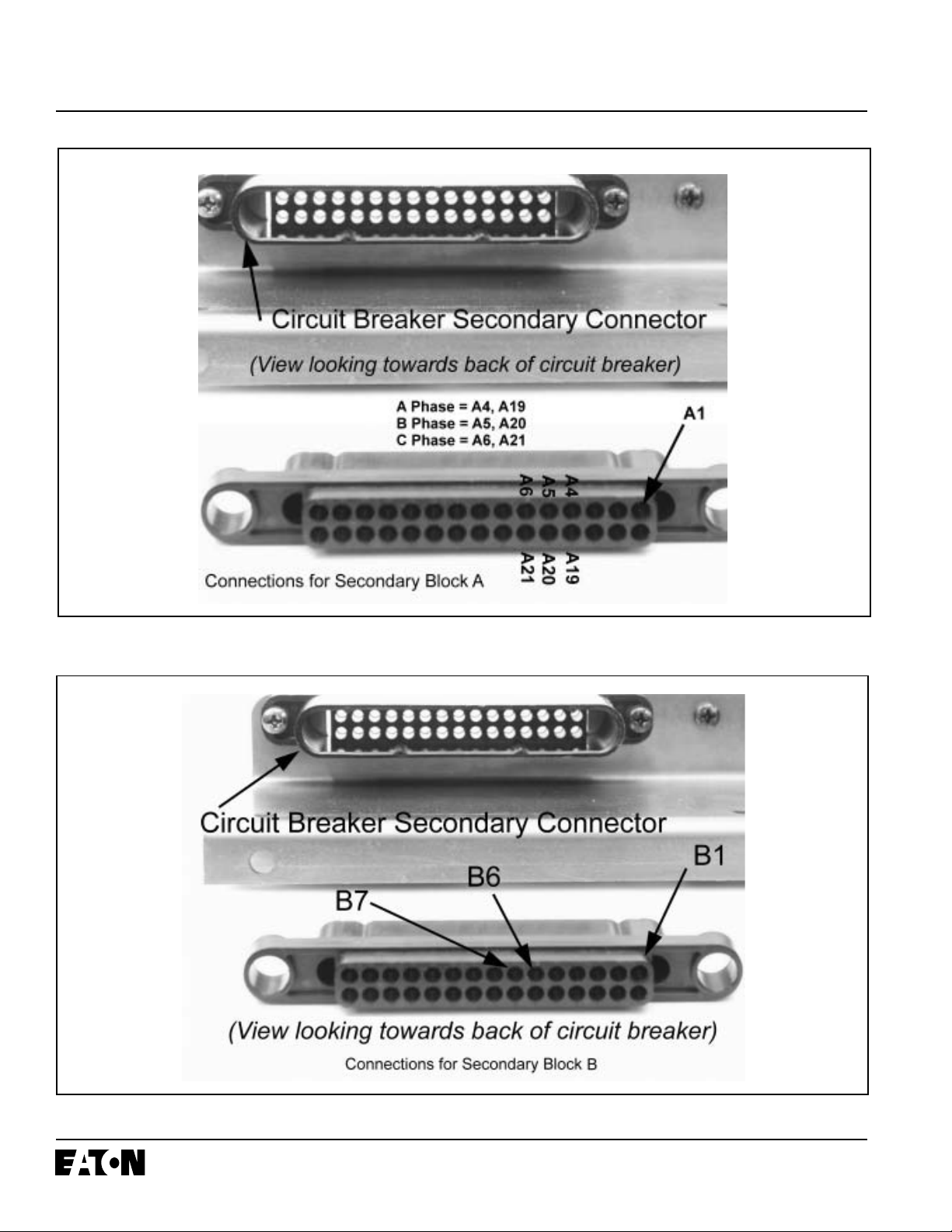

1.4 Installing the CH Type-V Current Sensors

The internal components of the circuit breaker, and how

they are wired out to the breaker secondary contacts are

shown in Figures 1.4, 1.5, 1.6 and 2.3. Also refer to the

master connection diagram provided in Appendix C.

1.4.1 Installation Procedure

The CH T ype-V Current Sensors/Rating Plug Kit supplied

with this breaker must be installed and wired by the user .

The installation steps are as follows:

a. PRIMARY - Mount one CH T ype-V current sensor on the

insulated bushing behind the circuit breaker . The bushing

must be rated for the system Lightning Impulse Withstand

Volt age (LIWV), and the ground (earth) shield terminal or

ground (earth) shield surface must be connected to the

ground (earth) bus. Confirm that the polarity mark (red dot)

on the front of the current sensor faces the circuit breaker.

b. SECONDARY - Connect secondary terminals of the

current sensor to the correct terminals in the switchgear

control circuit using #14 A WG T ype SIS wire. Terminal X1

is the one nearest to the polarity mark. Refer to Appendix

C for distinction between Fixed and Drawout variations.

Consult manufacturer if length of wire to device exceeds 12

feet (3.7m).

c. Use ring terminals on current sensor terminals. Use

AMP #66598-2 female sockets to connect to breaker’s

secondary connector.

d. Ground (Earth) the non polarity terminal of each sensor.

Also Ground the bushing shield surfaces.

circuit breaker when functional protection settings are

exceeded.

If the CH T ype-V current sensors and circuit breaker

enclosure label are changed to a different ratio, the rating

plug must also be changed. The associated rating plug

must match the current sensors installed and as specified

on the circuit breaker enclosure label. Refer to Figure 2.3

for CH T ype-V current sensors available.

1.5 Plexiglass Cover

A clear , tamper-proof, plexiglass door sits on the breaker

cover. This door allows the settings to be viewed but not

changed, except by authorized personnel. The plexiglass

cover meets applicable tamper-proof requirements. The

cover is held in place by two screws. Security is insured

by the insertion of a standard meter seal through the holes

in both of the cover retention screws. The plexiglass cover

has an access hole for the Reset/Battery T est push

button.

1.6 Ground Alarm/Power Supply Module (520MCV

Models Only)

The Ground Alarm/Power Supply Module (See Figure 1.7)

is a required accessory to enable communications on the

Digitrip 520MCV model. The module can be installed

beneath the metal mounting plate of the trip unit in the

Magnum Circuit Breaker. The module covers the following

input voltage ratings: 120 V AC (7802C83G1 1), 230 V AC

(7802C83G12), 24-48 VDC (7802C82G12) and 125VDC

(7802C8213). The burden of the Power/Relay Module is

10VA.

e. Install rating plug into the Digitrip 520V and 520MCV trip

units for the matching CH T ype-V current sensors. Also

attach the additional rating plug label to the circuit breaker

enclosure as a future reference indicating which CH T ype-V

current sensors used in this application.

1.4.2 CH Type-V Current Sensor Functionality

The three CH Type-V current sensors are inst alled external

to the circuit breaker over the main circuit conductors by

means of bushings equipped with a ground shield. The

current sensor rating defines the breaker rating (In)... i.e.

1200A:1A sensors are used on a 1200A rated breaker .

There are four auxiliary current transformers with a ratio of

10:1 which further step down the rated current to 100 milliamperes, which is equivalent to 100% (In) to the Digitrip.

The primary current sensors produce an output signal

proportional to the load current and furnish the Digitrip trip

units with the information and energy required to trip the

Effective 8/2006

Figure 1.4 CH T ype-V Current Sensor Installation

Page 6

I.L. 66A7534H04

Figure 1.5 Secondary Block “A” Connections

Figure 1.6 Secondary Block “B” Connections

Effective 8/2006

I.L. 66A7534H04

1.6.1 Auxiliary Power

When the module is wired as shown in Figure 1.8, it will

provide an auxiliary power supply so that the 520MCV

liquid crystal display (LCD) will be functional even when the

circuit breaker has no load. A Digitrip 520MCV tripunit

without auxiliary power will not display data until load

current reaches approximately 30% 1 phase or 10%

3 phase of the (In) rating.

1.6.2 Ground Alarm

A second function of the module is to provide either a

ground trip or ground alarm only output contact via the

relay supplied in the module. An LED on the front of the

unit also provides an indication of ground fault trip.

1.6.3 Ground Fault Trip

When the Ground Alarm/Power Supply module is used,

this unit will provide ground fault trip contacts when the

circuit breaker trips on a ground fault. You must then push

the Reset button on the Digitrip in order to reset the

contacts (See Figure 1.8, Note 3).

Page 7

1.6.4 Ground Fault Alarm

A ground fault alarm alerts a user to a ground fault condition without tripping the circuit breaker. A red Alarm Only

LED on the front of the trip unit will indicate the presence

of a ground fault condition that exceeds the programmed

setting.

The ground fault alarm relay is energized when the ground

current continuously exceeds the ground fault pickup

setting for a time in excess of a 0.1 second delay . The

alarm relay will reset automatically if the ground current is

less than the ground fault pickup (See Figure 1.8, Note 4).

1.7 Display Feature (520MCV only)

The Digitrip 520MCV model has a user interface in addition

to the green and red LED trip indicators. This seven

element display performs a metering function and can be

used to monitor load currents.

When the Step button on the face of the trip unit is

pressed and released, the display will show PH 1, for

Phase 1 or A, and the current value. If the S tep button is

not pressed again, the display will continue to show the

current value for Phase 1. Each time that the Step button

is pressed, the next monitored function will be displayed.

The other real time readings can be displayed in the

following sequence:

Figure 1.7 Ground Alarm/Power Supply Module for the

520MCV T rip Unit

PH 2 Phase 2 (B)

PH 3 Phase 3 (C)

PH 4 Neutral

PH 5 Ground

H I Highest phase current

OL Overload (Digitrip in overload mode)

Pushing the Step button while the unit is in the OL

mode will have the unit again display the overload

current value.

HELP This message can indicate more than one problem

with the trip unit. If the rating plug is missing, a

HELP message and an Instantaneous trip LED

light will be observed. The rating plug needs to be

installed and the Instantaneous trip LED must be

cleared by pressing the Reset/Battery Test button.

Effective 8/2006

Page 8

I.L. 66A7534H04

This message could also indicate that the trip unit

is out of calibration and should be replaced at the

earliest opportunity .

Ground

Control V oltage

2

3

Fault Trip

Remote

A-10

J3-3

J3-2

Output -

J3-1

G-Alarm

Ground Alarm / Power Supply Module

K2-3

K2-1

K2-6

G-ALM 1

Output +

1

Ground

Fault Alarm

A14

A-11

J4-4

J4-3

J4-2

ATR V o lt.

G-ALM 2

Digitrip 520MCV

1.8 UL, CSA and CE Recognition

The Digitrip 520V and 520MCV Trip Units are a UL

®

(Underwriters Laboratories, Inc.) Recognized Component

under File E146559 for use in Type VCP-T, VCP-TR and

Type T-V AC, T-V ACR Medium V oltage Circuit Breakers.

They have also been tested by the Canadian Standards

Association (CSA).

This Digitrip 520V and 520MCV have also passed the IEC

947-2 test program which includes radiated and conducted

A-15

J4-1

ATR CO M

emissions testing. As a result, all units carry the CE mark.

Co ntact Ra ting (r esist ive lo a d)

1

AC 0.5A @ 230VAC

Available

Input Voltages

120 VAC

230 VAC

24-48 VDC

125 VDC

Style

Number

7802C83G01

7802C83G02

7802C82G02

7802C82G02

7802C82G03

2

AC 1A @ 120VAC

DC 1A @ 48VDC

DC 0.35A@ 125VDC

Verify input voltage rating before energizing circuit.

2

When used in conjunction with a T. U. Cat .

3

5ARMVLSIG will indicate GF trip.

Figure 1.8 Wiring Diagram for 520MCV with Ground

Alarm/Power Supply Module

In addition, the Digitrip 520MCV will display and freeze the

magnitude of the trip value after a trip event if auxilary

power is available. Use the Step pushbutton to view each

phase value. The highest value that can be presented is

9999. Any fault current s greater than this value will be

shown as “HI.” Pushing the Reset pushbutton will clear

this data.

Also related to the phase value after a trip event are four

dashes “----”. This message means that the microprocessor could not complete its writing of the trip event’s

magnitude into its non volatile memory . A possible cause

of this would be the lack or loss of auxilary power during

the trip event.

2.0 GENERAL DESCRIPTION of VCP-T, VCP-TR or

T-V AC, T -V ACR CIRCUIT BREAKERS

2.1 General

The circuit breakers are tripped automatically on overload

and fault current conditions by the combined action of

three components:

1. The sensors, which measure the current level

2. The Digitrip Trip Unit, which provides a tripping signal to

the Trip Actuator , when current and time delay settings

are exceeded.

3. The low-energy T rip Actuator , which actually trips the

circuit breaker.

This arrangement provides a very flexible system, covering

a wide range of tripping characteristics described by the

time-current curves referenced in Section 9.2.

Effective 8/2006

I.L. 66A7534H04

Page 9

2.2 Low-Energy Trip Actuator

The mechanical force required to initiate the tripping action

of the circuit breaker is provided by a special low-energy

Trip Actuator . This device is located behind the molded

platform on which the Digitrip units are supported. (See

Figure 1.2) The T rip Actuator cont ains a permanent magnet

assembly , moving and stationary core assemblies, a

spring, and a coil. Nominal coil resistance is 25 ohms and

the black lead is positive. The circuit breaker mechanism

automatically resets the T rip Actuator each time the circuit

breaker opens.

When the T rip Actuator is reset by the operating mechanism, the moving core assembly is held in readiness

against the force of the compressed spring by the permanent magnet. When a tripping action is initiated, the lowenergy T rip Actuator coil receives a tripping pulse from the

Digitrip trip unit. This pulse overcomes the holding effect of

the permanent magnet, and the moving core is released to

upset the trip latch of the circuit breaker mechanism.

2.3 Ground Fault Protection

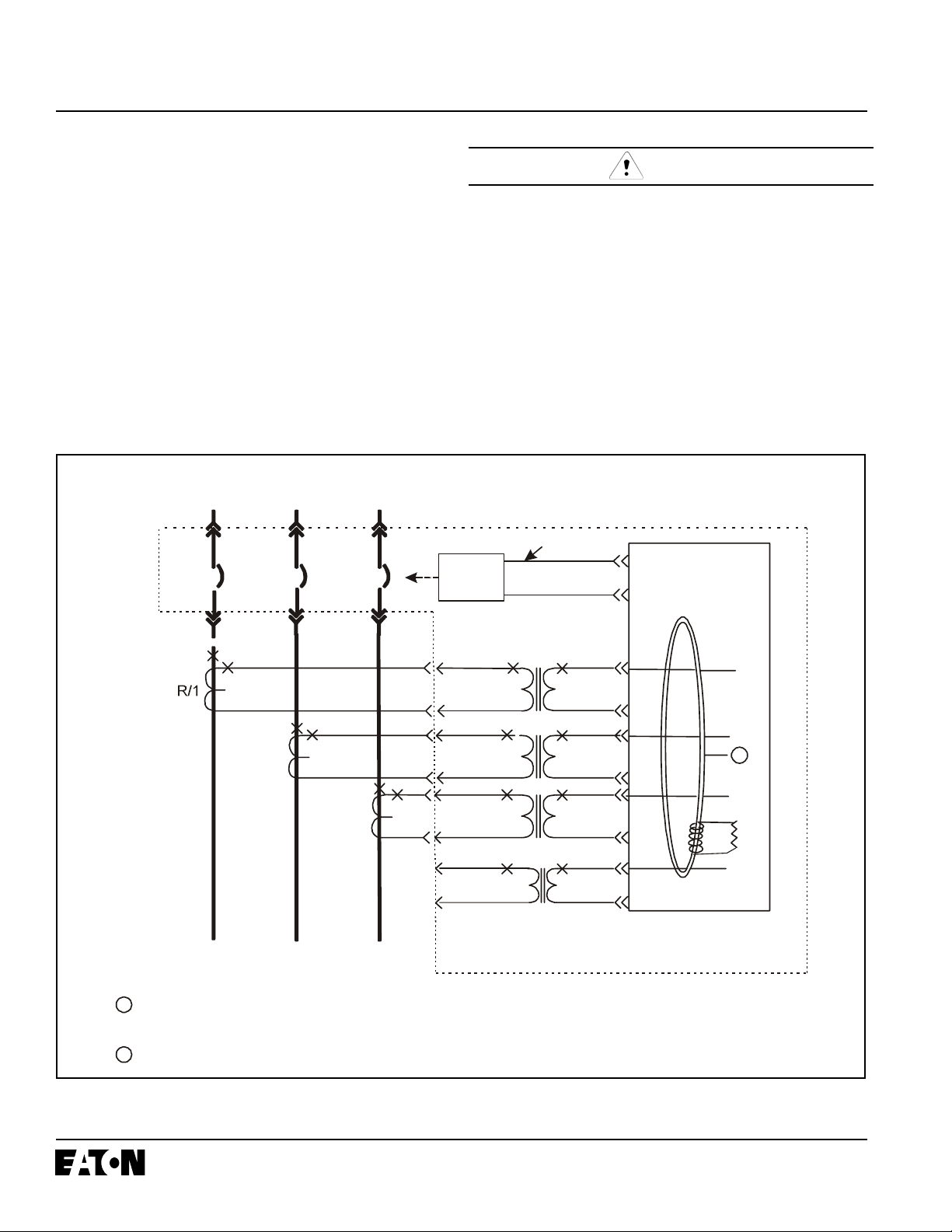

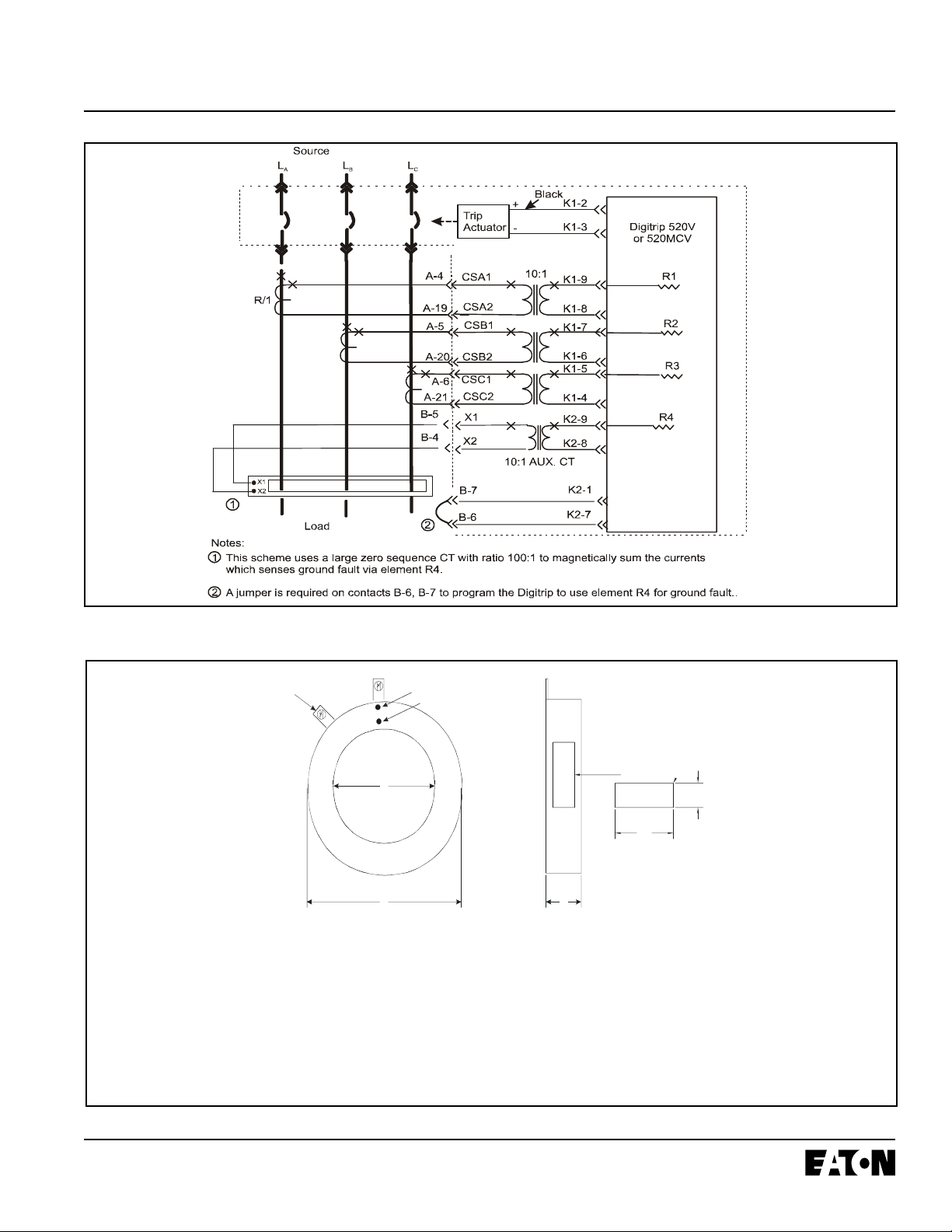

2.3.2 Zero Sequence Sensing

Zero Sequence Sensing, also referred to as vectorial

summation, is applicable to mains, feeders, and special

schemes involving zone protection. An optional CH Type-V

Zero Sequence current transformer (See Figure 2.1), having

taps for 100A and 200A ratings is available for this

application. The torroidal sensor has a 4.8” I.D. (12.192cm)

with a 7.6” O.D. (19.304cm). Its style number

69C3016G01. (See Figure 2.3 and Appendix C)

2.3.1 General

When employing a ground fault scheme, the distribution

system characteristics (i.e. system grounding, number of

sources, number and location of ground points, etc.) must

be considered along with the manner and location in which

the circuit breaker is applied to the system. These elements are discussed in Sections 2.3.2 through 2.3.4.

The Digitrip uses two modes of sensing to detect ground

fault currents: residual and zero sequence (See T able 2.1).

The breaker’s secondary contact inputs B-6, B-7, that

were shown in Figure 1.6, are used to configure the

breaker cell positions for the two schemes. Having no

jumper from B-6 to B-7 programs the unit for a residual

ground fault scheme, while installing a jumper from B-6 to

B-7 programs the unit for zero sequence configuration. If

present, this jumper resides on the stationary side of the

switchgear assembly . The proper current sensor input is

required on the external sensor input terminals B-4, B-5 of

the breaker secondary contacts.

Ground (Earth)

Fault

Sensing Method

Residual No Jumper 2.2 element R5

Zero Sequence Jumper B6 to B7 2.3 element R4

Breaker Se condary

Contacts Req’d Figure

Ref

Digitrip GF

Sensing

Element Used

Figure 2.1 Zero Sequence Current T ransformer

2.3.3 Residual Sensing

Residual is the standard operating mode of ground fault

sensing. This mode utilizes one current sensor on each

phase conductor (See Figure 2.2). If the system neutral is

grounded, but no phase to neutral loads are used, the

Digitrip includes all of the components necessary for

ground fault protection. This mode of sensing vectorily

sums the outputs of the three or four individual CH T ype-V

current sensors. Residual ground fault sensing features

are adaptable to main and feeder breaker applications.

T able 2.1 Digitrip Sensing Modes

Effective 8/2006

Page 10

A

A

A

I.L. 66A7534H04

2.3.4 Ground Fault Settings

The adjustment of the ground fault functional settings

(FLA T response or I

2

t) is discussed in Section 4.8. The

effect of these settings is illustrated in the ground fault

time-current curve referenced in Section 9. The residual

ground fault pick-up settings are from 0.25x, 0.3x, 0.35x,

0.4x, 0.5x, 0.6x, 0.75x and OFF.

Source

L

A

L

B

L

C

CAUTION

IF THE PHASE CONNECTIONS ARE INCORRECT , A

NUISANCE TRIP MA Y OCCUR. ALW A YS OBSER VE THE

POLARITY MARKINGS ON THE INST ALLA TION DRA WINGS. TO INSURE CORRECT GROUND F AUL T EQUIPMENT PERFORMANCE, CONDUCT FIELD TESTS TO

INSURE PROPER GROUND F AULT FUNCTIONALITY.

Black

K1-2

K1-3

Digitrip 520V

or 520MCV

Trip

Actuator

+

-

10:1

K1-9

K1-8

K1-7

1

K1-6

R/1

A-4

-19

A-5

-20

CSA1

CSA2

CSB1

CSB2

K1-5

R/1

A-6

-21

B-5

B-4

CSC1

CSC2

X1

X2

K1-4

K2-9

K2-8

10:1 AUX. CT

Load

Notes:

1

In this scheme, all breaker secondary currents (at the 100 mA level) are summed together at the PC

board donut transformer to sense ground fault via element R5.

2

Do not jumper secondary contacts B-6, B-7. This will defeat the residual ground fault protection.

R5

Figure 2.2 Breaker Using Residual GF Sensing

Effective 8/2006

I.L. 66A7534H04

A

B

C

100A 69C3011H01 3.42 5.35 1.55

2 X

17

1:1

0

0

200A 3.42 5.35 1.55

1

7

1

: 2

0

0

250A 3.42 5.35 1.55

1

8

1

: 2

5

0

300A 3.42 5.35 1.55

1

8

1

: 3

0

0

400A 3.42 5.35 1.55

1

7

1

: 4

0

0

600A 3.42 5.35 1.55

1

8

1

: 6

0

0

630A 3.42 5.35 1.55

1

8

1:

6

3

0

800A 3.42 5.35 1.55

1

9

1

:

80

0

1000A 3.42 5.35 1.55

1

9

1

:10

0

0

1200A 3.42 5.35 1.55

1

9

1

:12

0

0

1250A 3.42 5.35 1.55

1

9

1

:12

5

0

1600A

2000A

3.42

3.42

5.35

5.35

1.55

1.55

2

0

2

1

1:1

600

1

:

20

0

0

3.0

6

1.1

7

4

.67

7

.25

2

.

2

9

2.9

3

1

.

871

.

2

1

0.4

7

0.6

10.

5

6

0

.

310

.

0

9

R

d

c

(O

h

m

s +

/

-

1

5

%

)

RAT

I

O

W

IRE

G

A

U

G

E

C (max)B (max)A (min )DESCRIPTION

POLARITY MARK SECONDARY “X1

”

L

A

B

E

L

2

.

0

0.7

5

LA

B

EL

INF

O

R

M

A

TIO

N

:

CU

TLE

R-H

A

M

M

E

R P

A

R

T N

U

M

BER

RA

T

ING

C-

H

Ty

p

e

V

C

U

R

REN

T S

E

N

S

O

R

DA

T

E C

O

D

E (

YR

M

O

D

Y L

O

C

)

69C3011H02

69C3011H2 5

69C3011H03

69C3011H04

69C3011H06

69C3011H63

69C3011H08

69C3011H10

69C3011H12

69C3011H13

69C3011H16

69C3011H20

2 x 10-32 Bra ss

Slot Head Terminal Screws

POLARITY MARK PRIMARY “H1”

2500A

6

9C3

0

1

1

H

5

2

3.4

2

5.35 1. 55

1

: 2

5

0

0

8.9021

Page 11

R/1

R/1

Figure 2.3 Zero Sequence Sensing Scheme

Figure 2.4 Digitrip Phase Sensor (CH T ype-V)

Effective 8/2006

Loading...

Loading...