Eaton DG1-32012FB-C21C, DG1-323D7FB-C21C, DG1-324D8FB-C21C, DG1-32025FB-C21C, DG1-32048FB-C21C Installation Manual

...

PowerXL DG1 Series VFD

Installation Manual

Effective March 2014

New Information

Disclaimer of Warranties and Limitation of Liability

The information, recommendations, descriptions, and safety notations in this document are

based on Eaton’s experience and judgment and may not cover all contingencies. If further

information is required, an Eaton sales office should be consulted. Sale of the product shown

in this literature is subject to the terms and conditions outlined in appropriate Eaton selling

policies or other contractual agreement between Eaton and the purchaser.

THERE ARE NO UNDERSTANDINGS, AGREEMENTS, WARRANTIES, EXPRESSED OR

IMPLIED, INCLUDING WARRANTIES OF FITNESS FOR A PARTICULAR PURPOSE OR

MERCHANTABILITY, OTHER THAN THOSE SPECIFICALLY SET OUT IN ANY EXISTING

CONTRACT BETWEEN THE PARTIES. ANY SUCH CONTRACT STATES THE ENTIRE

OBLIGATION OF EATON. THE CONTENTS OF THIS DOCUMENT SHALL NOT BECOME

PART OF OR MODIFY ANY CONTRACT BETWEEN THE PARTIES.

In no event will Eaton be responsible to the purchaser or user in contract, in tort (including

negligence), strict liability, or otherwise for any special, indirect, incidental, or consequential

damage or loss whatsoever, including but not limited to damage or loss of use of equipment,

plant or power system, cost of capital, loss of power, additional expenses in the use of

existing power facilities, or claims against the purchaser or user by its customers resulting

from the use of the information, recommendations, and descriptions contained herein. The

information contained in this manual is subject to change without notice.

Cover Photo: Eaton PowerXL DG1 Series Drive

PowerXL DG1 Series VFD

PowerXL DG1 Series VFD MN040002EN—March 2014 www.eaton.com i

PowerXL DG1 Series VFD

Support Services

Support Services

The goal of Eaton is to ensure your greatest possible satisfaction with the operation of our

products. We are dedicated to providing fast, friendly, and accurate assistance. That is why

we offer you so many ways to get the support you need. Whether it is by phone, fax, or

email, you can access Eaton’s support information 24 hours a day, seven days a week.

Our wide range of services is listed below.

You should contact your local distributor for product pricing, availability, ordering, expediting,

and repairs.

Website

Use the Eaton Website to find product information. You can also find information on local

distributors or Eaton’s sales offices.

Website Address

www.eaton.com/drives

EatonCare Customer Support Center

Call the EatonCare Support Center if you need assistance with placing an order, stock

availability or proof of shipment, expediting an existing order, emergency shipments, product

price information, returns other than warranty returns, and information on local distributors or

sales offices.

Voice: 877-ETN-CARE (386-2273) (8:00 a.m.–6:00 p.m. EST)

After-Hours Emergency: 800-543-7038 (6:00 p.m.–8:00 a.m. EST)

Drives Technical Resource Center

Voice: 877-ETN-CARE (386-2273) option 2, option 6

(8:00 a.m.–5:00 p.m. Central Time U.S. [UTC –6])

email: TRCDrives@Eaton.com

For Customers in Europe, Contact

Phone: +49 (0) 228 6 02-3640

Hotline: +49 (0) 180 5 223822

email: AfterSalesEGBonn@Eaton.com

www.eaton.com/moeller/aftersales

ii PowerXL DG1 Series VFD MN040002EN—March 2014 www.eaton.com

Table of Contents

SAFETY

Before Commencing the Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Definitions and Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Hazardous High Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Warnings and Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Motor and Equipment Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

CHAPTER 1—DG1 SERIES OVERVIEW

How to Use this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Receiving and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Real Time Clock Battery Activation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Rating Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Carton Labels (U.S. and Europe) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Catalog Number System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Power Ratings and Product Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

CHAPTER 2—ENGINEERING CONSIDERATIONS

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Electrical Power Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Input Voltage and Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Input Voltage Balance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Total Harmonic Distortion (THD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Reactive Power Compensation Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

PowerXL DG1 Series VFD

CHAPTER 3—PRODUCT OVERVIEW

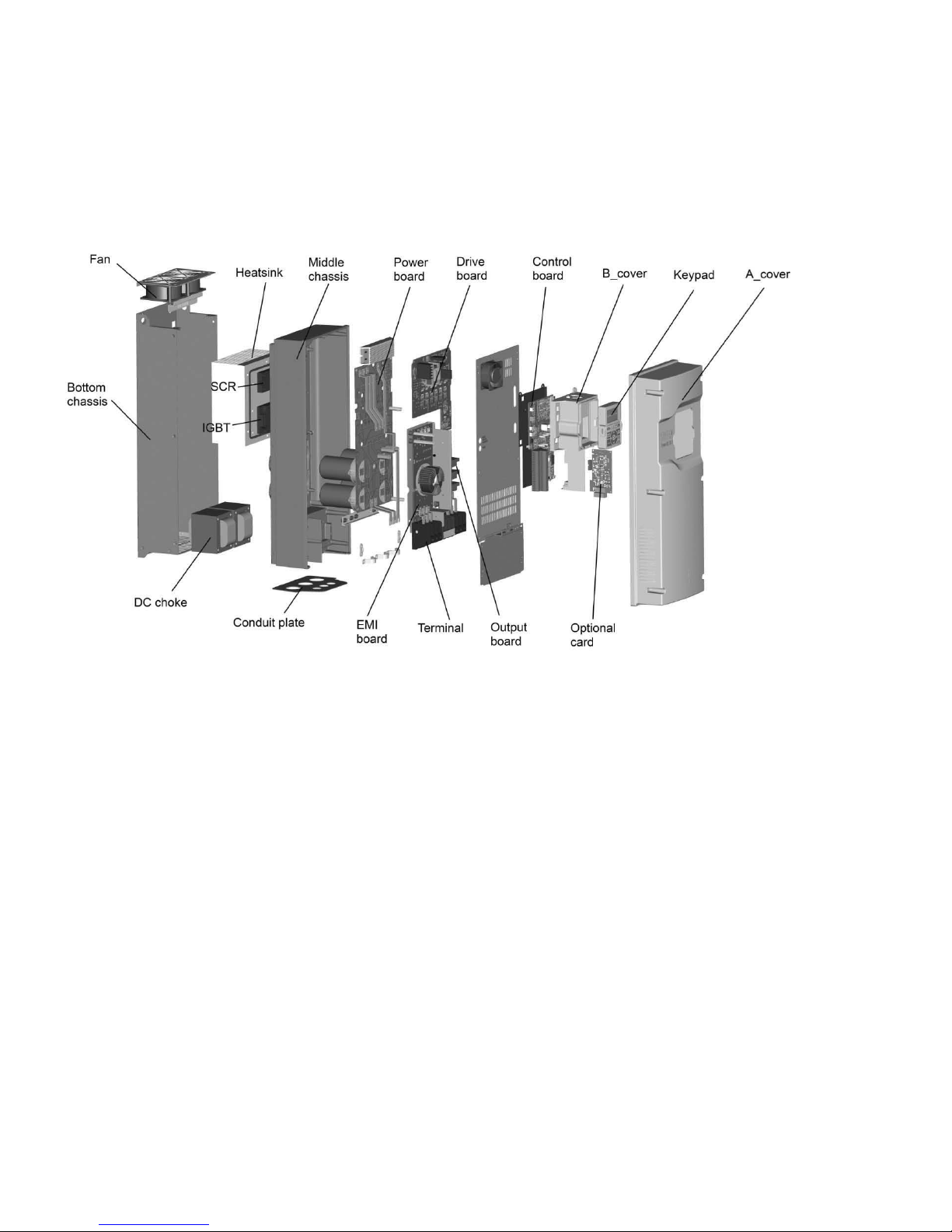

Component Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Selection Criteria . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Proper Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Maintenance and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Service and Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

CHAPTER 4—SAFETY AND SWITCHING

Fuses and Cable Cross-Sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Cables and Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Residual-Current Device (RCD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Input Contactor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

EMC Measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

CHAPTER 5—MOTOR AND APPLICATION

Motor Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Connecting Motors in Parallel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Parallel Connection of Several Motors to One Frequency Inverter . . . . . . . . . . 20

Motor and Circuit Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Bypass Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Connecting EX Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

PowerXL DG1 Series VFD MN040002EN—March 2014 www.eaton.com iii

PowerXL DG1 Series VFD

Table of Contents, continued

CHAPTER 6—INSTALLATION REQUIREMENTS

Electrical Installation Warnings and Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Standard Mounting Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Standard Drive Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Power Wiring Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Cable Selection: Power and Motor Leads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Line (Mains) and Motor Cable Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Connection Tightening Torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Cable Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Wiring the VFD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Rubber Grommet Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Safe Torque Off (STO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Connection to Power Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Three-Phase Input Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Terminal Designations in the Power Section . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Ground Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Product Modified Sticker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Checking the Cable and Motor Insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

CHAPTER 7—EMC INSTALLATION

EMC Measures in the Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Earthing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Screen Earth Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Installation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

International EMC Protection Cable Requirements . . . . . . . . . . . . . . . . . . . . . . 42

Installation in Corner-Grounded Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Installation in IT System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

APPENDIX A—TECHNICAL DATA AND SPECIFICATIONS

APPENDIX B—INSTALLATION GUIDELINES

Cable and Fuse Sizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Temperature Deratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Heat Loss Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Brake Resistor Sizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

APPENDIX C—DIMENSION DRAWINGS

APPENDIX D—SAFETY INSTRUCTIONS FOR UL AND CUL

UL Standards Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Field Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

iv PowerXL DG1 Series VFD MN040002EN—March 2014 www.eaton.com

List of Figures

Figure 1. RTC Battery Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2. Rating Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Figure 3. Catalog Numbering System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

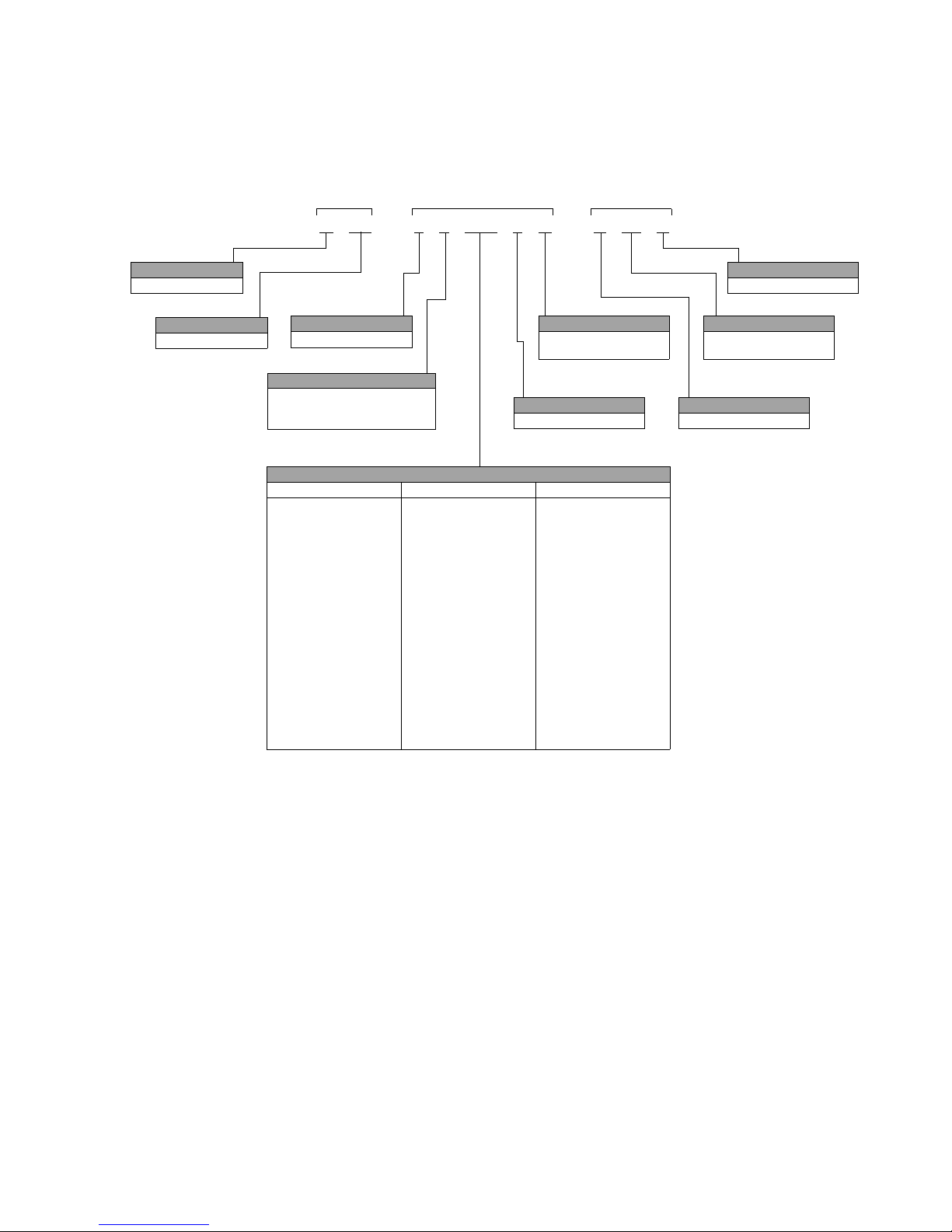

Figure 4. Drive System (PDS = Power Drive System) . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 5. AC Power Networks with Grounded Neutral Point (TN- / TT Networks) . . . . . 10

Figure 6. Description of the DG1 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 7. Block Diagram, Elements of DG1 Frequency Inverters . . . . . . . . . . . . . . . . . . 13

Figure 8. Selection Criteria . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 9. Identification on the FI Circuit Breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 10. EMC Measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 11. Parallel Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 12. Example of a Motor Ratings Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 13. Star and Delta Circuit Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 14. V/Hz Characteristic Curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 15. Bypass Motor Control (Example) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 16. Mounting Space . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 17. Type 1/12 Open Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 18. Input Power and Motor Cable Stripping Lengths . . . . . . . . . . . . . . . . . . . . . 30

Figure 19. Ground Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 20. Terminal Block Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 21. Basic Internal Control Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 22. DG1 Series Adjustable Frequency Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 23. Thermistor STO Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 24. Connection to Power Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 25. Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 26. Product Modified Sticker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 27. EMC-Compliant Setup—460/480 Vac . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 28. Cable Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 29. Locations of the EMC Screw in

Frame 1, Frame 2, Frame 3 and Frame 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 30. Locations of the EMC Screws in Frame 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 31. FR1 Dimension Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure 32. FR1 Dimension Drawing Flange Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Figure 33. FR2 Dimension Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Figure 34. FR2 Dimension Drawing Flange Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Figure 35. FR3 Dimension Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 36. FR3 Dimension Drawing Flange Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Figure 37. FR4 Dimension Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Figure 38. FR4 Dimension Drawing Flange Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 39. FR5 Dimension Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Figure 40. FR5 Dimension Drawing Flange Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

PowerXL DG1 Series VFD

PowerXL DG1 Series VFD MN040002EN—March 2014 www.eaton.com v

PowerXL DG1 Series VFD

List of Tables

Table 1. Common Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Table 2. Type 1/IP21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Table 3. Type 12/IP54 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Table 4. Type 1/IP21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Table 5. Type 12/IP54 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Table 6. Frame 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 7. Frame 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 8. Frame 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 9. Frame 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 10. Frame 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 11. Drive System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 12. Elements of DG1 Frequency Inverters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 13. Maintenance Measures and Intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 14. Maximum Motor Cable Length by Frame Size

without dV/dT Protected C2 Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 15. Assignment of Frequency Inverters to Example Motor Circuit . . . . . . . . . . . . 21

Table 16. Bypass Motor Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 17. Space Requirements for Mounting the DG1 Series VFD and Airflow . . . . . . . 24

Table 18. Mounting Drive Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 19. Tightening Torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 20. Spacing Between Parallel Motor Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 21. Maximum Motor Cable Length by Frame Size

without dV/dT Protected C2 Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 22. Input Power and Motor Cable Stripping and Wire Lengths . . . . . . . . . . . . . . 30

Table 23. I/O Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 24. I/O Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 25. 1st Environment 2nd Environment EMC Levels

According to EN 61800-3 (2004) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 26. Control Wiring Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 27. Cable Categories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 28. PowerXL Series—DG1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Table 29. North America Cable and Fuse Sizes—208 Vac to 240 Vac Ratings . . . . . . . . 46

Table 30. International Cable and Fuse Sizes—208 Vac to 240 Vac Ratings . . . . . . . . . 47

Table 31. North America Cable and Fuse Sizes—440 Vac to 500 Vac Ratings . . . . . . . . 48

Table 32. International Cable and Fuse Sizes—380 Vac to 440 Vac Ratings . . . . . . . . . 49

Table 33. 230V Temperature and Switching Frequency Deratings (VT) . . . . . . . . . . . . . 50

Table 34. 230V Temperature and Switching Frequency Deratings (CT) . . . . . . . . . . . . . 51

Table 35. 460V Temperature and Switching Frequency Deratings (VT) . . . . . . . . . . . . . 52

Table 36. 460V Temperature and Switching Frequency Deratings (CT) . . . . . . . . . . . . . 53

Table 37. Heat Loss Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table 38. Brake Resistor Sizing Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table 39. Fuse Ratings—400V Drive Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Table 40. Fuse Ratings—230V Drive Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Table 41. Required Line and Motor Wire Torque (400V) . . . . . . . . . . . . . . . . . . . . . . . . . 66

Table 42. Required Line and Motor Wire Torque (230V) . . . . . . . . . . . . . . . . . . . . . . . . 67

Table 43. Required Line and Motor Wire Torque (400V) . . . . . . . . . . . . . . . . . . . . . . . . 67

Table 44. Required Line and Motor Wire Torque (230V) . . . . . . . . . . . . . . . . . . . . . . . . 68

vi PowerXL DG1 Series VFD MN040002EN—March 2014 www.eaton.com

Safety

Warning!

Dangerous Electrical Voltage!

Before Commencing the Installation

●

Disconnect the power supply of the device

●

Ensure that devices cannot be accidentally restarted

●

Verify isolation from the supply

●

Earth and short circuit the device

●

Cover or enclose any adjacent live components

●

Only suitably qualified personnel in accordance with

EN 50110-1/-2 (VDE 0105 Part 100) may work on this

device/system

●

Before installation and before touching the device ensure

that you are free of electrostatic charge

●

The functional earth (FE, PES) must be connected to the

protective earth (PE) or the potential equalization. The

system installer is responsible for implementing this

connection

●

Connecting cables and signal lines should be installed so

that inductive or capacitive interference does not impair

the automation functions

●

Install automation devices and related operating elements

in such a way that they are well protected against

unintentional operation

●

Suitable safety hardware and software measures should

be implemented for the I/O interface so that an open

circuit on the signal side does not result in undefined

states in the automation devices

●

Ensure a reliable electrical isolation of the extra-low

voltage of the 24V supply. Only use power supply units

complying with IEC 60364-4-41 (VDE 0100 Part 410) or

HD384.4.41 S2

●

Deviations of the input voltage from the rated value must

not exceed the tolerance limits given in the specifications,

otherwise this may cause malfunction and dangerous

operation

●

Emergency stop devices complying with IEC/EN 60204-1

must be effective in all operating modes of the automation

devices. Unlatching the emergency-stop devices must not

cause a restart

●

Devices that are designed for mounting in housings or

control cabinets must only be operated and controlled after

they have been installed and with the housing closed.

Desktop or portable units must only be operated and

controlled in enclosed housings

PowerXL DG1 Series VFD

●

Measures should be taken to ensure the proper restart of

programs interrupted after a voltage dip or failure. This

should not cause dangerous operating states even for a

short time. If necessary, emergency-stop devices should

be implemented

●

Wherever faults in the automation system may cause

injury or material damage, external measures must be

implemented to ensure a safe operating state in the event

of a fault or malfunction (for example, by means of

separate limit switches, mechanical interlocks, and so on)

●

Depending on their degree of protection, adjustable

frequency drives may contain live bright metal parts,

moving or rotating components, or hot surfaces during and

immediately after operation

●

Removal of the required covers, improper installation, or

incorrect operation of motor or adjustable frequency drive

may cause the failure of the device and may lead to

serious injury or damage

●

The applicable national accident prevention and safety

regulations apply to all work carried out on live adjustable

frequency drives

●

The electrical installation must be carried out in

accordance with the relevant regulations (for example,

with regard to cable cross sections, fuses, PE)

●

Transport, installation, commissioning, and maintenance

work must be carried out only by qualified personnel

(IEC 60364, HD 384 and national occupational safety

regulations)

●

Installations containing adjustable frequency drives must

be provided with additional monitoring and protective

devices in accordance with the applicable safety

regulations. Modifications to the adjustable frequency

drives using the operating software are permitted

●

All covers and doors must be kept closed during operation

●

To reduce hazards for people or equipment, the user must

include in the machine design measures that restrict the

consequences of a malfunction or failure of the drive

(increased motor speed or sudden standstill of motor).

These measures include:

●

Other independent devices for monitoring safety-related

variables (speed, travel, end positions, and so on)

●

Electrical or non-electrical system-wide measures

(electrical or mechanical interlocks)

●

Never touch live parts or cable connections of the

adjustable frequency drive after it has been

disconnected from the power supply. Due to the charge

in the capacitors, these parts may still be live after

disconnection. Fit appropriate warning signs

PowerXL DG1 Series VFD MN040002EN—March 2014 www.eaton.com vii

PowerXL DG1 Series VFD

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

Read this manual thoroughly and make sure you understand

the procedures before you attempt to install, set up, operate

or carry out any maintenance work on this DG1 Adjustable

Frequency Drive.

Definitions and Symbols

WARNING

This symbol indicates high voltage. It calls your attention

to items or operations that could be dangerous to you

and other persons operating this equipment. Read the

message and follow the instructions carefully.

This symbol is the “Safety Alert Symbol.” It occurs with

either of two signal words: CAUTION or WARNING, as

described below.

WARNING

Indicates a potentially hazardous situation which, if not

avoided, can result in serious injury or death.

CAUTION

Indicates a potentially hazardous situation which, if not

avoided, can result in minor to moderate injury, or serious

damage to the product. The situation described in the

CAUTION may, if not avoided, lead to serious results.

Important safety measures are described in CAUTION (as

well as WARNING).

The components in the drive’s power section remain

energized after the supply voltage has been switched off.

After disconnecting the supply, wait at least five minutes

before removing the cover to allow the intermediate

circuit capacitors to discharge.

Pay attention to hazard warnings!

DANGER

5 MIN

Electric shock hazard—risk of injuries! Carry out wiring

work only if the unit is de-energized.

Do not perform any modifications on the AC drive when

it is connected to mains.

Warnings and Cautions

Hazardous High Voltage

WARNING

Motor control equipment and electronic controllers are

connected to hazardous line voltages. When servicing

drives and electronic controllers, there may be exposed

components with housings or protrusions at or above

line potential. Extreme care should be taken to protect

against shock.

●

Stand on an insulating pad and make it a habit to use

only one hand when checking components.

●

Always work with another person in case an

emergency occurs.

●

Disconnect power before checking controllers or

performing maintenance.

●

Be sure equipment is properly earthed.

●

Wear safety glasses whenever working on electronic

controllers or rotating machinery.

Be sure to ground the unit following the instructions in

this manual. Ungrounded units may cause electric shock

and/or fire.

This equipment should only be installed, adjusted, and

serviced by qualified electrical maintenance personnel

familiar with the construction and operation of this type

of equipment and the hazards involved. Failure to

observe this precaution could result in death or severe

injury.

Components within the drive are live when it is

connected to power. Contact with this voltage is

extremely dangerous and may cause death or severe

injury.

Line terminals (L1, L2, L3), motor terminals (U, V, W) and

the DC link/brake resistor terminals (DC–, DC+/R+, R–)

are live when the drive is connected to power, even if the

motor is not running. Contact with this voltage is

extremely dangerous and may cause death or severe

injury.

viii PowerXL DG1 Series VFD MN040002EN—March 2014 www.eaton.com

WARNING

WARNING

WARNING

WARNING

Even though the control I/O-terminals are isolated from

line voltage, the relay outputs and other I/O-terminals

may have dangerous voltage present even when the

drive is disconnected from power. Contact with this

voltage is extremely dangerous and may cause death or

severe injury.

WARNING

This equipment has a large capacitive leakage current

during operation, which can cause enclosure parts to be

above ground potential. Proper grounding, as described

in this manual, is required. Failure to observe this

precaution could result in death or severe injury.

WARNING

Before applying power to this drive, make sure that the

front and cable covers are closed and fastened to prevent

exposure to potential electrical fault conditions. Failure

to observe this precaution could result in death or severe

injury.

WARNING

An upstream disconnect/protective device must be

provided as required by the National Electric Code

(NEC®). Failure to follow this precaution may result in

death or severe injury.

WARNING

This drive can cause a DC current in the protective

earthing conductor. Where a residual current-operated

protective (RCD) or monitoring (RCM) device is used for

protection in case of direct or indirect contact, only an

RCD or RCM of Type B is allowed on the supply side of

this product.

PowerXL DG1 Series VFD

Before opening the drive covers:

●

Disconnect all power to the drive, including external

control power that may be present.

●

Wait a minimum of five minutes after all the lights on

the keypad are off. This allows time for the DC bus

capacitors to discharge.

●

A hazard voltage may still remain in the DC bus

capacitors even if the power has been turned off.

Confirm that the capacitors have fully discharged by

measuring their voltage using a multimeter set to

measure the DC voltage.

Failure to follow these precautions may cause death or

severe injury.

The opening of the branch-circuit protective device may

be an indication that a fault current has been interrupted.

To reduce the risk of fire or electric shock, current-carrying

parts and other components of the controller should

be examined and replaced if damaged. If burnout of the

current element of an overload relay occurs, the complete

overload relay must be replaced.

®

Operation of this equipment requires detailed

installation and operation instructions provided in the

Installation/Operation manual intended for use with this

product. This information is provided on the CD-ROM,

floppy diskette(s) or other storage device included in the

container this device was packaged in. it should be

retained with this device at all times. A hard copy of this

information may be ordered from Eaton literature

fulfillment.

WARNING

Carry out wiring work only after the drive has been

correctly mounted and secured.

PowerXL DG1 Series VFD MN040002EN—March 2014 www.eaton.com ix

PowerXL DG1 Series VFD

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

WARNING

Before servicing the drive:

●

Disconnect all power to the drive, including external

control power that may be present.

●

Place a “DO NOT TURN ON” label on the disconnect

device.

●

Lock the disconnect device in the open position.

Failure to follow these instructions will result in death or

serious injury.

WARNING

The drive outputs (U, V, W) must not be connected to the

input voltage or the utility line power as severe damage

to the device may occur and there may be a risk of fire.

Install this drive in a well-ventilated room that is not subject

to temperature extremes, high humidity, or condensation,

and avoid locations that are directly exposed to sunlight, or

have high concentrations of dust, corrosive gas, explosive

gas, inflammable gas, grinding fluid mist, etc. Improper

installation may result in a fire hazard.

When selecting the cable cross-section, take the voltage

drop under load conditions into account. The consideration of

other standards is the responsibility of the user.

The user is responsible for compliance with all international

and national electrical standards in force concerning

protective grounding of all equipment.

WARNING

The heat sink and/or outer enclosure may reach a high

temperature.

Pay attention to hazard warnings!

Hot Surface—Risk of Burn. DO NOT TOUCH!

CAUTION

Any electrical or mechanical modification to this drive without

prior written consent of Eaton will void all warranties and may

result in a safety hazard in addition and voiding of the UL

listing.

CAUTION

Install this drive on flame-resistant material such as a steel

plate to reduce the risk of fire.

CAUTION

Install this drive on a perpendicular surface that is able to

support the weight of the drive and is not subject to

vibration, to lessen the risk of the drive falling and being

damaged and/or causing personal injury.

CAUTION

Prevent foreign material such as wire clippings or metal

shavings from entering the drive enclosure, as this may

cause arcing damage and fire.

The specified minimum PE conductor cross-sections in this

manual must be maintained.

Touch current in this equipment exceeds 3.5 mA (AC). The

minimum size of the protective earthing conductor shall

comply with the requirements of EN 61800-5-1 and/or the

local safety regulations.

Touch currents in this frequency inverter are greater than

3.5 mA (AC). According to product standard IEC/EN

61800-5-1, an additional equipment grounding conductor of

the same cross-sectional area as the original protective

earthing conductor must be connected, or the cross-section

®

of the equipment grounding conductor must be at least

2

10 mm

be used.

Debounced inputs may not be used in the safety circuit

diagram. Residual current circuit breakers (RCD) are only to

be installed between the AC power supply network and the

drive.

Debounced inputs may not be used in the safety circuit

diagram. If you are connecting multiple motors on one drive,

you must design the contactors for the individual motors

according to utilization category AC-3.

Selecting the motor contactor is done according to the rated

operational current of the motor to be connected.

Cu. Drive requires that only copper conductor should

x PowerXL DG1 Series VFD MN040002EN—March 2014 www.eaton.com

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

Debounced inputs may not be used in the safety circuit

diagram. A changeover between the drive and the input

supply must take place in a voltage-free state.

PowerXL DG1 Series VFD

Do not touch any components on the circuit boards. Static

voltage discharge may damage the components.

CAUTION

Debounced inputs may not be used in the safety circuit

diagram. Fire hazard!

Only use cables, protective switches, and contactors that

feature the indicated permissible nominal current value.

CAUTION

Before connecting the drive to AC mains make sure that the

EMC protection class settings of the drive are appropriately

made according to instructions in this manual.

●

If the drive is to be used in a floating distribution network,

remove screws at MOV and EMC. See “Installation in

Corner-Grounded Network” on Page 43 and “Installation in

IT System” on Page 43 respectively.

●

Disconnect the internal EMC filter when installing the drive

on an IT system (an ungrounded power system or a

high-resistance-grounded [over 30 ohm] power system),

otherwise the system will be connected to ground

potential through the EMC filter capacitors. This may

cause danger, or damage the drive.

●

Disconnect the internal EMC filter when installing the drive

on a corner grounded TN system, otherwise the drive will

be damaged.

Note: When the internal EMC filter is disconnected, the

drive might be not EMC compatible.

Before starting the motor, check that the motor is mounted

properly and aligned with the driven equipment. Ensure that

starting the motor will not cause personal injury or damage

equipment connected to the motor.

Set the maximum motor speed (frequency) in the drive

according to the requirements of the motor and the

equipment connected to it. Incorrect maximum frequency

settings can cause motor or equipment damage and personal

injury.

Before reversing the motor rotation direction, ensure that

this will not cause personal injury or equipment damage.

Make sure that no power correction capacitors are

connected to the drive output or the motor terminals to

prevent drive malfunction and potential damage.

Make sure that the drive output terminals (U, V, W) are not

connected to the utility line power as severe damage to the

drive may occur.

●

Do not attempt to install or remove the MOV or EMC

screws while power is applied to the drive’s input

terminals.

Motor and Equipment Safety

CAUTION

Do not perform any meggar or voltage withstand tests on

any part of the drive or its components. Improper testing may

result in damage.

CAUTION

Prior to any tests or measurements of the motor or the

motor cable, disconnect the motor cable at the drive output

terminals (U, V, W) to avoid damaging the drive during motor

or cable testing.

PowerXL DG1 Series VFD MN040002EN—March 2014 www.eaton.com xi

When the control terminals of two or more drive units are

connected in parallel, the auxiliary voltage for these control

connections must be taken from a single source which can

either be one of the units or an external supply.

The drive will start up automatically after an input voltage

interruption if the external run command is on.

Do not control the motor with the disconnecting device

(disconnecting means); instead, use the control panel start

and stop keys and, or commands via the I/O board of the

drive. The maximum allowed number of charging cycles of

the DC capacitors (i.e. power-ups by applying power) is five in

ten minutes.

PowerXL DG1 Series VFD

CAUTION

Improper drive operation:

●

If the drive is not turned on for a long period, the

performance of its electrolytic capacitors will be reduced.

●

If it is stopped for a prolonged period, turn the drive on at

least every six months for at least 5 hours to restore the

performance of the capacitors, and then check its

operation. It is recommended that the drive is not

connected directly to the line voltage. The voltage should

be increased gradually using an adjustable AC source.

Failure to follow these instructions can result in injury

and/or equipment damage.

For more technical information, contact the factory or your

local Eaton sales representative.

xii PowerXL DG1 Series VFD MN040002EN—March 2014 www.eaton.com

Chapter 1—DG1 Series Overview

Chapter 1—DG1 Series Overview

This chapter describes the purpose and contents of this

manual, the receiving inspection recommendations and the

DG1 Series Open Drive catalog numbering system.

How to Use this Manual

The purpose of this manual is to provide you with information

necessary to install, set and customize parameters, start up,

troubleshoot and maintain the Eaton DG1 Series adjustable

frequency drive (AFD). To provide for safe installation and

operation of the equipment, read the safety guidelines at the

beginning of this manual and follow the procedures outlined

in the following chapters before connecting power to the

DG1 Series AFD. Keep this operating manual handy and

distribute to all users, technicians and maintenance

personnel for reference.

Receiving and Inspection

The DG1 Series AFD has met a stringent series of factory

quality requirements before shipment. It is possible that

packaging or equipment damage may have occurred during

shipment. After receiving your DG1 Series AFD, please

check for the following:

Check to make sure that the package includes the Instruction

Leaflet (IL040016EN), Quick Start Guide (MN040006EN),

User Manual CD (CD040002EN) and accessory packet. The

accessory packet includes:

●

Rubber grommets

●

Control cable grounding clamps

●

Additional grounding screw

Inspect the unit to ensure it was not damaged during

shipment.

Make sure that the part number indicated on the nameplate

corresponds with the catalog number on your order.

If shipping damage has occurred, please contact and file a

claim with the carrier involved immediately.

If the delivery does not correspond to your order, please

contact your Eaton Electrical representative.

Note: Do not destroy the packing. The template printed

on the protective cardboard can be used for marking

the mounting points of the DG1 AFD on the wall or

in a cabinet.

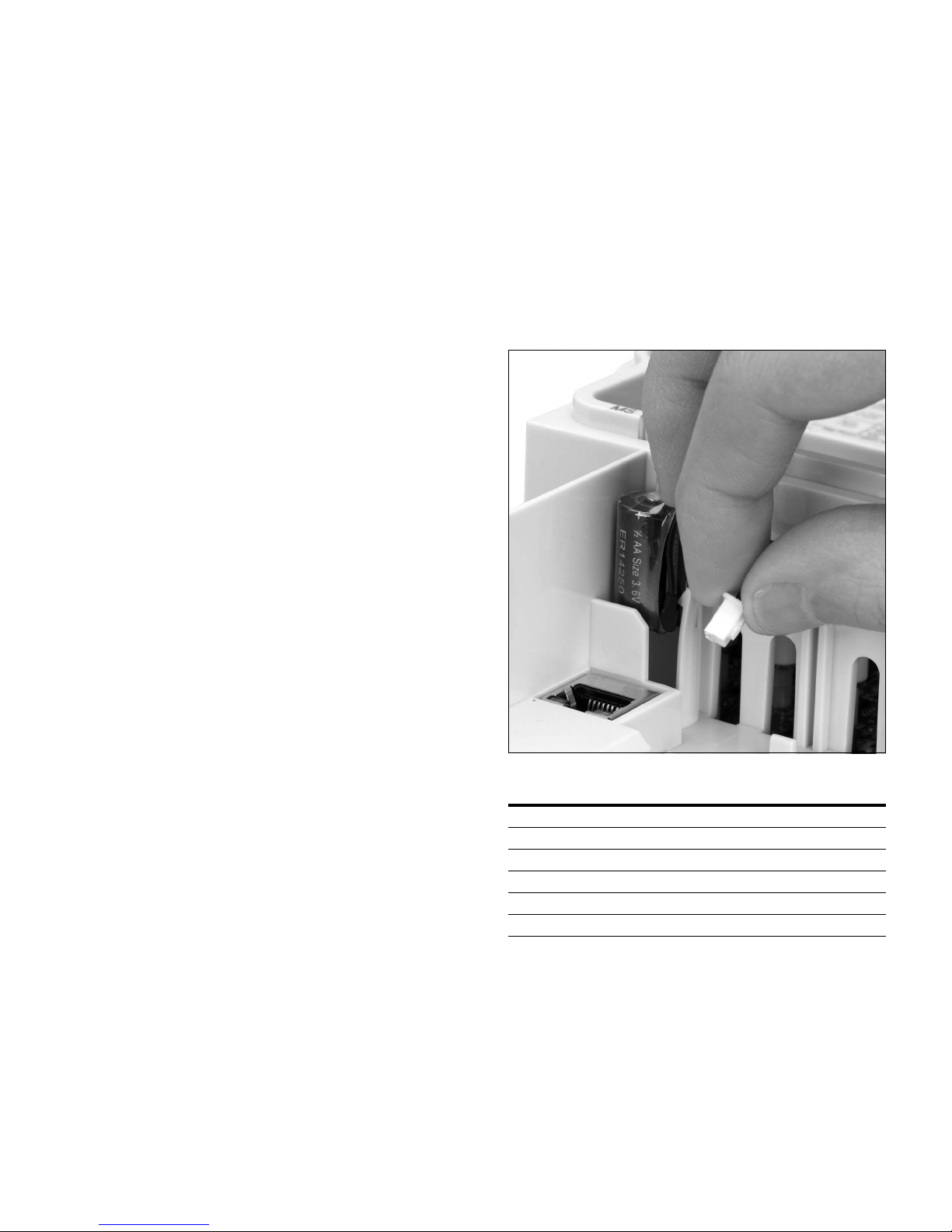

Real Time Clock Battery Activation

To activate the real time clock (RTC) functionality in the

PowerXL DG1 Series AFD, the RTC battery (already mounted

in the drive) must be connected to the control board.

Simply remove the primary drive cover, locate the RTC

battery directly below the keypad, and connect the white

2-wire connector to the receptacle on the control board.

Figure 1. RTC Battery Connection

Table 1. Common Abbreviations

Abbreviation Definition

CT Constant torque with high overload rating (150%)

VT Variable torque with low overload rating (110%)

I

H

I

L

AFD Adjustable Frequency Drive

VFD Variable Frequency Drive

High Overload (150%)

Low Overload (110%)

DG1 Series VFD MN040002EN—March 2014 www.eaton.com 1

Chapter 1—DG1 Series Overview

Contains

SN, PN,

Type, Date

Contains

EAN Code

Date Code: 20131118

Contains

NAED Code

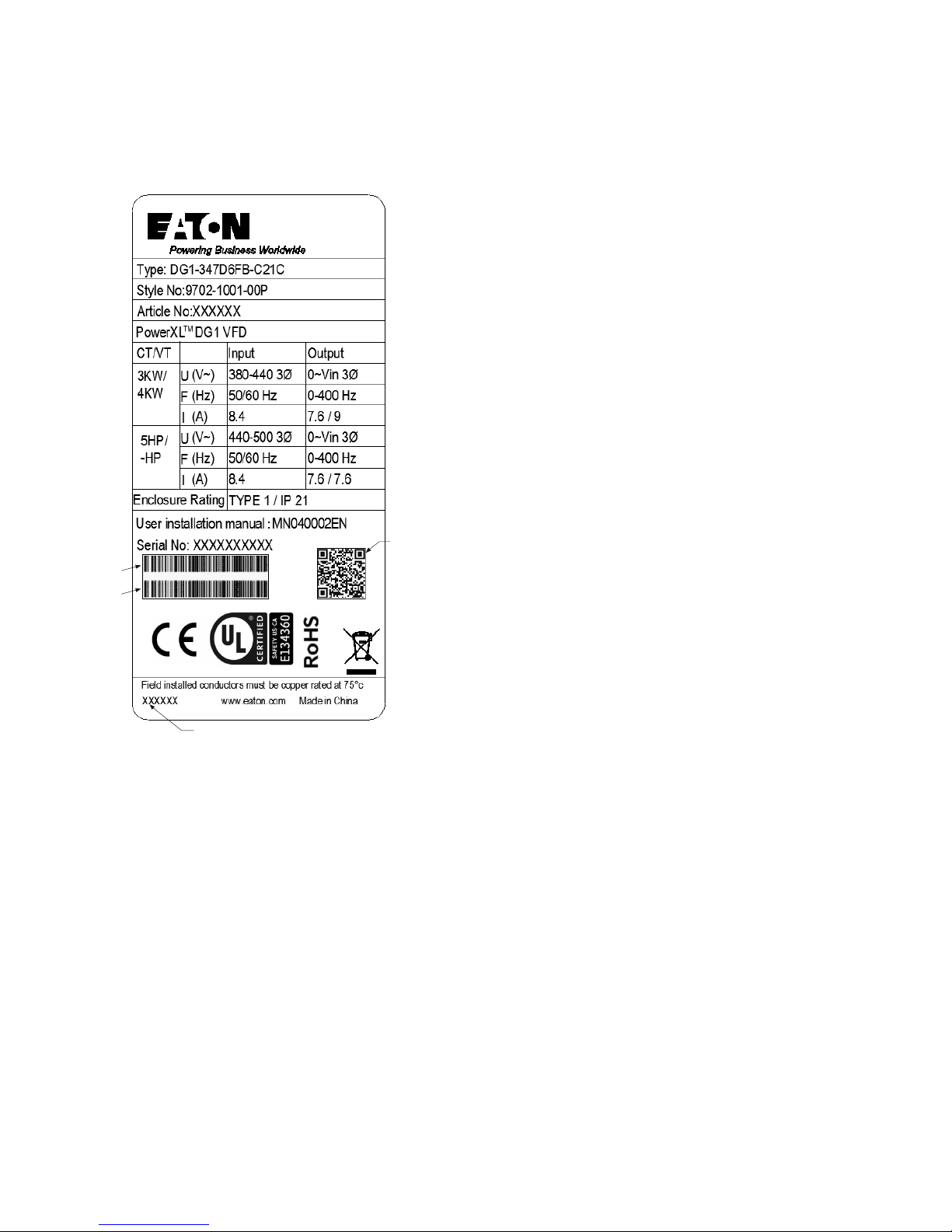

Rating Label

Figure 2. Rating Label

Carton Labels (U.S. and Europe)

Same as rating label shown above.

2 DG1 Series VFD MN040002EN—March 2014 www.eaton.com

Catalog Number System

Internal Brake Chopper

N = No brake chopper

B = Brake chopper

Series Power Part Options

D G1 –34 4D8 F B –C21 C

Input/Output Voltage Rating

2 = 230V (208–240V, –15%, +10%)

4 = 400V (380–500V, –15%, +10%)

5 = 575V (525–600V, –15%, +10%)

Basic Naming

D = Drive

Output Current Rating (CT)

208–240V 380–500V 525–600V

3D7 = 3.7A, 0.55 kW, 0.75 hp

4D8 = 4.8A, 0.75 kW, 1 hp

6D6 = 6.6A, 1.1 kW, 1.5 hp

7D8 = 7.8A, 1.5 kW, 2 hp

011 = 11A, 2.2 kW, 3 hp

012 = 12.5A, 3 kW, 5 hp (VT)

017 = 17.5A, 3.7 kW, 5 hp

025 = 25A, 5.5 kW, 7.5 hp

031 = 31A, 7.5 kW, 10 hp

048 = 48A, 11 kW, 15 hp

061 = 61A, 15 kW, 20 hp

075 = 75A, 18.5 kW, 25 hp

088 = 88A, 22 kW, 30 hp

114 = 114A, 30 kW, 40 hp

143 = 143A, 37 kW, 50 hp

170 = 170A, 45 kW, 60 hp

211 = 211A, 55 kW, 75 hp

261 = 261A, 75 kW, 100 hp

2D2 = 2.2A, 0.75 kW, 1 hp

3D3 = 3.3A, 1.1 kW, 1.5 hp

4D3 = 4.3A, 1.5 kW, 2 hp

5D6 = 5.6A, 2.2 kW, 3 hp

7D6 = 7.6A, 3 kW, 5 hp

9D0 = 9A, 4 kW, 7.5 hp (VT)

012 = 12A, 5.5 kW, 7.5 hp

016 = 16A, 7.5 kW, 10 hp

023 = 23A, 11 kW, 15 hp

031 = 31A, 15 kW, 20 hp

038 = 38A, 18 kW, 25 hp

046 = 46A, 22 kW, 30 hp

061 = 61A, 30 kW, 40 hp

072 = 72A, 37 kW, 50 hp

087 = 87A, 45 kW, 60 hp

105 = 105A, 55 kW, 75 hp

140 = 140A, 75 kW, 100 hp

170 = 170A, 90 kW, 125 hp

205 = 205A, 110 kW, 150 hp

261 = 261A, 132 kW, 200 hp

3D3 = 3.3A, 1.5 kW, 2 hp

4D5 = 4.5A, 2.2 kW, 3 hp

7D5 = 7.5A, 3.7 kW, 5 hp

010 = 10A, 5.5 kW, 7.5 hp

013 = 13.5A, 7.5 kW, 10 hp

018 = 18A, 11 kW, 15 hp

022 = 22A, 15 kW, 20 hp

027 = 27A, 18 kW, 25 hp

034 = 34A, 22 kW, 30 hp

041 = 41A, 30 kW, 40 hp

052 = 52A, 37 kW, 50 hp

062 = 62A, 45 kW, 60 hp

080 = 80A, 55 kW, 75 hp

100 = 100A, 75 kW, 100 hp

125 = 125A, 90 kW, 125 hp

144 = 144A, 110 kW, 150 hp

208 = 208A, 160 kW, 200 hp

Series

G1 = General purpose

Phase Reference

3 = 3~ INPUT/3~ OUTPUT

Internal EMC Filter

F = Internal EMC filter

Coating of Boards

C = Coated

Enclosure (IP Rating)

21 = IP21/Type 1

54 = IP54/Type 12

Display Option

C = LCD (graphical)

Figure 3. Catalog Numbering System

Chapter 1—DG1 Series Overview

DG1 Series VFD MN040002EN—March 2014 www.eaton.com 3

Chapter 1—DG1 Series Overview

Power Ratings and Product Selection

DG1 Series Drives—208–240 Volt

Table 2. Type 1/IP21

Frame Size

kW Rating (CT/IH)

FR1 0.55 0.75 0.75 1 3.7 4.8 DG1-323D7FB-C21C

0.75 1.1 1 1.5 4.8 6.6 DG1-324D8FB-C21C

1.1 1.5 1.5 2 6.6 7.8 DG1-326D6FB-C21C

1.5 2.2 2 3 7.8 11 DG1-327D8FB-C21C

2.2 3 3 — 11 12.5 DG1-32011FB-C21C

FR2 3 3.7 — 5 12.5 17.5 DG1-32012FB-C21C

3.7 5.5 5 7.5 17.5 25 DG1-32017FB-C21C

5.5 7.5 7.5 10 25 31 DG1-32025FB-C21C

FR37.5 11 10153148DG1-32031FB-C21C

11 15 15 20 48 61 DG1-32048FB-C21C

FR415 18.5 20256175DG1-32061FN-C21C

18.5 22 25307588DG1-32075FN-C21C

22 30 30 40 88 114 DG1-32088FN-C21C

FR5 30 37 40 50 114 143 DG1-32114FN-C21C

37 45 50 60 143 170 DG1-32143FN-C21C

45 55 60 75 170 211 DG1-32170FN-C21C

230V, 50 Hz

FR6

1

55 75 75 100 211 261 DG1-32211FN-C21C

75 90 100 125 261 312 DG1-32261FN-C21C

230V, 50 Hz

kW Rating (VT/IL)

230V, 60 Hz

hp (CT/IH)

230V, 60 Hz

hp (VT/IL)

Current

A (CT/IH)

Current

A (VT/IL) Catalog Number

Table 3. Type 12/IP54

Frame Size

230V, 50 Hz

kW Rating (CT/I

230V, 50 Hz

)

kW Rating (VT/IL)

H

230V, 60 Hz

hp (CT/IH)

230V, 60 Hz

hp (VT/IL)

Current

A (CT/IH)

Current

A (VT/IL) Catalog Number

FR1 0.55 0.75 0.75 1 3.7 4.8 DG1-323D7FB-C54C

0.75 1.1 1 1.5 4.8 6.6 DG1-324D8FB-C54C

1.1 1.5 1.5 2 6.6 7.8 DG1-326D6FB-C54C

1.5 2.2 2 3 7.8 11 DG1-327D8FB-C54C

2.2 3 3 — 11 12.5 DG1-32011FB-C54C

FR2 3 3.7 — 5 12.5 17.5 DG1-32012FB-C54C

3.7 5.5 5 7.5 17.5 25 DG1-32017FB-C54C

5.5 7.5 7.5 10 25 31 DG1-32025FB-C54C

FR37.5 11 10153148DG1-32031FB-C54C

11 15 15 20 48 61 DG1-32048FB-C54C

FR415 18.5 20256175DG1-32061FN-C54C

18.5 22 25307588DG1-32075FN-C54C

22 30 30 40 88 114 DG1-32088FN-C54C

FR5 30 37 40 50 114 143 DG1-32114FN-C54C

37 45 50 60 143 170 DG1-32143FN-C54C

45 55 60 75 170 211 DG1-32170FN-C54C

FR6

1

55 75 75 100 211 261 DG1-32211FN-C54C

75 90 100 125 261 312 DG1-32261FN-C54C

Note

1

FR6 available in 2015.

4 DG1 Series VFD MN040002EN—March 2014 www.eaton.com

Chapter 1—DG1 Series Overview

DG1 Series Drives—380–500 Volt

Table 4. Type 1/IP21

Frame Size

kW Rating (CT/IH)

FR1 0.75 1.1 1 1.5 2.2 3.3 DG1-342D2FB-C21C

1.1 1.5 1.5 2 3.3 4.3 DG1-343D3FB-C21C

1.5 2.2 2 3 4.3 5.6 DG1-344D3FB-C21C

2.2 3 3 5 5.6 7.6 DG1-345D6FB-C21C

345—7.69DG1-347D6FB-C21C

4 5.5 — 7.5 9 12 DG1-349D0FB-C21C

FR2 5.5 7.5 7.5 10 12 16 DG1-34012FB-C21C

7.5 11 10151623DG1-34016FB-C21C

11 15 15 20 23 31 DG1-34023FB-C21C

FR315 18.5 20253138DG1-34031FB-C21C

18.5 22 25303846DG1-34038FB-C21C

22 30 30 40 46 61 DG1-34046FB-C21C

FR430 37 40506172DG1-34061FN-C21C

37 45 50 60 72 87 DG1-34072FN-C21C

45 55 60 75 87 105 DG1-34087FN-C21C

FR5 55 75 75 100 105 140 DG1-34105FN-C21C

75 90 100 125 140 170 DG1-34140FN-C21C

90 110 125 150 170 205 DG1-34170FN-C21C

400V, 50 Hz

1

FR6

110 132 150 200 205 261 DG1-34205FN-C21C

132 160 200 250 261 310 DG1-34261FN-C21C

400V, 50 Hz

kW Rating (VT/IL)

460V, 60 Hz

hp (CT/IH)

460V, 60 Hz

hp (VT/IL)

Current

A (CT/IH)

Current

A (VT/IL) Catalog Number

Table 5. Type 12/IP54

Frame Size

400V, 50 Hz

kW Rating (CT/I

400V, 50 Hz

)

kW Rating (VT/IL)

H

460V, 60 Hz

hp (CT/IH)

460V, 60 Hz

hp (VT/IL)

Current

A (CT/IH)

Current

A (VT/IL) Catalog Number

FR1 0.75 1.1 1 1.5 2.2 3.3 DG1-342D2FB-C54C

1.1 1.5 1.5 2 3.3 4.3 DG1-343D3FB-C54C

1.5 2.2 2 3 4.3 5.6 DG1-344D3FB-C54C

2.2 3 3 5 5.6 7.6 DG1-345D6FB-C54C

345—7.69DG1-347D6FB-C54C

4 5.5 — 7.5 9 12 DG1-349D0FB-C54C

FR2 5.5 7.5 7.5 10 12 16 DG1-34012FB-C54C

7.5 11 10151623DG1-34016FB-C54C

11 15 15 20 23 31 DG1-34023FB-C54C

FR315 18.5 20253138DG1-34031FB-C54C

18.5 22 25303846DG1-34038FB-C54C

22 30 30 40 46 61 DG1-34046FB-C54C

FR430 37 40506172DG1-34061FN-C54C

37 45 50 60 72 87 DG1-34072FN-C54C

45 55 60 75 87 105 DG1-34087FN-C54C

FR5 55 75 75 100 105 140 DG1-34105FN-C54C

75 90 100 125 140 170 DG1-34140FN-C54C

90 110 125 150 170 205 DG1-34170FN-C54C

1

FR6

110 132 150 200 205 261 DG1-34205FN-C54C

132 160 200 250 261 310 DG1-34261FN-C54C

Note

1

FR6 available in 2015.

DG1 Series VFD MN040002EN—March 2014 www.eaton.com 5

Chapter 1—DG1 Series Overview

Replacement Parts

Table 6. Frame 1

Catalog Number Catalog Number Catalog Number

Description 230V 480V 575V

Standard keypad

Main control board

Control board cover DXG-SPR-BCOVER DXG-SPR-BCOVER DXG-SPR-BCOVER

Type 1/IP21 standard cover DXG-SPR-FR1CVR DXG-SPR-FR1CVR

Main fan kit

Control fan DXG-SPR-2FR1CF DXG-SPR-4FR1CF

Main power board DXG-SPR-2FR1MPB DXG-SPR-4FR1MPB

EMI board DXG-SPR-2FR1EB DXG-SPR-4FR1EB

Middle chassis cover DXG-SPR-FR1MCC DXG-SPR-FR1MCC

Outer housing DXG-SPR-FR1OH DXG-SPR-FR1OH

UL conduit plate DXG-SPR-FR1CPUL DXG-SPR-FR1CPUL

IEC conduit plate DXG-SPR-FR1CPIEC DXG-SPR-FR1CPIEC

Notes

1

Factory recommended spare parts.

2

575V available in 2015.

1

1

1

DXG-KEY-LCD DXG-KEY-LCD DXG-KEY-LCD

DXG-SPR-CTRLBOARD DXG-SPR-CTRLBOARD DXG-SPR-CTRLBOARD

2

DXG-SPR-FR1FAN DXG-SPR-FR1FAN

2

2

2

2

2

2

2

2

Table 7. Frame 2

Catalog Number Catalog Number Catalog Number

Description 230V 480V 575V

Standard keypad

Main control board

1

1

DXG-KEY-LCD DXG-KEY-LCD DXG-KEY-LCD

DXG-SPR-CTRLBOARD DXG-SPR-CTRLBOARD DXG-SPR-CTRLBOARD

Control board cover DXG-SPR-BCOVER DXG-SPR-BCOVER DXG-SPR-BCOVER

2

Type 1/IP21 standard cover DXG-SPR-FR2CVR DXG-SPR-FR2CVR

Main fan kit

1

DXG-SPR-FR2FAN DXG-SPR-FR2FAN

Control fan DXG-SPR-FR2CF DXG-SPR-FR2CF

Bus capacitor DXG-SPR-2FR2BC DXG-SPR-4FR24BC

Main power board DXG-SPR-2FR2MPB DXG-SPR-4FR2MPB

EMI board DXG-SPR-2FR2EB DXG-SPR-4FR2EB

IGBT module DXG-SPR-FR2IGBT DXG-SPR-FR2IGBT

Middle chassis cover DXG-SPR-FR2MCC DXG-SPR-FR2MCC

Outer housing DXG-SPR-FR2OH DXG-SPR-FR2OH

UL conduit plate DXG-SPR-FR2CPUL DXG-SPR-FR2CPUL

IEC conduit plate DXG-SPR-FR2CPIEC DXG-SPR-FR2CPIEC

Notes

1

Factory recommended spare parts.

2

575V available in 2015.

2

2

2

2

2

2

2

2

2

2

6 DG1 Series VFD MN040002EN—March 2014 www.eaton.com

Chapter 1—DG1 Series Overview

Table 8. Frame 3

Catalog Number Catalog Number Catalog Number

Description 230V 480V 575V

Standard keypad

Main control board

Control board cover DXG-SPR-BCOVER DXG-SPR-BCOVER DXG-SPR-BCOVER

Type 1/IP21 standard cover DXG-SPR-FR3CVR DXG-SPR-FR3CVR

Main fan kit

Control fan DXG-SPR-FR34CF DXG-SPR-FR34CF

Bus capacitor DXG-SPR-FR3BC DXG-SPR-FR3BC

Main power board DXG-SPR-2FR3MPB DXG-SPR-4FR3MPB

EMI board DXG-SPR-2FR3EB DXG-SPR-4FR3EB

Drive board DXG-SPR-2FR3DB DXG-SPR-4FR3DB

Output board DXG-SPR-FR3OB DXG-SPR-FR3OB

Middle chassis cover DXG-SPR-FR3MCC DXG-SPR-FR3MCC

Outer housing DXG-SPR-FR3OH DXG-SPR-FR3OH

UL conduit plate DXG-SPR-FR3CPUL DXG-SPR-FR3CPUL

IEC conduit plate DXG-SPR-FR3CPIEC DXG-SPR-FR3CPIEC

Notes

1

Factory recommended spare parts.

2

575V available in 2015.

1

1

1

DXG-KEY-LCD DXG-KEY-LCD DXG-KEY-LCD

DXG-SPR-CTRLBOARD DXG-SPR-CTRLBOARD DXG-SPR-CTRLBOARD

2

DXG-SPR-FR3FAN DXG-SPR-FR3FAN

2

2

2

2

2

2

2

2

2

2

2

Table 9. Frame 4

Catalog Number Catalog Number Catalog Number

Description 230V 480V 575V

Standard keypad

Main control board

1

1

DXG-KEY-LCD DXG-KEY-LCD DXG-KEY-LCD

DXG-SPR-CTRLBOARD DXG-SPR-CTRLBOARD DXG-SPR-CTRLBOARD

Control board cover DXG-SPR-BCOVER DXG-SPR-BCOVER DXG-SPR-BCOVER

2

Type 1/IP21 standard cover DXG-SPR-FR4CVR DXG-SPR-FR4CVR

Main fan kit

1

DXG-SPR-FR4FAN DXG-SPR-FR4FAN

Control fan DXG-SPR-FR34CF DXG-SPR-FR34CF

Bus capacitor DXG-SPR-2FR4BC DXG-SPR-4FR24BC

Main power board DXG-SPR-2FR4MPB DXG-SPR-4FR4MPB

EMI board DXG-SPR-2FR4EB DXG-SPR-4FR4EB

Softstart board DXG-SPR-2FR4SB DXG-SPR-4FR4SB

IGBT module DXG-SPR-2FR4IGBT DXG-SPR-4FR4IGBT

Rectifier module DXG-SPR-2FR4RM DXG-SPR-4FR4RM

Brake chopper module DXG-SPR-2FR4BCM DXG-SPR-4FR4BCM

Middle chassis cover DXG-SPR-FR4MCC DXG-SPR-FR4MCC

Outer housing DXG-SPR-FR4OH DXG-SPR-FR4OH

UL conduit plate DXG-SPR-FR4CPUL DXG-SPR-FR4CPUL

IEC conduit plate DXG-SPR-FR4CPIEC DXG-SPR-FR4CPIEC

Notes

1

Factory recommended spare parts.

2

575V available in 2015.

2

2

2

2

2

2

2

2

2

2

2

2

2

DG1 Series VFD MN040002EN—March 2014 www.eaton.com 7

Chapter 1—DG1 Series Overview

Table 10. Frame 5

Catalog Number Catalog Number Catalog Number

Description 230V 480V 575V

Standard keypad

Main control board

Control board cover DXG-SPR-BCOVER DXG-SPR-BCOVER DXG-SPR-BCOVER

Type 1/IP21 standard cover DXG-SPR-FR5CVR DXG-SPR-FR5CVR

Main fan kit

Control fan DXG-SPR-FR5CF DXG-SPR-FR5CF

Bus capacitor DXG-SPR-FR5BC DXG-SPR-FR5BC

Main power board DXG-SPR-2FR5MPB DXG-SPR-4FR5MPB

EMI-1 board DXG-SPR-2FR5E1B DXG-SPR-4FR5E1B

EMI-2 board DXG-SPR-2FR5E2B DXG-SPR-4FR5E2B

EMI-3 board DXG-SPR-FR5E3B DXG-SPR-FR5E3B

IGBT module DXG-SPR-FR5IGBT DXG-SPR-FR5IGBT

Rectifier module DXG-SPR-2FR5RM DXG-SPR-4FR5RM

Brake chopper module DXG-SPR-2FR5BCM DXG-SPR-4FR5BCM

Middle chassis cover DXG-SPR-FR5MCC DXG-SPR-FR5MCC

Outer housing DXG-SPR-FR5OH DXG-SPR-FR5OH

UL conduit plate DXG-SPR-FR5CPUL DXG-SPR-FR5CPUL

IEC conduit plate DXG-SPR-FR5IECCP DXG-SPR-FR5IECCP

Notes

1

Factory recommended spare parts.

2

575V available in 2015.

1

1

1

DXG-KEY-LCD DXG-KEY-LCD DXG-KEY-LCD

DXG-SPR-CTRLBOARD DXG-SPR-CTRLBOARD DXG-SPR-CTRLBOARD

2

DXG-SPR-FR5FAN DXG-SPR-FR5FAN

2

2

2

2

2

2

2

2

2

2

2

2

2

2

8 DG1 Series VFD MN040002EN—March 2014 www.eaton.com

Chapter 2—Engineering Considerations

RCD

PE L1 L2 L3

PE U V W

M

L1

L2

L3

PE

PES

#

CPU

78

Chapter 2—Engineering Considerations

Introduction

This chapter describes the most important features in the

energy circuit of a drive system that you should take into

consideration in your project planning.

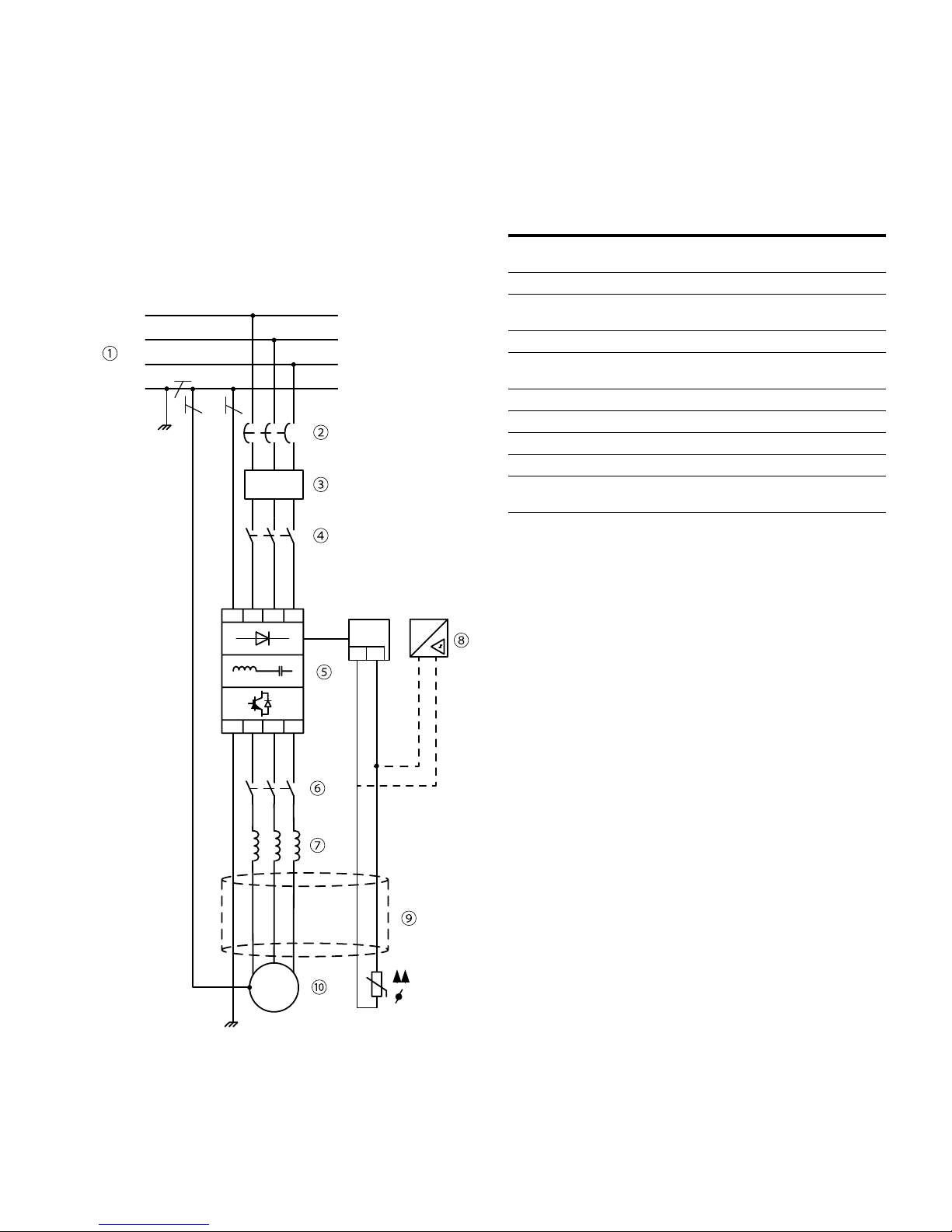

Figure 4. Drive System (PDS = Power Drive System)

Table 11. Drive System Components

Item No. Description

1 Power grid configuration, input voltage, input frequency,

interactions with PF correction systems

2 Breakers, fuses, cable cross-sections

3 Protection of persons and animals with residual-current

protective devices

4 Input contactor, disconnector

5 Frequency inverter: mounting, installation; power connection;

EMC measures; circuit examples

6 Output contactor, disconnector

7 Output reactor, dV/dT filter, sine-wave filter

8 Motor protection; thermistor (can be connected to drive directly)

9 Cable lengths, motor cables, shielding (EMC)

10 Motor and application, parallel operation of multiple motors on

a VFD, bypass circuit, DC braking

DG1 Series VFD MN040002EN—March 2014 www.eaton.com 9

Chapter 2—Engineering Considerations

L1

L2

L3

N

TT

L1

L2

L3

N

PE

TN-C-S

L1

L2

L3

N

PE

TN-S

L1

L2

L3

PEN

TN-C

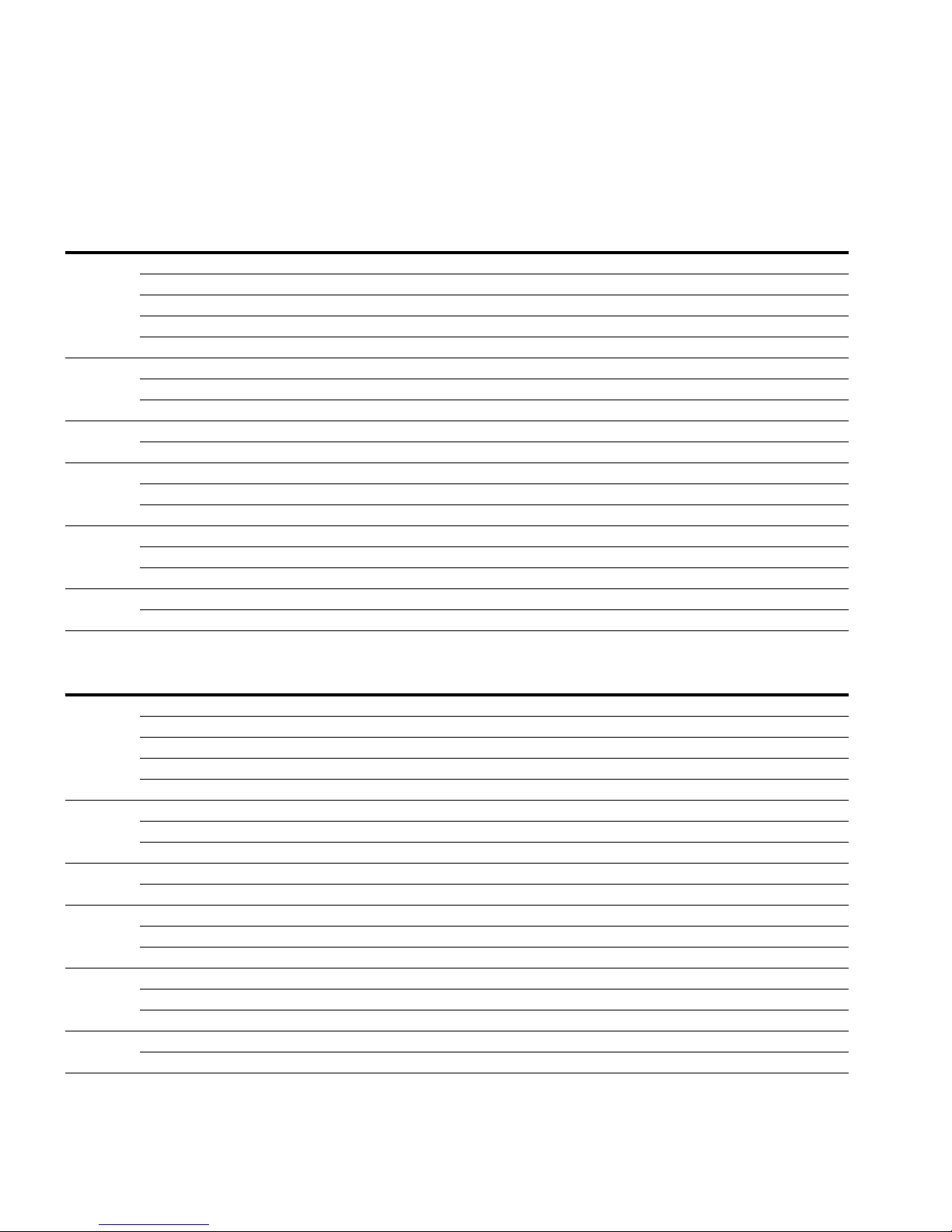

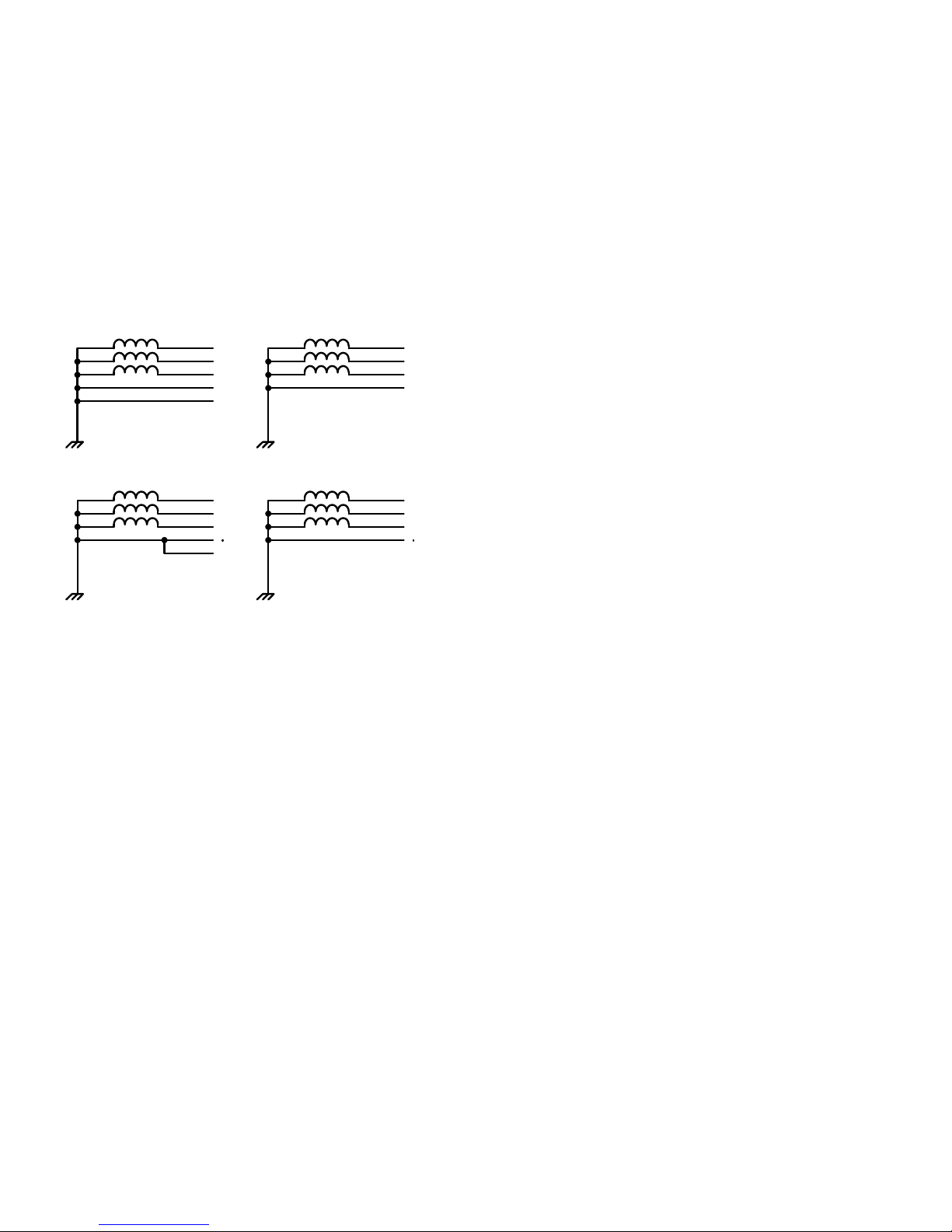

Electrical Power Network

Input Connection and Configuration

The DG1 Series frequency inverters can be connected and

operated with all control-point grounded AC power networks

(see IEC 60364 for more information).

Figure 5. AC Power Networks with Grounded Neutral

Point (TN- / TT Networks)

Input Voltage and Frequency

The standardized input voltages (IEC 60038, VDE017-1) for

energy suppliers (EVU) guarantee the following conditions at

the transition points:

●

Deviation from the rated value of voltage: Max. ±10%

●

Deviation in voltage phase balance: Max. ±3%

●

Deviation from rated value of the frequency: Max. ±4%

The board tolerance band of the DG1 frequency

inverter considers the rated value for European as

(EU: ULN = 230V / 400V, 50 Hz) and American as

(USA: U

●

●

For the bottom voltage value, the permitted voltage drop of

4% in the consumer circuits is also taken into account,

therefore a total of ULN –14%.

●

●

The permitted frequency range is 50/60 Hz (45 Hz –0% to

66 Hz +0%).

LN = 240V / 480V, 60 Hz) standard voltages:

230V, 50 Hz (EU) and 240V, 60 Hz (USA) at DG1-32_

400V, 50 Hz (EU) and 480V, 60 Hz (USA) at DG1-34_

230V device class (DG1-32_): 208V –15% to 240V +10%

(177V –0% to 264V +0%)

400V device class (DG1-34_): 380V –15% to 500V +10%

(323V –0% to 550V +0%)

The frequency inverter can be applied to all types of power

networks above. If multiple frequency inverters with

single-phase supplies are to be connected, a symmetrical

distribution to the three external conductors shall be taken

into account. In addition, the total current of all single-phase

consumers is not to cause an overload of the neutral

conductor (N-conductor).

The connection and operation of frequency inverters to

asymmetrically grounded TN networks (phase-grounded

delta network “Grounded Delta”, USA) or neutral point

ungrounded or high-resistance grounded (>30 ohms) IT

networks is only conditionally permissible. In these networks

above-mentioned, the internal interference suppression filter

of frequency inverter must be disconnected (unscrew the

screw marked ‘EMC’, see “Installation in IT System” on

Page 43). Then the required filtering for EMC

(electromagnetic compatibility) is no longer present (degrade

to Class T).

Measures for EMC are mandatory in a drive system in order

to meet the legal requirements for EMC and low voltage

regulations.

Good grounding measures are a prerequisite for the effective

insert of further measures such as shielding of filters.

Without respective grounding measures, further steps are

superfluous.

Input Voltage Balance

Due to the uneven loading on the conductor, and with the

direct connection of greater power ratings, deviations from

the ideal voltage form and asymmetrical voltages can be

caused in three-phase AC power networks. These

asymmetric divergences in the input voltage can lead to

different loading of the diodes in input rectifiers with

three-phase supplied frequency inverters, and as a result,

an advance failure of this diode.

In the project planning for the connection of three-phase

supplied frequency inverters, consider only AC power

networks that handle permitted asymmetric divergences in

the input voltage ≤ +3%.

If this condition is not fulfilled, or symmetry at the connection

location is uncertain, the use of an assigned AC choke is

recommended.

10 DG1 Series VFD MN040002EN—March 2014 www.eaton.com

Chapter 2—Engineering Considerations

Total Harmonic Distortion (THD)

Non-linear consumers (loads) in an AC supply system

produce harmonic voltages that again result in harmonic

currents. These harmonic currents at the inductive and

capacitive reactances of a mains supply system produce

additional voltage drops with different values that are then

overlaid on the sinusoidal mains voltage and result in

distortions. In supply systems, this form of “noise” can give

rise to problems in an installation if the sum of the harmonics

exceeds certain limit values.

Non-linear consumers (harmonics producers) include for

example:

●

Induction and arc furnaces, welding devices

●

Current converters, rectifiers and inverters, soft starters,

variable frequency drives

●

Switched-mode power supply units (computers, monitors,

lighting), uninterrupted power supply (UPS)

The THD value (THD = Total Harmonic Distortion) is defined

in standard IEC/EN 61800-3 as the ratio of the rms value of all

harmonic components to the rms value of the fundamental

frequency. It is given in percent of the total value.

THD

;

U

U

+

2

222

UU

++

34

U

1

???

2

n

100%

3

Reactive Power Compensation Devices

Special compensation measures on the power supply side is

not required for DG1 Series drives, which take on very little

reactive power of the fundamental harmonics from the AC

power supply network (cosw ~0.98).

In the AC power networks with non-choked reactive current

compensation devices, current deviations can enable parallel

resonance and undefinable circumstances.

In the project planning for the connection of frequency

inverters to AC power networks with undefined

circumstances, please consider using AC chokes.

fundamental component

—

U

1

th

U

n

order harmonic component

n

—

The THD value of the harmonic distortion is stated in relation

to the rms value of the total signal as a percentage. On a

variable frequency drive, the total harmonic distortion is

around 120%.

To assist in the calculation of system harmonics, a

Harmonic Estimation Calculator Tool is available at

www.eaton.com/drives.

DG1 Series VFD MN040002EN—March 2014 www.eaton.com 11

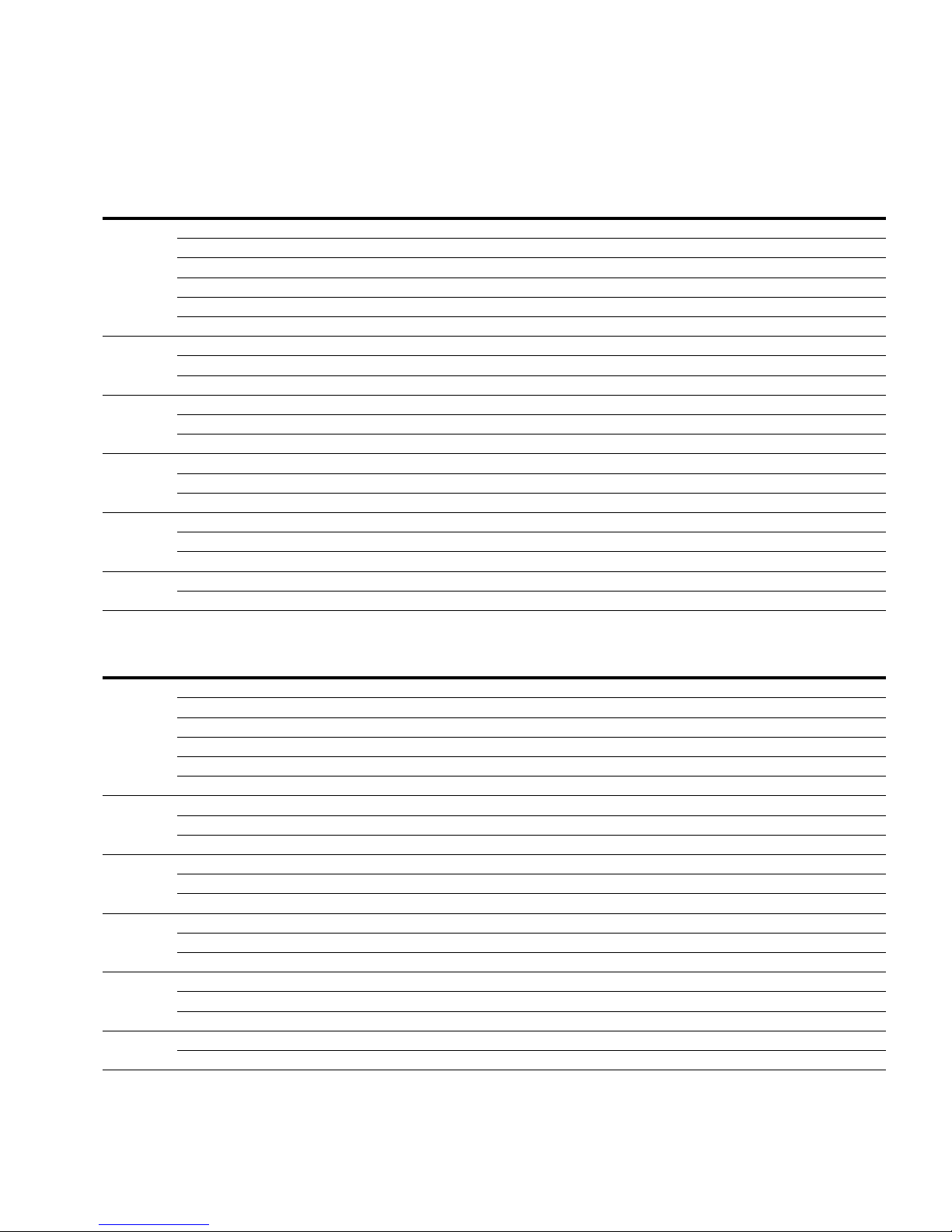

Chapter 3—Product Overview

Chapter 3—Product Overview

Component Identification

Figure 6. Description of the DG1 Series

Features

The DG1 frequency inverter converts the voltage and

frequency of an existing AC network into a DC voltage. This

DC voltage is used to generate a three-phase AC voltage

with adjustable frequency and assigned amplitude values for

the variable speed control of three-phase asynchronous

motors.

12 DG1 Series VFD MN040002EN—March 2014 www.eaton.com

Loading...

Loading...