Eaton DG1-347D6FB-C21C Quick Start Manual

PowerXL DG1 Series VFD

Courtesy of CMA/Flodyne/Hydradyne ▪ Motion Control ▪ Hydraulic ▪ Pneumatic ▪ Electrical ▪ Mechanical ▪ (800) 426-5480 ▪ www.cmafh.com

Quick Start Guide

Effective March 2014

New Information

CONTENTS

Step 1—PowerXL DG1 Series Overview . . . . . . . 1

Step 2—Keypad Operation Overview . . . . . . . . . 3

Step 3—Menu Navigation . . . . . . . . . . . . . . . . . . 6

Step 4—Startup Wizard . . . . . . . . . . . . . . . . . . . . 8

Step 5—Standard Parameter List . . . . . . . . . . . . 9

Step 6—Faults and Warning Codes . . . . . . . . . . . 26

Courtesy of CMA/Flodyne/Hydradyne ▪ Motion Control ▪ Hydraulic ▪ Pneumatic ▪ Electrical ▪ Mechanical ▪ (800) 426-5480 ▪ www.cmafh.com

Step 1—PowerXL DG1 Series Overview

Courtesy of CMA/Flodyne/Hydradyne ▪ Motion Control ▪ Hydraulic ▪ Pneumatic ▪ Electrical ▪ Mechanical ▪ (800) 426-5480 ▪ www.cmafh.com

Step 1—PowerXL DG1 Series Overview

This chapter describes the purpose and contents of this

manual, the receiving inspection recommendations and the

DG1 Series Open Drive catalog numbering system.

How to Use this Manual

The purpose of this manual is to provide you with information

necessary to install, set and customize parameters, start up,

troubleshoot and maintain the Eaton DG1 Series adjustable

frequency drive (AFD). To provide for safe installation and

operation of the equipment, read the safety guidelines at the

beginning of this manual and follow the procedures outlined

in the following chapters before connecting power to the

DG1 Series AFD. Keep this operating manual handy and

distribute to all users, technicians and maintenance

personnel for reference.

Receiving and Inspection

The DG1 Series AFD has met a stringent series of factory

quality requirements before shipment. It is possible that

packaging or equipment damage may have occurred during

shipment. After receiving your DG1 Series AFD, please

check for the following:

Check to make sure that the package includes the Instruction

Leaflet (IL040016EN), Quick Start Guide (MN040006EN),

User Manual CD (CD040002EN) and accessory packet. The

accessory packet includes:

●

Rubber grommets

●

Control cable grounding clamps

●

Additional grounding screw

Inspect the unit to ensure it was not damaged during

shipment.

Make sure that the part number indicated on the nameplate

corresponds with the catalog number on your order.

If shipping damage has occurred, please contact and file a

claim with the carrier involved immediately.

If the delivery does not correspond to your order, please

contact your Eaton Electrical representative.

Note: Do not destroy the packing. The template printed

on the protective cardboard can be used for marking

the mounting points of the DG1 AFD on the wall or

in a cabinet.

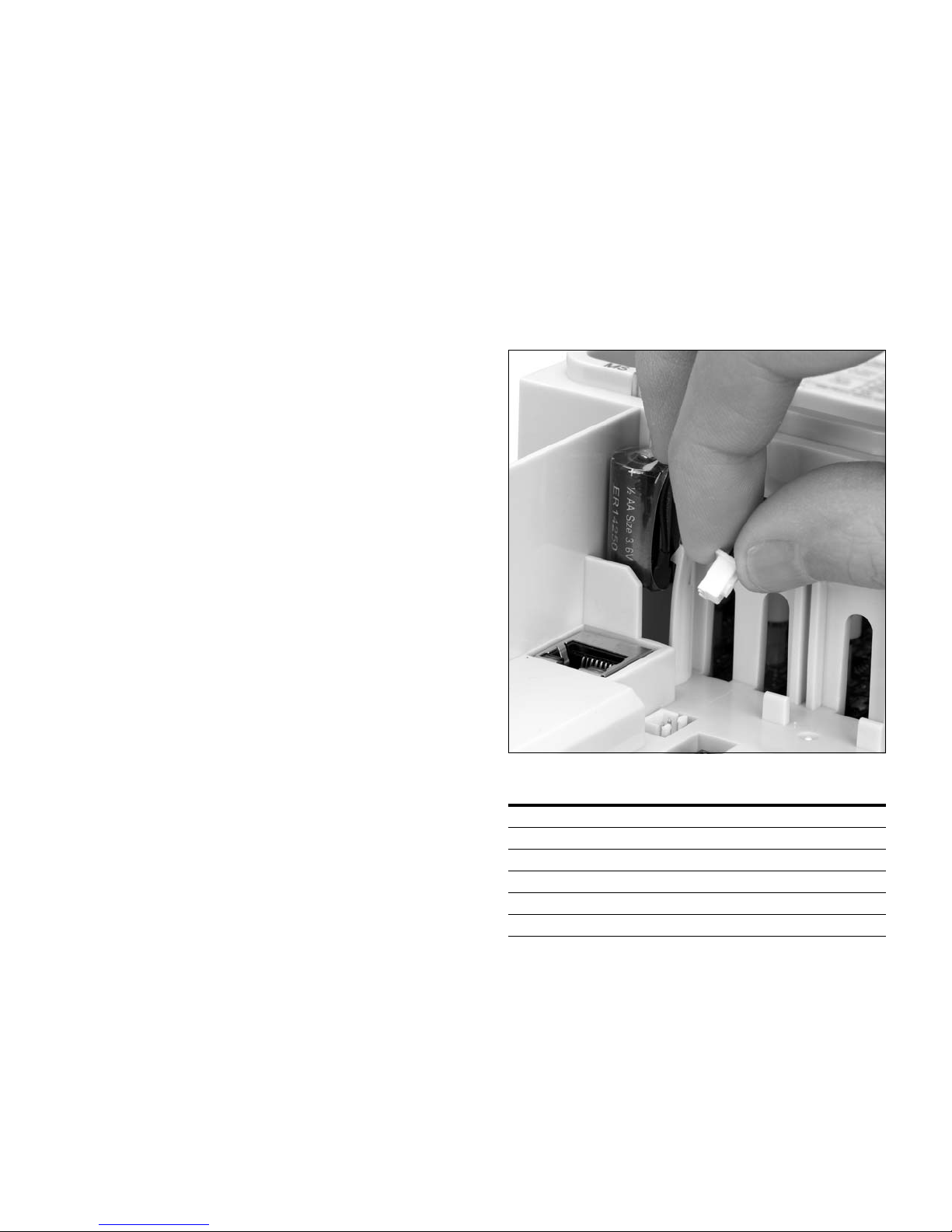

Real Time Clock Battery Activation

To activate the real time clock (RTC) functionality in the

PowerXL DG1 Series AFD, the RTC battery (already mounted

in the drive) must be connected to the control board.

Simply remove the primary drive cover, locate the RTC

battery directly below the keypad, and connect the white

2-wire connector to the receptacle on the control board.

Figure 1. RTC Battery Connection

Table 1. Common Abbreviations

Abbreviation Definition

CT Constant torque with high overload rating (150%)

VT Variable torque with low overload rating (110%)

I

H

I

L

AFD Adjustable Frequency Drive

VFD Variable Frequency Drive

High Overload (150%)

Low Overload (110%)

PowerXL DG1 Series Adjustable Frequency Drives MN040012EN—March 2014 www.eaton.com 1

Step 1—PowerXL DG1 Series Overview

Contains

EAN Code

Date Code: 20131118

Contains

NAED Code

Programmable

Soft Key 2

Change Control

Place Between

Local and Remote

Move Cursor

Right

Start Button

Stop Button

Back/Reset

Button

Increase

Value Scroll

Menu Up

Programmable

Soft Key 1

Decrease Value

Scroll Menu Down

Move Cursor

Left

Enter Menu

Conrm Selection

Courtesy of CMA/Flodyne/Hydradyne ▪ Motion Control ▪ Hydraulic ▪ Pneumatic ▪ Electrical ▪ Mechanical ▪ (800) 426-5480 ▪ www.cmafh.com

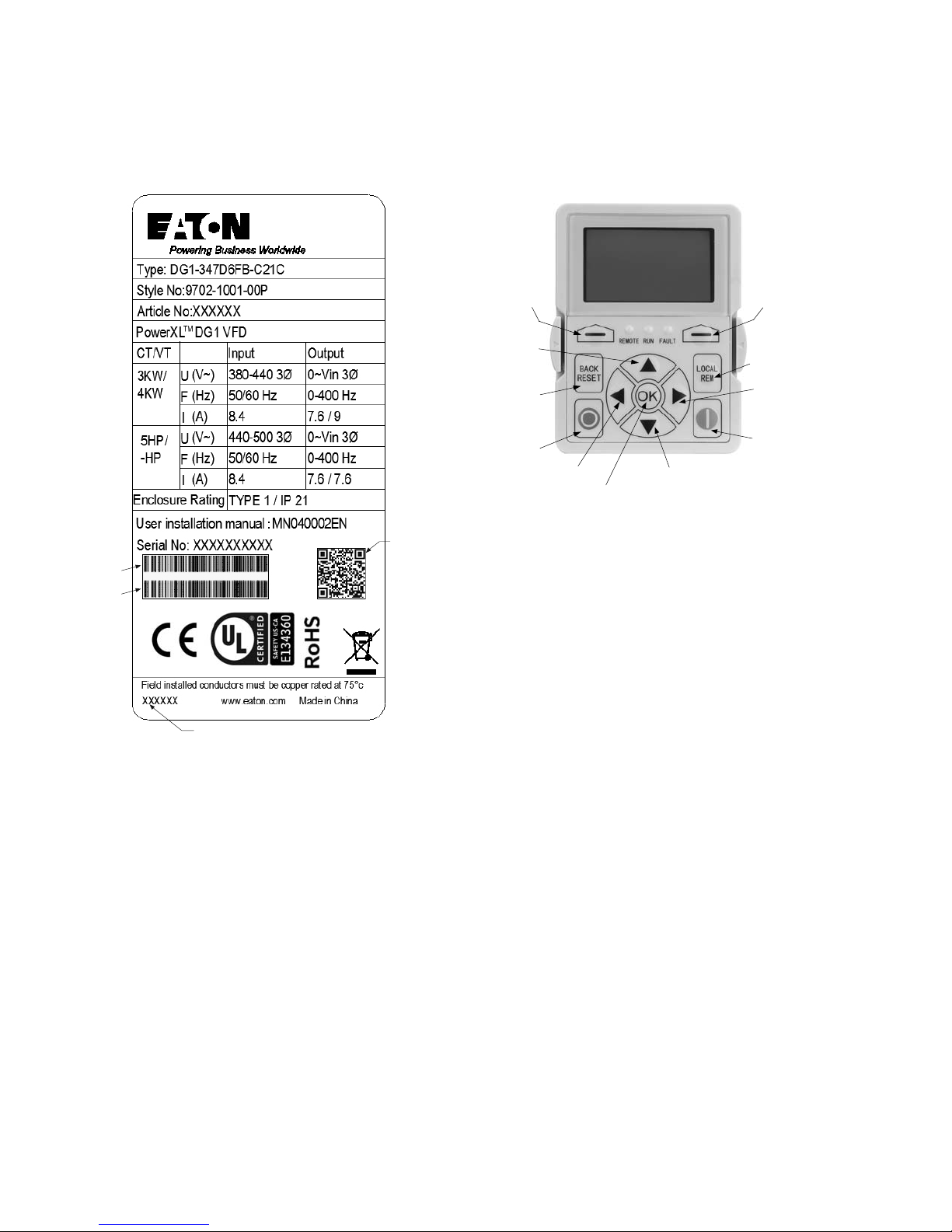

Rating Label

Figure 2. Rating Label

Contains

SN, PN,

Type, Date

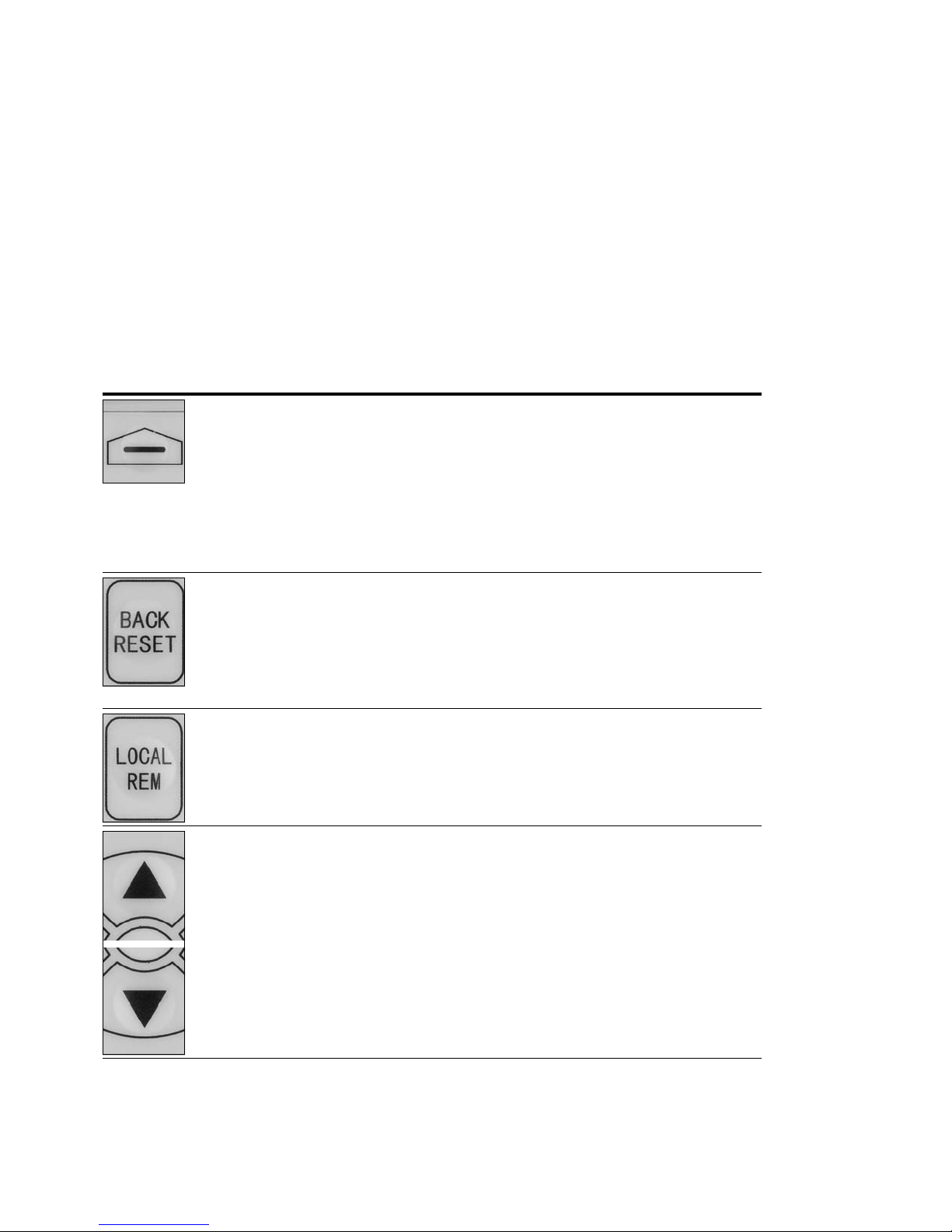

Keypad Overview

Figure 3. Keypad and Display

Carton Labels (U.S. and Europe)

Same as rating label shown above.

2 PowerXL DG1 Series Adjustable Frequency Drives MN040012EN—March 2014 www.eaton.com

Step 2—Keypad Operation Overview

Courtesy of CMA/Flodyne/Hydradyne ▪ Motion Control ▪ Hydraulic ▪ Pneumatic ▪ Electrical ▪ Mechanical ▪ (800) 426-5480 ▪ www.cmafh.com

The keypad is the interface between the drive and the user.

It features an LCD display, 3 LED lights and 11 buttons. With

the control keypad, it is possible to control the speed of a

motor, to supervise the state of the equipment and to set the

frequency converter’s parameters. See Figure 3.

Keypad Buttons

Step 2—Keypad Operation Over view

Buttons Description

Table 2. Keypad Buttons

Icon Button Description

Soft Key 1,

Soft Key 2

Back/Reset Back/Reset:

Local/Remote Local/Remote:

Soft Key 1, Soft Key 2:

The functions of these two buttons shall be the following:

Forward/Reverse, this shall change motor’s run direction.

Reset, this shall ask MCU to reset after some parameters are modified.

• Menu, this shall return to main menu.

• Details, this shall display the details of the fault.

• Bypass, this shall make drive go into bypass.

• Jog, this shall activate jog.

• Favorite, this shall add this parameter to the Favorite menu.

• Delete, this shall delete this parameter from the Favorite menu.

This button has three integrated functions. The button operates as backward button

during normal mode.

In edit mode, it is used as cancel operate. It is also used to reset faults when faults occur.

• Backs up one step.

• Cancels Modify in edit mode.

• Resets the active faults (all the active faults shall be reset by pressing this button

more than 2s in any page).

Switches between LOCAL and REMOTE control for start and speed reference. The control

locations corresponding to local and remote shall be selected within an application.

Up

Down

PowerXL DG1 Series Adjustable Frequency Drives MN040012EN—March 2014 www.eaton.com 3

Up and Down Arrows:

• Move either up or down a menu list to select the desired menu item.

• Editing a parameter bit by bit, while the active digit is scrolled.

• Increase/decrease the reference value of the selected parameter.

• In parameter comparison mode, scroll through the parameters of which current

value is different from comparison parameter value.

• In parameter page when in read mode, move to the previous or next brother

parameter of this parameter.

Step 2—Keypad Operation Over view

Courtesy of CMA/Flodyne/Hydradyne ▪ Motion Control ▪ Hydraulic ▪ Pneumatic ▪ Electrical ▪ Mechanical ▪ (800) 426-5480 ▪ www.cmafh.com

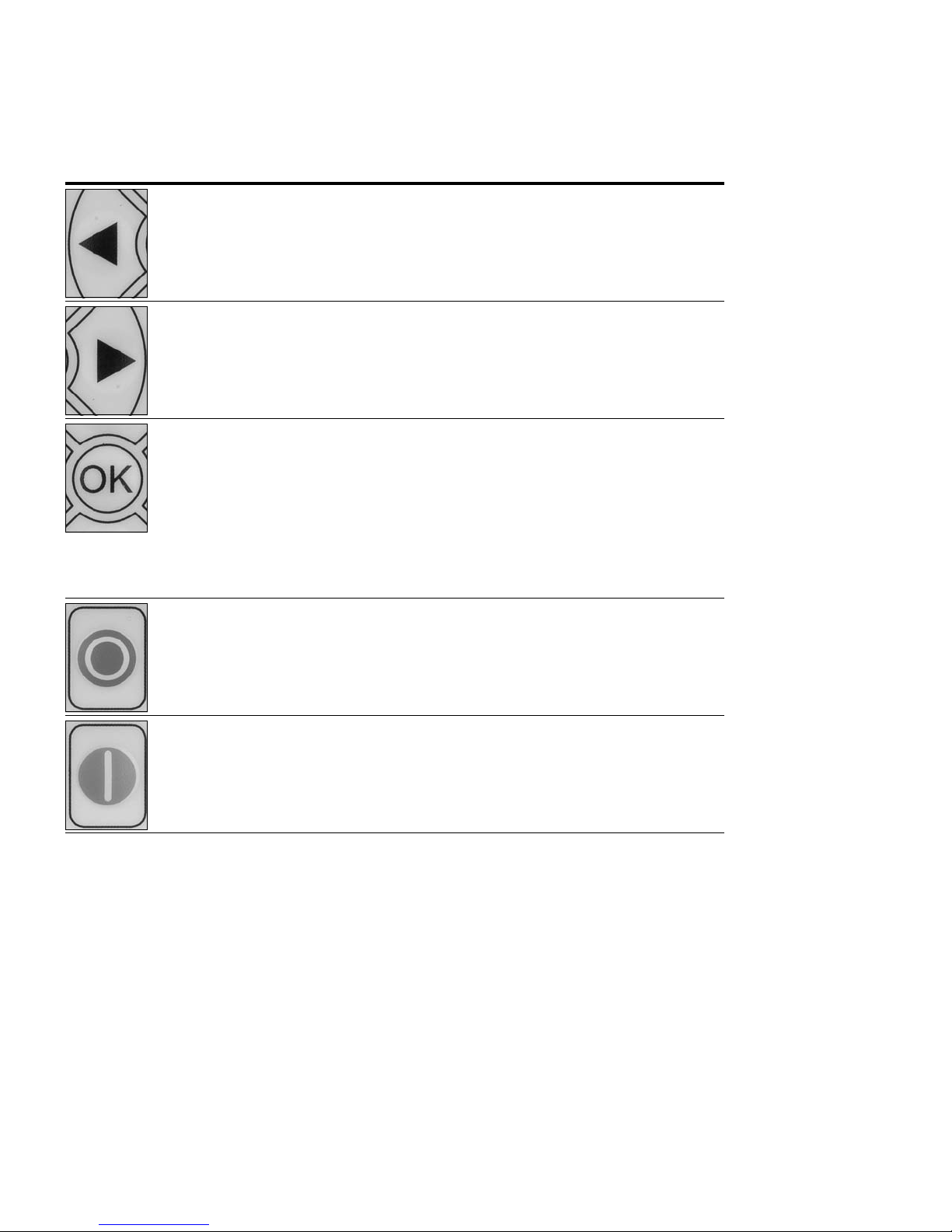

Table 2. Keypad Buttons, continued

Icon Button Description

Left Left Arrow:

• Navigation button, movement to left when editing a parameter digit by digit.

• Backs up one step.

Right Right Arrow:

• Enter parameter group mode.

• Enter parameter mode from group mode.

• Enter parameter whole edit mode when this parameter can be written.

• Enter parameter bit by bit edit mode from whole edit mode.

• Navigation button, movement to right when editing a parameter bit by bit.

OK OK:

• To clear all the Fault History if pressed for more than 5s (including 5s) in any

page.

• This button is used in the parameter edit mode to save the parameter setting.

• To confirm the start-up list at the end of the Start-Up Wizard.

• To confirm the comparison item in parameters comparison mode.

The following is the same with Right key:

• Enter parameter whole edit mode when this parameter can be written.

• Enter parameter group mode.

• Enter parameter mode from group mode.

Stop Stop:

This button operates as motor stop button for normal operation when the “Keypad” is

selected as the control source and keypad stop button is active, or stop button is always

enabled regardless of control source.

• Motor stop from the keypad.

Start Start:

This button operates as motor start button for normal operation when the “Keypad” is

selected as the active control source.

4 PowerXL DG1 Series Adjustable Frequency Drives MN040012EN—March 2014 www.eaton.com

Step 2—Keypad Operation Over view

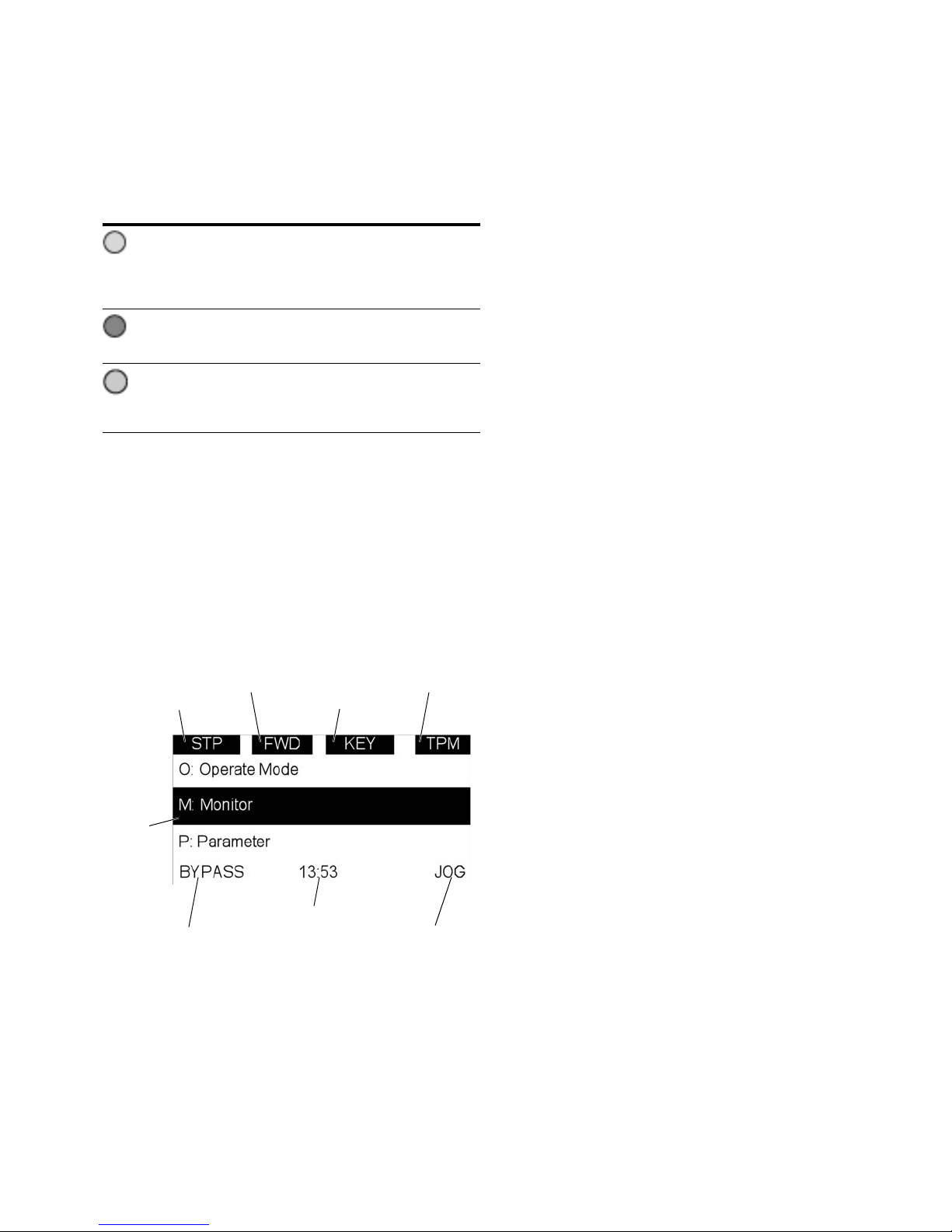

Drive Status

Direction Status

Control Place

Menu Location

Soft Key 2

Function Label

Soft Key 1

Function Label

Real Time Clock

(hh:mm)

Active

Selection

Courtesy of CMA/Flodyne/Hydradyne ▪ Motion Control ▪ Hydraulic ▪ Pneumatic ▪ Electrical ▪ Mechanical ▪ (800) 426-5480 ▪ www.cmafh.com

LED Lights

Table 3. LED State Indicators

Indicator Description

Run:

Indicates that the VFD is running and controlling the load in

Run

Drive or Bypass.

Blinks when a stop command has been given but the drive is

still ramping down.

Fault:

Turn on when there is one or more active drive fault(s).

Fault

Blinks when there is one or more active drive warning(s).

Local/Remote:

Local: If the local control place is selected, turn off the light.

Remote

Remote: If the remote control place is selected, turn on the

light.

LCD Display

The keypad LCD indicates the status of the motor and the

drive and any faults in motor or drive functions. On the LCD,

the user sees information about the current location in the

menu structure and the item displayed.

Overview

Five lines shall be displayed in the screen. General view is as

following in Figure 4.

Figure 4. General View of LCD

The lines definition is as below:

The first line is State line, shows:

●

RUN / STP / NRD—If motor is running, the run state shall

display “RUN”, otherwise the state display “STP”. “RUN”

blinks when the stop command is sent but the drive is

decelerating. “NRD” is displayed if the drive is not ready or

does not have a signal

●

FWD / REV—If the motor running direction is clockwise,

display “FWD”, otherwise display “REV”

●

KEY / I/O / BPS / BUS—If it is in bypass currently, display

“BPS”; otherwise, if the current control source is I/O

terminal, display “I/O”. If it is keypad, then display “KEY”;

otherwise display “BUS”

●

PAR / MON / FLT / OPE / QSW / FAV / TPM—If the

current page is parameter menu, display “PAR”; If monitor

menu, then display “MON”; If fault menu, then display

“FLT”; If operation menu, then display “OPE”; If quick

start wizard, then display “QSW”; If optional card menu,

then display “BOA”; If favorite menu, then display “FAV”;

If main menu, then display “TPM”

The second line is Code line, shows the menu code.

The third line is Name line, shows the menu name or

parameters name.

The fourth line is Value line, shows the submenu name or

parameters value.

The fifth line is Soft key line, the functions of Soft key 1 and

Soft key 2 are changeable, and the real time is in the middle.

PowerXL DG1 Series Adjustable Frequency Drives MN040012EN—March 2014 www.eaton.com 5

Step 3—Menu Navigation

Courtesy of CMA/Flodyne/Hydradyne ▪ Motion Control ▪ Hydraulic ▪ Pneumatic ▪ Electrical ▪ Mechanical ▪ (800) 426-5480 ▪ www.cmafh.com

Step 3—Menu Navigation

Menu Structure

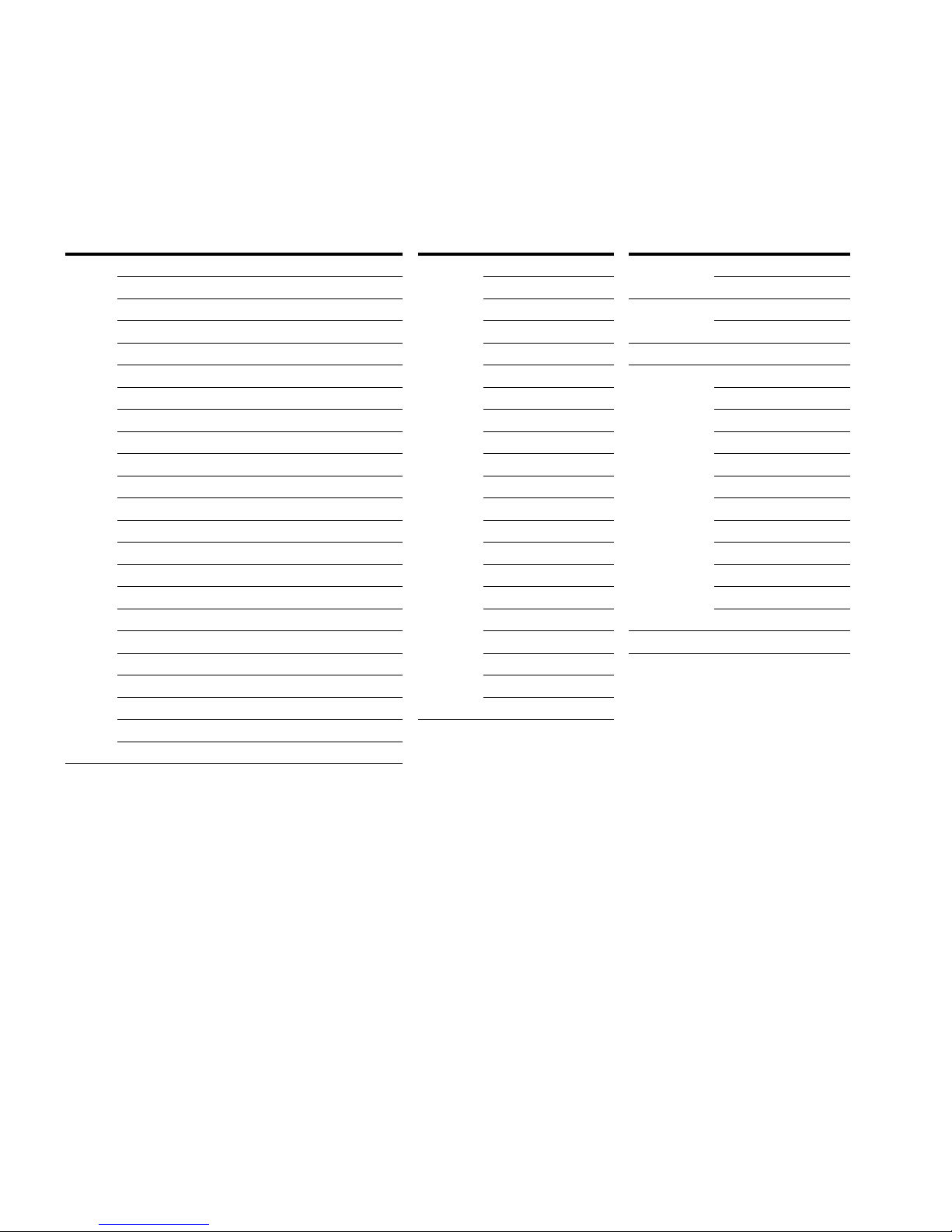

Table 4. Keypad Menus

Item Description Item Description Item Description

Monitor M1—Output Frequency M24—Interval 3 Parameters P1—Basic Parameters Fault F1—Active Fault

M2—Freq Reference M25—Interval 4 P2—Analog Input F2—History Fault

M3—Motor Speed M26—Interval 5 P3—Digital Input Optional Boards B1—SlotA

M4—Motor Current M27—Timer 1 P4—Analog Output B2—SlotB

M5—Motor Torque M28—Timer 2 P5—Digital Output Favorite —

M6—Motor Power M29—Timer 3 P6—Logic Function Operate Mode O1—Output Frequency

M7—Motor Voltage M30—PID1 Set Point P7—Drive Control O2—Freq Reference

M8—DC-link Voltage M31—PID1 Feedback P8—Motor Control O3—Motor Speed

M9—Unit Temperature M32—PID1 Error Value P9—Protections O4—Motor Current

M10—Motor Temperature M33—PID1 Output P10—PID Controller1 05—Motor Torque

M11—Torque Reference M34—PID1 Status P11—PID Controller2 O6—Motor Power

M12—Analog Input 1 M35—PID2 Set Point P12—Preset Speed O7—Motor Voltage

M13—Analog Input 2 M36—PID2 Feedback P13—Torque Control O8—DC-Link Voltage

M14—Analog Output 1 M37—PID2 Error Value P14—Brake O9—Unit Temperature

M15—Analog Output 2 M38—PID2 Output P15—Fire Mode O10—Motor Temperature

M16—DI1, DI2, DI3 M39—PID2 Status P16—Second Motor Para O11—Keypad Torque Ref

M17—DI4, DI5, DI6 M40—Running Aux Drives P17—Bypass 012—Keypad Reference

M18—DI7, DI8 M41—PT100 Temp P18—Multi-Pump Ctrl Startup Wizard S—Startup Wizard

M19—DO1 M42—Last Active Fault P19—Real Time Clock

M20—RO1, RO2, RO3 M43—RTC Battery Status P20—Communication

M21—TC1, TC2, TC3 M44—I

M22—Interval 1 M45—Energy Savings

M23—Interval 2 M46—Multi-Monitoring

nstance Motor Power

P21—System

Note: Will vary depending on application selected.

6 PowerXL DG1 Series Adjustable Frequency Drives MN040012EN—March 2014 www.eaton.com

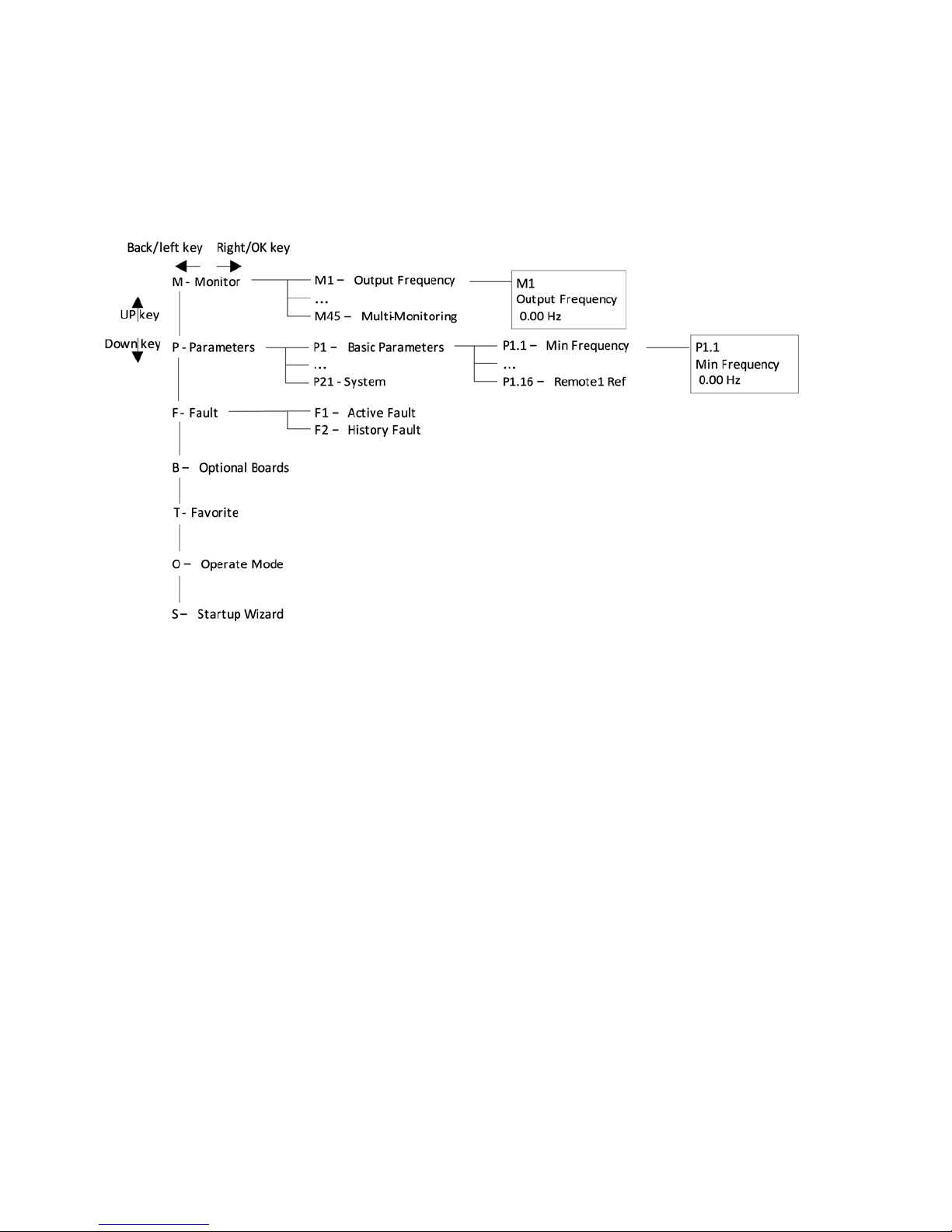

Menu Navigation

Courtesy of CMA/Flodyne/Hydradyne ▪ Motion Control ▪ Hydraulic ▪ Pneumatic ▪ Electrical ▪ Mechanical ▪ (800) 426-5480 ▪ www.cmafh.com

This section provides basic instruction on navigating each

section in the menu structure.

Figure 5. Main Menu Navigation

Step 3—Menu Navigation

PowerXL DG1 Series Adjustable Frequency Drives MN040012EN—March 2014 www.eaton.com 7

Step 4—Startup Wizard

Courtesy of CMA/Flodyne/Hydradyne ▪ Motion Control ▪ Hydraulic ▪ Pneumatic ▪ Electrical ▪ Mechanical ▪ (800) 426-5480 ▪ www.cmafh.com

Step 4—Startup Wizard

Startup Wizard

In the Startup Wizard, you will be prompted for essential

information needed by the drive so that it can start

controlling your process. In the Wizard, you will need

the following keypad buttons:

Up/Down buttons.

Use these to change value.

OK button.

Confirm selection with this button, and enter into

next question.

Back/Reset button.

If this button was pressed at the first question,

the Startup Wizard will be cancelled.

Once you have connected power to your Eaton PowerXL

DG1 frequency converter, and the Startup Wizard is enabled,

follow these instructions to easily set up your drive.

Table 5. Startup Wizard Instructions

Item Description

1 Startup Wizard Press OK?

2 Language 0 = English

1 = ѝ᮷

2 = Deutsch

3 Real Time Clock yy.mm.dd

hh:mm:ss

4 Daylight Saving 0 = Off

1 = EU

2 = US

5 Application 0 = Standard

1 = Multi-Pump

2 = Multi-PID

3 = Multi-Purpose

6 Min Frequency Min: 0.00Hz

Max: Max Frequency

7 Max Frequency Min: Min Frequency

Max: 400.00Hz

8 Motor Nom Current Min: 0.1A

Max: 500.0A

9 Current Limit Min: Ih*1/10

Max: Ih*2

10 Motor Nom Speed Min: Ih*1/10

Max: Ih*2

11 Motor PF Min: 0.30

Max: 1.0

12 Motor Nom Volt Min: 180V

Max: 690V

13 Motor Nom Freq Min: 30.00 Hz

Max: 400.00 Hz

14 Motor Nom Power Min: 0.1 kW

Max:5000.0 kW

15 Application Mini-Wizard Press OK?

8 PowerXL DG1 Series Adjustable Frequency Drives MN040012EN—March 2014 www.eaton.com

Now the Startup Wizard is done. It won’t show again when

next power up. If you want to reset it, please set the Startup

Wizard (P21.1.9) or select it from the main menu screen to

enable and cycle the power to the drive.

Loading...

Loading...